Patents

Literature

38results about How to "Give full play to the toughening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

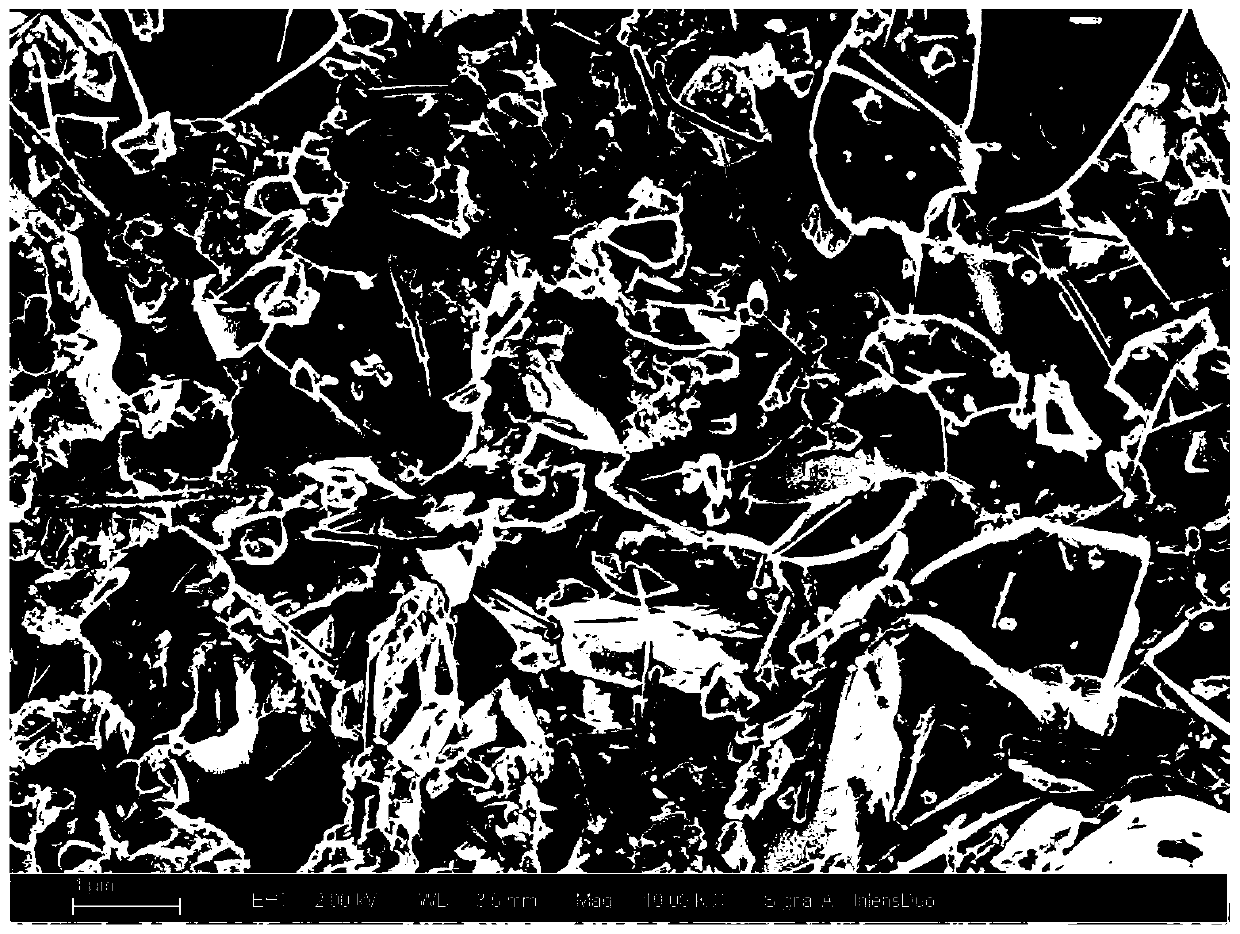

Method for preparing high-tenacity composite material with heat conducting function

ActiveCN103435998AHigh thermal conductivityHigh thermal conductivity systemHeat-exchange elementsMelt blendingHeat conducting

