Whole-range automatic testing method and device for gas desorbing speed of coal sample

A fully automatic and testing method technology, applied to the analysis of materials and instruments, can solve the problems of inaccurate coal sample gas desorption speed and desorption volume, loss of reliable basic parameters for gas control, unfavorable analysis of coal sample gas desorption law, etc., to achieve Extensive applicability and promotion and application value, visual graphing, and convenient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

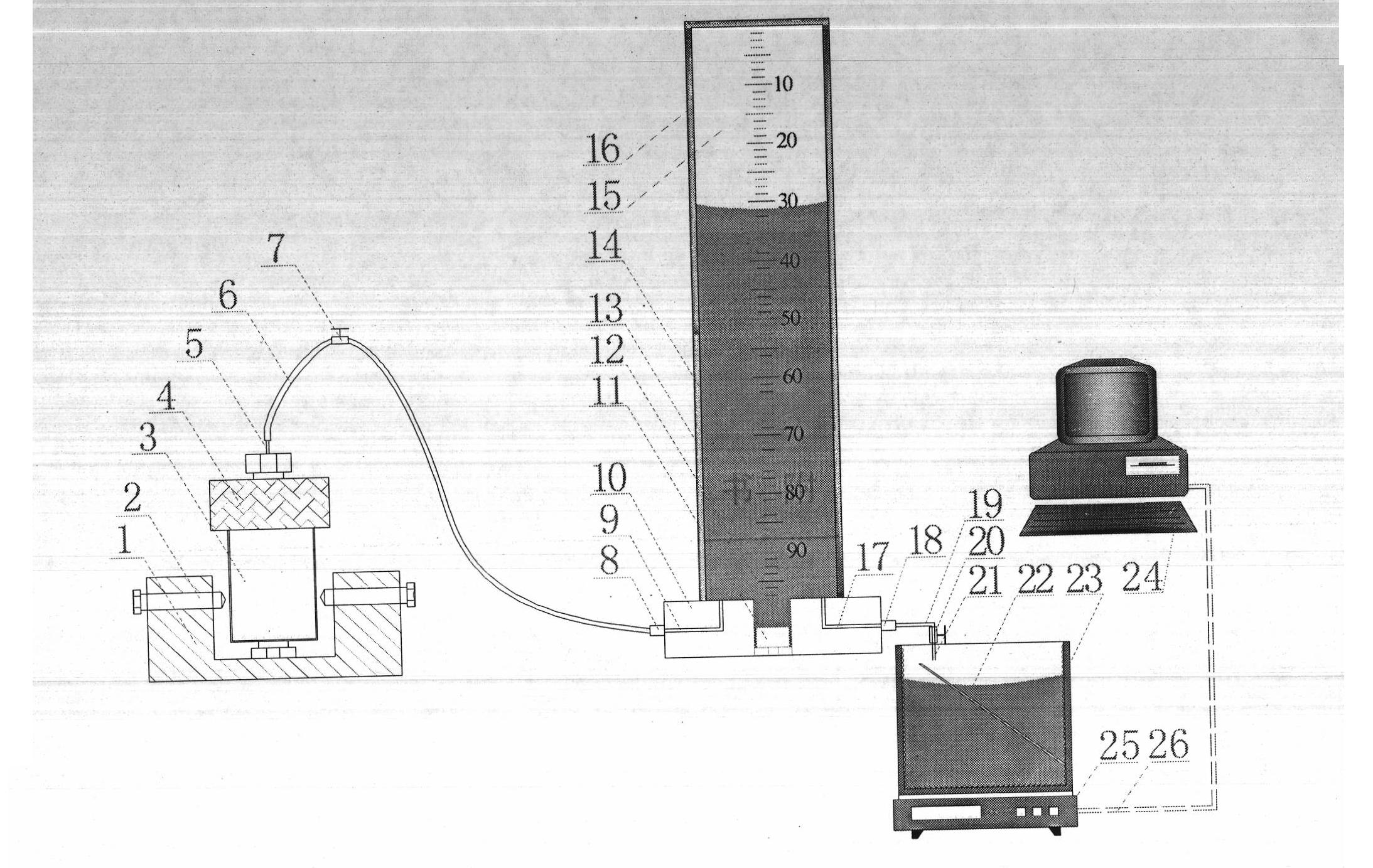

[0020] Example 1: Implementation of Gas Desorption of Laboratory Coal Samples

[0021] (1) Put the liquid into the desorption volume tube 16, then put the desorption volume tube upright, connect the air guide rubber tube 6, connect the guide tube 19, close the control valves 7 and 20, connect the data transmission line 26, and debug the electronic Balance 25, start intelligent module 24.

[0022] (2) self-made coal sample, the coal sample particle size is determined according to the research purpose, the prepared coal sample is put into the coal sample tank 3, the coal sample tank cover 4 is tightened immediately, the coal sample tank 3 is fixed on the fixed seat 1, and the The gas guide needle 5 is inserted into the pressure pad on the top of the coal sample tank cover.

[0023] (3) Open the control valves 7 and 20 at the same time, and the intelligent module 24 automatically tests and monitors the coal sample gas desorption process in the whole process. Automatic recording...

Embodiment 2

[0024] Example 2: Coal core gas desorption by underground drilling in coal mines:

[0025] (1) Find a relatively flat place around the position where the coal core is drilled in the coal mine, put down the device, put the liquid into the desorption volume tube 16, then put the desorption volume tube upright, connect the gas guide rubber tube 6, and connect the guide The flow pipe 19 closes the control valves 7 and 20, connects the data transmission line 26, adjusts the electronic balance 25, and starts the intelligent module 24.

[0026] (2) Drill the coal core according to the predetermined coal seam position, connect it to the coal sample tank, immediately tighten the coal sample tank cover, insert the gas guide needle into the pressure pad on the upper part of the coal sample tank cover, and record the coal sample desorption and measurement at the same time. Sample exposure time T1.

[0027] (3) Open the control valves 7 and 20 at the same time, and the intelligent module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com