Patents

Literature

81results about How to "Effective melting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

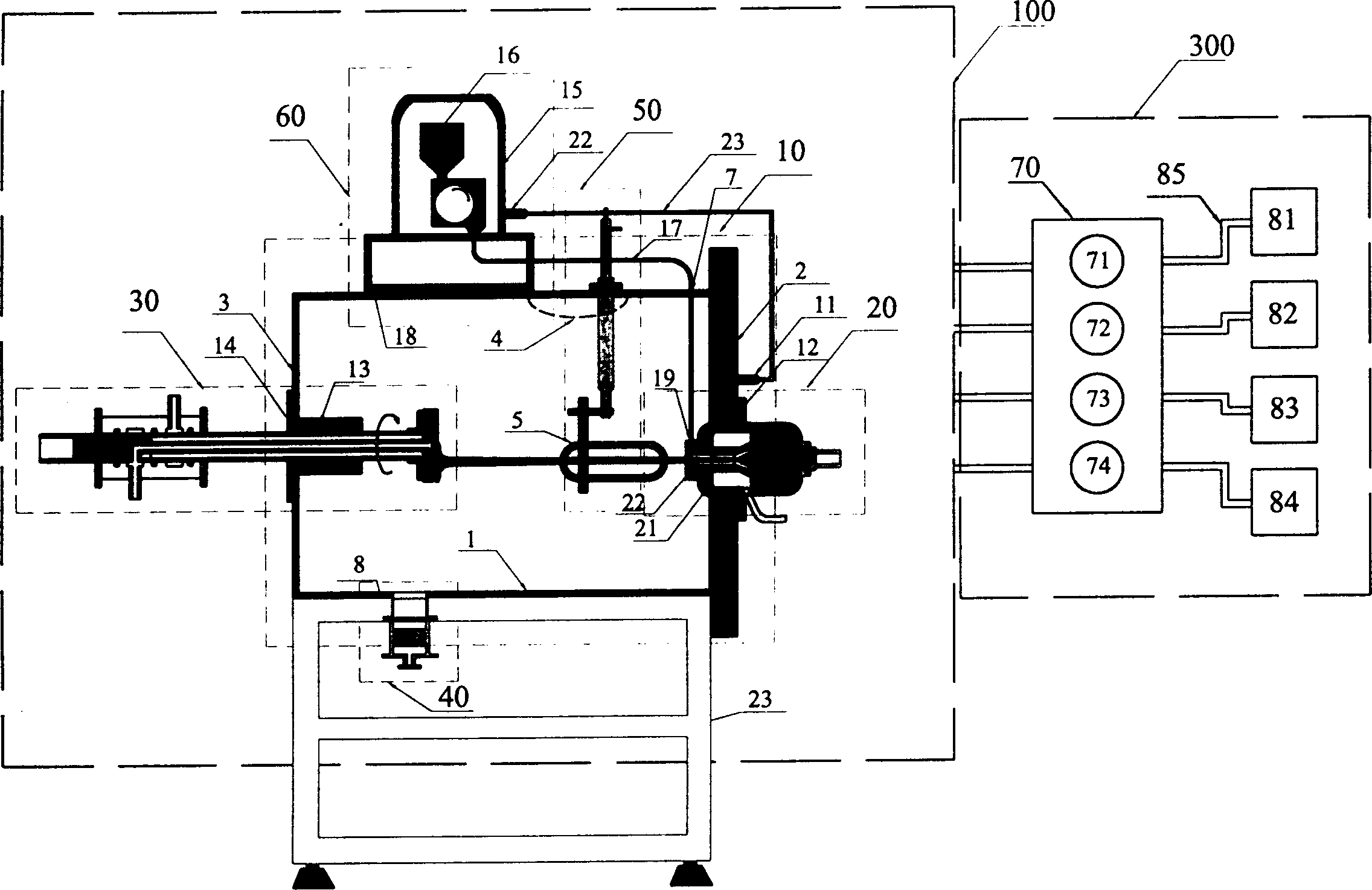

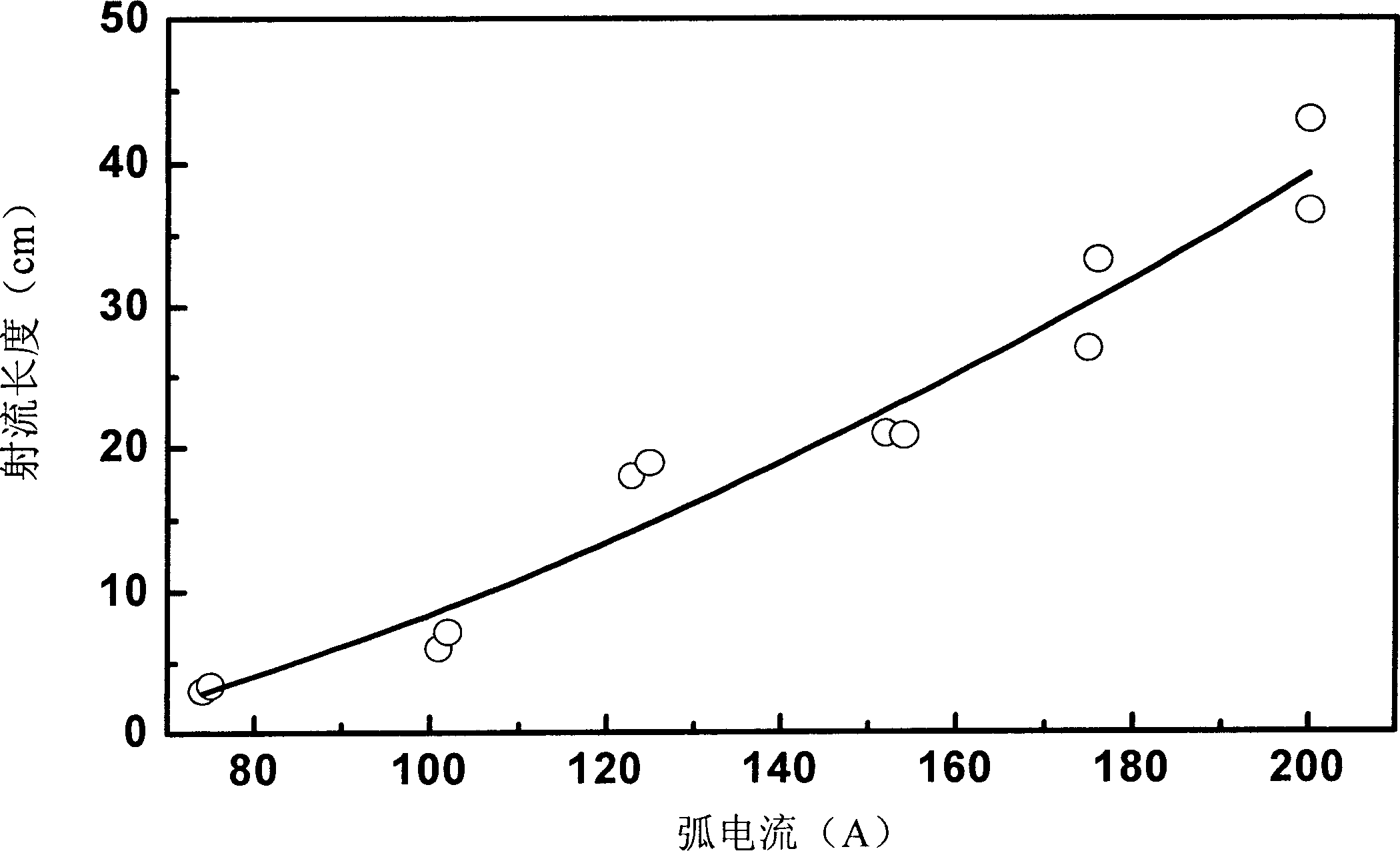

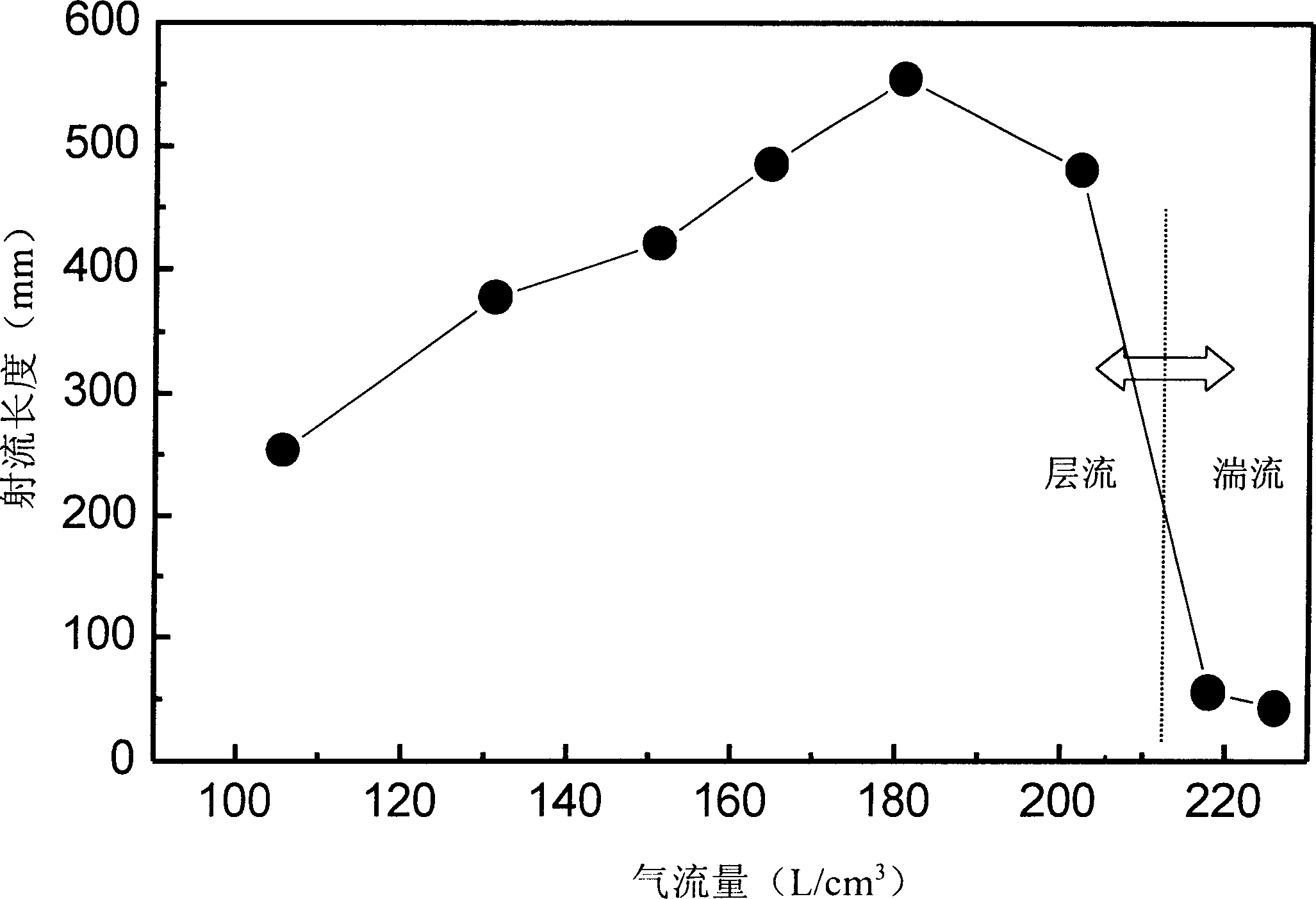

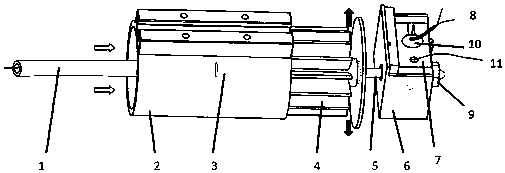

Laminar flow plasma spraying equipment and method

InactiveCN1421278AEffective meltingImprove interfacial adhesionLiquid spraying plantsLiquid surface applicatorsPlasma jetPlasma generator

The present invention is laminar flow plasma spraying equipment and method. A laminator flow plasma generator with different powder feeding modes, inside the gun or outside the gun and single port ormultiple ports, is used. While maintaining the laminar flow plasma jetting state in small power, air flow rate is increased to raise the heat efficiency of the jet. According to powder sort, materialproperty and particle size, proper jet energy and distribution and carrying air flow rate are selected to obtain high-quality coating. The present invention has les sintroduced impurity, high jet energy utilization, capacity of spraying high-smelting point coating at relatively low power condition, less oxidation of non-oxide coating and full heating of the powder material.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