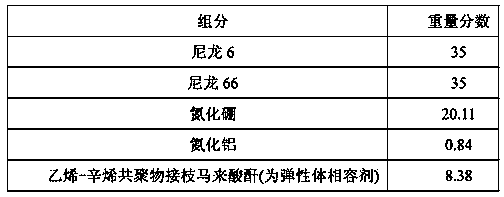

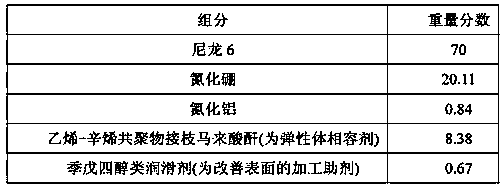

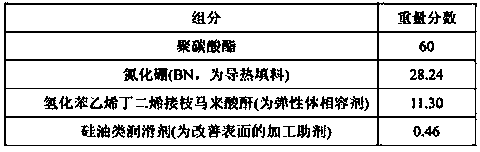

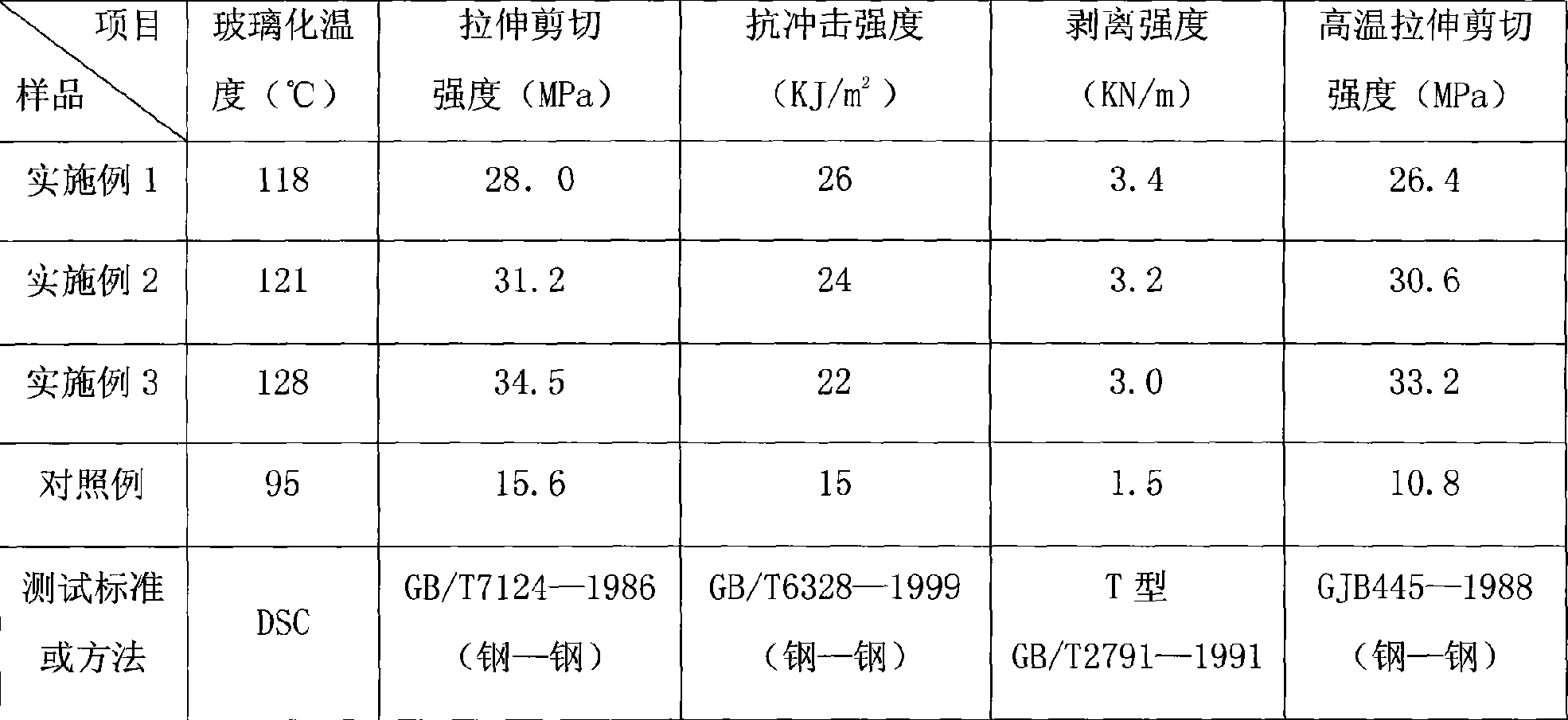

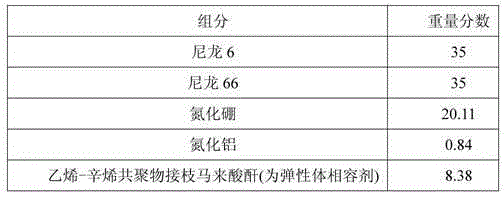

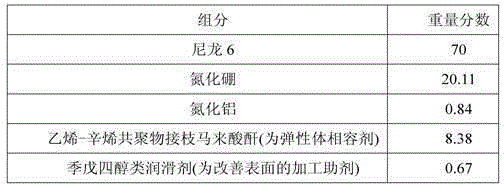

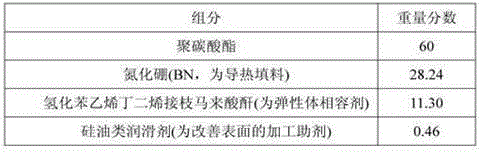

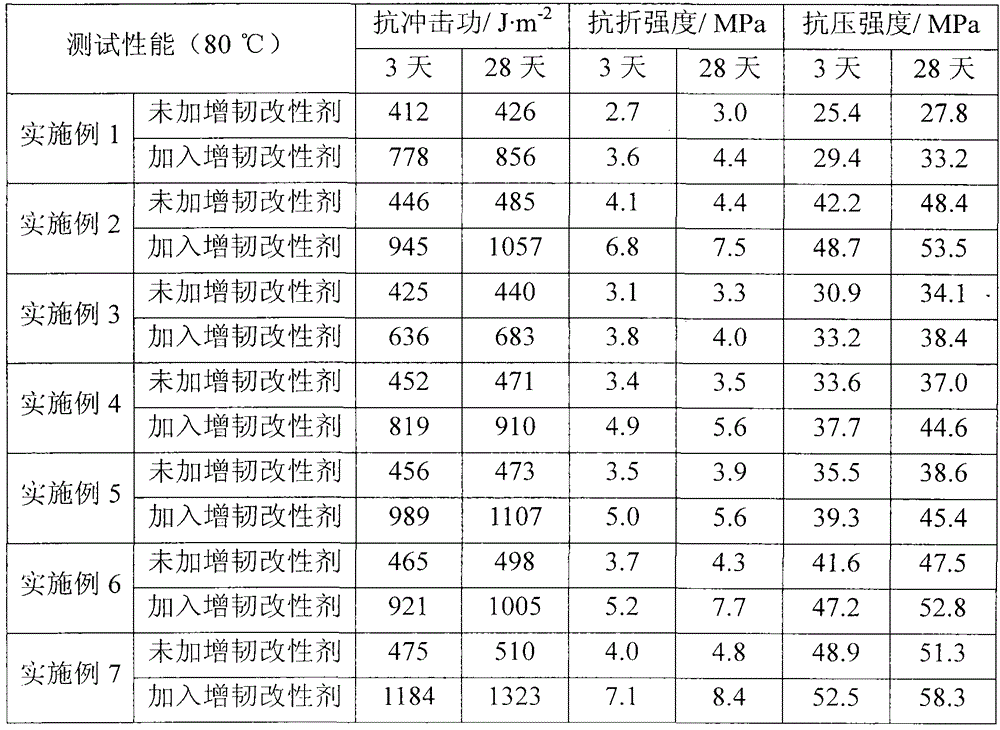

The invention relates to a method for preparing a high-tenacity composite material with a heat conducting function. The method for preparing the high-tenacity composite material with the heat conducting function adopts the basic principle that a core-shell structure can enhance tenacity, heat conducting filler is designed into a core, and an elastomer is designed into a shell, so that high filling is realized while the tenacity enhancing effect of the elastomer is fully played. The method for preparing the high-tenacity composite material with the heat conducting function comprises the following concrete steps: firstly preparing master batch of a heat conducting composite material from the heat conducting filler, an elastomer compatilizer and a processing aid, and then carrying out melt blending on the master batch of the heat conducting composite material with engineering plastic in a certain ratio. The high-tenacity composite material with the heat conducting function, prepared by adopting the preparation method, has the functions of high tenacity, high heat conductivity coefficient, good processing fluidity and the like, can be applied to moulding processing such as extrusion and injection, has a good application prospect, is simple in production process, easy to operate and control, stable in quality and high in production efficiency and has broad industrialization and market prospects.

Owner:SICHUAN UNIV

Epoxy binder modified by micropowder of crosslinked rubber, and preparation method

InactiveCN101050344ASmall particle sizeHuge surface energyNon-macromolecular adhesive additivesEpoxy resin adhesivesHeat resistanceNanometre

This invention relates to a method for preparing epoxy adhesive modified by nano-crosslinked rubber micropowder. The epoxy adhesive is composed of epoxy component and curing component. The epoxy component comprises bisphenol A type epoxy resin, nano-crosslinked rubber micropowder, and diluting agent. The curing component comprises modified amine curing agent, curing promoter, and coupling agent. The epoxy component and the curing component are separately prepared and packaged, and are mixed uniformly when used. The epoxy adhesive has high heat resistance without being influenced by curing agent variety or curing condition, high tensile / shear strength, high peel strength, and high impact resistance.

