Heat-conductive electromagnetic noise suppression sheet and preparation method thereof

A technology of electromagnetic noise and suppression sheet, which is applied in the field of electromagnetic noise suppression sheet with high thermal conductivity and strong wave absorption and its preparation, can solve the problems that it is difficult to meet the compatible design requirements of material heat dissipation performance, achieve a large degree of control freedom and performance improvement space, The effect of high-efficiency heat dissipation and high-efficiency absorbing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

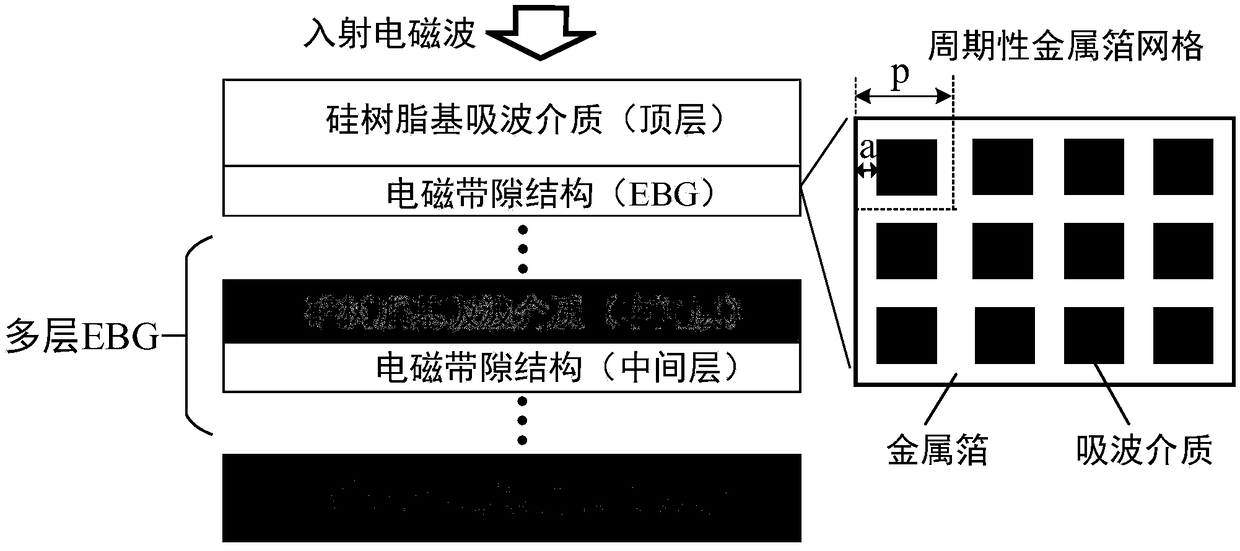

Embodiment 1

[0035] The thermally conductive electromagnetic noise suppression sheet provided in Example 1 has a three-layer structure, including a top layer of a absorbing medium, an electromagnetic band gap structure and a bottom layer of the absorbing medium. Both the top layer of the absorbing medium layer and the bottom layer of the absorbing medium are composed of a carbonyl iron powder absorbent and a silicone resin substrate. The thickness of the top layer of the absorbing medium is h1=1.9mm; the mass fraction of the carbonyl iron powder absorbent is 70%, and that of silicone resin is 30%; the thickness of the bottom layer of the absorbing medium is h2=0.1mm, and the mass fraction of the carbonyl iron powder absorbent is occupied by The mass fraction is 90%, and the organic silicon resin accounts for 10%. The total thickness h (h=h1+h2) of the top layer of the absorbing medium and the bottom layer of the absorbing medium is 2.0 mm. The mass fractions of the absorbent in the top and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com