Patents

Literature

64results about How to "Efficient thermal conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

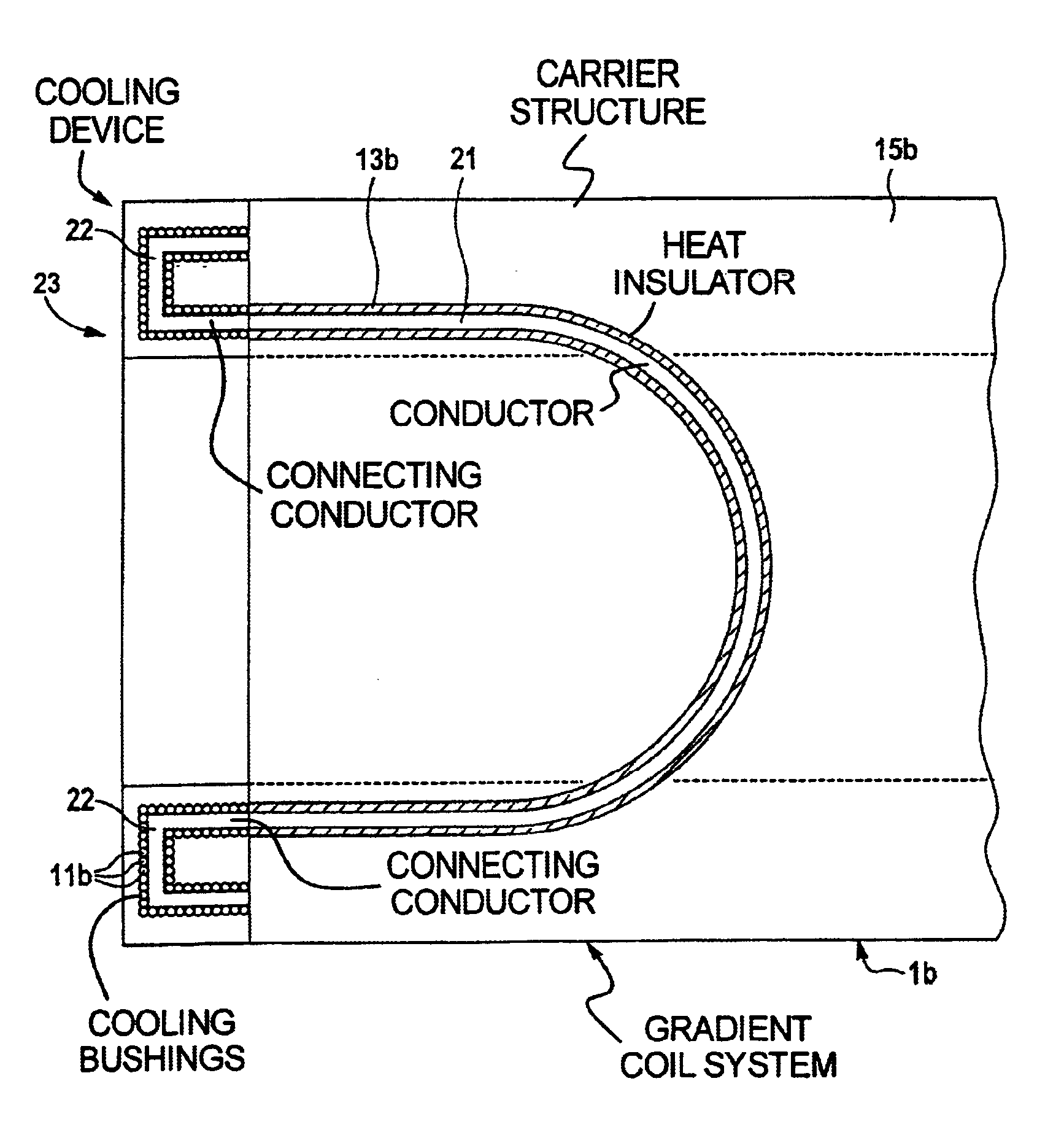

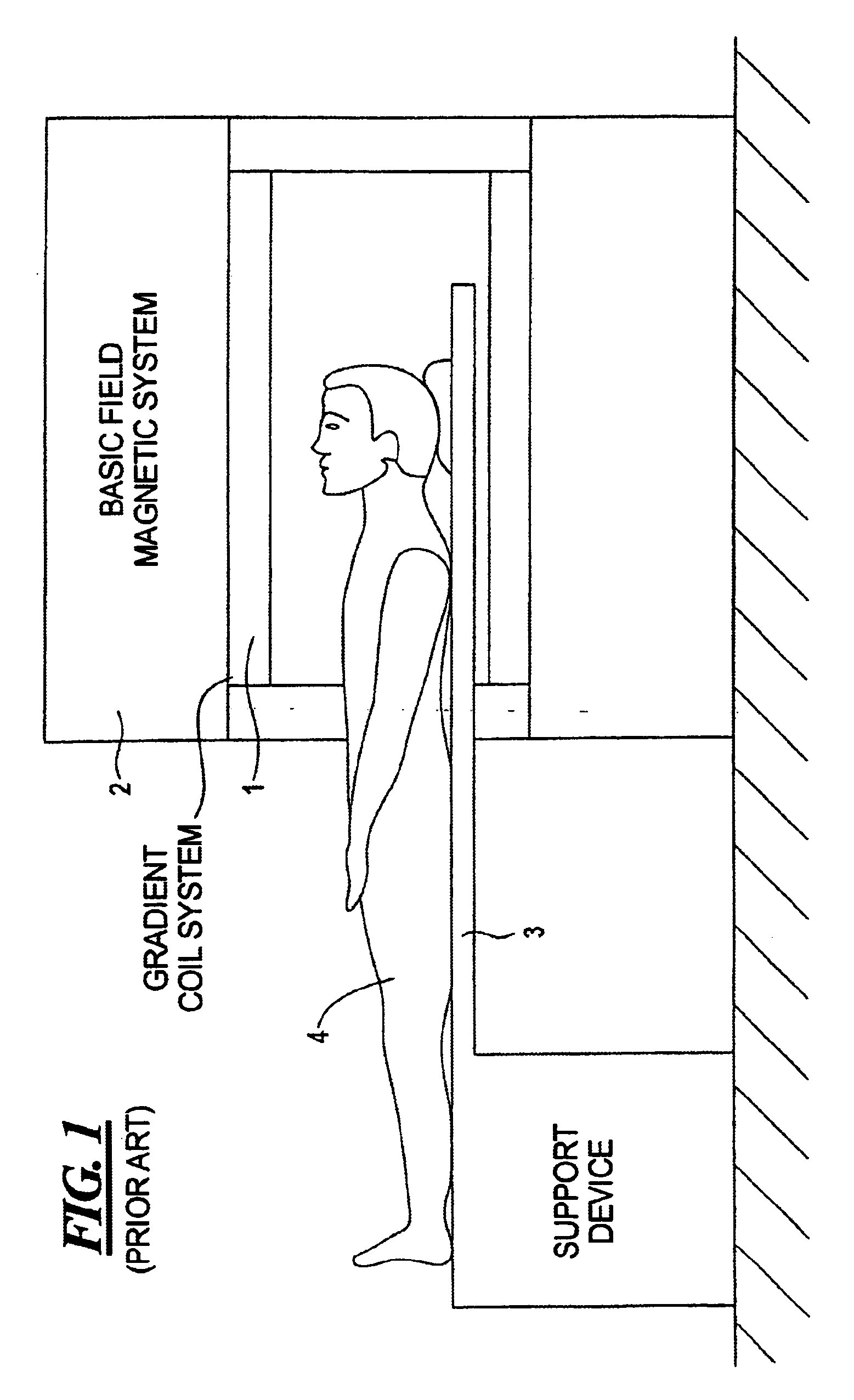

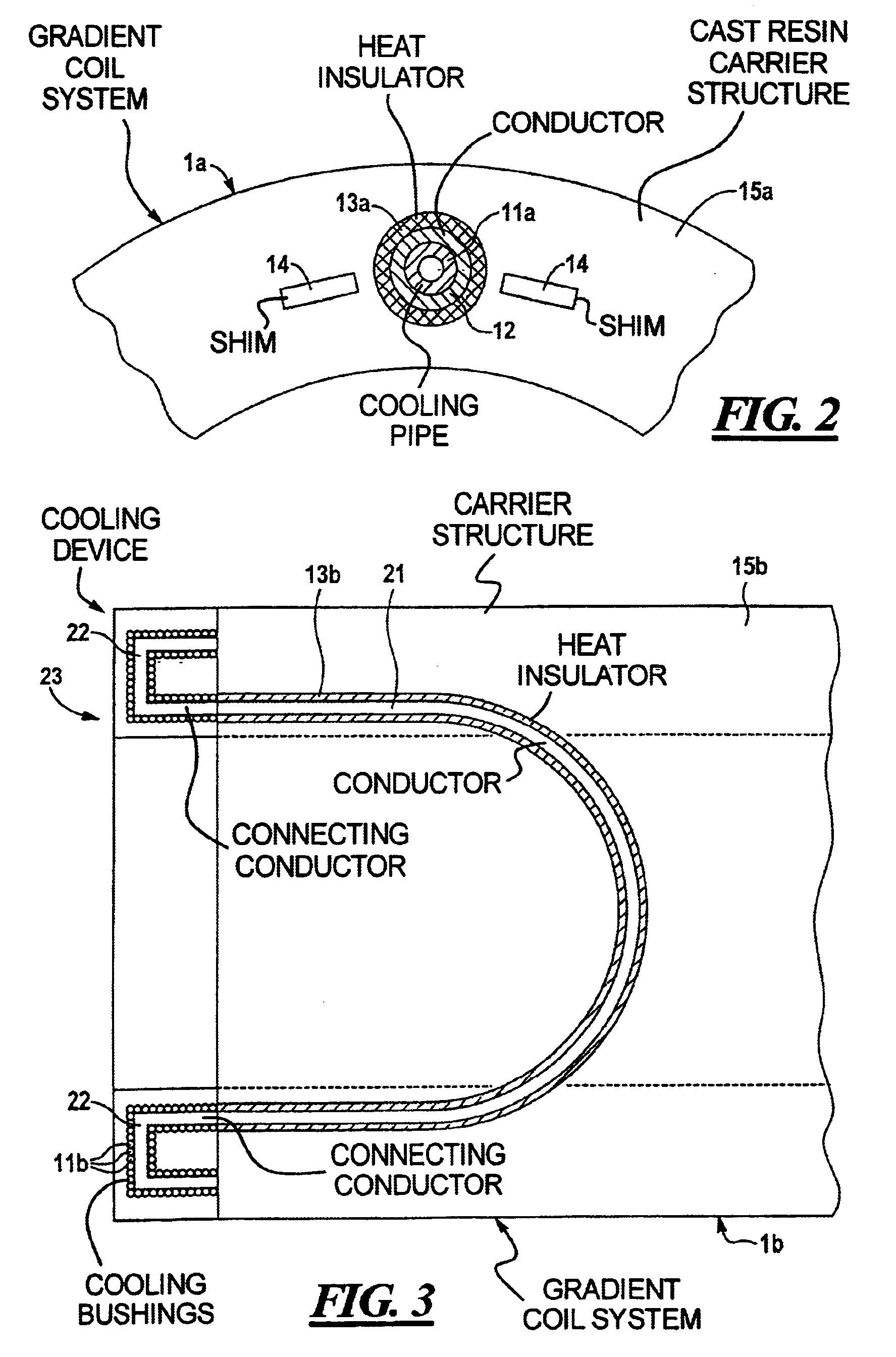

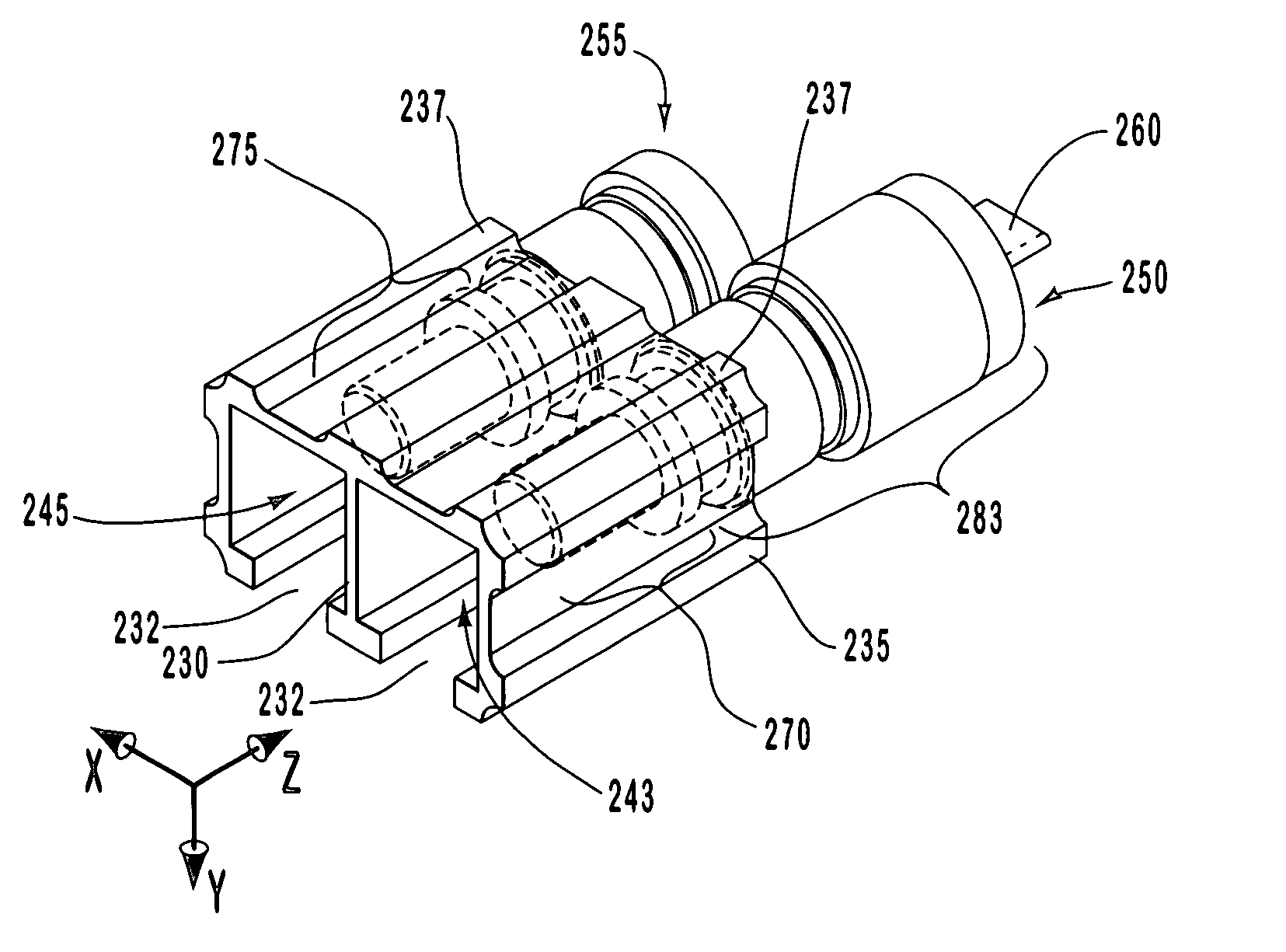

Magnetic resonance gradient coil with a heat insulator disposed between the electrical conductor and the carrier structure

InactiveUS6774631B2Efficient thermal conductivityEffect structureDiagnostic recording/measuringSensorsElectricityElectrical conductor

An electrical coil, particularly a gradient coil for a magnetic resonance apparatus, contains at least one electrical conductor, a carrier structure, at least one component of a cooling device and a heat insulator, which is arranged for at least one section of the conductor between the conductor and the carrier structure.

Owner:SIEMENS HEALTHCARE GMBH

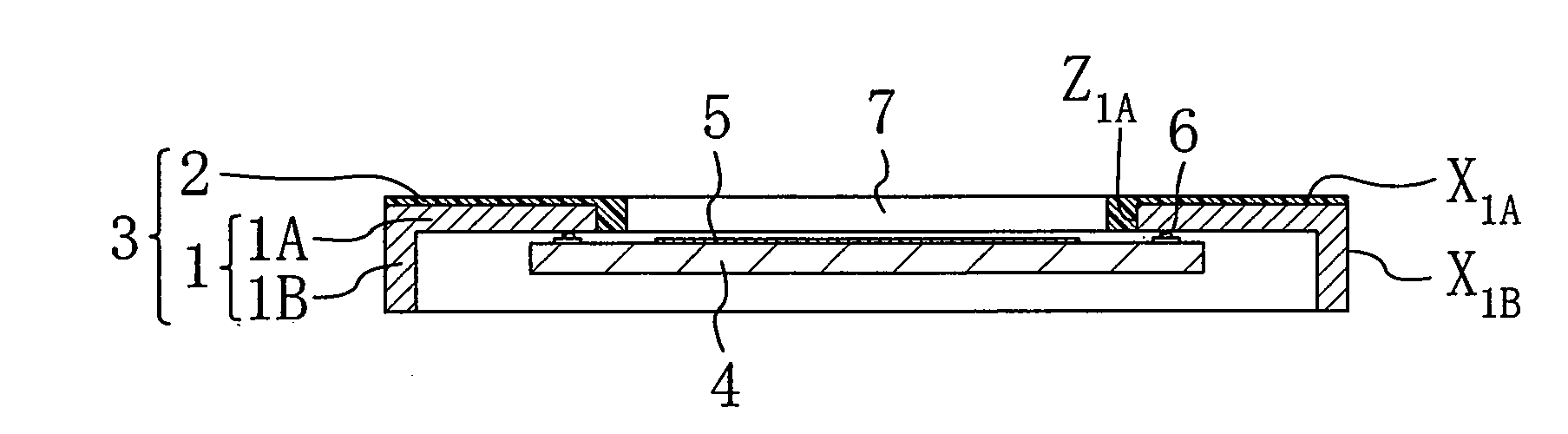

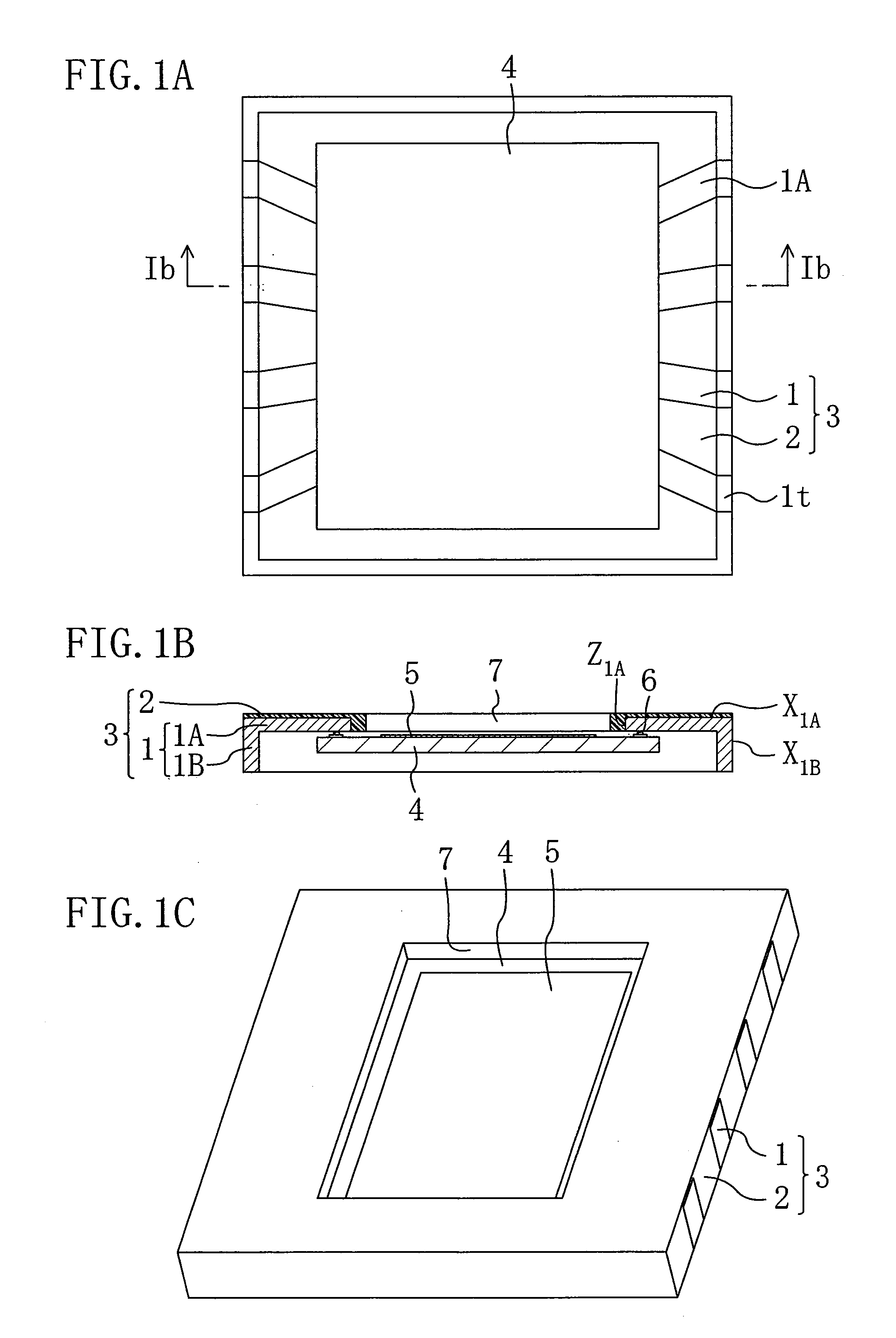

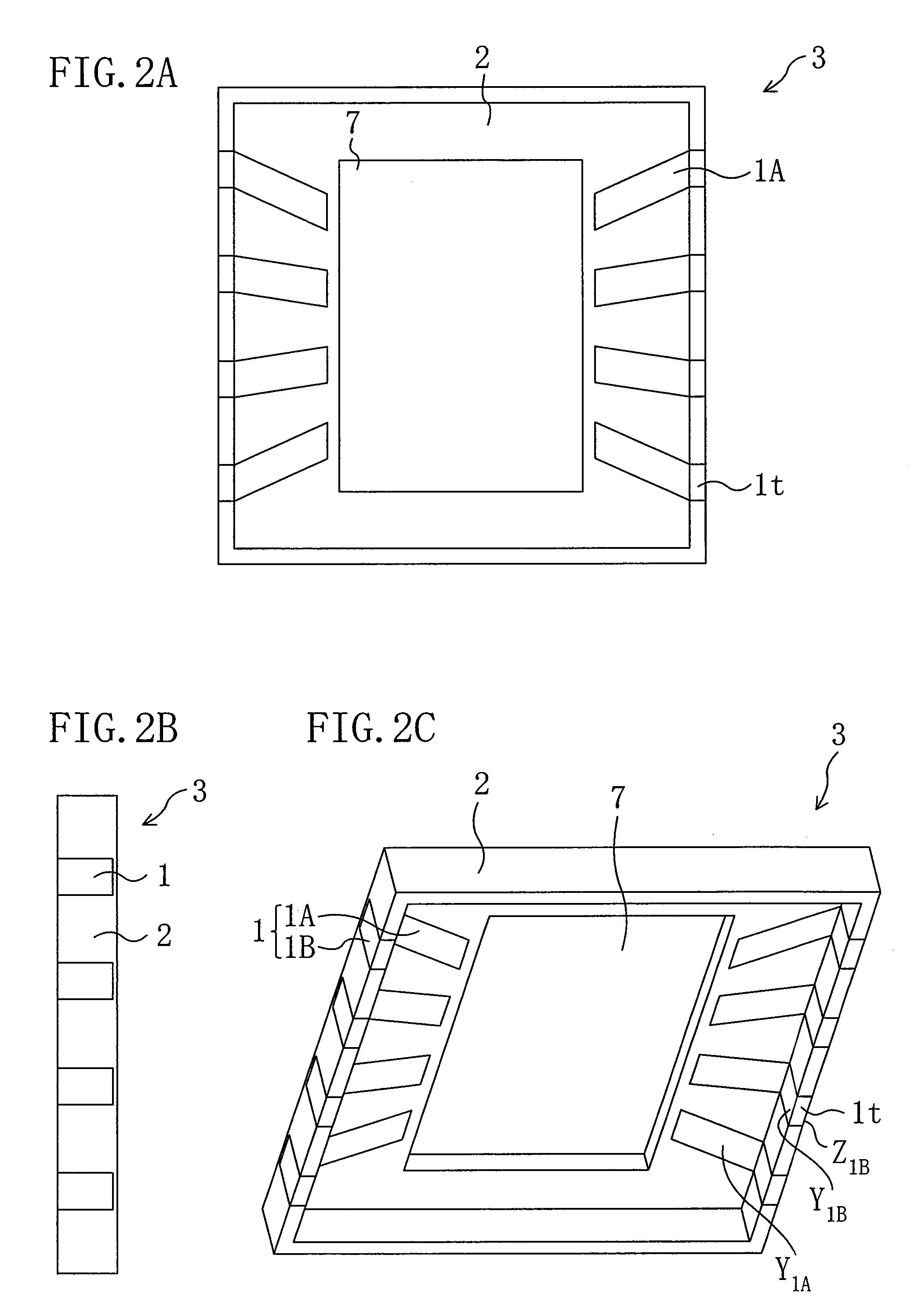

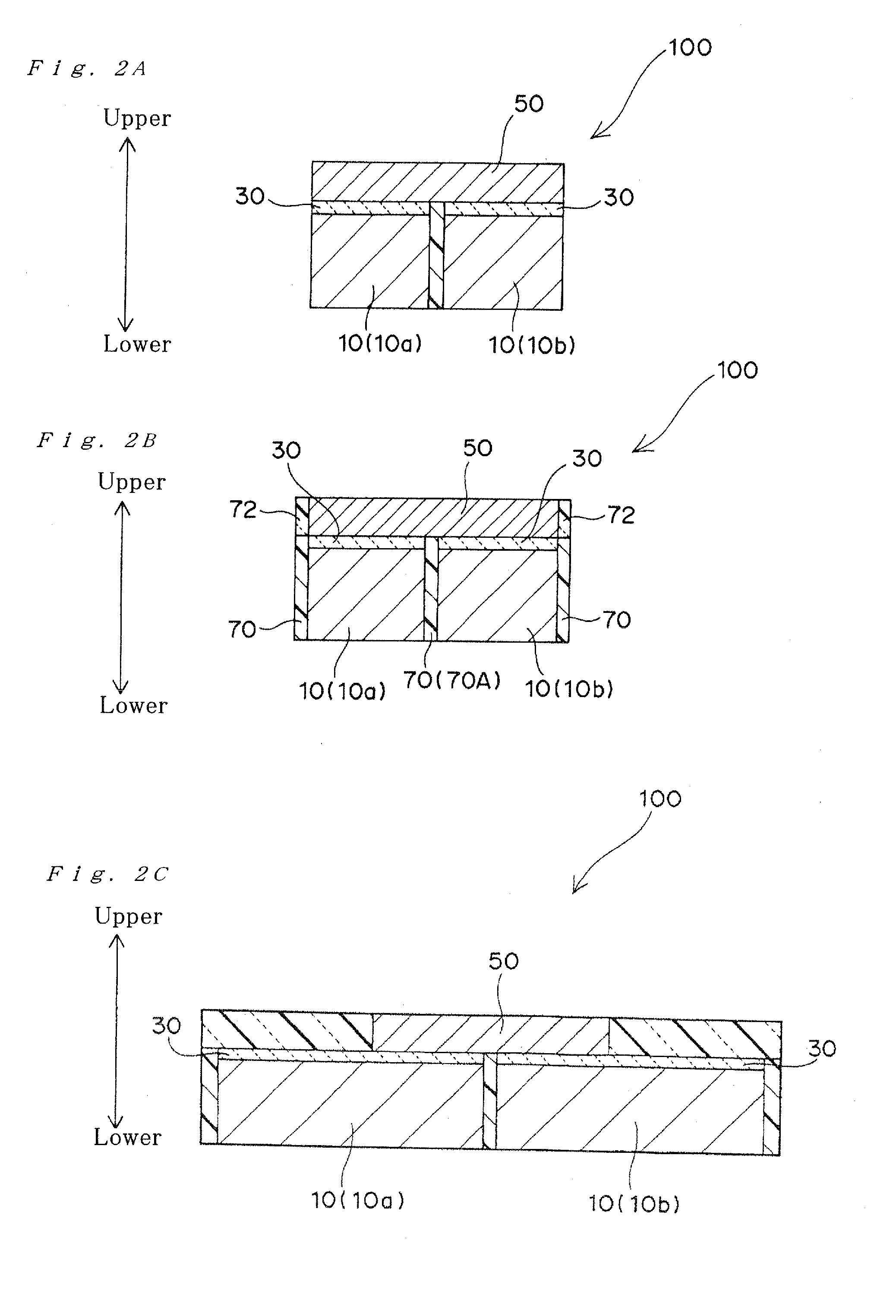

Optical device and manufacturing method thereof and semiconductor device

ActiveUS20090096048A1Improve cooling effectImprove cooling efficiencyTelevision system detailsSolid-state devicesDevice materialMechanical engineering

An optical device includes a base and an optical element. The base has a through hole in a center and includes leads and a resin. Each lead has an L-shaped cross-section and is formed by an inner lead extending from the center toward a peripheral edge and an outer lead connected to the inner lead and extending downward. The optical element is provided under the base so as to correspond to the through hole. Electrode pads of the optical element are connected to the leads of the base through bumps, respectively. The resin is formed so as to cover respective inner ends of the leads and respective front surfaces of the inner leads and to fill a gap between adjacent leads, and respective outer ends of the leads and respective front surfaces of the outer leads are exposed.

