Fiber grating intelligent plate made of fiber reinforced polymer in pulling extrusion and continuous forming mode and manufacturing method thereof

A fiber grating and fiber-reinforced technology, which is applied in building maintenance, building components, construction, etc., can solve the problem of not being able to sense surface strain with a single smart rib, and achieve easy popularization and application, good mechanical performance, and good corrosion resistance and anti-fatigue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

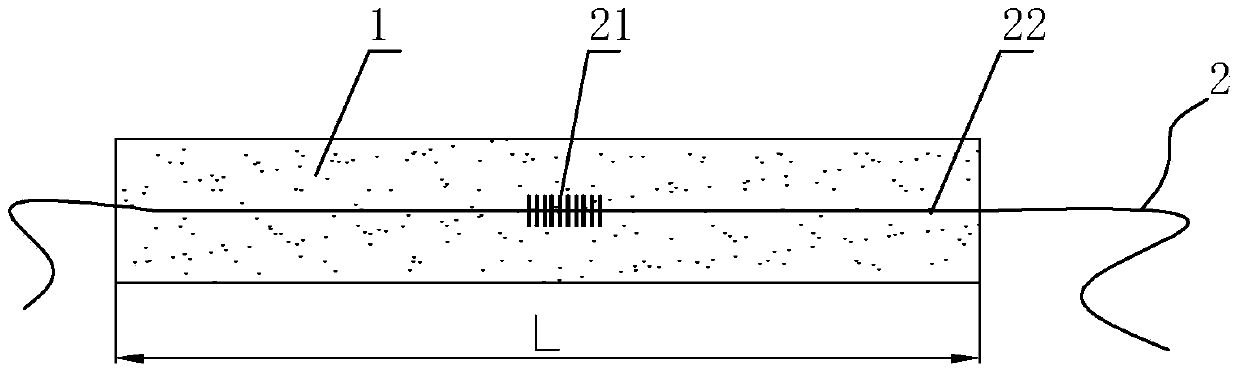

[0061] Embodiment 1: A fiber grating fiber-reinforced composite pultrusion continuous molding smart board, such as Figure 9 As shown, it includes a board main body 1 composed of fiber raw yarn and matrix resin. The board main body is filled with a sensing fiber 2 containing a fiber grating sensor 21 and a transmission fiber 22 along the fiber direction. The number of fibers is m, m=3; n fiber grating sensors are arranged on the single sensing fiber, n=3, that is, the fiber grating sensors are grating sensor strings welded with a certain length interval. The distance d1 between two adjacent sensing fibers in the vertical fiber direction and the distance d2 between two adjacent fiber grating sensors along the fiber direction on a single sensing fiber are the same. A section of transmission fiber for connecting the compensation fiber grating is led out from the end of the plate main body. The smart board is made by continuous pultrusion molding process, and the fiber volume con...

