All-position automatic welding method for pipeline circumferential weld

An automatic welding, all-position technology, applied in welding equipment, tubular objects, arc welding equipment, etc., can solve the problems of high requirements for welders' operating skills, high cost of welding equipment, poor performance of welding joints, etc., to shorten the construction period, reduce The effect of porosity sensitivity and less welding material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

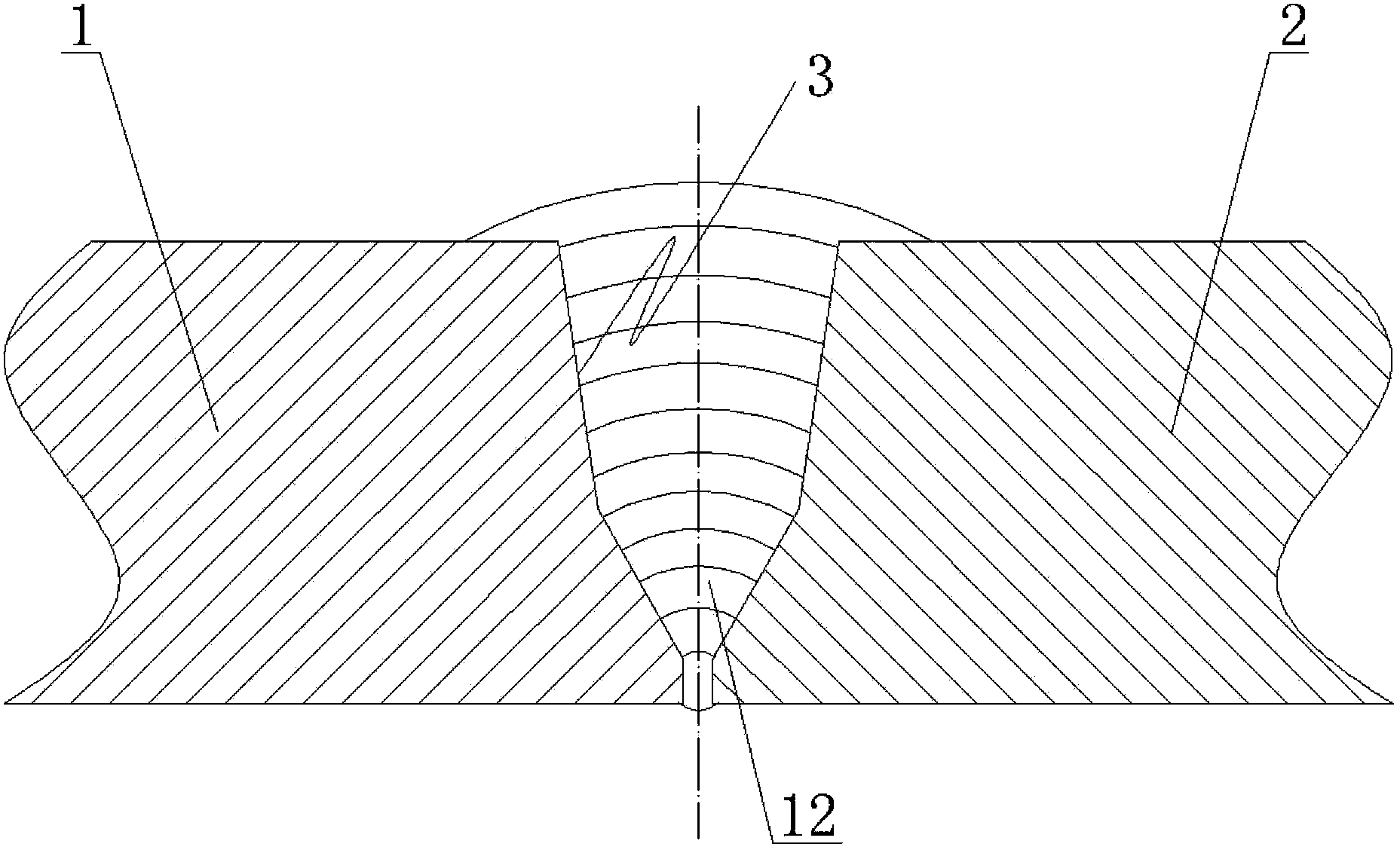

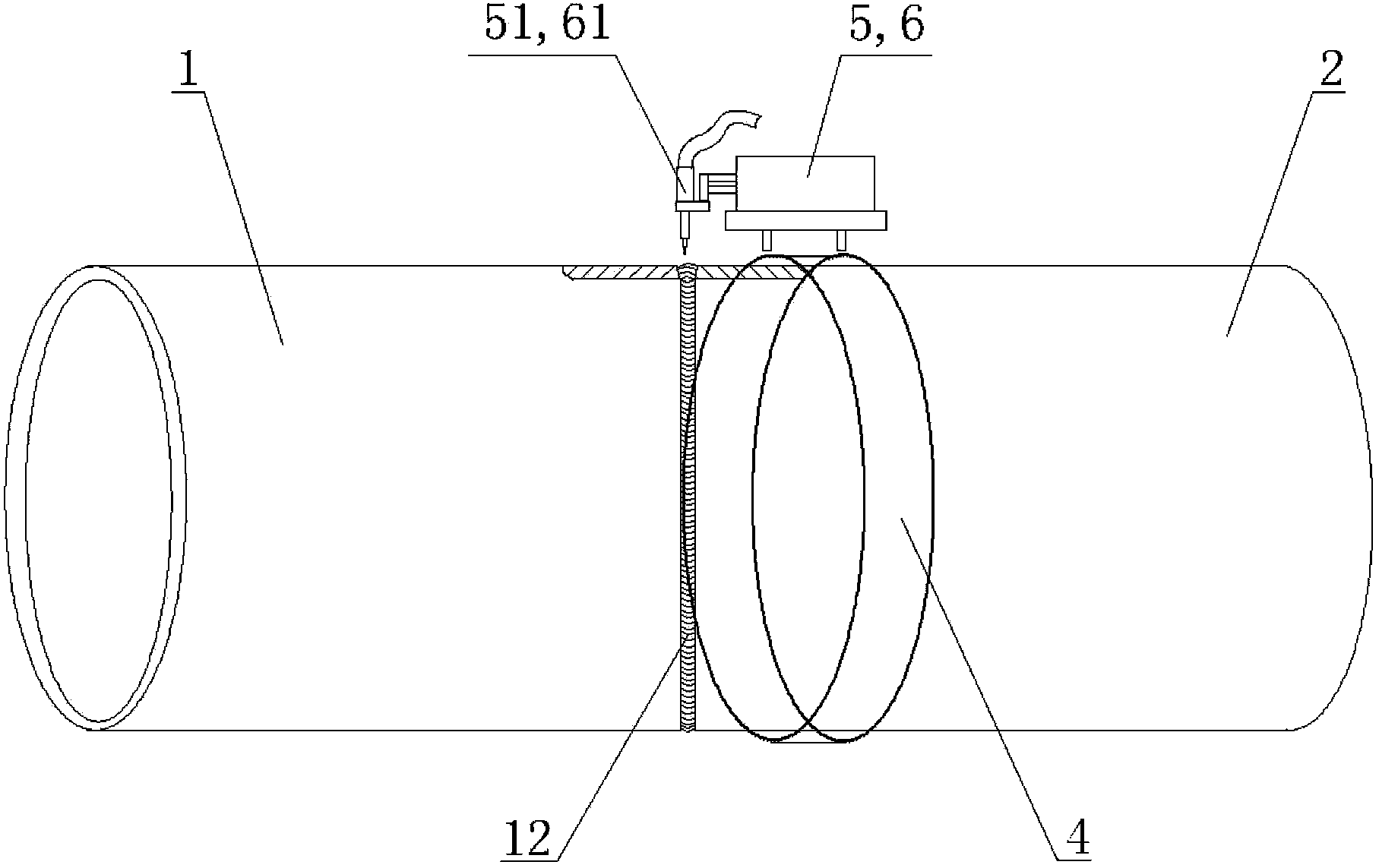

[0051] This embodiment provides an all-position automatic welding method for pipeline girth welds, see figure 1 and figure 2 , the method includes: single torch cold metal transfer (Cold Metal Transfer, abbreviated as CMT) all-position root welding and double-torch all-position automatic heat welding, filling and capping welding.

[0052] The specific steps of the all-position automatic welding method of the pipeline girth weld are:

