Thermosetting epoxy resin well cementation working solution

A water-based epoxy resin and epoxy resin technology, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems such as the inability to fully exert the advantages of resin material toughness and environmental pollution, and achieve good construction performance and reliable technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

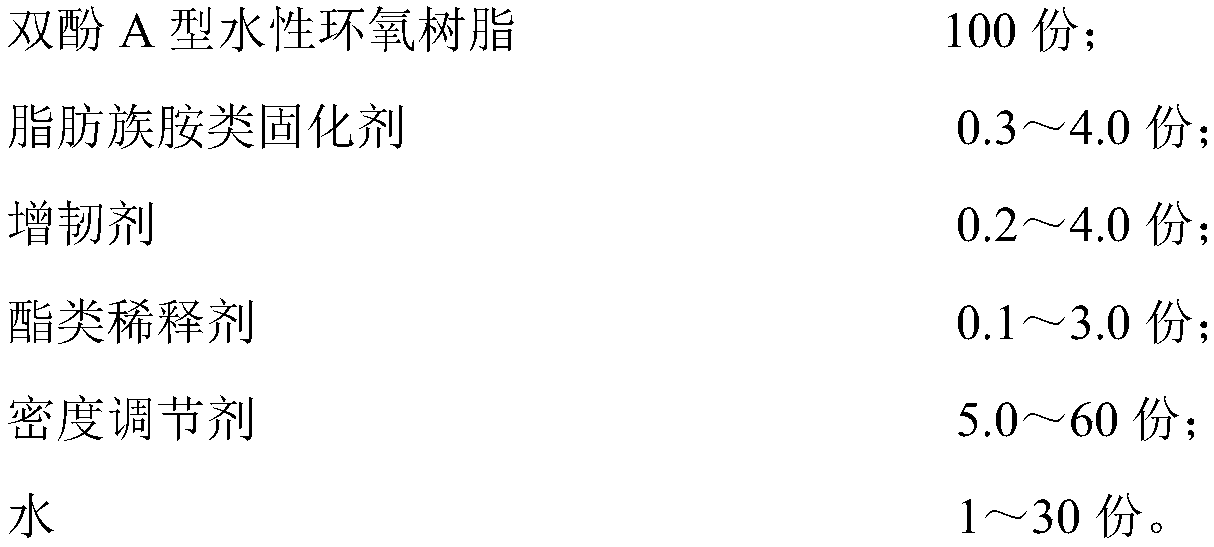

[0033] Formula: 100 parts of bisphenol A water-based epoxy resin, 1 part of aliphatic amine curing agent, 0.5 part of toughening agent, 1.0 part of ethyl acetate, 30 parts of barite, and 10 parts of water.

Embodiment 2

[0035] Formula: 100 parts of bisphenol A water-based epoxy resin, 3 parts of aliphatic amine curing agent, 1.5 parts of toughening agent, 2.5 parts of butyl acetate, 40 parts of iron ore powder, and 30 parts of water.

[0036] The composition and preparation of the toughening agent are the same as in Example 1.

Embodiment 3

[0038] Formula: 100 parts of bisphenol A water-based epoxy resin, 5 parts of aliphatic amine curing agent, 2.5 parts of toughening agent, 2.5 parts of ethyl acetate, 20 parts of hollow glass microspheres, and 20 parts of water.

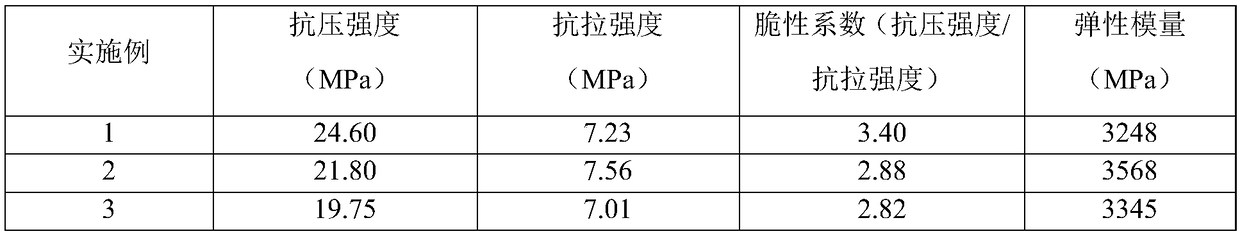

[0039] 2. Performance test of thermosetting epoxy resin cementing working fluid

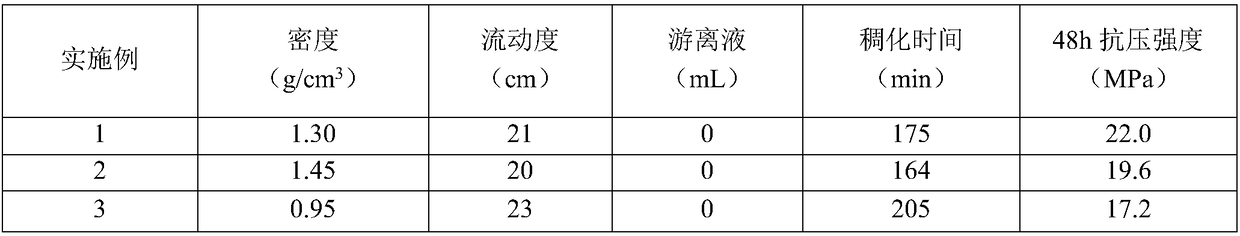

[0040] Example 1, Example 2, and Example 3 were prepared according to the national standard GB / T 19139-2012 for cementing working fluid, and the density, fluidity, free liquid, thickening time, and compressive strength of the cementing working fluid were measured. , the experimental results are shown in Table 1.

[0041] Table 1 Application properties of thermosetting epoxy resin cementing fluid (50°C)

[0042]

[0043] Note: Test conditions for thickening time: 50℃×25MPa (heating time 30min)

[0044] The experimental results in Table 1 show that the application performance of the thermosetting epoxy resin cementing working fluid of the present invention is good, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com