High thermal conductivity flexible printed circuit board

A flexible printing and circuit board technology, applied in the direction of circuit substrate materials, printed circuit components, etc., can solve the problems of reducing the power utilization rate of power components and affecting the service life of electronic products, so as to improve service life, avoid poor heat dissipation, The effect of improving the utilization rate of electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

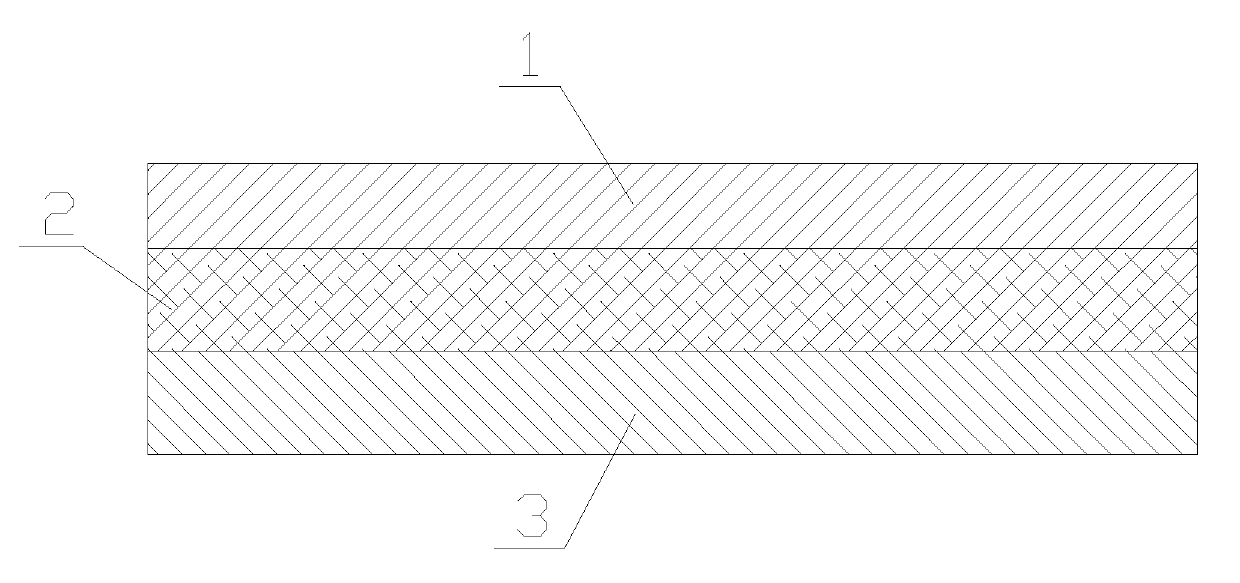

[0008] Such as figure 1 As shown, the high thermal conductivity flexible printed circuit board of the present invention includes a copper foil layer and a bonding layer, and also includes a bearing layer. The copper foil layer and the bearing layer are stacked and arranged through the copper foil layer and the bearing layer. The adhesive layer is bonded together, the adhesive layer is thermally conductive and insulating glue, and the carrying layer is a copper foil substrate or an aluminum foil substrate.

[0009] The structure of this circuit board is simple and easy to manufacture. Compared with traditional flexible printed circuit boards, the insulating layer of this circuit board is made of heat-conducting insulating glue. Embrittlement or cracking, removing polyimide (PI) or polyester plastic (PET) substrates in traditional flexible printed circuit boards, and using thermally conductive insulating adhesives instead of epoxy resins or polyester thermosetting adhesives to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com