Integrated circuit board and its manufacturing method

A manufacturing method and technology of collector plates, which are applied to electrode carriers/current collectors, circuits, electrical components, etc., can solve problems such as poor bonding, poor anticorrosion performance of collector plates, and corrosion of gold layers, and achieve good electrical conductivity, The best anti-corrosion effect, the effect of the best anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] The method for making a collector plate provided by the first embodiment of the present invention includes the following steps:

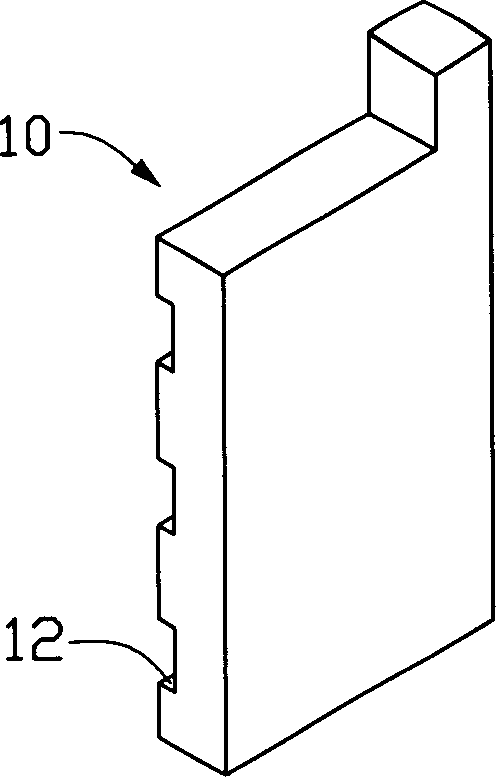

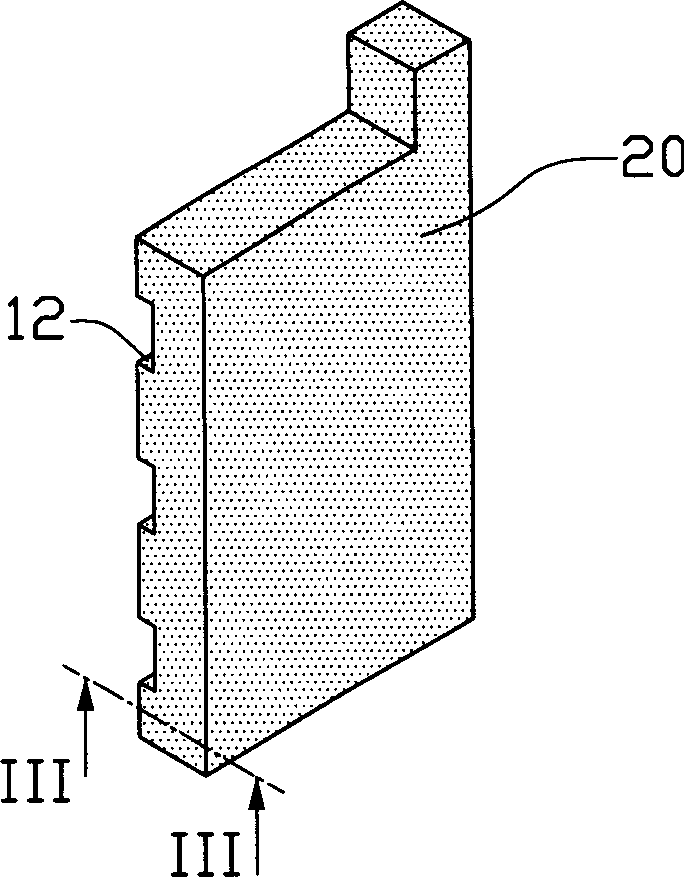

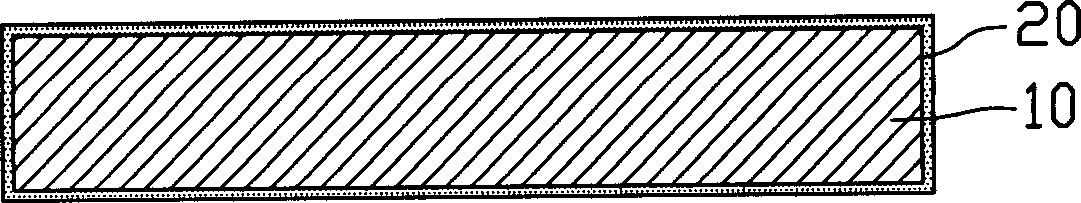

[0033] see figure 1 , first provide a current collector base 10 . The specific steps are:

[0034] Firstly, a metal plate such as a brass plate, stainless steel plate or aluminum plate is provided, which is machined into a prototype of the current collector plate, that is, the base 10 of the current collector plate. At least one surface of the current collector plate base 10 is formed with a plurality of guide grooves 12 for the entry and exit of fuel cell reactants, products and cooling fluid. In this embodiment, a single surface of the current collector plate base 10 has a guide groove 12, which can be used as an outer current collector plate for a fuel cell. Of course, flow guide grooves can also be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com