Method for diluting and eliminating center line segregation of continuous casting slab by utilizing additive material

A technology of continuous casting slab and center line, which is applied in the field of continuous casting, can solve the problems such as the implementation parameters are not proposed, and achieve the effect of small deviation and good three-dimensionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

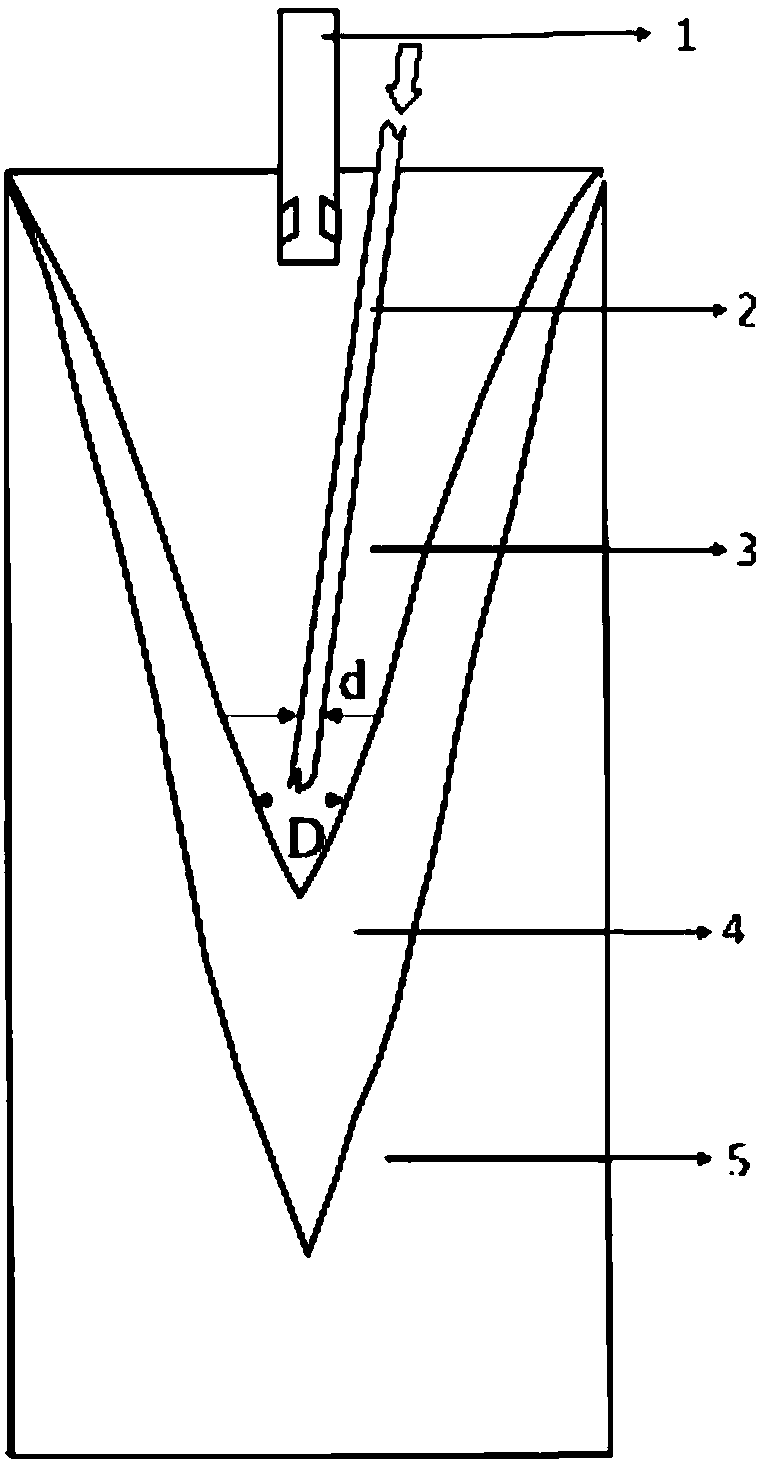

[0047] Such as figure 1 As shown, the casting liquid flows out from the nozzle 1, and the casting liquid flows into the crystallizer. The side wall of the crystallizer continuously cools the liquid phase cavity 3, so that the side and bottom of the liquid phase cavity 3 are continuously crystallized to form a mushy region 4, and the mushy region 4 continues to cool down to form a solidified shell 5. The solidified shell 5 is pulled out from below. The liquid phase cavity 3, the mushy region 4 and the solidified slab shell 5 continuously flow and evolve to form a continuous casting slab as a whole. Under the premise of constant conditions, the boundaries between the liquid-phase cavity 3 and the mushy region 4, and the boundaries between the mushy region 4 and the solidified shell 5 are stably in a certain position, and stably maintain a certain shape.