Owner:HUNAN SHENLI IND

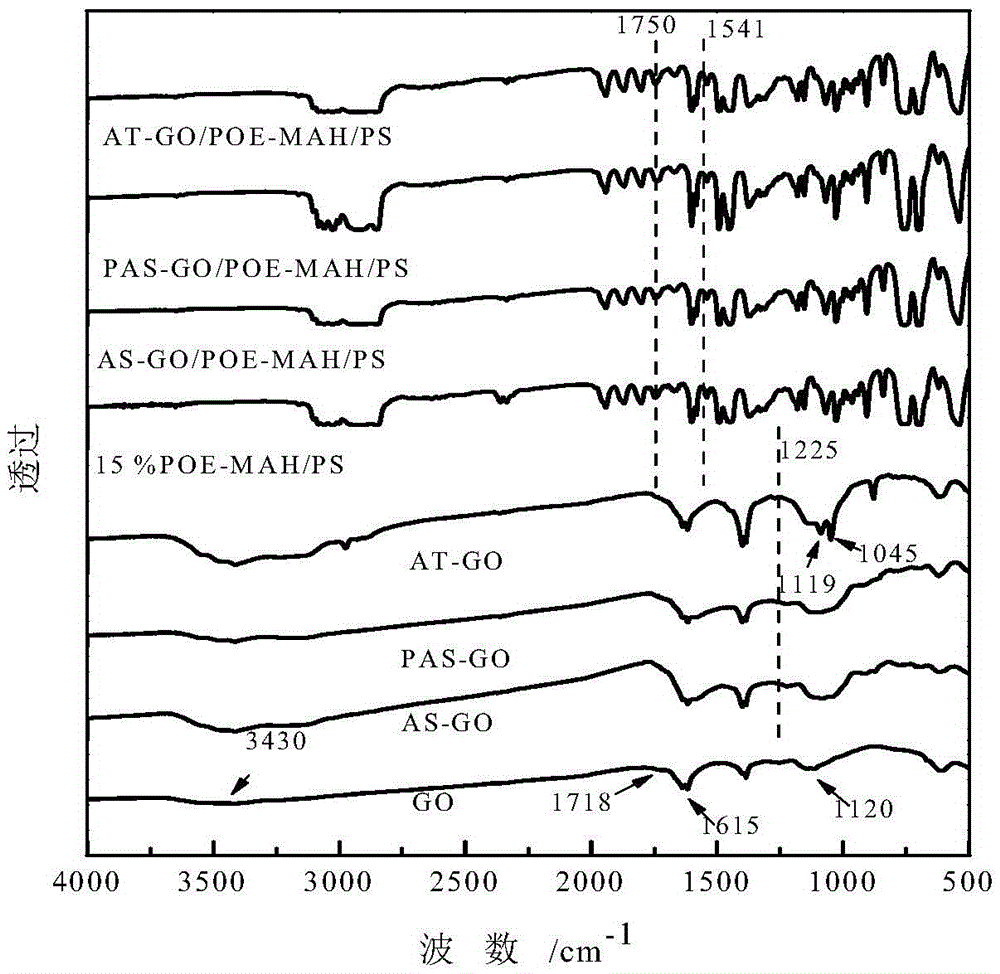

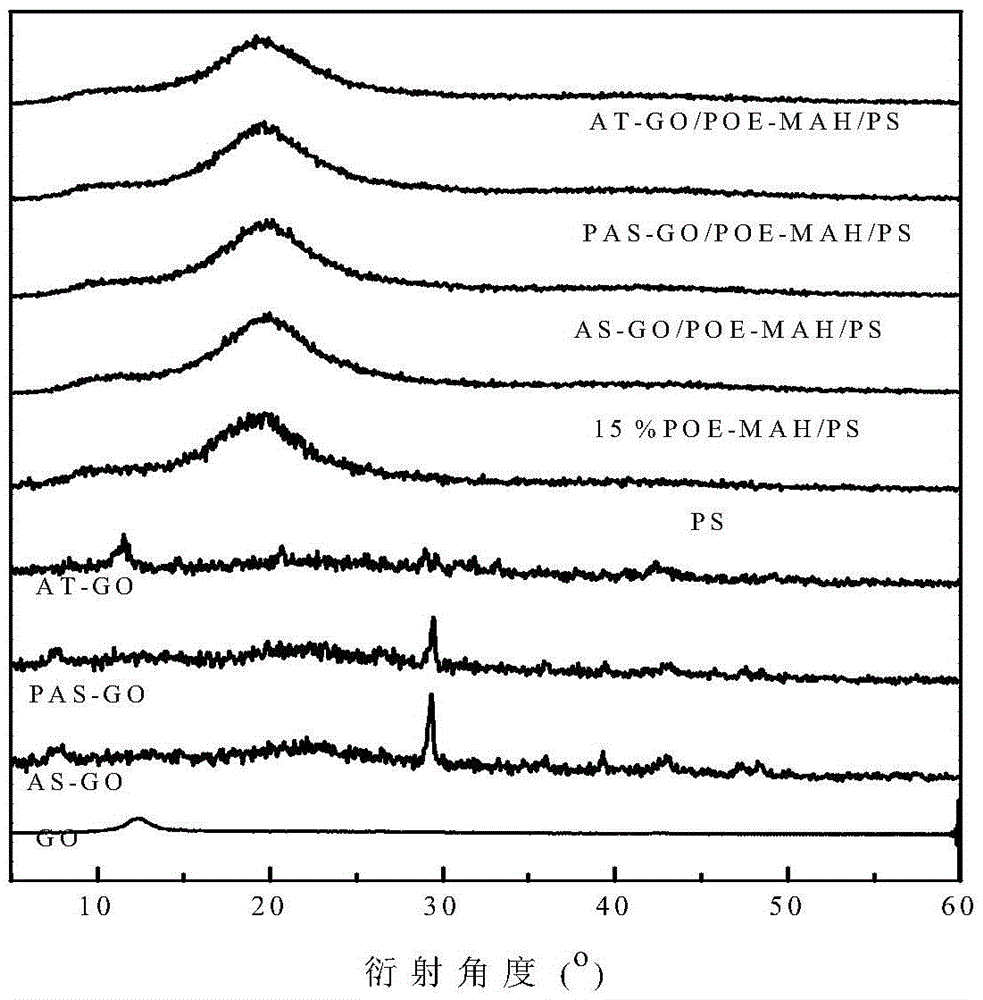

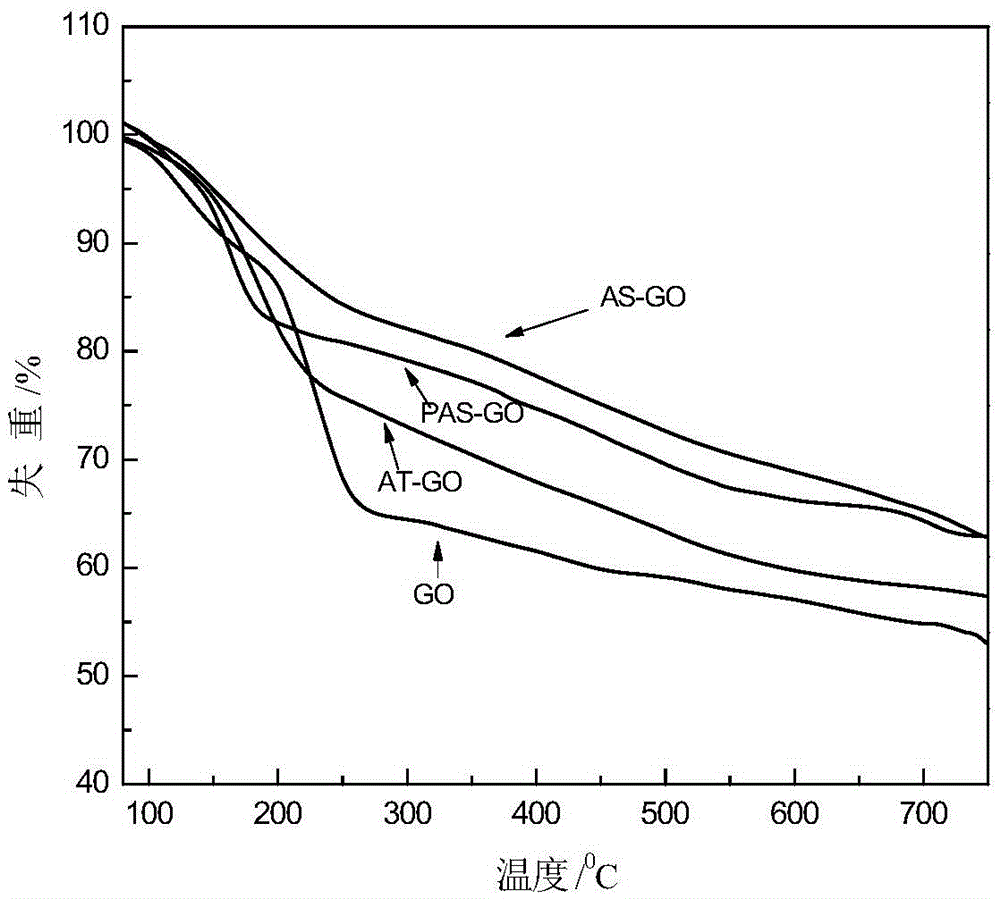

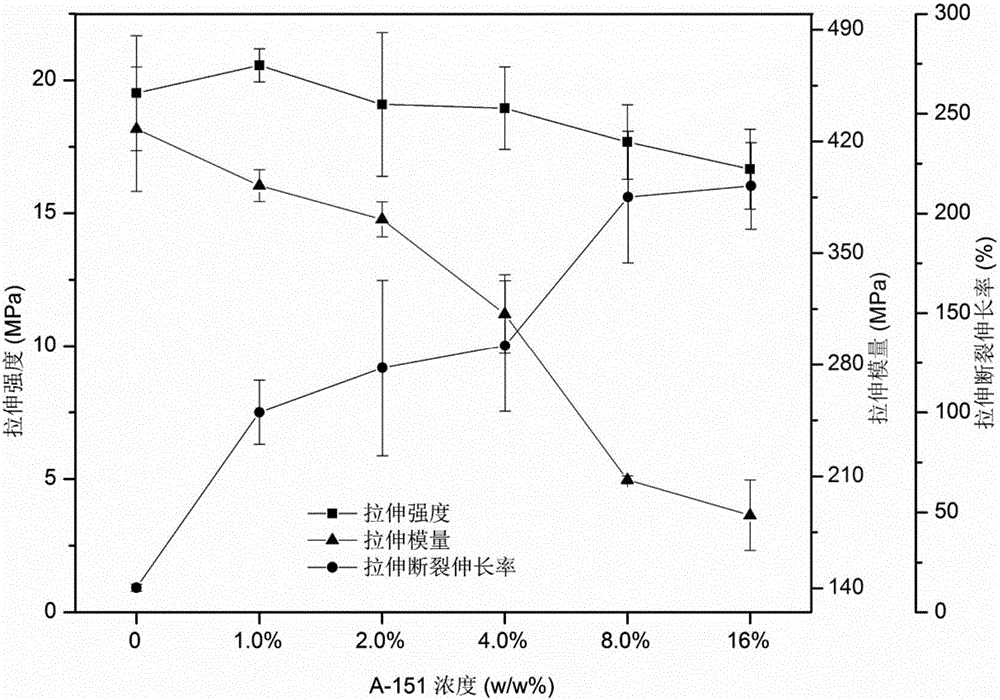

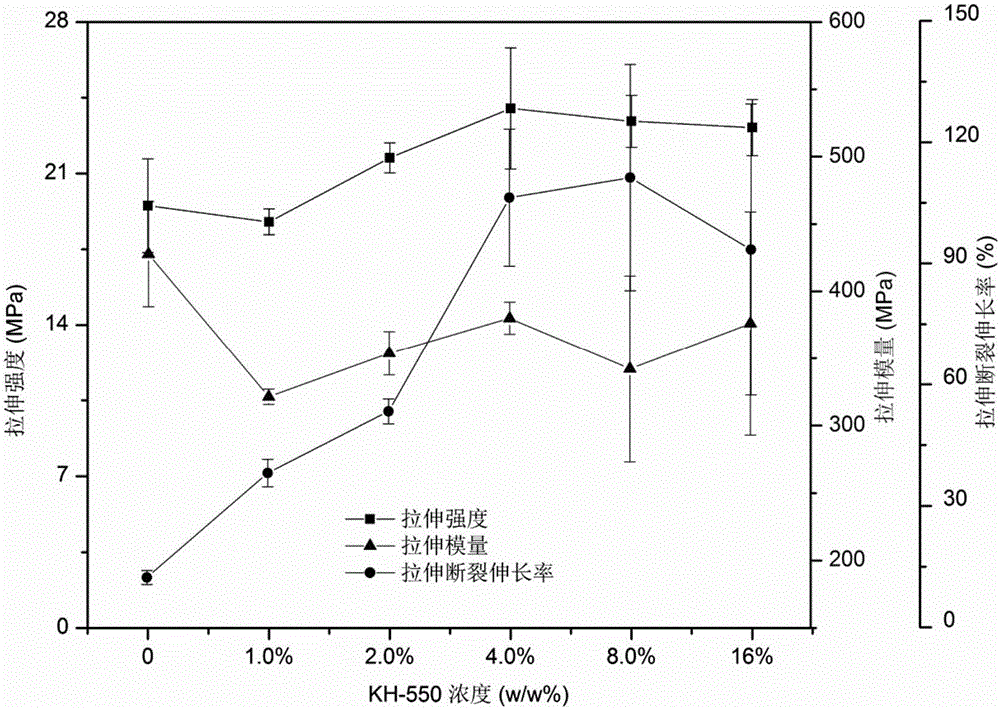

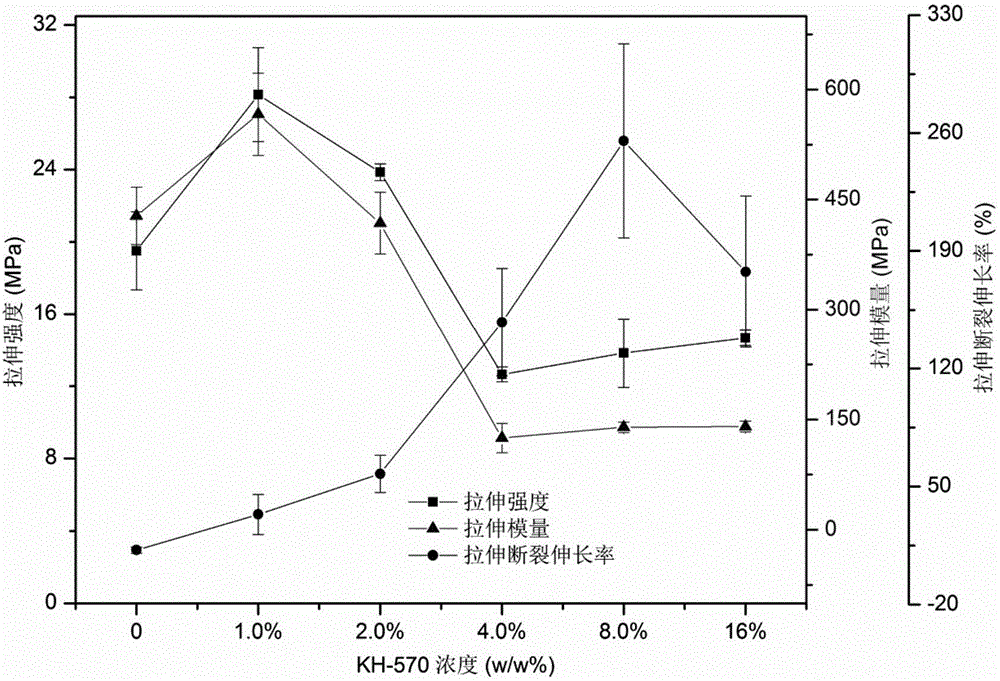

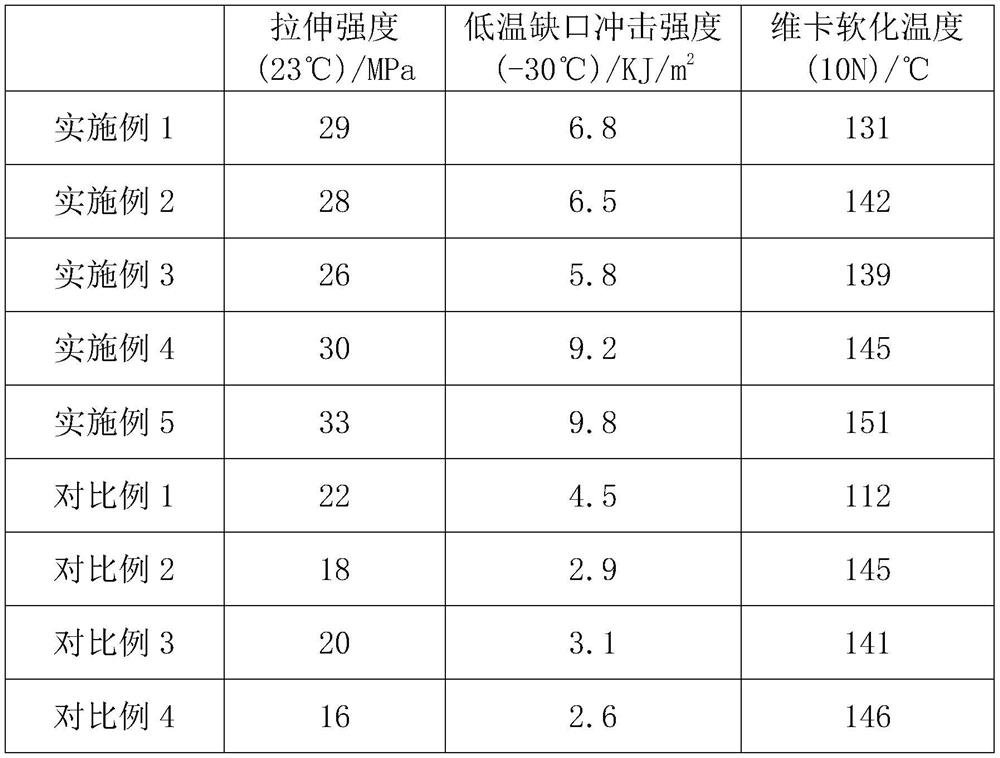

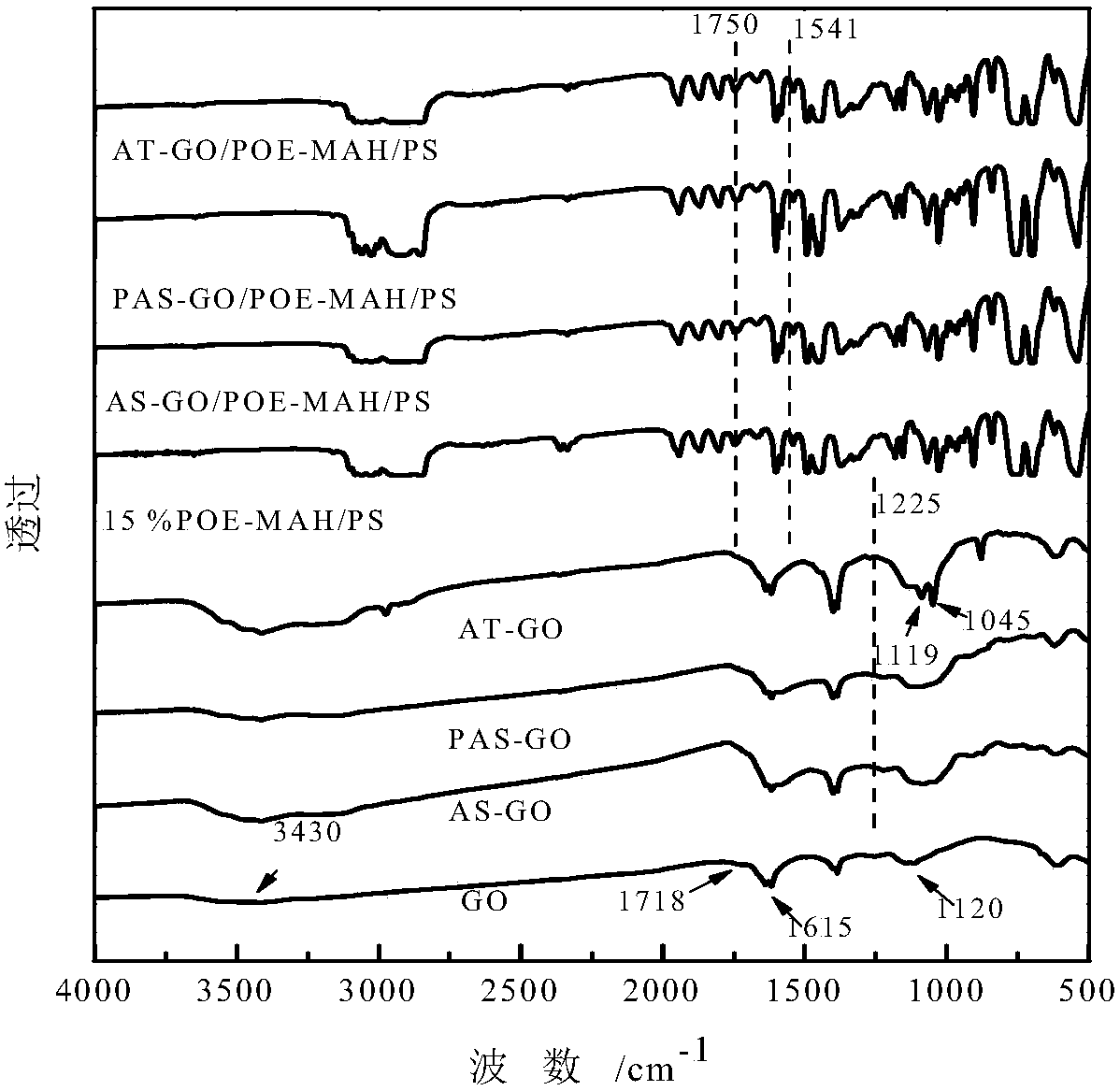

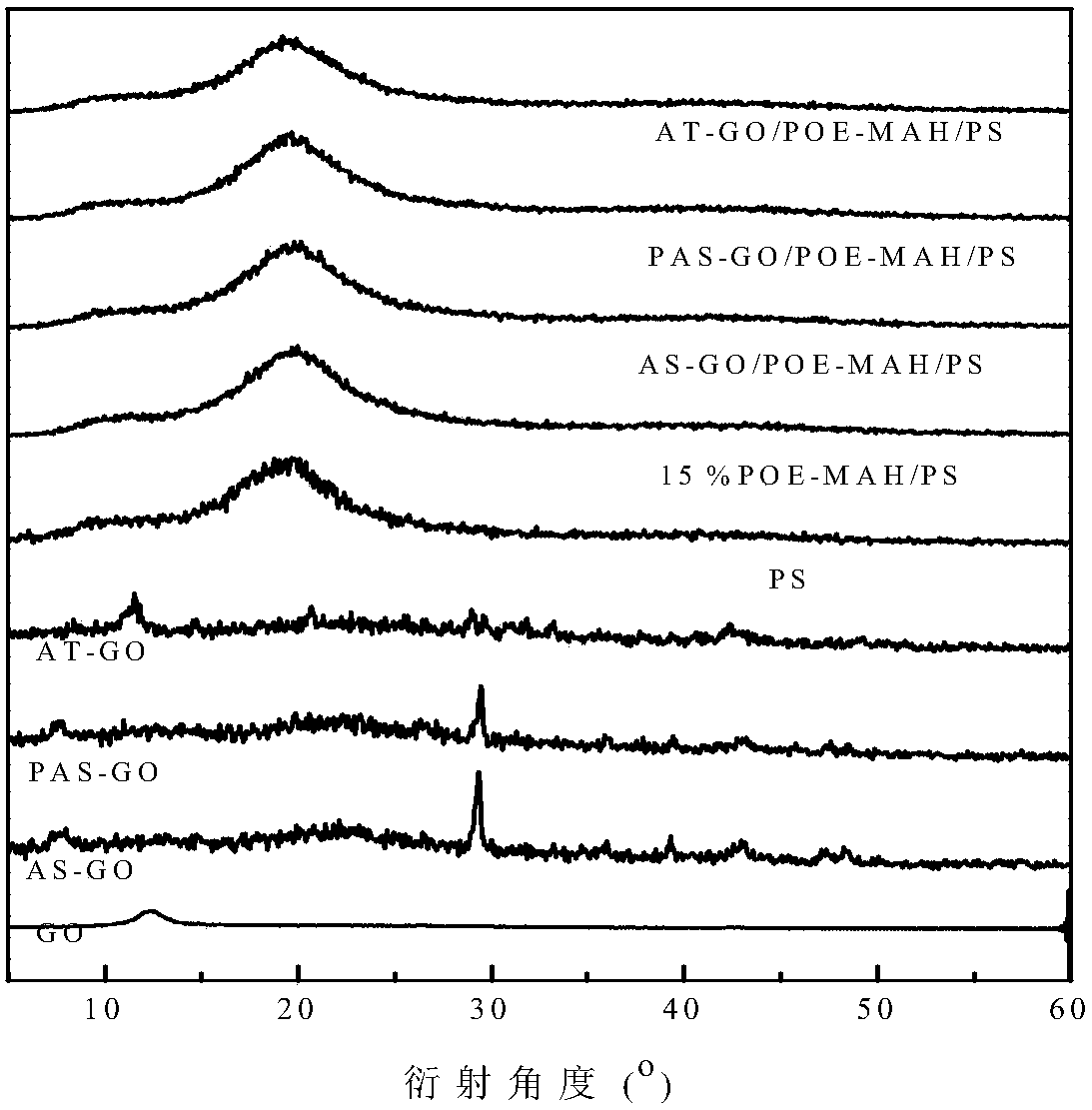

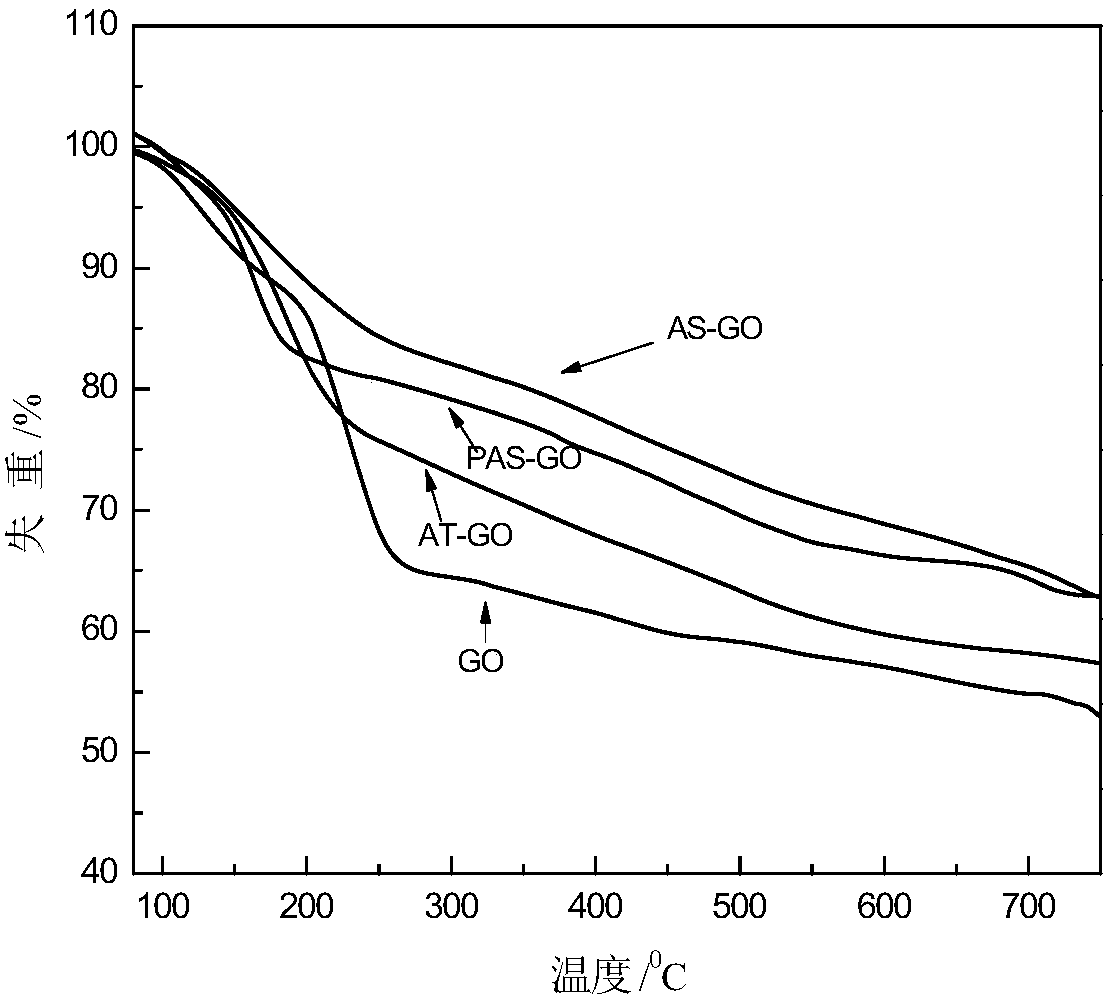

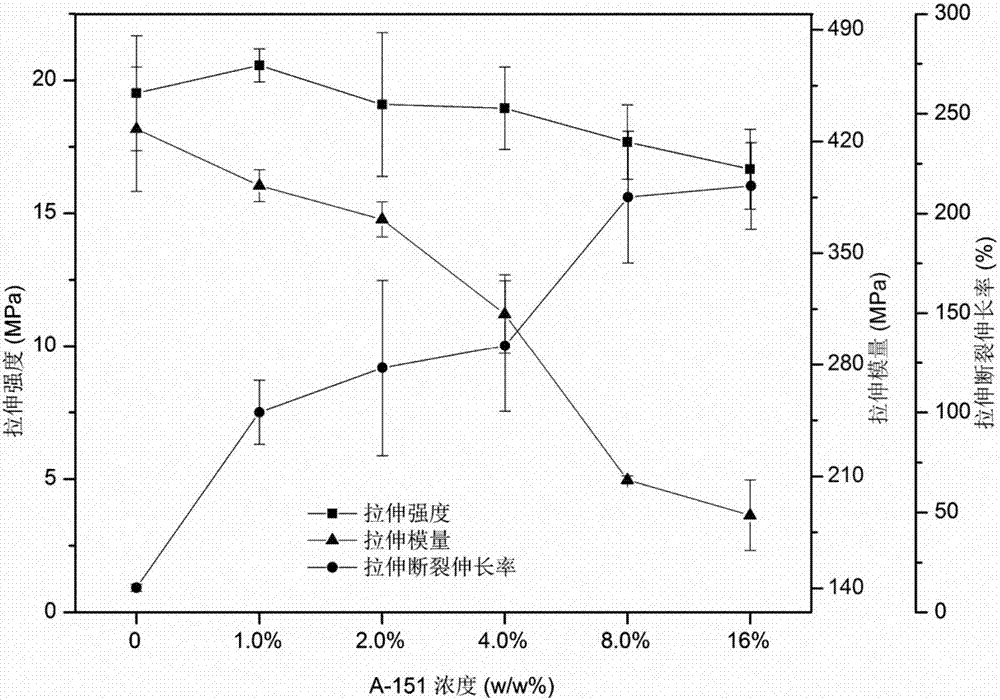

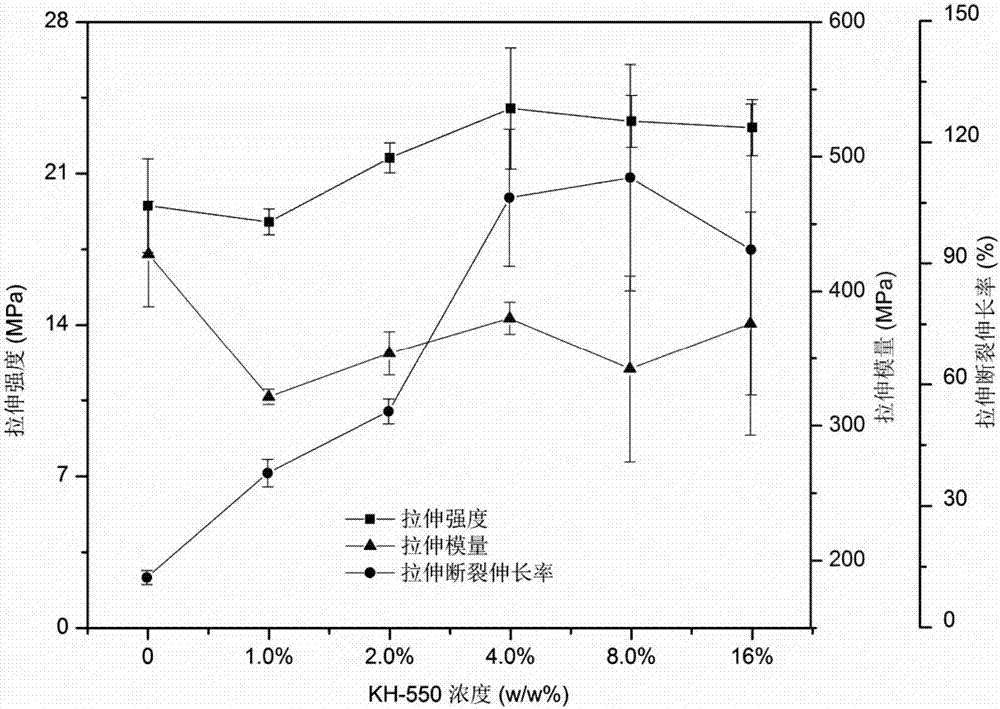

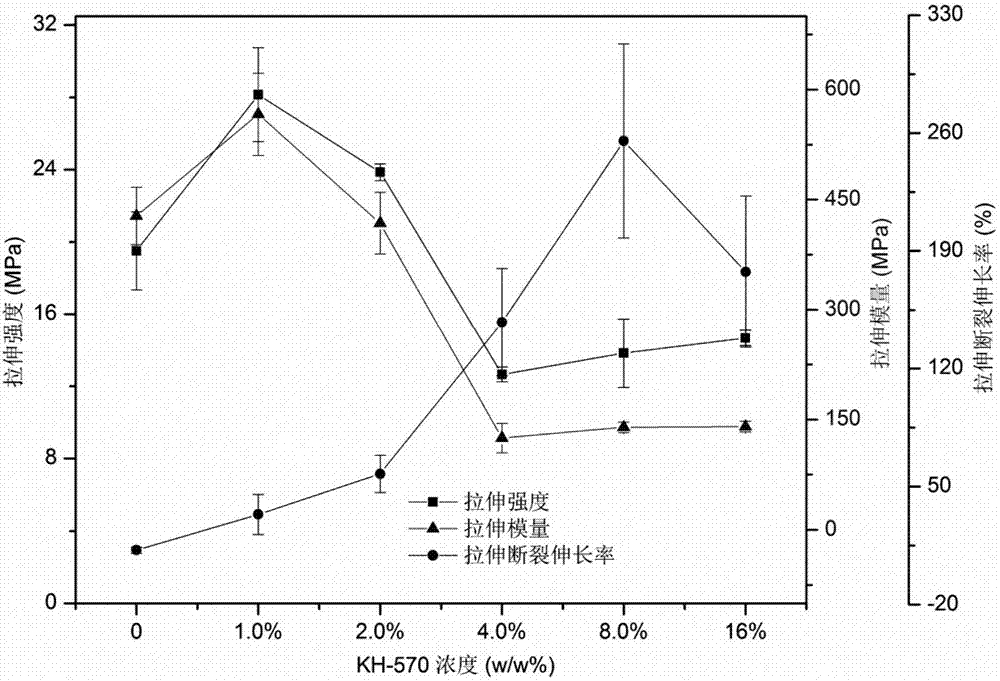

Polystyrene-resin-based composite material and preparation method thereof

The invention provides a polystyrene-resin-based composite material and a preparation method thereof and belongs to the field of materials. The polystyrene-resin-based composite material is prepared from polystyrene resin serving as a base