Owner:PANNOVA SEMIC

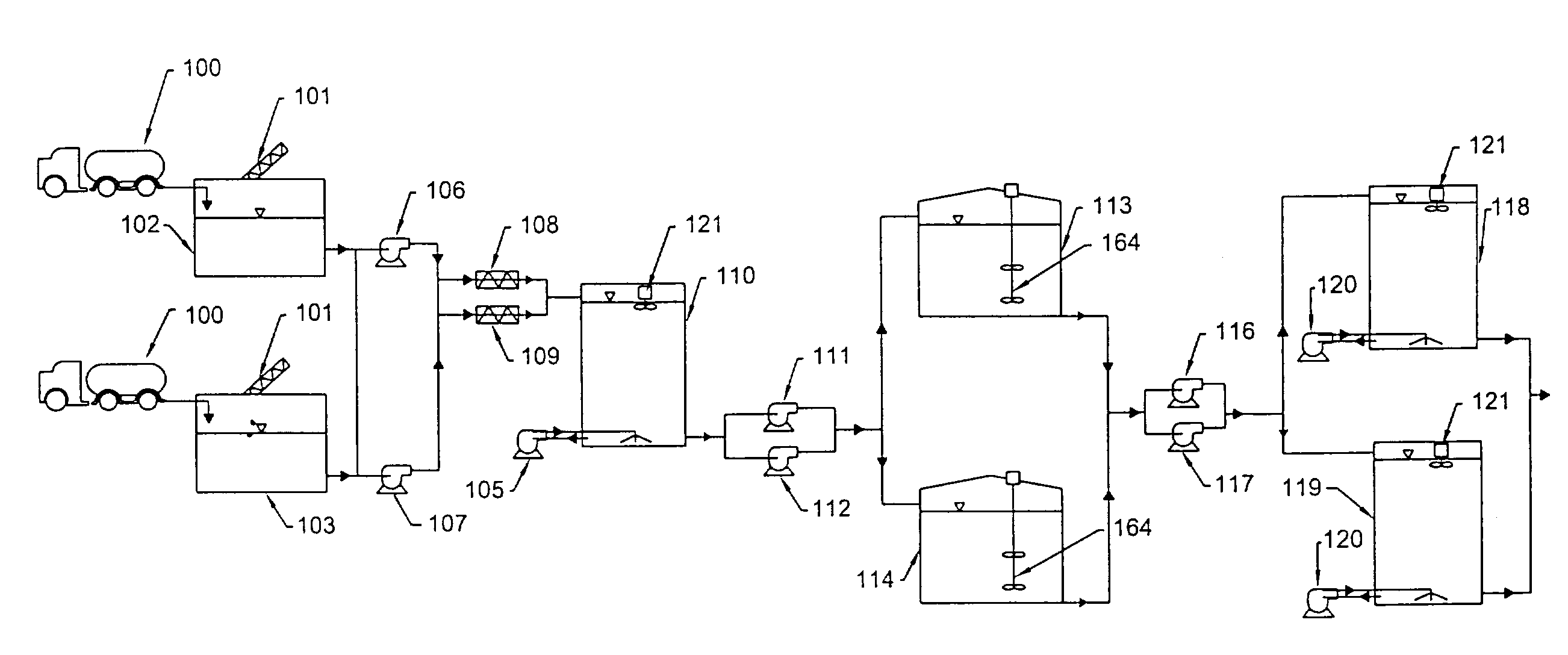

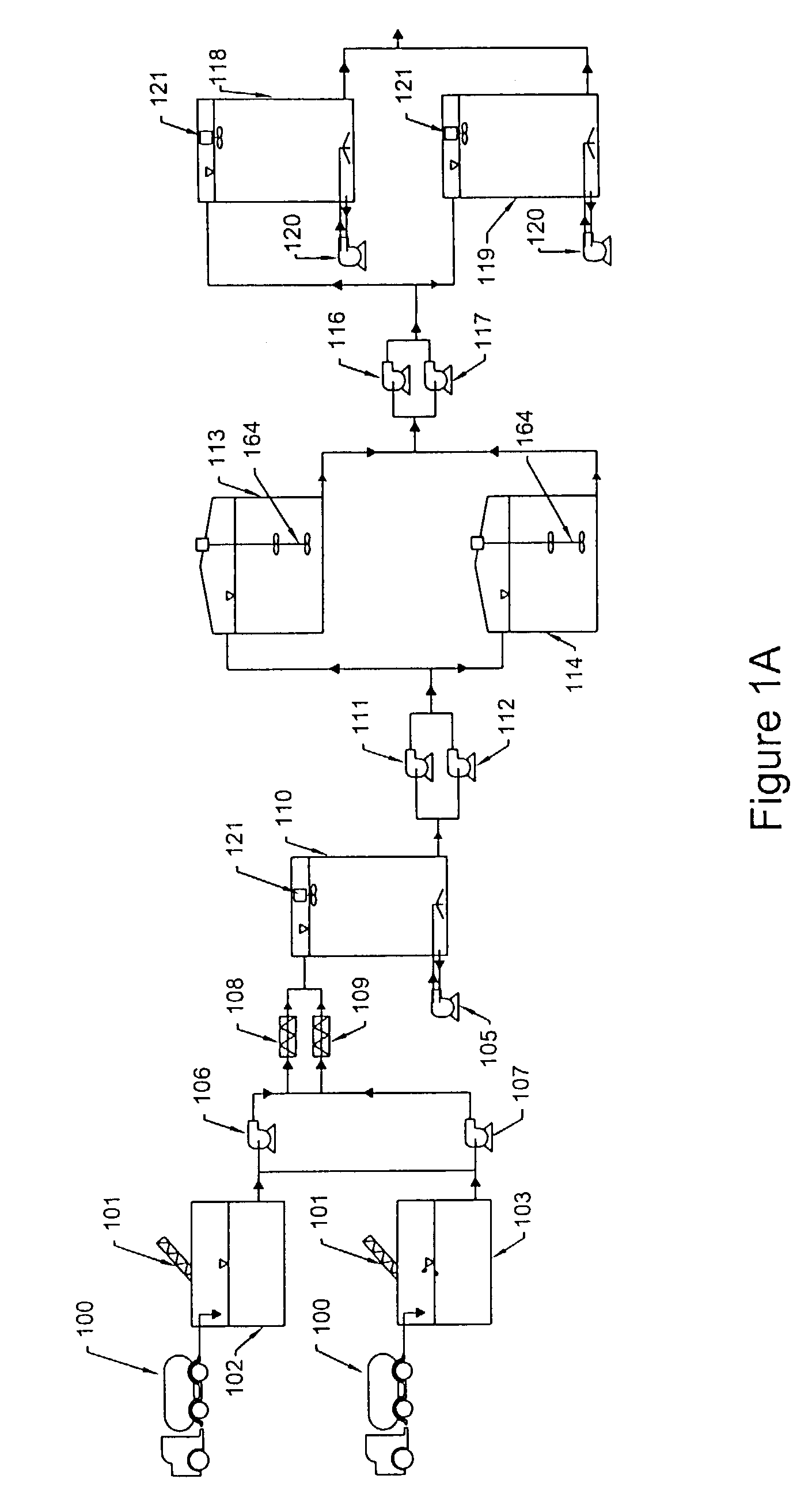

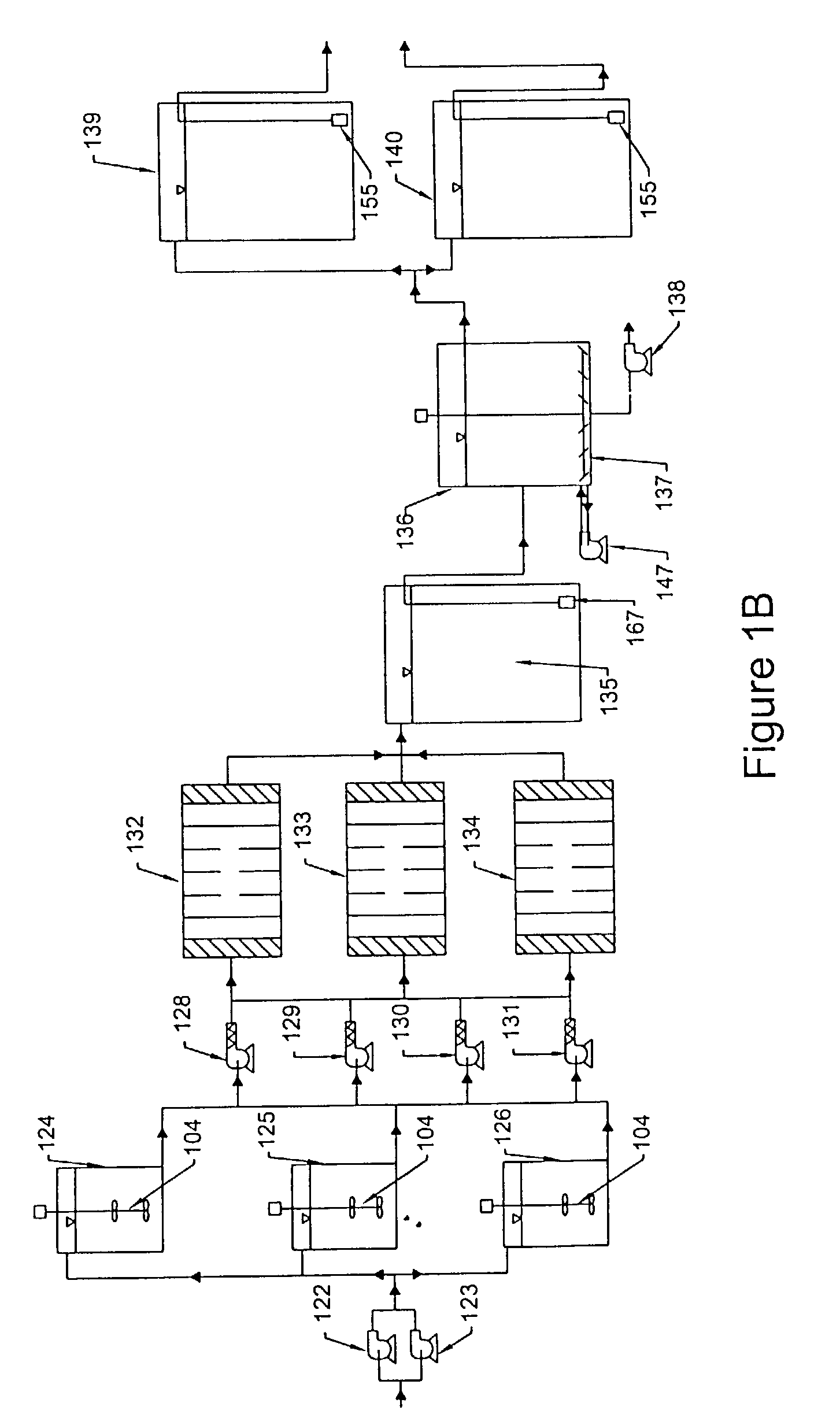

Process for treating septage

InactiveUS7070693B2Easy to dehydrateQuality improvementSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSolid fractionPasteurization

A process and apparatus for the treatment of septage, particularly grease trap waste, is disclosed. The inventive process will convert the septage into Biosolids (sludge) and water dischargeable to the environment. The treated septage achieves pathogen reduction, and reduced vector attraction. Treatment of septage by pasteurization causes the destruction of harmful pathogens. Pasteurization of septage having high water content provides for even temperature elevation and distribution of heat within the thermal mass of the septage allowing for consistent pathogen destruction. An alkaline compound is utilized to form a filter cake from the solids fraction of the pasteurized septage preventing vector attraction, while producing a beneficial bio-solid. The liquid fraction of the septage is treated by biological process allowing for its discharge into the environment.

Owner:KELLY ROBERT J

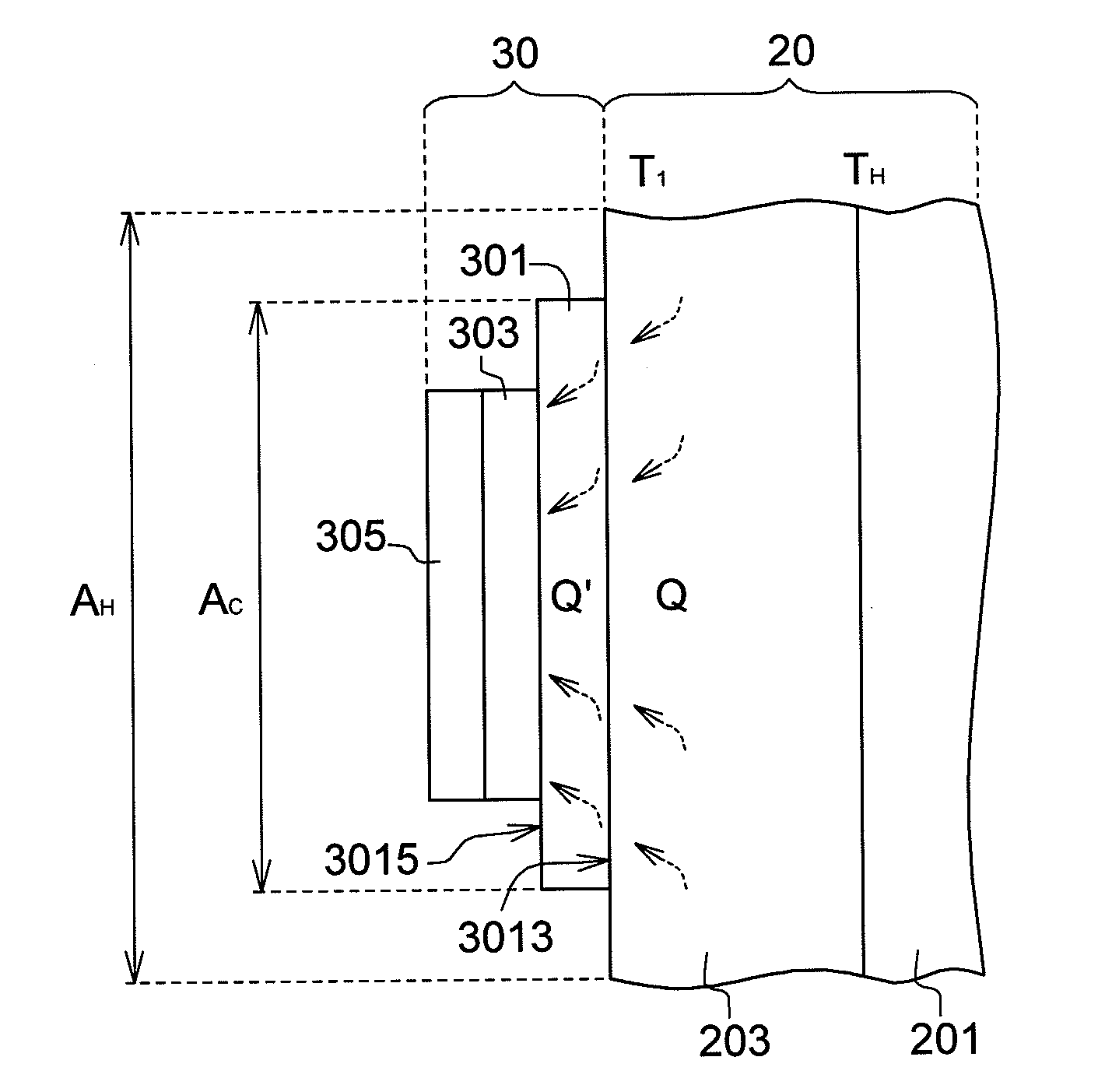

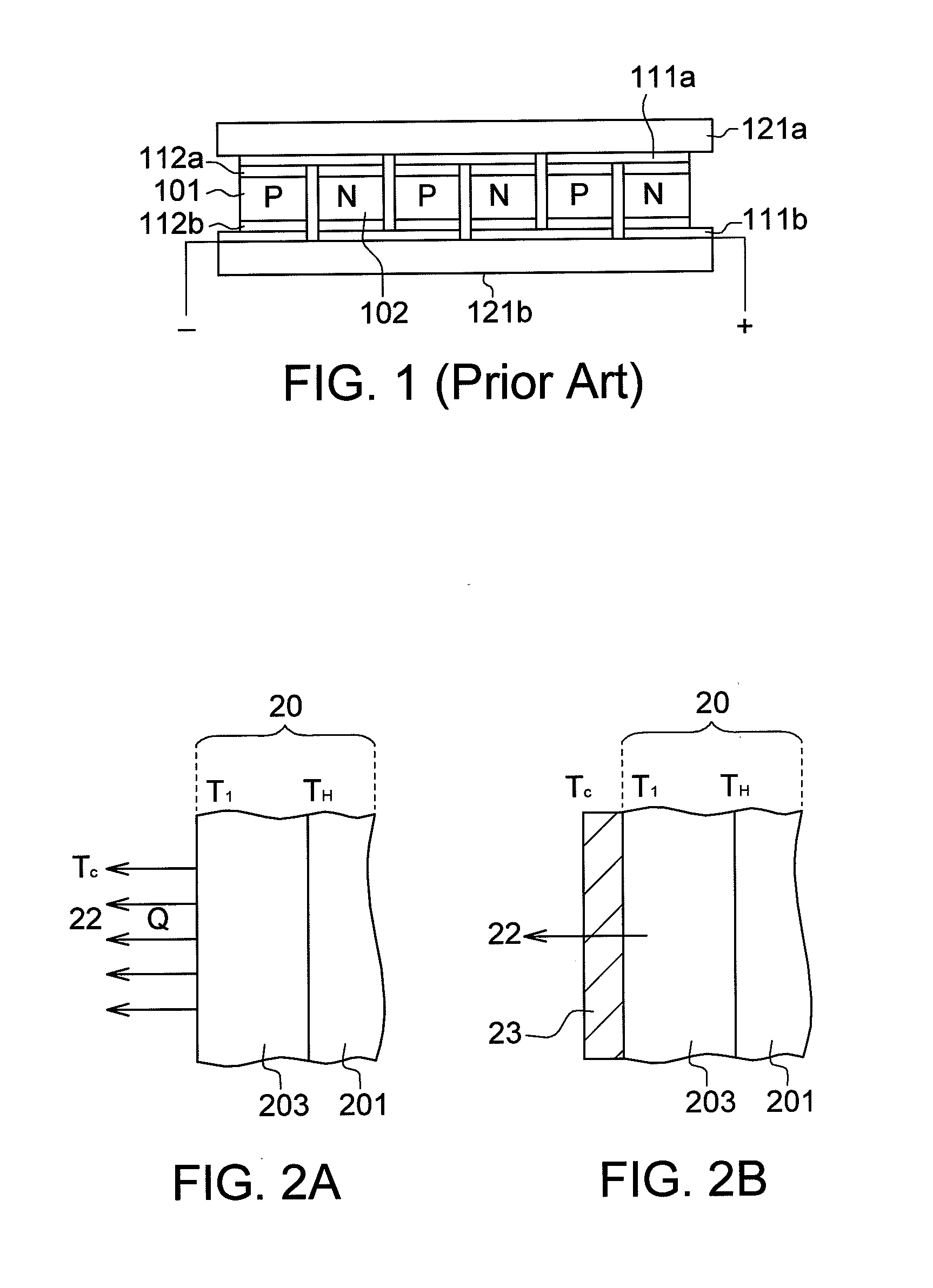

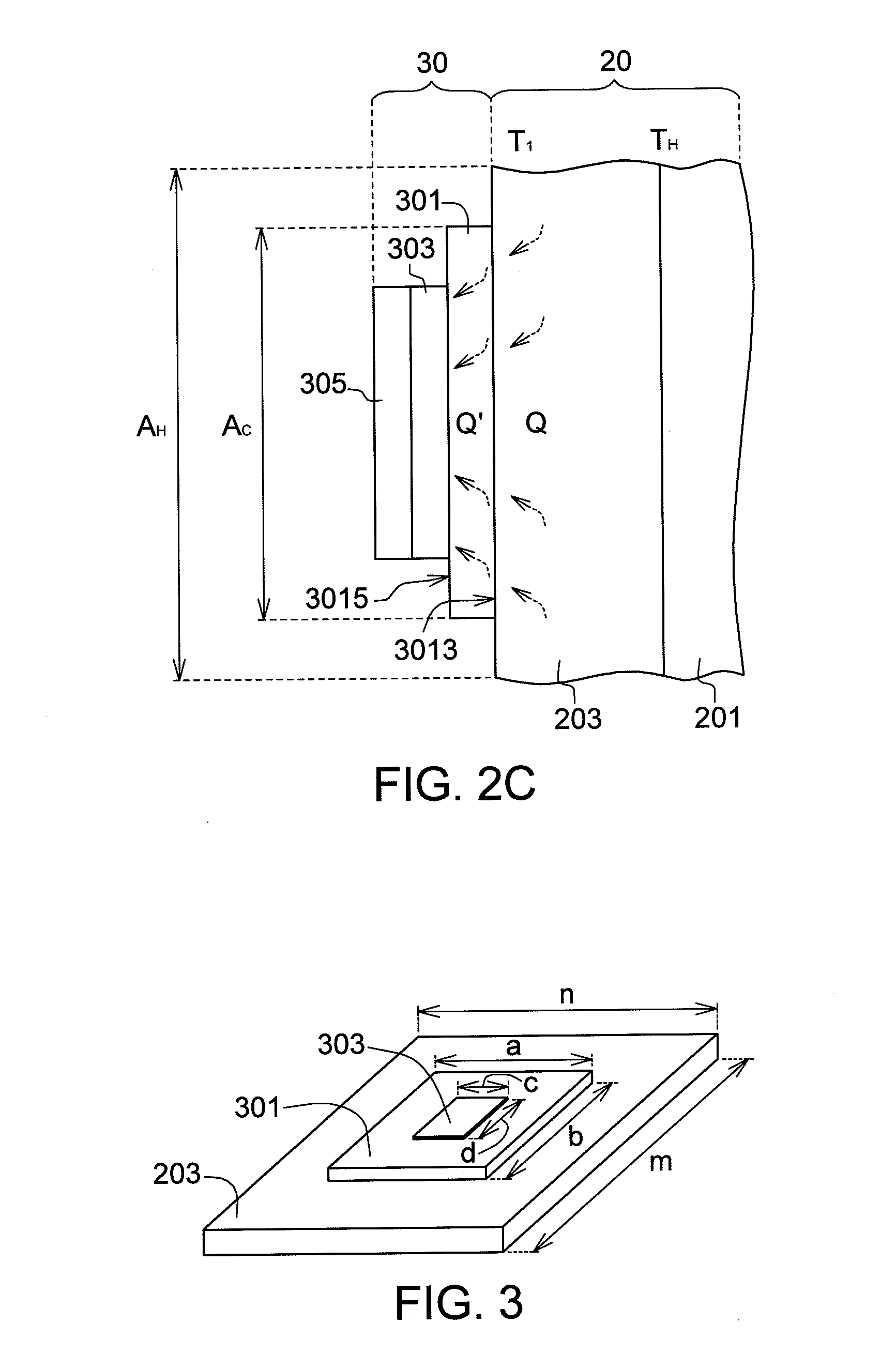

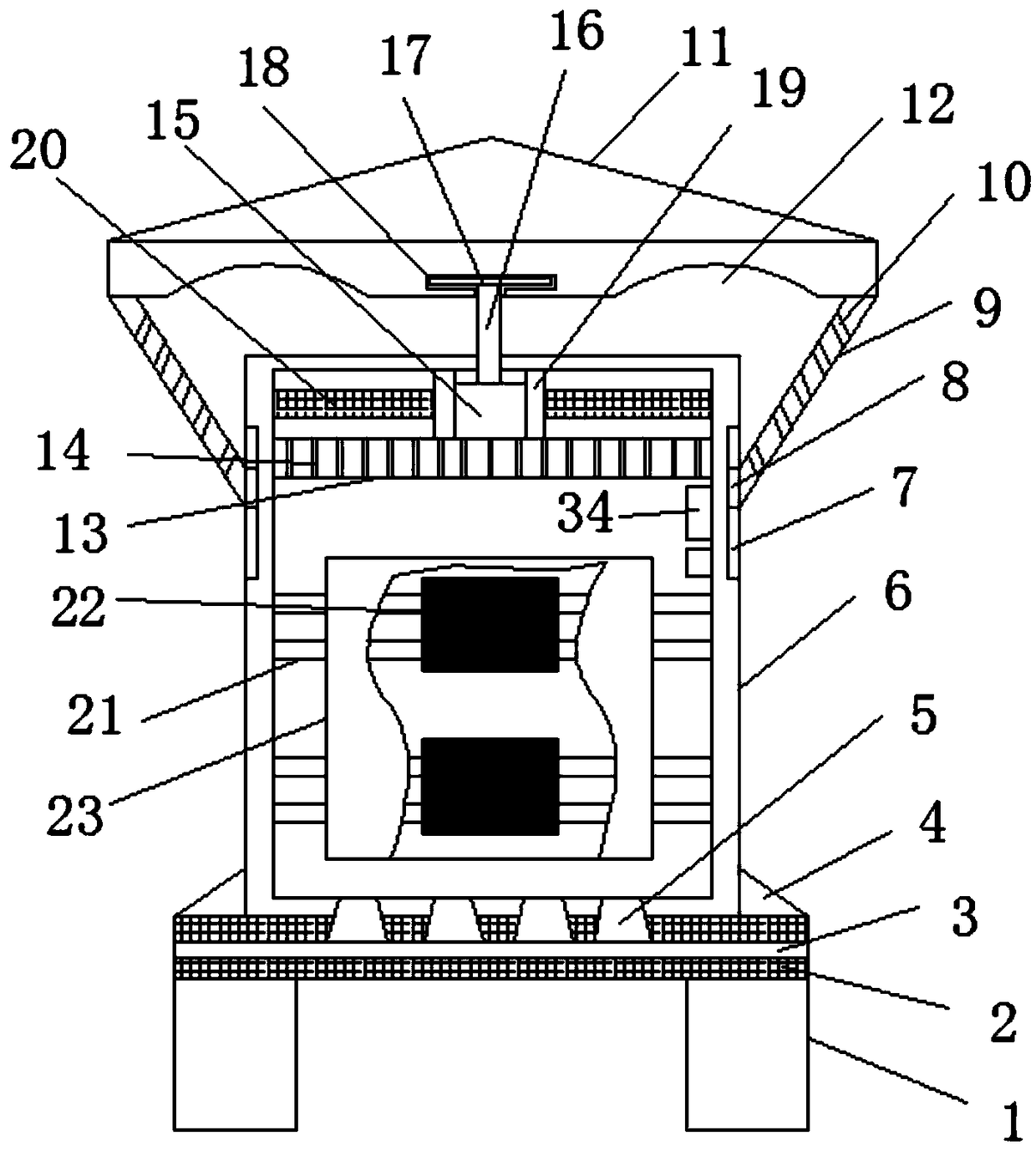

Thermoelectric generator apparatus with high thermoelectric conversion efficiency