[0048] The continuous casting slab in this embodiment is a low-carbon continuous casting thick slab, and the following meth...

Embodiment 2

[0065] As the calculation result of embodiment 1, select C 选1 =0.11wt%>C a1 , C 选2 =0.26wt%>C a2 ,C 选3 =1.40wt%>C a3 ,C 选4 =0.0137wt%>C a4 ,C 选5 =0.0012wt%>C a5 , C 选6 =0.011wt%>C a6 , manufacturing additives. The element ratio is better controlled, the additive manufacturing is convenient, and the process is simpler. It can also greatly reduce the central segregation of the continuous casting slab and solve the central shrinkage porosity.

Embodiment 3

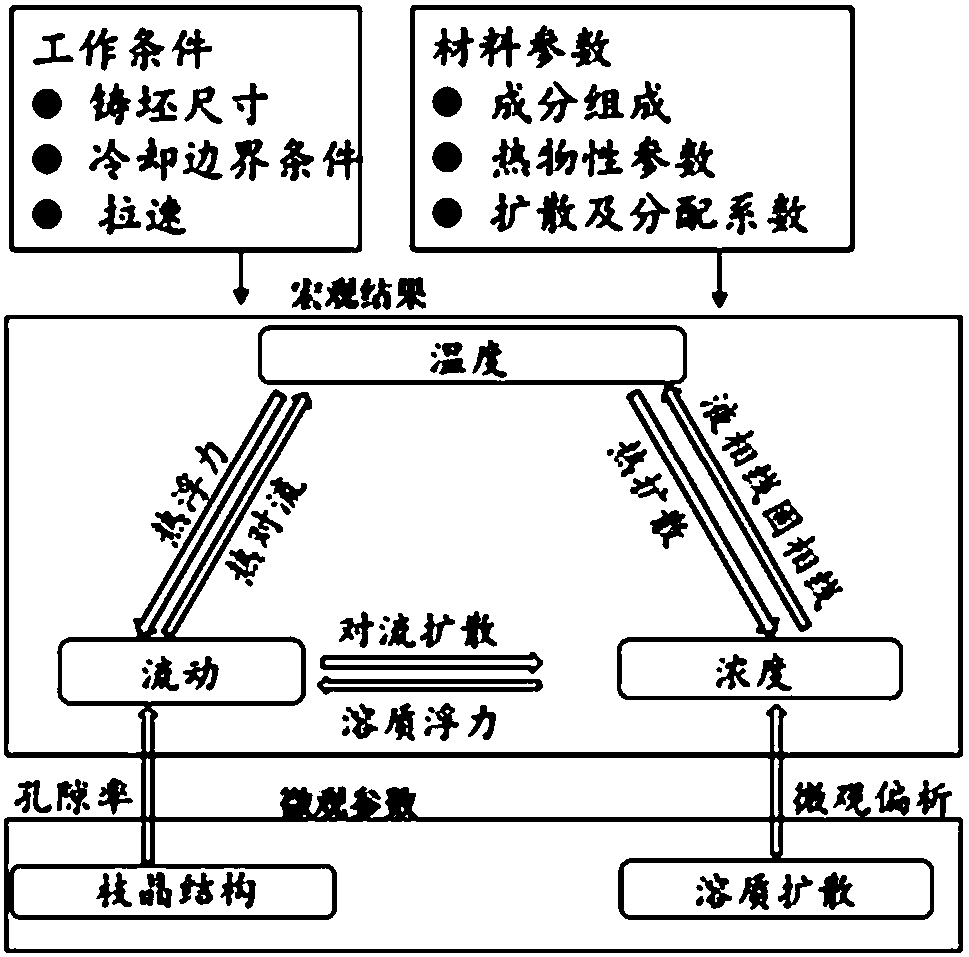

[0067] As in Example 1, the impurity concentration C is added to the input of the macroscopic model 标7 , the final output includes C a7 , choose C 选7 a7 Manufacture additives, the cross-section of additives is circular, the difference between the inner and outer radius of the ring is 3mm, and the area of the ring is equal to 30mm 2 , Additive manufacturing is convenient. During the process of feeding the additive, vibration with an amplitude of 2 mm and a vibration frequency of 500 Hz is applied to the additive body 2 . It can further improve the central performance of the continuous casting slab and solve the central shrinkage porosity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com