Patents

Literature

126results about How to "Good combination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grinder hammerhead with ceramic wearing coat and casting method thereof

InactiveCN101314145ANot easy to wearAvoid breakingFoundry moulding apparatusGrain treatmentsSurface layerHardness

The invention discloses a crusher hammer with a ceramic abrasion-resistant layer and a casting method thereof. The hammer adopts high boron cast steel as a parent body and a ceramic particle composite layer as a surface layer of the hammer, and is produced through a shape casting method that evaporated pattern casting is combined with casting by a cast-penetration process, and high temperature molten steel is taken as a parent body and is penetrated into the ceramic particle composite layer to form metallurgical bonding. The produced hammer has good strength and toughness as well as high hardness and wearing resistance.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Aramid fiber surface metallization treatment method

The invention belongs to the field of fiber material surface metallization treatment and particularly relates to an aramid fiber surface metallization treatment method which takes hypophosphite as reductant and metal salt as the plating solution of the main salt to deposit a metal coating on the surface of aramid fiber through chemical plating. The surface metallization treatment process includes the steps of unoiling, coarsening, sensitizing, activating, carrying out preplating and carrying out chemical plating. Through the metallization treatment method disclosed by the invention, a uniform compact nonporous metal coating can be plated on the surface of the aramid fiber, and therefore the electrical conductivity and the corrosion resistance of the aramid fiber can be improved and the service life of the aramid fiber can be prolonged. The aramid fiber plated with the metal coating can also be used as reinforcement of metal matrix composite material so as to improve the mechanical property of the composite material.

Owner:KUNMING UNIV OF SCI & TECH

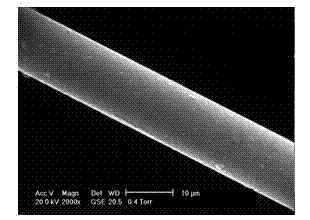

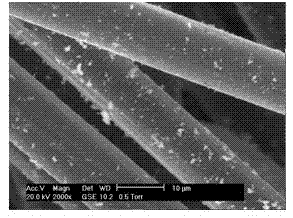

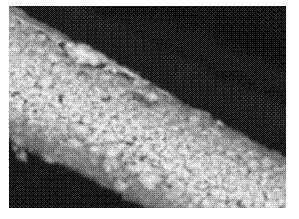

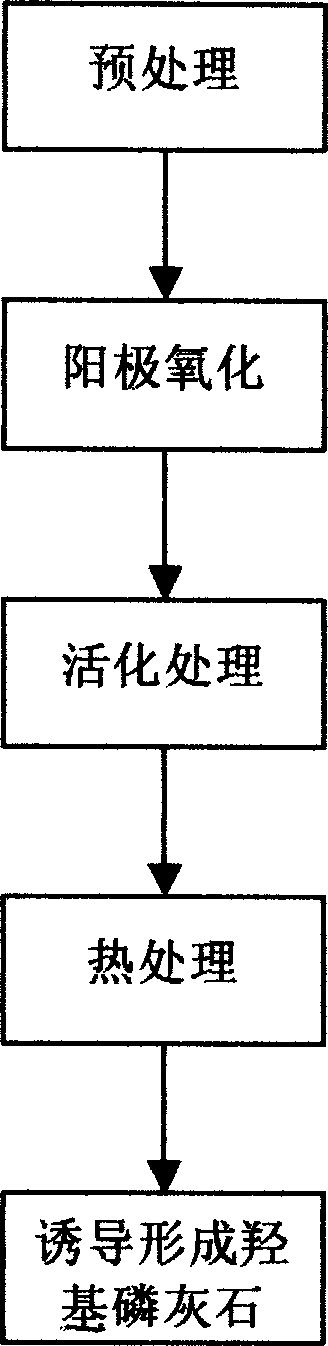

Preparation method of biologically active nanometer composite layer on medical-use metal surface

InactiveCN1769527AGood combinationImprove biological activitySuperimposed coating processApatiteBiological activation

This invention relates to a biological active nanometer compound layer making method for the medical metal surface, which includes the following steps: putting the medical metal titanium and its alloy radix into the diluent acid liquid to do corrad pretreatment; using the pretreated titanium and its alloy radix as the anode to do anode oxidation to create the compact titanium dioxide nanometer tube film on the surface of the metal; putting them into the alkali lye to do activation treatment, then doing heat treatment with them under 450íµí½650íµ for 0.5í½3 hours; Then putting them into the simulate liquid to produce hydroxyl apatite. The charater of this invention is that it provides a method that combines the anode oxidation and alkali heat treatment, and this invention impoves the biological compatibility of the medical metal greatly.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