InactiveUS20120132242A1High efficient thermal conductivityHeat flux of also increaseThermoelectric device with peltier/seeback effectCold sideHeat flux

A thermoelectric generator apparatus disposed on a high-temperature surface of an object (as a heat source), at least includes a heat concentrator, a thermoelectric module and a cold-side heat sink. The heat concentrator has a top surface and a bottom surface contacting a high-temperature surface of the object, and an area of the bottom surface is smaller than that of the high-temperature surface. The thermoelectric module is disposed on the top surface of the heat concentrator. The cold-side heat sink is disposed on the thermoelectric module. Heat generated by the heat source is concentrated on the heat concentrator and flows to the hot side of the thermoelectric module for increasing the heat flux (Q′) passing the thermoelectric module and the hot side temperature of the thermoelectric module. Consequently, the thermoelectric conversion efficiency (η) is improved, and the power generation of the thermoelectric module is increased.

Owner:IND TECH RES INST

Polymer-based insulating and heat conducting composite material with efficient heat conductivity and excellent mechanical properties

ActiveCN105175842AIncrease the conduction thresholdIncrease filling volumeFlat articlesInsulator (electricity)Polymer

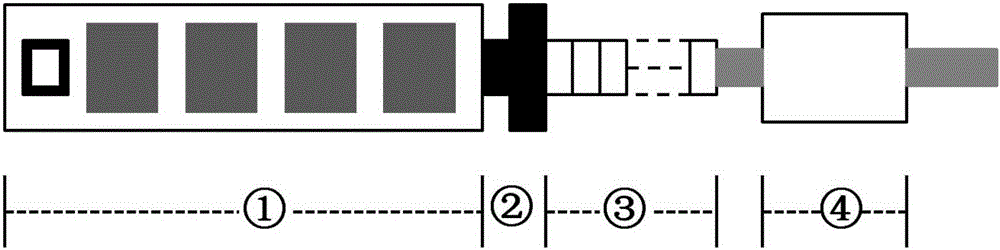

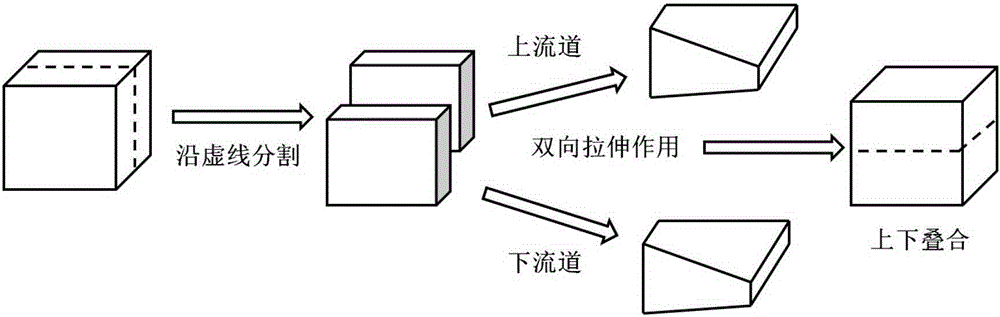

The invention discloses a polymer-based insulating and heat conducting composite material with efficient heat conductivity and excellent mechanical properties. The composite material is characterized in that in the preparation process, through a specific biaxial tensile force field, high dispersion of fillers in a composite system and complete orientation of anisotropic fillers can be effectively achieved, the quantity of the fillers can be increased, the integral heat conductivity of the material can be improved and the excellent mechanical properties of the material can be ensured. The greatest advantages of the composite material are that high filling of electricity and heat conducting fillers can be achieved and the integral insulativity of the material can be still maintained, thus the limitation of lower electricity conducting percolation threshold to the additive amount of the electricity and heat conducting fillers in an insulation system can be broken through and the advantage of high heat conductivity of the electricity and heat conducting fillers can be given play to. Meanwhile, the composite material has the advantages of simplicity in operation, convenience in control, continuous production and stable quality, has good industrialization capacity and market prospect and can be widely applied to preparation of plates, sheets and membrane materials with excellent mechanical properties and efficient insulativity and heat conductivity.

Owner:SICHUAN UNIV

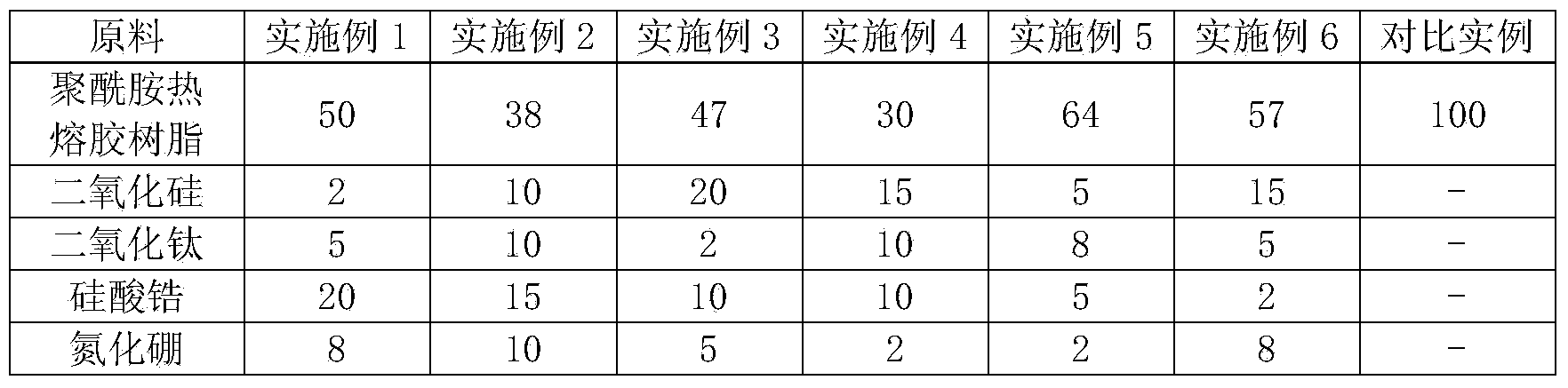

Heat-conducting hot melt adhesive and preparation method thereof

InactiveCN103555262AGood refractive indexEfficient thermal conductivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesThermal energyHeat conducting

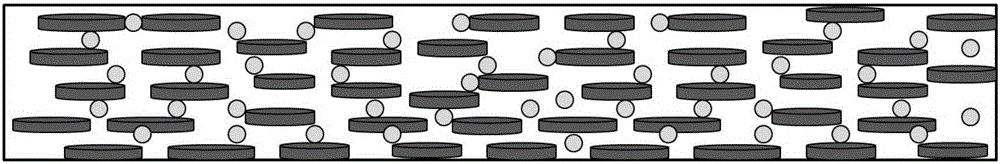

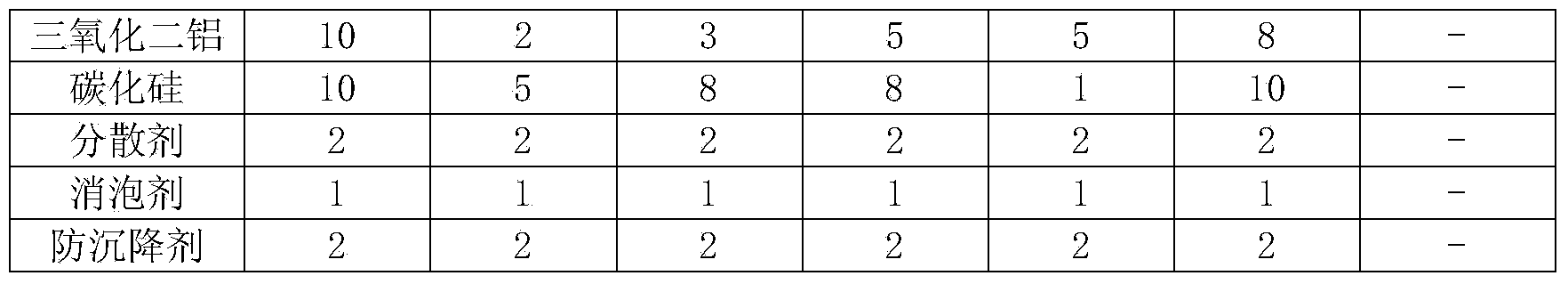

The invention relates to a heat-conducting hot melt adhesive, which comprises the following components by weight percent: 1%-20% of silicon dioxide, 1%-10% of titanium dioxide, 1%-20% of zirconium silicate, 1%-10% of boron nitride, 1%-10% of aluminum oxide, 1%-10% of silicon carbide. 0.5%-5% of dispersant, 0.5%-5% of anti-sedimentation agent, 0.5%-5% of defoamer and the balance of synthetic resin. According to the invention, elements having excellent refractive index, high axial heat source absorption capability and fine thermal conductivity such as aluminum, boron, titanium, silicon and zirconium are processed into oxides, nitrides and carbides, and the oxides, the nitrides and the carbides are ground into powdery particles within the range from 10 nm to 25 microns; next, the powdery particles are mixed with hot melt adhesive resin in a certain ratio to obtain the hot melt adhesive; and the obtained hot melt adhesive has efficiency heat conductivity and is capable of quickly transferring heat in three ways of conduction, convection and radiation.

Owner:YANTAI DARBOND TECH

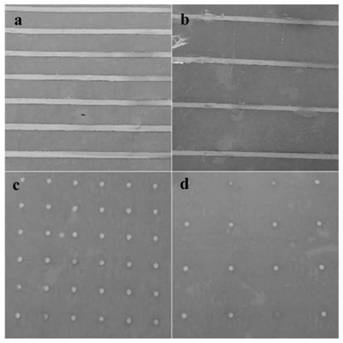

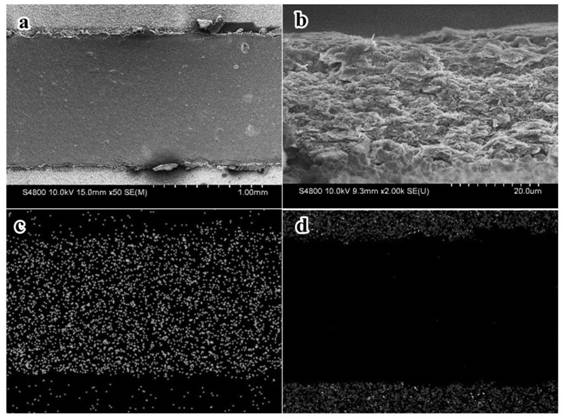

Diamond/graphene composite heat conduction film, preparation method thereof and heat dissipation system

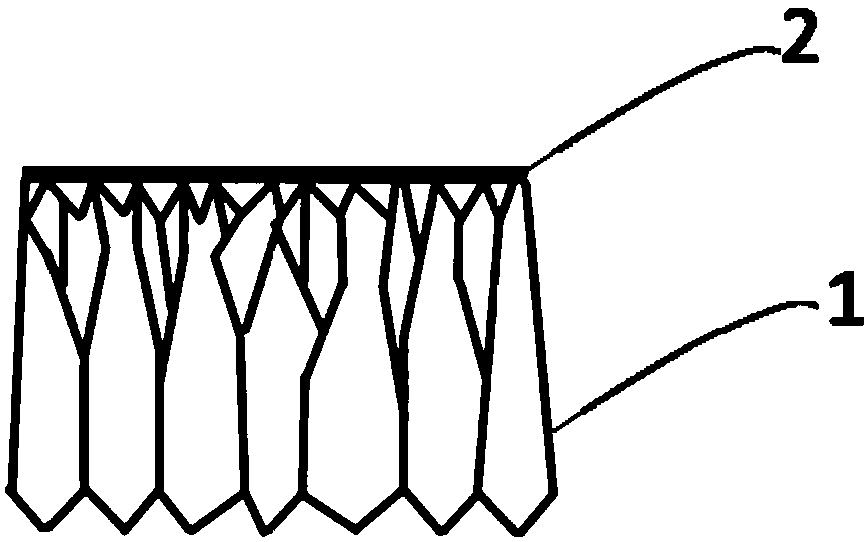

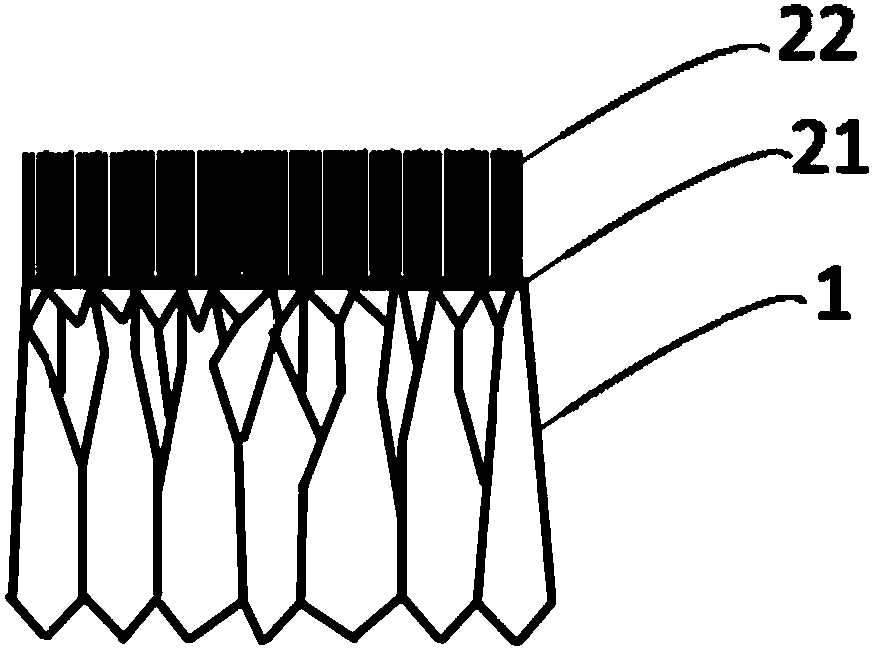

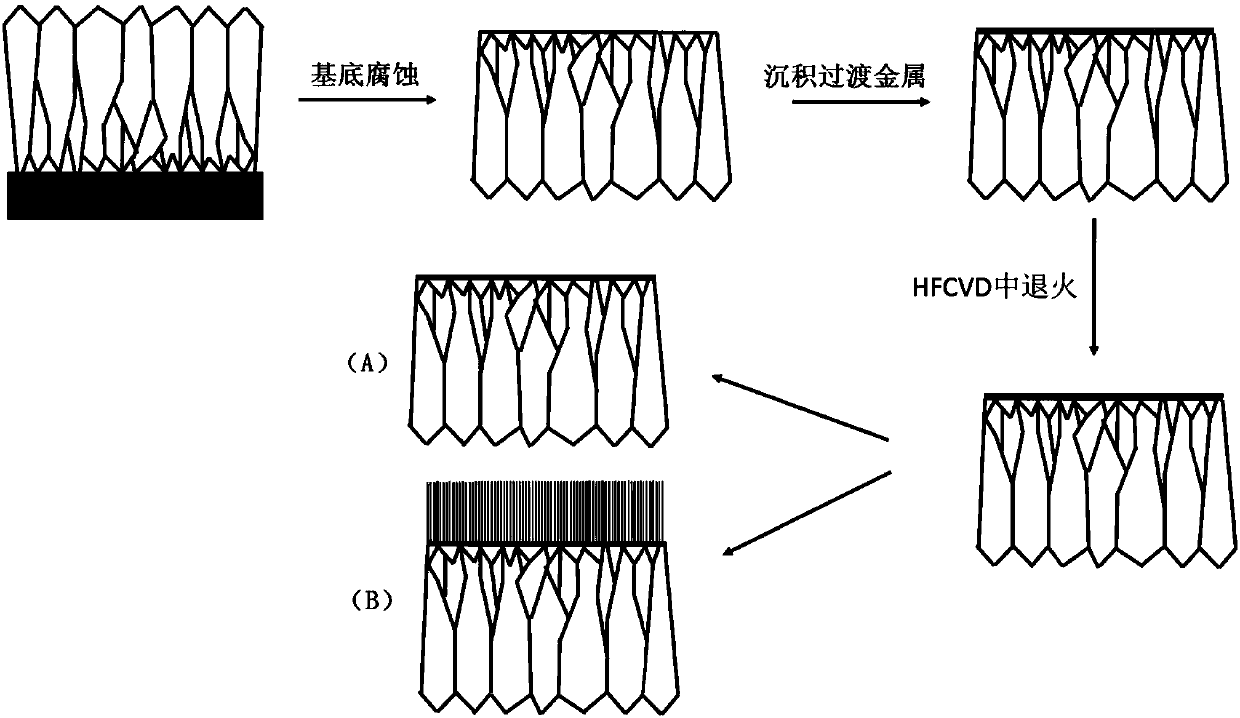

PendingCN109722641AGood thermal conductivityThe preparation method is simple and easy to operateHeat-exchange elementsChemical vapor deposition coatingCvd grapheneHot filament

The invention provides a diamond / graphene composite heat conduction film. The diamond / graphene composite heat conduction film comprises a micro-grain diamond thin film and a graphene layer arranged onthe surface of the micron-grain diamond thin film. The diamond and the graphene in the diamond / graphene composite heat conduction film form an excellent heat conduction structure, and the obtained composite heat conduction film has efficient heat conduction performance. The invention further provides a preparation method of the diamond / graphene composite heat conduction film. The preparation method comprises the following steps that a substrate is provided, and the micron-grain diamond thin film is deposited on the surface of the substrate; the substrate is corroded and removed, and the self-supported micron-grain diamond thin film is obtained; the self-supported micron-grain diamond thin film comprises a to-be-nucleated surface; and a transition metal layer is deposited on the to-be-nucleated surface, the self-supported micron-grain diamond thin film with the transition metal layer deposited is placed in a hot-filament vapor deposition chamber cavity for rapid annealing treatment toobtain the diamond / graphene composite heat conduction film, wherein the annealing temperature is 800-1100 DEG C, and the annealing time is 1-5 min. The invention further provides a heat dissipation system.

