Corrugated pipe orifice wrapping sealing machine and production line

A corrugated tube and sealing machine technology, which is applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of affecting the service life of corrugated tubes, spending a lot of energy on processing, and low processing efficiency, so as to achieve high production efficiency, Reasonable machine design and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

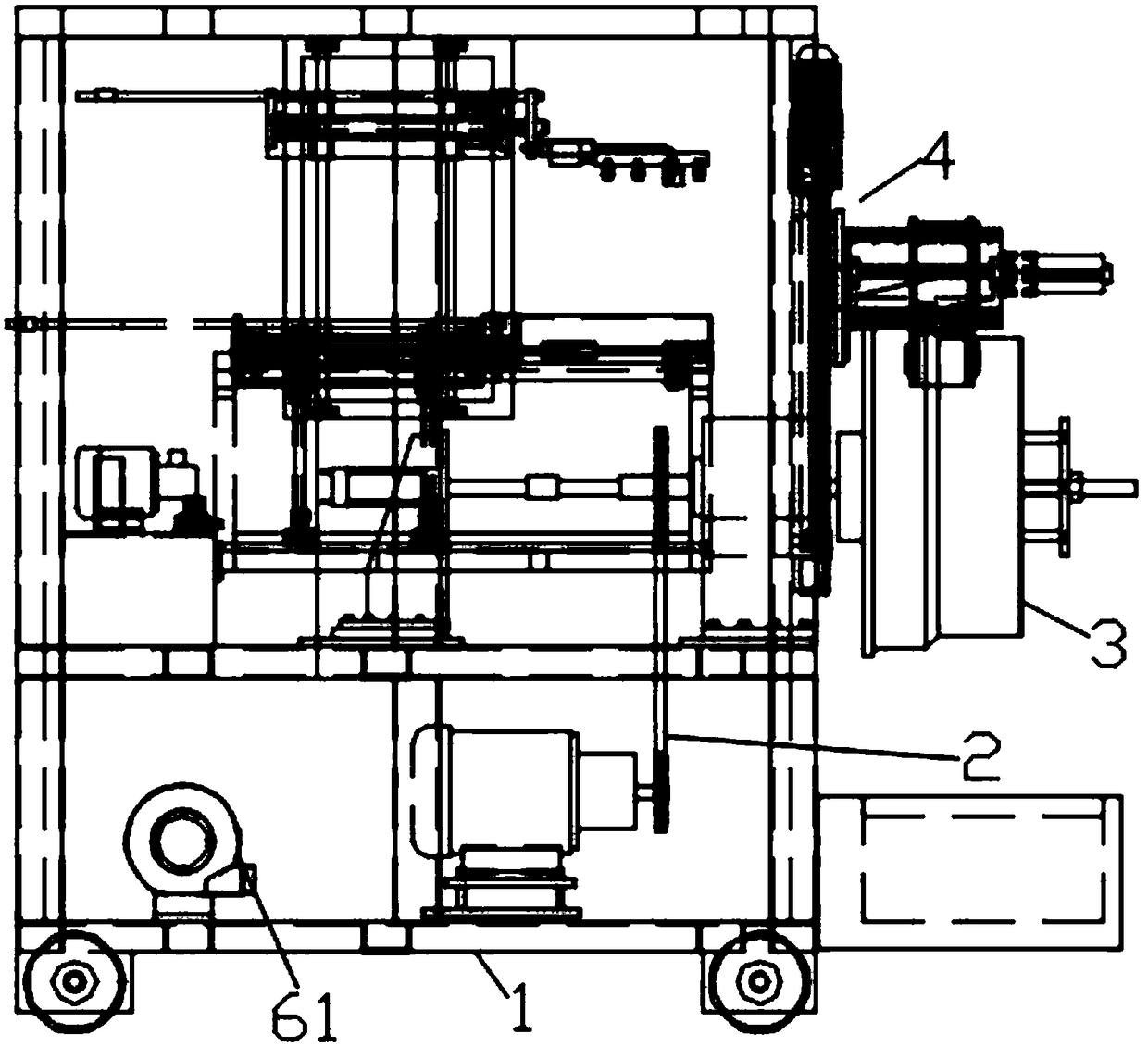

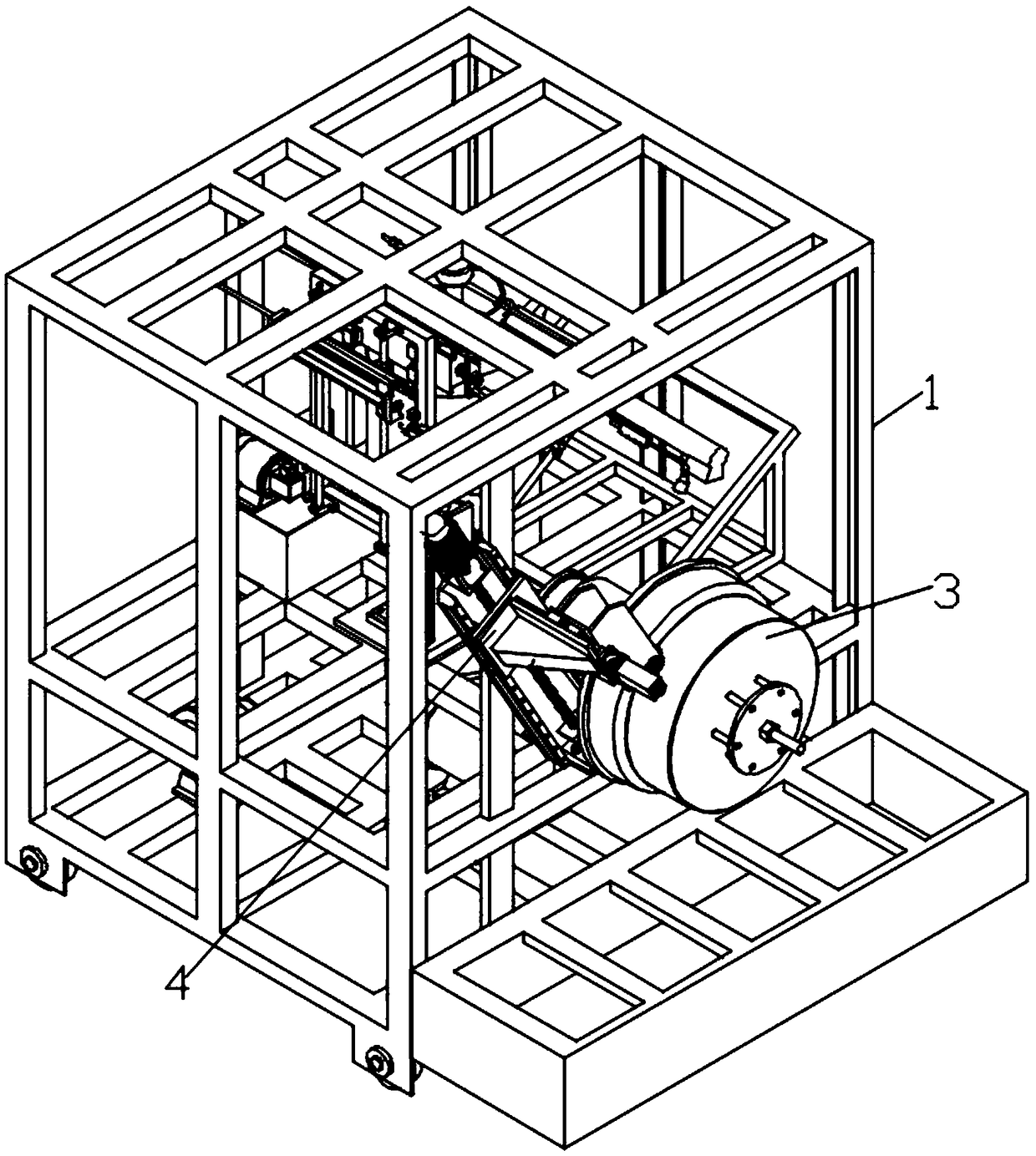

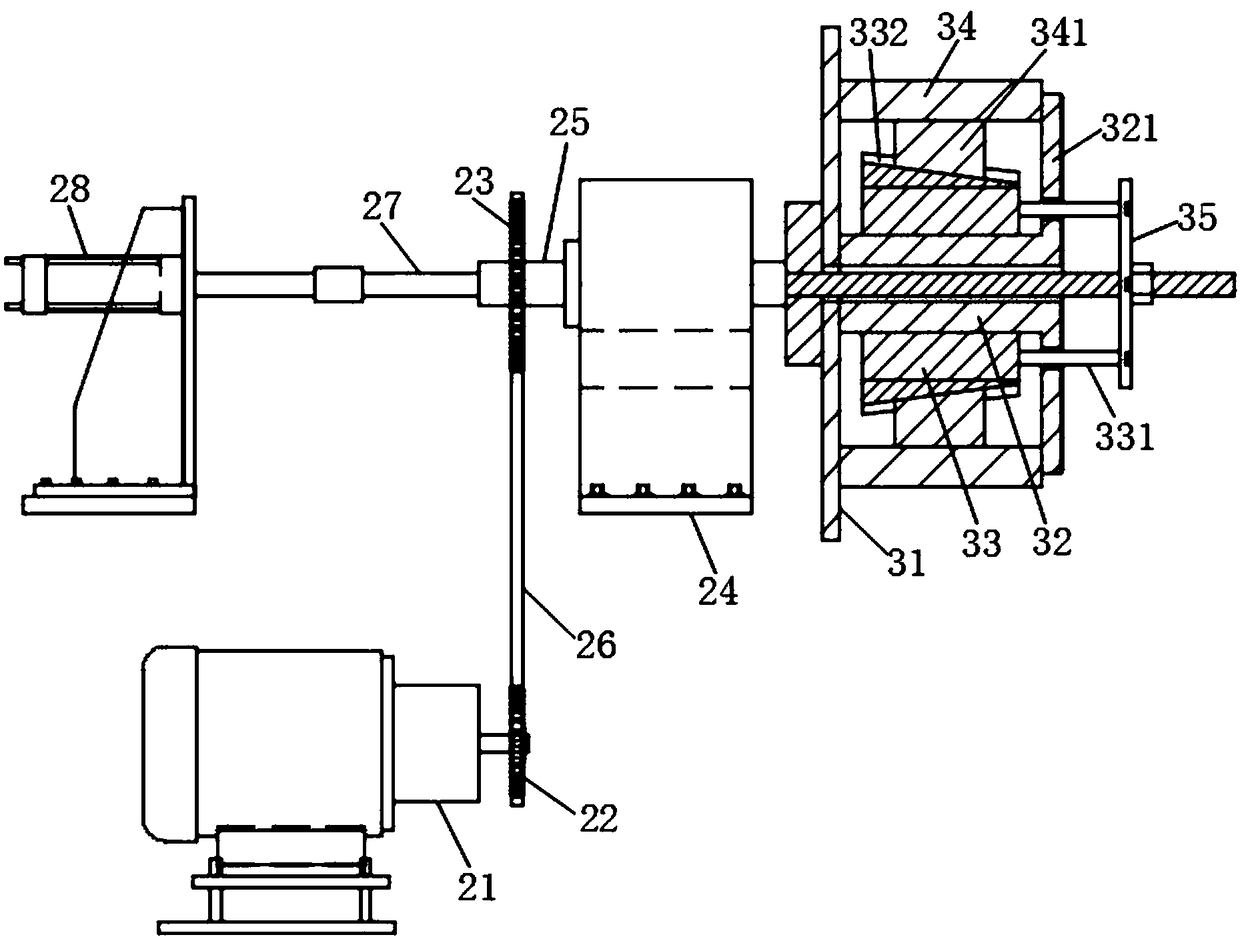

[0035] Example one: such as Figure 1 to 7 As shown, the corrugated tube nozzle sealing machine of this embodiment includes a case 1, a driving mechanism 2, a nozzle connector 3, a mobile pressing mechanism 4, a hot melt system and a cooling system;

