Cation light cured anti-corrosive coating

An anti-corrosion coating and cationic technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of loss of comprehensive performance and anti-corrosion performance of the coating film, and achieve the effect of strong corrosion resistance and good anti-corrosion effect.

Inactive Publication Date: 2013-01-02

SNTO TECH GRP

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the introduction of small molecule active diluents will cause a great loss to the overall performance of the coating film, especially the anti-corrosion performance, while improving the viscosity and reaction speed of the system.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

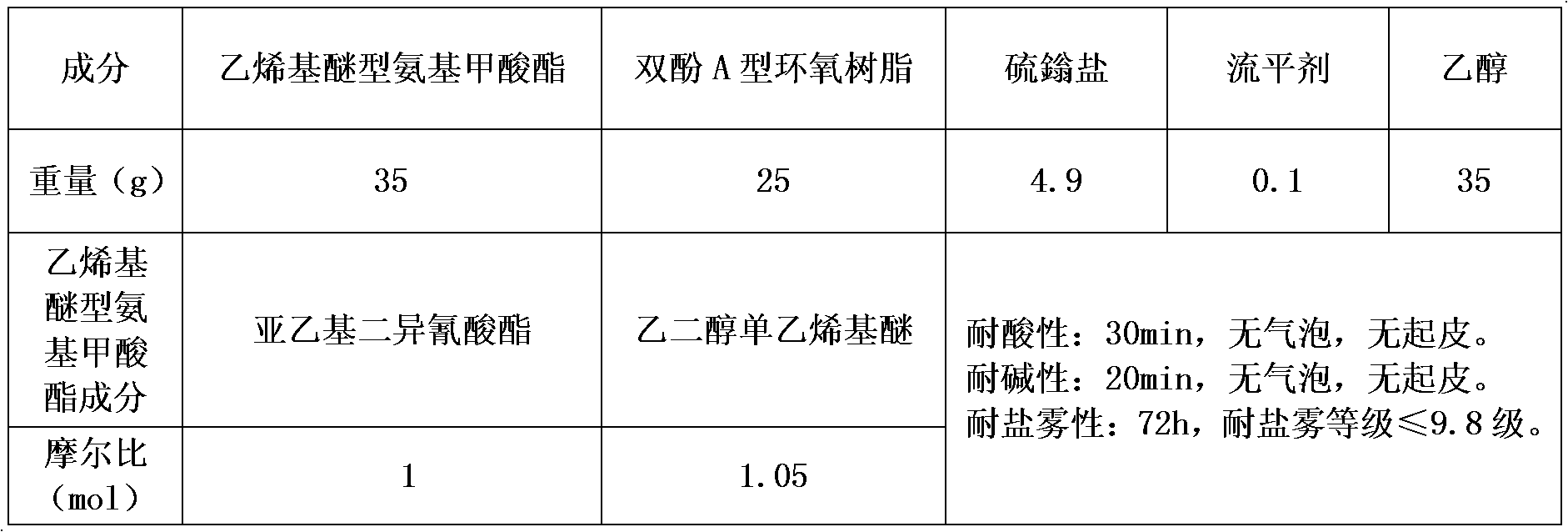

Embodiment 1

[0025]

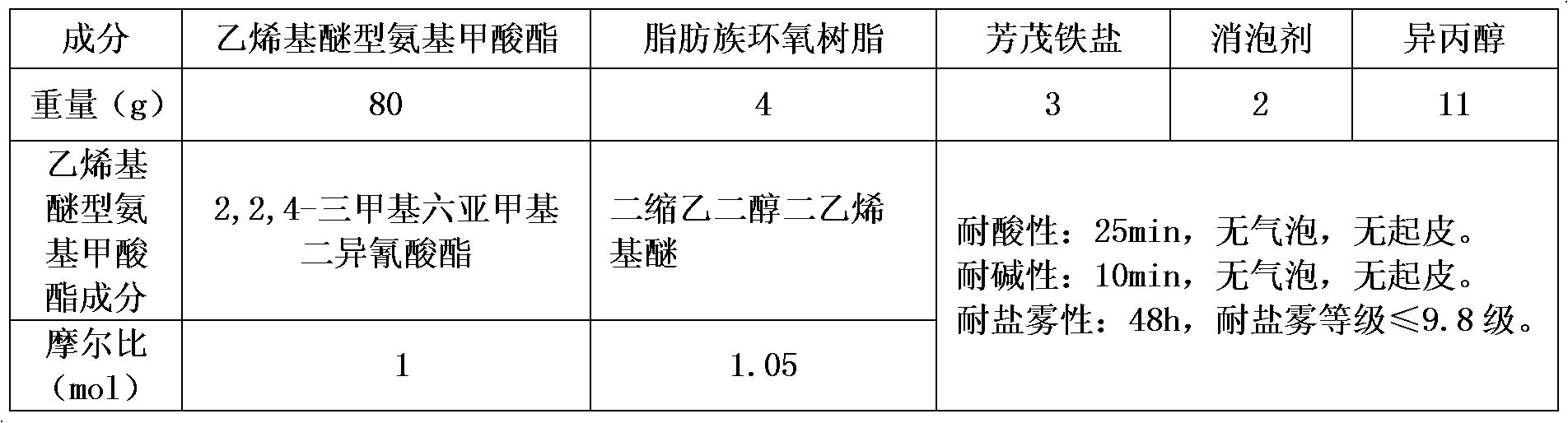

Embodiment 2

[0027]

