Laser-arc hybrid welding method of light sheet T type joint

A hybrid welding and arc technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unsmooth weld toe transition and the porosity at the root of the weld cannot be eliminated, and achieve uniform and smooth transition, great economy and technology. Significance, Effect of Solving Stomatal Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

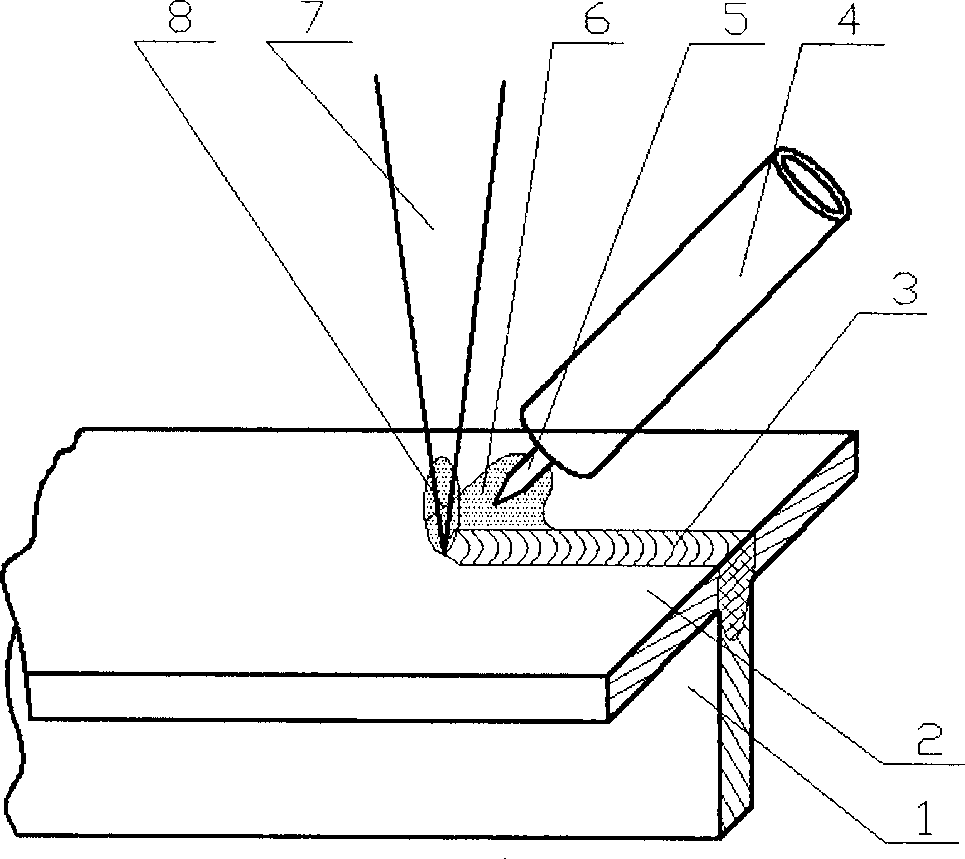

[0020] For the implementation of this embodiment, refer to the attached figure 2 , this embodiment uses CO 2 The laser-TIG arc composite heat source realizes welding from the top surface of the T-shaped joint bottom plate 2, wherein the laser beam 7 is vertically incident from the top surface of the bottom plate 2, and the TIG arc 6 is arranged behind the laser beam 7 paraxially relative to the laser beam 7, and the arc 6 and The included angle of the top surface of the bottom plate is 45°, the composite heat source composed of laser beam 7 and electric arc 6 acts on the top of the rib plate 1, and deep penetration welding is completed from the side of the bottom plate 2 of the T-joint. During welding, the laser beam 7, the arc 6 and the rib 1 are arranged in one plane.

[0021] Among them, the rib plate 1 and the bottom plate 2 are stainless steel plates with a thickness of 2 mm, the laser used is a DC035 SlabCO2 laser, and the TIG power supply is directly connected to DC. ...

Embodiment 2

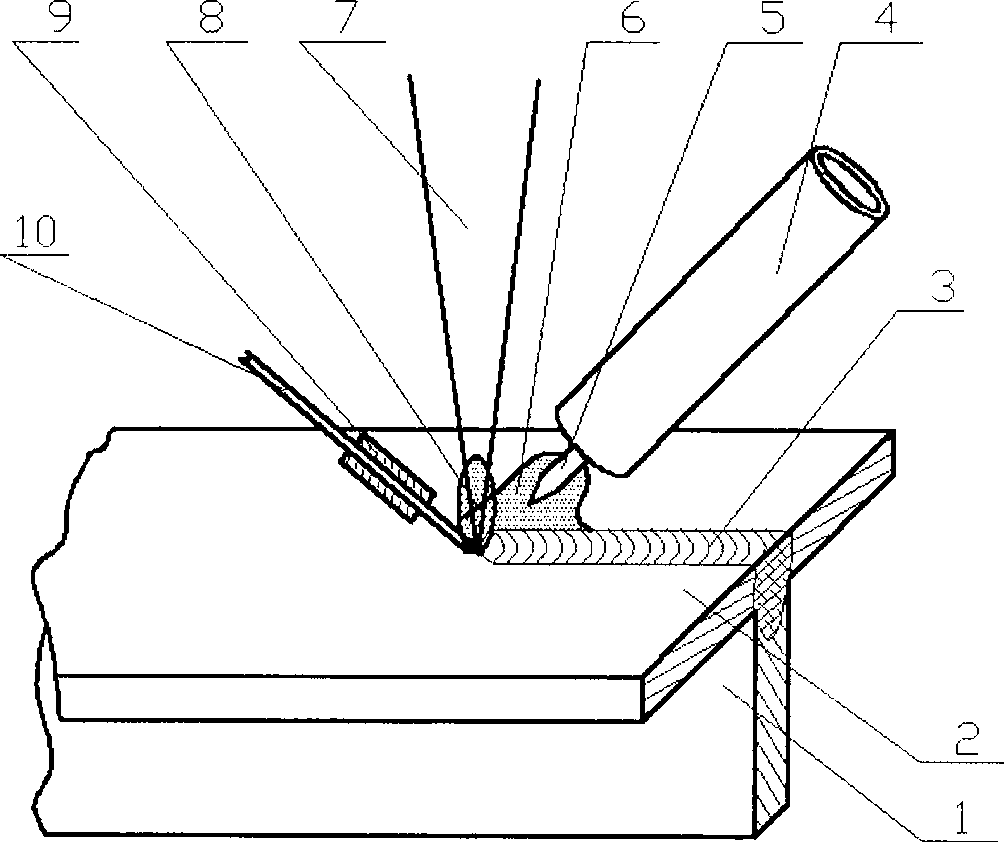

[0023] The method of this embodiment is basically the same as that of Embodiment 1, and the only difference is that this method adds a filler wire 10 when welding, see the attached image 3 . The welding wire 10 and the arc 6 are arranged on both sides of the laser beam 7, and the welding wire 10, the laser beam 7, the arc 6 and the rib 1 are arranged on a plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com