Owner:SHENZHEN INST OF ADVANCED TECH

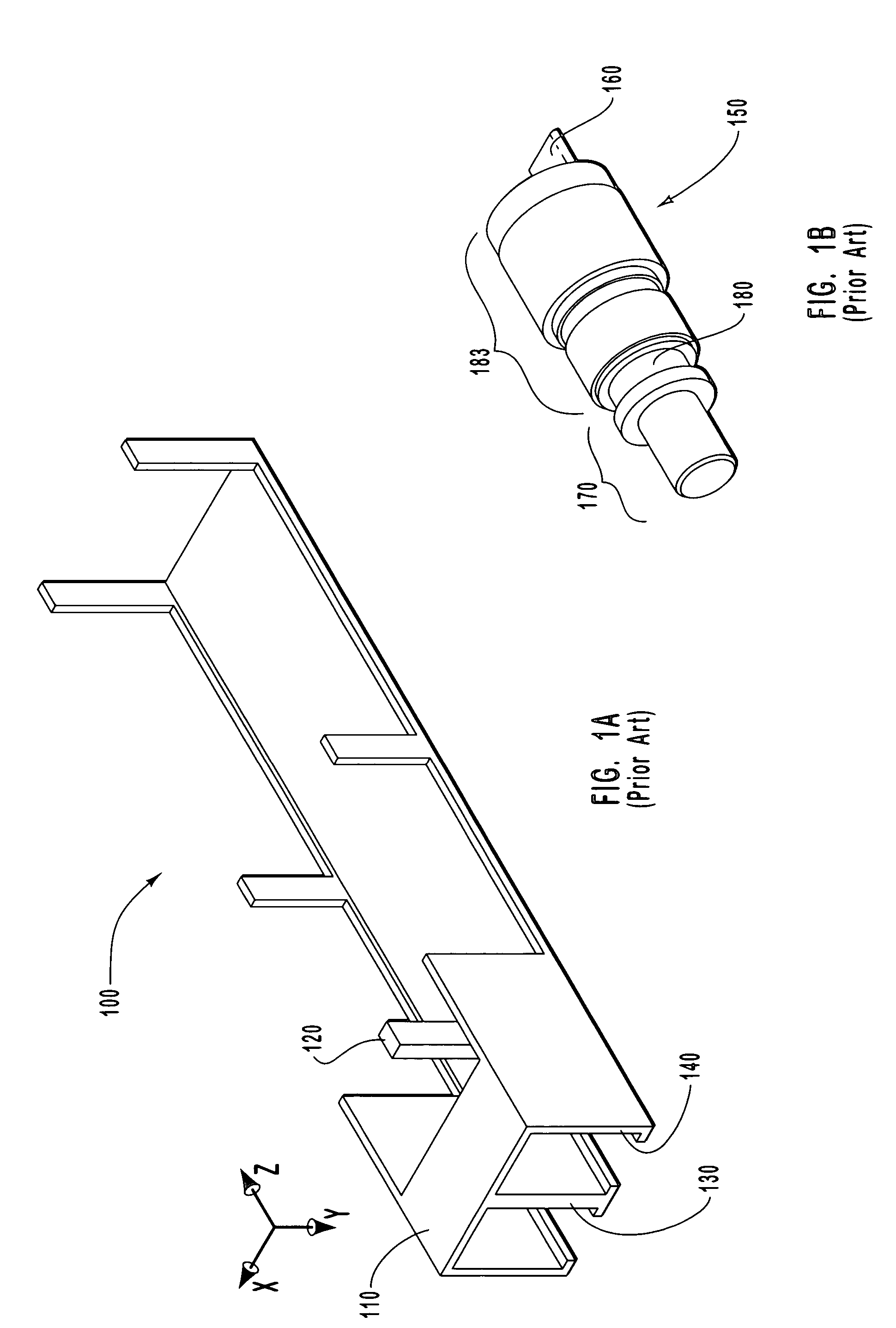

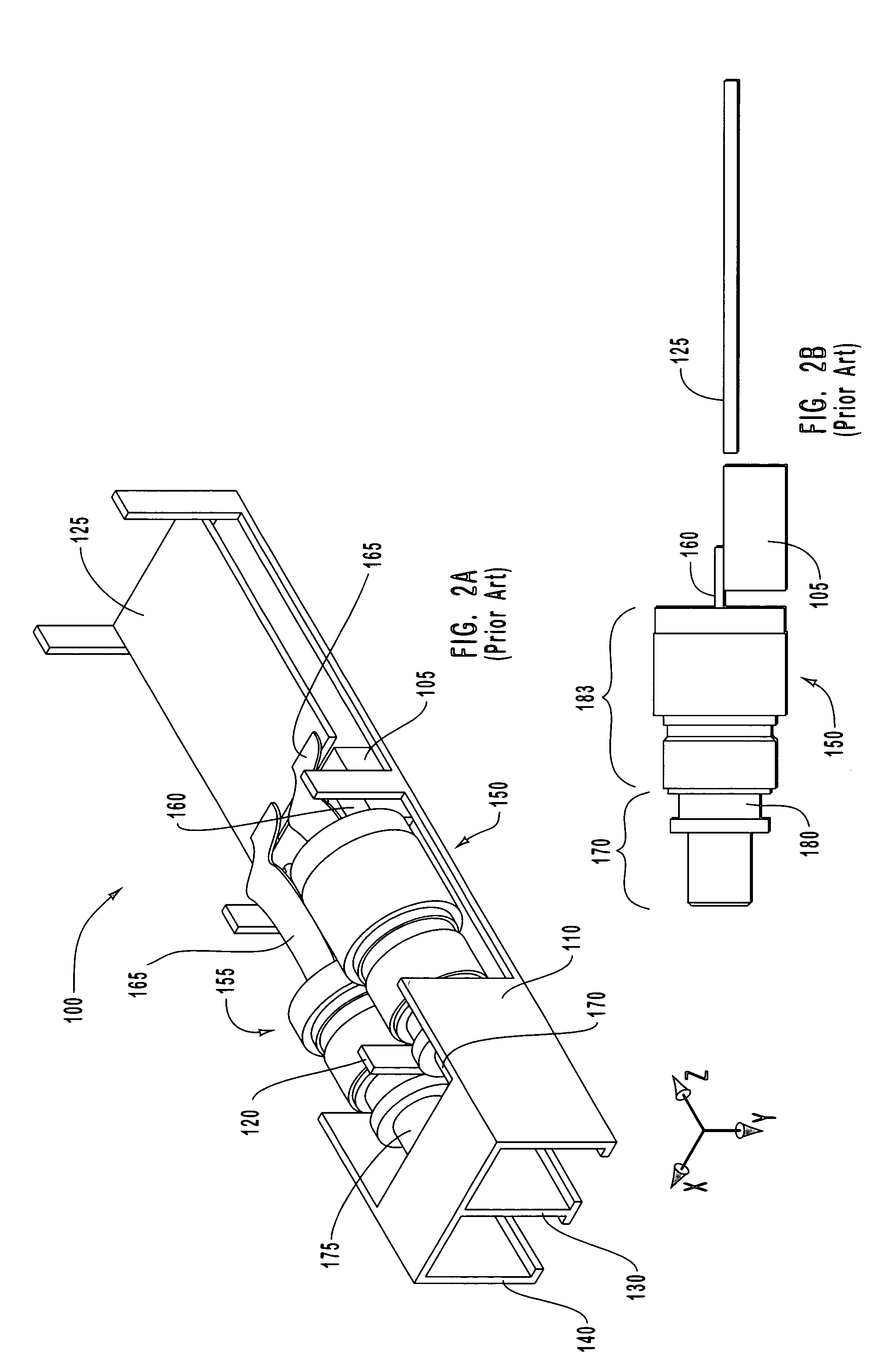

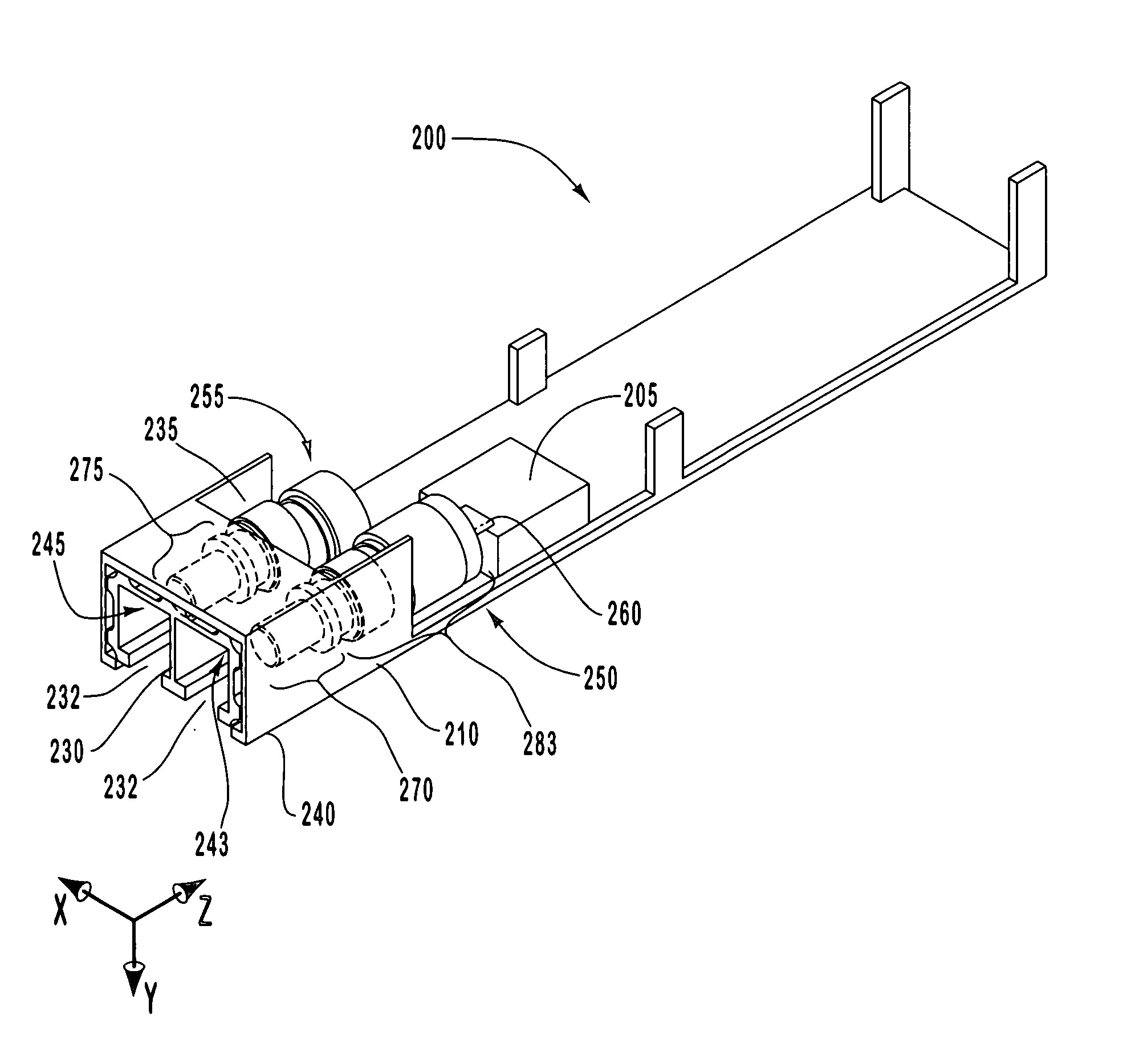

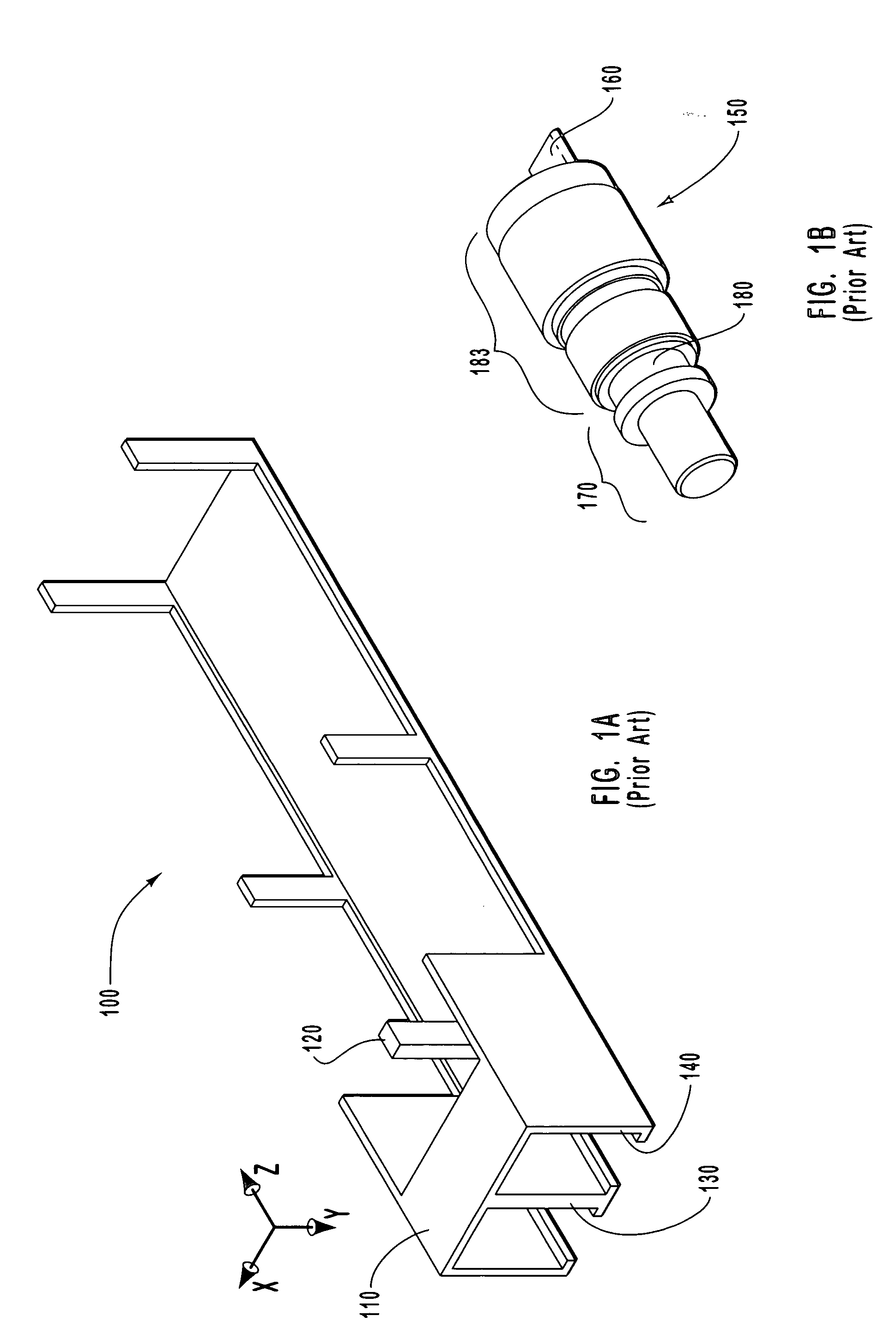

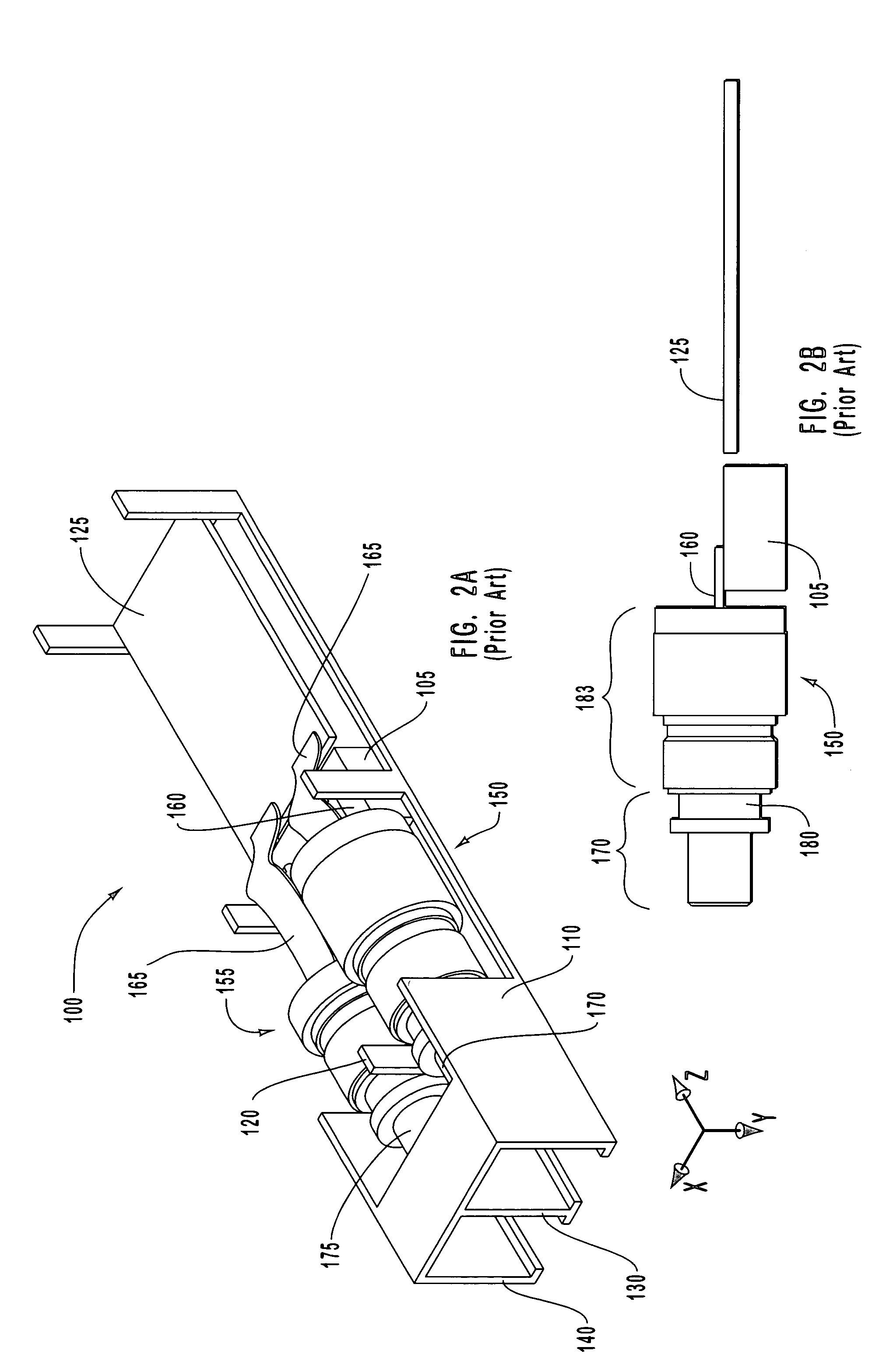

Optical transceiver with variably positioned insert

ActiveUS7670063B2Efficient thermal conductivityThe relative position is appropriateCoupling light guidesElectromagnetic transmissionSpatial OrientationsTransceiver

An optical transceiver includes a transceiver housing configured to receive an optical sub-assembly insert. The optical sub-assembly insert includes duplex cavities configured to hold a transmit optical sub-assembly front end and a receive optical sub-assembly front end in a fixed spatial orientation for a given optical connector interface. The optical sub-assembly insert is configurable to fit inside a transceiver housing with a relatively wide range of X and Y dimensional tolerance. In one implementation, the X-Y position of the optical sub-assembly insert is dictated by the position of the transmit optical-sub assembly front end after its corresponding back end has been mounted to a heat dissipation element. Any gaps that form between the optical sub-assembly insert and the inside surface of the transceiver housing as a result of the transmit optical sub-assembly position can be accommodated with filler material.

Owner:II VI DELAWARE INC

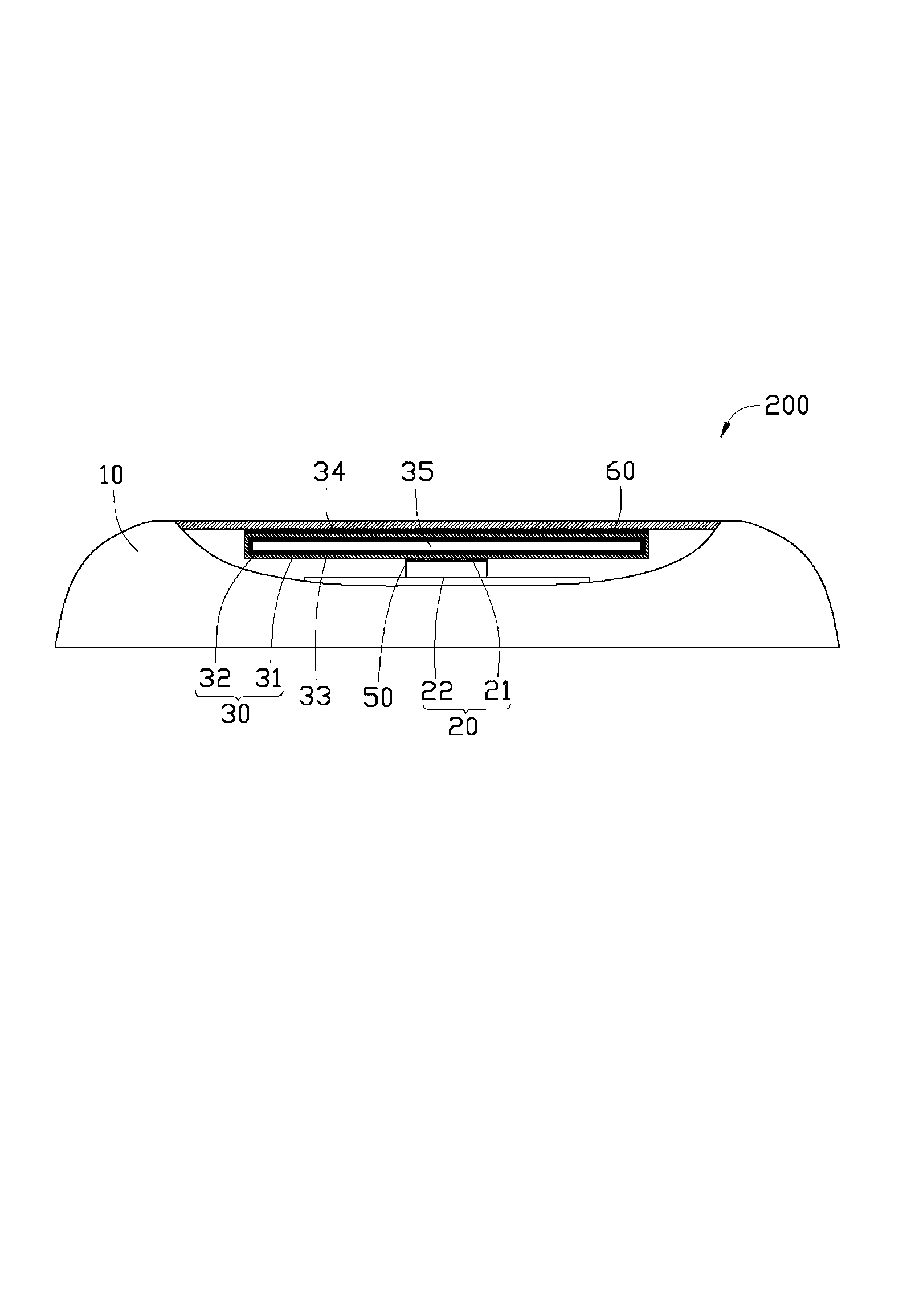

Electronic equipment

InactiveCN102811588AReduce volumeEfficient thermal conductivityDigital data processing detailsSemiconductor/solid-state device detailsEvaporationEngineering

Owner:FU ZHUN PRECISION IND SHENZHEN +1

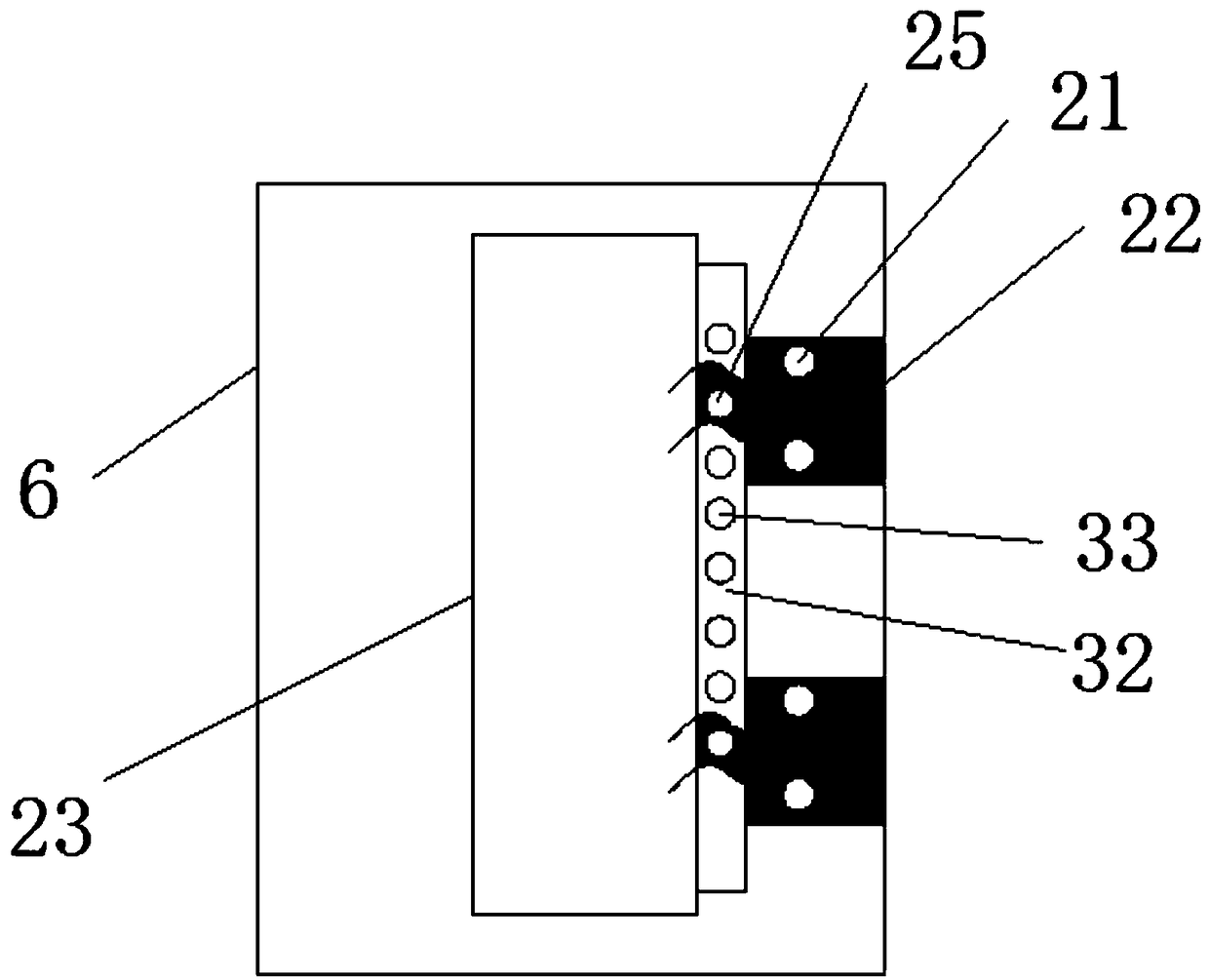

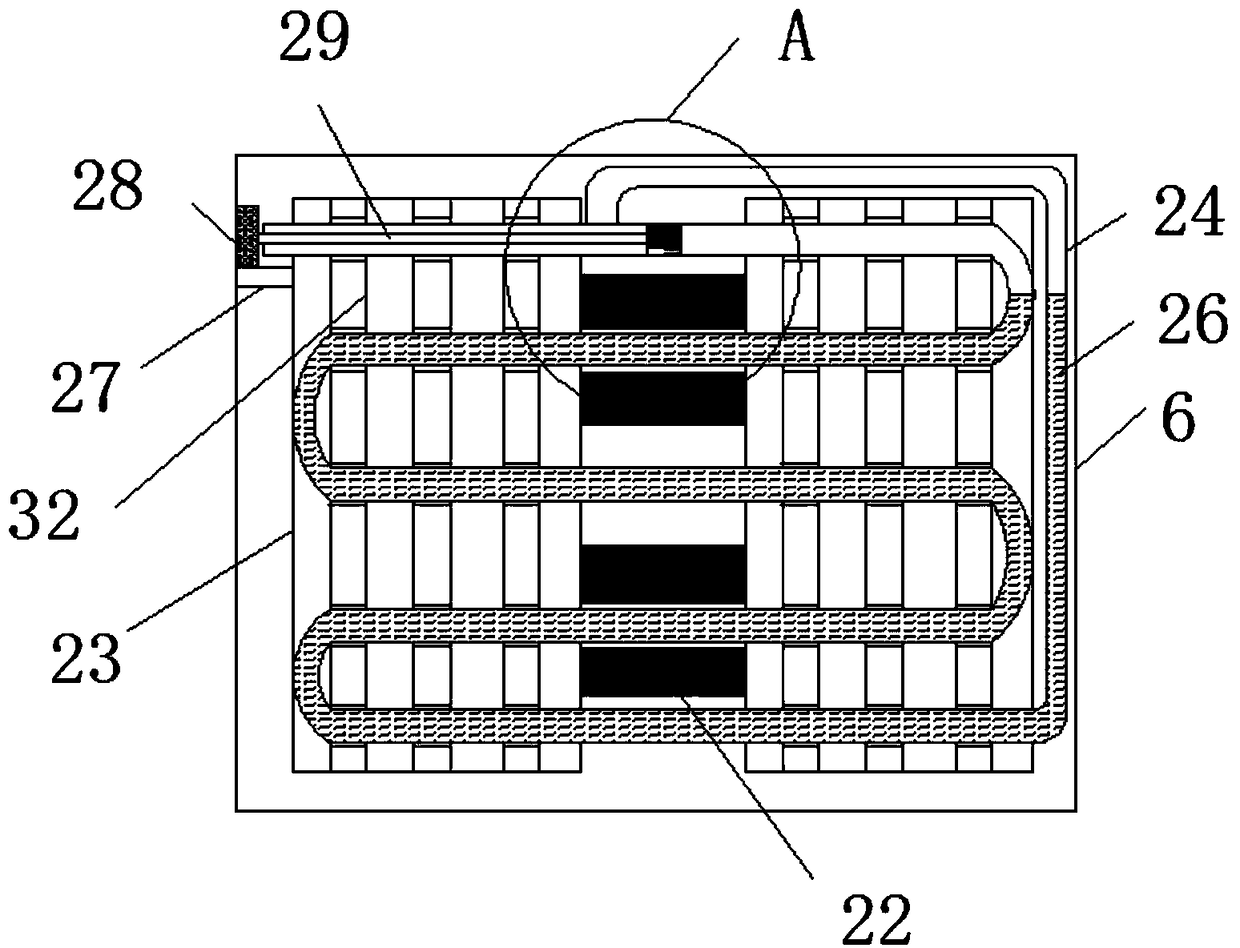

Semiconductor laser heat sink

InactiveCN106684700AInhibit deteriorationGuaranteed normal transmissionLaser detailsSemiconductor lasersHeat conductingThermal expansion

The invention discloses a semiconductor laser heat sink. The semiconductor laser heat sink has the characteristics of excellent heat-dissipation performance, difficult oxidation, long service life and stable heat dissipation. The semiconductor laser heat sink adopts a chemical vapor deposition (CVD) method to prepare a graphene thin-film layer with high thermal conductivity and low thermal expansion coefficient on the surface of a copper heat sink so as to realize coating of the copper heat sink. The semiconductor laser heat sink utilizes stable performance and high-efficiency heat-conducting performance of graphene materials to realize high-efficiency fast transmission of heat generated by a semiconductor laser chip to copper heat sink, and the heat transmitted from the graphene thin-film layer is dissipated into air or other cooling mediums by the copper heat sink. According to the semiconductor laser heat sink disclosed by the invention, the preparation process is simple, the cost is low, the heat dissipation performance is stable, the service life is long, the heat dissipation problem of the semiconductor laser can be effectively solved and the performance of a semiconductor laser device can be improved.