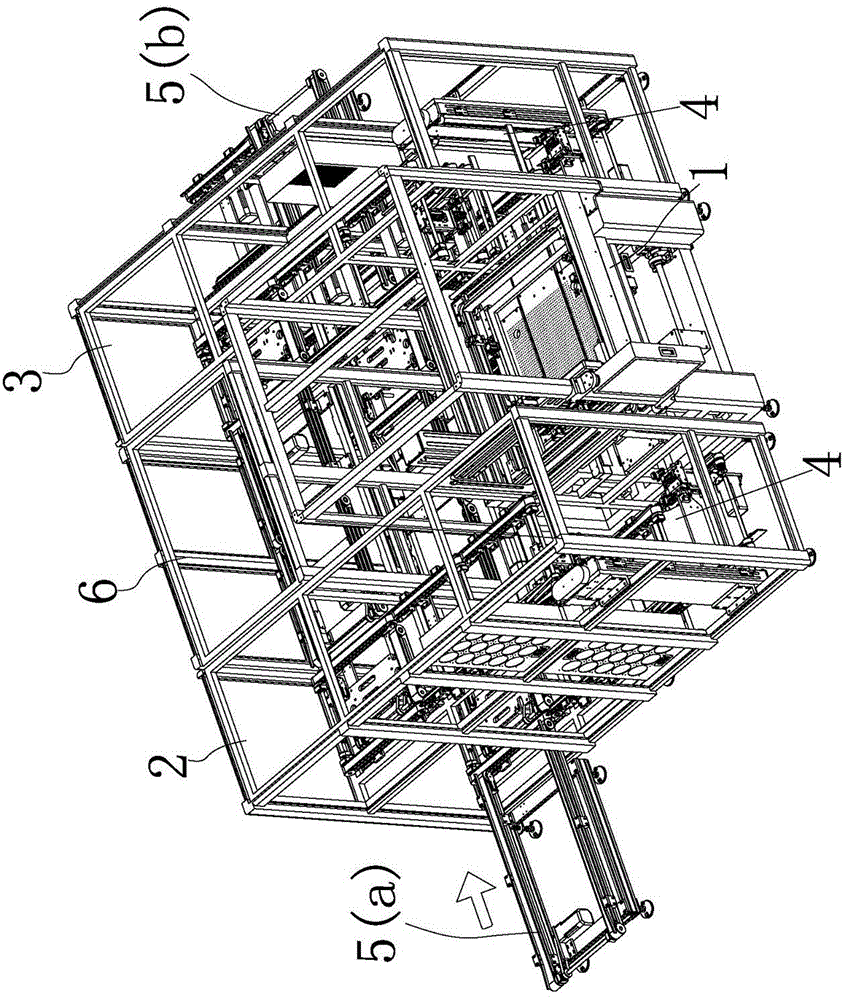

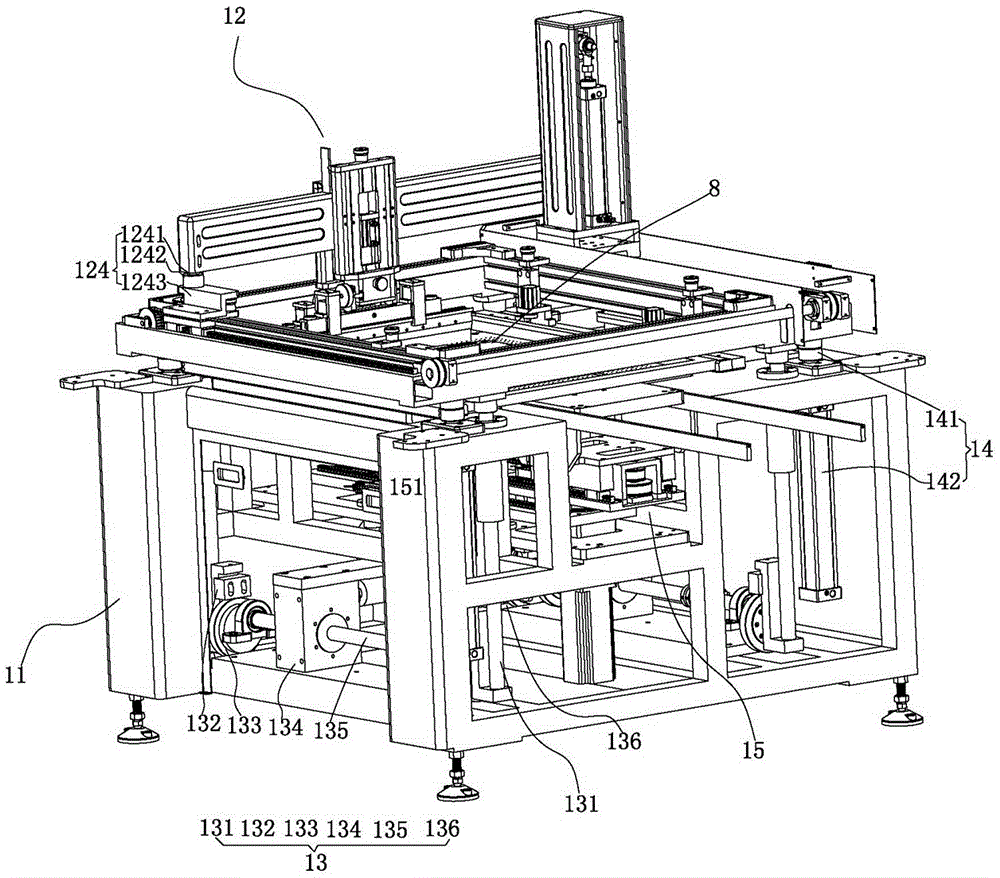

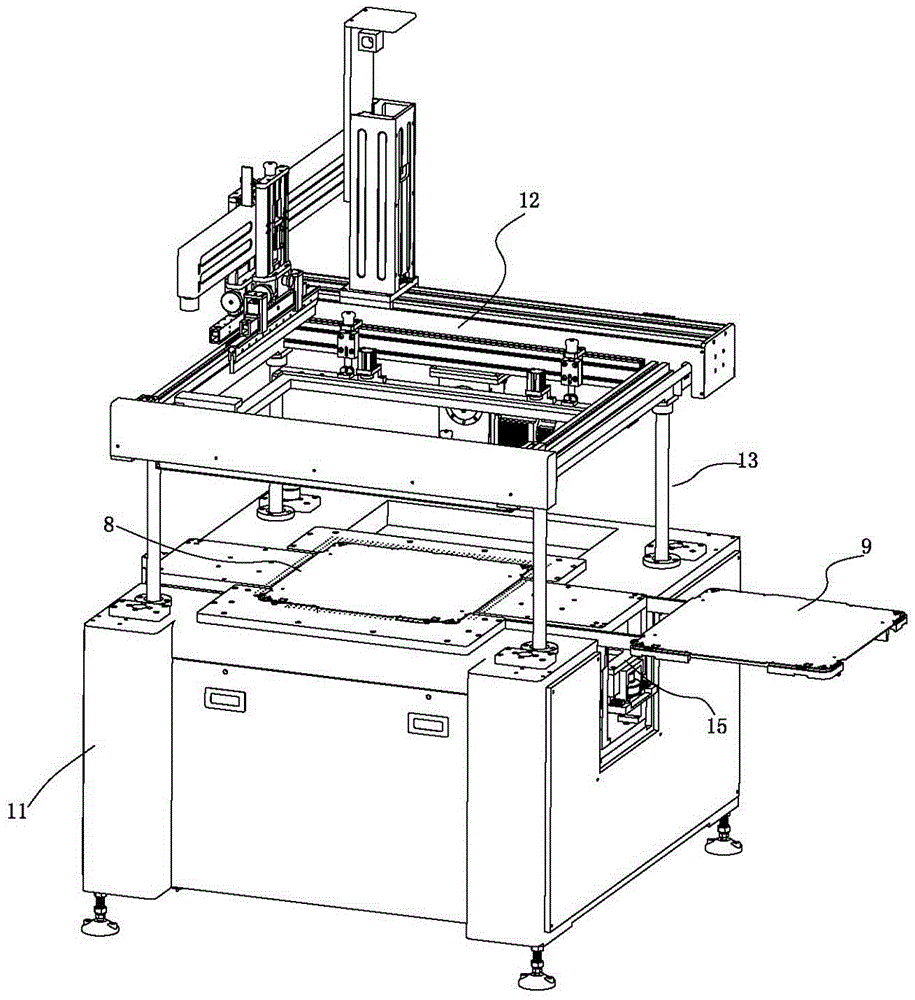

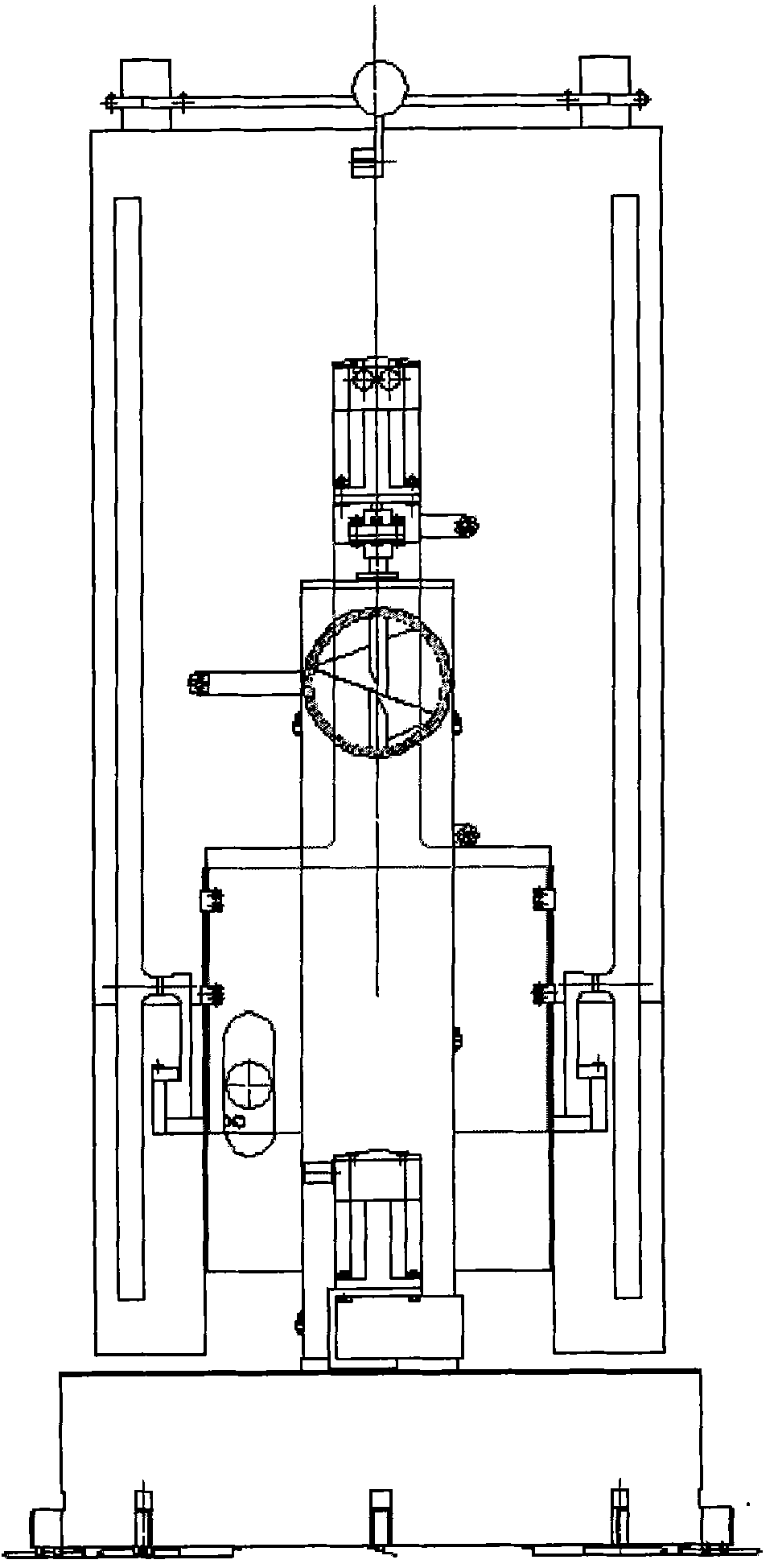

Full-automatic screen printing machine

The invention discloses a full-automatic screen printing machine comprising a control system, a rack, a printing assembly, a feeding mechanism, a material receiving mechanism, a circulating conveying mechanism and two conveying devices. The feeding mechanism and the material receiving mechanism are each internally provided with a plurality of conveying channels; joints between the feeding mechanism and the printing assembly and between the material receiving mechanism and the printing assembly are each provided with a vertical transfer device; the vertical transfer devices are used for transferring material carrying plates between all the layers of conveying channels and / or are used for transferring material carrying plates between the conveying channels and the printing assembly; a moving and loading assembly is arranged at the lower end position of the printing assembly; a printing positioning device is further arranged in a matched printing area of the lower end of the printing assembly; and the positions of the material carrying plates are corrected through the printing positioning device, and the printing assembly is made to complete accurate printing. According to the full-automatic screen printing machine, the feeding mechanism and the material receiving mechanism surround the printing assembly, the double-layer conveying channels are arranged in the feeding mechanism and the material receiving mechanism, the online plate number storage amount of the printing machine is increased, the functions of one printing machine are increased and extended, the full-automatic screen printing machine is suitable for multi-color printing of different category requirements, and the printing machine is high in utilizing rate and production efficiency and low in cost.

Owner:庄统壹 +1

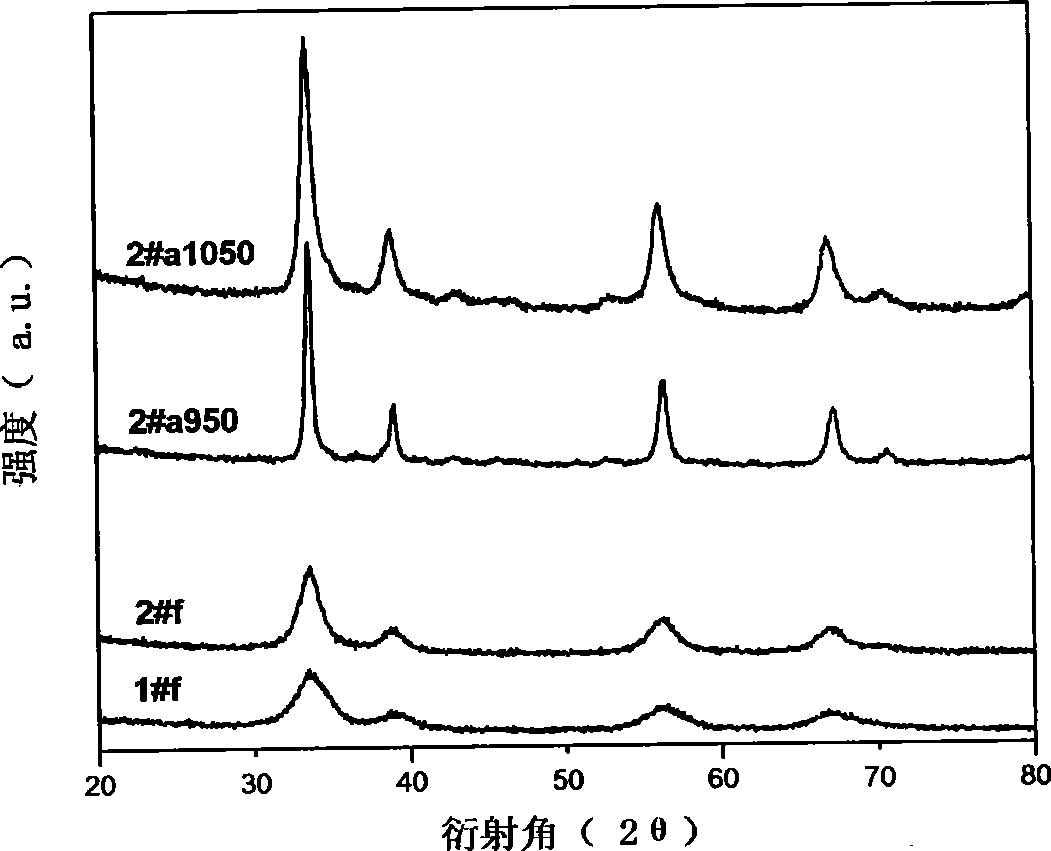

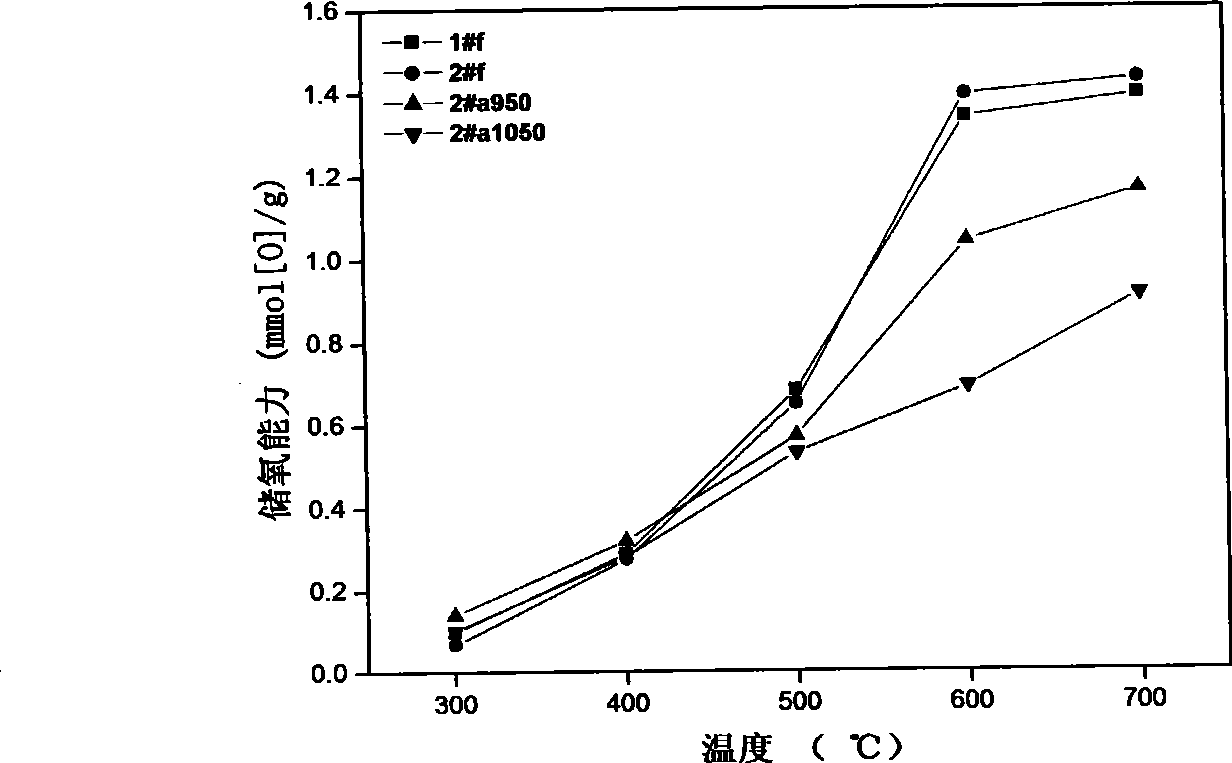

Preparation of homogeneous mischcrystal cerium-zirconium-aluminum coating material by coprecipitation method and technique thereof

InactiveCN101433831AImprove high temperature resistanceReduce specific surface area lossInternal combustion piston enginesDispersed particle separationCeriumCoating materials

The invention relates to preparation of a uniform solid solution Ce-Zr-Al based coating material by a coprecipitation method and a process method thereof. A mixed solution of soluble salts of Ce and Zr is coprecipitated by an alkaline solution, a soluble salt solution of Al is separately precipitated by the alkaline solution, the interaction degree of Ce-Zr and Al is regulated and controlled by controlling the aging time, and suspensions are evenly mixed after the aging and then are dried and baked. The method can obtain a Ce-Zr-Al three-phase solid solution with a uniform cubic phase structure. The method has a simple production technology and lower production energy consumption, and greatly improves performances of the Ce-Zr-Al based coating material such as specific surface area, thermal stability, oxygen storage performance and so on. The method ensures that a catalyst containing the Ce-Zr-Al based coating material becomes an excellent and high-performance three-effect catalyst for the purification of automobile tail gas.

Owner:TIANJIN UNIV

Preparation method and using method of carbon fiber compounded polyether sulfone resin sizing agent

The invention provides a preparation method and a using method of a carbon fiber compounded polyether sulfone resin sizing agent. A new carbon fiber sizing agent component for polyether sulfone resin is prepared for solving the problem that an epoxy sizing agent is not suitable for the carbon fiber compounded polyether sulfone material, and can effectively improve the interface bonding property of carbon fibers and polyether sulfone and improve the high temperature resistance of a composite material. A preparation method comprises the steps of processing polyether sulfone resin with a sulfonating agent to obtain a main component (sulfonic polyether sulfone) of the sizing agent; preparing a sizing solution and dipping the carbon fiber to obtain the sizing carbon fiber. The method can improve the interface bonding property of the carbon fiber compounded polyether sulfone resin and can fully achieve high specific strength of the carbon fiber and high temperature resistance of the polyether sulfone.