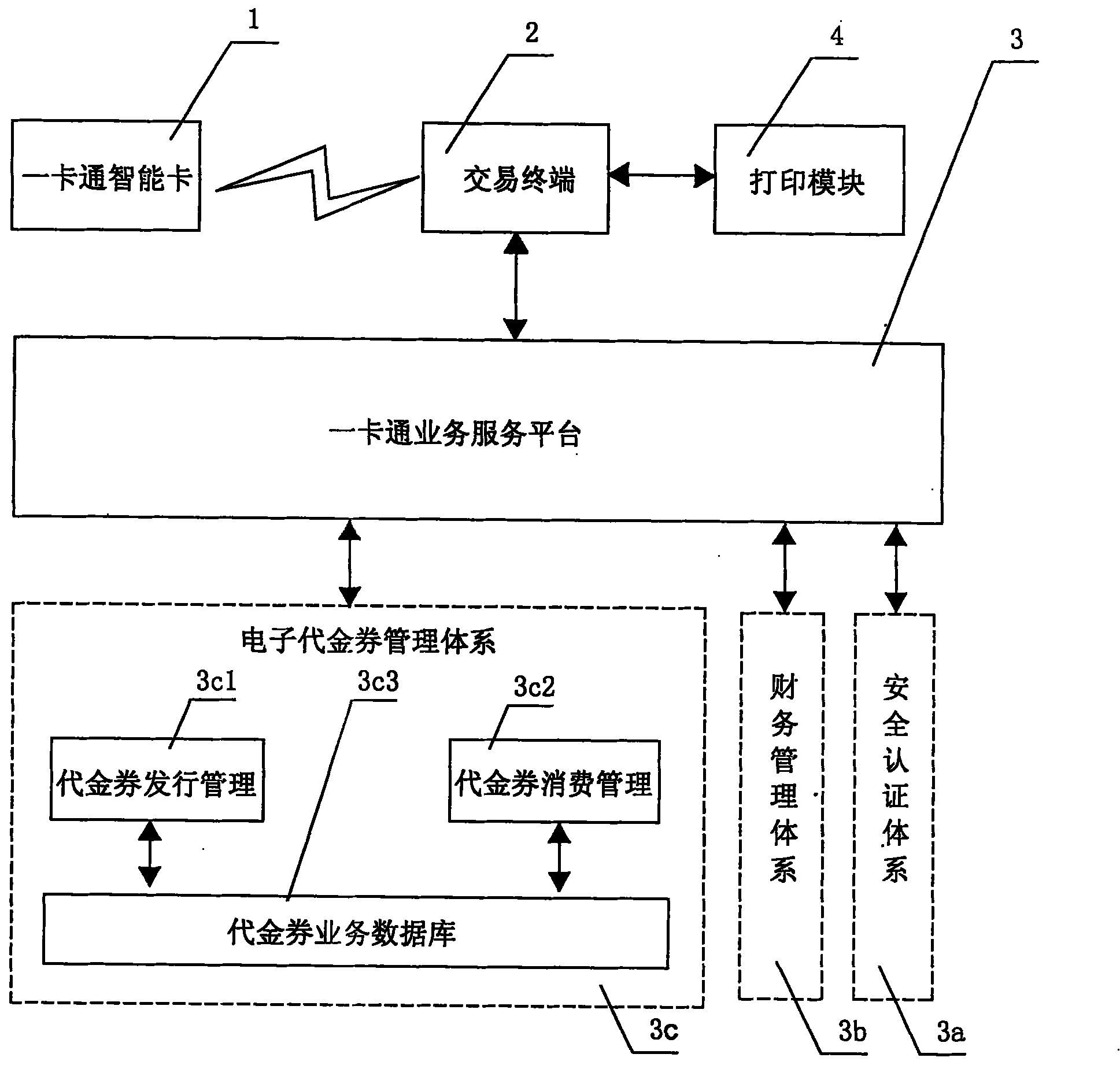

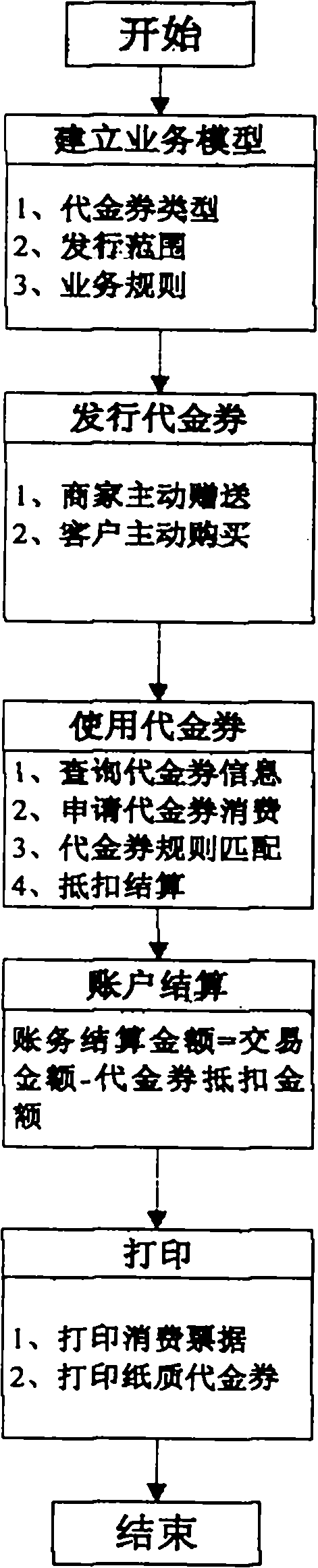

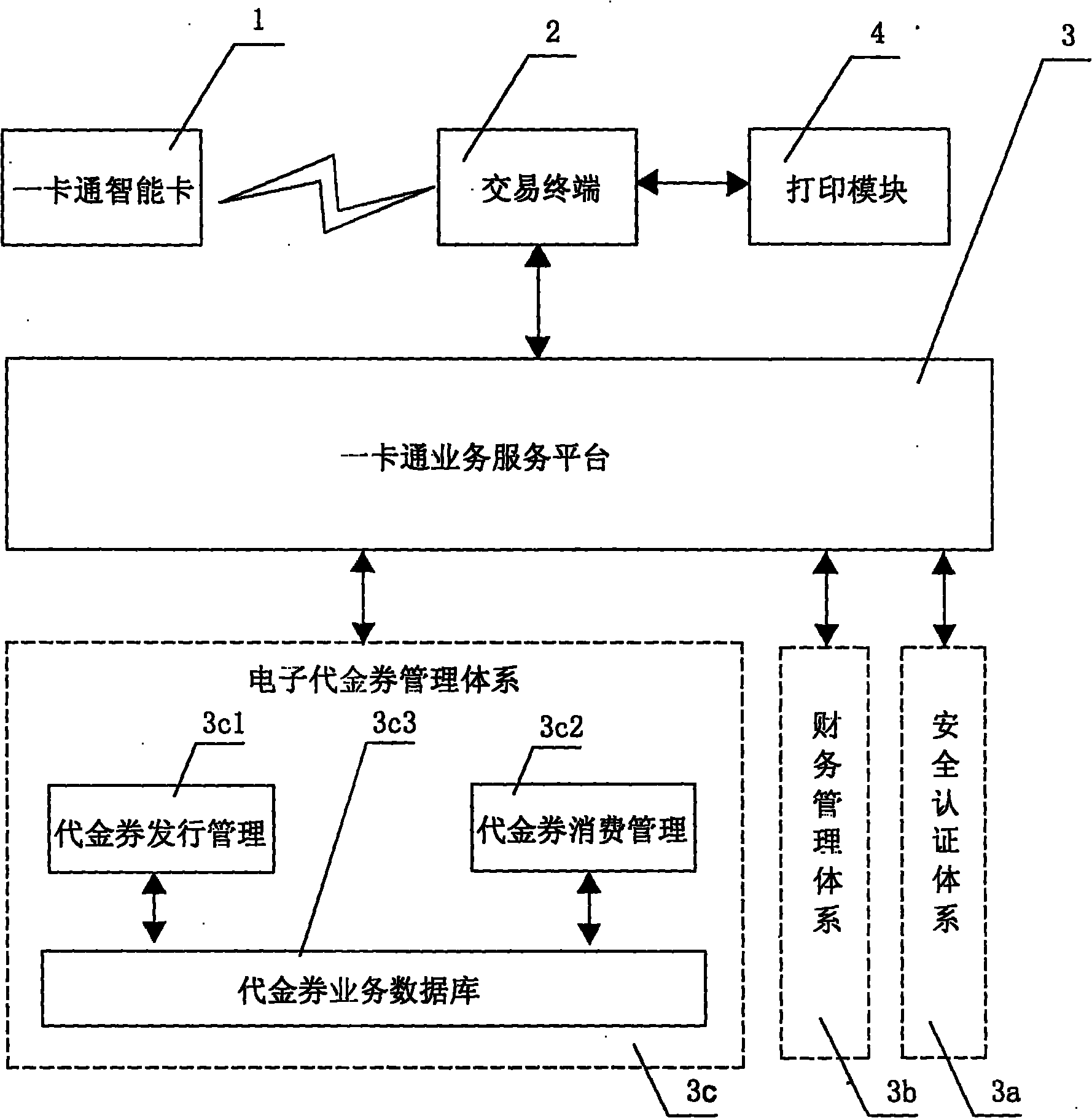

Electronic voucher purchase and payment system and method based on all-in-one card platform

The invention discloses an electronic voucher purchase and payment system based on an all-in-one card platform. The system comprises an all-in-one smart card, a transaction terminal and an all-in-one card service platform, wherein the all-in-one card service platform is provided with a security certification system and a financial management system. The system of the invention is characterized in that the system is also provided with an electronic voucher management system, and the electronic voucher management system is provided with a voucher release management system, a voucher consuming management system and a voucher business database. The invention also discloses an electronic voucher purchase and payment method. The method mainly comprises the following four steps: establishing a business model, issuing a voucher, using the voucher and performing account settlement. The remarkable effects of the method of the invention are as follows: the operation cost of voucher promotion mode of merchants is reduced greatly; and the perfect electronic voucher management means is provided for merchants so that the merchants can control the voucher in all dimensions from source to using. The system is convenient to operate, is safe and reliable and has extremely high practicability.

Owner:重庆市公众城市一卡通有限责任公司

Electroslag remelting hot-working die steel and preparing method thereof

The invention belongs to the technical field of special steel forge piece and heat treatment, and particularly relates to a low-cost electroslag remelting hot-working die steel material and a preparing method thereof. The hot-working die steel comprises, by weight percent, 0.35 to 0.40% of C, 0.10 to 0.30% of Si, 0.30 to 0.50% of Mn, 4.80 to 5.50% of Cr, 1.60 to 1.80% of Mo, 0.40 to 0.60% of V, not larger than 0.015% of P, not larger than 0.005% of S, not larger than 0.25% of Cu, not larger than 0.25% of Ni, not larger than 2ppm of [H], not larger than 20 ppm of [O], not larger than 120 ppm of[N] and the balance Fe and inevitable impurities. The forge piece impact toughness reaches above 20 J after component adjusting according to the above range from the common forge piece V port impactsmaller than 14 J, meanwhile, the early cracking resistance is greatly improved, a made mold is adjusted to reach above 10 times from the original time being short of 50000 times, in the preparing process, the water cooling superrefining treatment is adopted, the grain structure of the large-specification mold is obviously improved, the ASTM comparison method is used for measuring, the grain sizereaches above 6 stages, and the spheroidized structure reaches above AS5 stage in the North American die casting association standard NADCA#207 chart.

Owner:浙江自贸区北重金属科技有限公司

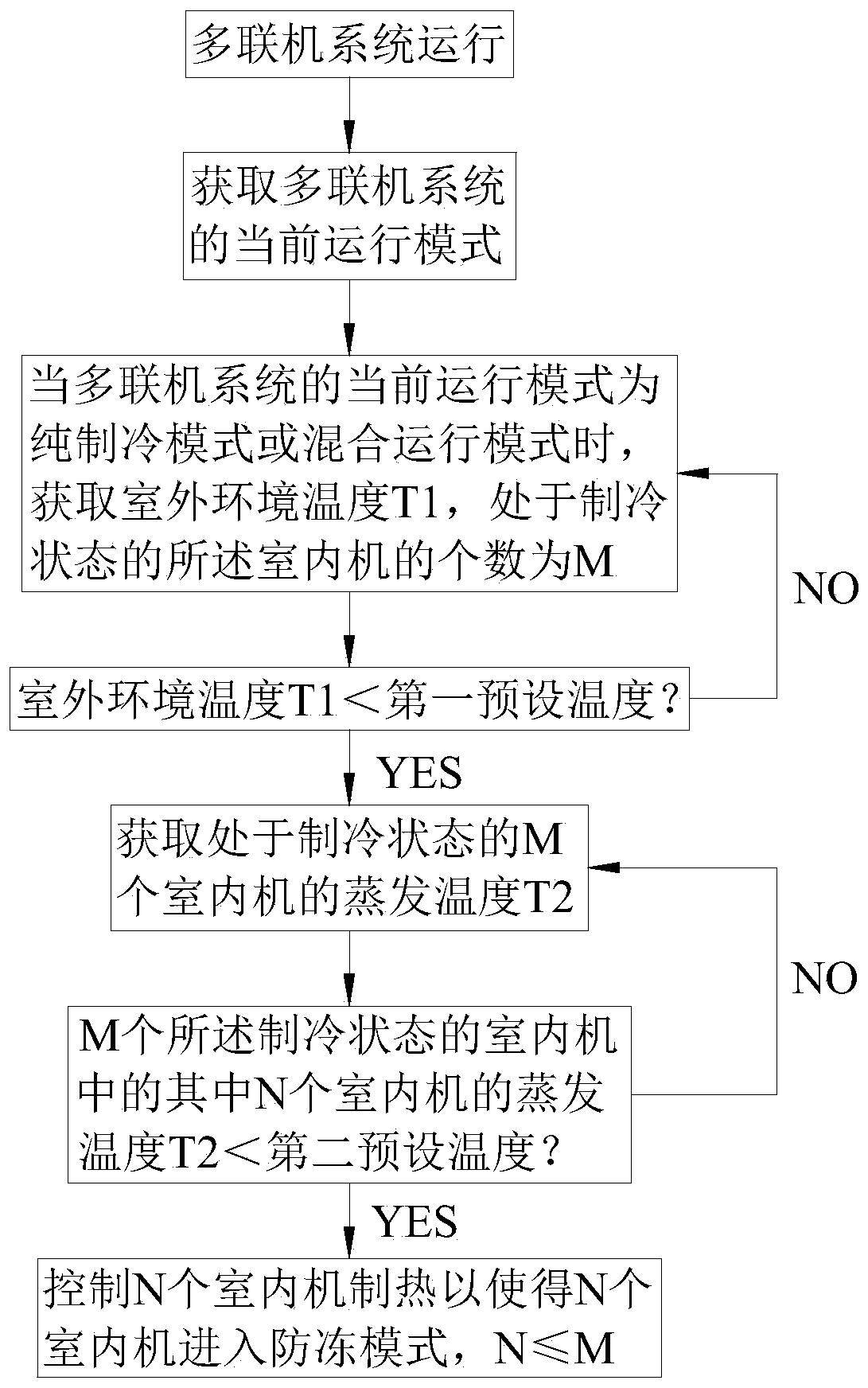

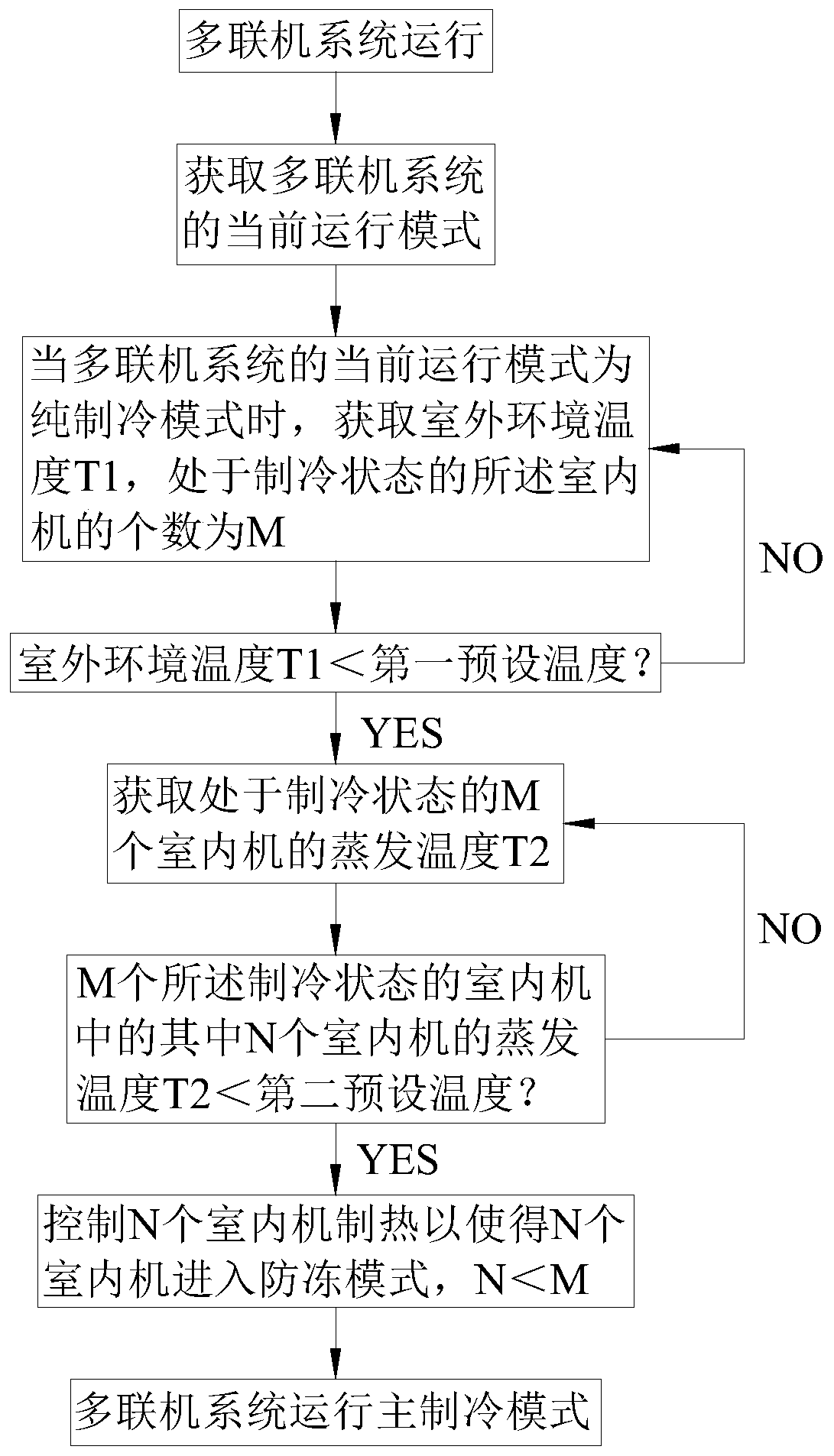

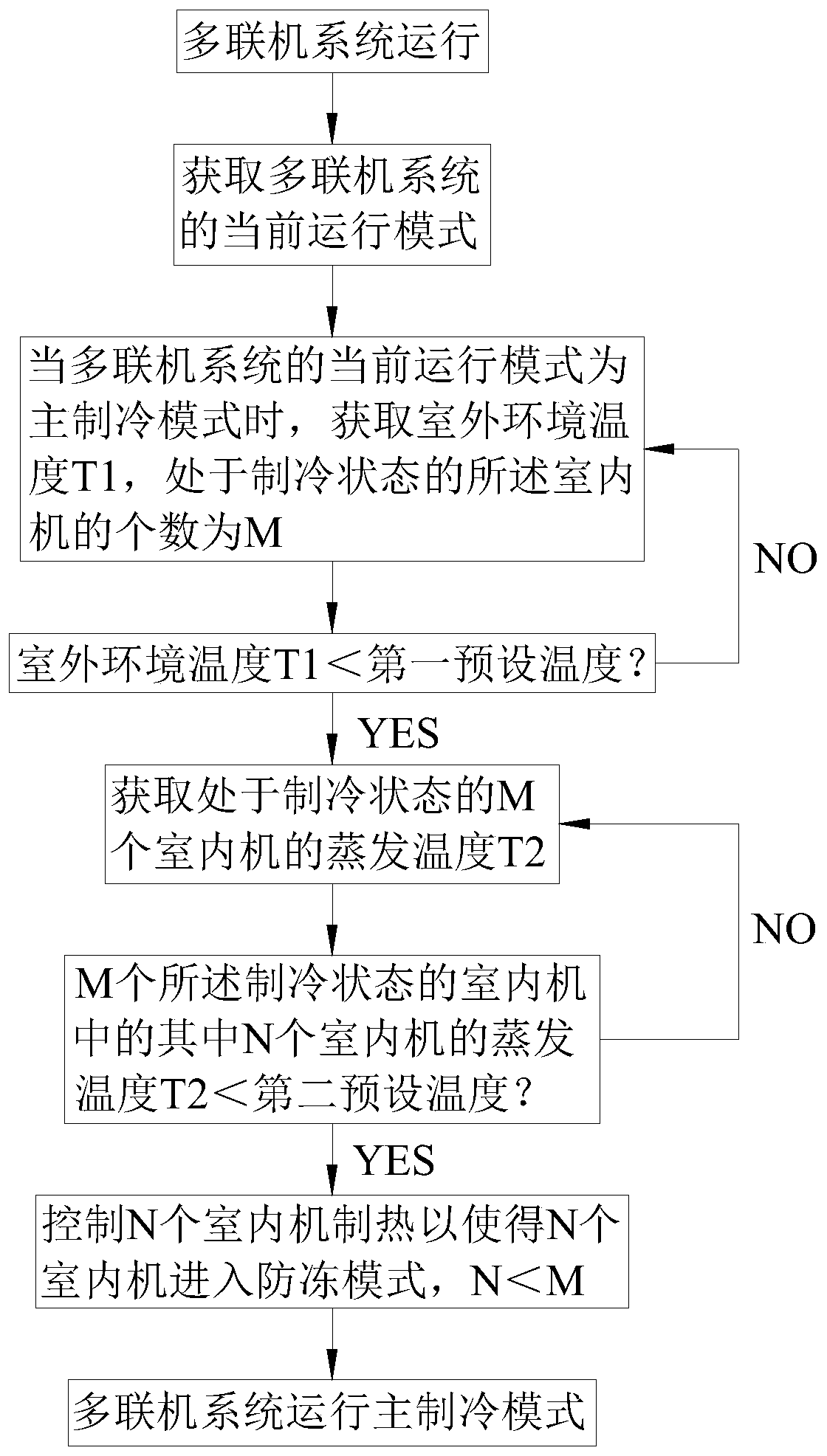

Control method of multi-split air conditioning system

InactiveCN110030705AGuaranteed energy efficiencyNo need to change the structureMechanical apparatusSpace heating and ventilation safety systemsAnti freezingOperation mode