Owner:CHANGCHUN UNIV OF SCI & TECH

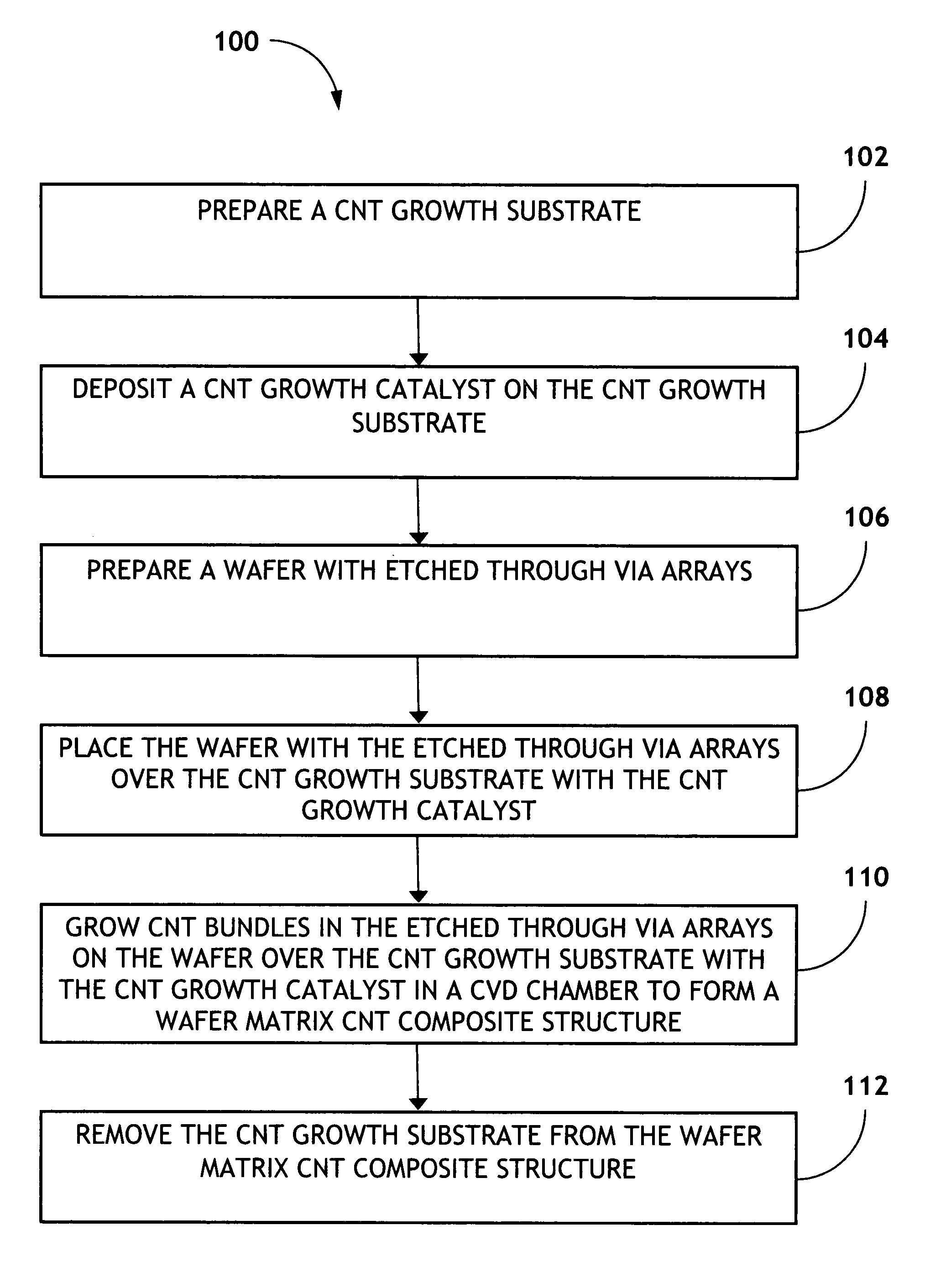

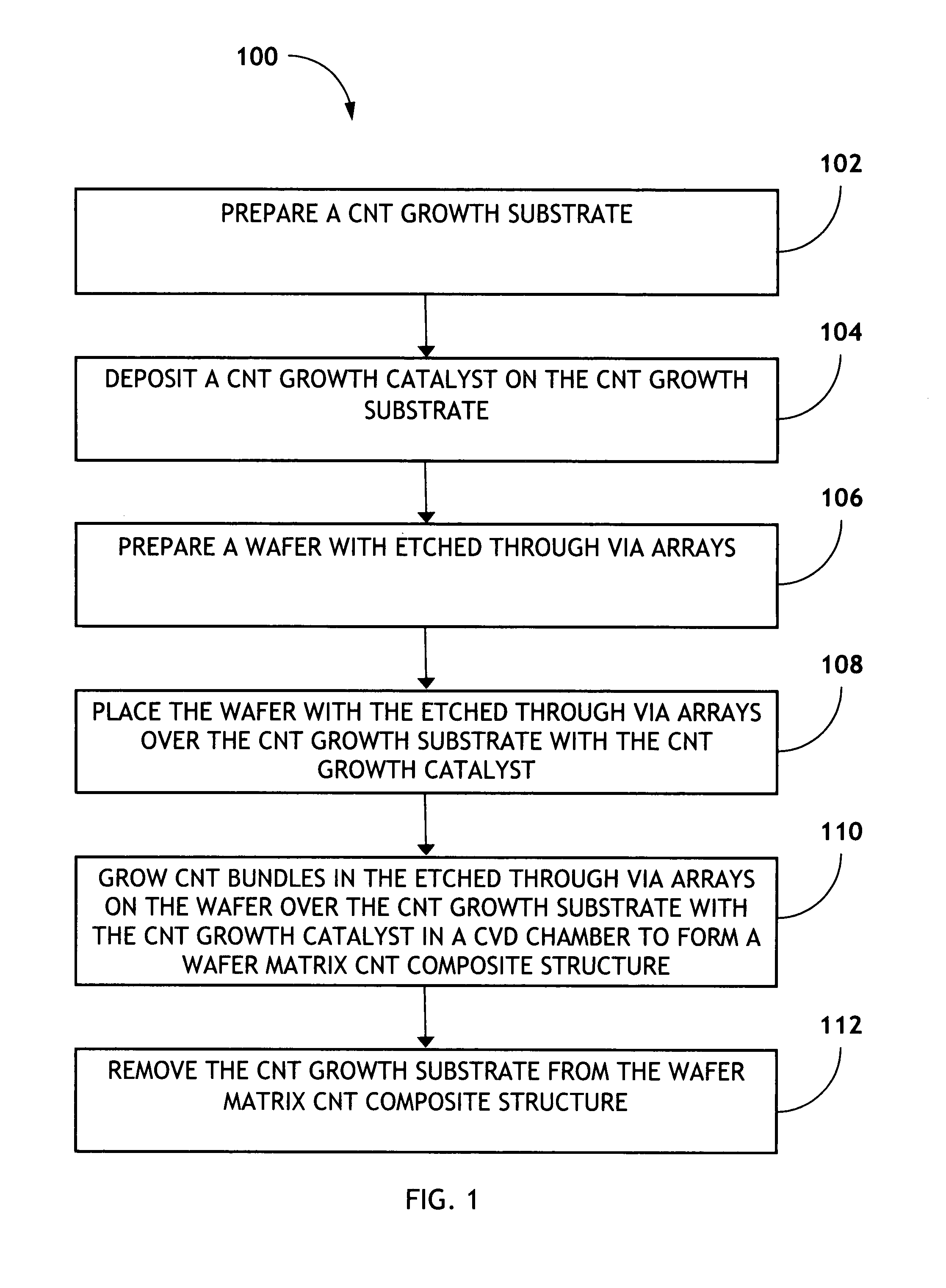

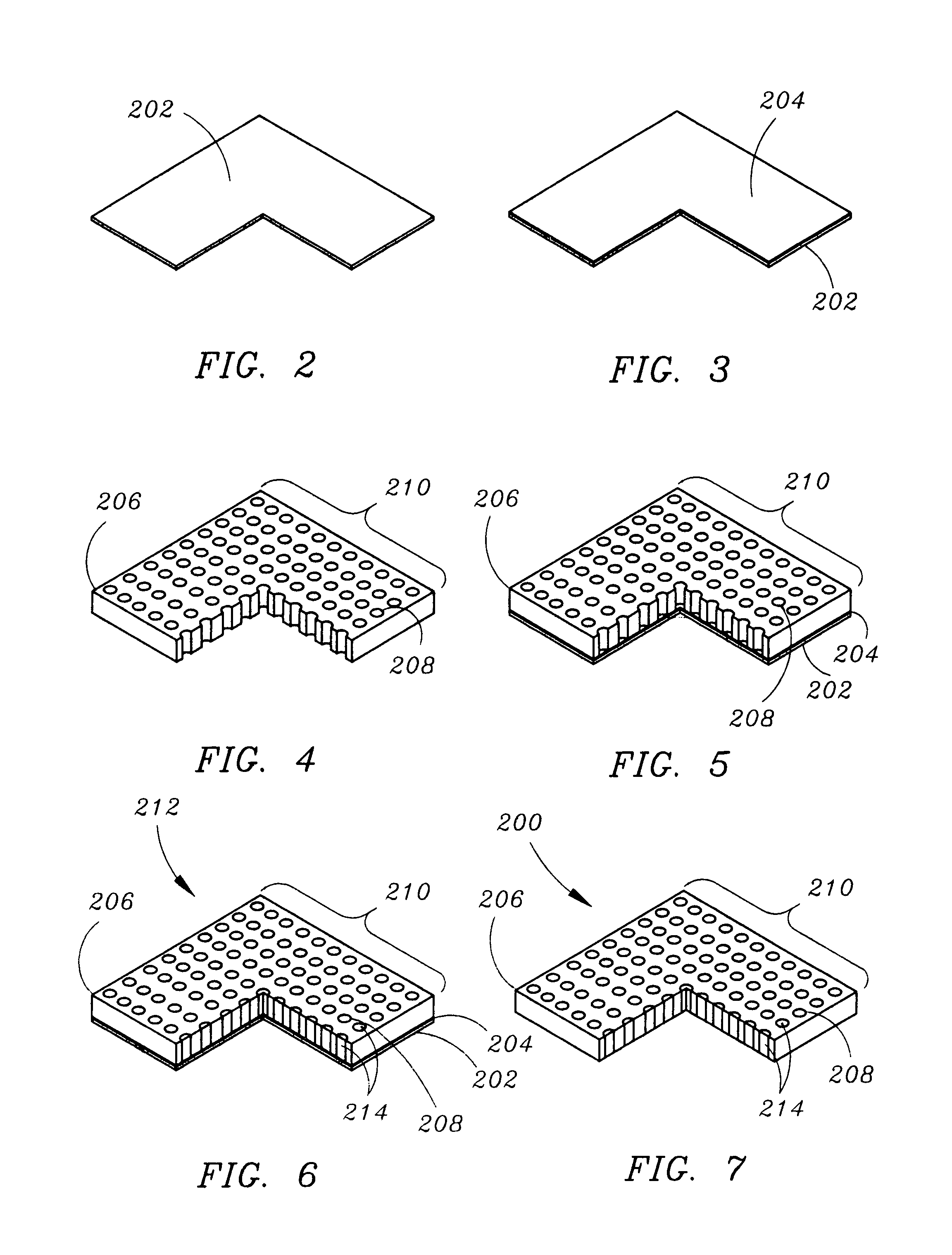

Composite plate comprising carbon nanotube bundles with high thermal conductivity and method for making the same

ActiveUS7867620B1Improve thermal conductivityEfficient thermal conductivityMaterial nanotechnologyChemical vapor deposition coatingAlloy substrateThermal conductivity

A composite plate comprising CNT bundles with high thermal conductivity is formed by the method comprising preparing a CNT growth substrate, depositing a CNT growth catalyst on the CNT growth substrate, preparing a wafer with etched through via arrays, placing the wafer with the etched through via arrays over the CNT growth substrate with the CNT growth catalyst, growing CNT bundles in the etched through via arrays on the wafer over the CNT growth substrate with the CNT growth catalyst in a CVD chamber to form a wafer matrix CNT composite structure; and removing the CNT growth substrate from the wafer matrix CNT composite structure. The formed composite plate comprising CNT bundles with high thermal conductivity has improved CTE silicon match, has a more effective thermal conductivity than a silicon matrix or Cu or Cu alloy substrate, and contains nanotubes that remain vertical.

Owner:ROCKWELL COLLINS INC +1

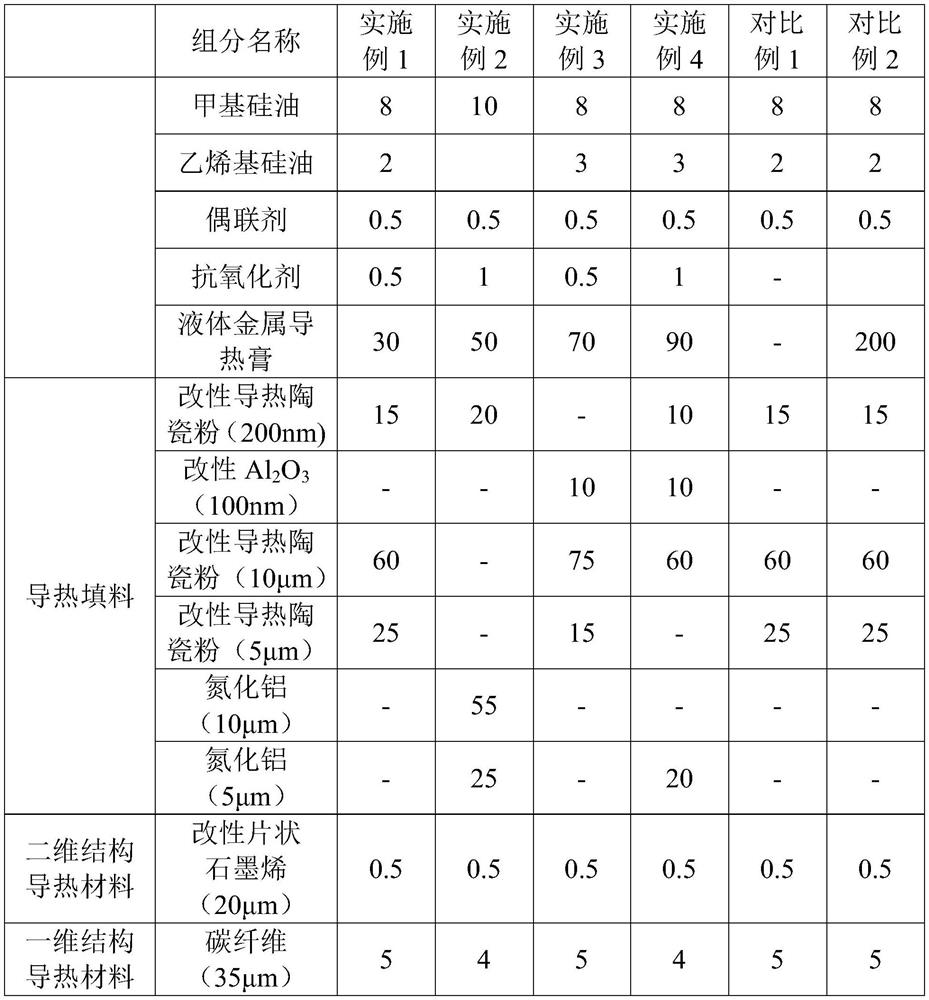

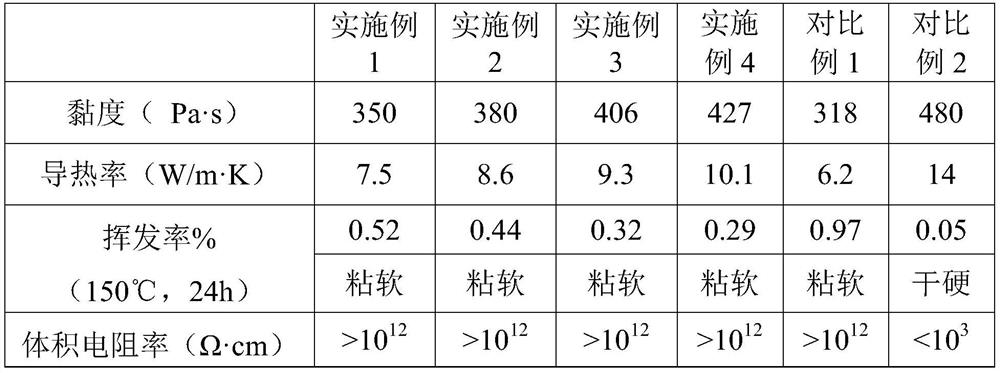

Insulated efficient heat-conducting silicone grease and preparation method thereof

InactiveCN111777995AReduce thermal contact resistanceGood thermal conductivityHeat-exchange elementsFiller particleSilane coupling

The invention discloses an insulated efficient heat-conducting silicone grease and a preparation method thereof. The heat-conducting silicone grease comprises the following components in parts by weight: 80-100 parts of a composite spherical heat-conducting filler, 0.5-5 parts of a one-dimensional structure heat-conducting material, 0.5-5 parts of a two-dimensional structure heat-conducting material, 20-100 parts of liquid metal heat-conducting paste, 4-20 parts of silicone oil, 0.25-2 parts of a silane coupling agent and 0.1-1 part of an antioxidant. Tiny gaps on the surface of a composite spherical heat-conducting filler are filled with the liquid metal heat-conducting paste; the contact thermal resistance among filler particles is effectively reduced, the good insulating property of theheat-conducting silicone grease can still be kept while the efficient heat-conducting property is obtained, and meanwhile, by adopting the efficient heat-conducting silicone grease, the problems thattraditional heat-conducting silicone grease is low in filling amount, poor in heat-conducting effect, prone to dry cracking and prone to oil seepage are effectively solved.