Embodiment 2

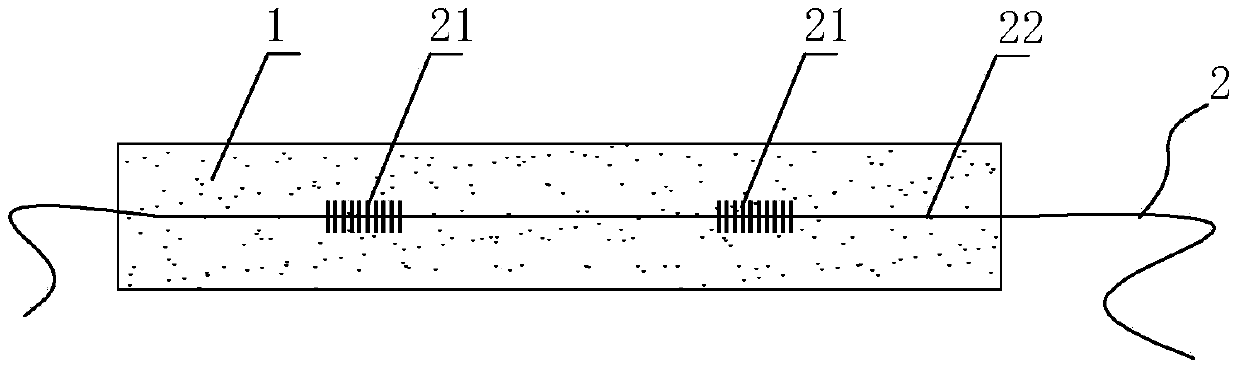

[0062] Embodiment 2: A fiber grating fiber reinforced composite material pultrusion continuous molding smart board, such as Figure 10 As shown, it includes a board main body 1 composed of fiber raw yarn and matrix resin. The board main body is filled with a sensing fiber 2 containing a fiber grating sensor 21 and a transmission fiber 22 along the fiber direction. The number is m, m=3; n fiber grating sensors are arranged on the single sensing fiber, n=2 or 3. The distance d1 of two adjacent sensing fibers in the vertical fiber direction is the same, and the distance d2 of two adjacent fiber grating sensors along the fiber direction on a single sensing fiber is different. A section of transmission fiber for connecting the compensation fiber grating is led out from the end of the plate main body. The smart board is made by continuous pultrusion molding process, and the fiber volume content of the smart board is not less than 60%.

Embodiment 3

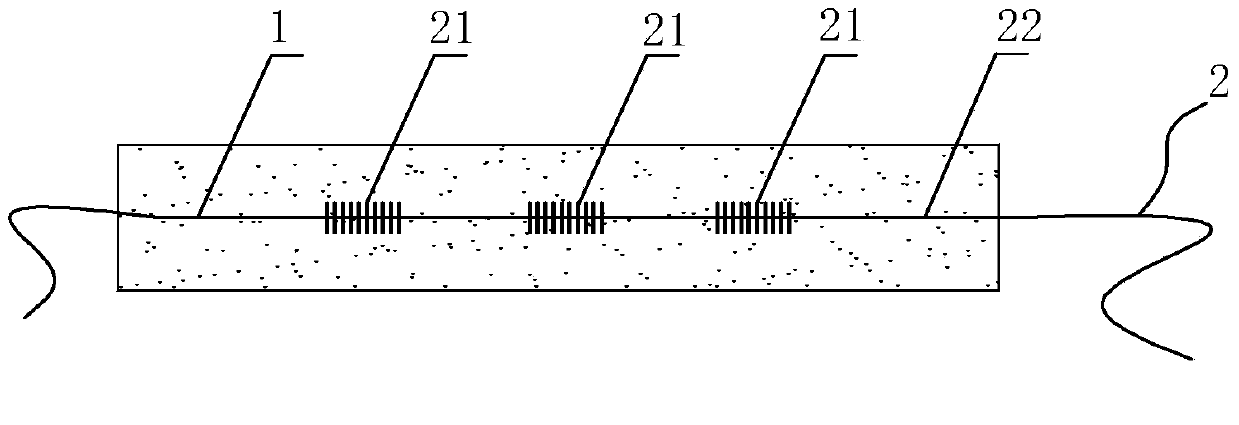

[0063] Embodiment 3: A fiber grating fiber reinforced composite material pultrusion continuous molding smart board, such as Figure 11 As shown, it includes a board main body 1 composed of fiber raw yarn and matrix resin. The board main body is filled with a sensing fiber 2 containing a fiber grating sensor 21 and a transmission fiber 22 along the fiber direction. The number is m, m=3; n fiber grating sensors are arranged on the single sensing fiber, n=2 or 3. The distance d1 between two adjacent sensing fibers in the vertical fiber direction and the distance d2 between two adjacent fiber grating sensors along the fiber direction on a single sensing fiber are different. A section of transmission fiber for connecting the compensation fiber grating is led out from the end of the plate main body. The smart board is made by continuous pultrusion molding process, and the fiber volume content of the smart board is not less than 60%.

[0064] The fiber raw yarn described in embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com