The invention discloses a control method of a multi-split air conditioning system. The multi-split air conditioning system comprises an outdoor unit and a plurality of indoor units, wherein the outdoor unit comprises a compressor, an outdoor heat exchanger and a main throttling element. The control method of the multi-split air conditioning system comprises the following steps that a current operation mode of the multi-split air conditioning system is acquired, when the current operation mode of the multi-split air conditioning system is a pure refrigeration mode or a hybrid operation mode, anoutdoor ambient temperature T1 is obtained, wherein the number of the indoor units in a refrigeration state is M; when the outdoor ambient temperature T1 is less than a first preset temperature, an evaporation temperature T2 of the M indoor units in the refrigeration state is obtained; and when the evaporation temperature T2 of N indoor units in the M indoor units in the refrigeration state is less than a second preset temperature, the N indoor units are controlled to generate heat to enable the N indoor units to enter in an anti-freezing mode, wherein N is less than or equal to M. Accordingto the control method of the multi-split air conditioning system, the indoor units entering in the anti-freezing mode can quickly exit the anti-freezing mode.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

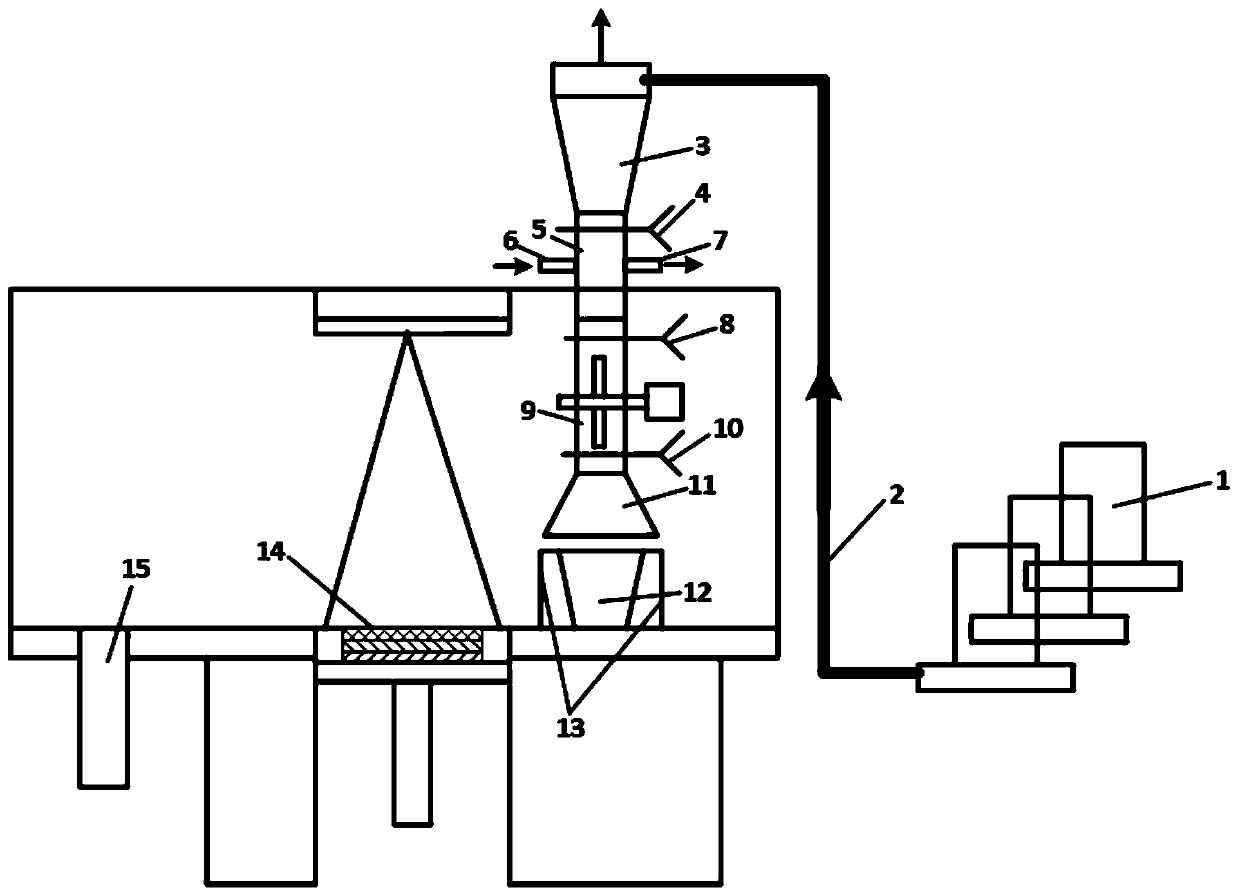

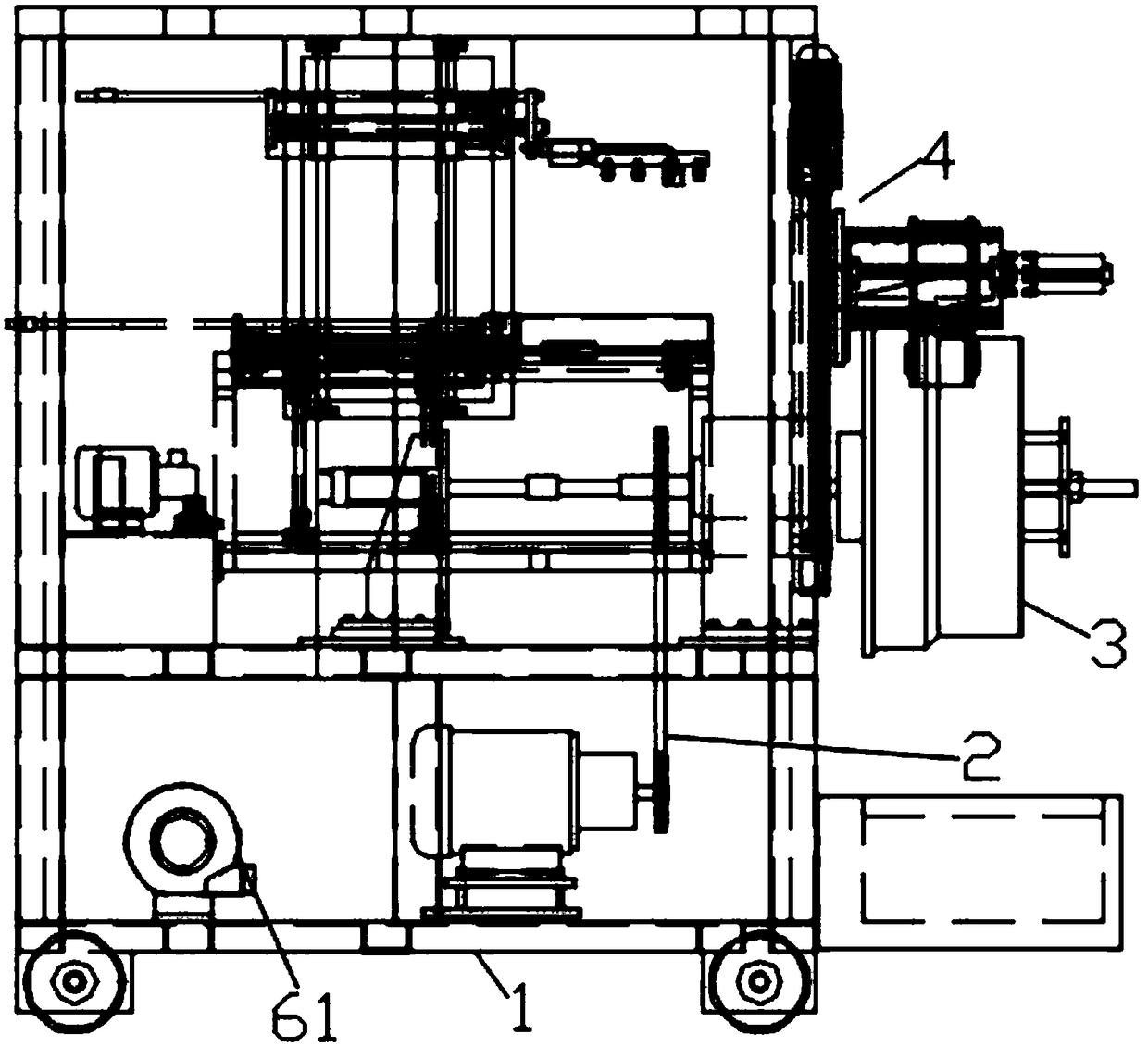

High-throughput forming device and forming method for additive material

ActiveCN110039054AImprove production efficiencyReduce replacementAdditive manufacturing apparatusIncreasing energy efficiencyMulti materialMaterials preparation

The invention discloses a high-throughput forming device and a forming method for an additive material; by arranging a powder bed laser melting cavity, a powder feeder system, a transition chamber anda powder mixing device as well as forming a transition chamber through hole in the wall of the powder bed laser melting cavity, the transition chamber is fixed in the transition chamber through hole;an upper sealing valve and a lower sealing valve are arranged in the transition chamber to form a transition chamber structure in the transition chamber, and a transition cavity pipe wall of the transition chamber is provided with an inflation pipe and an exhaust pipe, and the powder to be added is subjected to environmental replacement by using the transition cavity structure in the transition chamber so as to avoid replacing the environment in a molding cavity when adding powder again; the effect of screening various materials in one molding is realized; the material preparation efficiencyis doubled; the environmental replacement in the molding cavity is reduced; the device can realize accurate supply of powder at different positions by controlling the supply of powder, and can quicklyreplace different added powder, and metal particles can be molten effectively by a mixing device so that ingredients are uniformly mixed.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

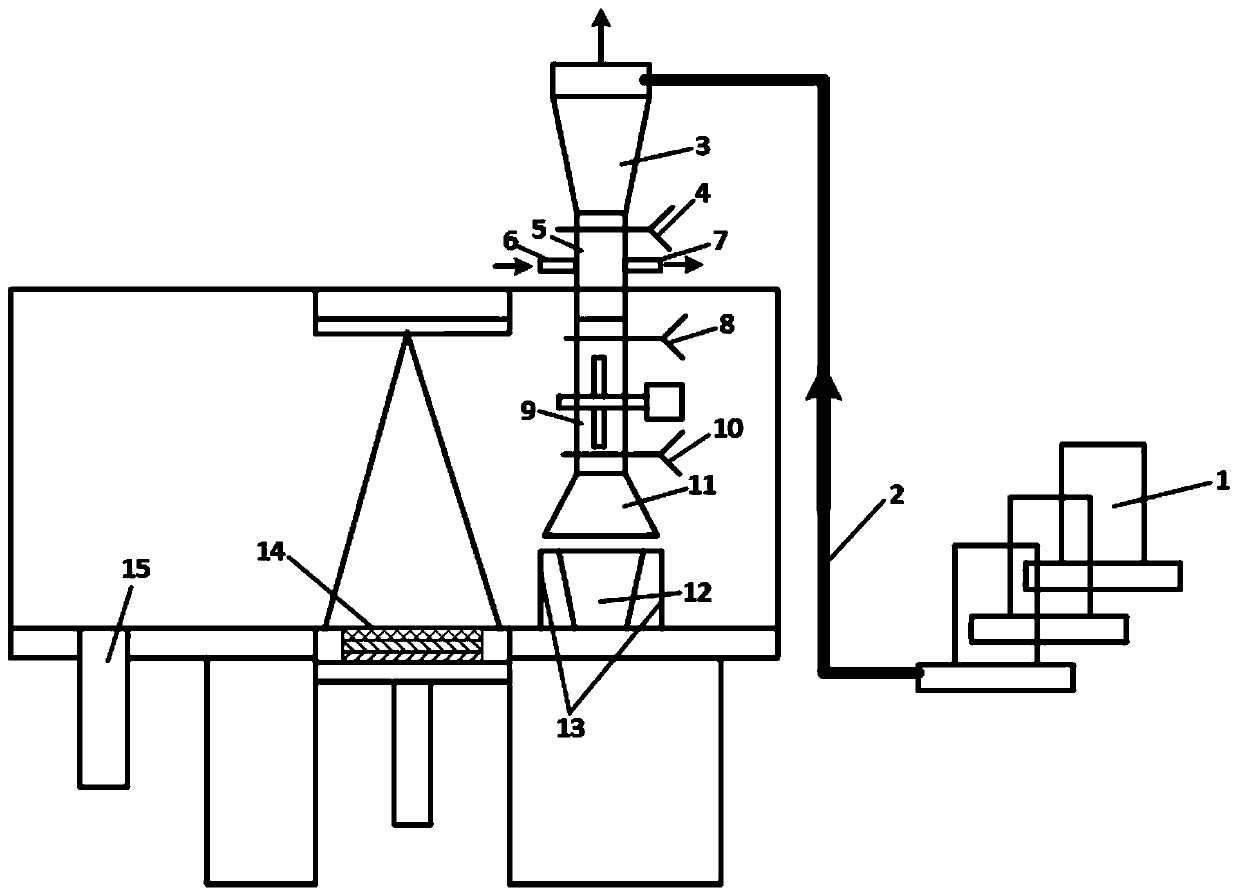

Semiconductor laser synchronous welding set and operating mode thereof

InactiveCN105109035AConstant seam widthFast welding speedWelding/cutting auxillary devicesAuxillary welding devicesFiberSemiconductor

The invention discloses a semiconductor laser synchronous welding set and an operating mode thereof. The semiconductor laser synchronous welding set comprises an upper die fixture and a lower die fixture. The lower die fixture is provided with a positioning device. The upper die fixture has a plurality of fiber output ends which right face a welding area of a device to be welded. The operating mode includes: placing the device to be welded in the lower die fixture and securing the device through the positioning device; allowing a lifting device to drive the lower die fixture to get close and connect to the upper die fixture; reflecting laser by an inner chamber to form compressed continuous spots, and irradiating the welding area of the device to be detected with the spots so as to melt the surface of the device. During using of the semiconductor laser synchronous welding set and the operating mode thereof, laser synchronous welding is used, welding speed is high, a seam in the welding area has constant width, single-step forming is achieved, welding quality and firming capacity are effectively improved, and no any additional fluxes are required.

Owner:SHANGHAI SEEYAO ELECTRONICS CO LTD

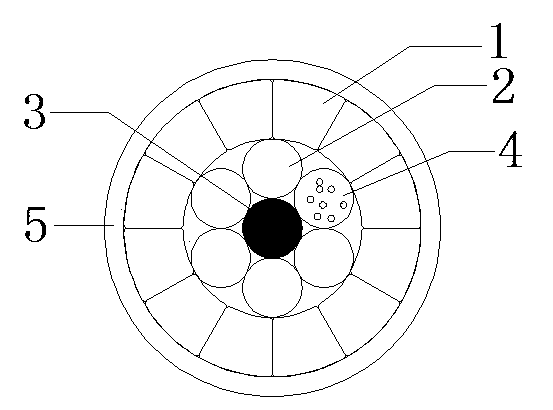

Reinforced optical fiber composite high-temperature-resistant overhead insulating cable

The invention discloses a reinforced optical fiber composite high-temperature-resistant overhead insulating cable which comprises a carbon fiber composite reinforced core. A plurality of round flexible aluminum wires and a stainless steel sleeve light unit are stranded on the outer side of the carbon fiber composite reinforced core in a concentric mode. A plurality of special-shaped flexible aluminum monofilaments which are distributed in a round shape are arranged on the outer sides of the round flexible aluminum wires and the outside of the stainless steel sleeve light unit, and a high-temperature-resistant insulating layer is arranged on the outer sides of the special-shaped flexible aluminum monofilaments. The reinforced optical fiber composite high-temperature-resistant overhead insulating cable is simple in structure, long in service life and suitable for reconstruction and construction of power grid overhead lines in urban and rural areas, can bear the tension strength of 2400Mpa, allows long-time operation temperature to be more than 180 DEG C, has communication and monitoring functions, can effectively solve the dropping problem of the cable, and guarantees safe operation of lines.