Owner:广东陆祥新材料科技有限公司

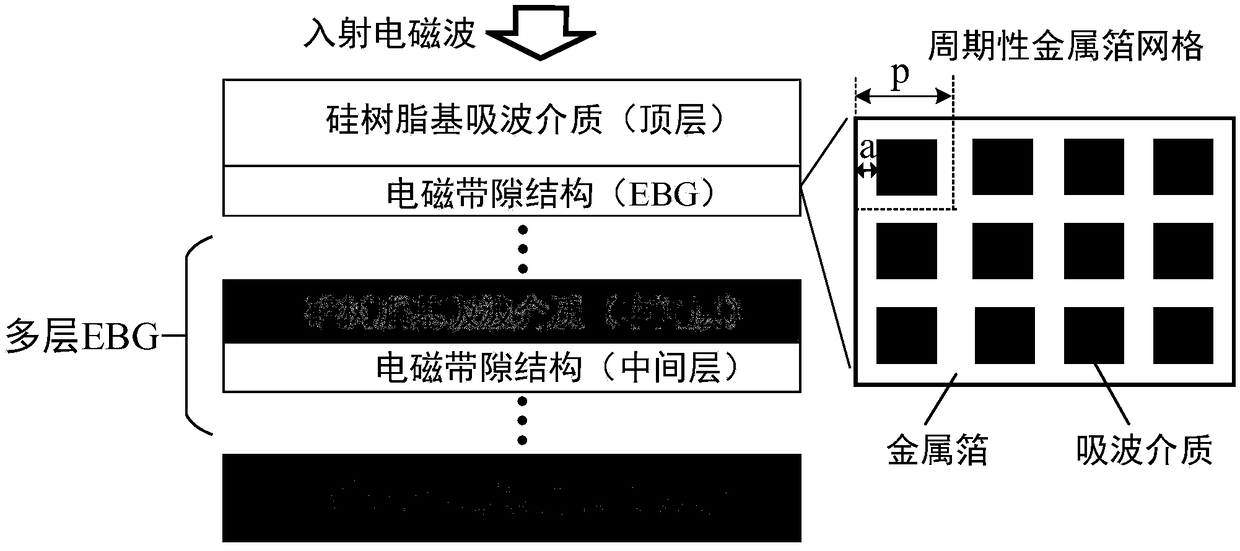

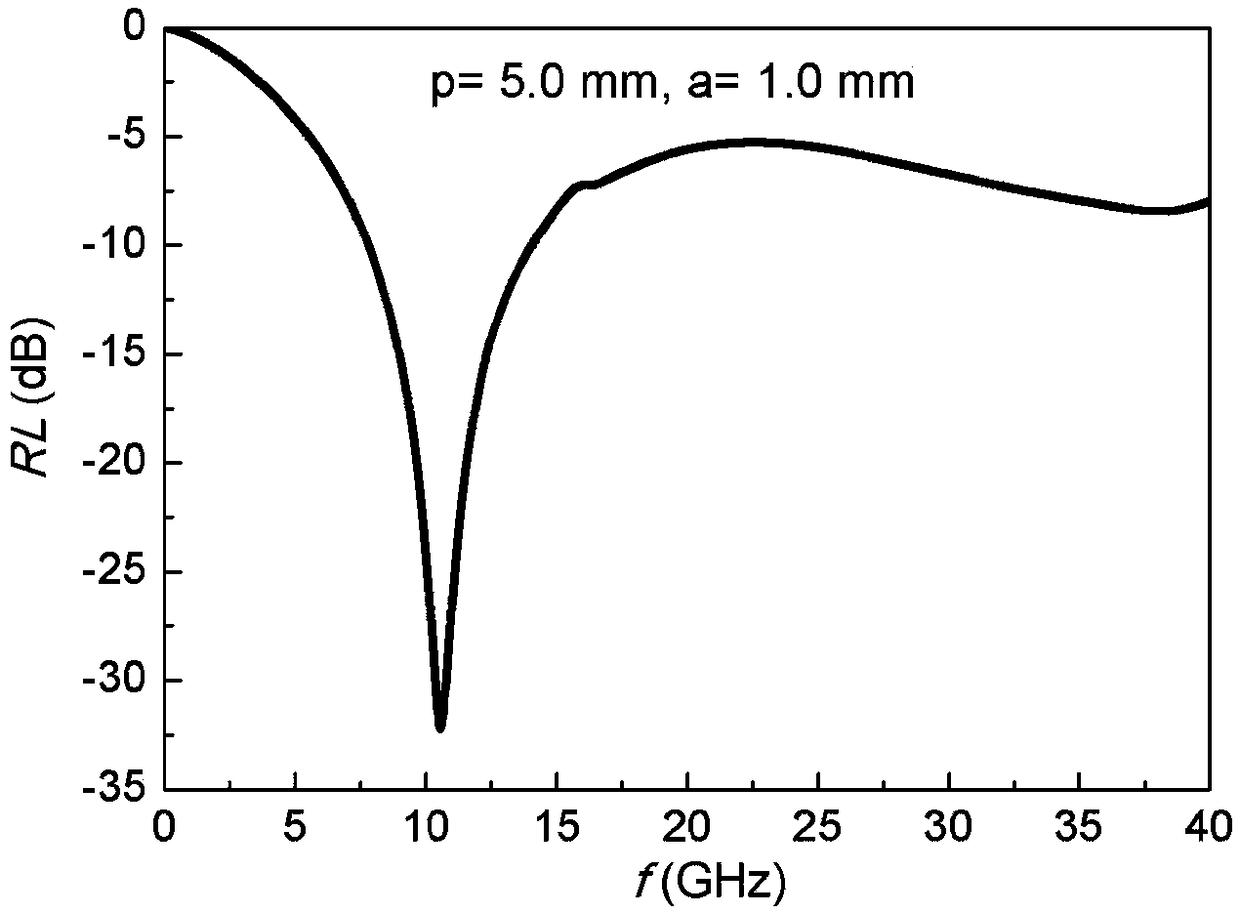

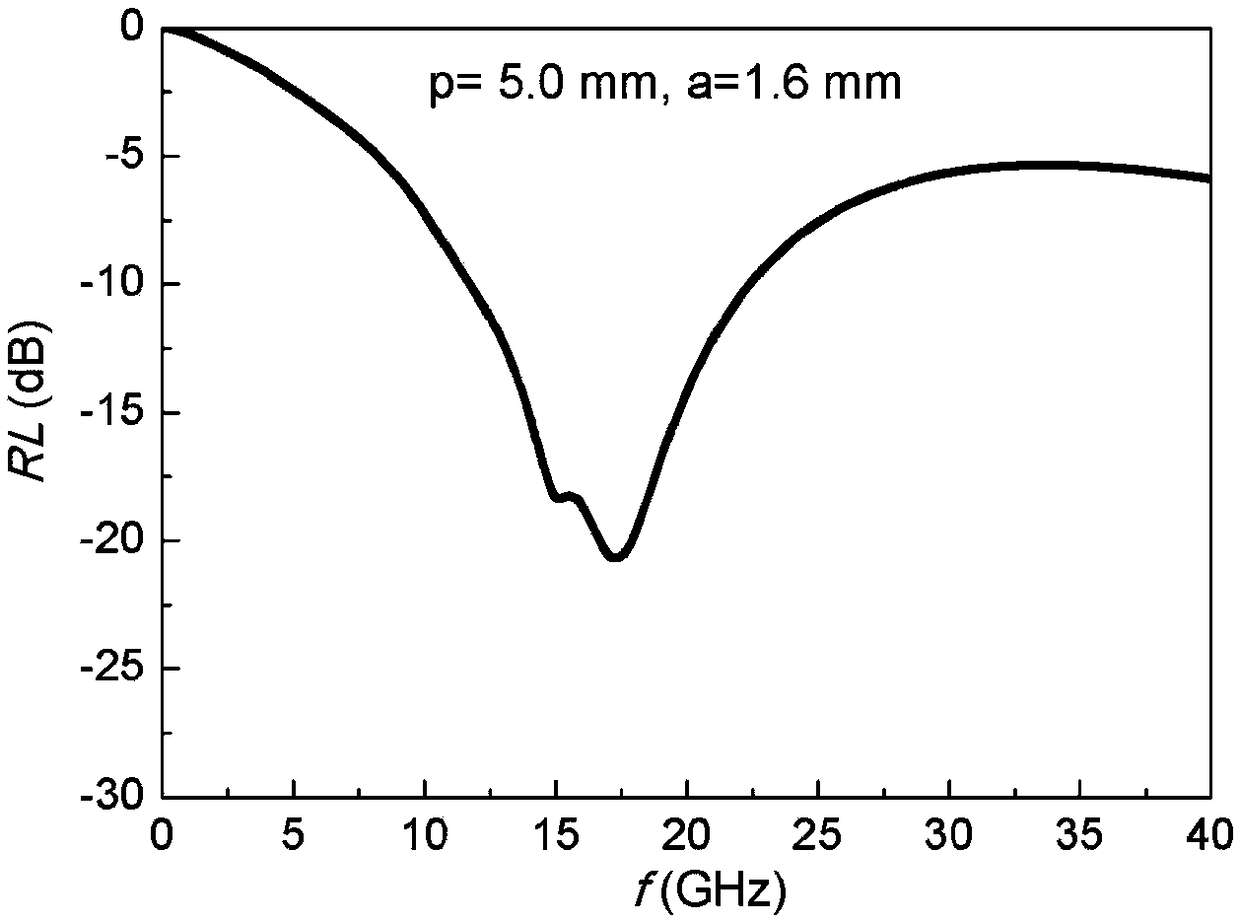

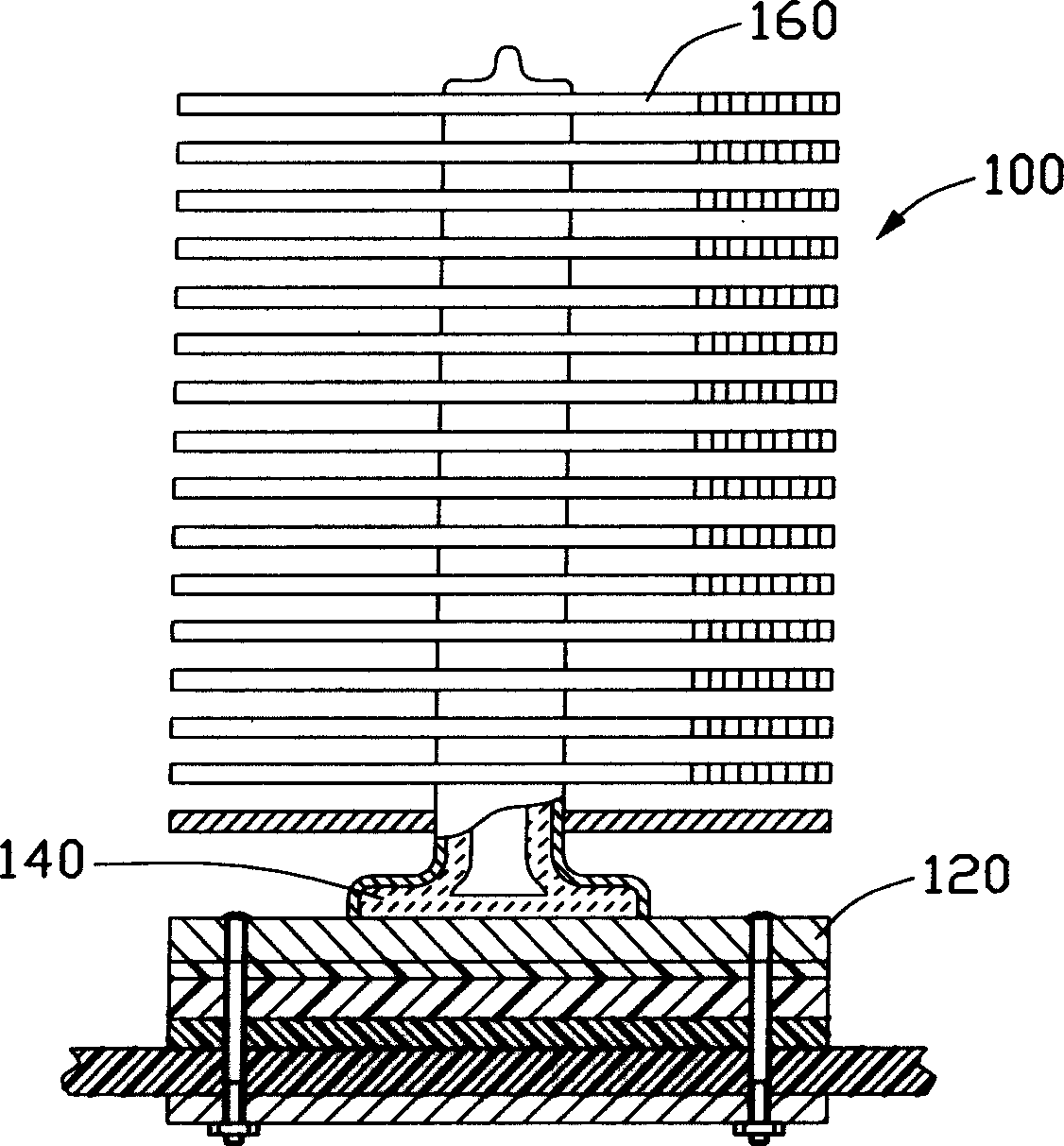

Heat-conductive electromagnetic noise suppression sheet and preparation method thereof

PendingCN108909113AEfficient thermal conductivityEfficient FeaturesSynthetic resin layered productsMetal layered productsElectromagnetic wave absorberMetal foil

The invention belongs to the technical field of electromagnetic noise absorption, and discloses a heat-conductive electromagnetic noise suppression sheet and a preparation method thereof, the heat-conductive electromagnetic noise suppression sheet comprises an organic silicon resin-based wave-absorbing medium top layer, an organic silicon resin-based wave-absorbing medium bottom layer, and an electromagnetic band gap structure layer embedded between the organic silicon resin-based wave-absorbing medium top layer and the organic silicon resin-based wave-absorbing medium bottom layer; each organic silicon resin-based wave-absorbing medium layer is an organic silicon resin and electromagnetic wave absorber composite; the electromagnetic band gap structure layer comprises a plurality of metalfoil grids and a wave-absorbing medium layer, the metal foil grids are uniformly distributed and fixed on the wave-absorbing medium layer; a heat conduction network is constructed in an organic silicon resin-based wave-absorbing medium by use of an electromagnetic band gap structure, by use of electromagnetic wave regulation characteristics, wave absorbing ability is enhanced, the thermal conductivity and the electromagnetic noise suppression capability of the heat-conductive electromagnetic noise suppression sheet can be significantly improved, and the wave-absorbing bandwidth and the centerfrequency loss intensity are significantly improved compared with the existing heat-conductive electromagnetic noise suppression sheet.

Owner:深圳市飞鸿达科技有限公司 +1

Teflon-based polyphenylene sulfide-doped heat radiation material for LED light source and preparation method thereof

The invention relates to a LED heat radiation material and especially relates to a Teflon-based polyphenylene sulfide-doped heat radiation material for a LED light source and a preparation method thereof. The Teflon-based polyphenylene sulfide-doped heat radiation material is prepared from 3-5 parts by weight of tin bronze micro-powder of 150-300 meshes, 2-3 parts by weight of nanometer nickel powder, 4-5 parts by weight of silica sol with solid content of 20-25%, 5-8 parts by weight of polyphenylene sulfide, 2-3 parts by weight of aluminum dihydrogen phosphate, 1-3 parts by weight of sodium silicate, 30-40 parts by weight of an ethanol aqueous solution with content of 5%, 20-25 parts by weight of aluminum nitride micro-powder of 400-600 meshes, 40-50 parts by weight of Teflon micro-powder of 200-300 meshes and 2-3 parts by weight of an assistant. The LED heat radiation material has the advantages of high efficiency, uniform and stable thermal conductivity, environment corrosion resistance, light aging resistance, cleanliness, stain resistance, safety, insulation and cutting easiness and is an ideal LED lamp heat radiation material.

Owner:明光泰源安防科技有限公司

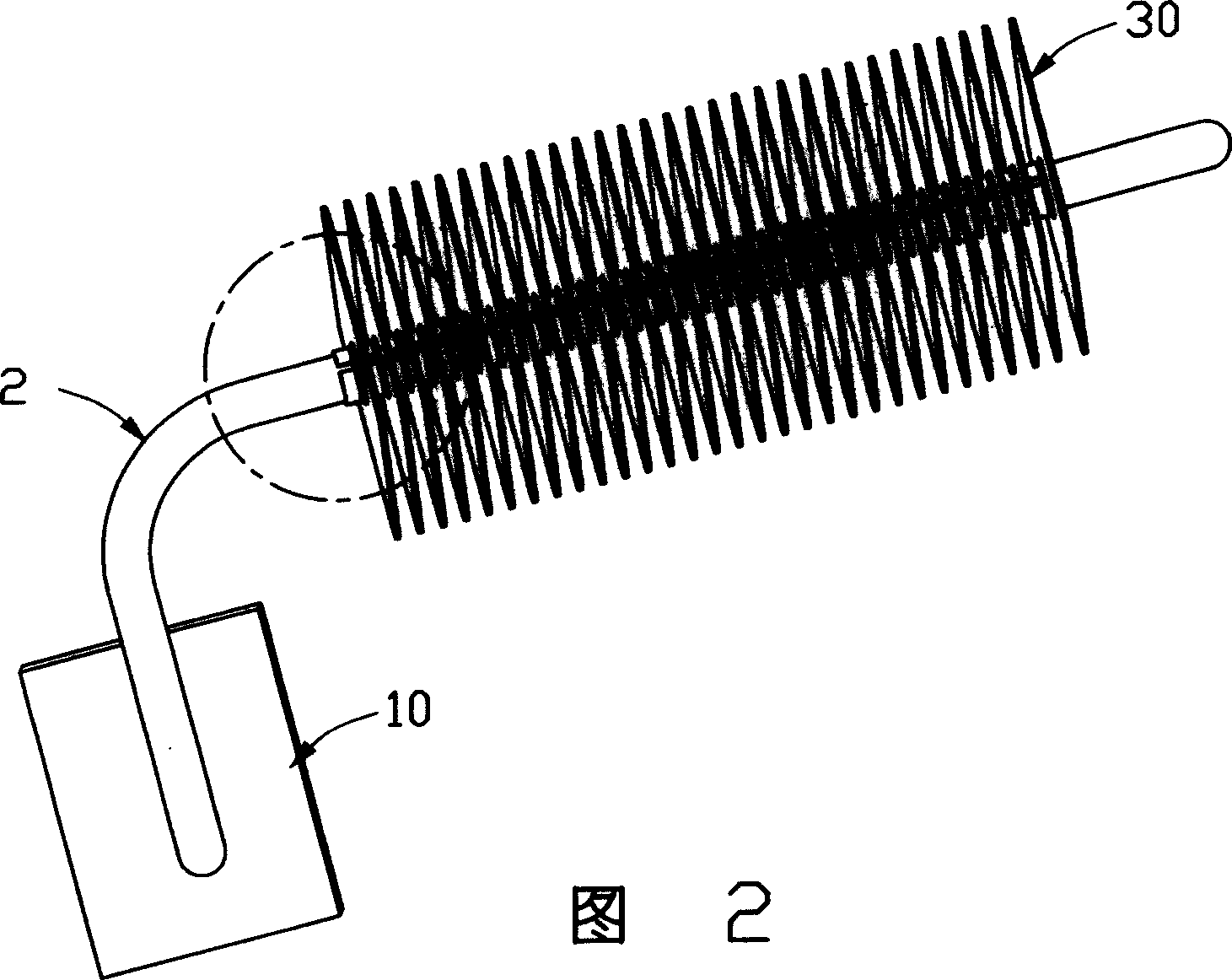

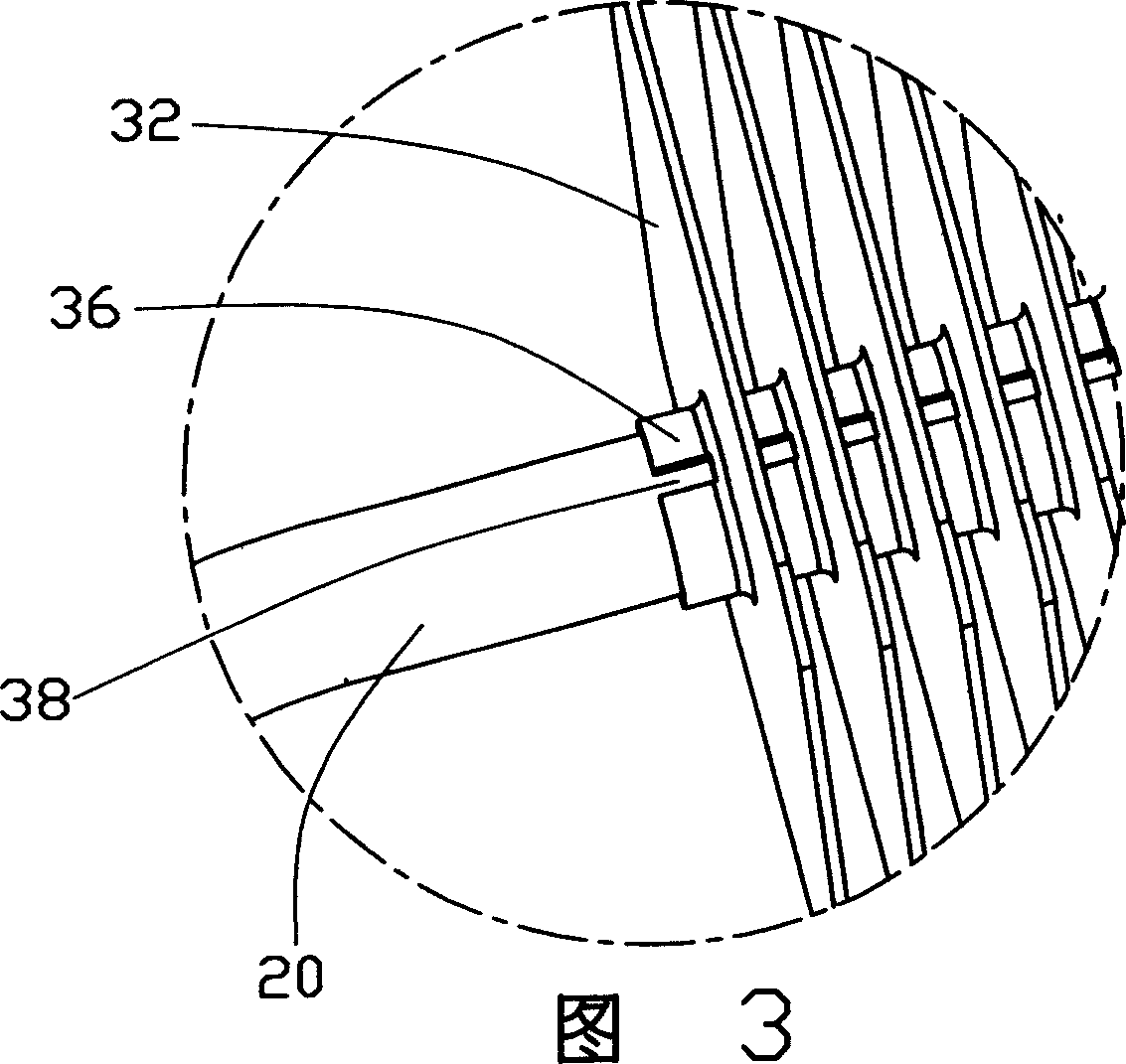

Combining method for heat pipes and radiating fins

InactiveCN1566887AEfficient thermal conductivityImprove operational efficiencyIndirect heat exchangersEngineeringHeat pipe

The invention provides a combining method for a heat pipe and a radiating fin. A threading hole is arranged on radiating fin body. At fringe of the threading hole is arranged an edgefold with a notch. The radiating fin is used to thread the heat pipe through the threading hole, and heatconducting tin paste is smeared at the notch. Then combination of the radiating fin and the heat pipe is placed in high temperature environment to be heated, and is divorced from the high temperature environment. The radiating fin and the heat pipe will be welded together after cooling.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

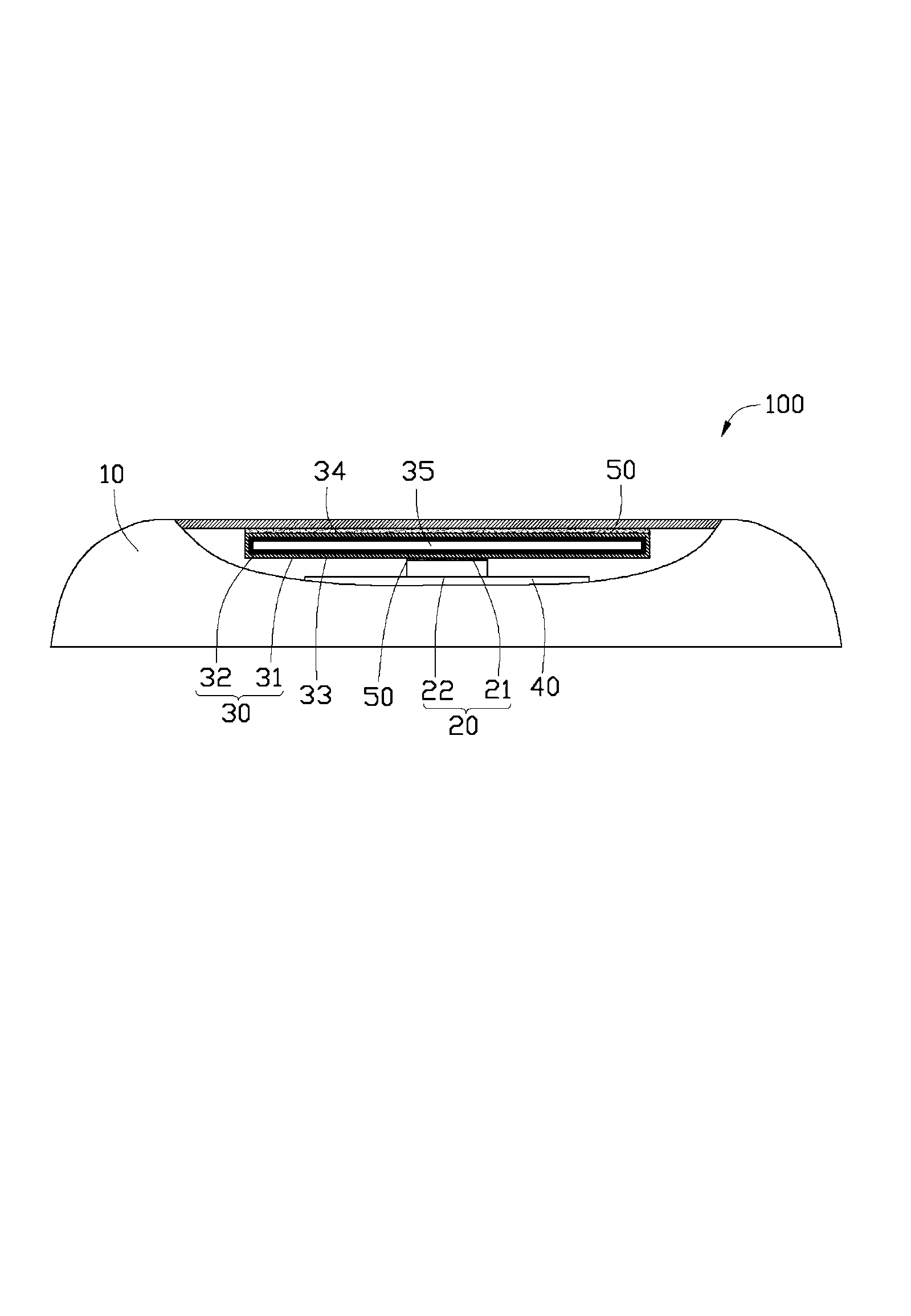

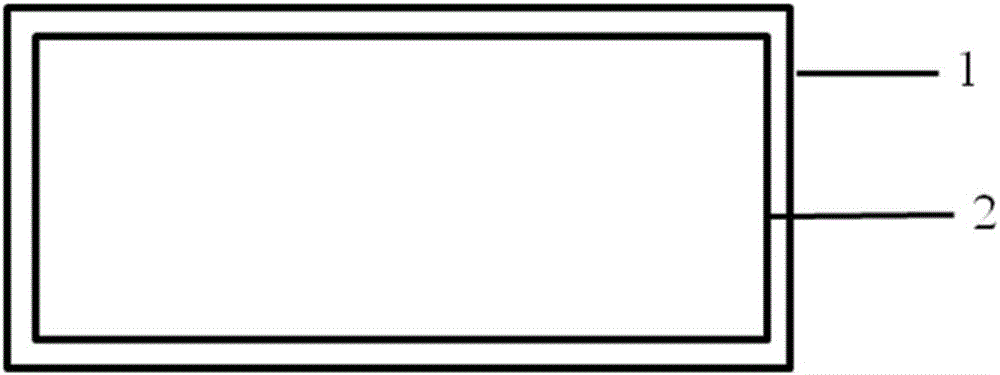

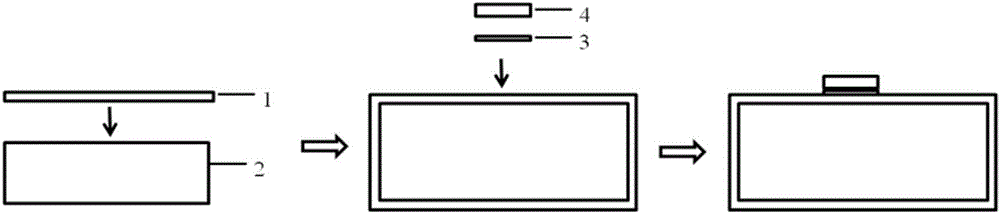

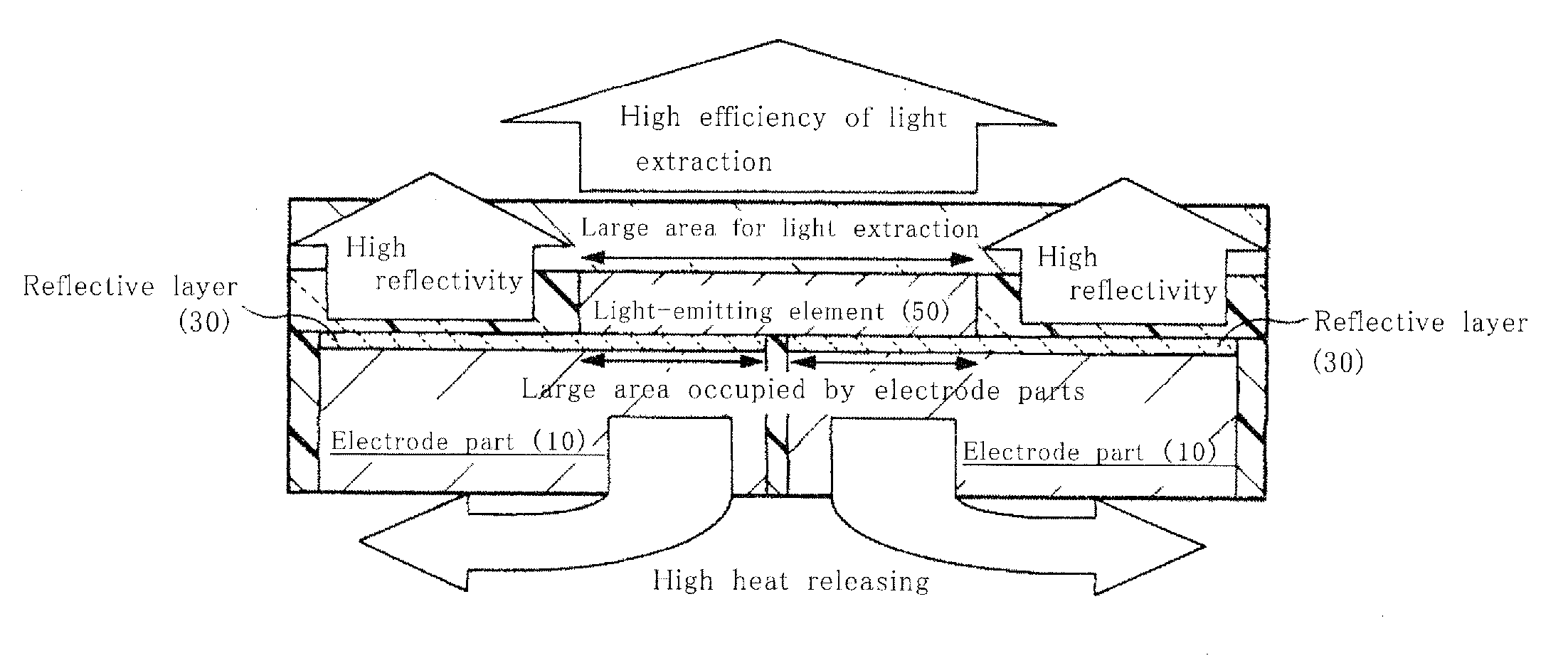

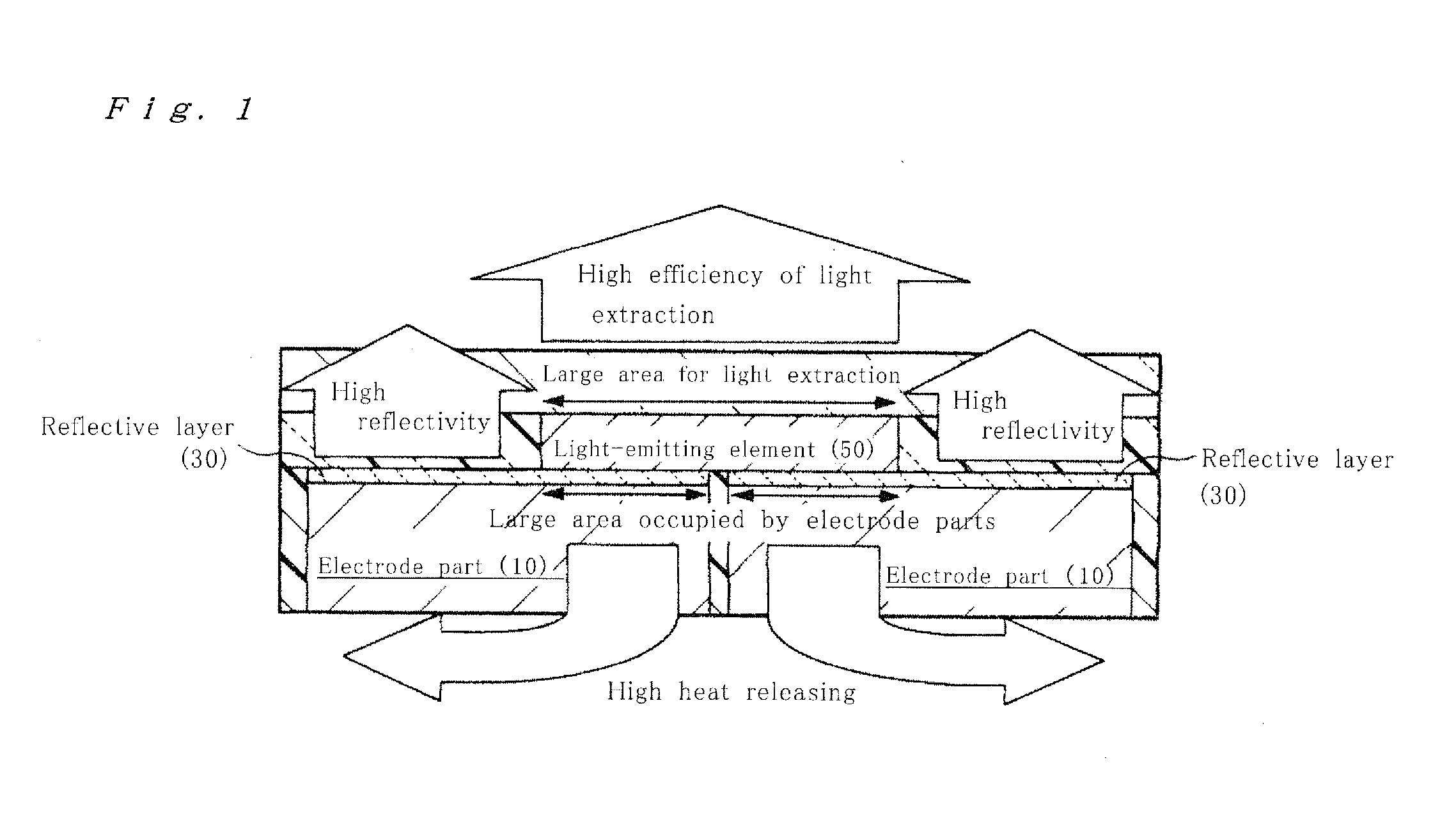

Light-emitting device and method for manufacturing the same

InactiveUS20150008467A1Wide range of fieldsImprove cooling effectSolid-state devicesSemiconductor/solid-state device manufacturingElectrical connectionEngineering