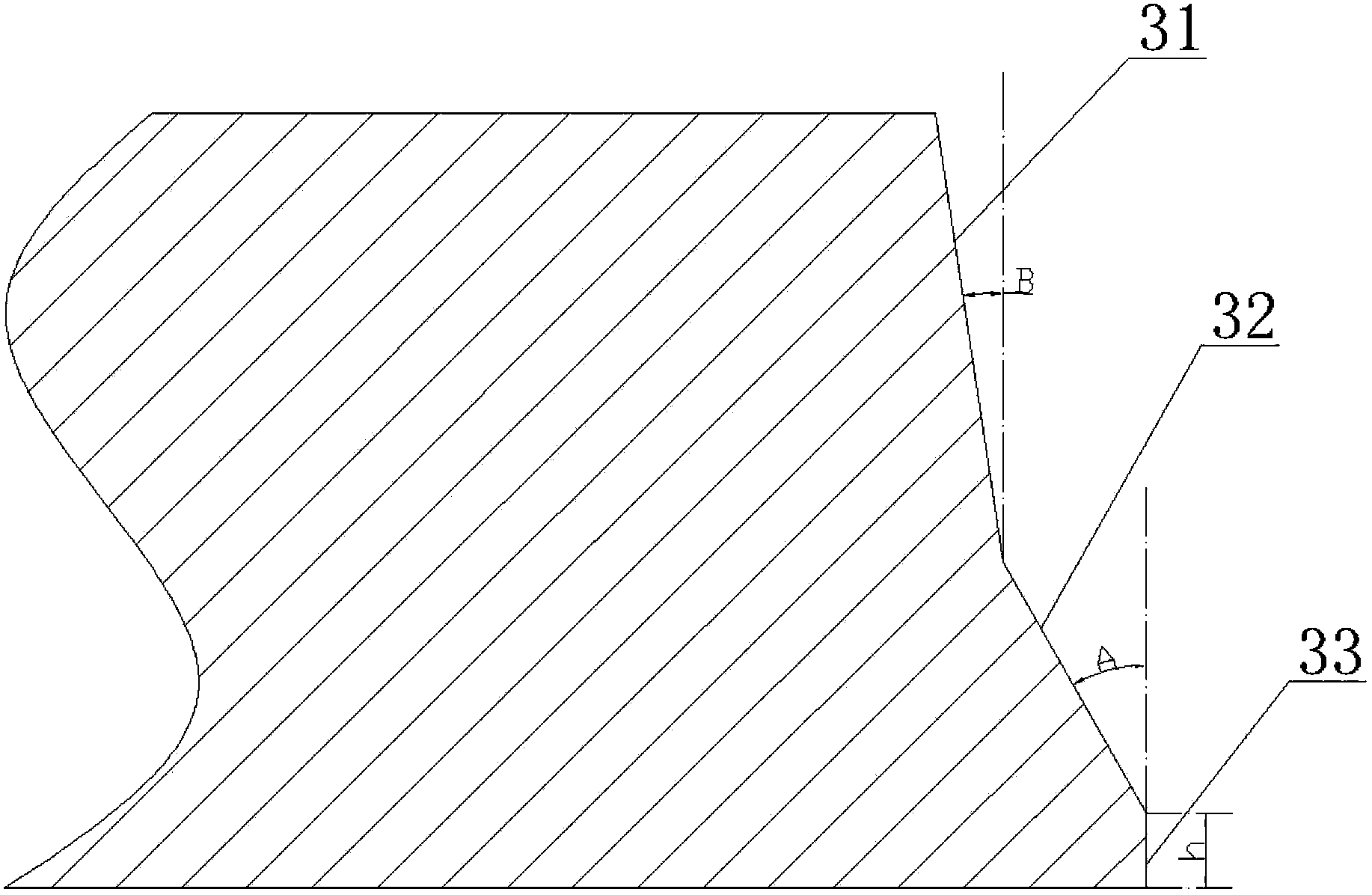

[0053] S1, process the welding end of the first steel pipe 1 and the second steel pipe 2 to be welded into a groove end face 3, the shape of the groove end face is a double V-shaped composite groove, and the groove end face 3 includes the outer wall of the steel pipe to the inner wall of the steel pipe An upslope surface 31 , a downslope surface 32 and a blunt edge 33 are provided in sequence. Preferably, the inclination angle B of the upper broken surface 31 is 5° to 15°, that is, the angle B between the upper broken surface 31 and the vertic...

Embodiment 2

[0073] An embodiment of the present invention provides an all-position automatic welding method for a pipeline girth weld, which is described by taking Φ508 mm×14.3 mm X65 steel grade submarine pipeline girth weld welding as an example. According to APIStandard 1104-2005 "Steel Pipeline Welding and Acceptance" standard, the welding quality acceptance of the girth weld is carried out.

[0074] 1. Pipe end bevel processing

[0075] During the manufacturing process of the Φ508mm×14.3mm X65 steel pipe, the pipe factory processes grooves on both ends of the first steel pipe 1 and the second steel pipe 2. The groove type is double V-shaped composite groove 12, and the angle A of the lower broken surface 32 is 30°, 31 angle B of the upslope surface is 9°, the inflection point C of the downslope surface and the upslope surface transitions smoothly, the distance from the inflection point C to the inner wall of the steel pipe is 7.5mm, the distance from the inflection point C to the out...

Embodiment 3

[0102]The embodiment of the present invention provides an all-position automatic welding method for pipeline girth welds. The girth weld welding of Φ1219mm×22.0mm X80 steel grade land long-distance pipeline is taken as an example to illustrate this embodiment. According to API Standard 1104-2005 "Steel Pipeline Welding and Acceptance" and Q / SY GJX 0110-2007 "Technical Specifications for Line Welding of the Second West-East Gas Pipeline Project", the welding quality acceptance of the girth weld is carried out.

[0103] 1. Pipe end bevel processing

[0104] During the manufacturing process of Φ1219mm×22.0mm X80 steel pipe, the pipe factory processes the groove surface on both ends of the first steel pipe 1 and the second steel pipe 2. °, the angle B of the upslope surface is 9°, the inflection point C of the downslope surface and the upslope surface transitions smoothly, the distance from the inflection point C to the inner wall of the steel pipe is 7.5mm, the distance from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com