Owner:HENAN KOSEN CABLE

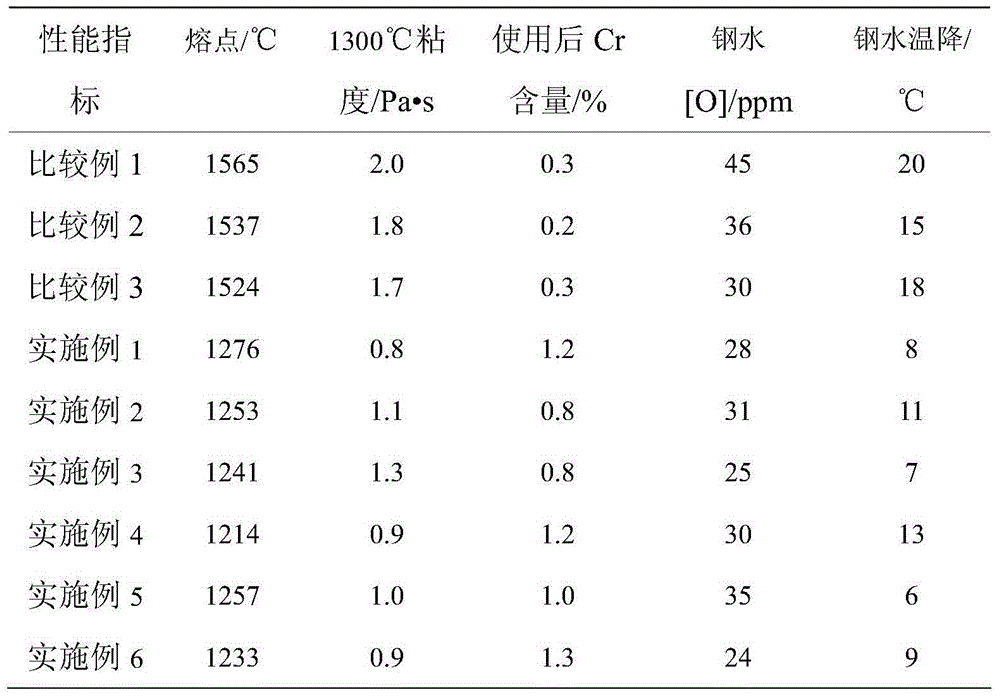

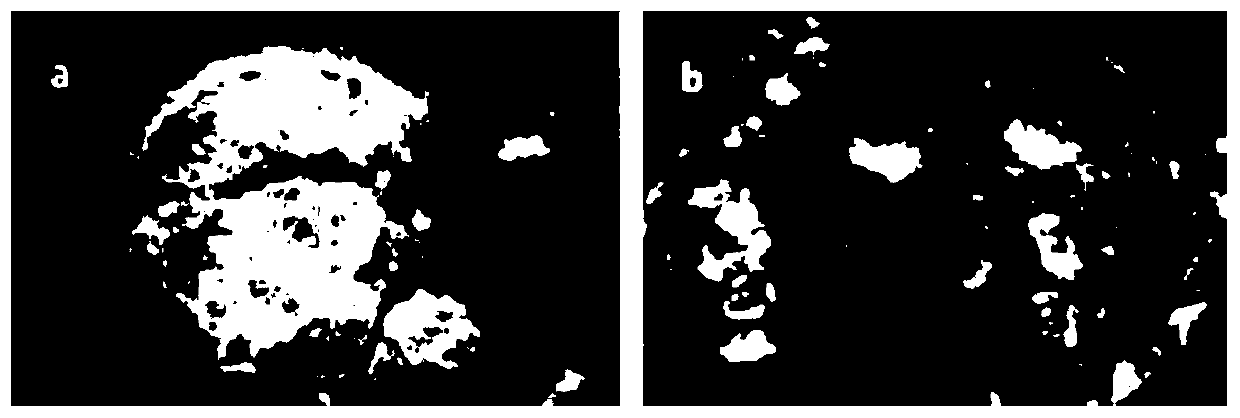

Tundish covering agent used for chrome-bearing steel and application thereof

InactiveCN104874755AEffective absorption and meltingSuitable for continuous castingAlkalinityMetallurgy

The invention relates to a tundish covering agent used for chrome-bearing steel and application thereof and belongs to the technical field of tundishes in the continuous casting process. The tundish covering agent comprises, by mass percent, 30%-45% of CaO, 5%-10% of SiO2, 30%-35% of Al2O3, 5%-10% of MgO, 1%-4% of B2O3 and 6%-15% of (Na2O+Li2O). The tundish covering agent has the advantages that the melting point is low and is 1200-1300 DEG C, the viscosity is high and is 0.7-1.5Pa*s at the temperature of 1300 DEG C, and the alkalinity is high and is 3.0-5.0. The tundish covering agent is applicable to the process of the tundishes produced through continuous casting of the chrome-bearing steel. The tundish covering agent is applied to the continuous casting production process of the chrome-bearing steel, Cr2O3 inclusion can be effectively absorbed and dissolved, Cr2O3 is prevented from entering a crystallizer, the cleanliness degree of molten steel is improved, and therefore the quality of cast blanks is improved.

Owner:CENT SOUTH UNIV

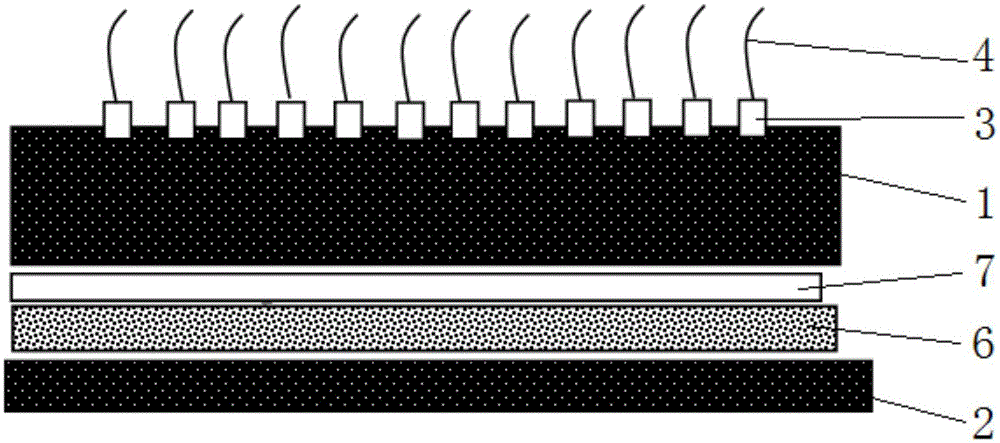

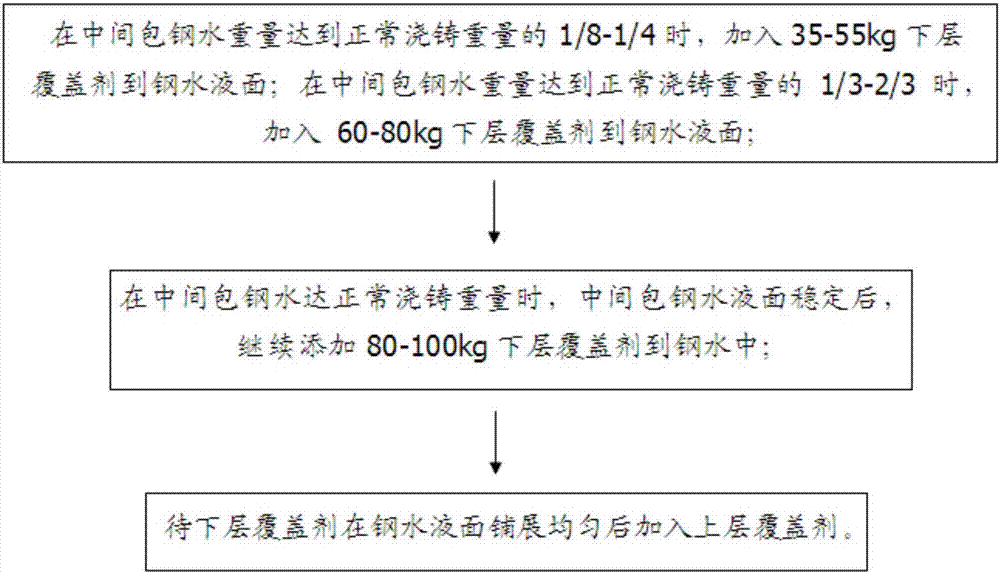

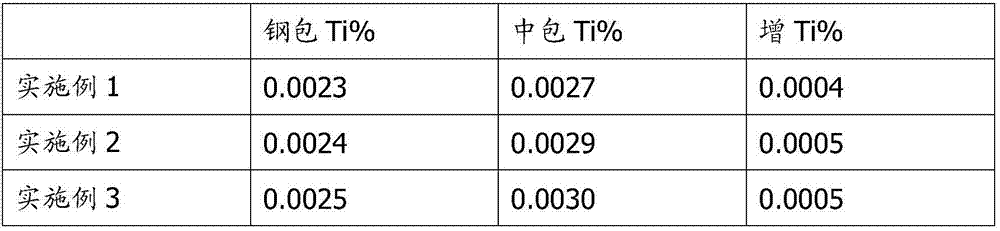

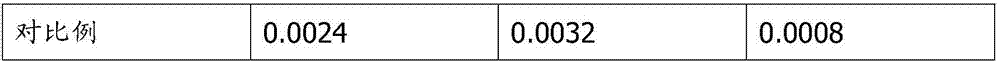

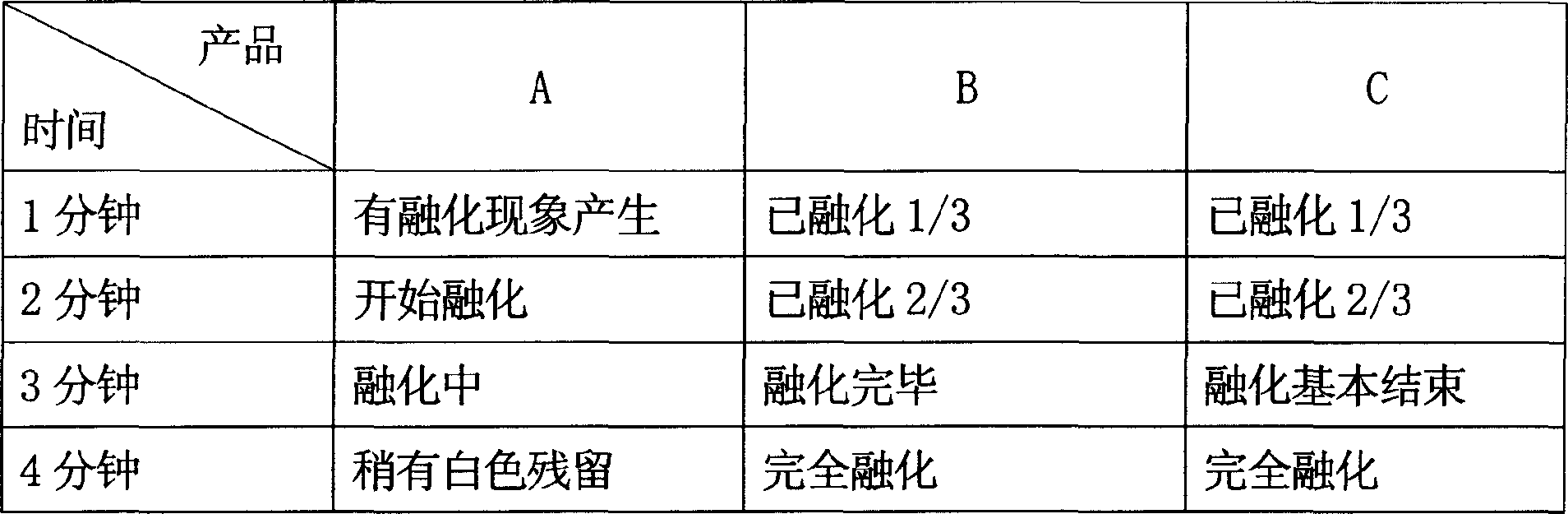

Low-titanium-content double-layer covering agent for silicon steel and use method of low-titanium-content double-layer covering agent

The invention provides a low-titanium-content double-layer covering agent for silicon steel and a use method of the low-titanium-content double-layer covering agent. The low-titanium-content double-layer covering agent comprises an upper layer covering agent part and a lower layer covering agent part; the lower layer covering agent part is contacted with molten steel; the upper layer covering agent part is located above the lower layer covering agent part; the upper layer covering agent part comprises the following raw materials, by weight percentage, 44-62% of SiO2, 2-10% of MgO, 1-10% of CaO, greater than 0 and less than or equal to 7% of Fe2O3, 20-38% of Al2O3, greater than 0 and less than or equal to 1% of C (all), greater than 0 and less than or equal to 0.5% of TiO2, and the balance ignition lost; and the lower layer covering agent part comprises the following raw materials, by weight percentage, 15-25% of SiO2, 3-8% of MgO, 48-68% of CaO, 2-10% of Fe2O3, greater than 0 and less than or equal to 1% of Al2O3, greater than 0 and less than or equal to 1% of C (all), greater than 0 and less than or equal to 0.2% of TiO2, and the balance ignition loss. With the use of the low-titanium-content double-layer covering agent, the content of titanium in molten silicon steel can be reduced effectively.

Owner:BEIJING SHOUGANG CO LTD

Antifreezing agent composition and its production process

InactiveCN1847356APrevent slippingReduce congestionOther chemical processesRoad surfaceTrisodium citrate

The present invention discloses one kind of antifreezing agent composition and its production process. The antifreezing agent composition is produced with sodium chloride 40-60 weight portions, calcium chloride 5-15 weight portions, magnesium chloride 30-45 weight portions and corrosion inhibiting additive 1-3 weight portions. The corrosion inhibiting additive is mixture of trisodium citrate or trisodium phosphate and magnesium sulfate in the equal ratio. The production process includes the steps of sorting material, drying, sieving and mixing. The antifreezing agent composition is spread in road with ice and snow and can thaw ice and snow effectively to ensure traffic safety.

Owner:WEIFANG CHANGDA CHEM

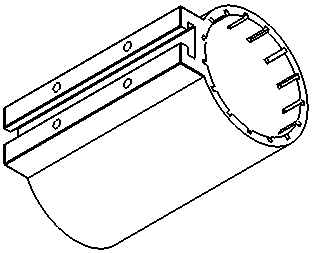

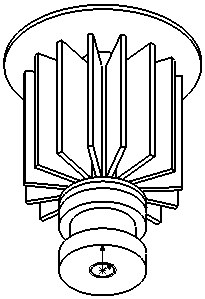

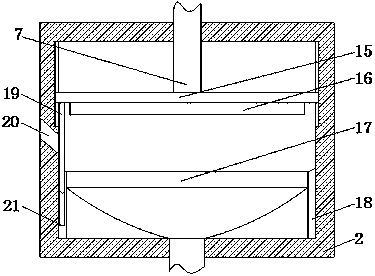

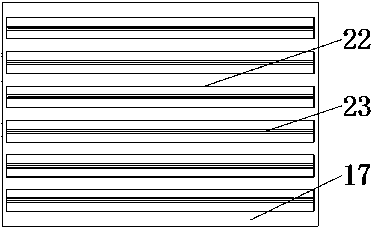

Softening and early-fusing protective device for 3D printing material filament

InactiveCN107718543AEfficient heatingHeating evenlyAdditive manufacturing apparatus3D object support structuresCircular discSpray nozzle

The invention discloses a softening and early-fusing protective device for a 3D printing material filament. The softening and early-fusing protective device comprises a feeding guide tube, an air tube, a guide tube clamp, a heat dissipation tube, a throat tube, a heating block sheath, a heating block and a spray nozzle, wherein the feeding guide tube enters the air tube outside a processing cavityand enters the processing cavity along with the air tube, and air is fed to the heat dissipation tube along the air tube from the outer part of the processing cavity for cooling; heat dissipation fanblades of the heat dissipation tube extend axially while stretching outwards in the radial direction; an air baffle circular disc at the bottom of the heat dissipation tube changes an air feeding direction, so that air is prevented from being blown to the heating block; and the heating block sheath is additionally arranged on the heating block. The softening and early-fusing protective device effectively solves the problem that the spray nozzle is blocked as a fan cannot be adopted for cooling in the processing cavity, and the material filament is softened and fused early before reaching thespray nozzle during high-temperature plastic 3D printing, guarantees uniformity of heat, in a processing process, of the heating block, and is not affected by a printing temperature. The device does not need a complex water cooling channel, has the characteristics of being simple in structure, low in cost and easy to assemble, and has relatively high practicability and good economic benefits.