There is provided a light-emitting device comprising a light-emitting element. The light-emitting device of the present invention comprises an electrode part for the light-emitting element; a reflective layer provided on the electrode part; and the light-emitting element provided on the reflective layer such that the light-emitting element is in contact with at least a part of the reflective layer, wherein the light-emitting element and the electrode part are in an electrical connection with each other by mutual surface contact via the at least a part of the reflective layer, wherein the electrode part serves as a supporting layer for supporting the light-emitting element, and wherein the electrode part extends toward the outside of the light-emitting element and beyond the light-emitting element.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

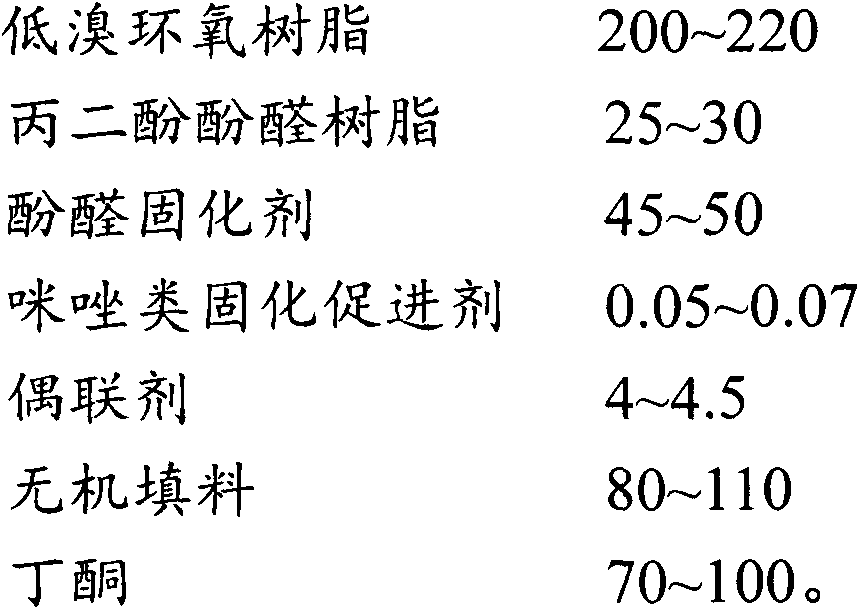

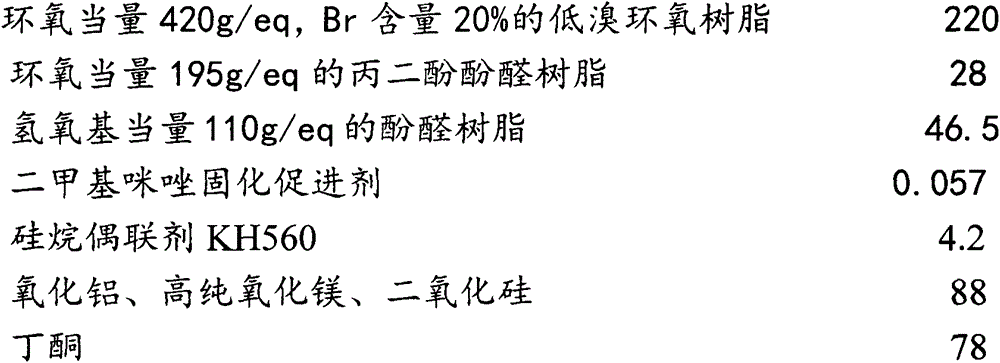

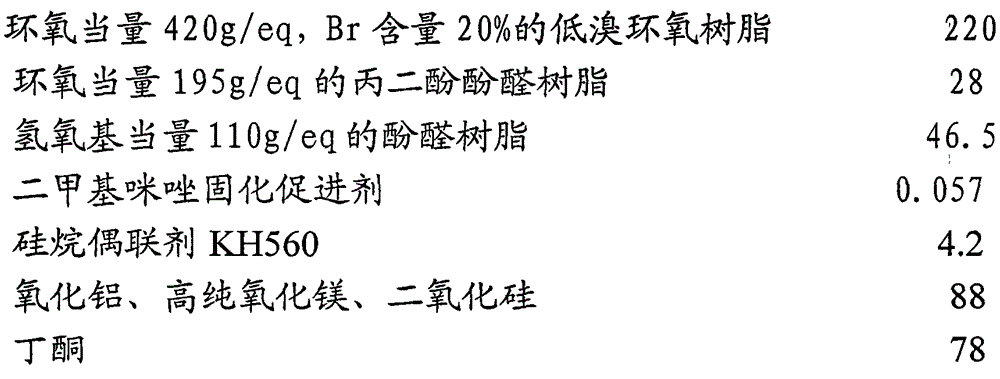

Making method for super-thick copper foil and high heat-conducting copper clad laminate

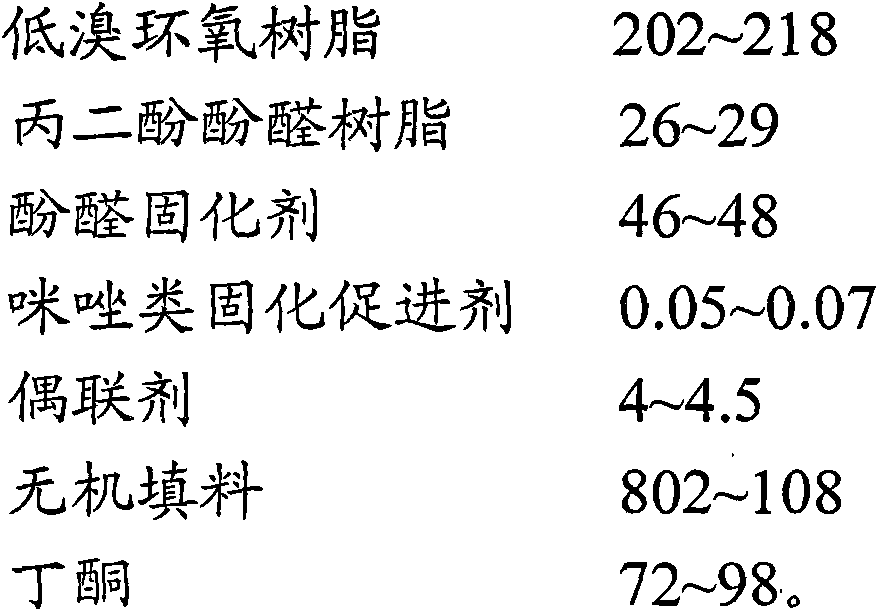

InactiveCN104002538ASolve difficult puzzlesReduce heat dissipationLamination ancillary operationsNon-macromolecular adhesive additivesEpoxyHeat conducting

The invention discloses a making method for a super-thick copper foil and high heat-conducting copper clad laminate. The method includes the steps of: glue solution preparation, gluing, superposition and hot pressing. Specifically, the glue solution comprises: low-bromine epoxy resin / phenolic curing system, a coupling agent, an imidazole curing accelerator and an inorganic filler, and a solvent butanone. By adjusting the production technological conditions, the method provided by the invention solves the difficult making problem of super-thick copper clad laminates, and is simple and convenient. The prepared super-thick copper clad laminate has good flatness, and the bonding force between the super-thick copper foil and a base material is good. At the same time, by adding a lot of excellent and efficient heat-conducting filler to the formula, the molded base plate has efficient heat-conducting property, and the thermal conductivity is greater than 1.6W / mk, thus well solving the rapid heat dissipation problem of heavy current base plates. The prepared super-thick and high heat-conducting copper clad laminate also has excellent heat resistance, with T260 being greater than 30min. Meanwhile, the invention can also meet the demands of a PCB lead-free making process.

Owner:NANTONG RODA ELECTRON

Gradient-boron-doped diamond strengthened metal matrix composite and preparation method and application thereof

ActiveCN111778506AImprove thermal conductivitySmall coefficient of thermal expansionSemiconductor/solid-state device detailsVacuum evaporation coatingLinear configurationMetal matrix composite

The invention discloses a gradient-boron-doped diamond strengthened metal matrix composite and a preparation method and application thereof. The composite includes gradient-boron-doped diamond strengthened bodies, and metal matrices, and the gradient-boron-doped diamond strengthened bodies include diamond strengthened bodies, and gradient-boron-doped diamond modified layers arranged on the surfaces of the diamond strengthened bodies. The configuration of the diamond strengthened bodies include one or more of a zero-dimensional particle configuration, a one-dimensional linear configuration, a two-dimensional piece-shaped configuration, and a three-dimensional continuous network skeleton configuration. The coupling of the gradient-boron-doped diamond strengthened bodies with different dimensions can greatly improve the mass of diamonds on the composite, and improve the heat conductivity. In addition, according to the added gradient-boron-doped diamond strengthened bodies, the gradient-boron-doped diamond modified layers account for less, so that the heat conductivity of the diamonds can not be affected, and the humidity between the diamonds and metal can be greatly improved.

Owner:CENT SOUTH UNIV

Optical transceiver with variably positioned insert

ActiveUS20050185963A1Efficient thermal conductivityThe relative position is appropriateCoupling light guidesElectromagnetic transmissionSpatial OrientationsTransceiver

An optical transceiver includes a transceiver housing configured to receive an optical sub-assembly insert. The optical sub-assembly insert includes duplex cavities configured to hold a transmit optical sub-assembly front end and a receive optical sub-assembly front end in a fixed spatial orientation for a given optical connector interface. The optical sub-assembly insert is configurable to fit inside a transceiver housing with a relatively wide range of X and Y dimensional tolerance. In one implementation, the X-Y position of the optical sub-assembly insert is dictated by the position of the transmit optical-sub assembly front end after its corresponding back end has been mounted to a heat dissipation element. Any gaps that form between the optical sub-assembly insert and the inside surface of the transceiver housing as a result of the transmit optical sub-assembly position can be accommodated with filler material.

Owner:II VI DELAWARE INC

High-impact-toughness foamed aluminum based on A356 aluminum alloy and production process of high-impact-toughness foamed aluminum

The invention relates to a foamed aluminum material, in particular to high-impact-toughness foamed aluminum based on A356 aluminum alloy and a production process of the high-impact-toughness foamed aluminum. The production process comprises the steps that (1) 12-20 parts, by weight, of a foaming agent is ground and screened through a sieve with 100-180 meshes; (2) 100 parts, by weight, of A356 aluminum alloy ingots are crushed, ground into particles and then evenly mixed with 8-15 parts, by weight, of inorganic nano-whiskers and 10-12 parts, by weight, carbon nano-tubes, then a mixture is placed into a smelting furnace and completely molten in an inert gas atmosphere, afterwards, the foaming agent is sucked in to the smelting furnace under negative pressure, and a molten aluminum mixture is obtained after uniform mixing; (3) the molten aluminum mixture obtained in the step (2) is poured into a mold, the mold is then pushed into a foaming furnace, and heat preservation is conducted for1-2h at the temperature of 680-700 DEG C; and (4) the mold enters a cooling system to be cooled, and thus the foamed aluminum is obtained. According to the high-impact-toughness foamed aluminum basedon the A356 aluminum alloy and the production process of the high-impact-toughness foamed aluminum, the mixture of the inorganic nano-whiskers and the carbon nano-tubes is added in the forming processof the foamed aluminum, and thus the impact toughness of the aluminum is remarkably improved.

Owner:JIESHOU JINGHUA TECH INFORMATION CONSULTING SERVICE CO LTD +1

A kind of cobalt-based Fischer-Tropsch synthesis catalyst and preparation method thereof

ActiveCN102861583BImprove wear resistanceNot brokenCatalyst carriersHydrocarbon from carbon oxidesFiberActive component

The invention discloses a cobalt-based Fischer-Tropasch synthetic catalyst and a preparation method, the cobalt-based Fischer-Tropasch synthetic catalyst comprises the following components by weight: 1-15% of carbon nanofiber,, 5-35% of active component cobalt, 0.5-6% of metal auxiliary agent X1, 0.1-3% of metal auxiliary agent X2 and the balance of silica. The metal auxiliary agent X1 is one or more of Re, Zr, Hf, Ce, Th and the like, the metal auxiliary agent X2 is one or more of Ni, Mo and W. The preparation method of the cobalt-based Fischer-Tropasch synthetic catalyst comprises the following steps: in-situ loading the carbon nanofiber on a silica gel carrier, then an immersion method is employed for loading the metal auxiliary agent X1, the metal auxiliary agent X2 and the active component Co. The cobalt-based Fischer-Tropasch synthetic catalyst has the advantages of good wear resistance, strong collision resistance capability, low cost and high activicity stability, and is adapted to the slurry bed or boiling bed ft synthesis reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

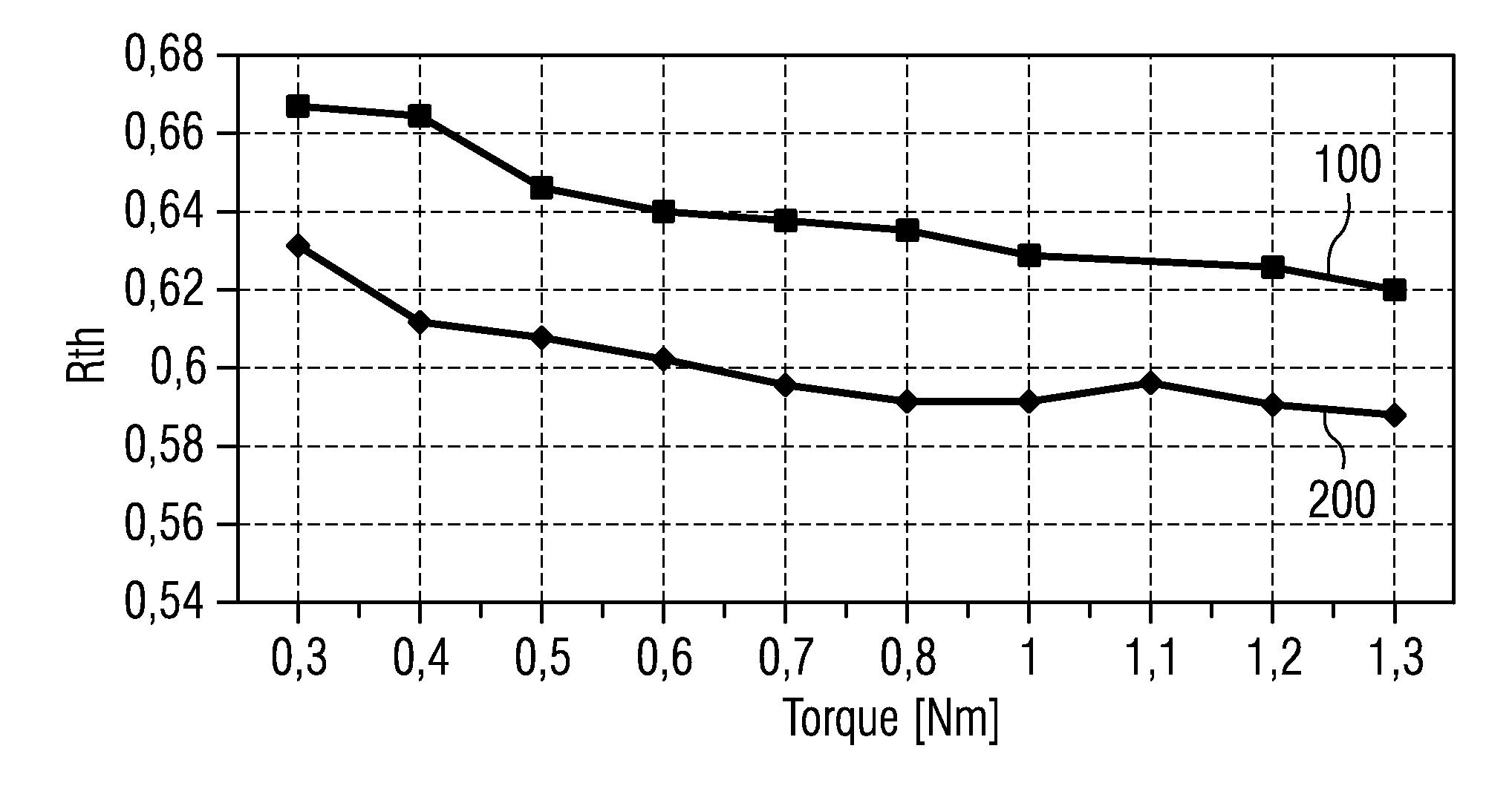

Semiconductor Housing with Rear-Side Structuring

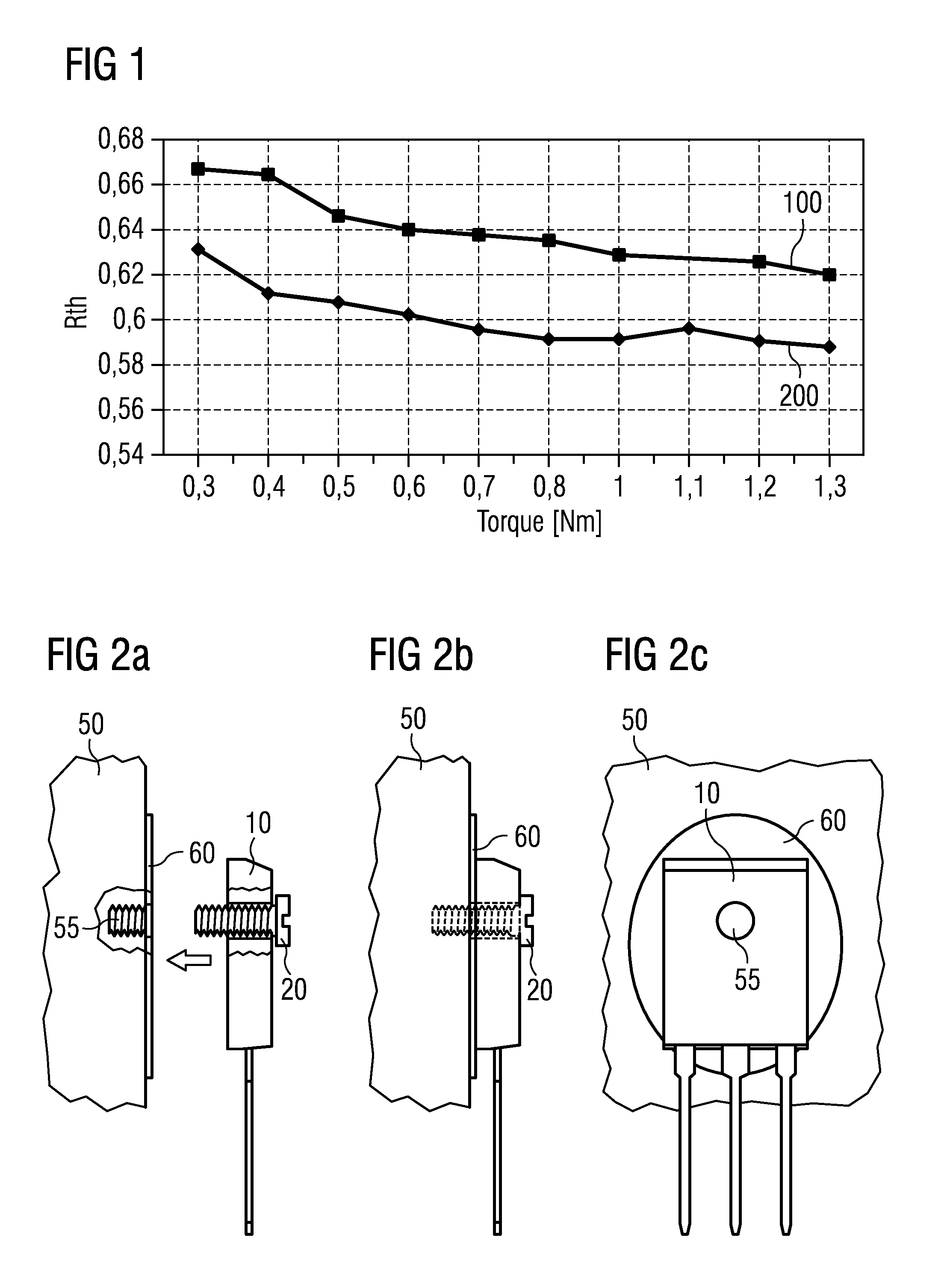

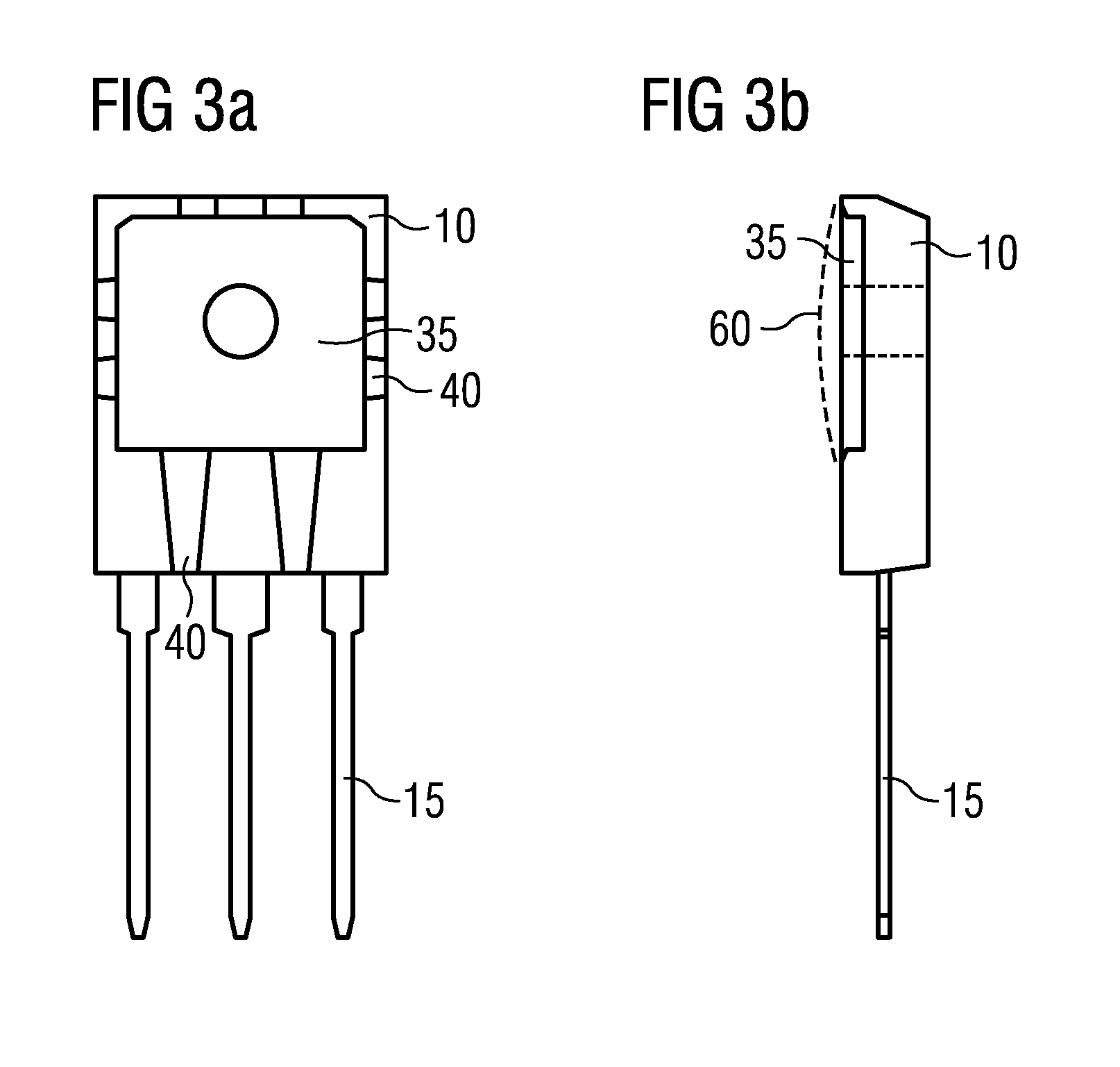

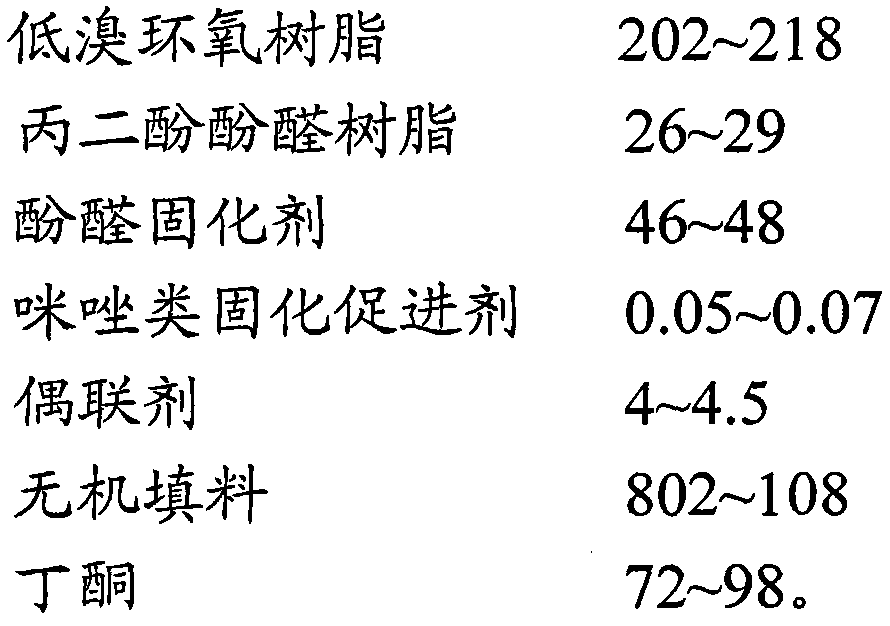

ActiveUS20140084449A1Efficient thermal conductivityEffective regulationSemiconductor/solid-state device detailsSolid-state devicesConductive pasteEngineering

A semiconductor housing includes a fixing mechanism and at least one side having structurings. A method for producing a semiconductor device is provided in which a thermally conductive paste is applied on the at least one side of the semiconductor housing and / or of a heat sink. The semiconductor housing is fixed to the heat sink by means of the fixing mechanism. A pressure is exerted on the thermally conductive paste by means of the fixing mechanism and the thermally conductive paste is diverted by means of diversion channels depending on the pressure exerted.

