High-temperature heat storage and evaporation integrated device

A high temperature, heat storage technology, applied in the field of heat storage and evaporation integrated devices, can solve the problems of different expansion rates between metal pipes and concrete, the inability to further significantly reduce costs, and cracks in concrete structures, so as to achieve good economy and operational reliability. Good heat transfer characteristics and reliability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

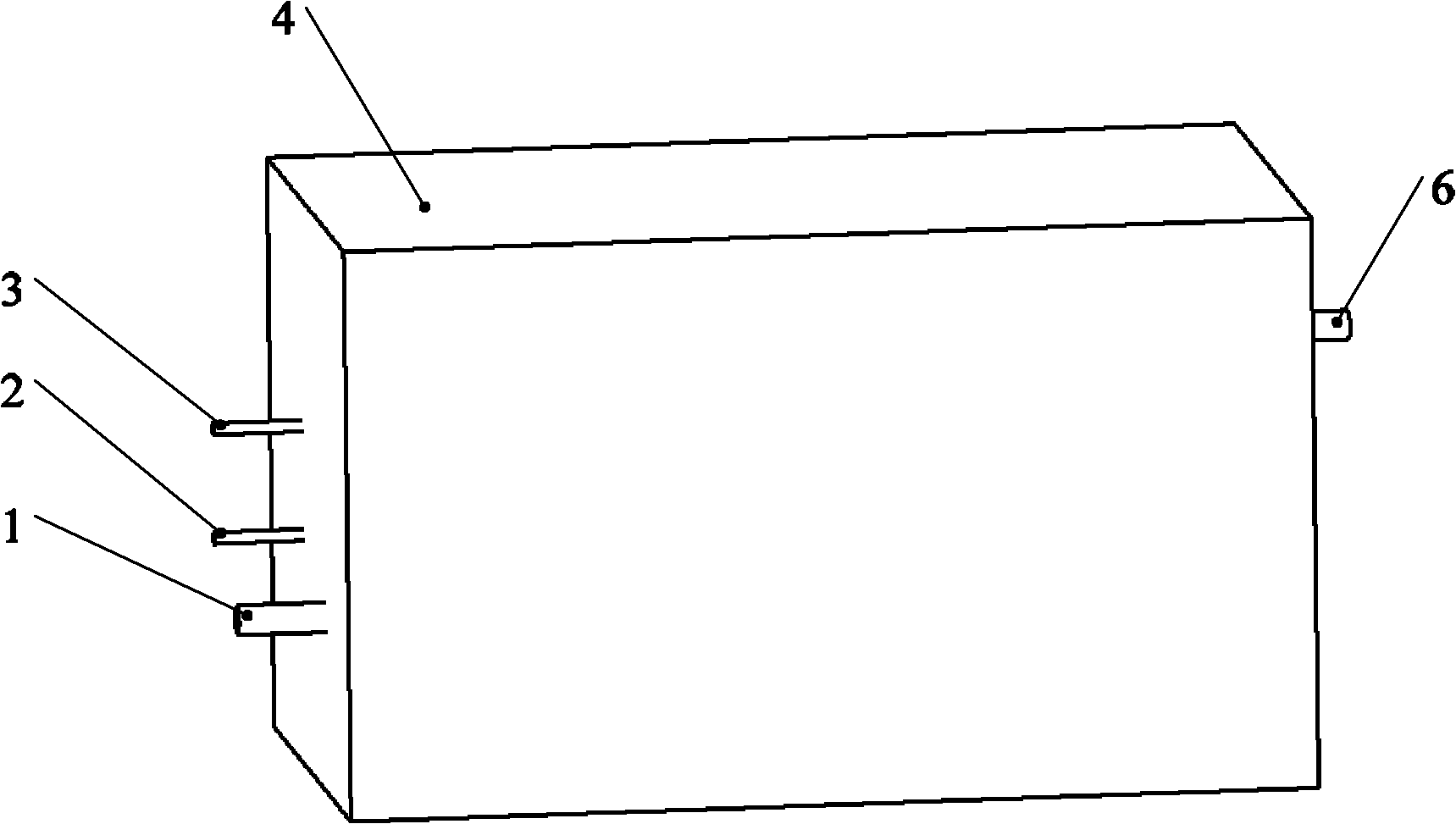

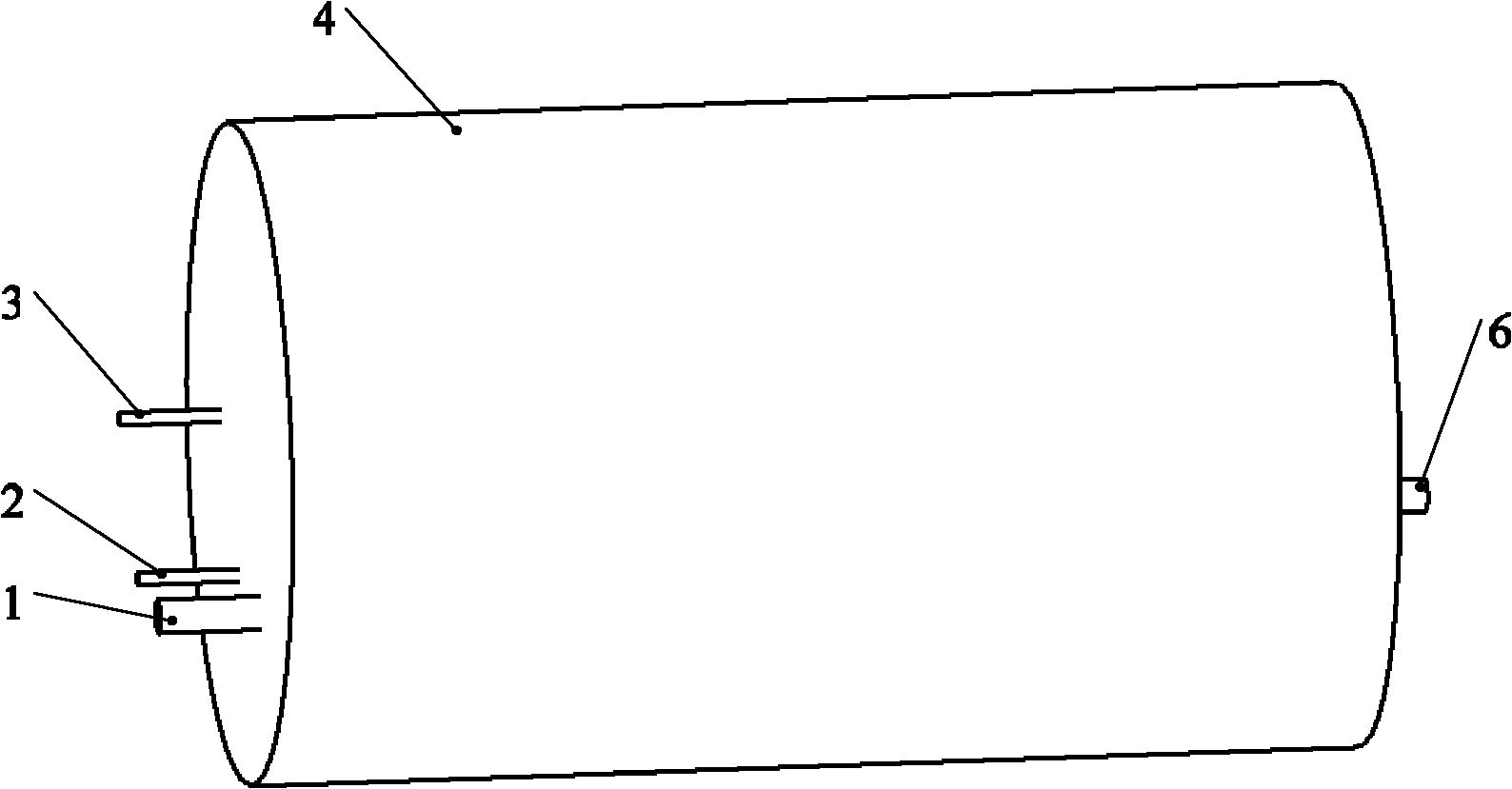

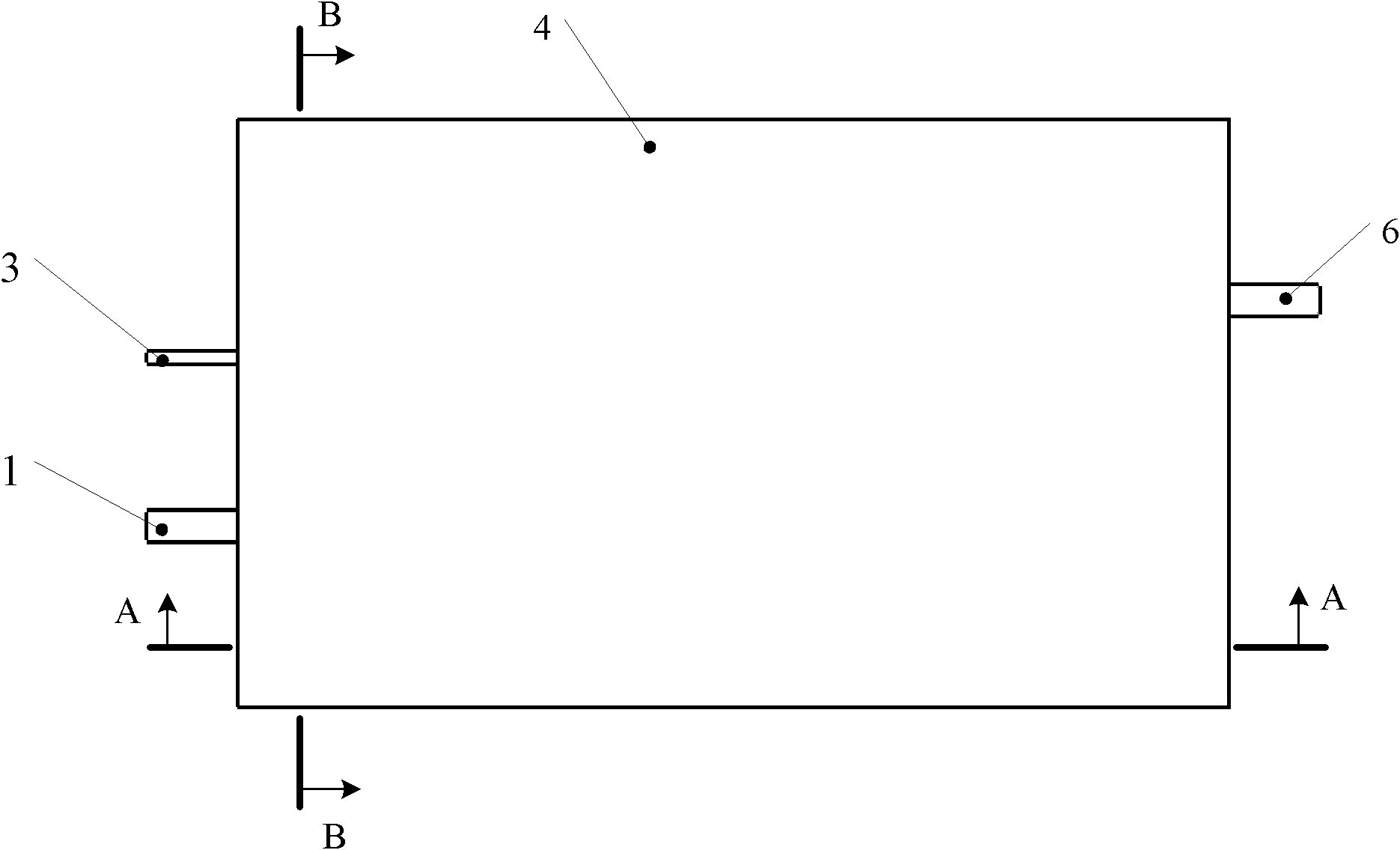

[0026] like figure 1 As shown, the high-temperature heat storage and evaporation integrated device has a cuboid structure in shape. The outermost side of the high-temperature heat storage and evaporation integrated device is the insulation layer 4 . The inlet 1 of the heating pipe, the outlet 6 of the heating pipe, the inlet 2 of the evaporating pipe, and the outlet 3 of the evaporating pipe extend out of the liquid storage tank 7 and the outer side of the insulation layer 4 . When the high-temperature heat storage and evaporation integrated device is used for the first time, or when it is started after a long-term shutdown due to maintenance and other reasons, hot water or low-temperature steam flows in from the inlet 2 of the evaporation tube and flows out from the outlet 3 of the evaporation tube, completing the integration of high-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com