Owner:GUANGXI UNIV +1

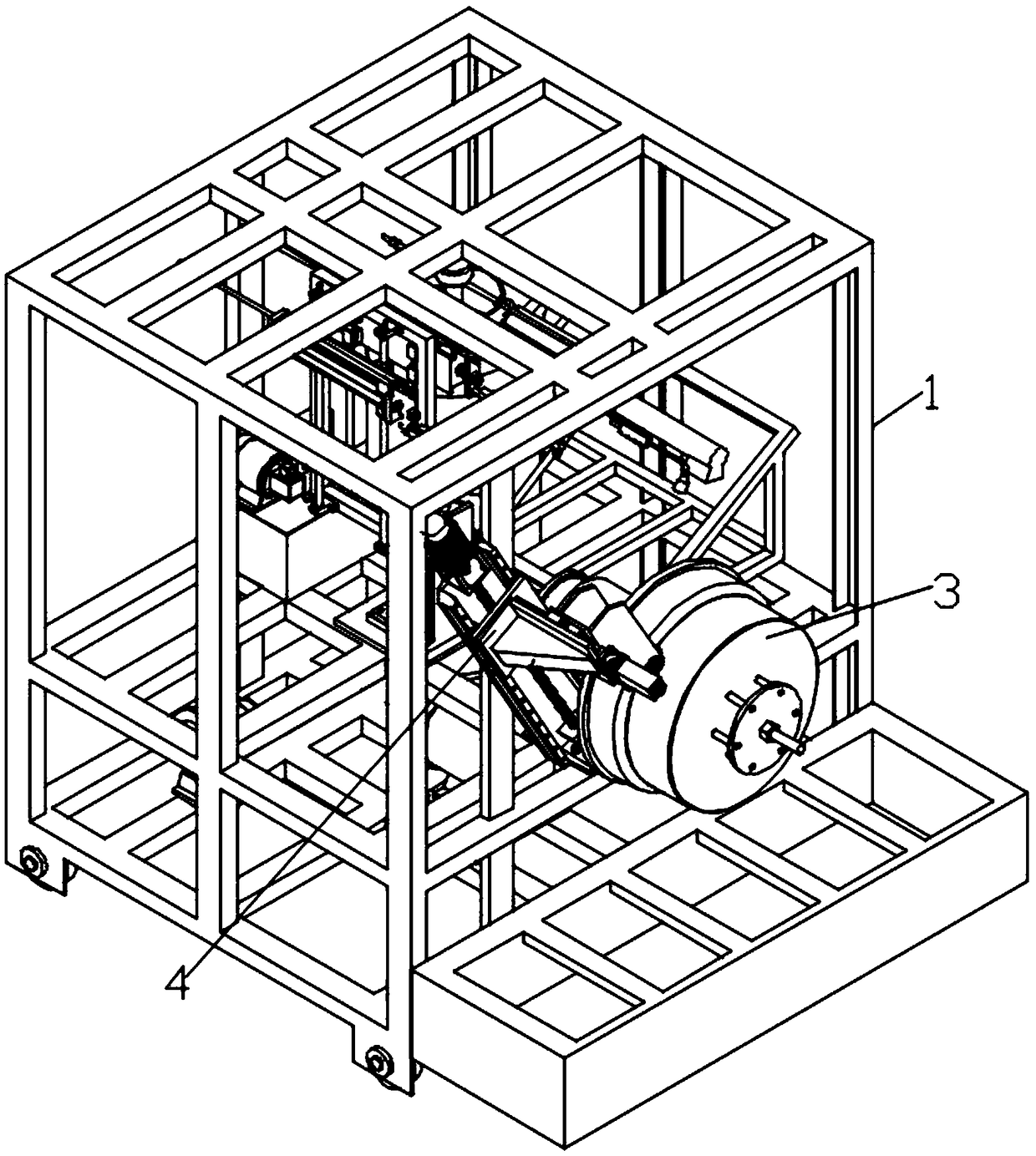

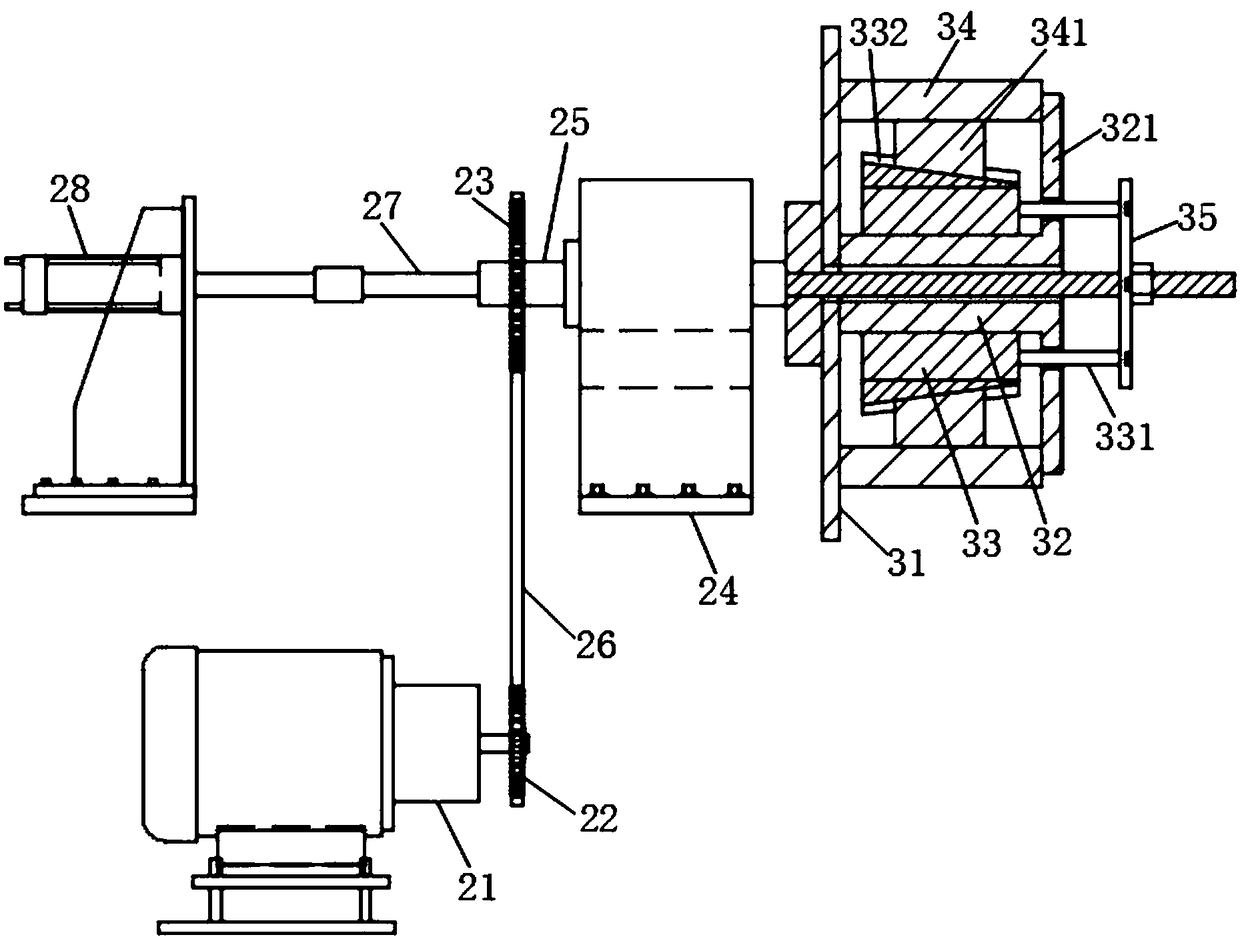

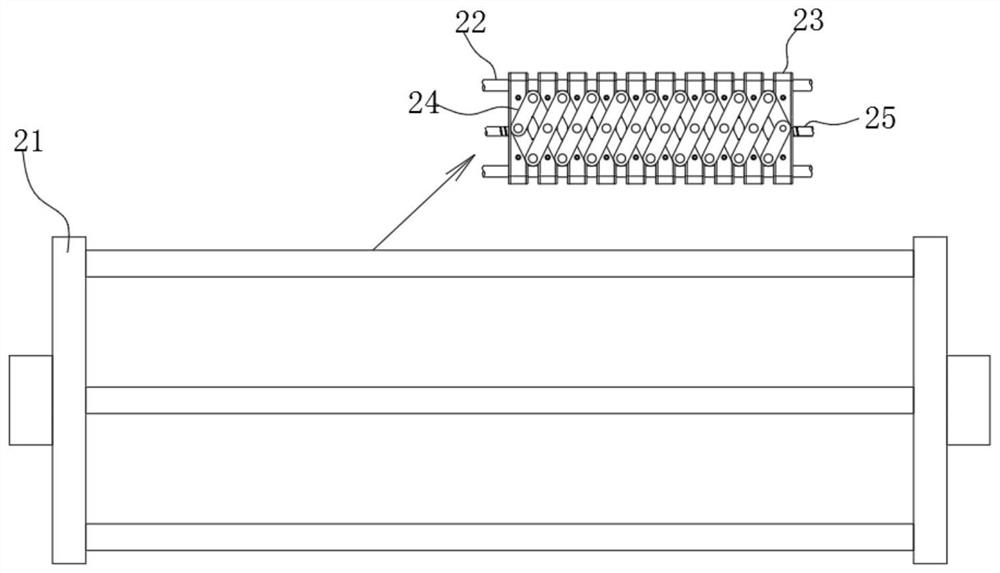

Corrugated pipe orifice wrapping sealing machine and production line

PendingCN108422653AReasonable designEffective edge treatmentWrapper twisting/gatheringProduction lineEngineering

The invention relates to a corrugated pipe orifice wrapping sealing machine and a production line. The corrugated pipe orifice wrapping sealing machine comprises a case, a driving mechanism, an orifice connector, a movable compressing mechanism, a hot melting system and a cooling system. A plane is arranged at an end of the case, the orifice connector is arranged at an end of the case, the drivingmechanism is mounted in the case and is in transmission connection with the orifice connector, and the orifice connector can be driven by the driving mechanism to rotate; an orifice in an end of a corrugated pipe can sleeve the orifice connector, and pipe wrapping plastic is laid on the outer surface of the orifice in the end of the corrugated pipe; the hot melting system is arranged on the case;the movable compressing mechanism is mounted at an end of the case, and a compressing wheel is arranged on the movable compressing mechanism and can be driven by the movable compressing mechanism tomove towards the orifice connector or away from the orifice connector; the cooling system is mounted on the case. The corrugated pipe orifice wrapping sealing machine and the production line have theadvantages that the corrugated pipe orifice wrapping sealing machine is reasonable in design, plastic edge sealing treatment can be effectively carried out on orifices of corrugated pipes, and accordingly the corrugated pipe orifice wrapping sealing machine and the production line are high in production efficiency and good in quality.

Owner:高明芳

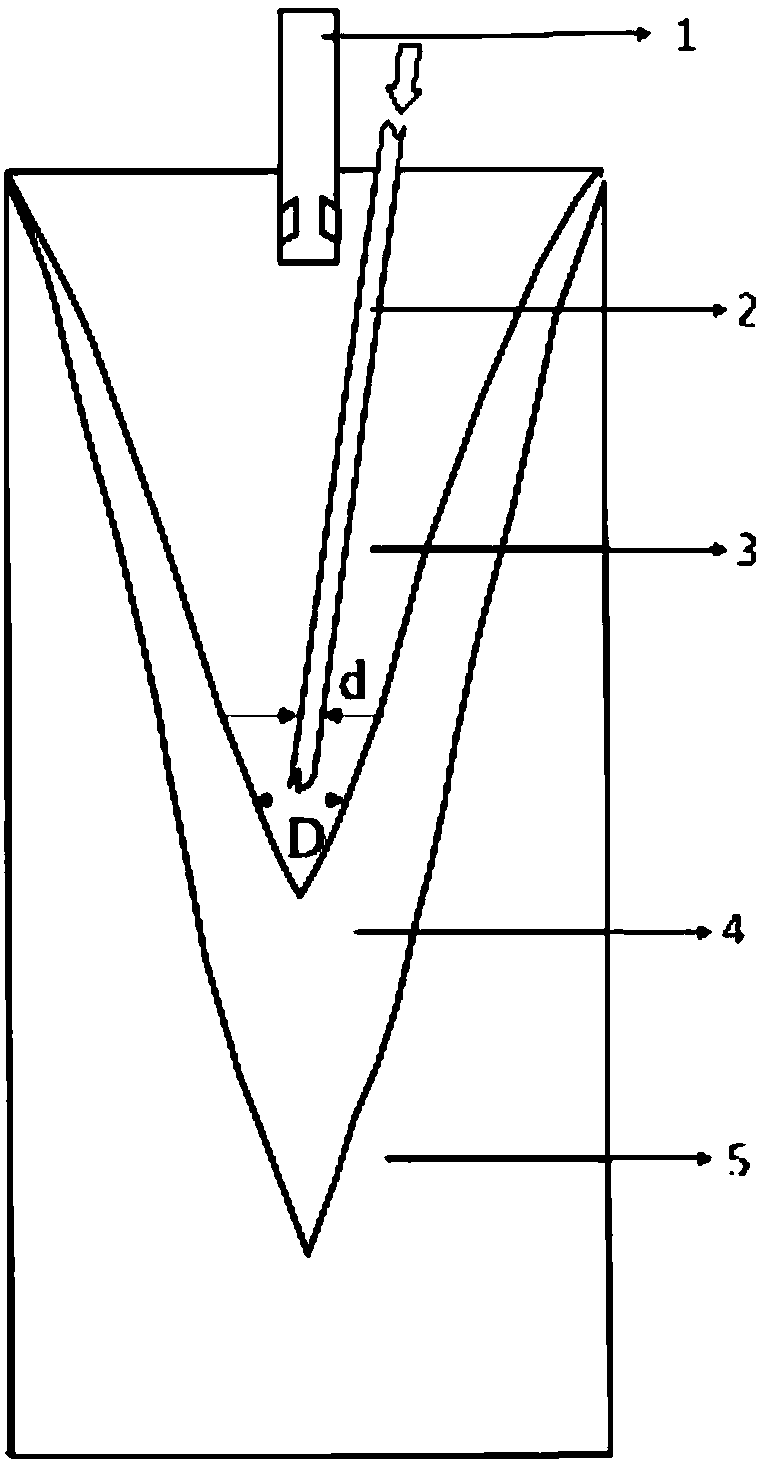

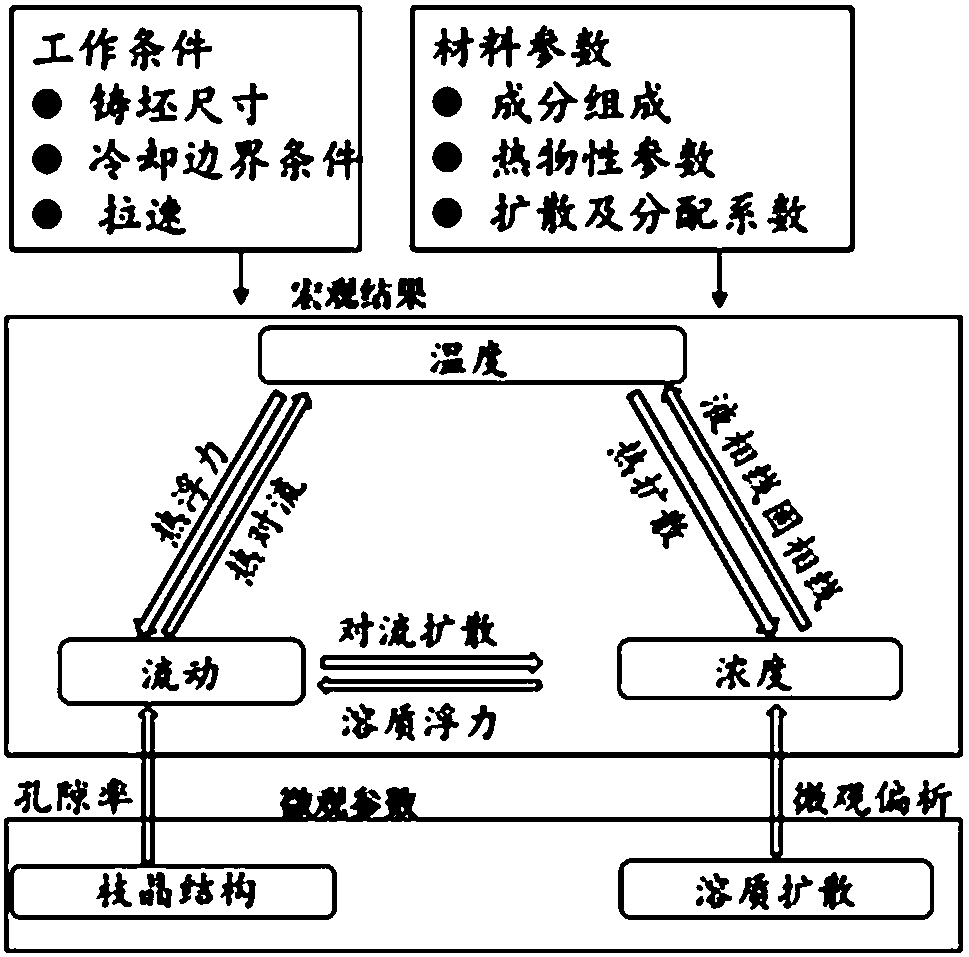

Method for diluting and eliminating center line segregation of continuous casting slab by utilizing additive material

The invention relates to a method for diluting and eliminating center line segregation of a continuous casting slab by utilizing an additive material. The method comprises the following steps: acquiring the parameters of production working conditions; determining supply speed va, the thickness d of the additive material and the width w of the additive material, wherein w is larger than d; calculating a segregation index of the tail end of a liquid core based on a standard solute concentration C<standard> to obtain a solute concentration Coi, and adopting an inverse method to obtain a solute concentration Ca of the additive material; obtaining a selection concentration C<selection> according to a formula that C<selection> is larger than or equal to Ca and smaller than C<standard>; selectingand / or manufacturing the additive material according to the thickness d of the additive material, the width w of the additive material and the selection concentration C<selection>, and continuously conveying the additive material to the tail end of the liquid core in a vibrating manner. According to the method for diluting and eliminating center line segregation of the continuous casting slab byutilizing the additive material provided by the invention, the center line segregation is alleviated and eliminated by utilizing proportioning of alloy components, and meanwhile the additive materialcan eliminate center loosening. The additive material is completely molten after reaching the tail end of the liquid core; under a vibration effect, the molten liquid group is totally mixed with casting liquid inside the tail end of the liquid core, so two great internal quality defects about center line segregation and center loosening inside the continuous casting slab are simultaneously prevented.

Owner:NORTHEASTERN UNIV

Wood surface hydrophobic treatment method

ActiveCN107379179AImprove corrosion resistanceEffective combinationRadiation/waves wood treatmentElectric wood treatmentMicrowaveWorking life

The invention discloses a wood surface hydrophobic treatment method and relates to the technical field of wood treatment. The wood surface hydrophobic treatment method comprises the following steps: (1) pre-treatment; (2) microwave treatment; (3) vacuum impregnation; (4) low-temperature plasma treatment; when wood is treated through the wood surface hydrophobic treatment method disclosed by the invention, not only can the hydrophobic properties of wood surfaces be effectively improved, but also the corrosion resistance of the wood surfaces can be effectively improved, so that the application range and the working life of the wood can be effectively improved.

Owner:安徽嘉美工艺品有限公司

Fusion device capable of simultaneously treating polymorphic hazardous wastes

ActiveCN105716093AEfficient dischargeEffective secondary meltingIncinerator apparatusCombustorCombustion chamber

The invention discloses a fusion device capable of simultaneously treating polymorphic hazardous wastes, and relates to a fusion device. The existing solid or liquid hazardous wastes need classified treatment, and the treatment process is complicated, difficult to realize the effects of effective fusion and non-toxic discharge, low in ignition stability and bad in heat energy utilization rate. The top end of a vertical combustion chamber is an inlet end for thin-particle size hazardous wastes; the interior of the vertical combustion chamber is a vertical combustion hearth; a horizontal combustion chamber is arranged below the vertical combustion chamber in an inclined manner; the high end of the horizontal combustion chamber is communicated with the bottom end of the vertical combustion chamber; a first discharging channel and a second discharging channel are formed in the horizontal combustion chamber in sequence; the interior of the horizontal combustion chamber is a horizontal combustion hearth; the interior of the horizontal combustion chamber is divided into a preliminary fusion chamber and a thermal insulation warming chamber in sequence; a reciprocating grate is arranged in the preliminary fusion chamber; and a plurality of warming combustor are arranged in the thermal insulation warming chamber. The fusion device disclosed in the invention is used for treating hazardous wastes.

Owner:国泥工程中心(哈尔滨)有限公司

Blend asphalt for coating graphite anode material

ActiveCN106675054AEffective meltingLow volatileCell electrodesBuilding insulationsGranularityGraphite

The invention discloses blend asphalt for coating a graphite anode material. The blend asphalt is prepared from the following components in percentage by weight: 50%-80% of coal asphalt and 20%-50% of petroleum asphalt, the softening point is at the temperature of 110-140 DEG C, the volatile matter is smaller than or equal to 60%, and the coking value is larger than or equal to 40%. The blend asphalt can reduce the volatile matter, increases the coking value and is easy to operate. Meanwhile, by means of the blend asphalt, the qualified rate of granularity of the coated graphite anode material can be increased by 5% or higher, the tap density can be increased by 5%-10%, and the comprehensive performance of the graphite anode material is improved finally.

