Preparation method of fine copper surface laser in-situ synthesis ceramic reinforced cladding layer

An in-situ autogenous, laser cladding technology, applied in the direction of coating, metal material coating process, etc., can solve the problem of poor bonding between ceramic materials and copper, achieve significant enhancement effect, reduce thermal stress cracking, and good bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

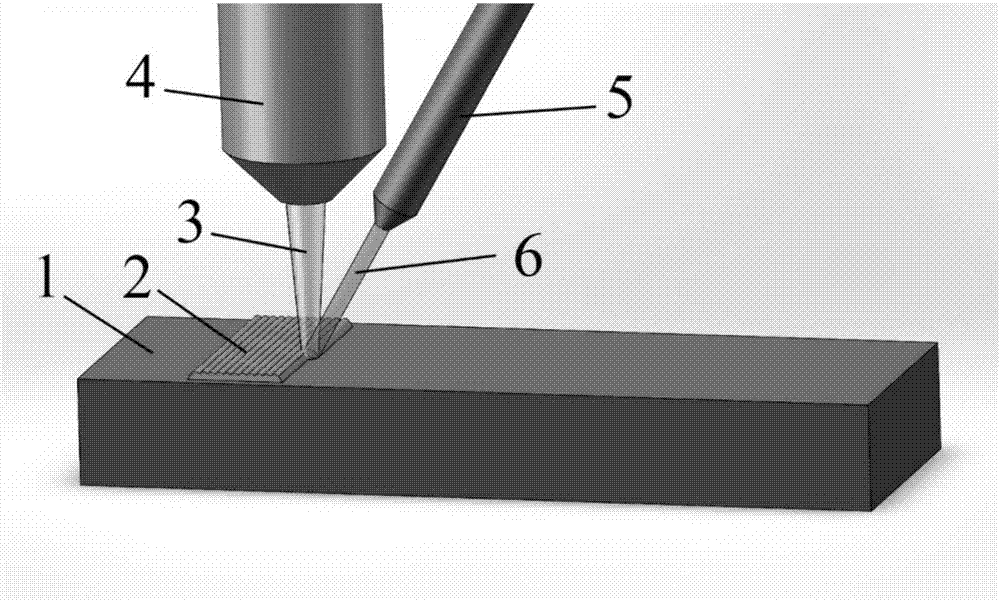

[0037] A method for preparing a laser in-situ self-generated ceramic reinforced cladding layer on a pure copper surface, comprising the following steps:

[0038] Prepare cladding powder, the amount of each component is by weight percentage: 2.03% Al powder, 6.94% ZrO 2 powder, 1.73% Ni package B 4 C powder, 9.30% Ni powder, 80% Cu powder; after accurately weighing the above powder, put it into a V-shaped mixer, stir it at a speed of 15r / min for 2 hours, then put the cladding powder into a drying box, and Dry at 120°C for 1 hour to remove moisture from the powder to obtain cladding powder.

[0039] Surface pretreatment of the pure copper substrate to be clad, use sandpaper to polish the pure copper substrate to be clad to remove surface stains and oxides; use absolute ethanol to wipe the surface of the pure copper substrate to be clad; use a brush to clean the pure copper substrate Paint a layer of carbon ink on the surface, put it in a drying oven, and dry it at 120°C for 10...

Embodiment 2

[0043] A method for preparing a laser in-situ self-generated ceramic reinforced cladding layer on a pure copper surface, comprising the following steps:

[0044] Prepare cladding powder, the amount of each component is by weight percentage: 4.06% Al powder, 13.88% ZrO 2 powder, 3.46% Ni package B 4 C powder, 18.6% Ni powder, 60% Cu powder; after accurately weighing the above powder, put it into a V-type mixer, stir it at a speed of 15r / min for 2 hours, then put the cladding powder into a drying box, and Dry at 120°C for 1 hour to remove moisture from the powder to obtain cladding powder.

[0045] Surface pretreatment of the pure copper substrate to be clad, use sandpaper to polish the pure copper substrate to be clad to remove surface stains and oxides; use absolute ethanol to wipe the surface of the pure copper substrate to be clad; use a brush to clean the pure copper substrate Paint a layer of carbon ink on the surface, put it in a drying oven, and dry it at 120°C for 10 ...

Embodiment 3

[0049] A method for preparing a laser in-situ self-generated ceramic reinforced cladding layer on a pure copper surface, comprising the following steps:

[0050] Prepare cladding powder, the amount of each component is by weight percentage: 6.09% Al powder, 20.82% ZrO 2 powder, 5.19% Ni package B 4 C powder, 27.90% Ni powder, 40% Cu powder; after accurately weighing the above powder, put it into a V-type mixer, stir at a speed of 15r / min for 2 hours, then put the cladding powder into a drying box, and Dry at 120°C for 1 hour to remove moisture from the powder to obtain cladding powder.

[0051] Surface pretreatment of the pure copper substrate to be clad, use sandpaper to polish the pure copper substrate to be clad to remove surface stains and oxides; use absolute ethanol to wipe the surface of the pure copper substrate to be clad; use a brush to clean the pure copper substrate Paint a layer of carbon ink on the surface, put it in a drying oven, and dry it at 120°C for 10 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average microhardness | aaaaa | aaaaa |

| Average microhardness | aaaaa | aaaaa |

| Average microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com