Method for preparing small molecule peptide by using compound enzyme to hydrolyze oyster protein

A compound enzymatic hydrolysis and small molecular peptide technology, which is applied in the field of small molecular peptide preparation, can solve the problems of large molecular weight, etc., and achieve the effects of small molecular weight, shortened enzymatic hydrolysis time, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Wash the oysters, add water 7 times the weight of the oysters, then add ficin at 0.03% of the weight of the oysters, adjust the pH value to 4.7, heat up to 54°C, enzymatically hydrolyze for 20 minutes, and take the oyster meat;

[0024] (2) Break the oyster meat into pieces, add water 4 times its weight, and stir evenly to obtain the oyster slurry;

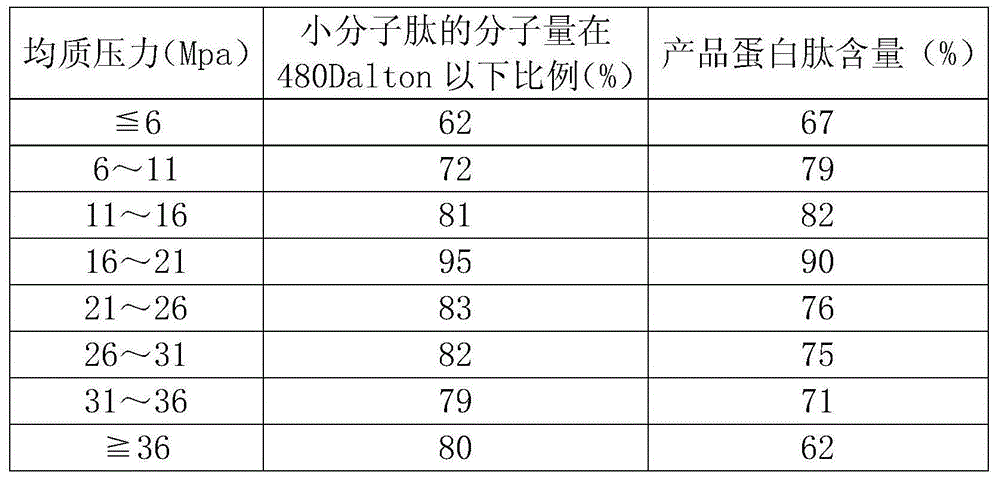

[0025] (3) Add 0.09% compound enzyme by weight of oyster meat, adjust the pH to 6.5, raise the temperature to 46°C, under the pressure of 16Mpa, homogenize for 140min, raise the temperature to 75°C to kill the enzyme, and obtain the enzymatic solution, Described composite enzyme is the mixture of ficin, pronase and subtilisin with a weight ratio of 4:2:1;

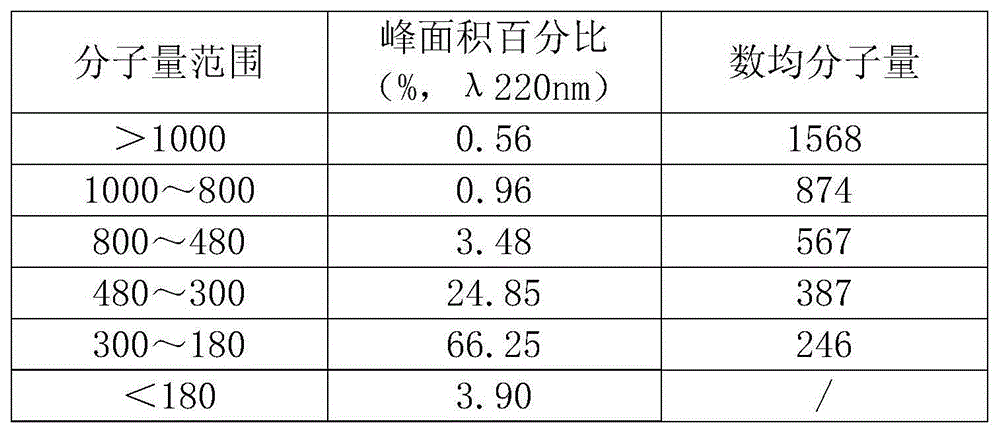

[0026] (4) Ultrafiltration and freeze-drying of the enzymatic hydrolyzate to obtain oyster small molecule peptides.

Embodiment 2

[0028] (1) Wash the oysters, add water 8 times the weight of the oysters, then add 0.04% of the weight of the oysters ficin, adjust the pH value to 4.9, heat up to 52°C, enzymatically hydrolyze for 18 minutes, and take the oyster meat;

[0029] (2) Break the oyster meat into pieces, add water 3 times its weight, and stir evenly to obtain the oyster slurry;

[0030] (3) Add 0.08% compound enzyme by weight of oyster meat, adjust the pH to 5.3, raise the temperature to 47°C, under the pressure of 17Mpa, homogenize for 130min, raise the temperature to 76°C to inactivate the enzyme, and obtain the enzymatic solution, Described composite enzyme is the mixture of ficin, pronase and subtilisin with a weight ratio of 4:2:1;

[0031] (4) Ultrafiltration and freeze-drying of the enzymatic hydrolyzate to obtain oyster small molecule peptides.

Embodiment 3

[0033] (1) Wash the oysters, add water 9 times the weight of the oysters, then add 0.05% of the weight of the oysters ficin, adjust the pH value to 4.8, heat up to 53°C, enzymatically hydrolyze for 15 minutes, and take the oyster meat;

[0034] (2) Break the oyster meat into pieces, add water 3 times its weight, and stir evenly to obtain the oyster slurry;

[0035] (3) Add 0.07% compound enzyme by weight of oyster meat, adjust the pH to 5.9, increase the temperature to 49°C, and homogenize for 120min under a pressure of 18Mpa, and increase the temperature to 77°C to inactivate the enzyme to obtain an enzymatic hydrolysis solution, Described composite enzyme is the mixture of ficin, pronase and subtilisin with a weight ratio of 4:2:1;

[0036] (4) Ultrafiltration and freeze-drying of the enzymatic hydrolyzate to obtain oyster small molecule peptides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com