Owner:BEIJING UNIV OF CHEM TECH

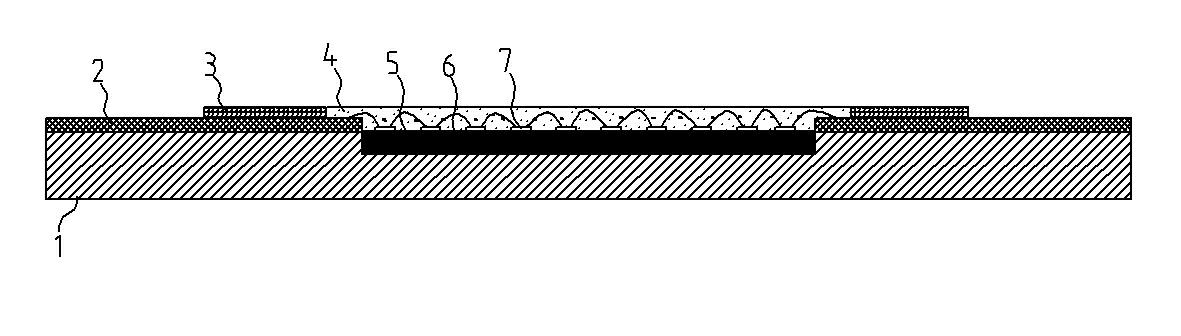

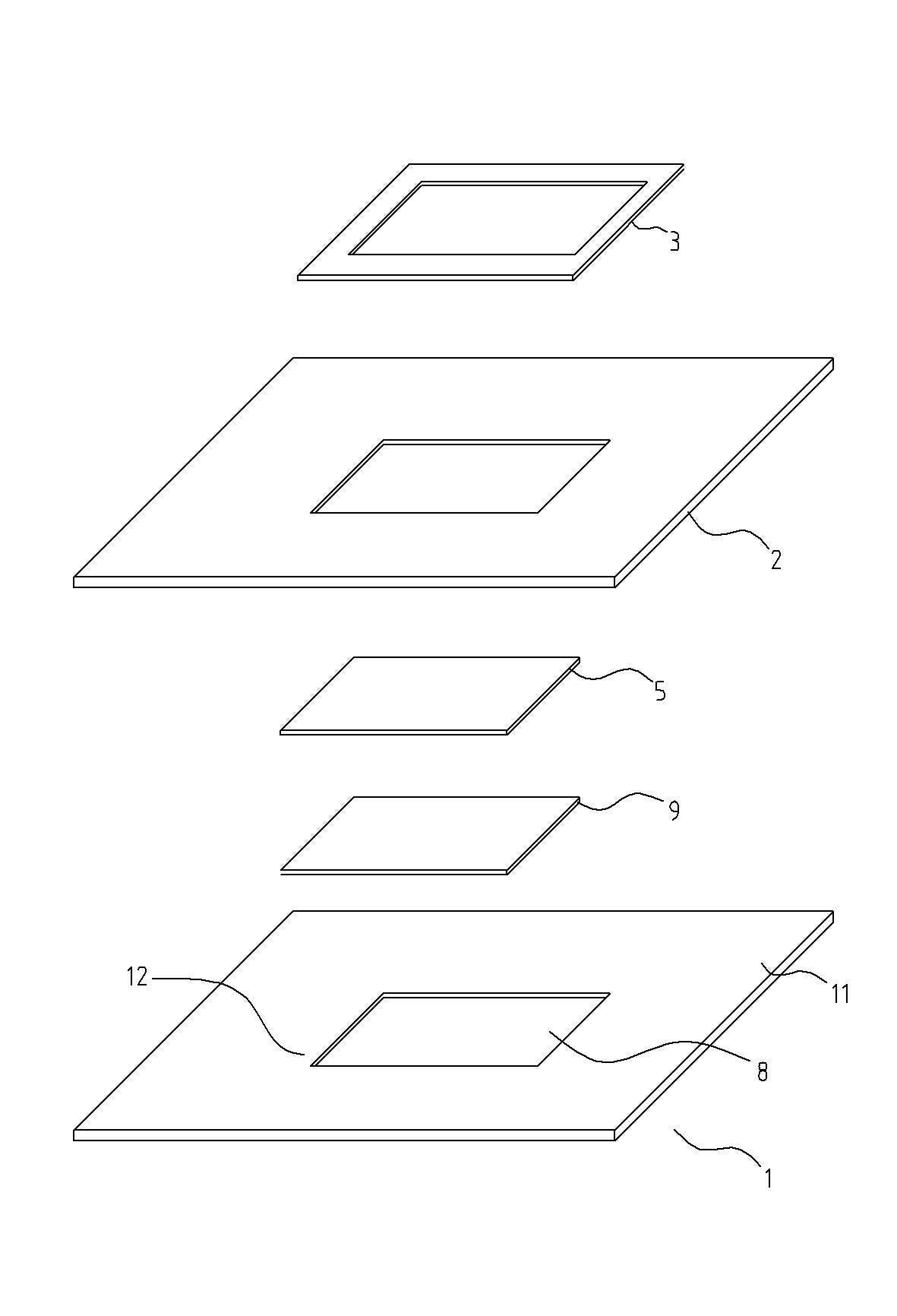

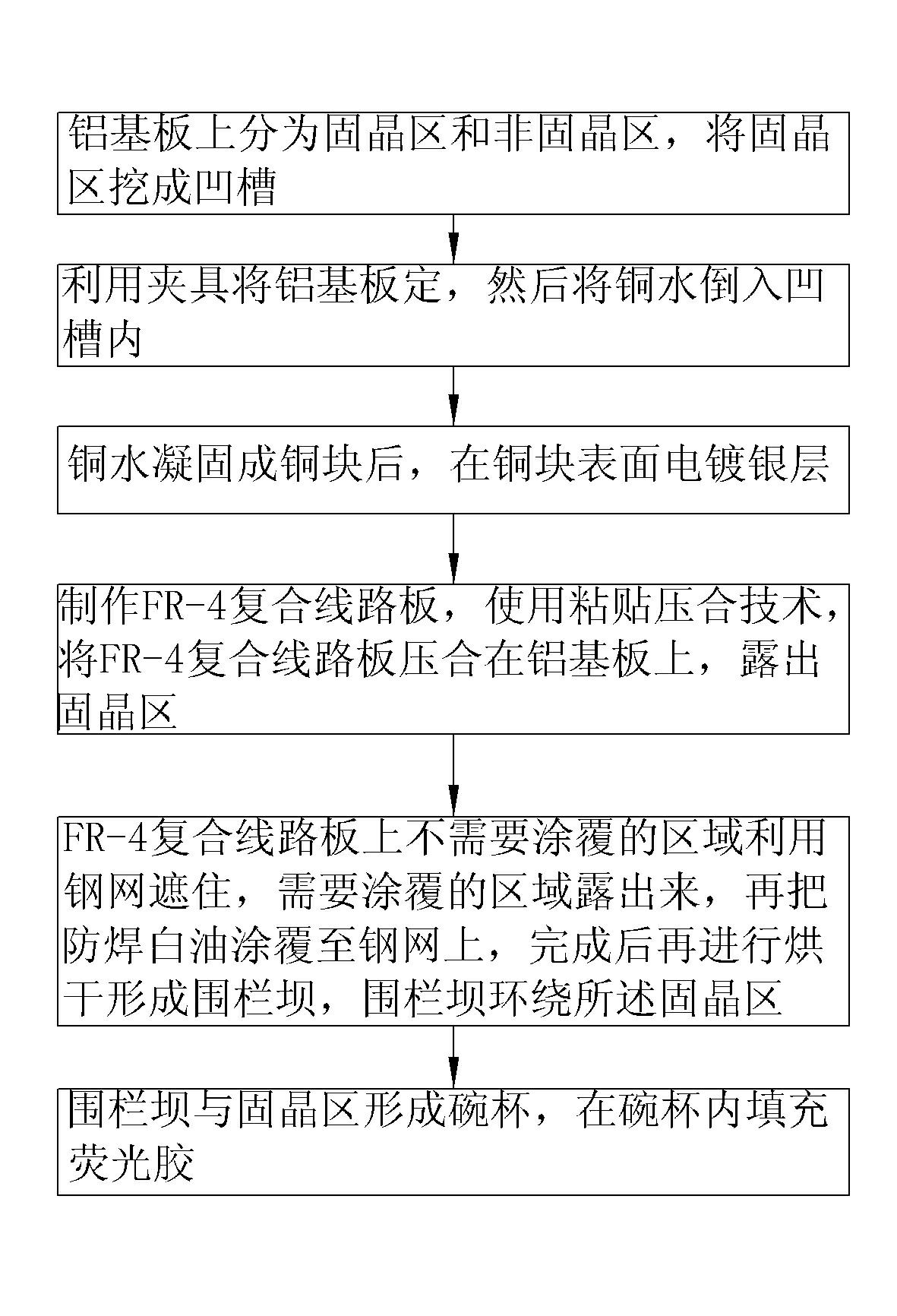

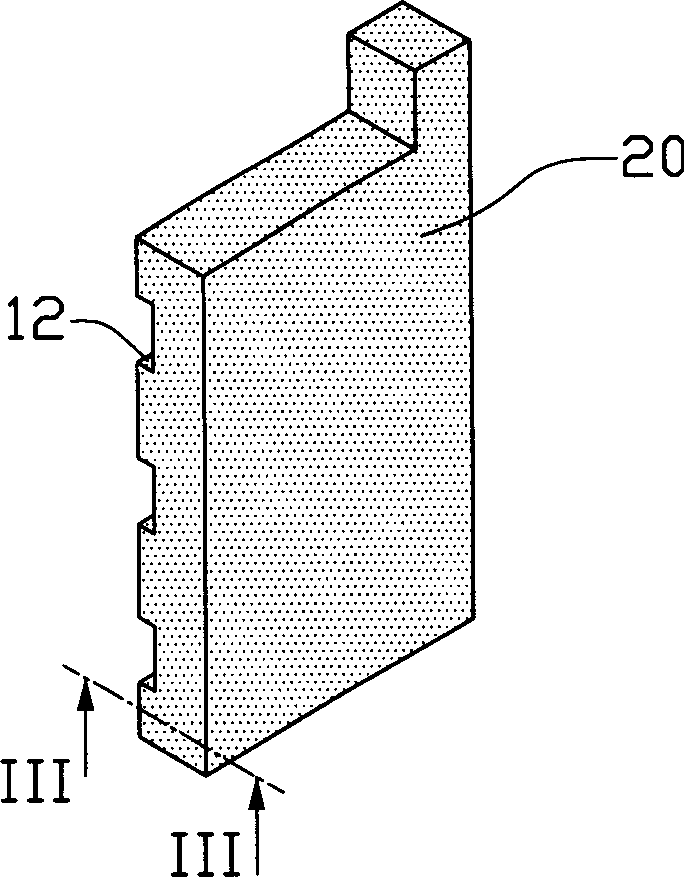

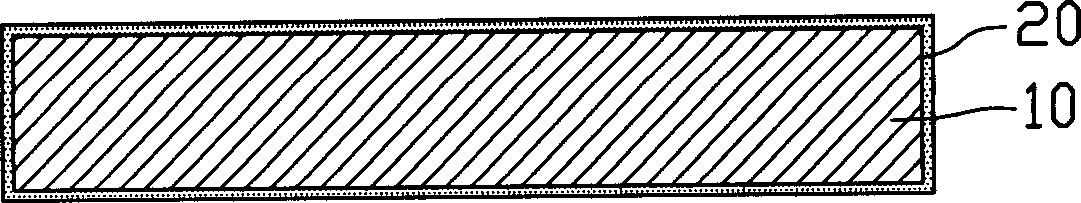

Chip on board (COB) aluminum substrate with high reflectivity and good heat dissipation performance and manufacturing process thereof

ActiveCN102623617AGood combinationImprove export rate and cooling capacitySemiconductor devicesHigh reflectivityFR-4

The invention provides a chip on board (COB) aluminum substrate with high reflectivity and good heat dissipation performance and a manufacturing process thereof. The manufacturing process comprises the steps that (1) the aluminum substrate is divided into a solid crystal area and a non solid crystal area, wherein a groove is dug in the solid crystal area; (2) the aluminum substrate is fixed by utilizing a fixture, and then copper liquid is poured into the groove; (3) after the copper liquid is solidified to form a copper block, a silver-plated layer is manufactured on the surface of the copper block; (4) an FR-4 composite circuit board is manufactured and then pressed on the aluminum substrate by using a pasting and pressing technology, and the solid crystal area is exposed; (5) an area on the FR-4 composite circuit board, which does not need to be coated, is blocked by utilizing a steel mesh, an area needing to be coated is exposed, the solder preventing white oil is coated on the steel mesh and then dried to form a fen dam, and the solid crystal area is surrounded by the fen dam; and (6) a bowl cup is formed by the fence dam and the solid crystal area, and fluorescent glue is filled into the bowl cup. The aluminum substrate manufactured by adopting the process has the advantages of high reflectivity and good heat dissipation performance, and the manufacturing process is simple.

Owner:HONGLI ZHIHUI GRP CO LTD

Preparation method for metallic oxide loaded activated carbon

InactiveCN107413329AGood combinationNot easy for catalyst to fall offCatalyst carriersCatalyst activation/preparationBiomassActivated carbon

The invention relates to a preparation method for metallic oxide loaded activated carbon. The preparation technology is characterized by comprising the following preparation steps: step 1 of smashing and screening biomass and carbonizing the biomass by high temperature; further smashing the carbide, then putting the carbide into diluted mineral acid, boiling refluxing, and filtering washing to neutral; putting the carbide processed by the acid into an alkali metal hydroxide solution, and boiling refluxing; filtering washing to neutral and drying; step 2 of weighing an additive and adding deionized water to prepare an additive solution; adding metal salt into the additive solution to be completely dissolved; step 3 of taking the carbide and the alkali metallic oxide treated in the step 1 and jointly smashing by a smashing machine; adding the solution prepared in the step 2 and stirring to prepare a pretreated raw material; step 4 of putting the raw materials in the step 3 into an inert atmosphere to be roasted; step 5 of smashing the roasted product in the step 4, washing to neutral and completely drying to obtain the metallic oxide modified biomass loaded activated carbon material. The preparation technology has the advantages of simpleness and easiness in control, safety, low cost and easiness in scale production.

Owner:CHINA FIRST AUTOMOBILE

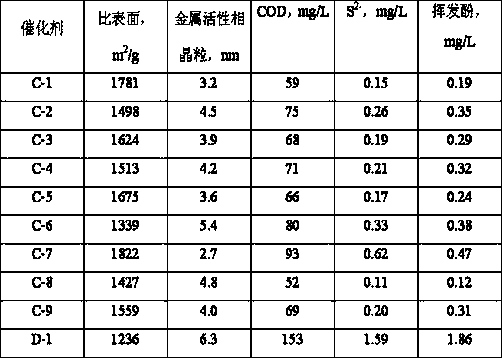

Ozone catalytic oxidation catalyst and preparation method thereof

ActiveCN111375406AHigh activityFacilitates electron transferEnergy based wastewater treatmentMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

The invention discloses an ozone catalytic oxidation catalyst and a preparation method thereof, the catalyst comprises an active component, an auxiliary agent and a carrier; the active component is one or more of Mn, Ni, Fe, V, Cu and Co, the auxiliary agent is one or more of Ti, Zn and Ce, and the carrier is petroleum coke-based activated carbon. The preparation method comprises the following steps: (1) pretreating petroleum coke; (2) uniformly mixing the obtained petroleum coke, an auxiliary component-containing compound and an activating agent, and activating; (3) washing and drying a sample obtained after activation, mixing the sample with an active metal-containing compound and an activating agent, and activating after uniform mixing; and (4) washing the obtained sample, treating thewashed sample with a hydrogen peroxide solution, and drying to obtain the catalyst. The active components of the catalyst prepared by the method are highly dispersed in the carrier, and the activity and stability of the catalyst are greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Underground pipe heat exchanger drilling hole refilling material

InactiveCN1868959AImprove thermal conductivityImprove work performanceSolid waste managementEngineeringQuartz

A refiller material for the drilled hole used for the buried pipe of geothermic exchanger in geothermic air conditioner system is proportionally prepared from cementing material, quartz sand, defoaming agent, bentone, and water reducing agent. It is applied through mixing it with water in situ, and filling the mixture in said hole.

