Plane capillary core evaporimeter for CPL

A capillary core and evaporator technology, applied in the direction of instruments, instrument cooling, instrument parts, etc., can solve the problems of reducing system heat transfer efficiency, insufficient system liquid supply, system operation failure, etc., to improve heat transfer efficiency, Ease of use and the effect of reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

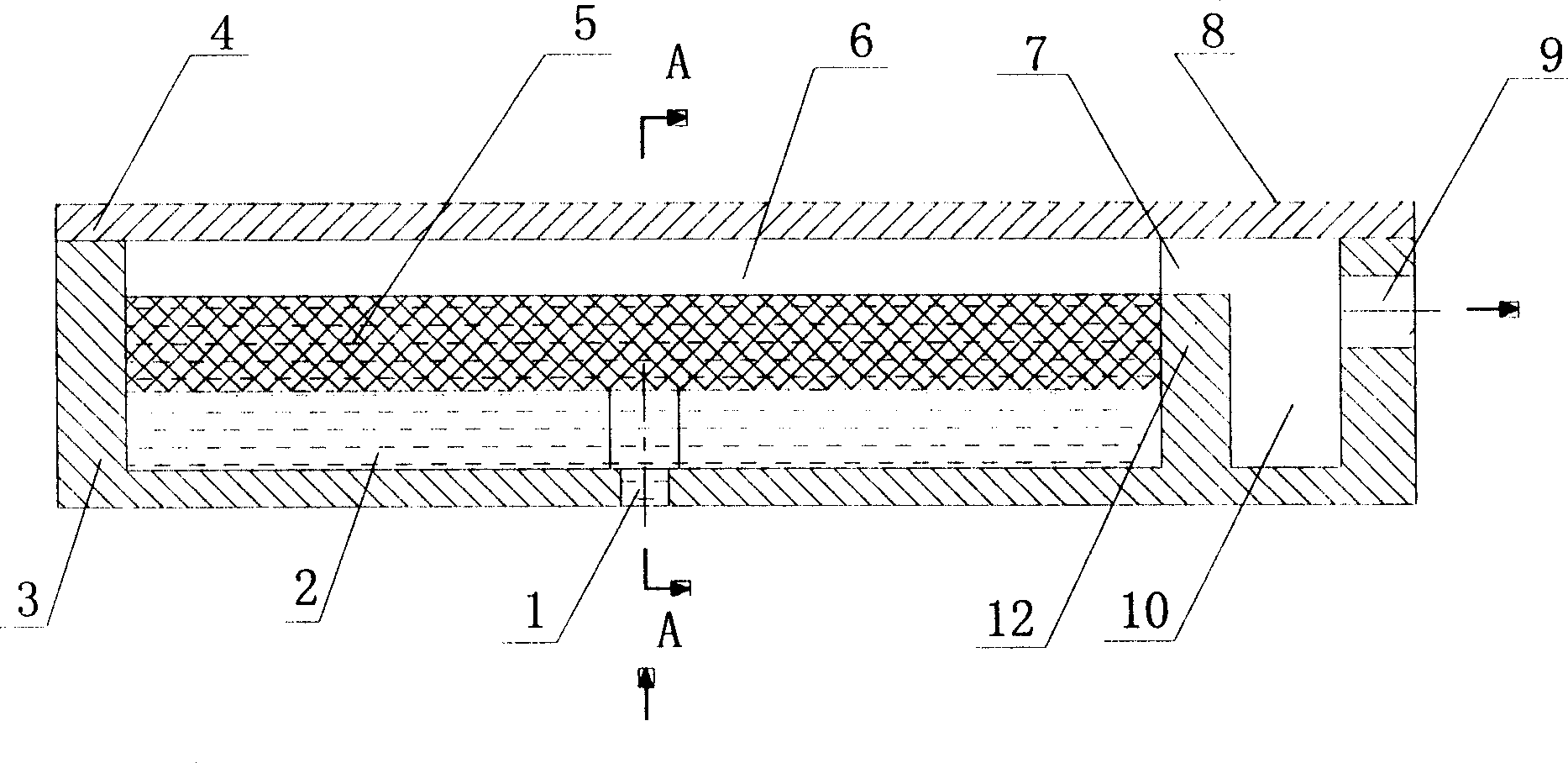

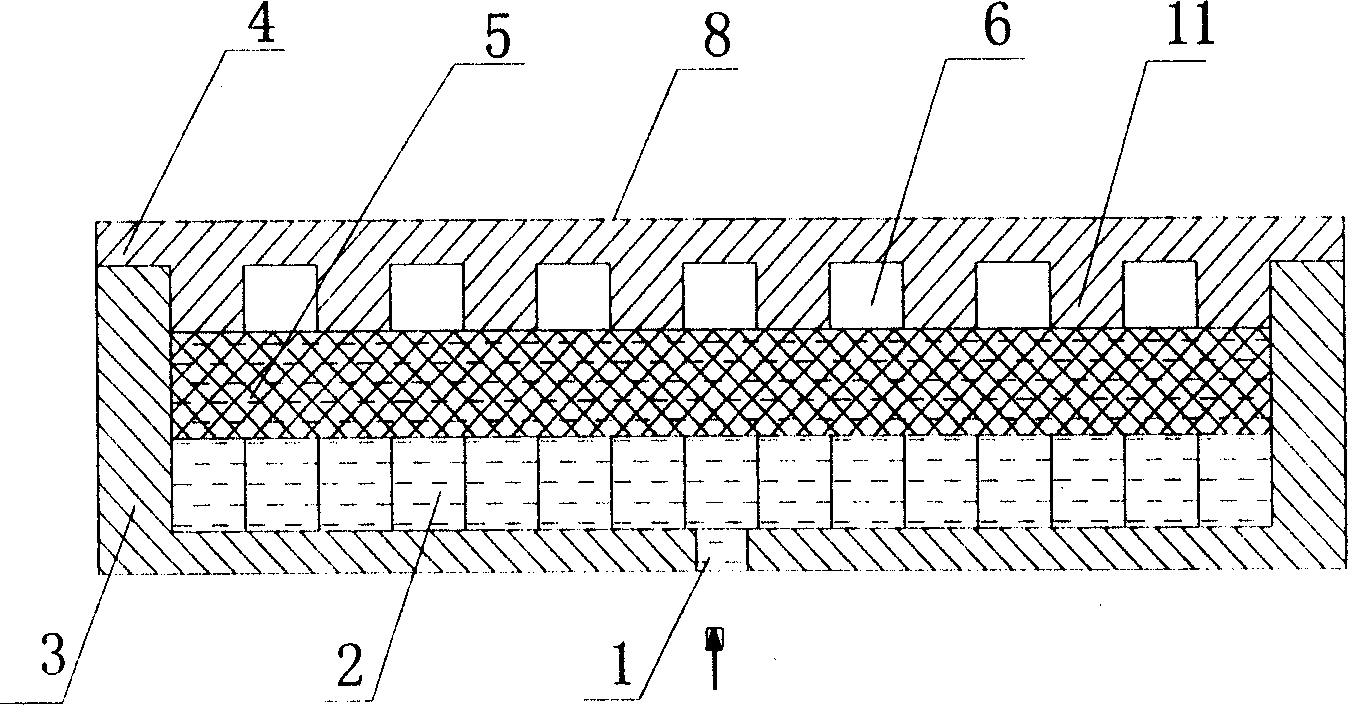

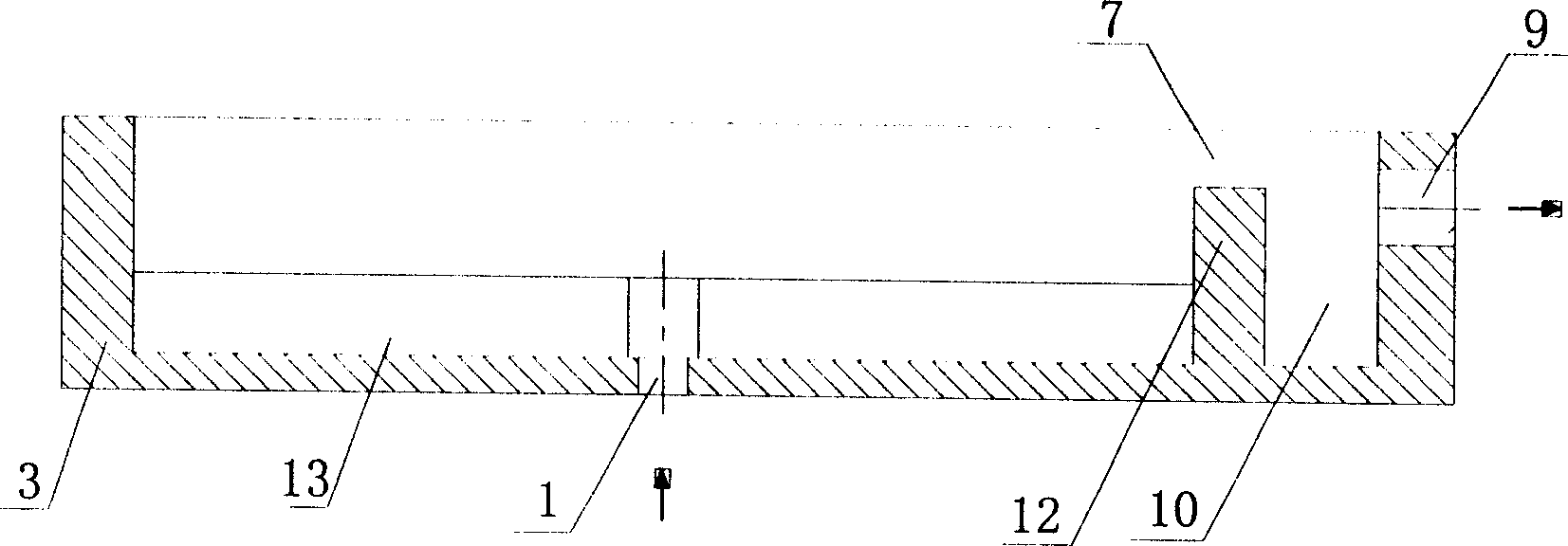

[0023] Depend on Figure 1 to Figure 6 As shown, the present invention is a planar structure as a whole, including a base 3, an upper cover 4, and a capillary core 5. The base 3 and the upper cover 4 are fixed and sealed, and can be welded or flanged and bolted. , The sealing form adopts O-ring sealing, and the capillary core 5 can be easily replaced in this way, reducing the development cost of the system.

[0024] In order to improve the heat dissipation efficiency of the evaporator, the upper cover 4 is made of metal materials with high thermal conductivity, such as copper and aluminum. The capillary core 5 can be pressed by multi-layer wire mesh or sintered by powder materials. The capillary core 5 is an important part of the evaporator. main driver of operation. In the CPL system, the higher the subcooling degree of the inlet return liquid, the better the carrying capacity and working performance of the system. In order to reduce the heat conduction effect of the heat l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com