body, a graphene sheet functionally modified by a silane coupling agent and serving as filler and elastomer POE-g-MAH serving as flexibilizer through a melt blending method. The elastic strength, the tensile strength and the elasticity modulus of the polystyrene-resin-based composite material are remarkably improved compared with polystyrene resin.

Owner:黑龙江昆和新材料科技有限公司

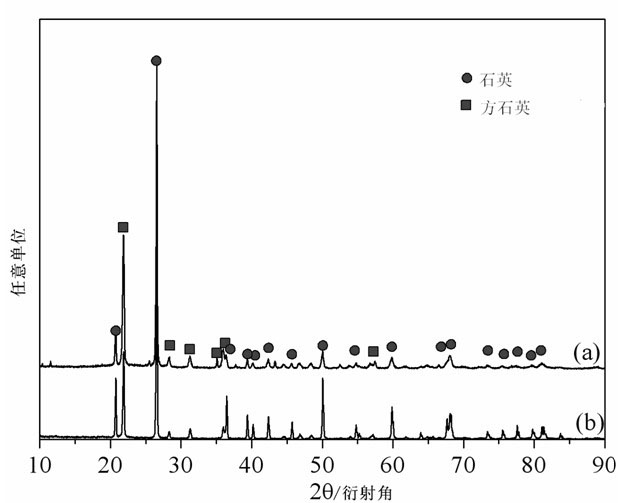

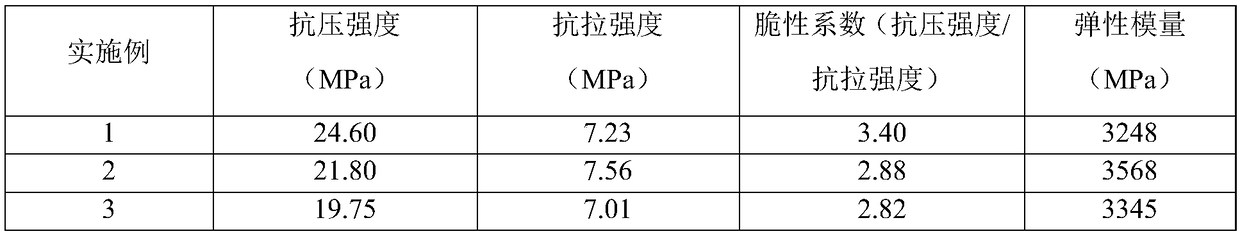

Preparation method of boron nitride nanotube-intensified silicon oxide ceramic

The invention relates to a preparation method of a boron nitride nanotube-intensified silicon oxide ceramic, which comprises the following steps of: A. pre-treating boron nitride nanotubes; B. weighing the boron nitride nanotubes and nano-grade and micron-grade silicon oxides; C. treating with different surface active agents; D. adding to a ball-milling pot, and compounding; E. drying, and screening; F. carrying out the hot pressed sintering in a multifunctional high-temperature sintering furnace in the shielding gas atmosphere; G. maintaining the temperature, then stopping heating, and naturally cooling to the room temperature; and H. machining the sintered ceramic block, and then testing the performance. The invention is a method which effectively improves the mechanical property of the silicon oxide, and greatly improves the mechanical property of the silicon oxide. The bend strength of the boron nitride nanotube-intensified silicon oxide ceramic is up to 130MPa, and is 6.5 times higher than that of the pure silicon oxide ceramic (19.6MPa).The process improves the mechanical property of the silicon oxide ceramic, and has the advantages of simple process, stability, high safety, easy operation and large scale production.