Owner:JIANGSU LIANZHONG CASING

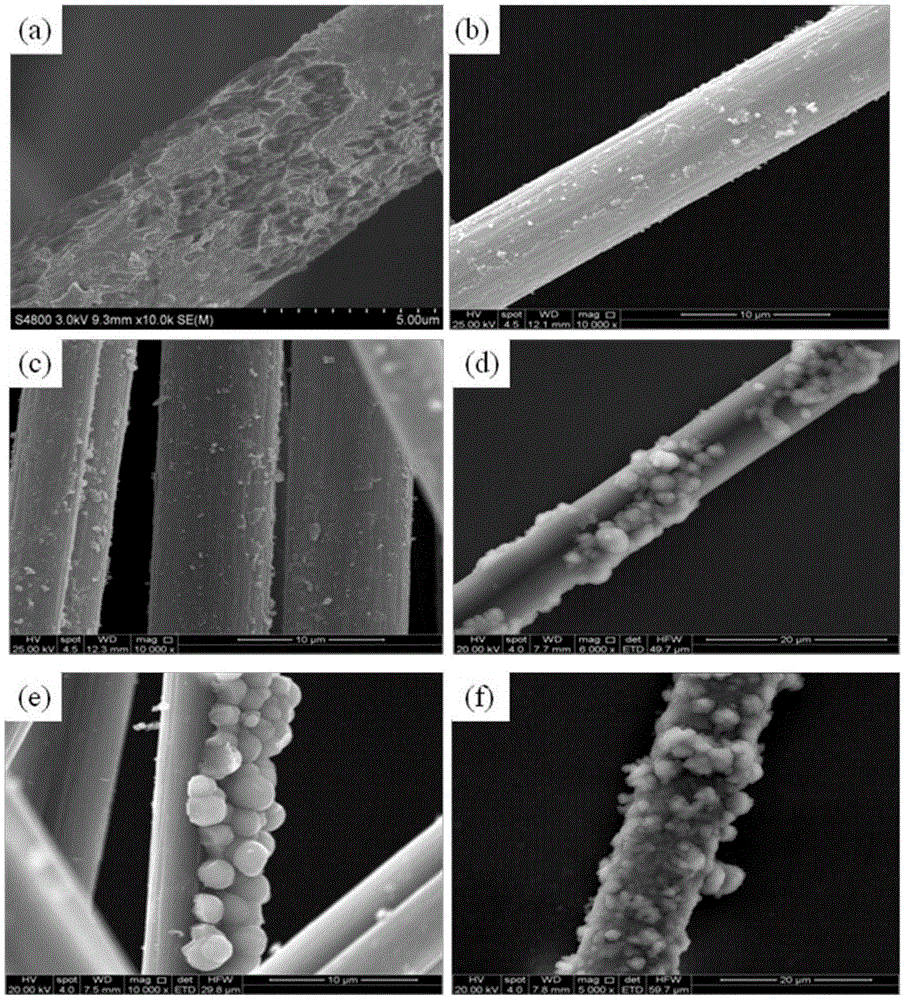

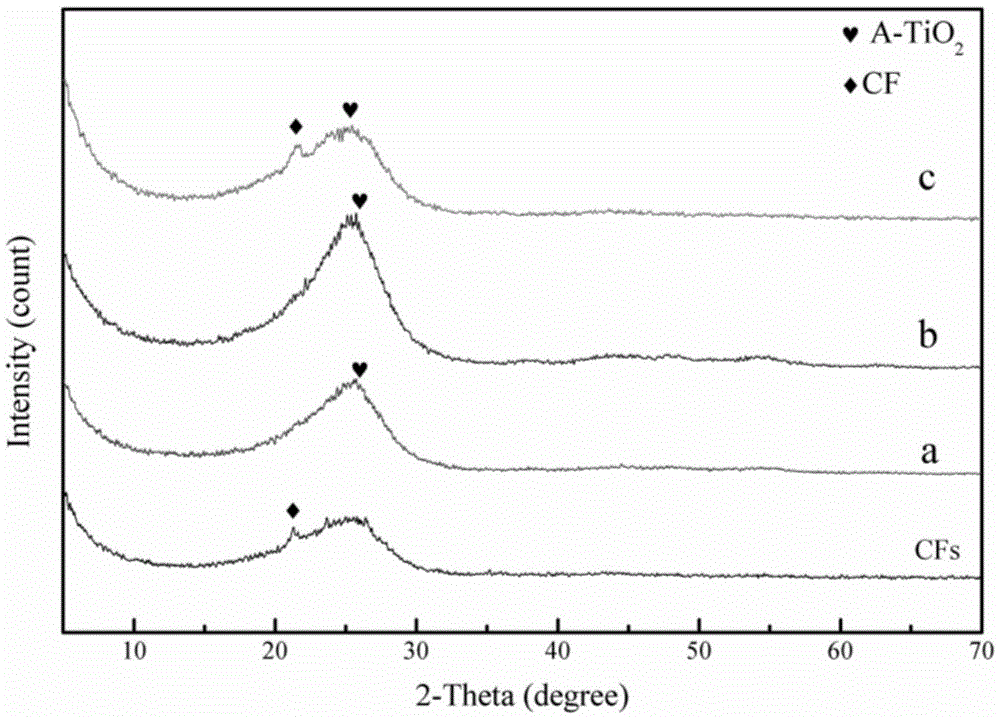

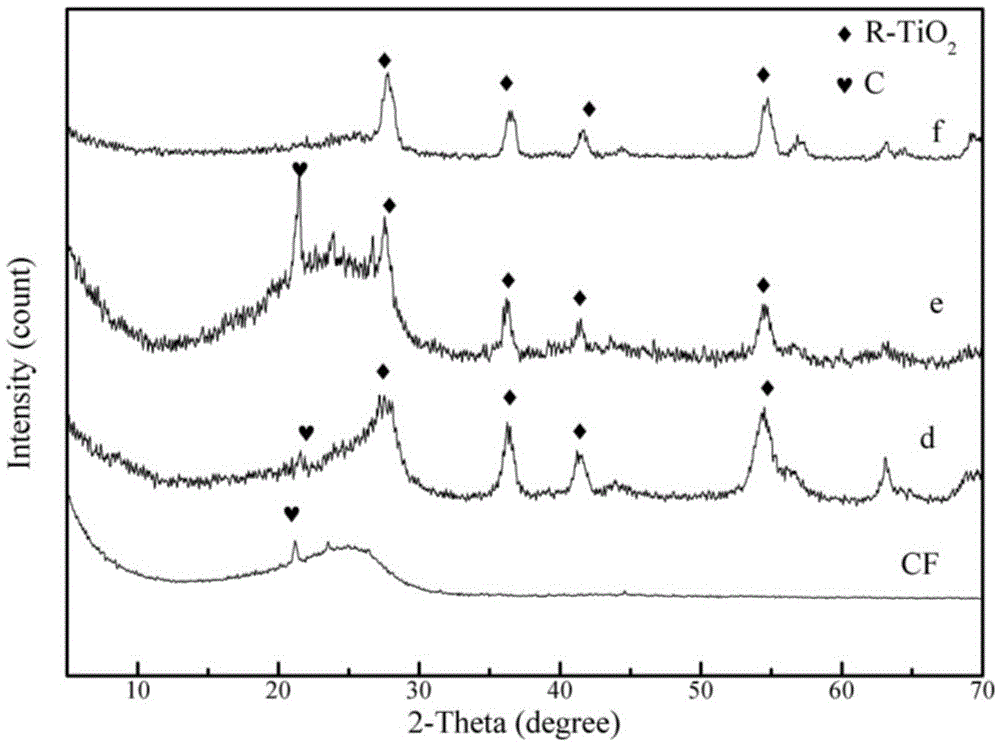

Preparation method of titanium-dioxide-modified carbon-fiber-reinforced resin-base composite material

The invention discloses a preparation method of a titanium-dioxide-modified carbon-fiber-reinforced resin-base composite material. The preparation method comprises the following steps: pretreating carbon fibers with concentrated nitric acid under certain conditions, and carrying out hydrothermal reaction on the pretreated carbon fibers and a titanium source in a water solution using concentrated hydrochloric acid as an acidic medium; and after the reaction finishes, sufficiently washing the modified fibers, drying, and preparing the reinforced resin-base composite material by using the modified carbon fibers as reinforcing fibers. The tensile strength of the modified carbon-fiber-reinforced resin-base composite material is enhanced by 134.8-153.1%; the porosity is reduced from 45.7-40.5% to 19.3%-15.6%; the pore size distribution is uniform; and the friction factor of the reinforced resin-base composite material is kept at 0.12-0.14, and the abrasion loss is lowered by 37.1-50.3%, thereby sufficiently embodying the excellent friction reduction action of the modified carbon fibers applied to a wet friction material.

Owner:SHAANXI UNIV OF SCI & TECH

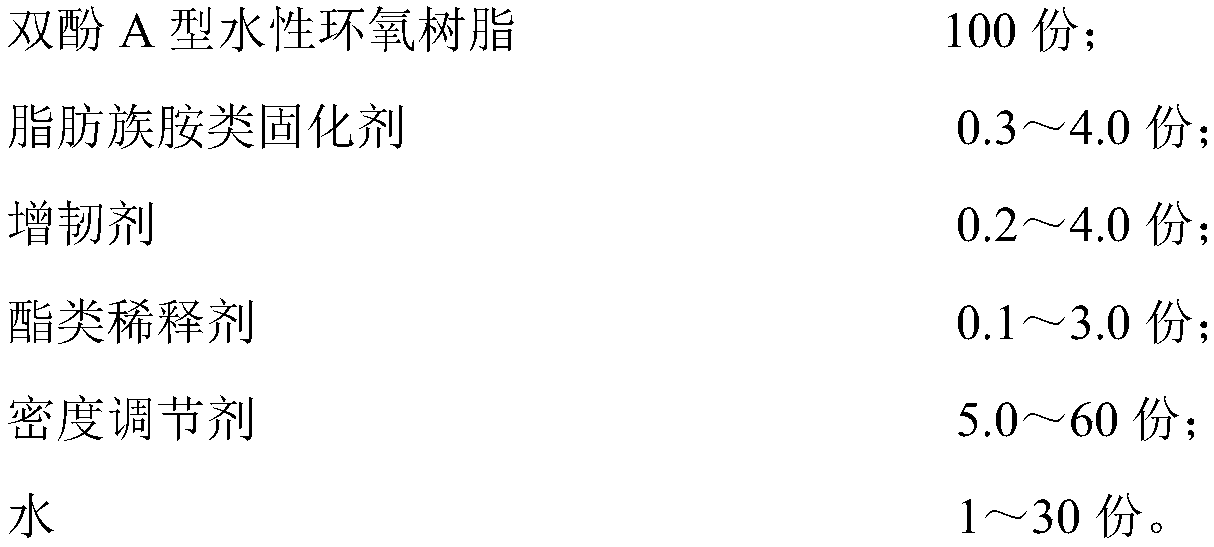

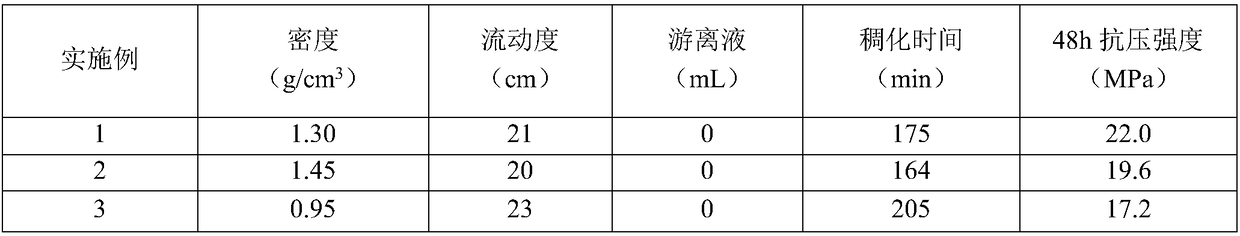

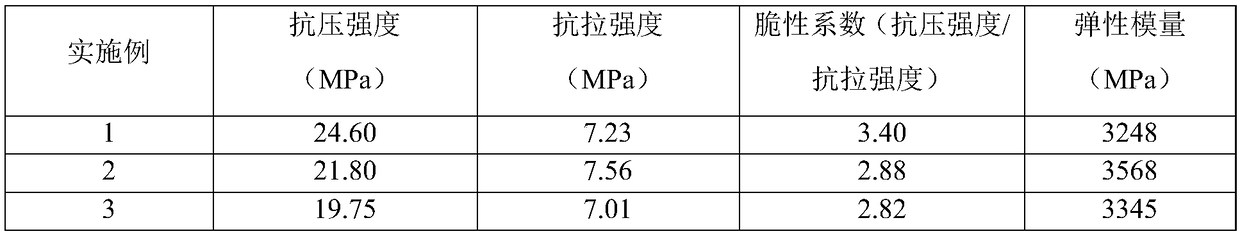

Thermosetting epoxy resin well cementation working solution

The invention discloses a thermosetting epoxy resin well cementation working solution which is prepared from the following ingredients in parts by weight: 100 parts of bisphenol A type waterborne epoxy resin, 0.3 to 4.0 parts of an aliphatic amine curing agent, 0.2 to 4.0 parts of a flexibilizer, 0.1 to 3.0 parts of an ester diluent, 5.0 to 60 parts of a density modifier and 1 to 30 parts of water, wherein the flexibilizer is a mixture of modified carbon nanotube and modified magnesium borate crystal whisker according to a part-by-weight proportion of 0.2 to 3.0; the modified nanotube is prepared by a carbon nanotube surface modifying method, the carbon nano tube is oxidized at first, and the carbon nano tube is treated by sodium hypochlorite; the modified magnesium borate crystal whiskeris prepared by a magnesium borate crystal whisker coupling treatment method. The thermosetting epoxy resin well cementation working solution disclosed by the invention has the characteristics of hightensile strength, high rupture strength and good toughness, can be directly applied to oil gas well cementation, also can be applied to repairing of damaged cement sheaths on which micro cracks arre generated and has a wide market application prospect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Backfill to buried pipe heat exchanger through hole

The present invention belongs to the field of building material technology, and is especially backfill material for buried pipe in earth source heat pump air conditioning system. The backfill material for buried pipe in earth source heat pump air conditioning system consists of cement 100 weight portions, quartzite 200-250 weight portions, defoaming agent 0.05-0.1 weight portion, bentonite 1-2 weight portions and water reducing agent 0.2-2 weight portions. When used, the said components are mixed while adding water in the construction site, and the mixture is injected into the drilled hole. The backfill material has high heat conducting coefficient, high operation performance, high impermeability, high strength and no environmental pollution.

Owner:山东中瑞新能源科技有限公司

Fruit and vegetable grafting aid solution

ActiveCN1907032AGood combinationImprove survival rateBiocidePlant growth regulatorsChemistryGrafting