Owner:赣州市瑞富特科技有限公司

Gas mixture substituting for MAPP gas

The invention relates to an MAPP gas which is formed by mixing propane, propylene and dimethyl ether according to a certain proportion, wherein, the propane takes up 18 to 22 percent of the total components, the propylene takes up 36 to 44 percent of the total components, and the dimethyl ether takes up 36 to 44 percent of the total components. By using special welding sets and packing containers, the actual combustion temperature of the MAPP gas can reach above 1350 DEG C (in general, the actual combustion temperature of liquid gas is 600 to 800 degrees) in the situation that no pure oxygen is used for supporting combustion. The MAPP gas of the invention has wide and stable source of raw materials, low price, higher security, easy carrying, and no phenomena such as black smoke and tempering, etc. in the combustion process, and is a solder brazing gas which can be directly used for brazing without the help of oxygen.

Owner:NINGBO KOMANS REFRIGERATION IND

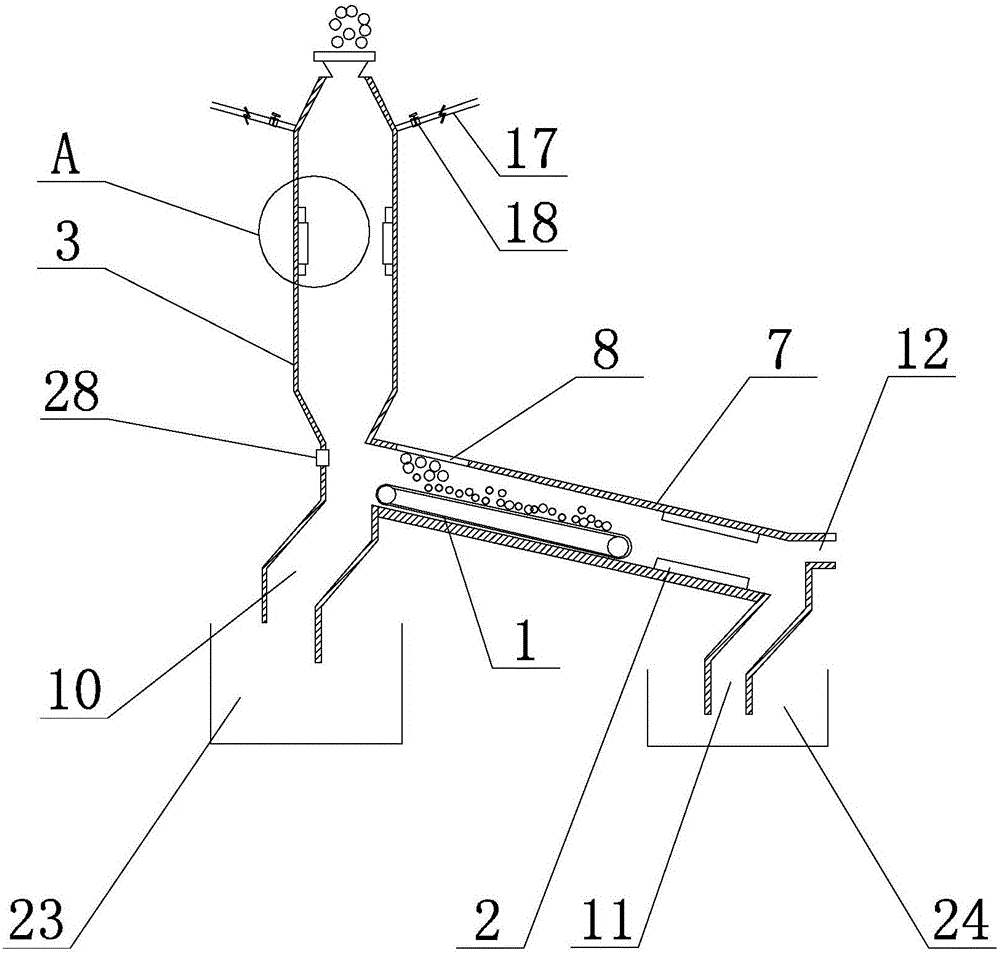

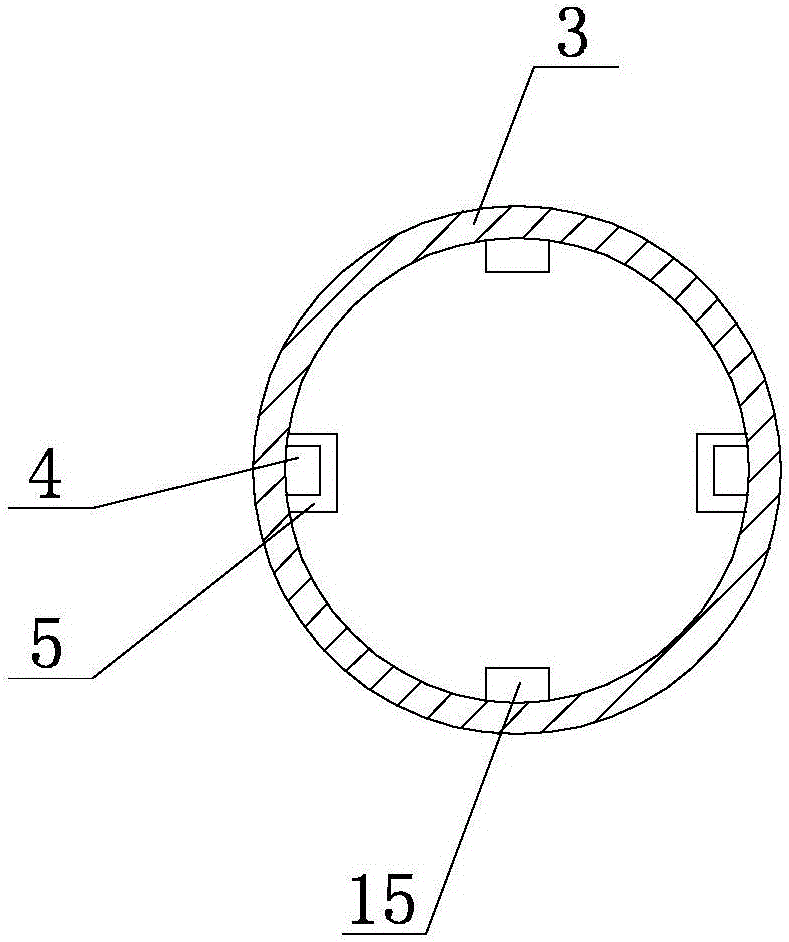

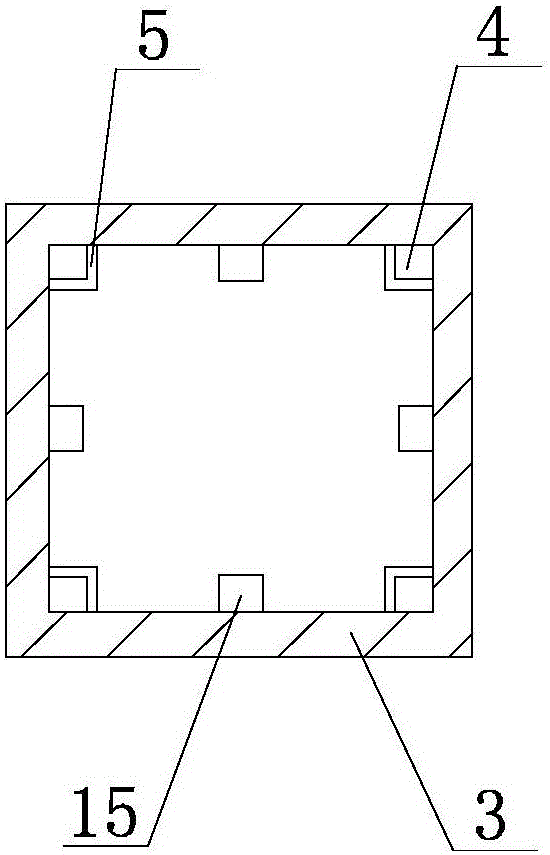

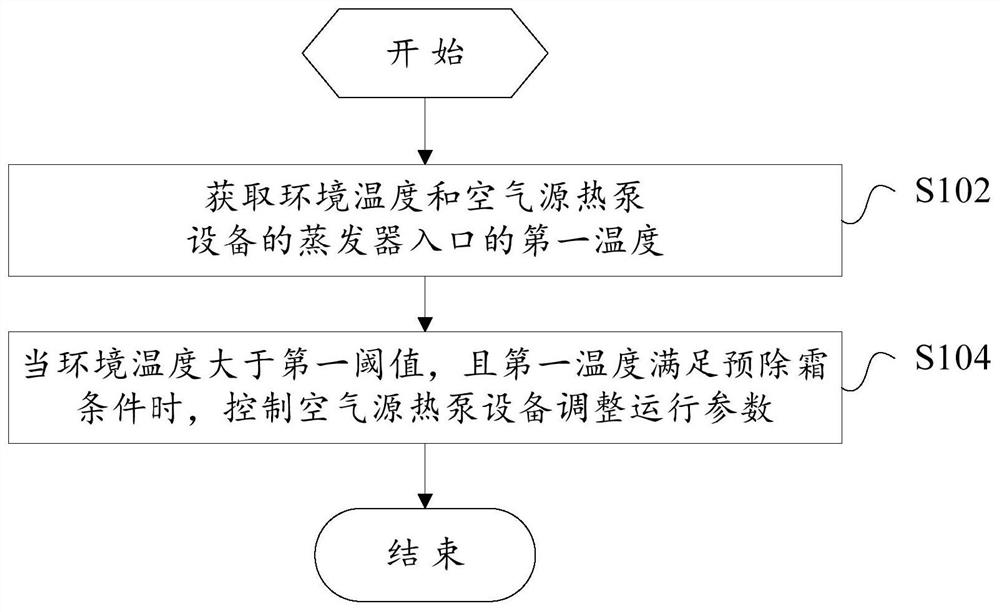

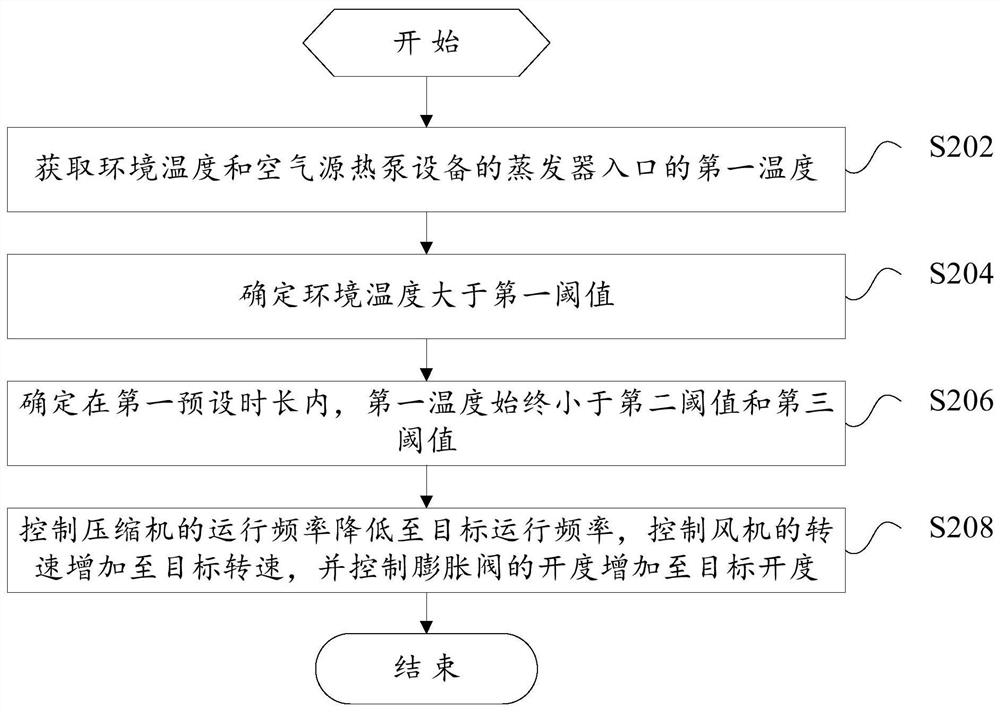

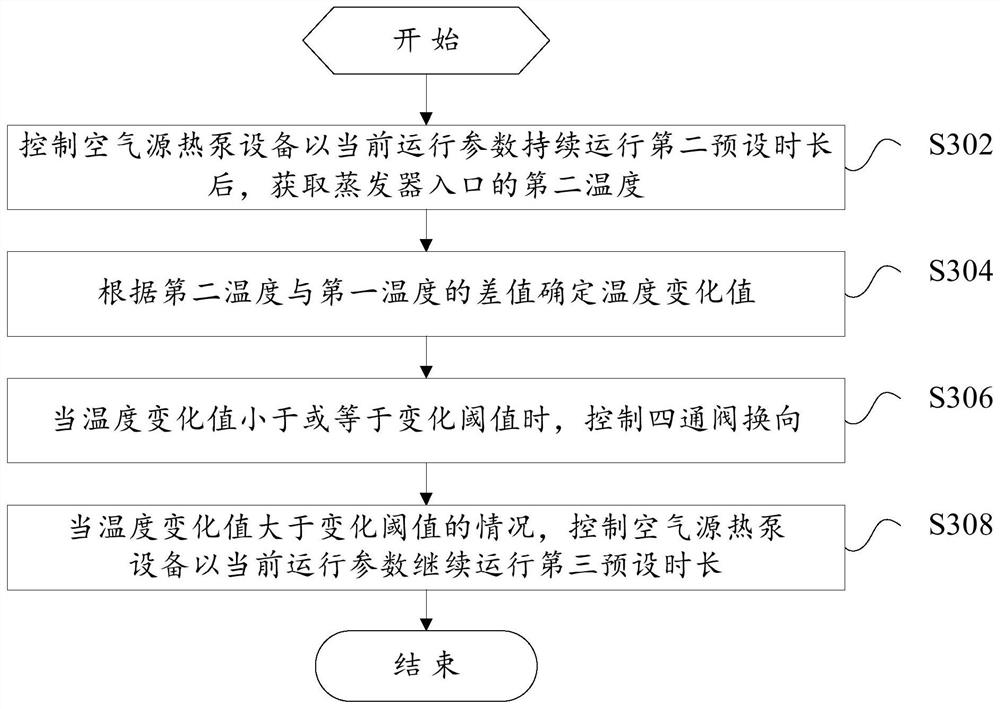

Control method and device for air source heat pump equipment, air source heat pump equipment and readable storage medium

ActiveCN111964300AImprove user experienceSmall attenuationCorrosion preventionEfficient regulation technologiesFour-way valveProcess engineering

The invention provides a control method and device for air source heat pump equipment, the air source heat pump equipment and a readable storage medium. The control method comprises the following steps of: obtaining an environment temperature and a first temperature of an evaporator inlet of the air source heat pump equipment; and on the basis of a situation that the environment temperature is greater than a first threshold value and the first temperature meets a pre-defrosting condition, controlling the air source heat pump equipment to regulate an operation parameter. By use of the embodiment of the invention, a pre-defrosting mode is set, so that the air source heat pump equipment can carry out pre-defrosting on an evaporator through the heat of the external environment under a non-stopcondition, so that a phenomenon that when the evaporator is slightly frosts, four-way valve reversing causes the temperature of user side air to be lowered or the temperature of a water tank on a user side to be lowered, and the heat generation quantity and the energy efficiency of the heat pump are low in attenuation can be avoided, in addition, a pressure impact on the system due to four-way valve reversing can be reduced, so that system operation reliability and the service life of the equipment can be improved, and user use experience is improved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

