LED lampwick and LED illuminating lamp thereof

A technology of LED lighting and LED wicks, applied in the field of LED lighting, can solve the problems of not being able to form a general standard, not easy to replace, and unsatisfactory heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

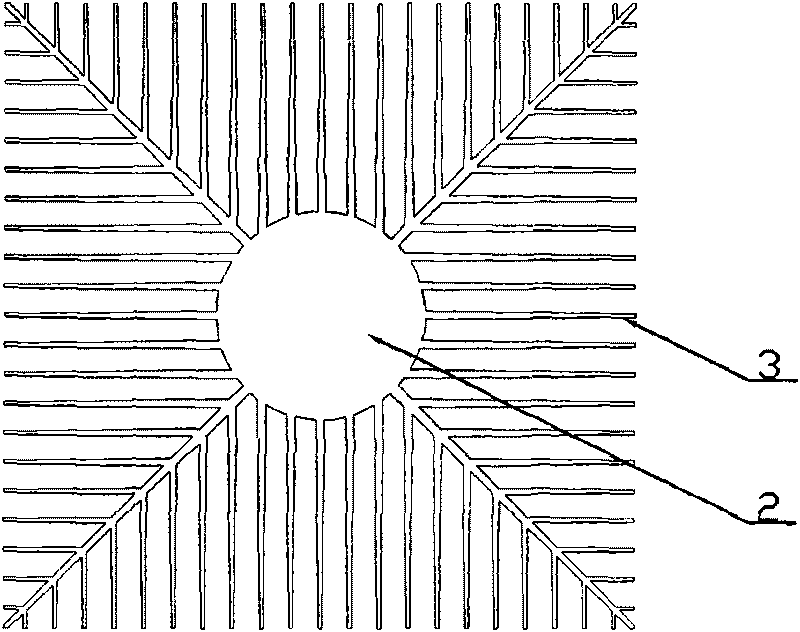

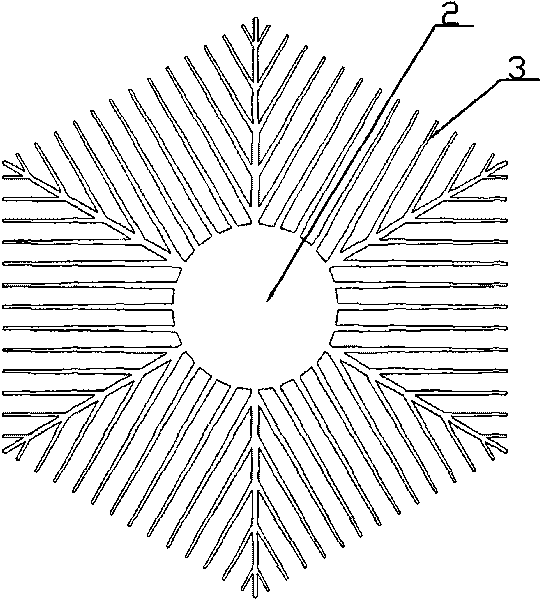

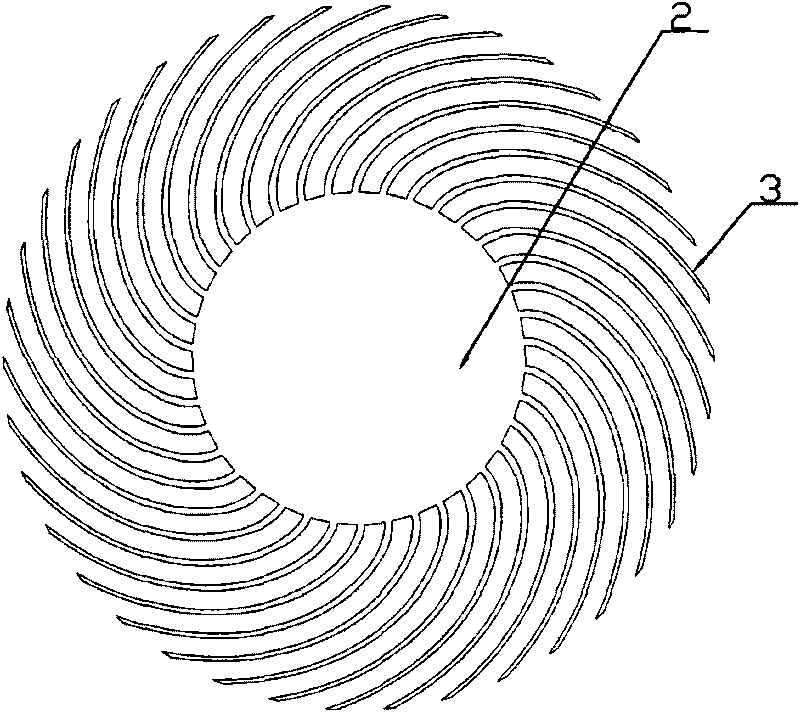

[0025] figure 1 , 2 , 3 respectively show the schematic diagrams of the characteristics of three kinds of solar fancy heat sinks. Their structural characteristics (that is, the structural characteristics of sunflowers), the center is the heat conduction column 2 (there are solid and hollow, the figure is solid), and the ribs 3 protrude from the cylindrical surface of the heat conduction column 2. The function of the heat conduction column is to The heat of the LED core is transferred from the end surface (also called the cross section) of the heat conduction column to the fins on the cylinder surface in the form of heat conduction. The advantages of the sunflower structure: the heat conduction part (that is, the heat conduction column) is small in size, the heat conduction path is short, and the heat dissipation area of the fin is large.

[0026] Figure 4 , 5 The characteristic structures of two typical LED lighting lamps of the present invention are shown. There is a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com