Owner:WUXI MISHO ECOLOGY LANDSCAPE

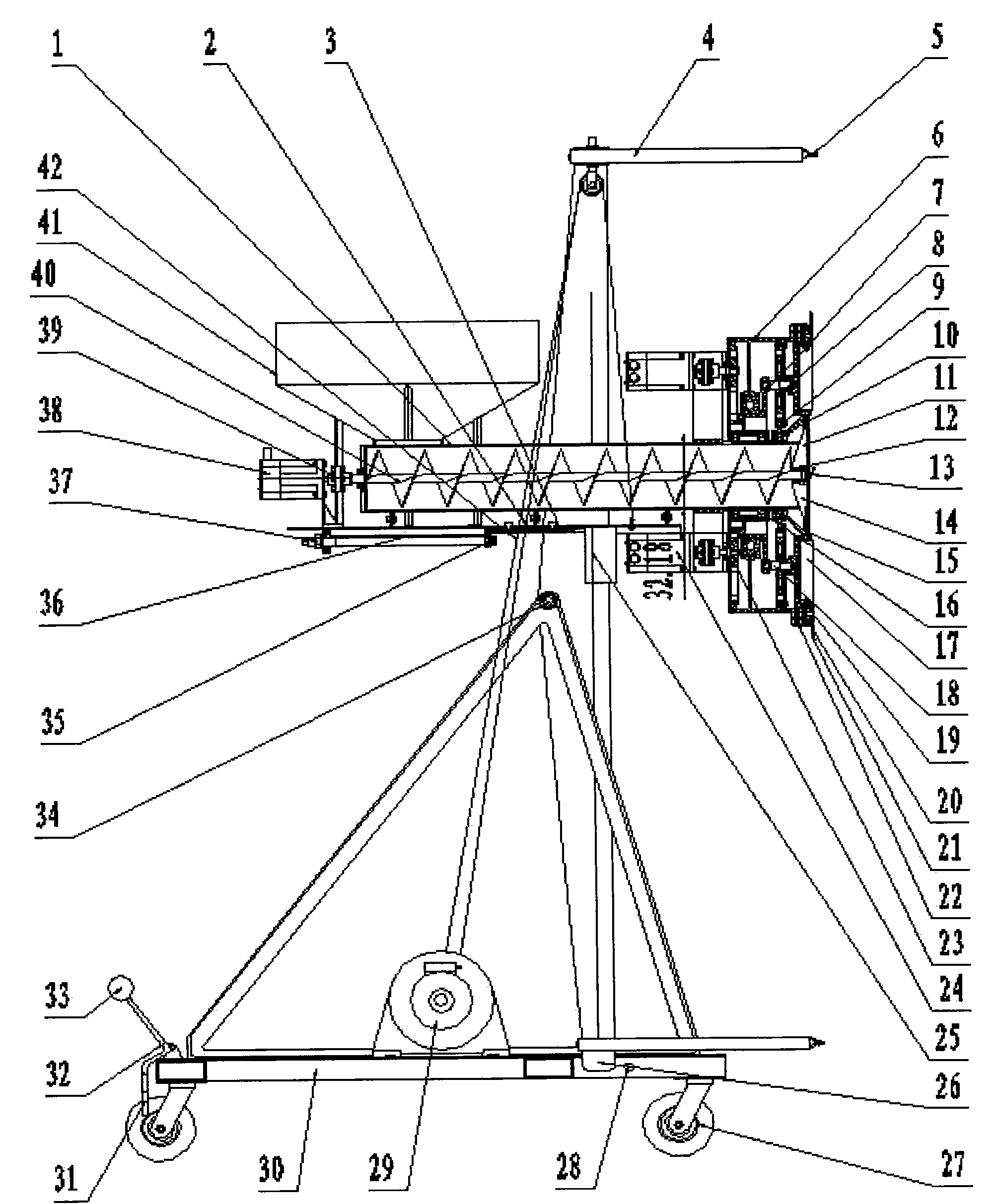

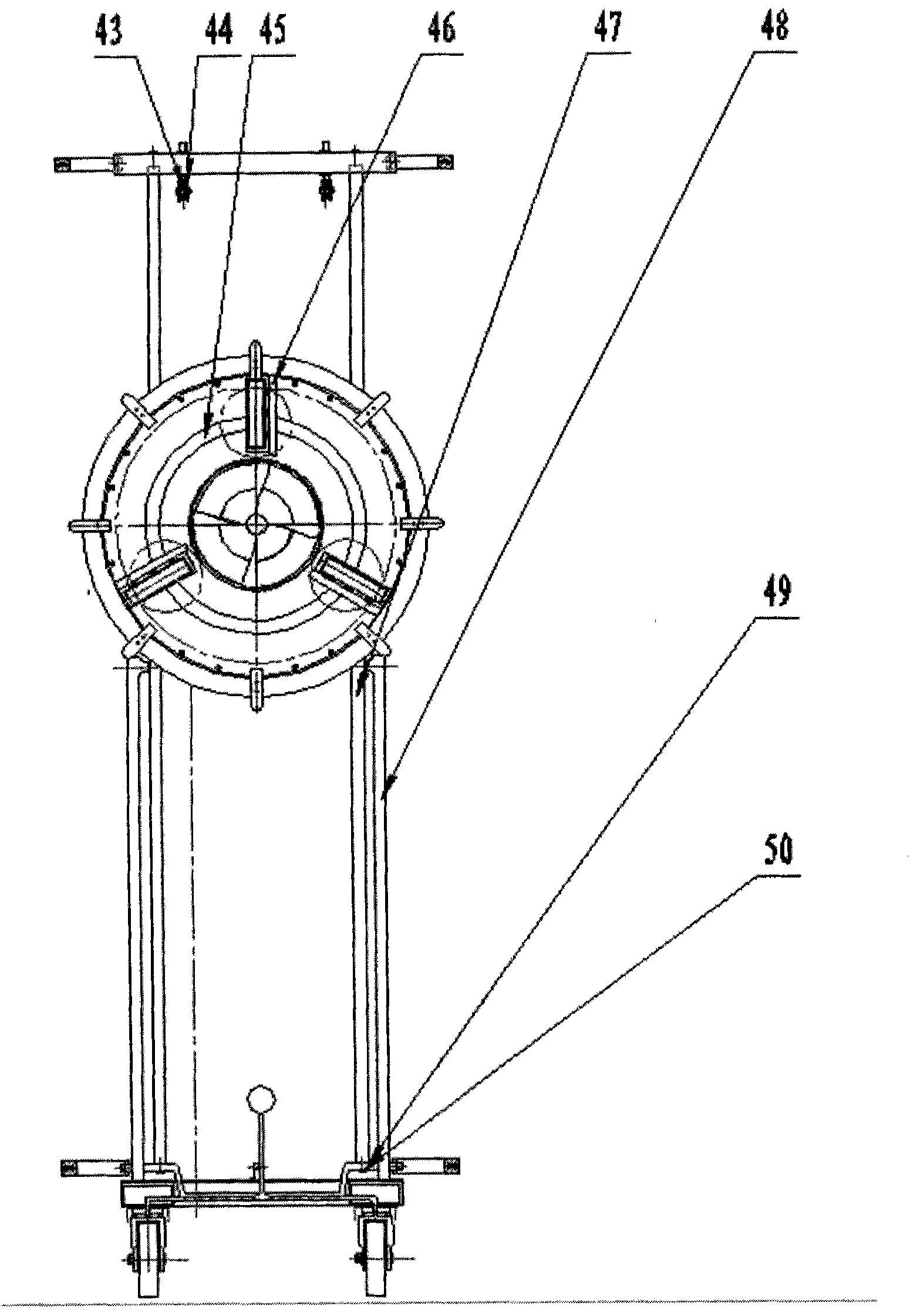

Differential type plastering device

InactiveCN102121306AImprove plastering efficiencyGood combinationBuilding constructionsSystem structureImpeller

The invention belongs to the technical field of building machinery, and relates to a differential type plastering device. The device comprises a mortar conveying mechanism, a differential plastering mechanism, an oscillation guide rail mechanism, a mortar thickness control device and a universal support cart, wherein the differential plastering mechanism is sleeved at the front end of a sleeve of a helical conveyor of the mortar conveying mechanism, is fixed along the axial direction, and is arranged on a support frame plate of the oscillation guide rail mechanism together with the mortar conveying mechanism through a support sliding plate, thus forming the core component of the differential type plastering device which is formed by variation of a differential wheel system structure; and the spiral conveyer of the mortar conveying mechanism conveys mortar to a centrifugal dash impeller on the end face of a small hollow central gear at the front end of the sleeve, so that the mortar is dashed to the wall surface. The differential type plastering device has a reasonable structure and excellent performance, can well simulate manual plastering, and can realize mechanical plastering for building walls.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

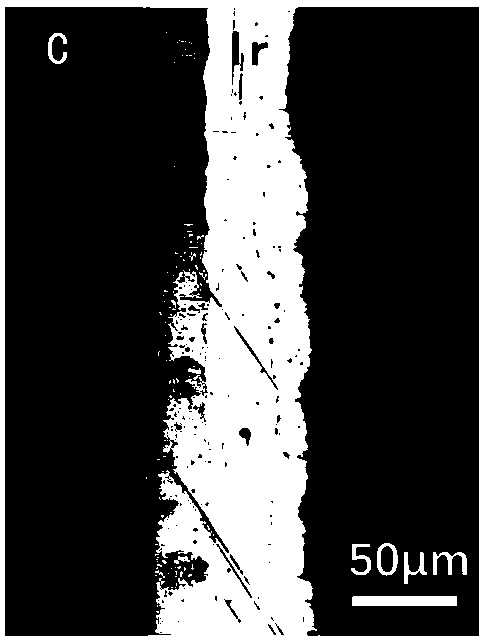

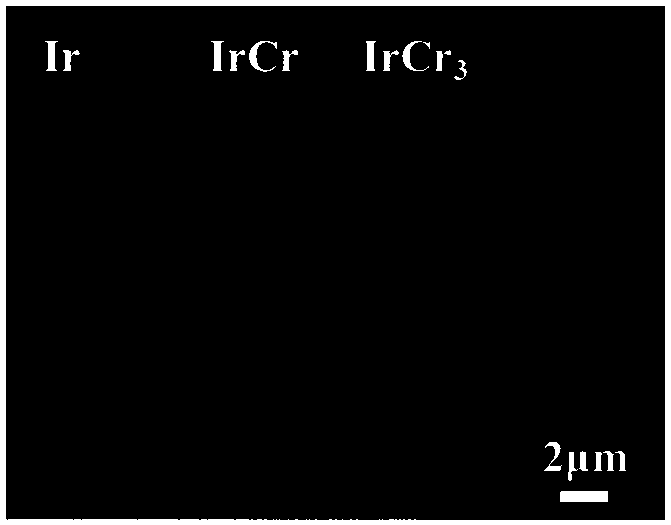

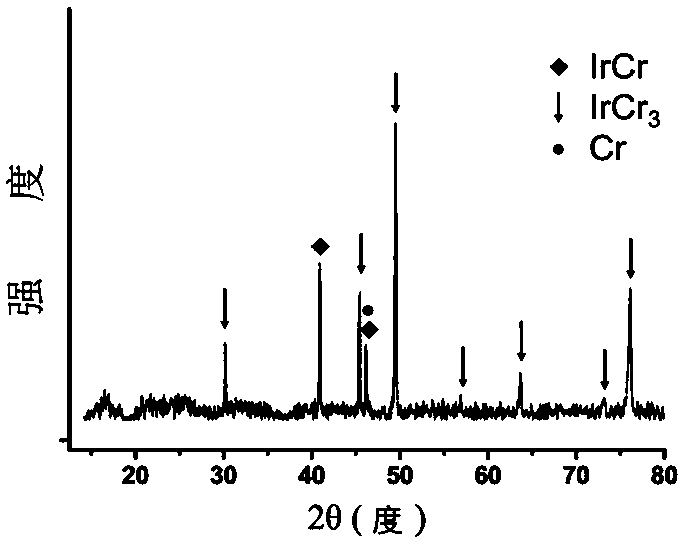

Ir-X coating based on surface alloying modification and preparation method thereof

InactiveCN107740039AControllable thicknessGood combinationSolid state diffusion coatingCoating systemIridium

The invention discloses an Ir-X coating based on surface alloying modification and a preparation method thereof. The preparation method of the Ir-X coating is characterized in that a transition layer,namely a rhenium coating and an iridium coating are deposited on a carbon composite material or a graphite substrate in sequence, and then metal X powder, metallic oxide XO powder corresponding to the metal X and a chloride activating agent are mixed to obtain a permeating agent, and a powder pack cementation method is adopted for enabling the iridium coating to be subjected to surface alloying modification, so as to obtain the Ir-X coating. The Ir-X coating based on surface alloying modification has a low surface catalytic effect and surface temperature in an aerodynamic environment, and isgreatly improved in service performance when compared with the conventional silicide coating system.

Owner:NAT UNIV OF DEFENSE TECH

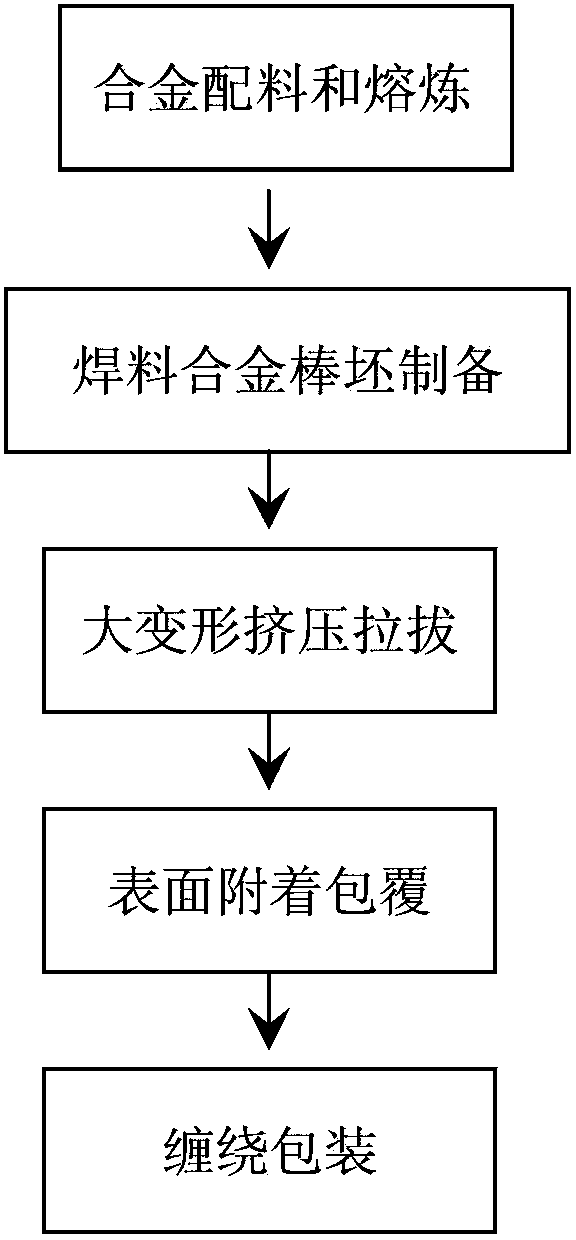

Anti-oxidation high-temperature soft-solder solid wire and manufacturing method thereof

InactiveCN104070303AImprove mechanical propertiesImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaManufacturing technologyConductor Coil

The invention relates to an anti-oxidation high-temperature soft-solder solid wire and a manufacturing method thereof and belongs to the technical field of solder production. The anti-oxidation solid wire comprises a high-temperature soft-solder solid wire and an anti-oxidation protective layer covering the solid wire. The high-temperature soft-solder solid wire comprises, by weight, Sn 2-15wt%, Ag 0-5wt%, one or multiple of P, Ge, Ga, Bi, Sb and Zn 0.01-1wt% and the balance Pb. Solder wires manufactured by the method effectively solve the problems such as black oxide of a surface layer of a lead-based solder, poor wetting during brazing without soldering flux and clamminess and damage to the surface of the solder wires in winding and use. The solder wires have the advantages of strong bonding strength, round welding spot, bright halation, good sealing performance, high reliability, long service life and the like in brazing and use.

Owner:BEIJING COMPO ADVANCED TECH

Polyvinyl chloride cable material with excellent mechanical properties

InactiveCN106674810AImprove insulation effectIncrease spacingPlastic/resin/waxes insulatorsBuilding insulationsEpoxyEthyl hydroxybenzoate

The invention discloses a polyvinyl chloride cable material with excellent mechanical properties. The polyvinyl chloride cable material is prepared from the following raw materials in parts by weight: 15-25 parts of polypropylene, 20-40 parts of polyvinyl chloride, 10-18 parts of epoxy resin, 4-8 parts of modified bentonite, 10-15 parts of silk fiber, 4-10 parts of illite, 3-9 parts of zinc borate, 2-6 parts of a silane coupling agent KH550, 8-12 parts of potassium titanate fiber, 6-12 parts of asbestos fiber, 1.5-3.5 parts of glyoxal, 0.4-1.2 parts of dioctyl adipate, 2-6 parts of coal tar, 0.7-1.1 parts of ethyl p-hydroxybenzoate, 10-20 parts of sweet potato flour, 0.8-1.6 parts of urea, 2-4 parts of tertiary butylhydroquinone and 6-10 parts of tall oil. The polyvinyl chloride cable material with excellent mechanical properties has good thermal insulation property, biodegradability, tensile property and shock resistance and has a low water absorption rate.