Owner:SHANDONG UNIV

Thermosetting epoxy resin well cementation working solution

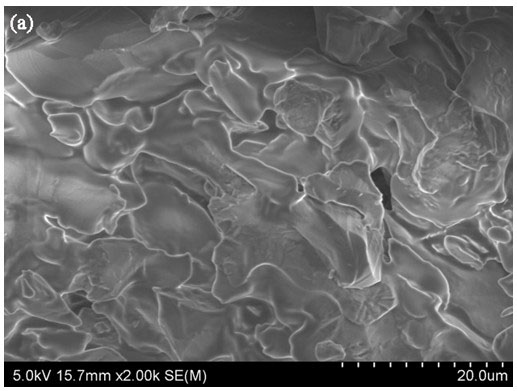

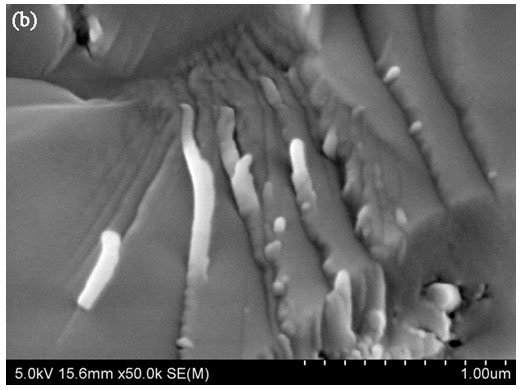

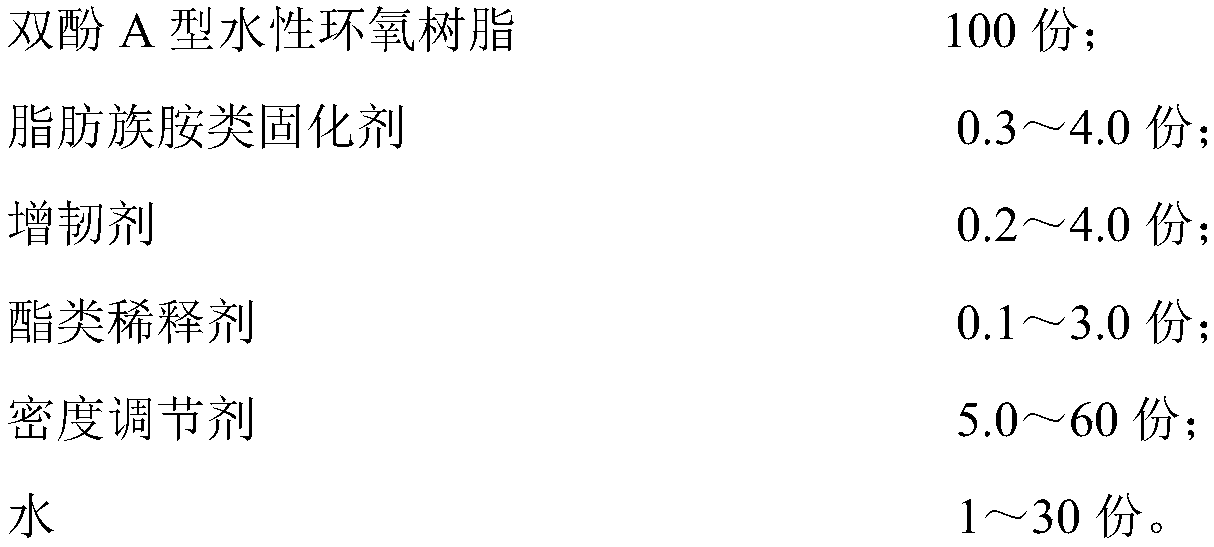

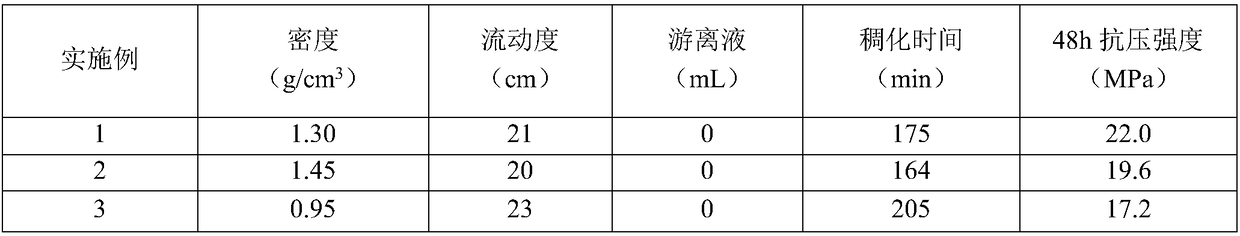

The invention discloses a thermosetting epoxy resin well cementation working solution which is prepared from the following ingredients in parts by weight: 100 parts of bisphenol A type waterborne epoxy resin, 0.3 to 4.0 parts of an aliphatic amine curing agent, 0.2 to 4.0 parts of a flexibilizer, 0.1 to 3.0 parts of an ester diluent, 5.0 to 60 parts of a density modifier and 1 to 30 parts of water, wherein the flexibilizer is a mixture of modified carbon nanotube and modified magnesium borate crystal whisker according to a part-by-weight proportion of 0.2 to 3.0; the modified nanotube is prepared by a carbon nanotube surface modifying method, the carbon nano tube is oxidized at first, and the carbon nano tube is treated by sodium hypochlorite; the modified magnesium borate crystal whiskeris prepared by a magnesium borate crystal whisker coupling treatment method. The thermosetting epoxy resin well cementation working solution disclosed by the invention has the characteristics of hightensile strength, high rupture strength and good toughness, can be directly applied to oil gas well cementation, also can be applied to repairing of damaged cement sheaths on which micro cracks arre generated and has a wide market application prospect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