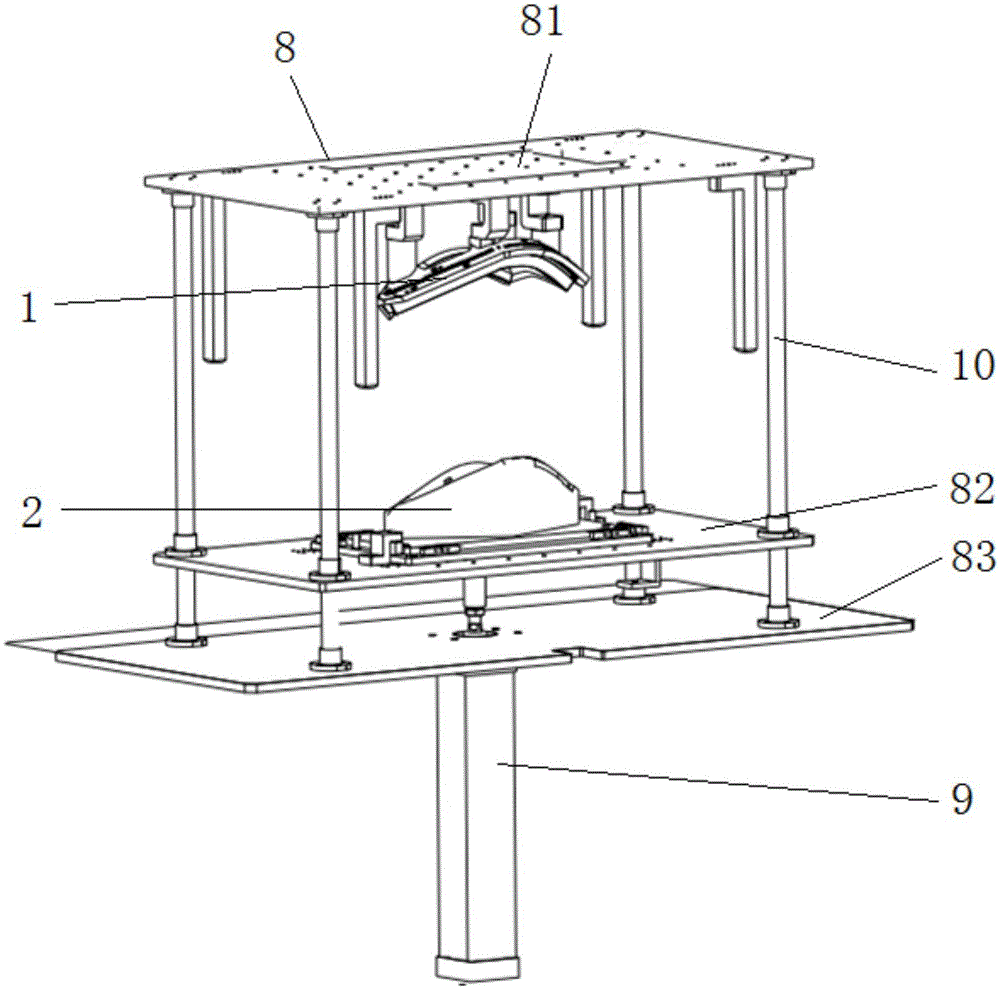

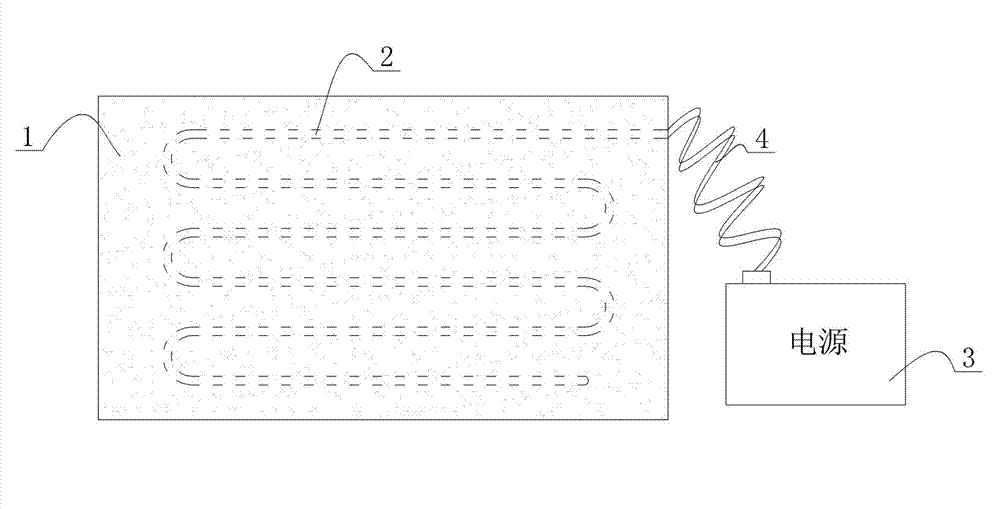

Icy frost remover for automobile glass

InactiveCN102951125AEasy to cleanEffective meltingCleaning apparatus for vehicle exteriorsFrostResistance wire

The invention relates to an icy frost remover for automobile glass. The icy frost remover for automobile glass comprises a wiping body made of an insulating material and a power supply for providing electric energy. The icy frost remover for automobile glass is characterized in that the wiping body is internally provided with heating resistance wires uniformly, wherein the heating resistance wires are connected with the power supply through a power supply line. According to the icy frost remover for automobile glass provided by the invention, the icy frost on the automobile glass can be effectively melted by arranging the heating resistance wires inside the insulating wiping body and connecting the heating resistance wires with the power supply through the power supply line, so that the purpose of quickly removing the icy frost is realized. A water absorbing layer can be further arranged on the outer surface of the wiping body to absorb melted water effectively so as to clean the automobile glass quickly.

Owner:王慧婷

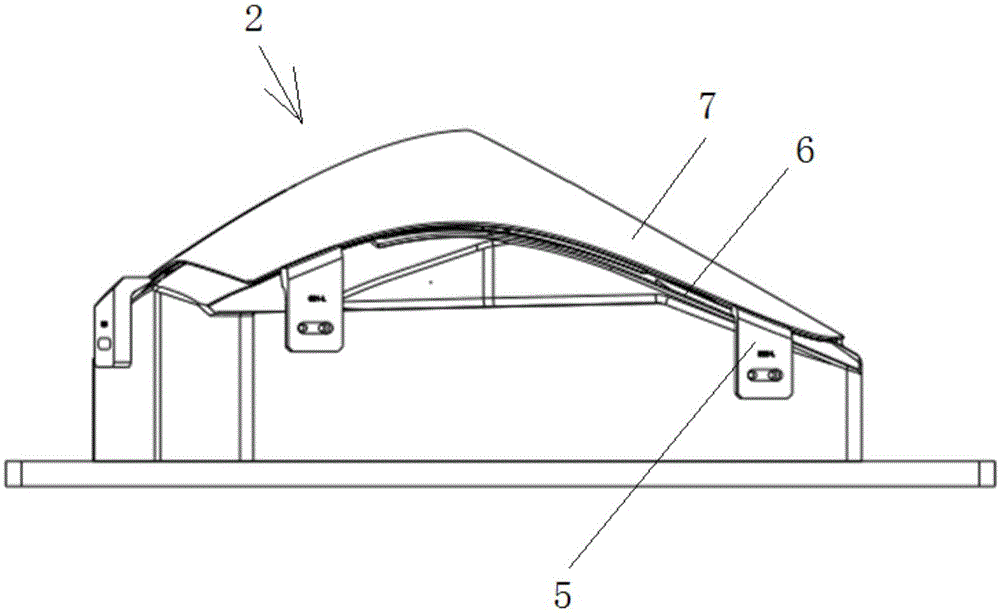

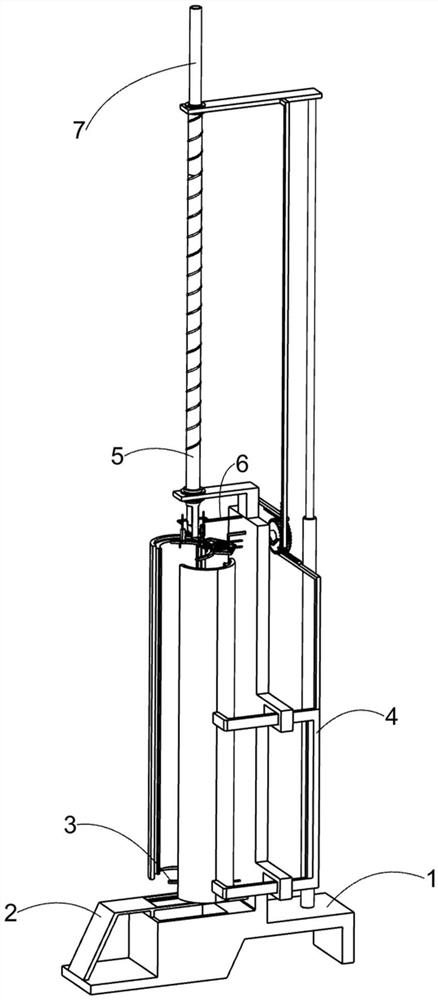

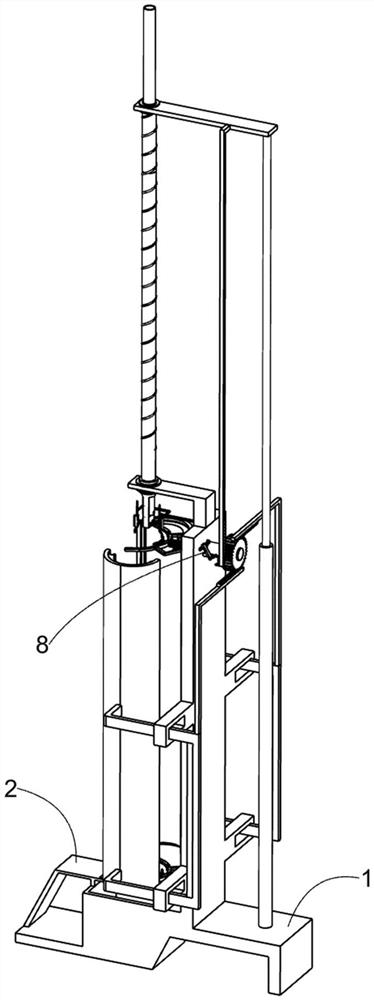

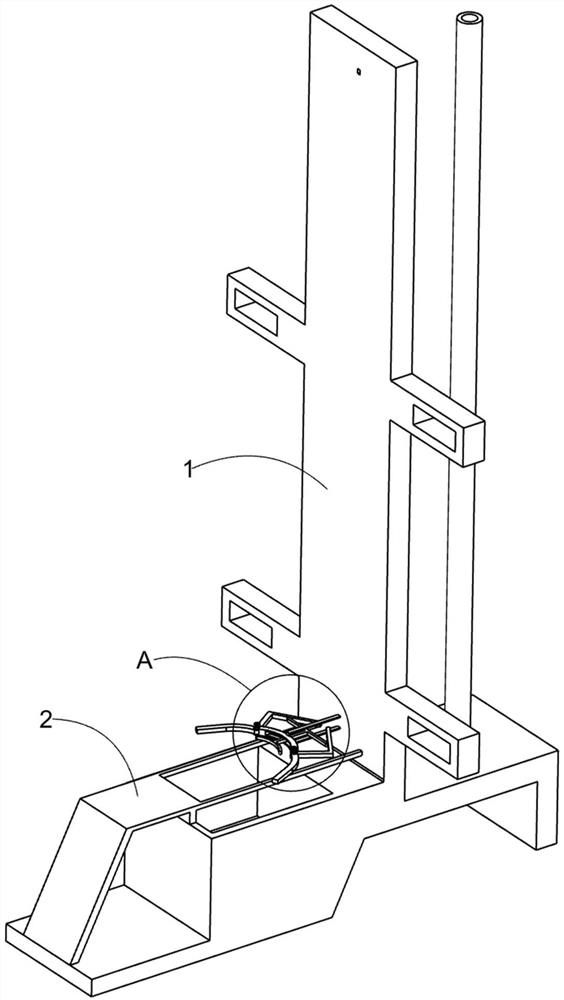

Device for removing solidified oil stains on inner wall of petroleum pipe

PendingCN113426769APrevent hand injuriesEffective meltingHollow article cleaningGeneral water supply conservationPetroleumMechanical engineering

The invention relates to the field of petroleum exploitation, in particular to a device for removing solidified oil stains on the inner wall of a petroleum pipe. The device comprises a base, a containing plate, a positioning assembly, a clamping and heating assembly, a rotary scraping assembly and the like. The containing plate is connected to the base, the positioning assembly is arranged on the base, the clamping and heating assembly is arranged on the base, and the rotary scraping assembly is arranged on the base. By means of a heating arc-shaped plate, the heating arc-shaped plate can be tightly attached to the petroleum pipe on the containing plate, the heating arc-shaped plate can clamp the petroleum pipe on the containing plate so as to facilitate follow-up operation, meanwhile, the heating arc-shaped plate can heat the petroleum pipe on the containing plate, and therefore the solidified oil stains on the inner wall of the petroleum pipe on the containing plate are molten into a liquid state; and the effect that the solidified oil stains on the inner wall of the petroleum pipe can be effectively melted so that the oil stains can be conveniently cleaned away in the follow-up process is achieved.

Owner:刘美亮

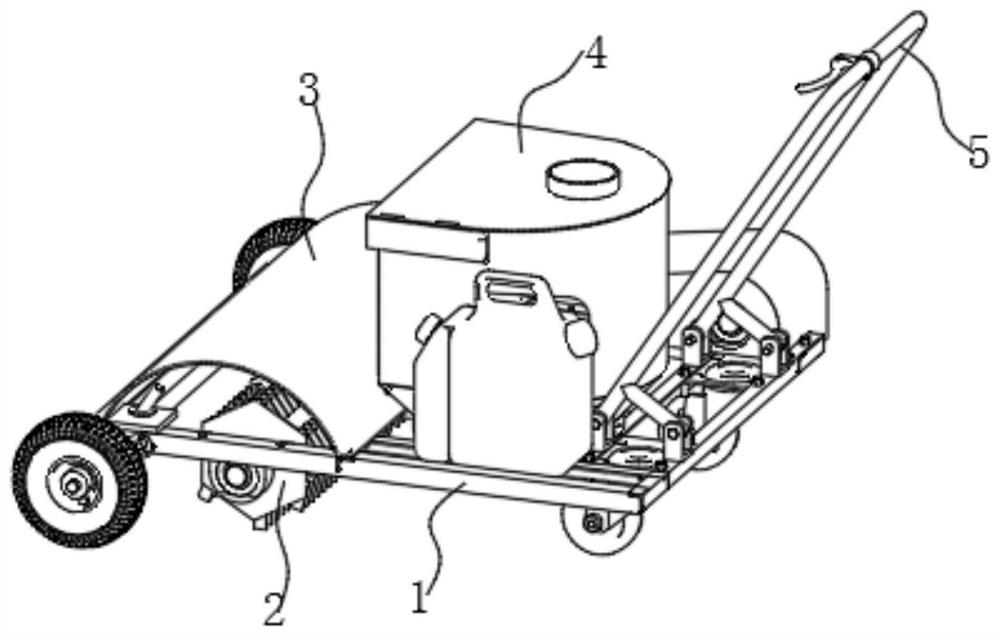

Intelligent swinging hammer type deicing device for highway bridge

ActiveCN112878266AChange spacingEffective cleaning rangeClimate change adaptationSnow cleaningRoad surfaceCentrifugal force

The invention discloses an intelligent swinging hammer type deicing device for a highway bridge. The device can adjust the effective cleaning range and the effective cleaning capability of a swinging hammer assembly according to the width of a road surface and the icing condition of the road surface. During deicing, the swinging hammer assembly rotates along with rotation of a swinging hammer control assembly, so that a swinging hammer inner arm is thrown out by means of centrifugal force, an ice breaking ball on a hinge arm is driven to impact an ice body, and deicing is achieved; when the ice breaking ball is used for deicing, under the combined action of a damper and a torsion spring, after the ice body is hammered by the ice breaking ball, multiple times of oscillation hammering are carried out, so that the deicing capability is improved; and in the deicing process, a fan continuously rotates, negative pressure is generated, ice block disintegrating slag and the like on the ground are sucked into a flow guide pipe, fall into a temporary storage bin and are heated and melted by a heater to form liquid to be sprayed out, hot water is sprayed near the swinging hammer assembly, ice slag attached to the ice breaking ball can be effectively melted, and dissolution of ice blocks on the road surface can be accelerated.

Owner:李风增

High thermal stability density silicon carbide ceramic circuit board substrate material and preparation method thereof

InactiveCN105367060ALower sintering temperatureSmall coefficient of thermal expansionComposite ceramicPolyethylene glycol

The invention discloses a high thermal stability density silicon carbide ceramic circuit board substrate material, which has lower sintering temperature and lower coefficient of thermal expansion by compositing and using micron grade silicon carbide powder, cordierite powder and nanometer level alumina powder, enables various materials to uniformly disperse and coat because polyethylene glycol composite solvents containing nano ceramic powder transparent liquid are strong in wettability and bonding ability for power, achieves effective melting enhancing effects, is compact and tight in prepared green bodies, can obtain high relative density and high thermal stability composite ceramic substrates in relatively lower sintering temperature, and is safe and environmentally friendly and large in utilization potentiality.