Owner:安徽新立电缆材料有限公司

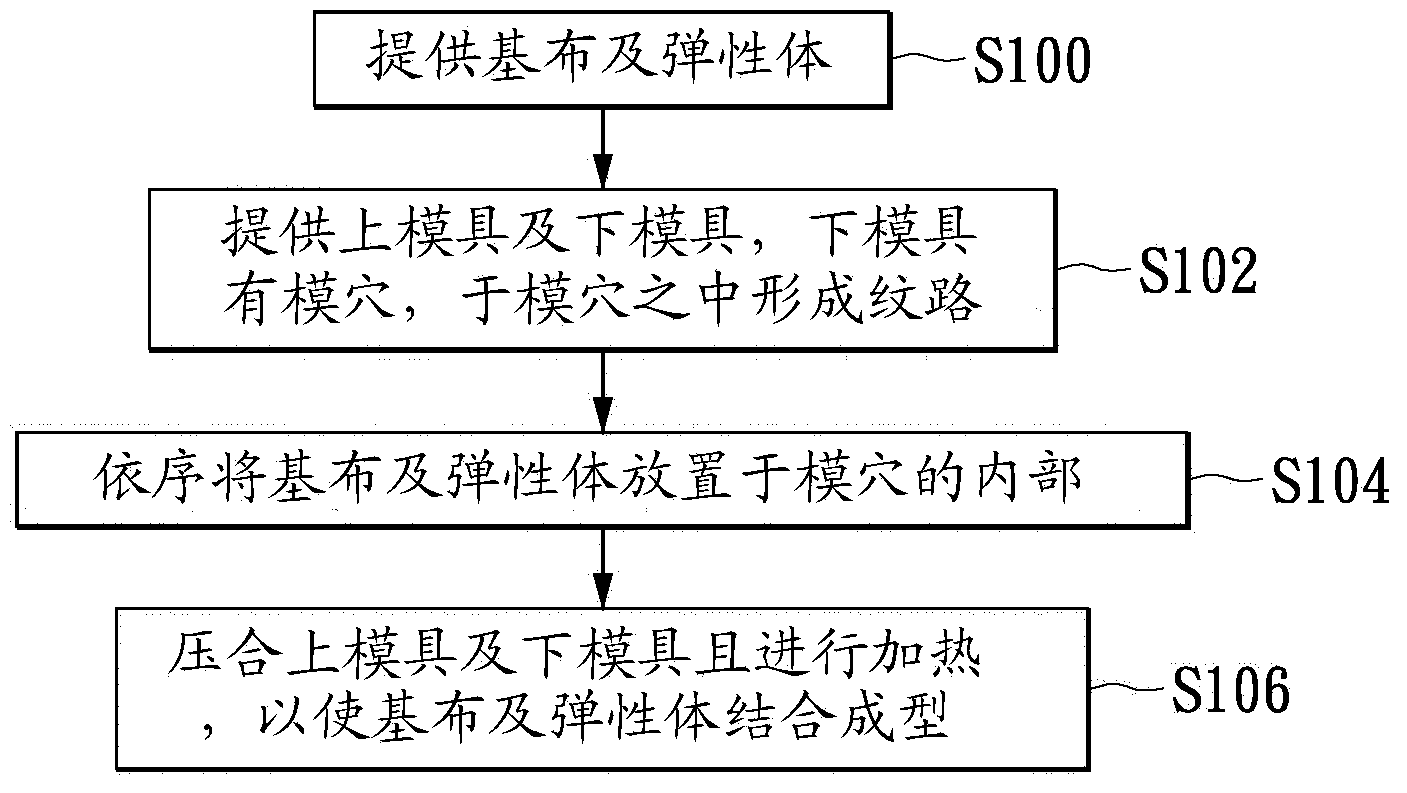

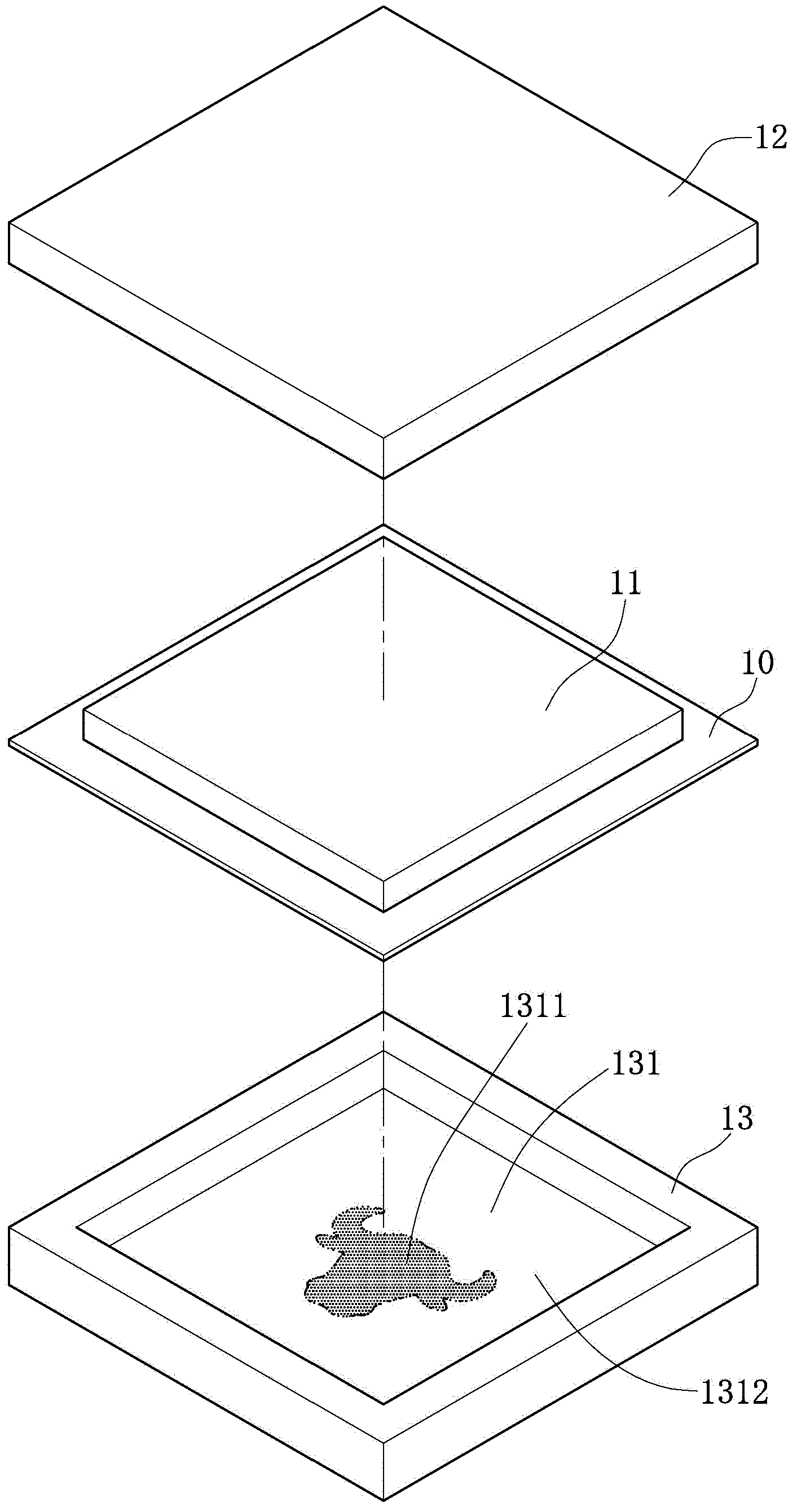

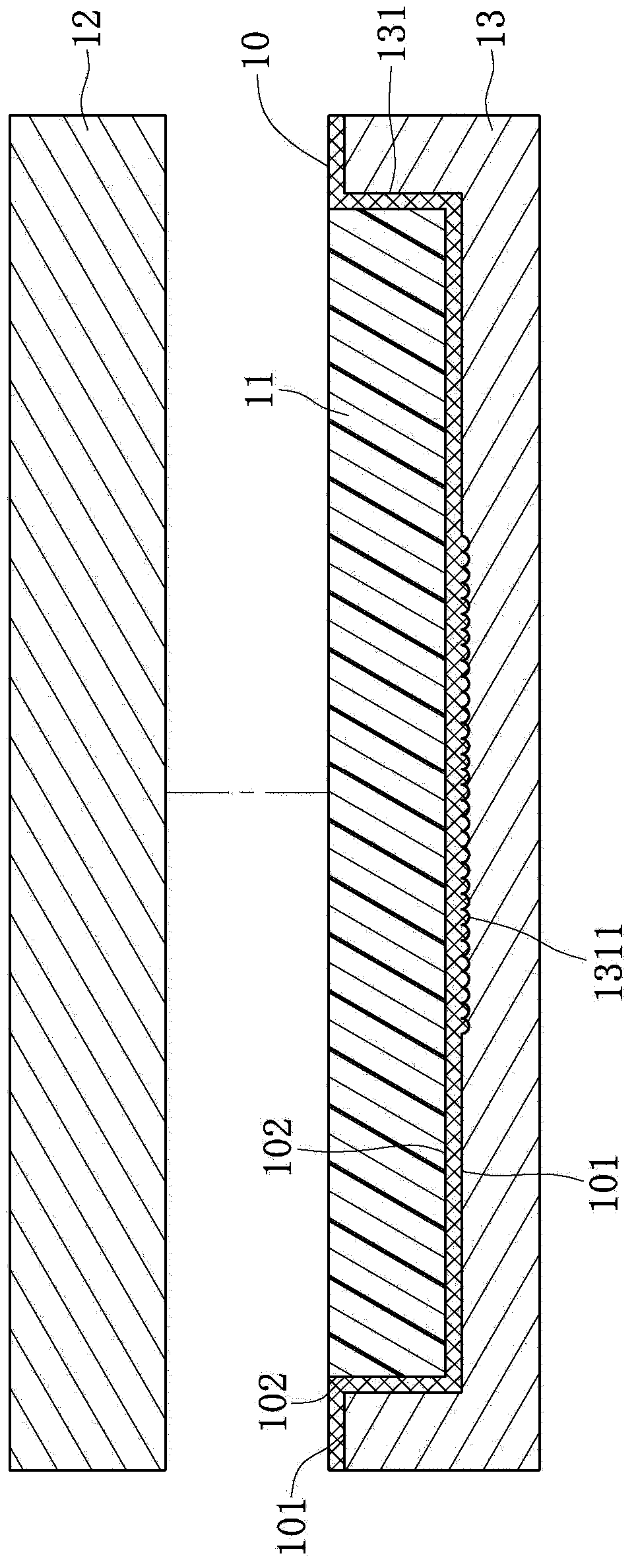

Mouse pad structure and manufacturing method for same

ActiveCN103576937AAdd beauty and textureGood combinationLaminationLamination apparatusMaterials scienceElastomer

Owner:HADES GAMING CORP

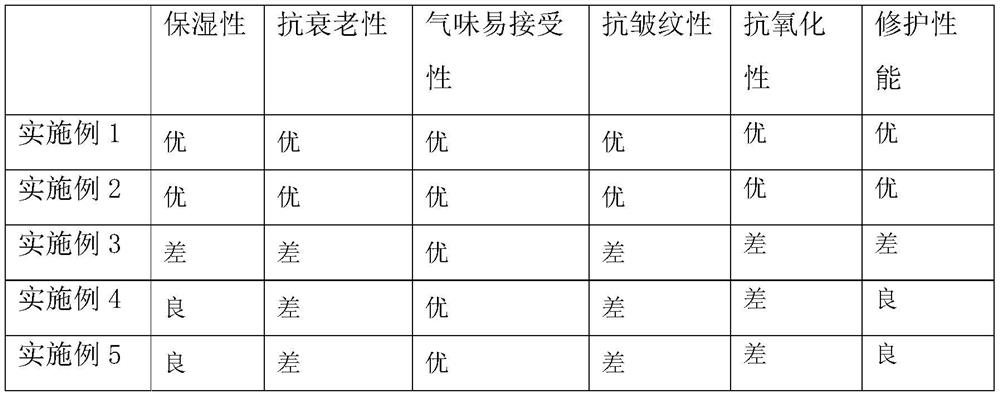

Moisturizing, repairing, anti-aging and anti-saccharificationcomposition and application thereof

PendingCN112891276AGood moisturizing effectImprove repair abilityCosmetic preparationsToilet preparationsBiotechnologyActive enzyme

The invention belongs to the technical field of skin care products, and particularly relates to a moisturizing, repairing, anti-aging and anti-saccharification composition and application thereof. The moisturizing, repairing, anti-aging and anti-saccharification composition is characterized by being prepared from the following raw materials in parts by weight: 0.1-8 parts of vitamin palmitates, 1-6 parts of vitamine, 1-20 parts of a plant extract, 0.1-4 parts of ergothioneine, 0.01-0.5 part of astaxanthin, 1-13 parts of argireline, 0.5-6 parts of fullerene, 0.1-6 parts of a peptide compound, 0.1-7 parts of hydrolyzed collagen, 0.01-0.2 part of an antioxidant active enzyme and 0.1-4 parts of a coenzyme. The composition in the technical scheme is applied to moisturizers, emulsions, creams, essence stock solutions and masks to keep the moisture and elasticity of cells, promote regeneration of damaged tissues, improve the repairing capacity of the skin, delay aging of the cells and improve the anti-aging capacity and anti-saccharification capacity of the skin.