[0036] One end of the case 1 is flat, the nozzle connector 3 is arranged at one end of the case 1, and the driving mechanism 2 is installed in the case 1, and is connected to the nozzle connector 3 in transmission, and can drive the nozzle The connector 3 rotates;

[0037] One end of the corrugated pipe is sleeved outside the aforementioned nozzle connector 3, and one end of the nozzle is covered with plastic covering;

[0038] The above-mentioned hot-melting system is arranged on the above-mentioned chassis 1 for hot-melting the plastic of the tube to the outer surface of one end of the above-mentioned corrugated tube;

[0039] The mobile pressing mechanism 4 is installed at one end of the case 1, and there is a pressing wheel 41 there...

Embodiment 2

[0053] Embodiment two: such as Figure 5 As shown (only one bellows nozzle covering and sealing machine is shown in the figure), the bellows nozzle covering and sealing production line of this embodiment includes a bracket 7 and two bellows nozzle covering and sealing machines as in the first embodiment , The two above-mentioned bellows spout sealing and sealing machines are respectively arranged at two ends of the above-mentioned bracket 7 at intervals, and the above-mentioned spout connectors 3 of the two are relatively close and coaxially arranged, and the bellows are placed on the above-mentioned bracket 7 The bellows can be rotated relative to the bracket 7, and the nozzles at both ends are respectively sleeved outside the nozzle connectors 3 of the two bellows nozzle capping and sealing machines. The entire production line can simultaneously align both ends of the bellows The nozzle is covered and sealed with high processing efficiency, good effect and simple production li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com