Ultra-hydrophilic-superoleophobic reduced graphene oxide filtering membrane and use

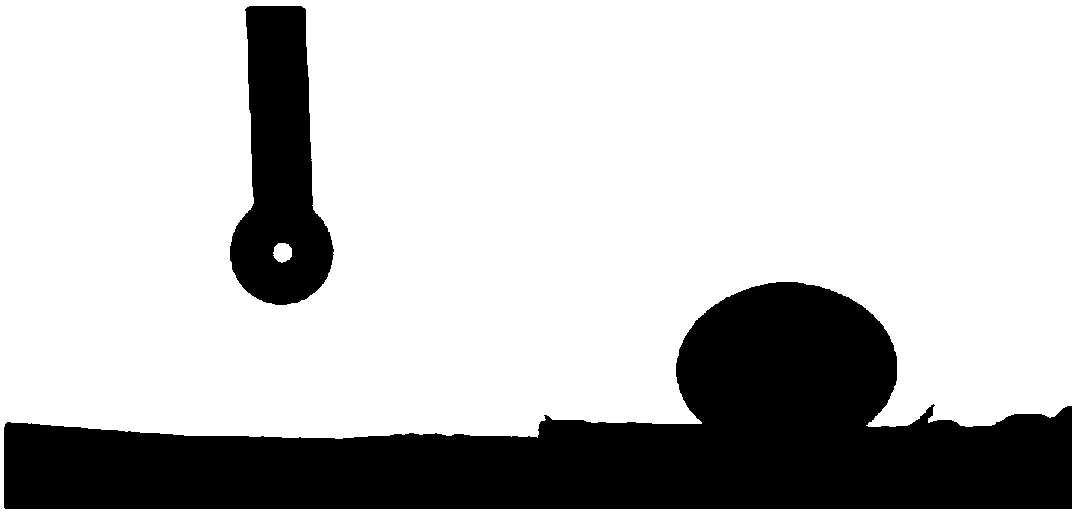

A graphene, super-hydrophilic technology, applied in membrane, membrane technology, semi-permeable membrane separation and other directions, can solve the problems of basement membrane affecting anti-fouling, incomplete membrane separation technology, and decreased processing efficiency, etc., to improve the anti-membrane Pollution performance, high water permeation selectivity, easy thickness control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