Owner:皓雨(广州)化妆品制造有限公司

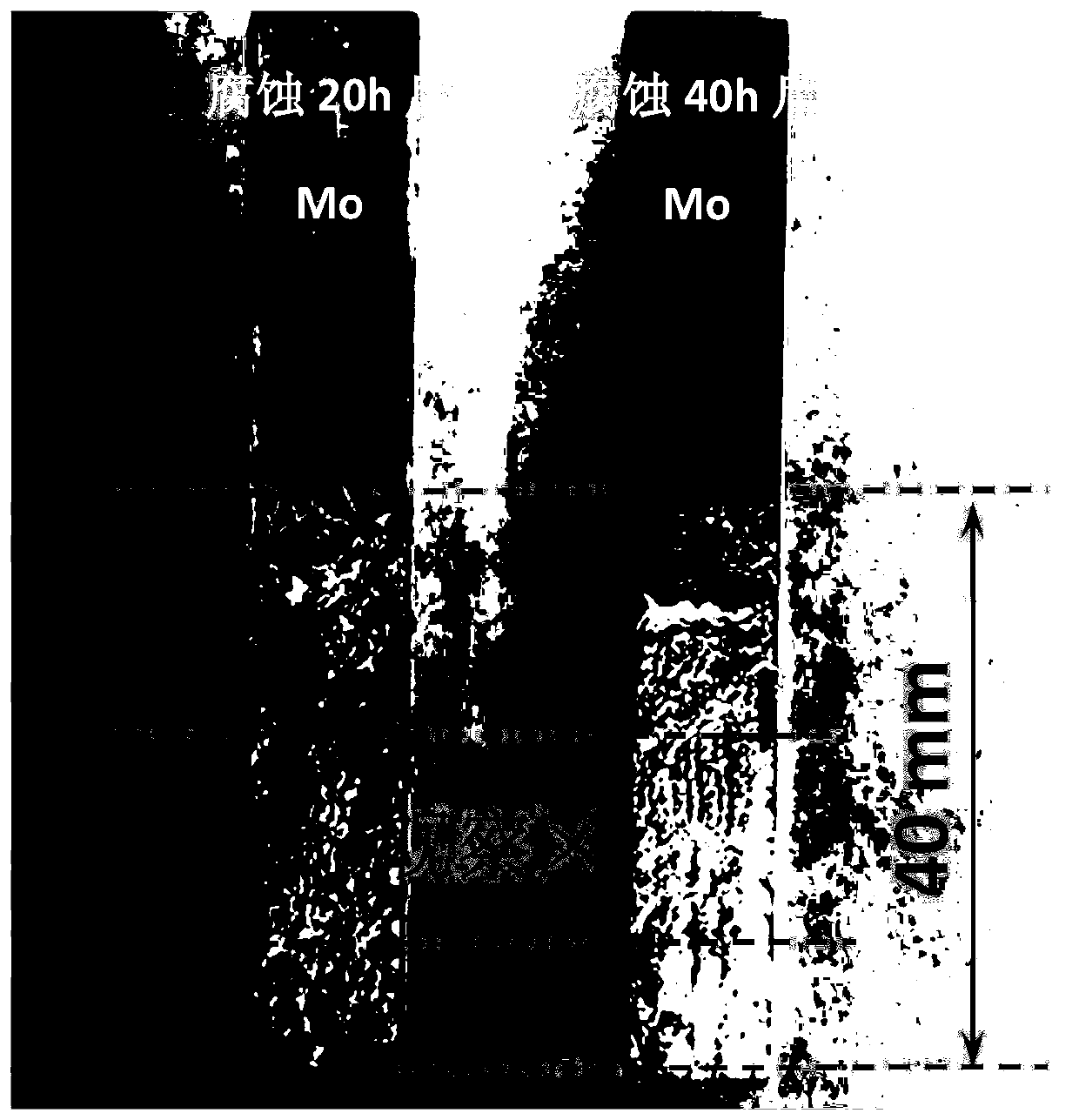

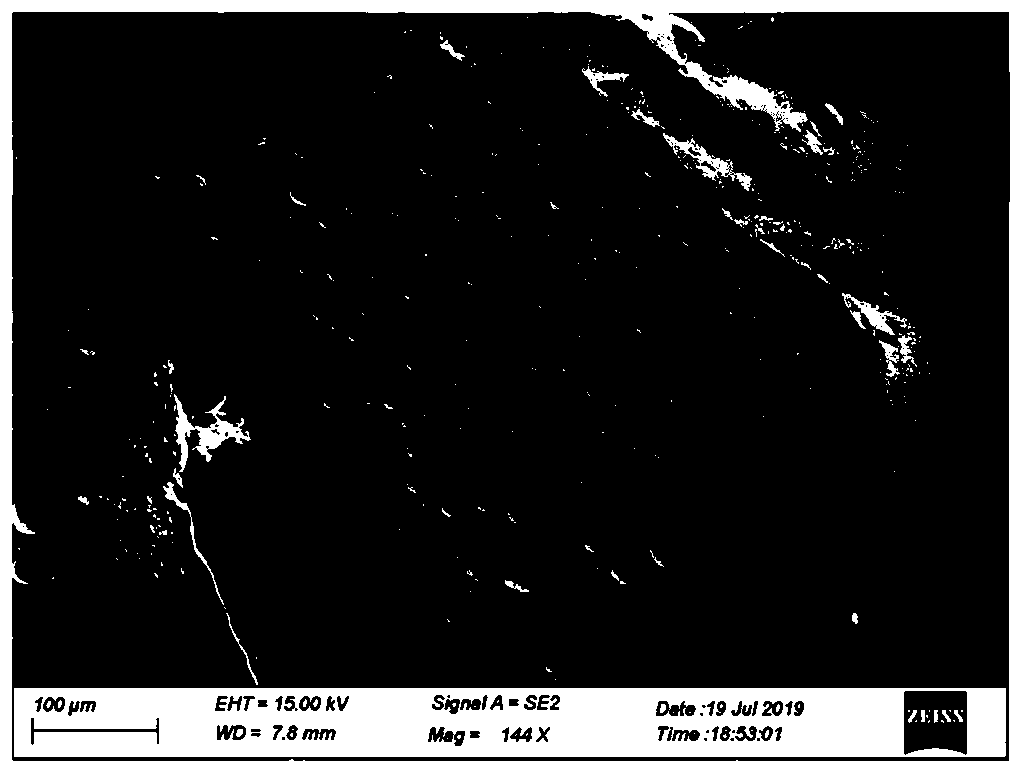

Preparation method of refractory metal molybdenum protective film resisting liquid lead-bismuth corrosion

ActiveCN111020552AGood stabilityGood combinationMetallic material coating processesMuffle furnacePowder metallurgy

The invention discloses a preparation method of a refractory metal molybdenum protective film resisting liquid lead-bismuth corrosion. The preparation method comprises the steps of preparing molybdenum by a powder metallurgy method, forging, extruding and processing the molybdenum into a rod, cutting the rod into an experimental sample, and performing annealing; placing a lead-bismuth alloy in a muffle furnace to be melted into liquid lead-bismuth alloy; inserting the molybdenum rod experimental sample into a crucible containing a liquid lead-bismuth alloy, keeping the temperature and the oxygen concentration in the crucible in a saturated state, and performing corroding; cooling the liquid lead-bismuth alloy, rapidly taking out the molybdenum rod experimental sample, and placing the molybdenum rod experimental sample on a stainless steel sheet for rapid cooling; and obtaining a compact PbMoO4 / Pb2MoO5 double-layer structure metal protective film. Through detection and characterization,specific components, morphology, thickness, compactness and other comprehensive information of the protective film are obtained. The PbMoO4 / Pb2MoO5 double-layer protective film prepared by the methodgreatly prolongs the service life of the refractory metal molybdenum in the liquid lead and bismuth, and accelerates the application of the refractory metal molybdenum in the liquid lead and bismuth.

Owner:XI AN JIAOTONG UNIV

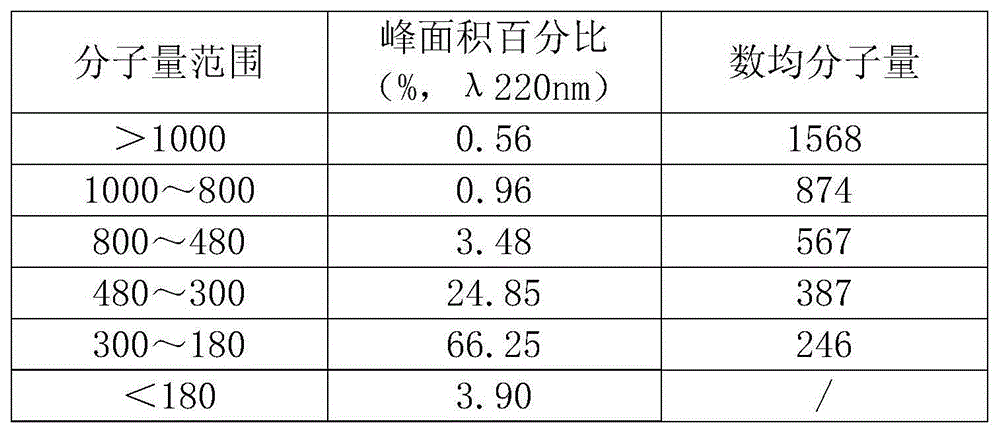

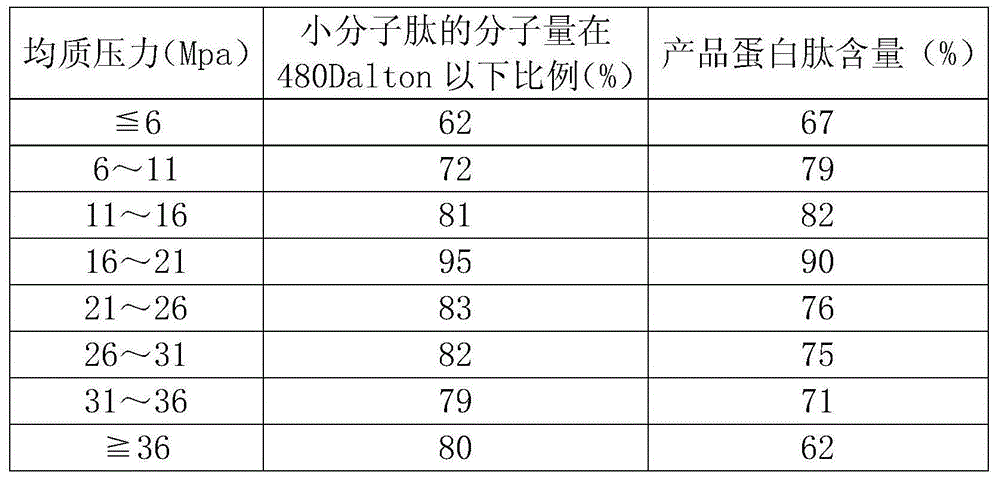

Method for preparing small molecule peptide by using compound enzyme to hydrolyze oyster protein

The invention relates to the technical field of preparation of small molecule peptide, in particular to a method for preparing the small molecule peptide by using compound enzyme to hydrolyze oyster protein. The method comprises the steps that firstly, oysters are cleaned, water and ficin are added to the cleaned oysters, and enzymolysis is conducted on the oysters to obtain oyster meat; secondly, the oyster meat is smashed, water is added into the smashed oyster meat, the smashed oyster meat and the added water are evenly stirred to obtain an oyster slurry liquid; thirdly, the compound enzyme is added, and enzymolysis and enzyme deactivation are performed to obtain enzymolysis liquid; fourthly, ultrafiltration is conducted on the enzymolysis liquid, the enzymolysis liquid is cooled and dried to obtain the oyster small molecule peptide. The method is simple in process and easy to operate, shells are removed through an enzymolysis device, time is saved, a production cycle is shortened, and the prepared protein peptide is the small molecule peptide, small in molecular weight and high in activity.

Owner:广西还珠海洋生物科技有限公司

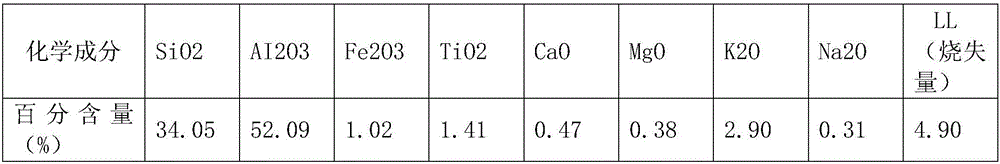

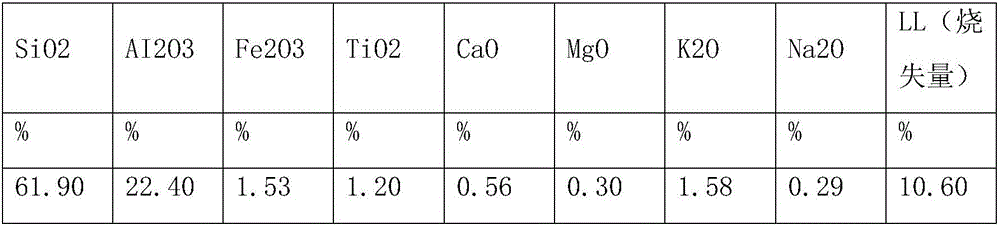

High-voltage porcelain insulating semiconductor glaze

The invention relates to the technical field of semiconductor glaze, and in particular relates to a high-voltage porcelain insulating semiconductor glaze. The semiconductor glaze is prepared from the following components in parts by weight: 25-35 parts of high-potassium and low-iron feldspar, 8-14 parts of mud, 4-10 parts of Dongsheng soil, 1-4 parts of calcined talc, 20-30 parts of quartz powder, 2-4 parts of barium carbonate, 12-18 parts of iron oxide red, 1-3 parts of chrome oxide green, 9-12 parts of titanium dioxide and 1-2 parts of spodumene. The semiconductor glaze is high in structure stability, fine in surface and glossy in surface, the eutectic point is reduced, and the melting efficiency is improved; and meanwhile, the combining capacity of the semiconductor glaze after being glazed is improved by adopting the Dongsheng soil and mud.

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

Cement dry-mixed mortar applicable to 3D printing and preparation method thereof

PendingCN109704672ADeformable associativityGood combinationAdditive manufacturing apparatusEmulsionFiber

The invention relates to the field of raw materials for 3D-printed buildings, specifically to a cement dry-mixed mortar applicable to 3D printing and a preparation method thereof. The cement dry-mixedmortar comprises the following components: cement, dry sand, an admixture, fiber, an additive, an acrylic emulsion, a water reducing agent and water. The cement dry-mixed mortar has deformability andgood bonding property, can deform and is insusceptible to cracking under external force, and still maintains an unchanged original shape when the external force is removed; when the cement dry-mixedmortar is utilized for 3D printing, a 3D-printed building can be rapidly molded and does not collapse under the state of no mold; the rheological characteristic of a traditional cement material is changed, and the cement dry-mixed mortar has dough-like plasticity; the cement dry-mixed mortar can be rapidly molded and does not collapse in the process of use, thereby achieving the purposes of capability of preparing a special-shaped member and continuous construction without arrangement of a mold; in addition, through formula components and the preparation method provided by the invention, the cement dry-mixed mortar can reach a strength of 35 MPa and an impermeability grade of P8.

Owner:北汇绿建集团有限公司

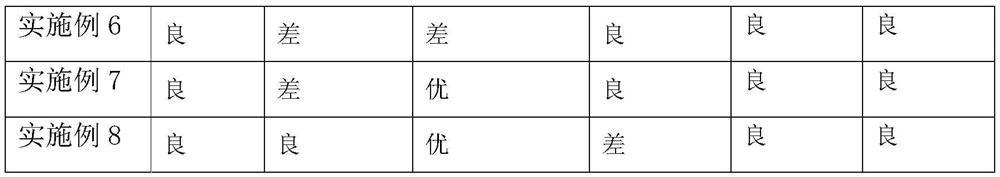

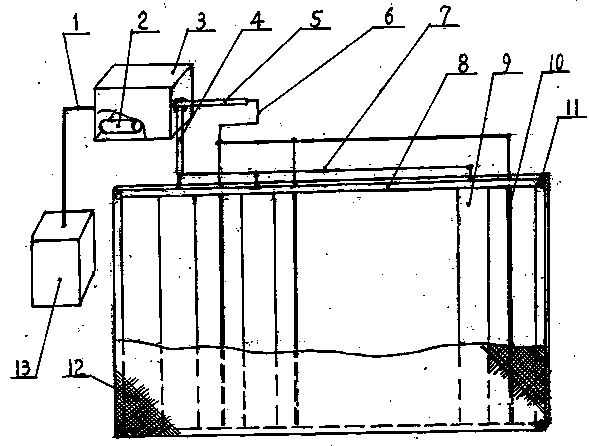

Isolation and elimination device for haze

InactiveCN103721847AGood combinationImprove bindingExternal electric electrostatic seperatorAir purifiersAir filter

The invention belongs to an environment-friendly dust removal device and in particular relates to an isolation and elimination device for haze. The isolation and elimination device comprises a power box (3), an insulation bracket (8), an ultrasonic atomizer (13) and air filter nets (12), wherein a plurality of positive electrode electrostatic dust collection nets (9) and negative electrode columns (10) are vertically fixed in the insulation bracket (8) at intervals; the upper ends of the positive electrode electrostatic dust collection nets (9) are connected with the power box (3) through a positive electrode wire (7) and a positive electrode cable (4); the negative electrode columns (10) are connected with the power box (3) through a negative electrode wire (6) and a negative electrode cable (5); a humidity sensor (2) is arranged on the power box (3); the other side of the power box (3) is connected with the ultrasonic atomizer (13) through an atomizer wire (1); the air filter nets (12) of which the sizes are the same as that of the insulation bracket (8) are arranged at four corners of the insulation bracket (8) through fixing screws (11). The isolation and elimination device for haze is suitable for static isolation in various rooms and has a good effect for the use after being combined with an air conditioner air purifier and the like.

