Semiconductor laser synchronous welding set and operating mode thereof

A welding device and semiconductor technology, applied in laser welding equipment, auxiliary equipment, welding equipment, etc., can solve the problems of foreign objects, unsightly welding seams, high cost, etc., and achieve small mechanical stress, fast welding speed, and small thermal stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

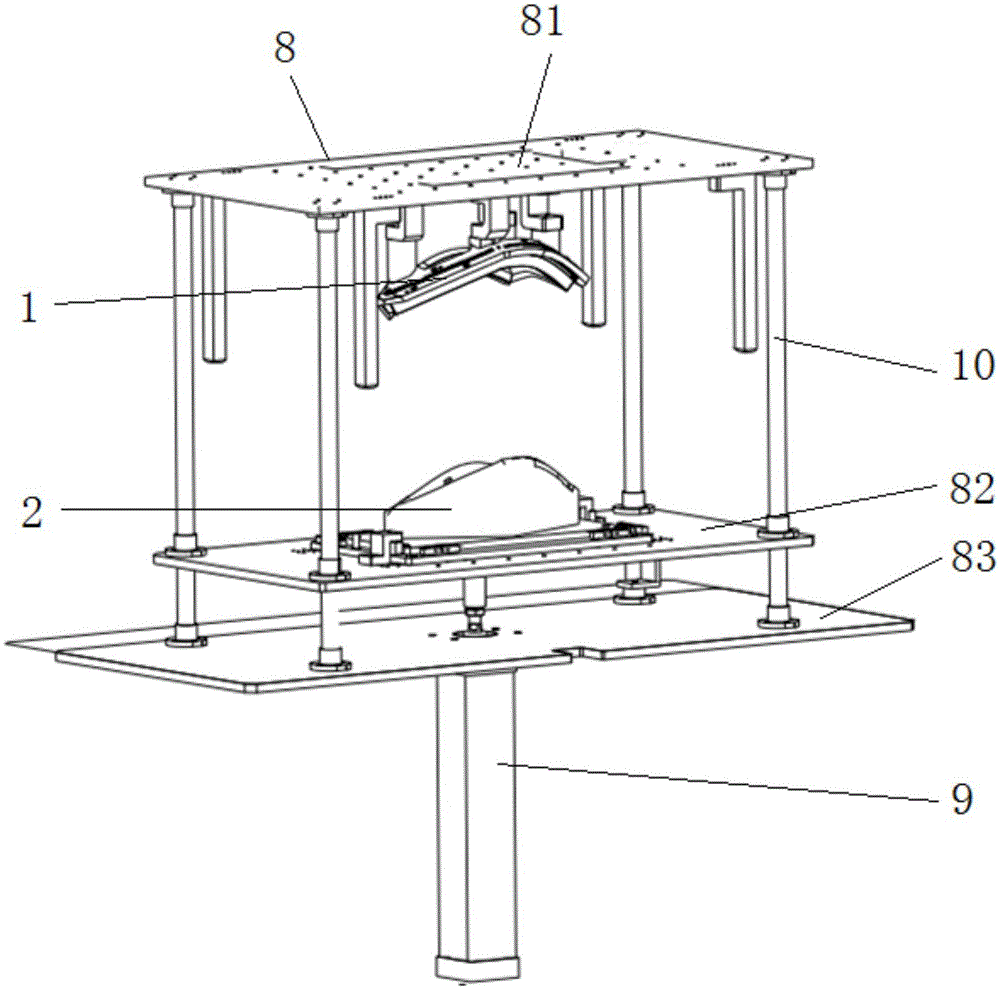

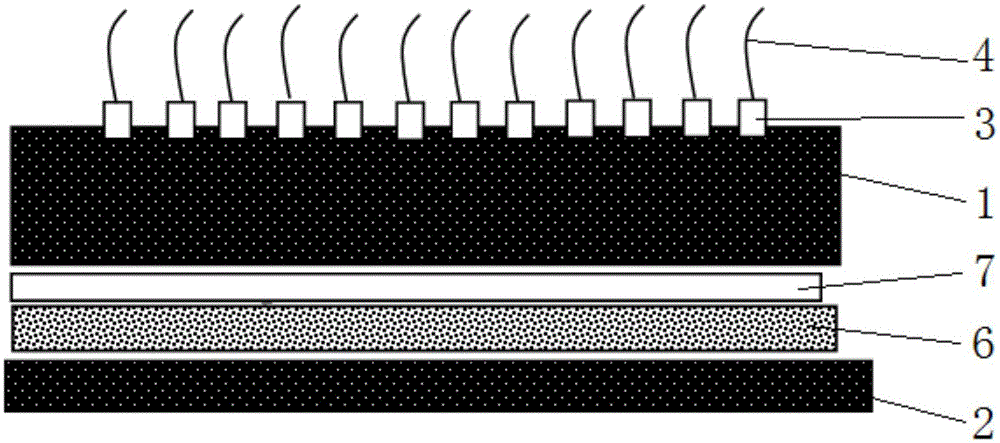

[0027] figure 1 It is a schematic diagram of a semiconductor laser synchronous welding device, please refer to figure 1 shown. A semiconductor laser synchronous welding device of a preferred