Owner:INFINEON TECH AG

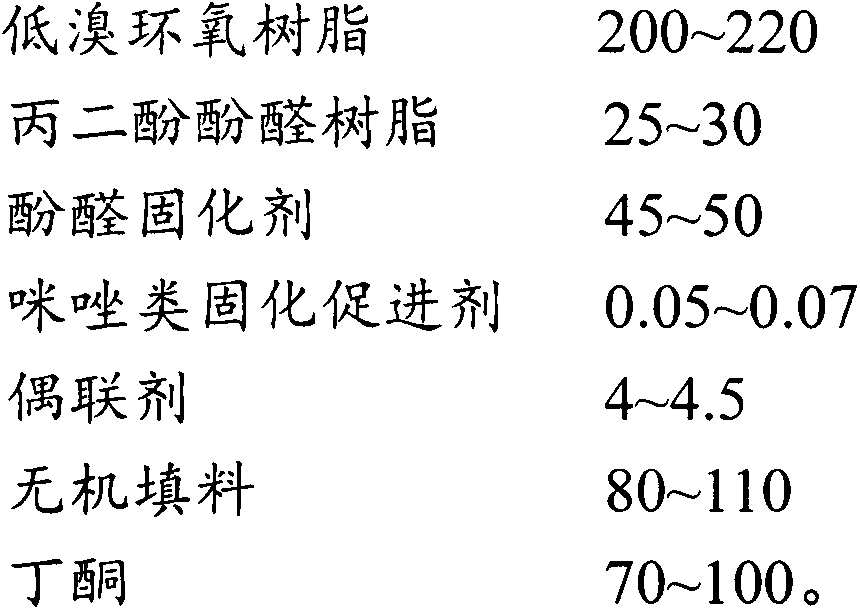

Manufacturing method for thick copper foil copper-clad plate

InactiveCN104943298ASolve difficult puzzlesReduce heat dissipationSynthetic resin layered productsLaminationEpoxyPower flow

The invention discloses a manufacturing method for a thick copper foil copper-clad plate. The manufacturing method comprises the following steps: preparing a glue solution, gluing, overlapping and hot-pressing, wherein the glue solution comprises a low brominated epoxy resin / phenolic-cured system, a coupling agent, an imidazole curing catalyst and a nonorganic filler, and butanone is used as a solvent for preparation. Through the adjustment of the conditions of the production process, the problem that a super-thick copper-clad plate is difficult to manufacture is solved, the method is simple and quick, the manufactured super-thick copper-clad plate is better in smoothness, and the bonding force between super-thick copper foil and a substrate is better; besides, a large amount of excellent and efficient heat conducting fillers is added in the formula, so that the formed substrate has efficient heat conduction performance, the heat conduction rate of the formed substrate is larger than 1.6 W / mk, and a large current substrate can dissipate heat well; the manufactured super-thick and high-heat conductivity copper-clad plate has excellent heat resistance, T260 is longer than 30 min, and in addition, the requirement on the PCB lead-free process can also be met.

Owner:吴俊娟

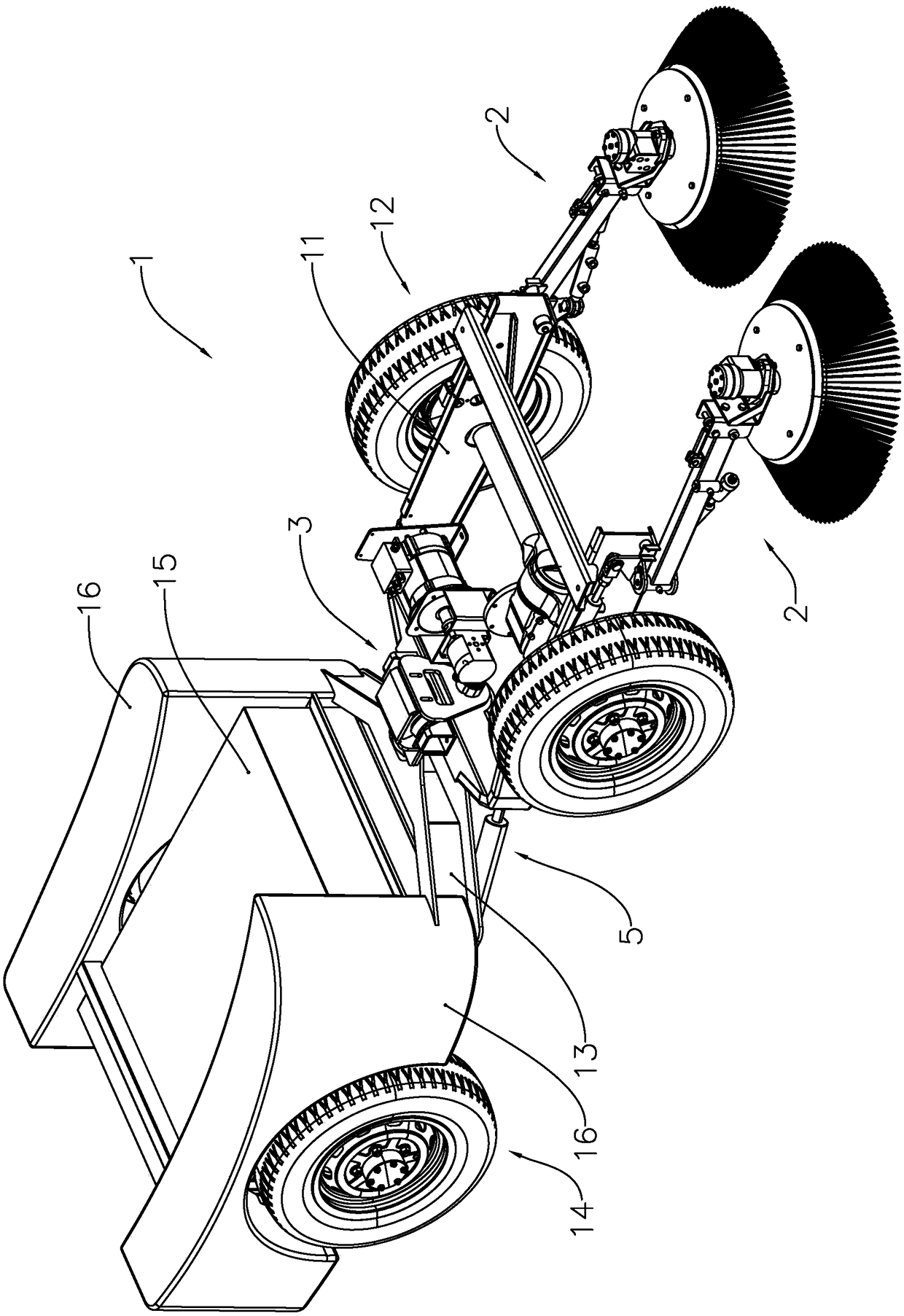

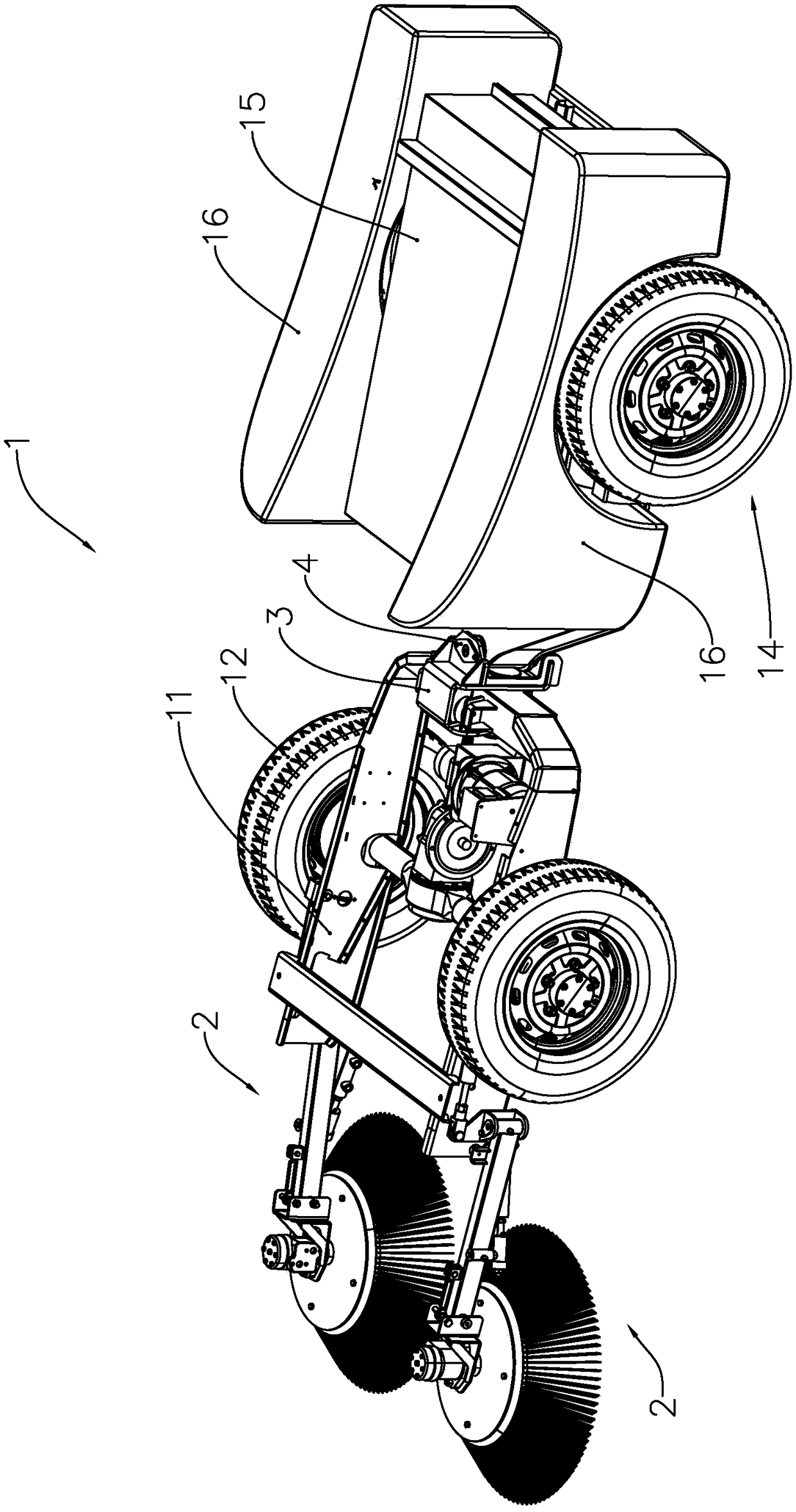

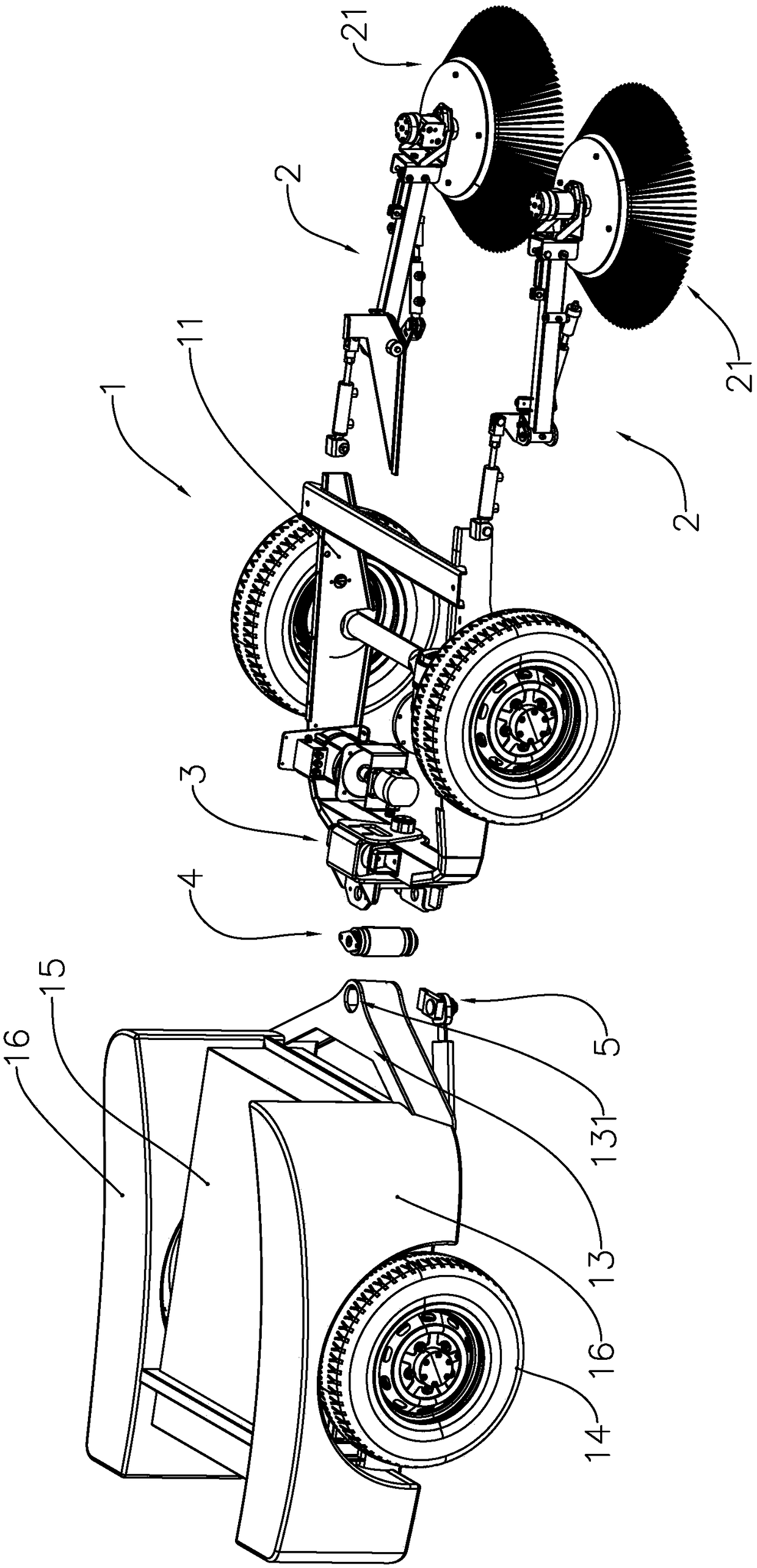

Bearing with graphite copper sleeve, articulated frame and sweeper

PendingCN109027005AReduce frictionGood thermal conductivityRoad cleaningBearing unit rigid supportCopperGraphite

The invention provides a bearing with a graphite copper sleeve, an articulated frame and a sweeper. The bearing comprises a shaft sleeve, a connecting shaft, the graphite copper sleeve, a first planebearing, a first end cover, a second plane bearing and a second end cover, wherein the shaft sleeve is provided with a through hole along the axial direction in a penetrating way; the connecting shaftpenetrates through the through hole; the graphite copper sleeve is arranged in the through hole and sleeves outside the connecting shaft; the first plane bearing sleeves outside the connecting shaftand is arranged at the first axial end of the shaft sleeve; the connecting shaft penetrates through the first end cover; and the first end cover covers the outside of the first plane bearing and is fixed onto the first axial end of the shaft sleeve. The graphite copper sleeve is connected between the connecting shaft and the shaft sleeve, and a self-lubricating function of the graphite copper sleeve is utilized, so that the friction of the connecting shaft is effectively reduced; and meanwhile, the graphite copper sleeve has a high-efficiency heat-conducting performance, and the plane bearingsand the end covers are arranged at two axial end parts, so that the bearing is simple in structure.

Owner:ZHUHAI YIHUA ELECTRIC VEHICLE

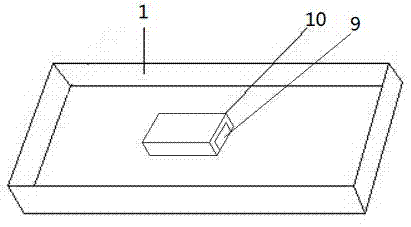

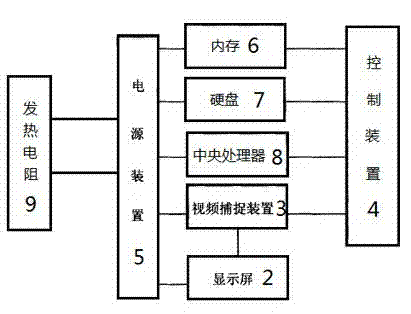

Cold-proof type tablet personal computer

InactiveCN103092274AIncrease temperatureEfficient thermal conductivityDigital data processing detailsHuman bodyElectrical resistance and conductance

The invention provides a cold-proof type tablet personal computer which comprises a housing case and a display screen, the display screen is installed on the front portion of the housing case, a video capturing device, a control device, a power supply device, an internal memory, a hard disk and a central processing unit are arranged in the housing case, all the elements are electrically connected with the power supply device, and a heating resistor is further arranged on the inner surface of the housing case and is electrically connected with the power supply device. Due to the fact that the heating resistor is further arranged on the inner surface of the housing case and evenly transmits heat to a human body, a user is capable of operating the computer comfortably in the cold environment. The cold-proof type tablet personal computer is not only simple in design, but also strong in practicability.

Owner:JIANGSU XUFENG SOFTWARE TECH

Tough and high-elastic composite silicon-carbide-based ceramic circuit board base board material and preparation method thereof

InactiveCN105367108AEfficient thermal conductivityImprove wettabilityComposite ceramicPolyethylene glycol

The invention discloses a tough and high-elastic composite silicon-carbide-based ceramic circuit board base board material. According to a silicon-carbide-based ceramic base board, micron-grade silicon carbide powder and nano-scale aluminum nitride powder are used in a composited mode, so that the base material can have more efficient thermal conductivity, polyethylene glycol composite solvent containing yttrium sol and nanometer ceramic powder transparent liquid is great in wettability and bonding capability for powder, all materials can be evenly dispersed and cladded, the effects of effective melting enhancement and strength improvement are achieved, the composite ceramic base board high in compactness, elasticity and strength can be obtained at the lower sintering temperature, and the material is good in electric insulating property, high in heat conduction and dissipation efficiency, safe and environment-friendly in production process and great in utilization potentiality.

Owner:HEFEI LONG DUO ELECTRONICS SCI & TECH

Efficient water-cooling heat dissipation liquid for computers

InactiveCN107794007AGood thermal conductivityHeat dissipation fastHeat-exchange elementsChemistryPotassium permanganate

The invention discloses efficient water-cooling heat dissipation liquid for computers. The efficient water-cooling heat dissipation liquid is prepared from distilled water, benzotriazole, ethyl alcohol, potassium borate, triethanolamine, potassium phosphate, potassium permanganate, potassium carbonate, polymethylacrylic acid, trisodium phosphate, calcium chloride, potassium hydroxide and propyleneglycol. Compared with the prior art, the efficient water-cooling heat dissipation liquid prepared according to the formulation and the method has advantages of high efficiency in heat conduction, quickness in heat absorption and heat dissipation in radiators, improvement of water-cooling heat dissipation performances of the computers and high popularization and application values.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

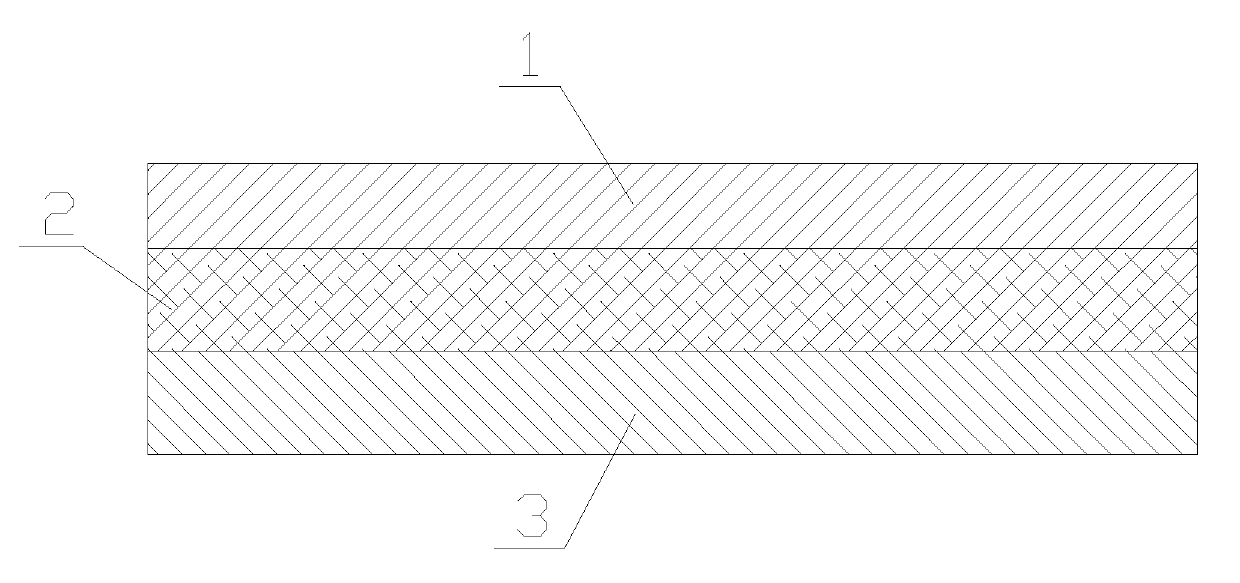

High thermal conductivity flexible printed circuit board

InactiveCN103687286AEfficient thermal conductivityImprove cooling effectCircuit susbtrate materialsWhole bodyCopper foil

The invention discloses a high thermal conductivity flexible printed circuit board which comprises a copper foil layer, an adherence layer and a bearing layer. The copper layer and the bearing layer are bonded together to form a whole body through the adherence layer. The adherence layer is thermal conductivity insulation rubber. The bearing layer is a copper foil substrate or an aluminum foil substrate. According to the circuit board, the highly efficient thermal conductivity performance can be provided, the heat radiation of electronic components on the circuit board is facilitated, especially the electric energy utilization rate is raised for a power element, the damage of the electronic components or the printed circuit board caused by poor heat radiation is avoided, and the service life of an electric product is raised.

Owner:SHANGHAI WLCP ELECTRICAL & TECH

Efficient heat dissipation device of automatic power cabinet

InactiveCN108879423AIncrease contact areaEfficient thermal conductivityTemperatue controlSubstation/switching arrangement cooling/ventilationTransverse planeEngineering

Owner:太仓市友达电气技术有限公司

Polyimide double-sided flexible heat-conducting copper-clad plate as well as preparation method and application thereof

ActiveCN112373148AImprove thermal conductivityEfficient out-of-planeLaminationLamination apparatusAdhesive cementImide

The invention discloses a polyimide double-sided flexible heat-conducting copper-clad plate as well as a preparation method and an application thereof. The preparation method comprises the following steps: coating sodium cholate modified hexagonal boron nitride nanosheets and a thermoplastic polyimide adhesive on the surfaces of copper foils in a patterning manner, filling and coating a polyimideacid solution containing dihydromyricetin modified hexagonal boron nitride micron sheets to obtain single-sided polyimide copper foils, superposing the two single-sided polyimide copper foils to obtain the copper-clad laminate, and carrying out hot pressing and thermal imidization to obtain the polyimide double-sided flexible heat-conducting copper-clad plate. The polyimide double-sided flexible heat-conducting copper-clad plate prepared by the method has efficient out-of-plane and in-plane heat-conducting passages, and is good in peel strength and heat resistance.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com