Owner:黑龙江中凯泽生物科技有限公司

Composite CuNiIn powder, preparation method and application thereof

ActiveCN108425085AHigh strengthImprove the binding effectMolten spray coatingTransportation and packagingThermal sprayingUltimate tensile strength

The invention discloses composite CuNiIn powder, a preparation method and an application thereof. The composite CuNiIn powder comprises a dispersion strengthening phase and a self-lubricating phase. The preparation method comprises the following steps that ball milling and mixing on In powder, nickel-coated molybdenum disulfide powder and A12O3 dispersion strengthening Cu powder are carried out soas to prepare mixed raw materials; a spray drying granulator is adopted to carry out centrifugal atomization granulation on the mixed raw materials to prepare dried granules; and vacuum sintering iscarried out on the dried particles, and then the dried particles are crushed and screened to obtain the composite CuNiIn powder. The composite CuNiIn powder can be prepared into a composite CuNiIn coating containing the dispersion strengthening phase and the self-lubricating phase by adopting a thermal spraying method. The distribution state of the self-lubricating phase is changed, the strength and the toughness of the coating are improved, the generation of micro-cracks of the coating is effectively avoided, the self-lubricating service life of the coating is prolonged, and the composite CuNiIn powder has a good application value in the industries of aviation engines, gas turbines and the like.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

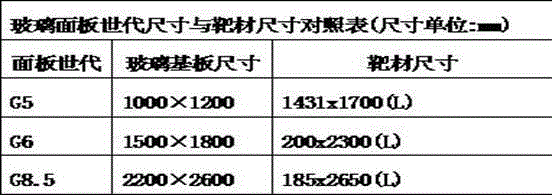

Continuous casting technology of belt material aluminum pipe and aluminum alloy rotating target materials

InactiveCN104907539AImprove microstructureImprove bindingVacuum evaporation coatingSputtering coatingBinding forceSteel tube

The invention discloses a continuous casting technology of a belt material aluminum pipe and aluminum alloy rotating target materials. The method comprises the steps of screened pipe preparing, aluminum or aluminum alloy melting and metal liquid casting and molding. By means of the technology, the micro-structure of the surface of the screened pipe is improved, the binding force between the metal aluminum and a steel pipe is increased, it is guaranteed that the metal aluminum in the liquid phase is combined with the steel pipe completely and firmly in the solidification process, and in the subsequent using process, it is guaranteed that the metal aluminum in the liquid phase is not separated from the steel pipe; all the elements are mixed uniformly, by controlling the atmosphere of a casting furnace body, the pouring speed and the cooling speed, it is guaranteed that the great micro-structure is obtained by the target materials, the combination degree between the target materials and the steel pipe is guaranteed, and air pores are prevented from occurring. The utilization rate of the target materials is improved, and the service lives of the target materials are prolonged; the production cost is reduced, the compactness of the target materials is high, gains are uniform in size and distribution, and the technology is applicable to the manufacturing of connecting membranes of flat display panels.

Owner:GEMCH MATERIAL TECH SUZHOU

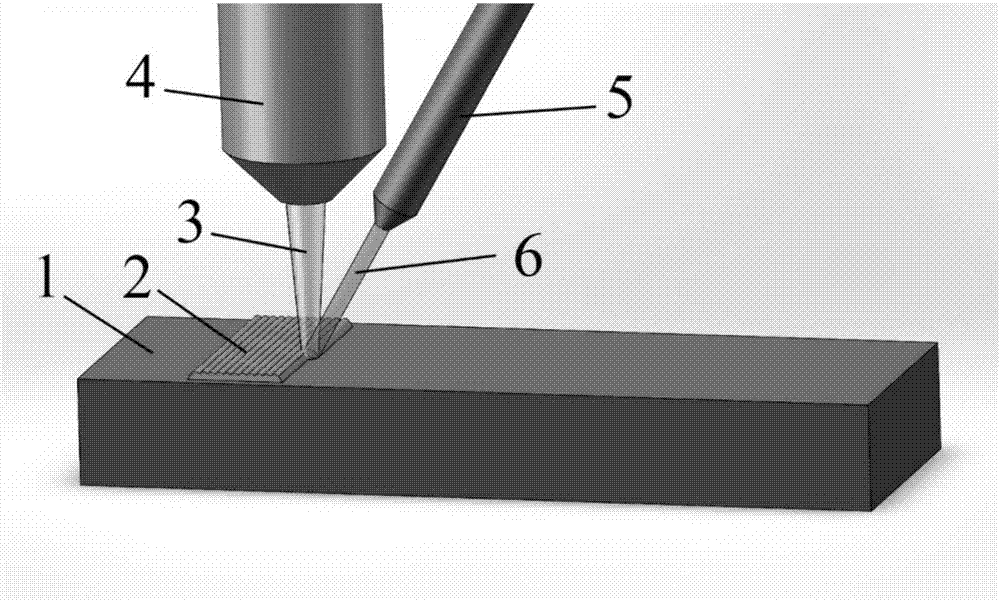

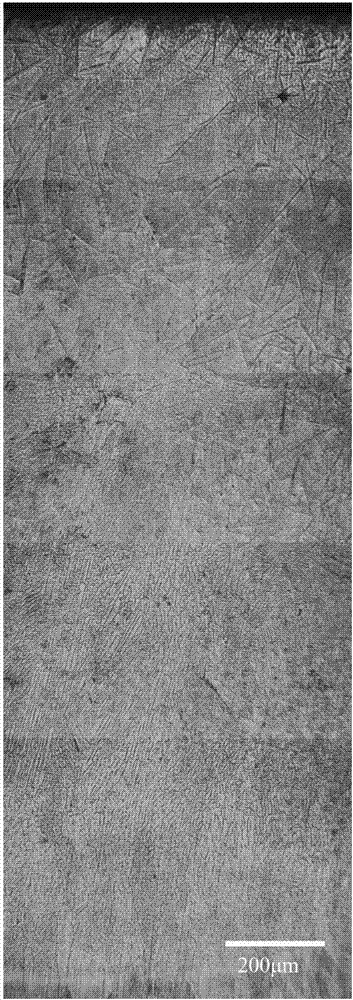

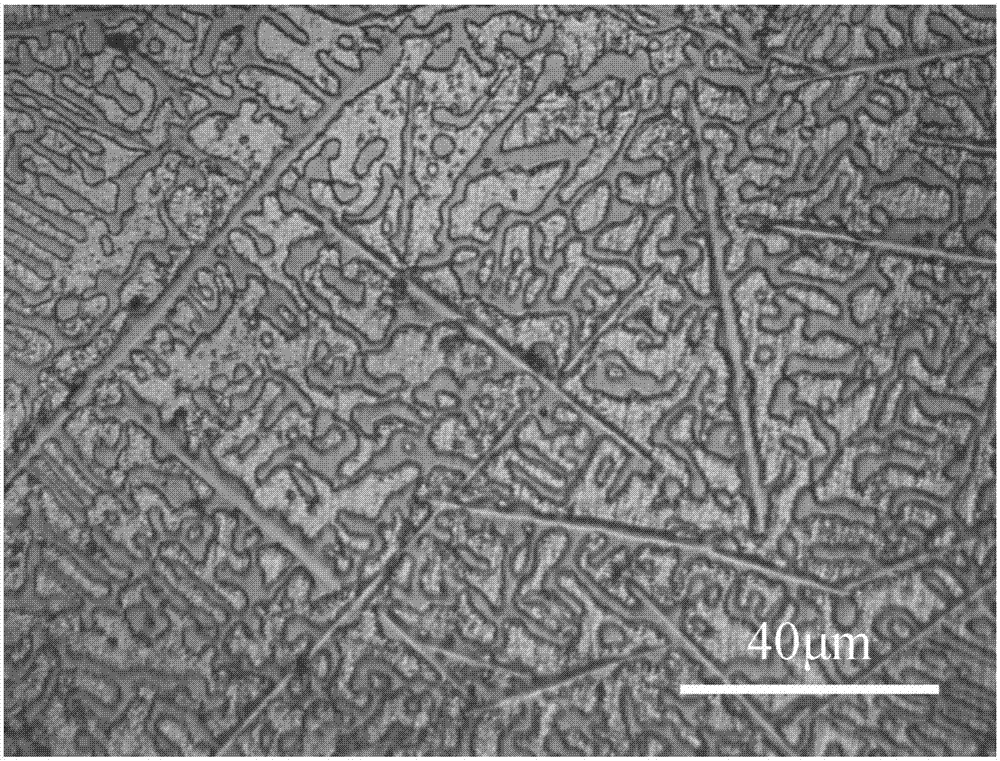

Preparation method of fine copper surface laser in-situ synthesis ceramic reinforced cladding layer

ActiveCN107299343AGood combinationEnhancement effect is goodMetallic material coating processesCopper matrixHardness

The invention discloses a preparation method of a fine copper surface laser in-situ synthesis ceramic reinforced cladding layer. The method comprises the following steps: preparing cladding powder; pretreating the surface of a to-be-cladded fine copper matrix; rapidly fusing the cladding powder on the surface of the fine copper matrix by using a laser cladding device in a synchronous powder feeding mode, and forming the ZrB2-ZrC-Al2O3 ceramic reinforced cladding layer. According to the obtained cladding layer, the composite ceramic cladding layer and the matrix are well combined, no pore and impurity are produced, the content of a synthesized ceramic reinforced phase increases and is in graded distribution from the matrix to the surface in the cladding layer, meanwhile, three different ceramic phases are generated, the morphological structures of the ceramic phases are different, and the hardness is obviously improved.

Owner:YANSHAN UNIV

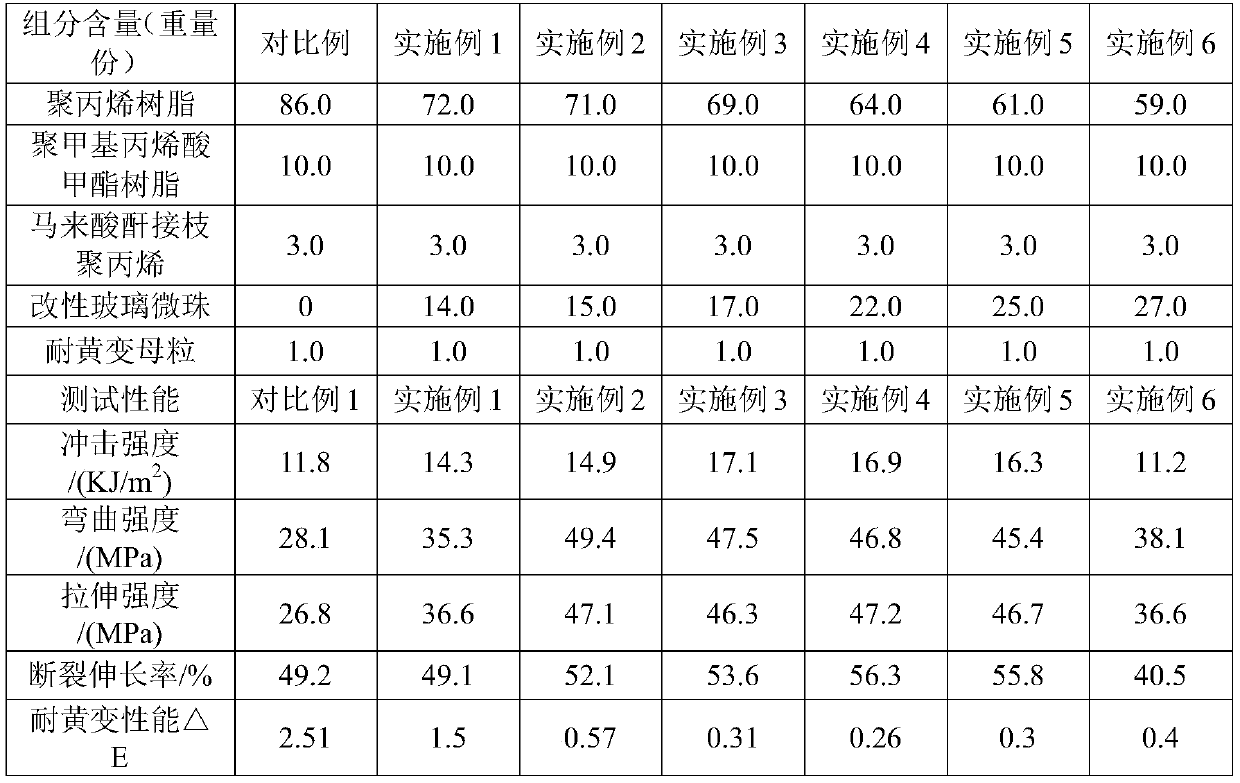

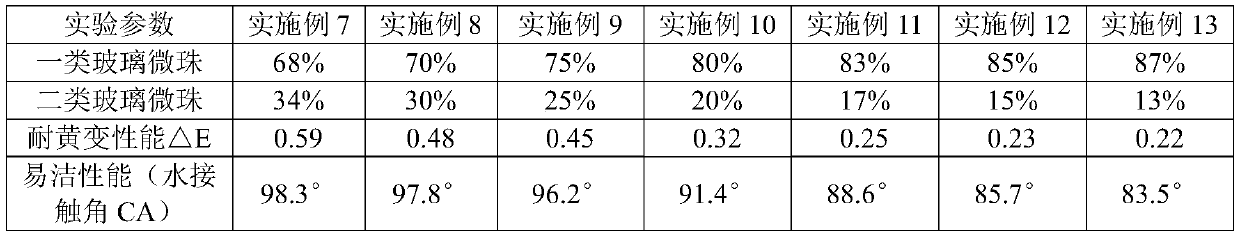

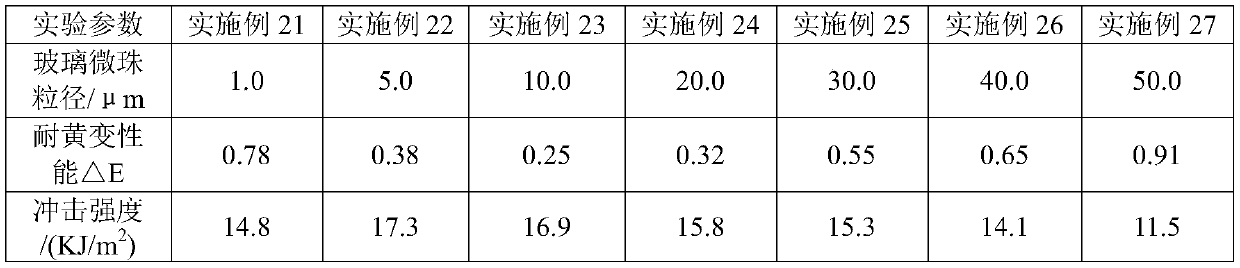

Modified glass microsphere and preparation method thereof and method for preparing composite resin product by using modified glass microsphere

The invention discloses a modified glass microsphere and a preparation method thereof and a method for preparing a composite resin product by using the modified glass microsphere. The modified glass microsphere includes a first class glass microsphere and a second class glass microsphere, a discontinuous metal layer and an ultraviolet absorbent wrap the surface of the first class glass microsphere, a hydrophobic material wraps the surface of the second class glass microphere, the coverage rate of the metal layer on the surface of the first glass microsphere is 45.0%-85.0%, and the modified glass microbead is added into the component of a common anti-yellowing product to improve the anti-yellowing property and the mechanical property of the product.

Owner:JOMOO KITCHEN & BATHROOM

Integrated circuit board and its manufacturing method

InactiveCN1913205AGood anti-corrosion effectGood combinationFinal product manufactureElectrode carriers/collectorsIntegrated circuitNickel

This invention relates to a collecting board including: a collecting board matrix, a Ni layer on the surface of the board and a golden layer on the surface of the NI layer, in which, said board is a metal material matrix, one Ni layer is formed on the matrix then a golden layer on the Ni layer. Since the Ni layer has good anti-corrosion effect and very well combined with the matrix and the golden layer with good conductivity and small contact resistance.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com