embodiment is shown, which includes an upper mold clamp 1 and a lower mold clamp 2, and the lower mold clamp 2 can be matched with the upper mold clamp 1, that is, the lower mold clamp 2 can be moved The upper mold clamp 1 is connected closely, or the upper mold clamp 1 can be connected with the lower mold clamp 2 by moving. Of course, it also includes an organic base, which is used for fixedly installing the upper mold fixture 1 and the lower mold fixture 2, and the machine base will be described in detail below.

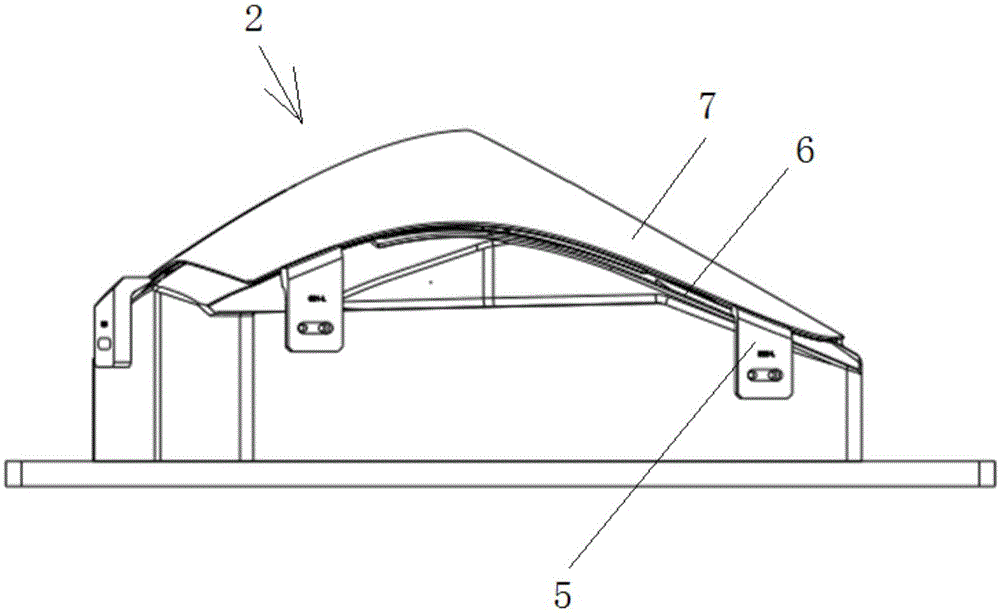

[0028] In addition, the lower mold fixture 2 is provided with a positioning device, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com