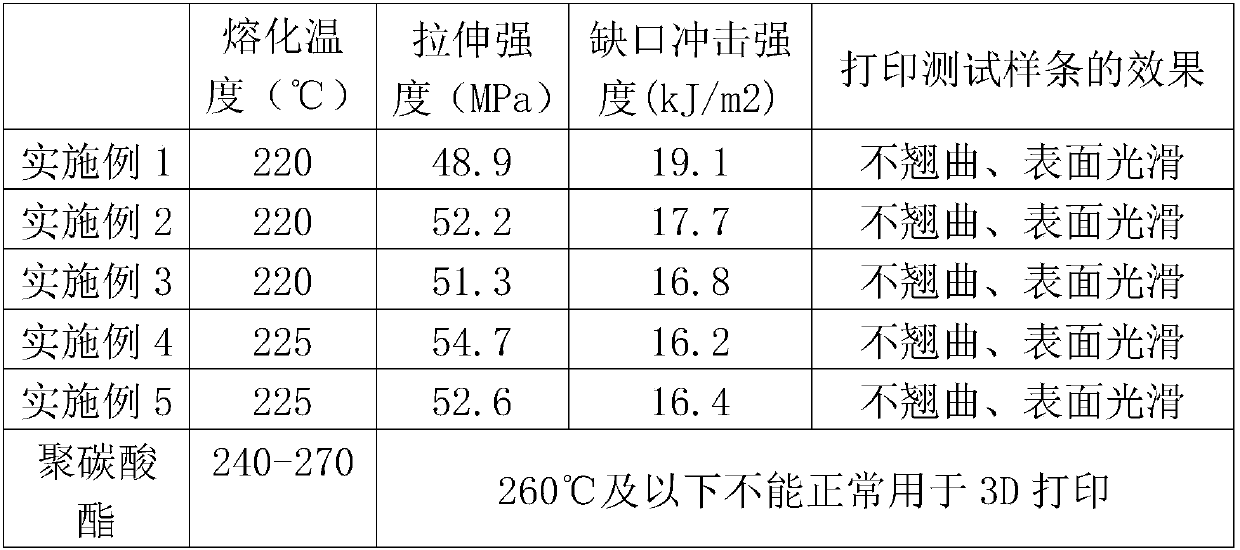

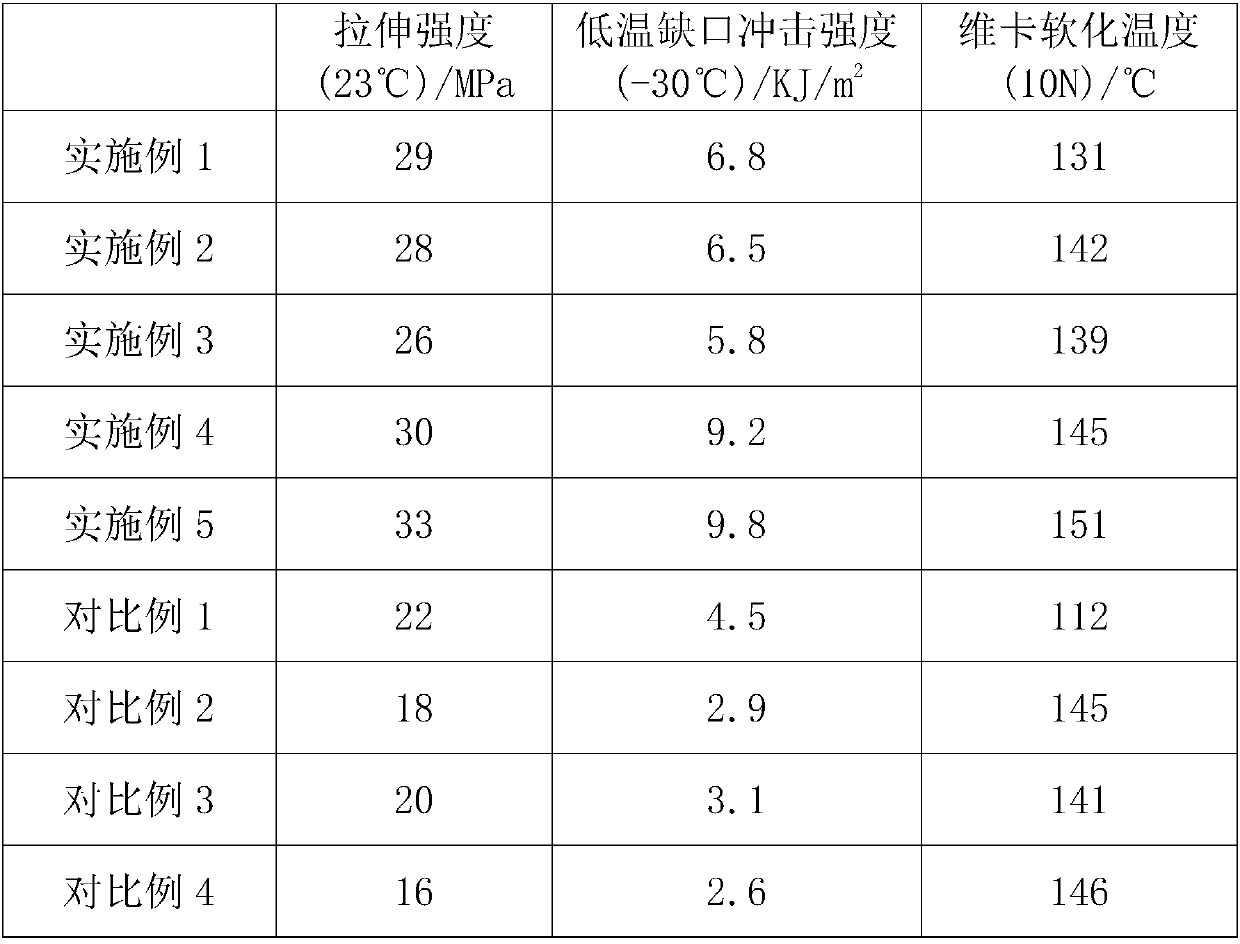

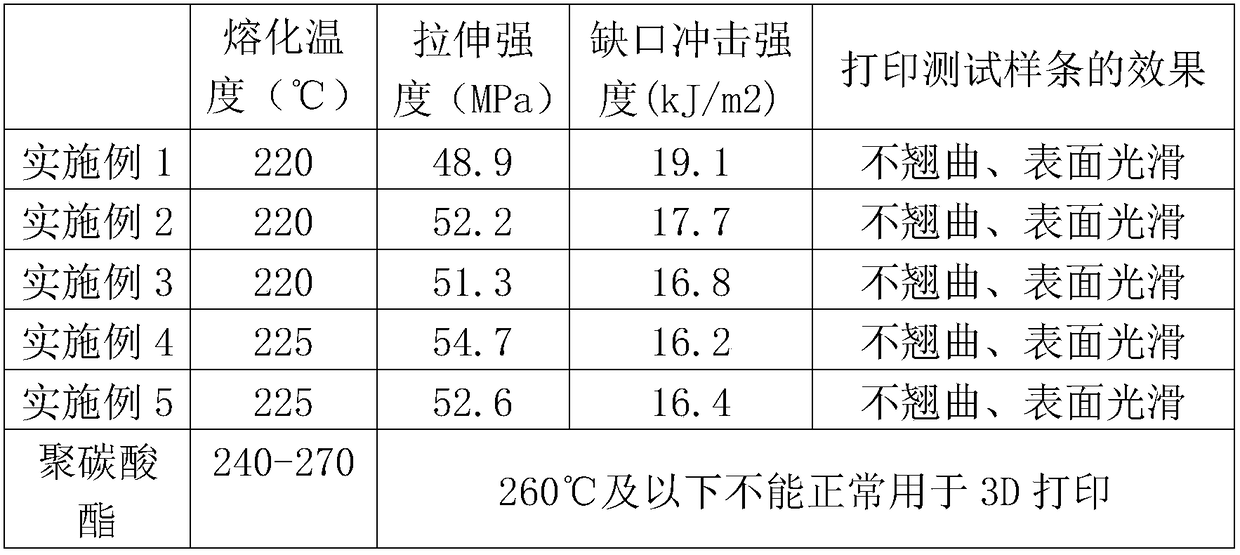

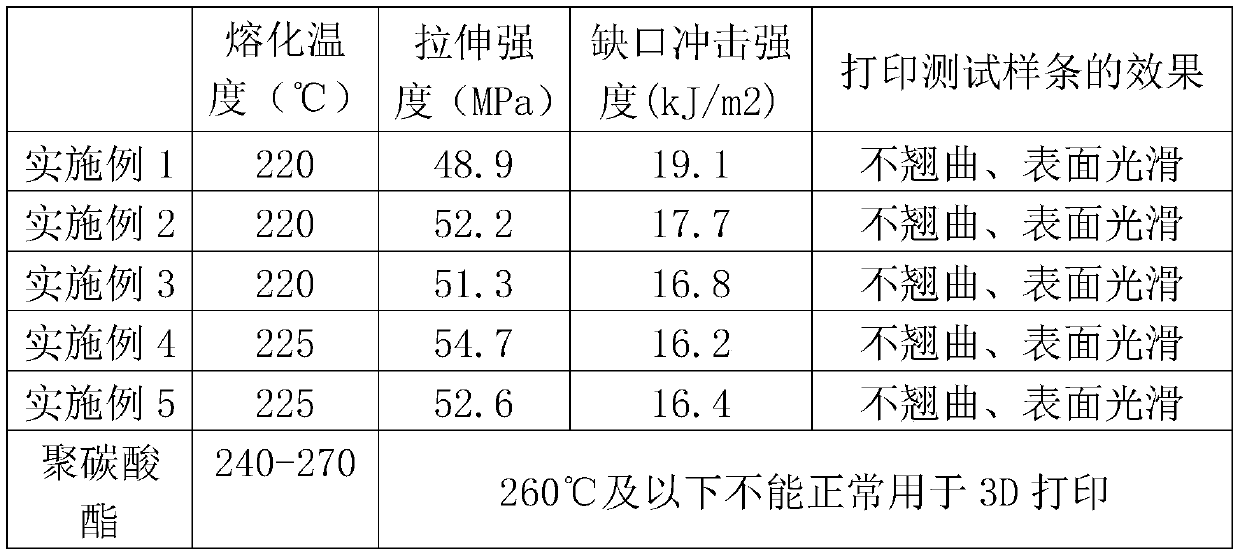

Modified polycarbonate material applied to 3D printing

ActiveCN108034217AAvoid crackingNo warpingAdditive manufacturing apparatusPolycarbonateSilicon dioxide

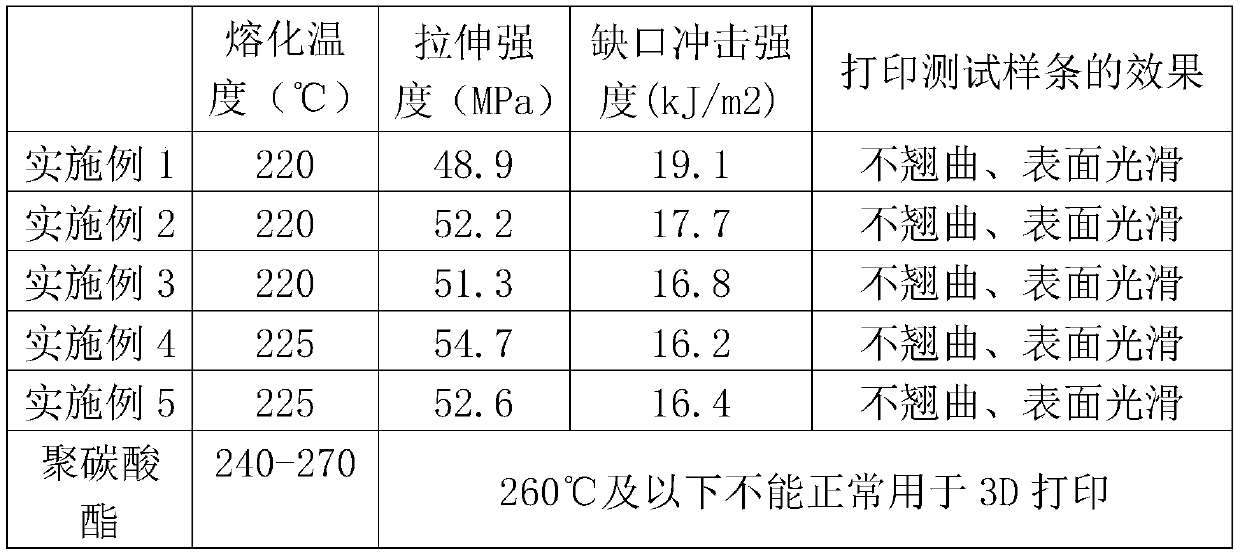

The invention relates to a modified polycarbonate material applied to 3D printing. The modified polycarbonate material is prepared from the following components in parts by weight: 100 parts of polycarbonate, 0 to 10 parts of a thermotropic liquid crystal polymer, 10 to 25 parts of polycaprolactone, 8 to 15 parts of a flexibilizer, 0 to 2 parts of hydrophobic fumed silica, 0.2 to 0.5 part of a hindered phenol antioxidant and 0.2 to 0.5 part of a phosphite antioxidant. The modified polycarbonate material applied to 3D printing can be printed and molded at a temperature of 260 DEG C, and is highin mechanical property, relatively high in tensile strength and notch impact strength and has low probability of thermal degrading; a printed product has no warping and deformation, has low probability of cracking and has a smooth and flat surface.

Owner:诺思贝瑞新材料科技(苏州)有限公司

Method for preparing polylactic acid, bamboo nano-cellulose whisker and ultrafine bamboo charcoal composite material film

InactiveCN106009570ASolve the problem of poor tensile toughnessResolve Tensile StrengthOrganic solventSolvent evaporation

The invention discloses a method for preparing a polylactic acid, bamboo nano-cellulose whisker and ultrafine bamboo charcoal composite material film. The method comprises the following steps: (1) performing surface modification treatment on bamboo nano-cellulose whiskers to obtain modified bamboo nano-cellulose whiskers; (2) performing surface modification treatment on ultrafine bamboo charcoal particles to obtain modified ultrafine bamboo charcoal particles; (3) conducting a solution pouring-solvent evaporation method: adding an organic solvent into polylactic acid, heating and stirring till polylactic acid is completely dissolved, then adding the modified bamboo nano-cellulose whiskers and the modified ultrafine bamboo charcoal particles, performing dispersion treatment to obtain a blend system, pouring the blend system in a die to manufacture a film, and drying to obtain the polylactic acid, bamboo nano-cellulose whisker and ultrafine bamboo charcoal composite material film. The method provided by the invention can endow a composite material with favorable tensile strength and tensile modulus of elasticity while toughening the polylactic acid composite material.

