Insulated efficient heat-conducting silicone grease and preparation method thereof

A heat-conducting silicone grease and high-efficiency technology, which is applied in the field of insulating high-efficiency heat-conducting silicone grease and its preparation, can solve the problems of easy dry cracking, poor heat conduction effect, oil leakage, etc., and achieve easy operation, low indirect contact thermal resistance, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

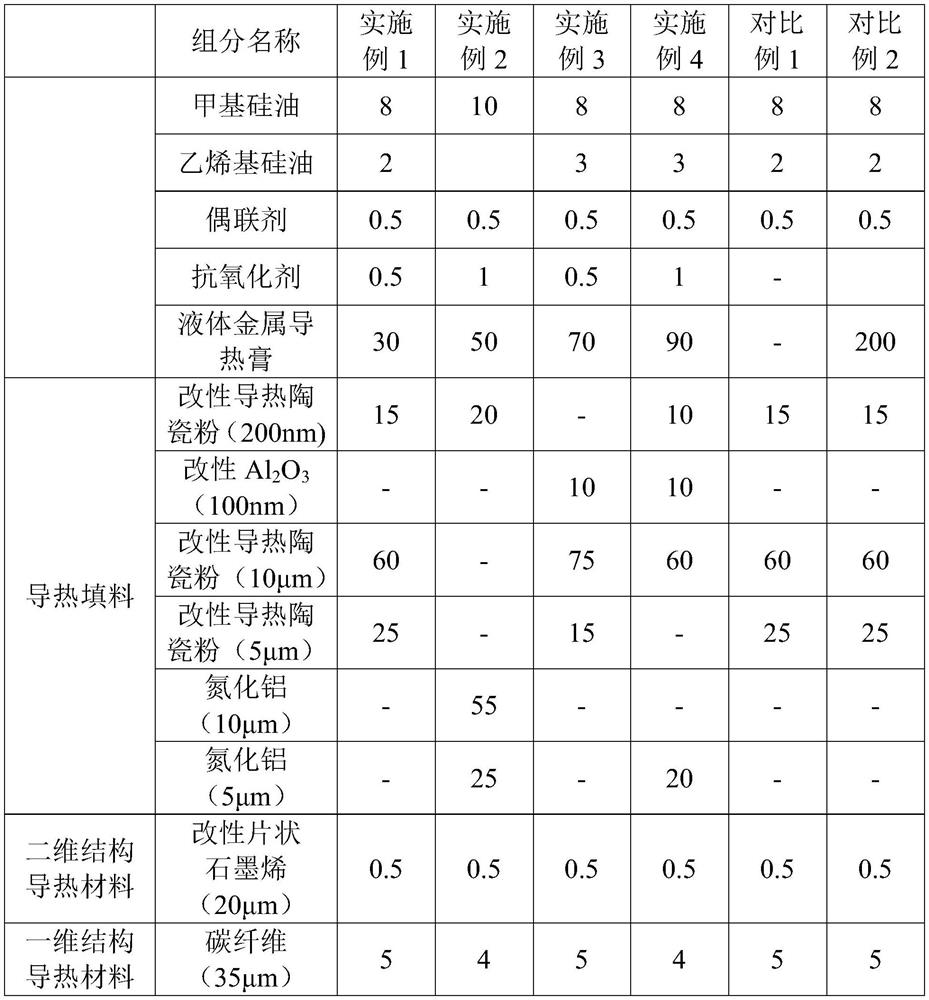

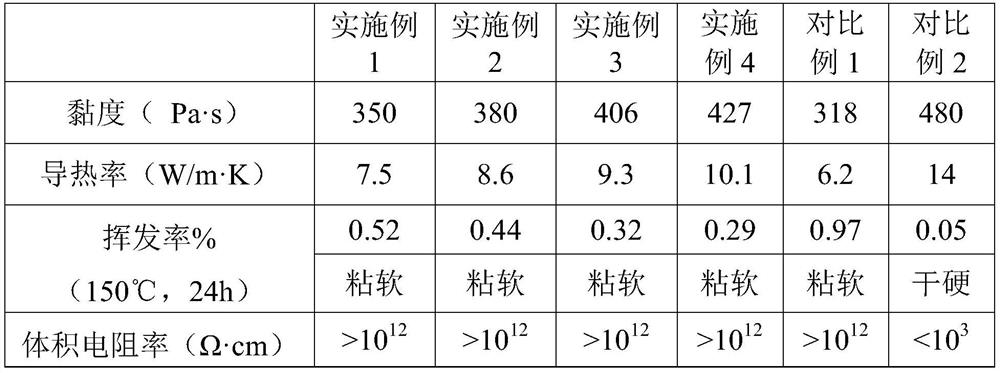

Embodiment 1

[0029] The insulating high-efficiency heat-conducting silicone grease provided in Example 1 includes the following components in parts by weight:

[0030] 65 parts of modified thermally conductive ceramic powder with an average particle size of 10 μm, 25 parts of modified thermally conductive ceramic powder with an average particle size of 5 μm, 15 parts of modified thermally conductive ceramic powder with an average particle size of 200 nm, modified 0.5 parts of flake graphene, 5 parts of modified carbon fiber with an average particle size of 35 μm, 30 parts of liquid metal thermal paste, 8 parts of methyl silicone oil with a viscosity of 1000CP, 2 parts of vinyl silicone oil with a viscosity of 500CP, dodecyl 0.5 part of trimethoxysilane, 0.5 part of antioxidant 1010.

[0031] By calculation, in the above components, the weight ratio of the liquid metal thermal paste to the weight of the composite spherical thermal conductive filler is 1:3.5; the weight ratio of the weight o...

Embodiment 2

[0039] The insulating high-efficiency heat-conducting silicone grease provided in Example 1 includes the following components in parts by weight:

[0040] 55 parts of aluminum nitride with an average particle size of 10 μm, 25 parts of aluminum nitride with an average particle size of 5 μm, 20 parts of modified thermally conductive ceramic powder with an average particle size of 200 nm, and modified sheet-shaped graphene with an average particle size of 20 μm 0.5 parts, 4 parts of modified carbon fiber with an average particle size of 50 μm, 50 parts of liquid metal thermal paste, 10 parts of methyl silicone oil with a viscosity of 1000CP, 0.5 parts of dodecyltrimethoxysilane, and 1 part of antioxidant 1010.

[0041] By calculation, in the above components, the weight ratio of the liquid metal thermal paste to the composite spherical thermal conductive filler is 1:2; the weight ratio of the micron-sized spherical thermal conductive filler in the composite spherical thermal cond...

Embodiment 3

[0049] An insulating high-efficiency heat-conducting silicone grease provided in Example 3 includes the following components in parts by weight:

[0050] 75 parts of modified thermally conductive ceramic powder with an average particle size of 10 μm, 15 parts of modified thermally conductive ceramic powder with an average particle size of 5 μm, 10 parts of modified alumina powder with an average particle size of 100 nm, modified 0.5 parts of flake graphene, 5 parts of modified carbon fiber with an average particle size of 35 μm, 70 parts of liquid metal thermal paste, 8 parts of methyl silicone oil with a viscosity of 1000CP, 3 parts of vinyl silicone oil with a viscosity of 500CP, dodecyl 0.5 part of trimethoxysilane, 0.5 part of antioxidant 1076.

[0051] By calculation, in the above components, the weight ratio of the liquid metal thermal paste to the weight of the composite spherical thermal conductive filler is 1:1.43; the weight ratio of the weight of the micron-sized sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com