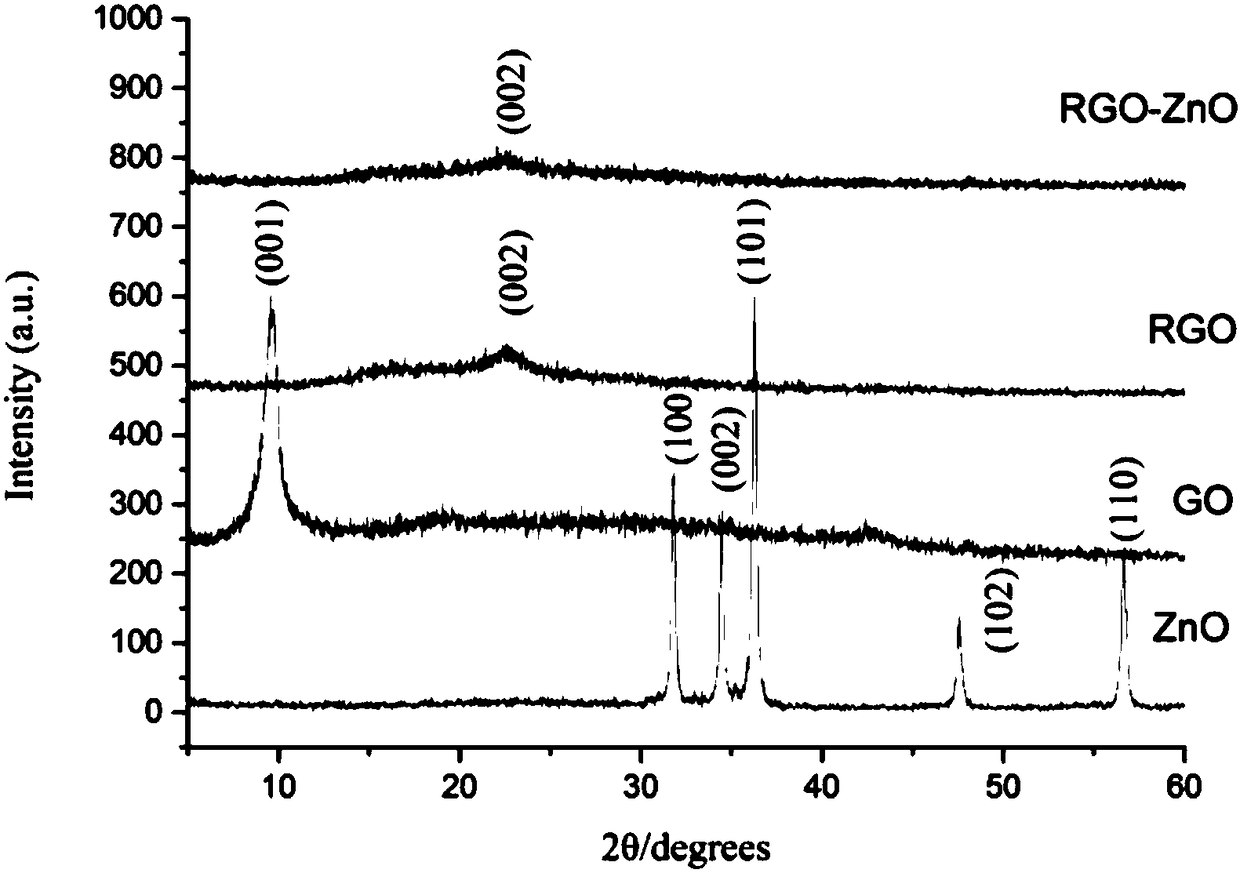

[0029] (1) Preparation of graphene oxide by modified Hummers method

[0030] In the state of ice bath, add 3g of graphite powder, 40mL of concentrated phosphoric acid and 360mL of concentrated sulfuric acid into a 500mL three-neck flask and stir evenly with magnetic force. Then slowly add 18g of potassium permanganate in batches, and after fully stirring the reaction, transfer the three-neck flask from the ice bath to the oil bath and raise the temperature to 50°C for 12 hours while stirring.

[0031] After the mixture was cooled to room temperature, it was placed in an ice-water bath, diluted with 1 L of distilled water and added dropwise with 30% hydrogen peroxide until the solution was bright yellow. Vacuum filter cake was rinsed with dilute hydrochloric acid, centrifuged at 8000rpm for 5 minutes, and washed with acid three times to remove sulfate ions in the solution. Centrifuge at 10,000 rpm for 10 minutes, wash with water 5 times, adjust the pH of the solution to neutra...

Embodiment 2

[0044] (1) Preparation of graphene oxide by modified Hummers method

[0045] In the state of ice bath, add 3g of graphite powder, 40mL of concentrated phosphoric acid and 360mL of concentrated sulfuric acid into a 500mL three-neck flask and stir evenly with magnetic force. Then slowly add 18g of potassium permanganate in batches, and after fully stirring the reaction, transfer the three-neck flask from the ice bath to the oil bath and raise the temperature to 50°C for 12 hours while stirring.

[0046] After the mixture was cooled to room temperature, it was placed in an ice-water bath, diluted with 1 L of distilled water and added dropwise with 30% hydrogen peroxide until the solution was bright yellow. Vacuum filter cake was rinsed with dilute hydrochloric acid, centrifuged at 8000rpm for 5 minutes, and washed with acid three times to remove sulfate ions in the solution. Centrifuge at 10,000 rpm for 10 minutes, wash with water 5 times, adjust the pH of the solution to neutra...

Embodiment 3

[0060] (1) Preparation of graphene oxide by modified Hummers method

[0061] In the state of ice bath, add 3g of graphite powder, 40mL of concentrated phosphoric acid and 360mL of concentrated sulfuric acid into a 500mL three-neck flask and stir evenly with magnetic force. Then slowly add 18g of potassium permanganate in batches, and after fully stirring the reaction, transfer the three-neck flask from the ice bath to the oil bath and raise the temperature to 50°C for 12 hours while stirring.

[0062] After the mixture was cooled to room temperature, it was placed in an ice-water bath, diluted with 1 L of distilled water and added dropwise with 30% hydrogen peroxide until the solution was bright yellow. Vacuum filter cake was rinsed with dilute hydrochloric acid, centrifuged at 8000rpm for 5 minutes, and washed with acid three times to remove sulfate ions in the solution. Centrifuge at 10,000 rpm for 10 minutes, wash with water 5 times, adjust the pH of the solution to neutra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com