Temperature field detection method and device of calcination rotary kiln

A detection method and detection device technology, applied in the direction of measuring devices, thermometers, electrical devices, etc., can solve the problems of high investment cost of measuring equipment, unsuitability for automatic control, large measurement errors, etc., to increase measurement cost investment and cheap spare parts , The effect of reducing production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

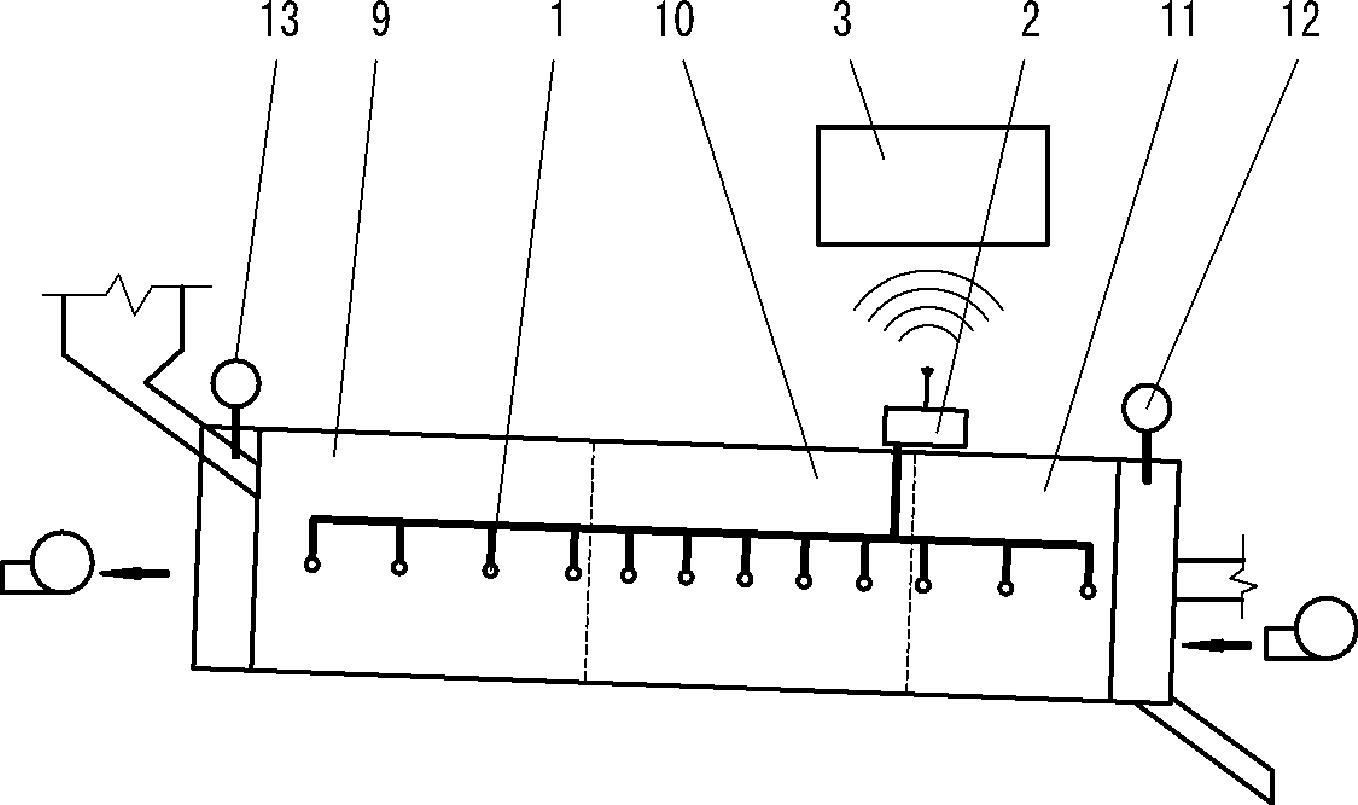

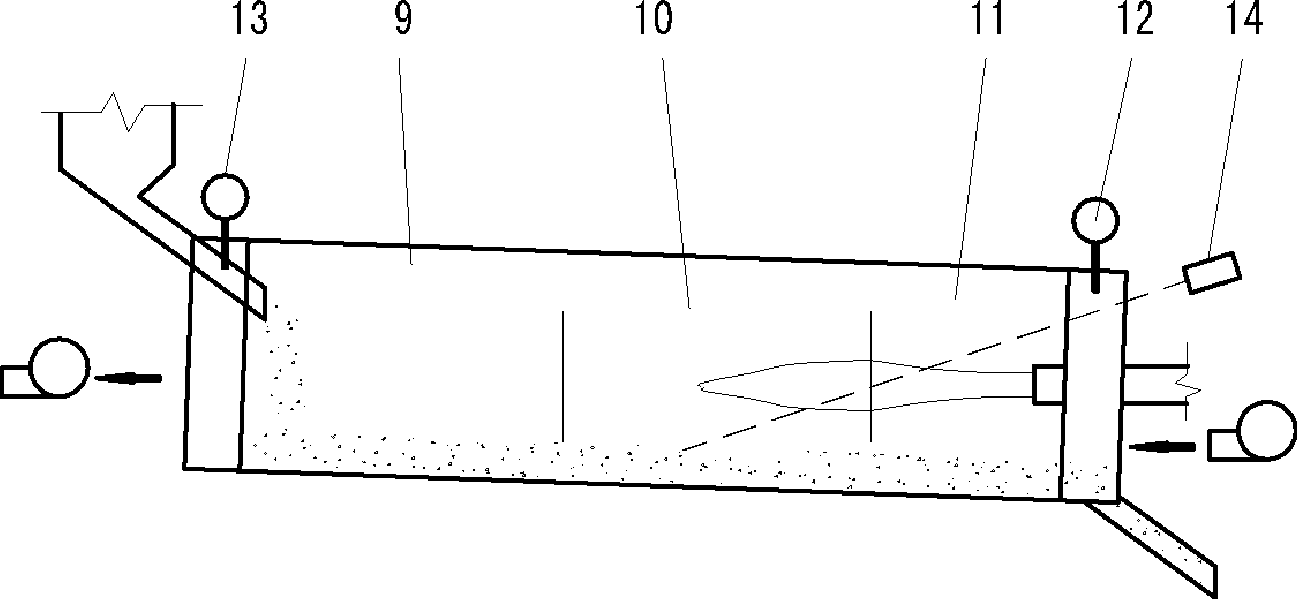

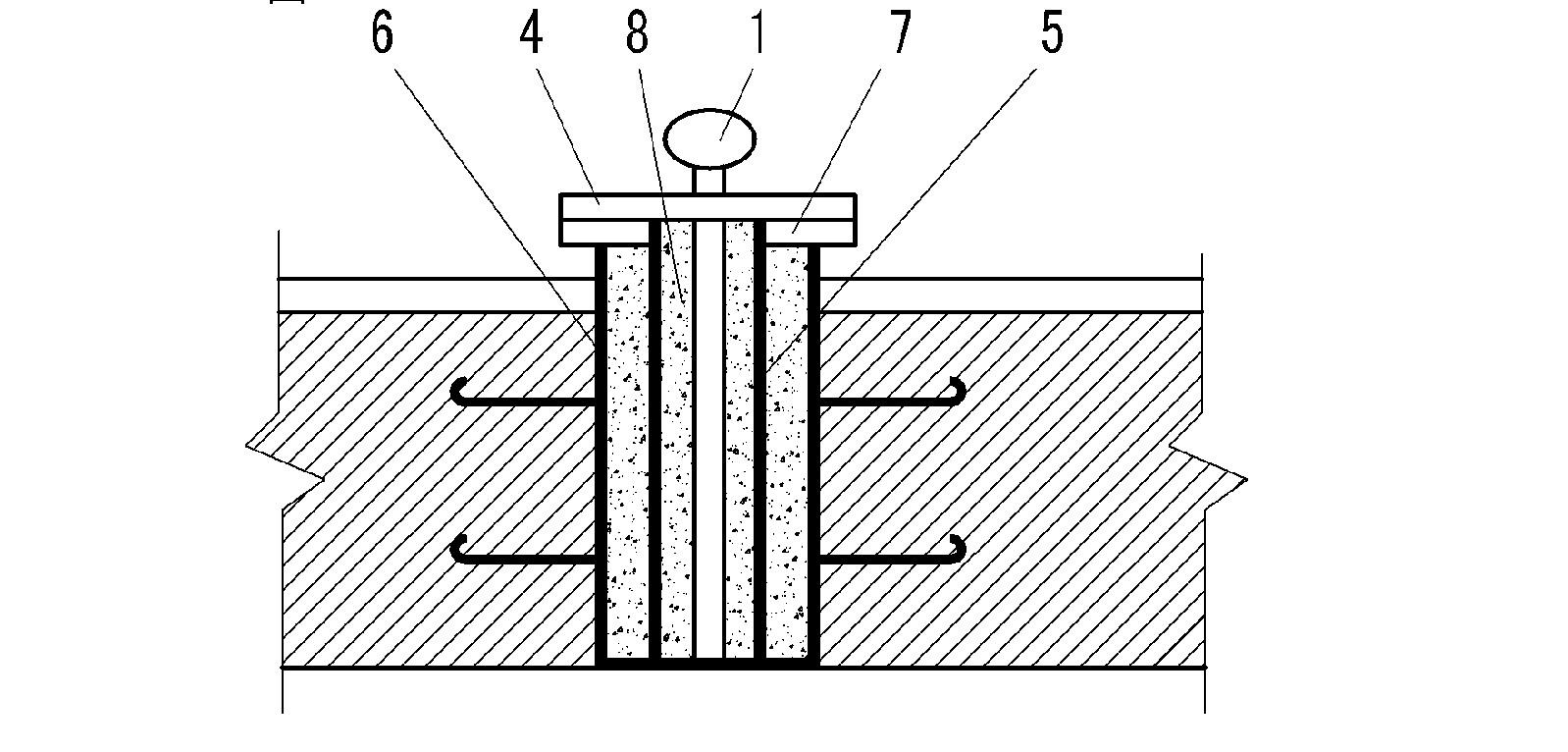

[0024] Embodiments of the present invention: the temperature field detection method of the calcining rotary kiln of the present invention, such as figure 1 As shown, in this method, a group of temperature measuring thermocouples 1 are installed in the kiln body lining of the calcining rotary kiln along the kiln body axial direction; and cooling section 11 to determine the temperature measurement accuracy requirements; each thermocouple 1 is connected to the wireless communication box 2 installed on the shell of the calcining rotary kiln body, and the wireless communication box 2 sends the temperature signal of each thermocouple 1 to the computer in real time Analyze 3 systems. A signal input module (not shown) and a signal transmission module (not shown) are provided in the wireless communication box 2 on the shell of the calcined rotary kiln body, and the signal input module is used to collect dynamic continuous temperature signals of each thermocouple, The signal sending mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com