Device for removing solidified oil stains on inner wall of petroleum pipe

An oil pollution removal and oil pipe technology, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of a large amount of waste, inability to effectively remove oil pollution, etc., and achieve the effect of preventing hand injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

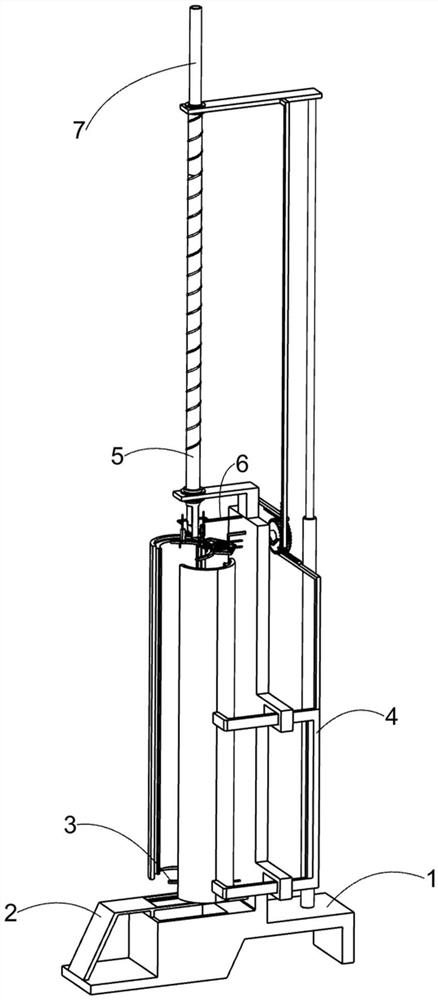

[0028] A device for removing solidified oil stains on the inner wall of an oil pipe, such as Figure 1-9 As shown, it includes a base 1, a placing plate 2, a positioning component 3, a clamping heating component 4, a rotating scraping component 5 and a limiting component 6. The placing plate 2 is connected to the base 1, and the positioning component 3 is arranged on the base 1. The clamping heating assembly 4 is arranged on the base 1, and the clamping heating assembly 4 is used for clamping and heating the oil pipe on the placement plate 2, and the rotating scraping assembly 5 is arranged on the base 1, and the rotating scraping assembly 5 is used for The melted oil stains on the inner wall of the oil pipe on the placement plate 2 are scraped off, and the limiting assembly 6 is arranged on the base 1 .

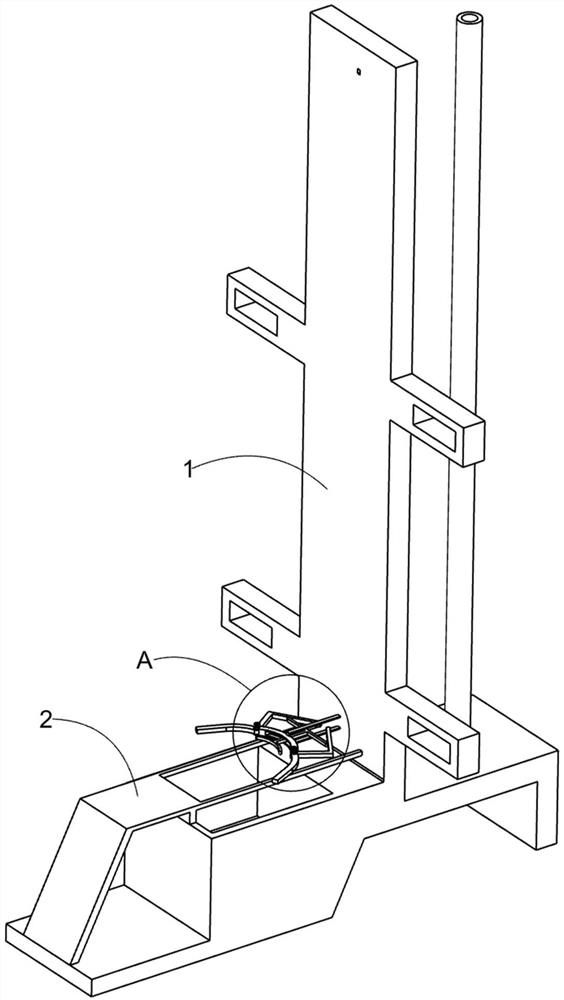

[0029] The positioning assembly 3 includes a fixed frame 31, a clamping rod 32, a torsion spring 33 and a push rod 34. A pair of fixed frames 31 are connected to one side of...

Embodiment 2

[0037] On the basis of Example 1, such as Figure 8 As shown, it also includes a fixed connection pipe 7, which is connected with a fixed connection pipe 7 on the inner wall of the scraper rod 53. The fixed connection pipe 7 is used to clean up the residual oil stains on the inner wall of the oil pipe. The lower part of the fixed connection pipe 7 is provided with two circles hole.

[0038] The top of the fixed connecting pipe 7 communicates with the external high-pressure place. During the process of cleaning the inner wall of the oil pipe by the sliding scraper 55, the external air pressure device connected to the fixed connecting pipe 7 is manually controlled to start, so that the high-pressure airflow in the fixed connecting pipe 7 passes through the fixed connection. The round hole on the pipe 7 is blown onto the inner wall of the oil pipe on the placement plate 2. Since there will be some residual oil after the oil stain melted on the inner wall of the oil pipe is scrape...

Embodiment 3

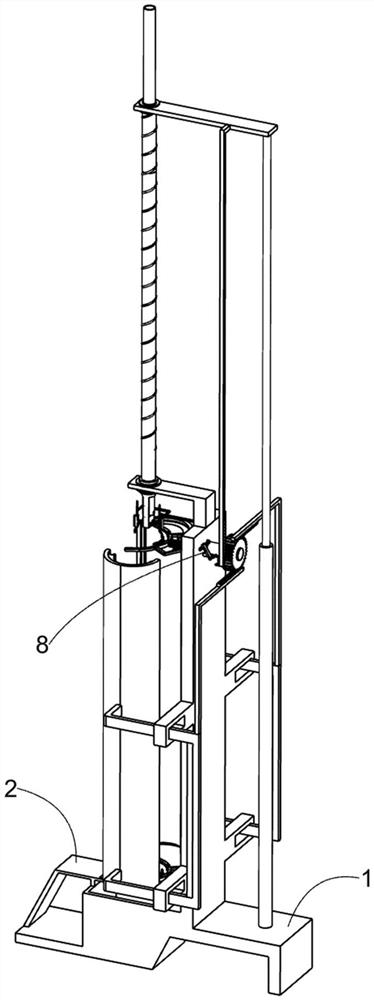

[0040] On the basis of Example 2, such as Figure 9 As shown, a reset assembly 8 is also included, and the reset assembly 8 is arranged on the base 1. The reset assembly 8 is used to push out the cleaned oil pipe on the placement plate 2. The reset assembly 8 includes a sliding push rod 81, a support plate 82 , swing bar 83, fixed round bar 84, compression spring 85 and sliding pressure plate 86, on the base 1, sliding type is connected with sliding push rod 81, and sliding push rod 81 is used for promoting swing rod 83 to rotate, and sliding push rod 81 is in the top The push rod 34 is in contact, and the other side of the base 1 is connected with a support plate 82, and the support plate 82 is rotatably connected with a swing rod 83. The swing rod 83 is used to push the sliding pressure plate 86 to move downward, and the swing rod 83 is in contact with the sliding push rod 81. , the lifting rack 43 is connected with a fixed round rod 84, and the fixed round rod 84 is slidabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com