Antifreezing agent composition and its production process

A manufacturing method and composition technology, applied in the field of antifreeze composition, can solve the problems of corrosion of vehicles, bridges and pavement facilities, increase the frequency of traffic accidents, and lengthen the braking distance of motor vehicles, so as to avoid traffic accidents, promote Dissolving speed, the effect of fast dissolving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0017] In the general sodium chloride raw material, the moisture is 4-6%, exists in the form of free water, by weight, get 250 parts of sodium chloride with a water content of 4-6%, in a drying oven with an outlet temperature of 200-240 degree, time 8-12 minutes, until the water content is below 2.5%, preferably below 1%, 150 parts of magnesium chloride 6 hydrate and 50 parts of calcium chloride 2 hydrate; sieve the above raw materials through a rotary sieve to obtain the particle size The material is 1mm-5mm, and the material that does not meet the particle size requirements is crushed by the crushing process and then sieved.

[0018] Select 60 parts of sodium chloride, 30 parts of magnesium chloride, and 5 parts of calcium chloride after the above screening, and mix them on an automatic mixer to obtain an antifreeze composition, and the product is marked as A.

experiment example 2

[0020] Select 40 parts of sodium chloride, 45 parts of magnesium chloride, and 15 parts of calcium chloride after the above screening, and mix them on an automatic mixer to obtain an antifreeze composition, and the product is marked as B.

experiment example 3

[0022] Select 50 parts of sodium chloride after the above screening, 30 parts of magnesium chloride, 10 parts of calcium chloride, and 2 parts of a mixture of trisodium citrate and magnesium sulfate in parts by weight of 1:1 or trisodium phosphate and magnesium sulfate in parts by weight The mixture of 1: 1 is mixed on an automatic mixer to obtain an antifreeze composition, and the product is marked as C.

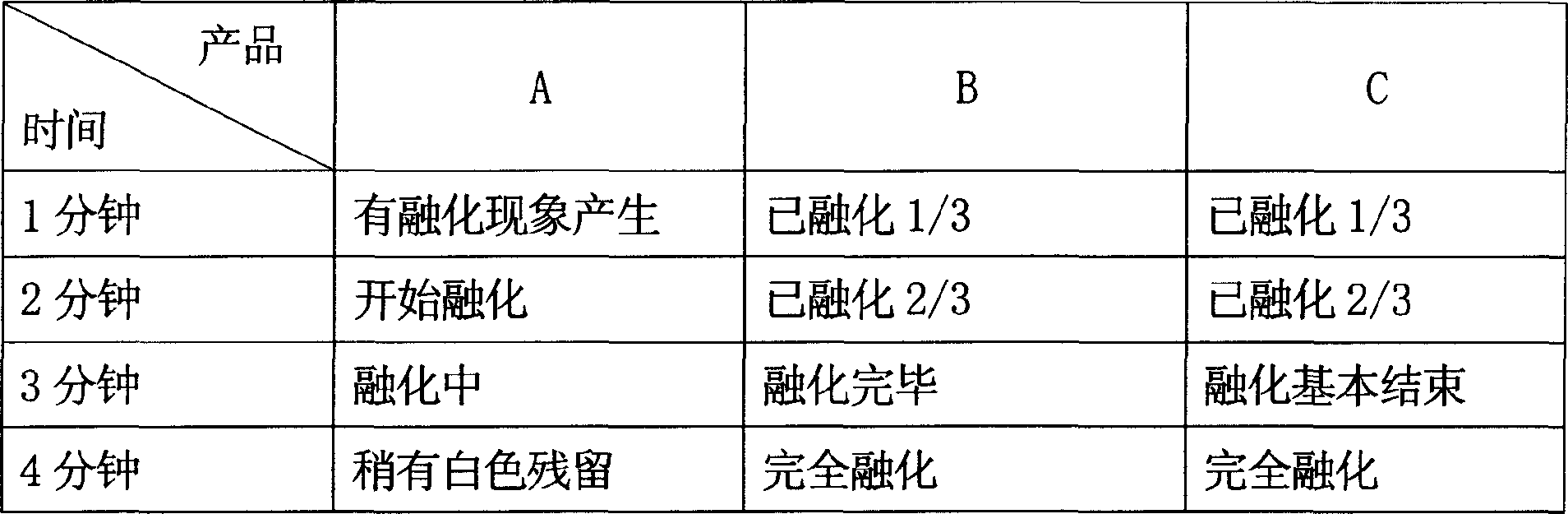

[0023] In experiment 1, three snow fields with the same temperature of 1 square meter were selected, and the thickness of the snow layer was 5cm, and the snow melting experiment was carried out. The experimental results are as follows:

[0024]

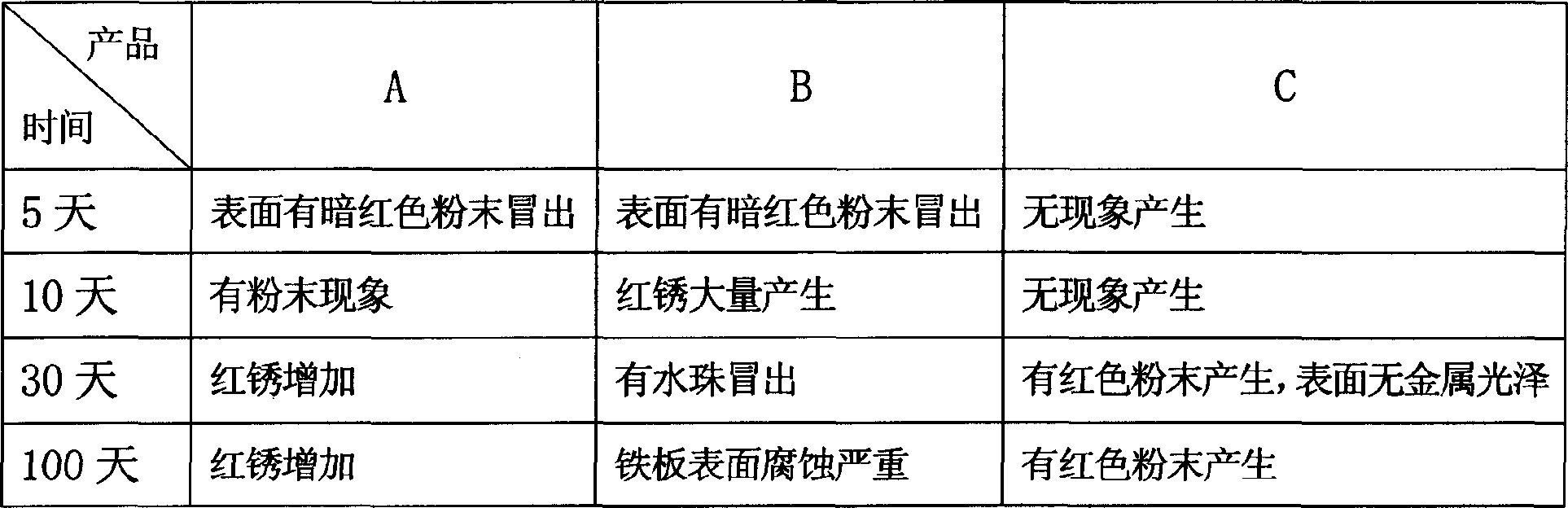

[0025] In experiment 2, three iron plates of 1 square meter were selected to carry out the corrosion resistance experiment. The experimental results are as follows:

[0026]

[0027] Experiment 3, choose an asphalt road covered with ice and snow with the same road conditions, sprinkle product C on one section, and not sprinkl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com