Manufacturing method for thick copper foil copper-clad plate

A manufacturing method and technology of copper-clad laminates, which are applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve the difficulties in making ultra-thick copper-clad copper-clad laminates, poor bonding strength between copper foil and internal materials, and board materials Poor flatness and other problems, to achieve the effect of solving the problem of rapid heat dissipation, good bonding strength, and efficient thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through specific embodiments.

[0023] The manufacturing method of thick copper foil copper clad laminate provided by the present invention includes the following steps: preparing glue liquid-gluing-lamination and hot pressing.

[0024] S1: Preparation of glue

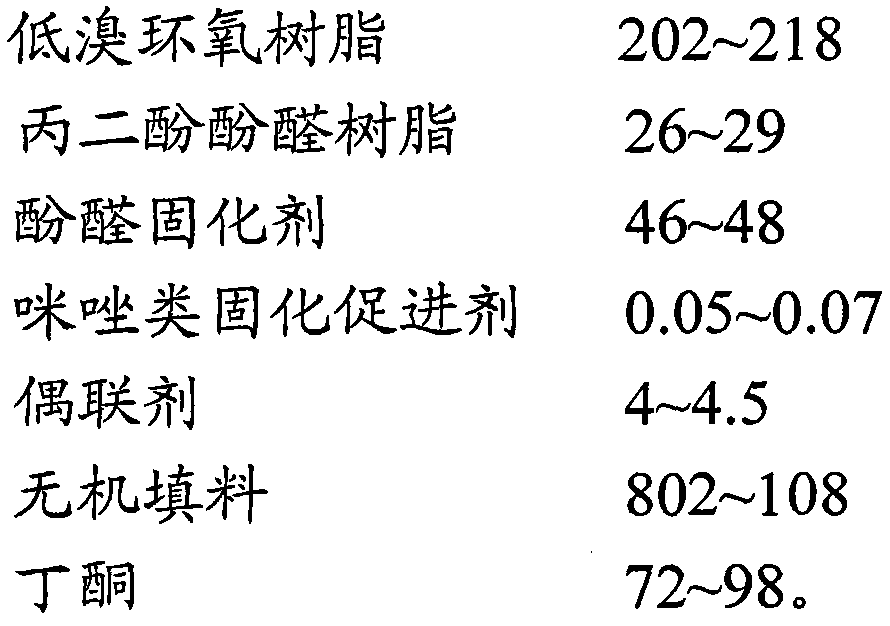

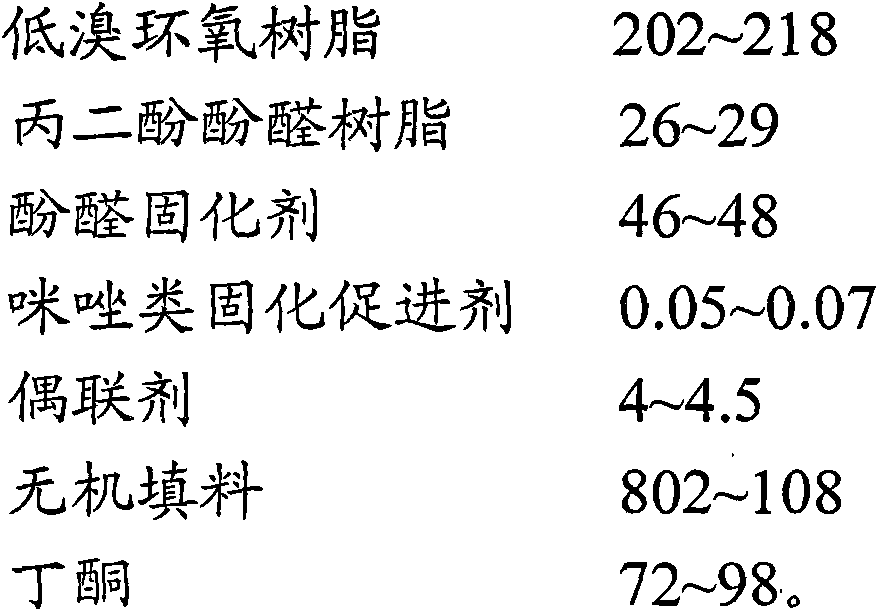

[0025] The glue includes the following components (parts by weight):

[0026]

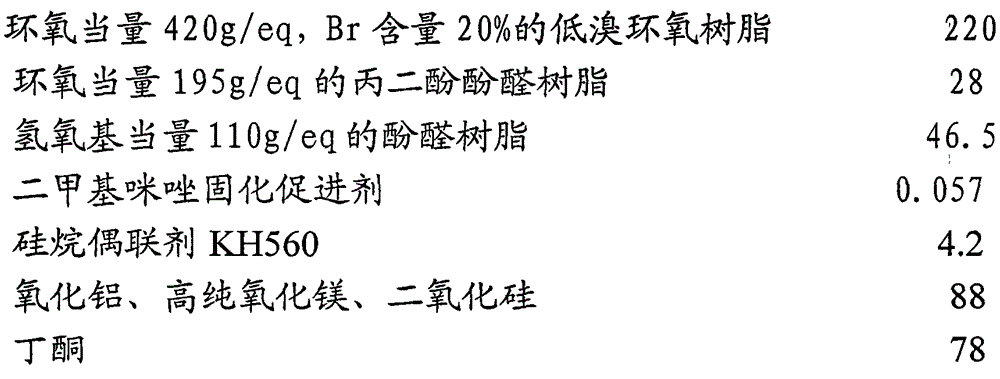

[0027] According to the above ratio, the gelation time of the glue is 266S.

[0028] Among them, low bromine epoxy resin with epoxy equivalent of 420g / eq and Br content of 20% is used as the main resin;

[0029] Propylene glycol phenolic resin with epoxy equivalent of 195g / eq, its main function is to improve the heat resistance of the board and the adhesion of the substrate and the copper foil;

[0030] Phenolic resin with a hydroxyl equivalent of 110g / eq is used as a curing agent; it is recommended not to use latent curing agents, such as dicyandiamide, when making ultra-thick copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com