Owner:HEFEI LONG DUO ELECTRONICS SCI & TECH

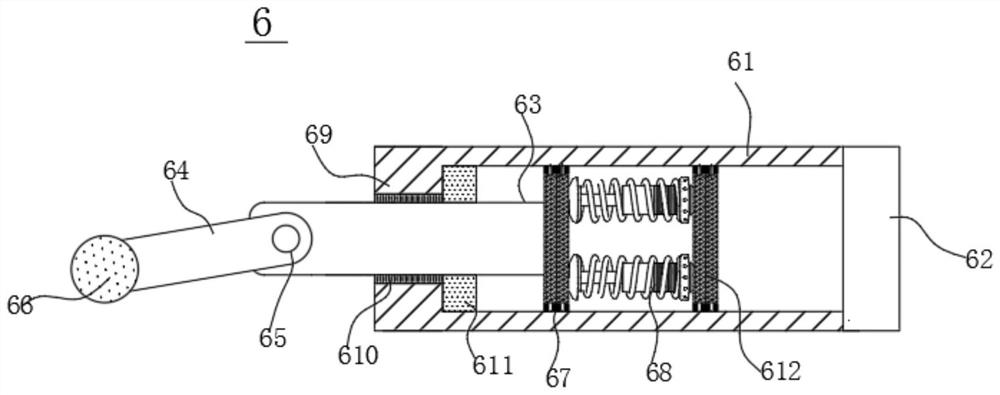

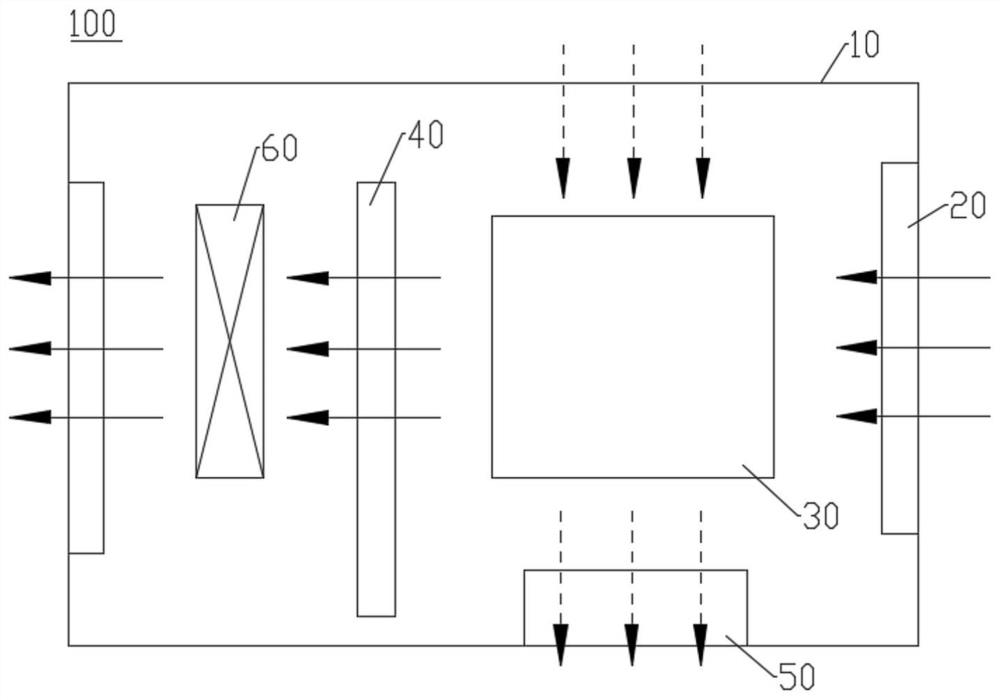

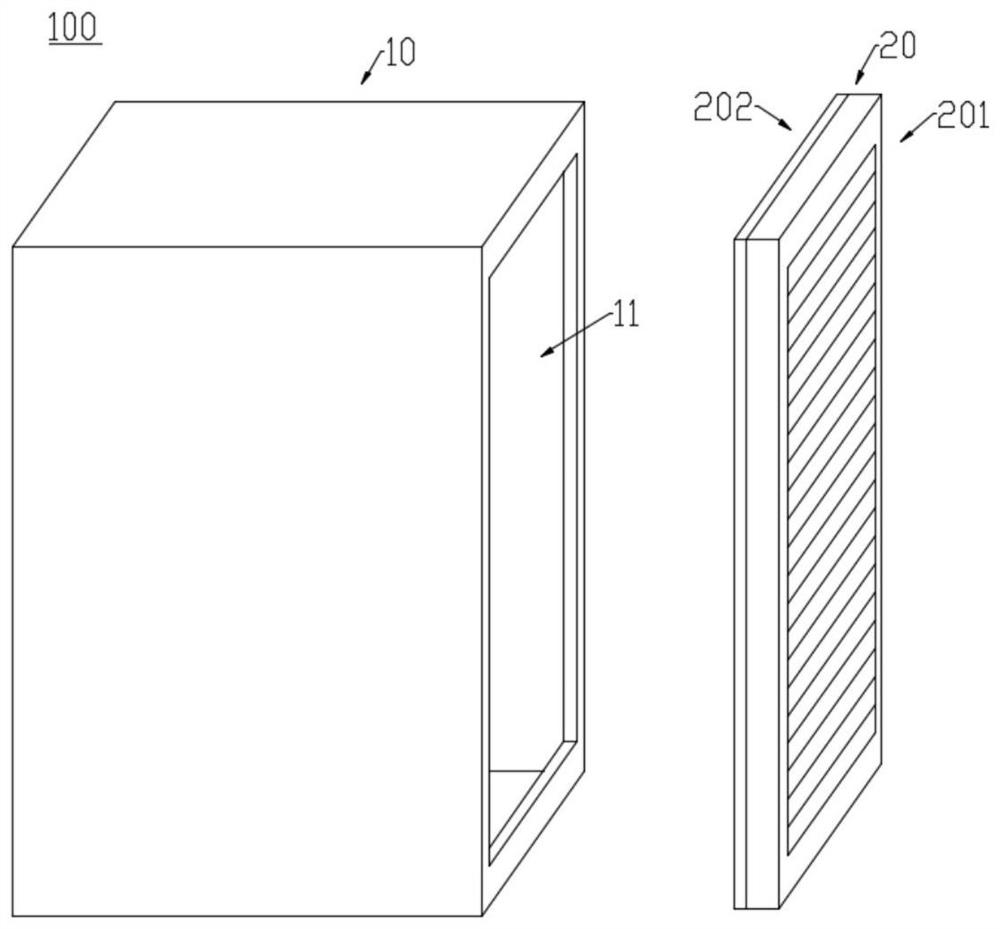

Ventilation device, control method thereof and electronic equipment

PendingCN112672623AAvoid enteringDissipate heat in timeCooling/ventilation/heating modificationsLouverPhysics

The embodiment of the invention provides a ventilation device and electronic equipment comprising the ventilation device. The ventilation device comprises a louver and heating pieces, the louver comprises a fixing frame and a plurality of louver blades, the louver blades are installed on the fixing frame at intervals in a first direction, an air duct is formed between every two adjacent louver blades, each air duct comprises an air inlet and an air outlet, the air inlets and the air outlets are arranged in a staggered mode in a direction perpendicular to the first direction, and the heating pieces are arranged on the surfaces of or in the louver blades. The invention aims to obtain the ventilation device capable of effectively melting ice and snow and the electronic equipment.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

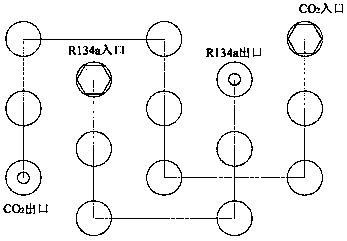

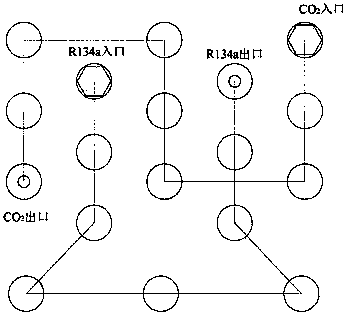

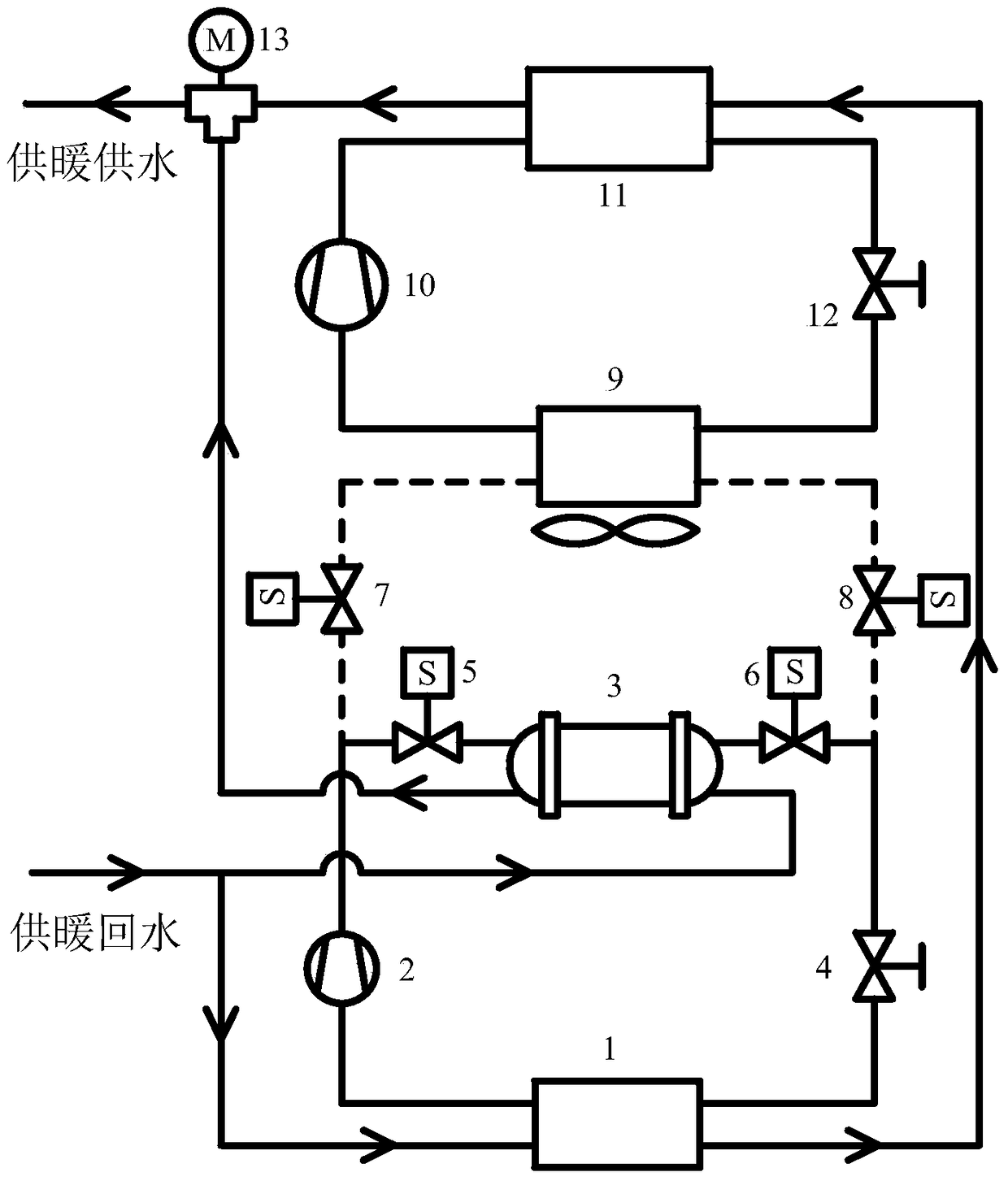

A transcritical co2 heat pump heating system with fast defrost function

ActiveCN105509125BImprove heating effectImprove cycle efficiencyMechanical apparatusCompression machinesSolenoid valveEngineering

The invention discloses a transcritical CO2 heat pump heating system with fast defrosting function, comprising a first evaporator, a first compressor, a first condenser, a first expansion valve, an evaporative condenser, a second compressor, a gas Cooler and second expansion valve; two sets of independent heat pump systems are used, and the low-temperature return water from the radiator is heated by the transcritical CO2 heat pump system to heat the heat storage temperature of the radiator; the invention adjusts the gas cooler in the transcritical CO2 heat pump The inlet water temperature ensures that the heat pump system operates at the maximum heating energy efficiency ratio; the present invention adopts an evaporative condenser and sets four solenoid valves, and by adjusting the opening / closing of the solenoid valves, the system flow is changed to realize the rapid removal of the transcritical CO2 heat pump heating system. At the same time, it can effectively heat the heating return water without adversely affecting the heating users, and improves the energy efficiency ratio of the transcritical CO2 heat pump heating system at low ambient temperature.

Owner:NINGBO SAISEN ENERGY SAVING EQUIP CO LTD

Tough and high-elastic composite silicon-carbide-based ceramic circuit board base board material and preparation method thereof

InactiveCN105367108AEfficient thermal conductivityImprove wettabilityComposite ceramicPolyethylene glycol

The invention discloses a tough and high-elastic composite silicon-carbide-based ceramic circuit board base board material. According to a silicon-carbide-based ceramic base board, micron-grade silicon carbide powder and nano-scale aluminum nitride powder are used in a composited mode, so that the base material can have more efficient thermal conductivity, polyethylene glycol composite solvent containing yttrium sol and nanometer ceramic powder transparent liquid is great in wettability and bonding capability for powder, all materials can be evenly dispersed and cladded, the effects of effective melting enhancement and strength improvement are achieved, the composite ceramic base board high in compactness, elasticity and strength can be obtained at the lower sintering temperature, and the material is good in electric insulating property, high in heat conduction and dissipation efficiency, safe and environment-friendly in production process and great in utilization potentiality.

Owner:HEFEI LONG DUO ELECTRONICS SCI & TECH

Potassium titanate whisker toughened silicon carbide-based ceramic circuit board substrate material and preparation method thereof

The invention discloses a silicon carbide-based ceramic circuit board substrate material toughened by potassium titanate whiskers. The silicon carbide-based ceramic substrate is compounded with micron-sized silicon carbide powder, fluorite, and nanometer-sized spherical alumina micropowder. Use, the sintering temperature of the base material is reduced, the sintering density is higher, and the polyethylene glycol composite solvent containing the transparent liquid of nano-ceramic powder has strong wettability and bonding ability between the powders, which can make the materials evenly dispersed , to achieve effective melting and activation effects, and a high-density, high-gloss composite ceramic substrate can be obtained at a relatively low sintering temperature. It has good electrical insulation, high thermal conductivity, and great application potential.

Owner:岳西县吉奥电子器件有限公司

Snow-melting and deicing emulsion coating and construction method thereof

InactiveCN110698986APrevents ice from attachingStrong adhesionIn situ pavingsOther chemical processesActive agentAdhesive cement

Owner:江西省交通科学研究院

Heat-preservation anti-freezing road and construction method thereof

InactiveCN111254775ASolve energy lossEffective meltingIn situ pavingsPaving detailsInsulation layerCrushed stone

The invention relates to a heat-preservation anti-freezing road and a construction method thereof, and belongs to the field of building materials and construction. The road is formed by sequentially laying a crushed stone layer, a cement stabilized layer, a heat insulation layer, a heating layer, an asphalt concrete layer and a heat-preservation coating layer on a leveled and cleaned pavement baselayer from bottom to top, external solar energy is used for heating, and silica aerogel is used as a substrate, so that the problem of energy consumption loss caused by the fact that heat of the heating layer is transmitted to the ground can be effectively solved, heat conduction oil adopted by the heating layer has an extremely strong absorption and conduction effect on solar energy heat release, and an iced road surface can be effectively melted. Good application prospects are realized on road ice melting in cold regions.

Owner:江西省昭昀建设工程有限公司

Plastic particle melting device for plastic bag processing

The invention discloses a plastic particle melting device for plastic bag processing. The plastic particle melting device comprises a melting device body. A melting box is fixedly mounted on the melting device body through cushion blocks mounted on the two sides of the bottom of the inner wall of the melting device body. Hearing bars are fixedly mounted at the positions, located on the two sides of the melting box, of the bottom of the inner wall of the melting device body. A hot air device is fixedly mounted at the top of the right side of the melting device body. According to the plastic particle melting device for plastic bag processing, through cooperative use of a first rotary motor, a cam plate, an extrusion plate, an extrusion rod, a reset spring, a moving seat, an extrusion block,a cutting seat, cutting troughs and blades, plastic particles can be extruded, the blades are used for cutting the plastic particles, each plastic particle is divided into two parts, and the size of the plastic particles is greatly reduced; and this, before being molten, the plastic particles can be effectively divided, and it can be effectively guaranteed that the plastic particles can be moltenthoroughly.

Owner:CHAOHU JINBANG PLASTIC PACKAGING

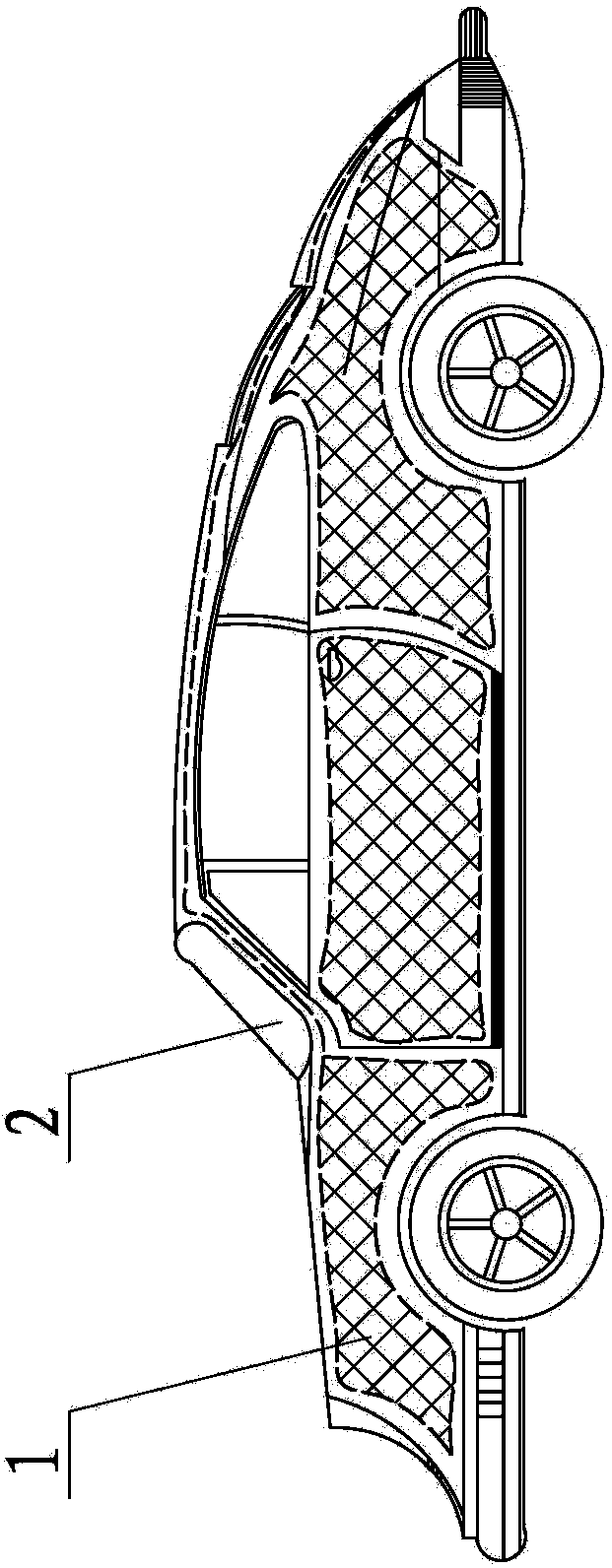

Motor vehicle with whole-vehicle heating system

InactiveCN104249614AEffective meltingTo achieve the purpose of initial warm-upAir-treating devicesVehicle heating/cooling devicesElectricityIn vehicle

The invention discloses a motor vehicle with a whole-vehicle heating system, and belongs to the field of motor vehicles. An electric heating net is arranged on the inner wall of a vehicle shell of a motor vehicle body, and is connected with a vehicle-mounted storage battery. A remote switch is arranged on the electric heating net. A user can indoors and distantly control the electric heating net of the outside vehicle to begin to perform heating operation indoors. The motor vehicle can melt ice and snow effectively, achieves the aim of warming the vehicle preliminarily, effectively saves manpower and is good in use effect and efficiency.

Owner:淄博金墨知识产权顾问有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com