Softening and early-fusing protective device for 3D printing material filament

A 3D printing and protective device technology, applied in 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problems of uneven melting temperature of filament, uneven temperature of heating block, affecting the quality of molded parts, etc., to achieve a simple structure , low cost, effective heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

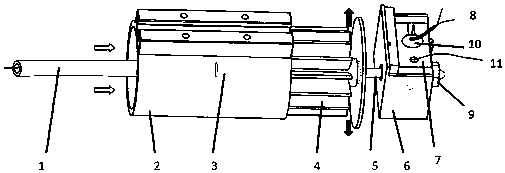

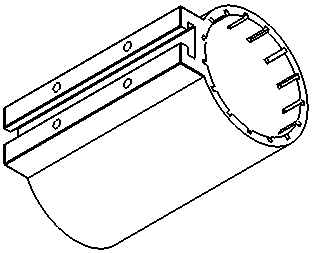

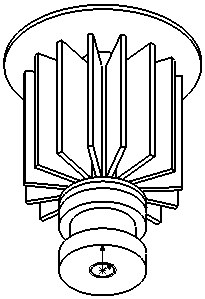

[0020] like figure 1 It is a specific embodiment of the 3D printing filament softening and premature melting protection device of the present invention. It includes feeding conduit 1, air pipe 2, conduit holder 3, heat dissipation pipe 4, throat pipe 5, heating block sheath 6, heating block 7, screw 8, nozzle 9, heater 10 and thermocouple 11. In this way, a 3D printing filament softening and premature melting protection device with simple structure, low cost and easy assembly is formed.

[0021] As a specific embodiment, in the present invention, the feeding conduit 1 provides guidance for the feeding of the silk material, preventing the silk material from being folded during the feeding process; the feeding conduit 1 is incorporated into the air duct 2 outside the processing chamber, and Enter the processing chamber together from outside the processing chamber; the end of the feed conduit 1 passes through the conduit holder 3, and the conduit holder 3 clamps the feed conduit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com