Vehicle axle counting method based on steel rail deformation / stress parameters

A technology of stress parameters and vehicle running direction, applied in vehicle route interaction equipment, railway car body components, railway signal and safety, etc., can solve the problems of sensor migration, no implementation solution, splashing and gravel damage, etc., to achieve stability The effect of high, reducing the probability of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

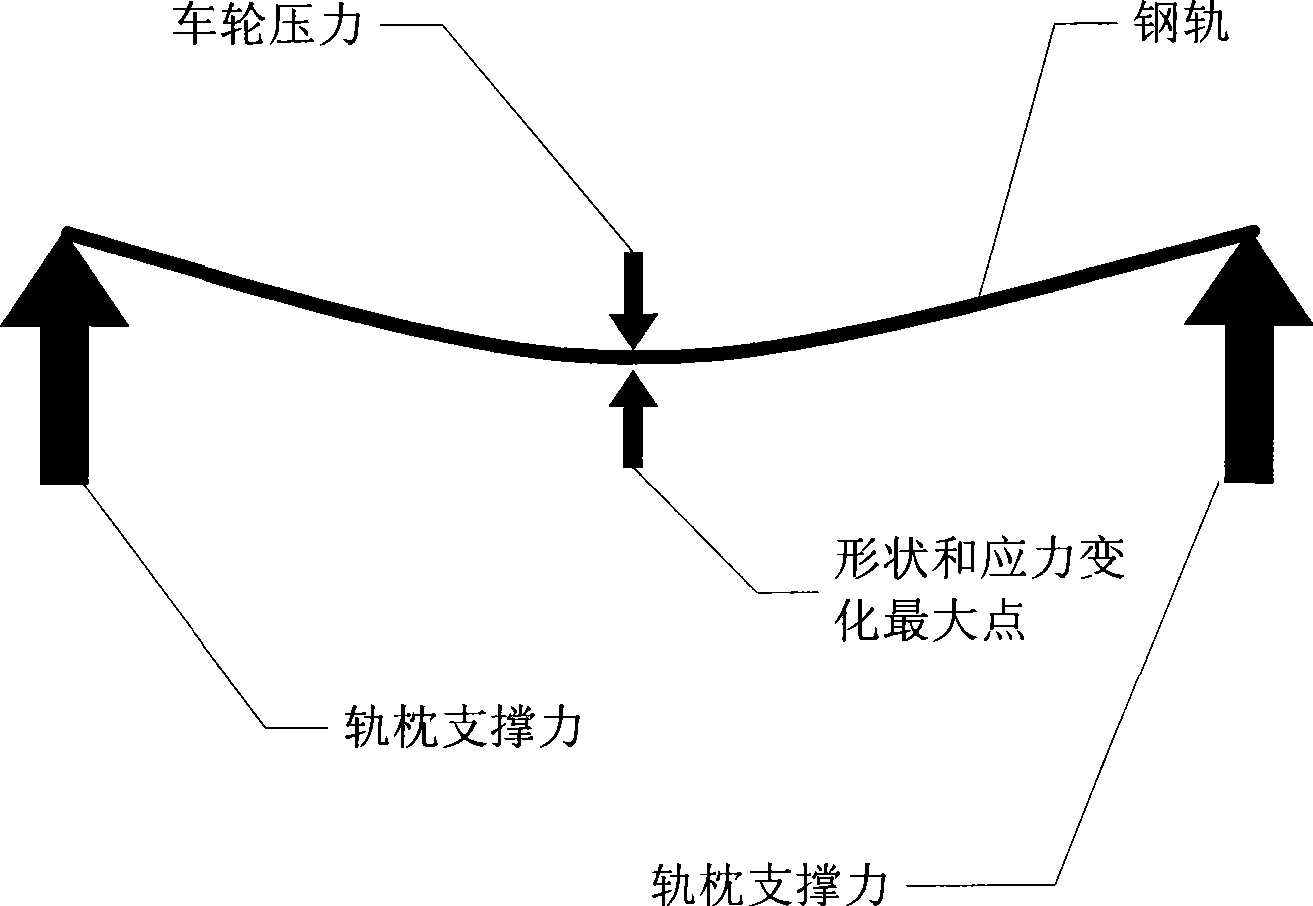

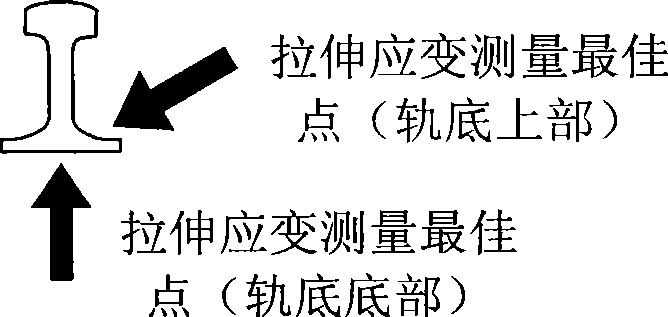

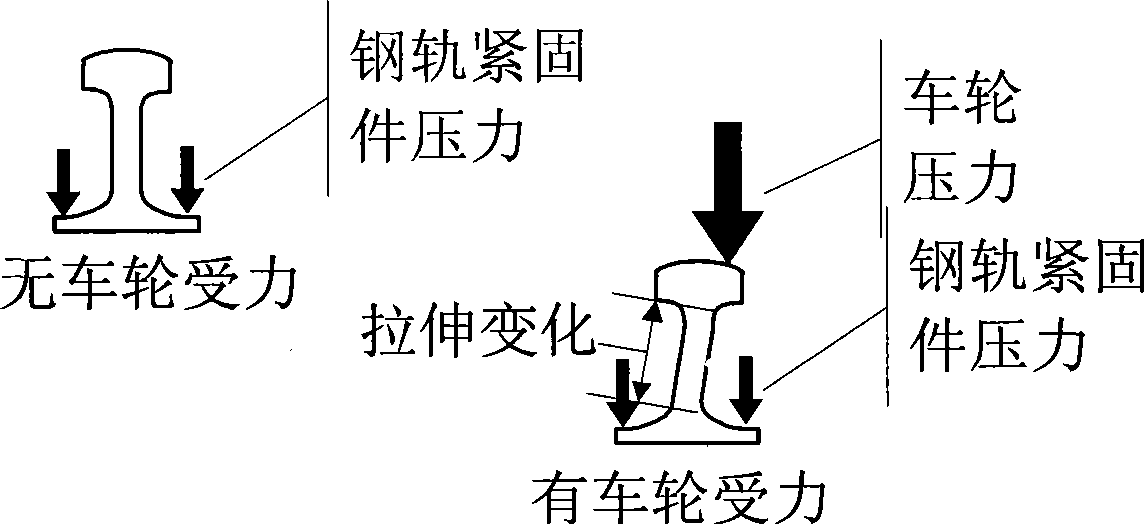

[0043] The vehicle axle counting method based on rail deformation / stress parameters provided by the present invention mainly includes the following steps: first, a sensor for inductive rail deformation is installed on the rail; then the threshold threshold of the sensor is flexibly set according to different axle counting requirements; when the vehicle's When the axle passes the rail position where the sensor is located, if the lateral deformation or tensile deformation of the rail exceeds the threshold threshold, the state of the sensor is recorded as 1, otherwise the state is recorded as 0; according to the state information of the sensor, the axle of the passing vehicle is determined number.

[0044] The specific implementation manners of the above steps will be described in detail below.

[0045] In the present invention, the sensor used to sense the deformation / stress parameter of the rail may be a fiber grating installed on the rail, an electrical strain gauge or other s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com