Embodiment 3

[0029]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

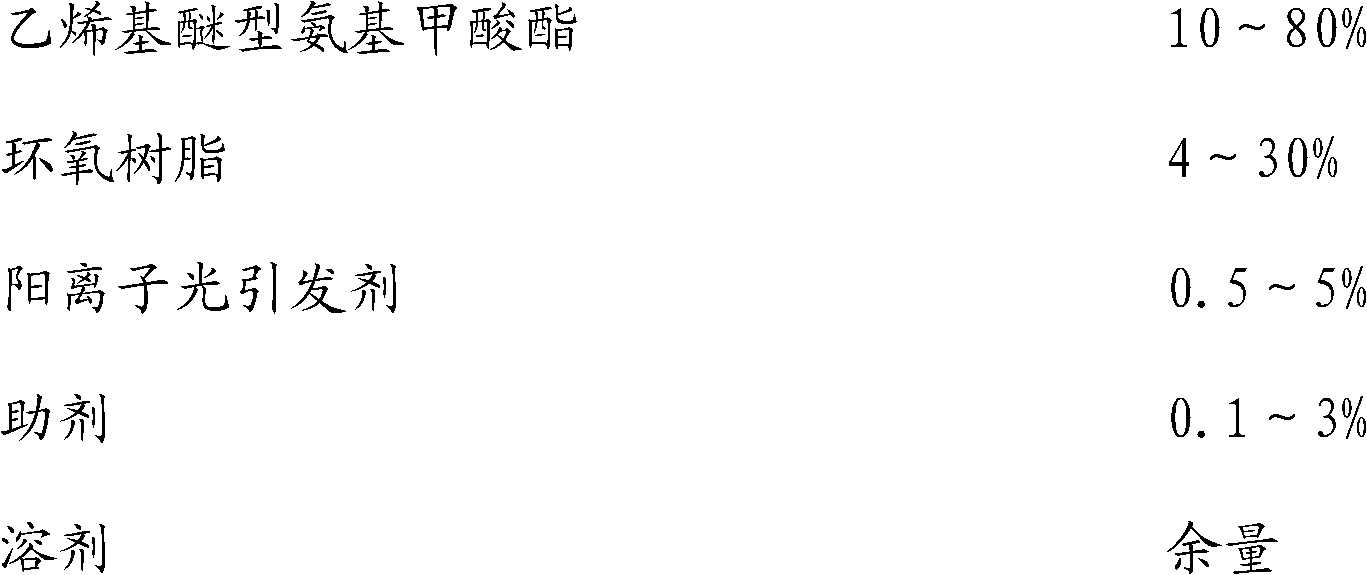

The invention discloses a cation light cured anti-corrosive coating. The coating is prepared from (by wt%) vinyl ether carbamate 10-80, epoxy resin 4-30, cation photoinitiator 0.5-5, assistant 0.1-3, and solvent in balance. By adopting reaction of polyisocyanate and multi-functional vinyl ether to synthesize vinyl ether carbamate with high reactivity, which is used as reactive diluent of epoxy resin curing, system viscosity can be reduced effectively, and light curing reaction speed can be fastened. The inventive coating has low viscosity and good adhesive force, and is especially suitable for endowing material surface with good anti-corrosive property under thin-coating condition.

Description

Technical field [0001] The invention belongs to the technical field of ultraviolet light curing coatings, and particularly relates to a cationic light curing anticorrosive coating. Background technique [0002] Ultraviolet curing coatings (UV coatings) use the energy of ultraviolet light to initiate polymerization and crosslinking reactions between low-molecular prepolymers or oligomers in the coating and monomer molecules as reactive diluents to obtain a hardened paint film A kind of paint that has the characteristics of fast curing, low energy consumption, no environmental pollution, and excellent coating performance. The cationic light curing system plays an important role in UV curing coatings. It has a small volume shrinkage rate during curing, strong adhesion to the substrate, the curing process is not blocked by oxygen, and the curing reaction is not easy to terminate. It is suitable for the light of the film. Curing and other advantages. Cationic light curing systems ge...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D163/00C09D163/02C09D7/12C09D5/08

Inventor 梁勇

Owner SNTO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com