Owner:ZHEJIANG UNIV

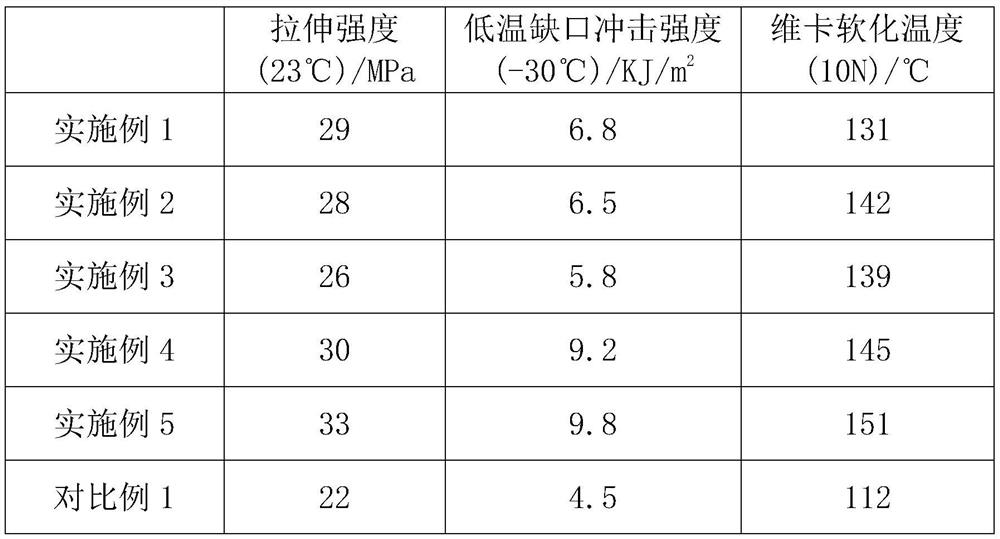

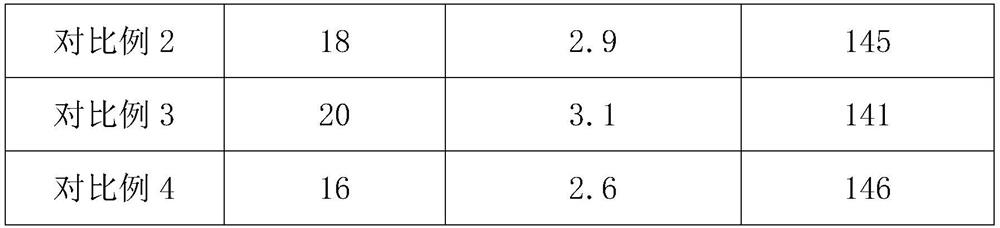

High-toughness matte modified polylactic acid material for 3D printing and preparation method of high-toughness matte modified polylactic acid material

ActiveCN109575539AImprove poor toughnessImprove anti-agingAdditive manufacturing apparatusElastomerAntioxidant

The invention relates to a high-toughness matte modified polylactic acid material for 3D printing and a preparation method of the high-toughness matte modified polylactic acid material. The modified polylactic acid material is prepared from, by weight, 100 parts of polylactic acid, 10-15 parts of a main toughening agent, 5-8 parts of an auxiliary toughening agent, 20-40 parts of filler, 3-6 partsof silicon dioxide matting powder, 0.1-0.5 part of a titanate coupling agent, 0.1-0.6 part of an antioxidant, 0.1-0.6 part of a light stabilizer and 0.2-0.5 part of a lubricant, wherein the main toughening agent is a soft-core hard-shell type core-shell copolymer with methyl methacrylate as a shell, the auxiliary toughening agent refers to an elastomer toughening agent containing anhydride or epoxy group, and the filler refers to barium sulfate powder or calcium carbonate powder. The high-toughness matte modified polylactic acid material for 3D printing is excellent in toughness, remarkable inaging resistance and great in matte surface effect.

Owner:诺思贝瑞新材料科技(苏州)有限公司

PPR (polypropylene random copolymer) pipe with copper texture

The invention relates to a PPR (polypropylene random copolymer) pipe with copper texture. The PPR pipe comprises, by weight, 100 parts of PPR, 15-30 parts of granular copper powder, 1-5 parts of flakycopper powder, 10-15 parts of dispersing agents, 8-18 parts of carbon fibers, 1-3 parts of coupling agents, 5-15 parts of soft-core hard-shelled core shell copolymer toughening agents and 1.3-3 partsof antioxidants. The PPR pipe has good copper texture and is good in low-temperature toughness, free from embrittlement and good in heat resistance.

Owner:江西陈氏科技集团股份有限公司

Preparation method of modified polycarbonate material for 3D printing

ActiveCN108164961AAvoid crackingNo warpingAdditive manufacturing apparatusSilicon dioxidePolycarbonate

The invention relates to a preparation method of a modified polycarbonate material for 3D printing. The method comprises the following steps: weighing, by weight, 100 parts of polycarbonate, 0-10 parts of a thermotropic liquid crystal polymer, 10-25 parts of polycaprolactone, 8-15 parts of a toughening agent, 0-2 parts of hydrophobic fumed silica, 0.2-0.5 part of a hindered phenolic antioxidant and 0.2-0.5 part of a phosphite antioxidant, mixing above raw materials, adding the obtained mixture into a twin-screw extruder, performing extruding granulation, drying obtained pellets, adding the dried pellets into a single-screw extruder, performing extrusion to obtain a plastic melt, and performing hot water treatment, cold water cooling setting and air drying on the plastic melt to obtain a wire. The method is convenient and economical, and is suitable for mass production, the prepared modified polycarbonate material for 3D printing has the advantages of realization of printing at a temperature of 260 DEG C or less, high tensile strength, high notched impact strength, and no thermal degradation, and products printed by using the material do not warp and have a smooth surface.

Owner:诺思贝瑞新材料科技(苏州)有限公司

Preparation method of carbon nanotube toughened silicon carbide ceramic

The invention discloses a preparation method of carbon nanotube toughened silicon carbide ceramic, and belongs to the technical field of composite ceramic materials. The preparation method of the carbon nanotube toughened silicon carbide ceramic comprises the following steps: S1, uniformly mixing silicon carbide, carbon black, silicon nitride coated carbon nanotubes, water-soluble phenolic resin and pure water to obtain uniformly dispersed slurry with the solid content of 48-52%; S2, heating the slurry obtained in the step S1, evaporating to remove water to obtain a blocky material, carrying out dry pressing on the blocky material, and carrying out one-step molding to obtain a green body; S3, covering the surface of the green body with monatomic silicon, putting the green body into a vacuum high-pressure sintering furnace, heating to 1300-1400 DEG C, keeping the temperature for a certain period of time, and converting amorphous silicon nitride on the surface of the carbon nano tubes into hexagonal silicon nitride; and heating up to 1450-1500DEG C, and keeping the temperature for a certain period of time to obtain the carbon nanotube toughened silicon carbide ceramic; the fiber structure of the carbon nanotubes can be reserved in the reaction sintering process, the toughening effect of carbon fiber is fully exerted, and the performance of the composite ceramic material is enhanced.

Owner:赛福纳米科技(徐州)有限公司

Fiber-reinforced extinction flame-retardant PC/ABS alloy and preparation method thereof

The invention relates to a fiber-reinforced extinction flame-retardant PC / ABS alloy and a preparation method thereof. The fiber-reinforced extinction flame-retardant PC / ABS alloy comprises the following components in parts by weight: 40-50 parts of PC resin, 20-30 parts of ABS resin, 10-15 parts of a DOPO-based nitrogen-phosphorus fire retardant, 5-10 parts of Kevlar chopped fibers, 15-30 parts ofcalcium silicate powder, 3-6 parts of silicon dioxide extinction powder, 3-8 parts of a toughening agent, 0.5-1 part of hyperbranched resin, and 0.2-1 part of an antioxidant. The fiber-reinforced extinction flame-retardant PC / ABS alloy is good in mechanical property without a fiber floating phenomenon, good in flame retardant effect, wherein a flame retardant level reaches a level V0, and low inglossiness, and has the apparent matte effect.

Owner:苏州市同发塑业有限公司

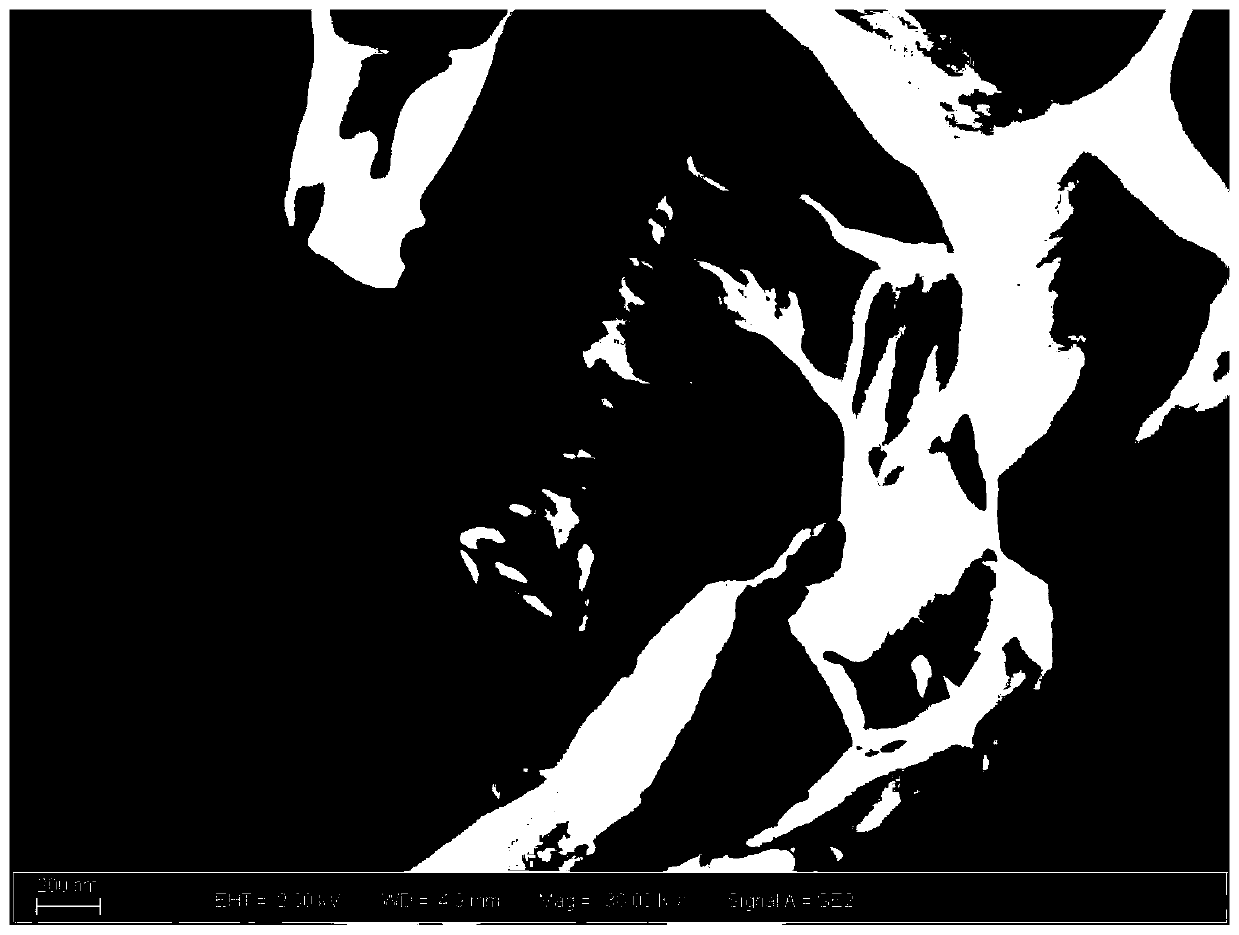

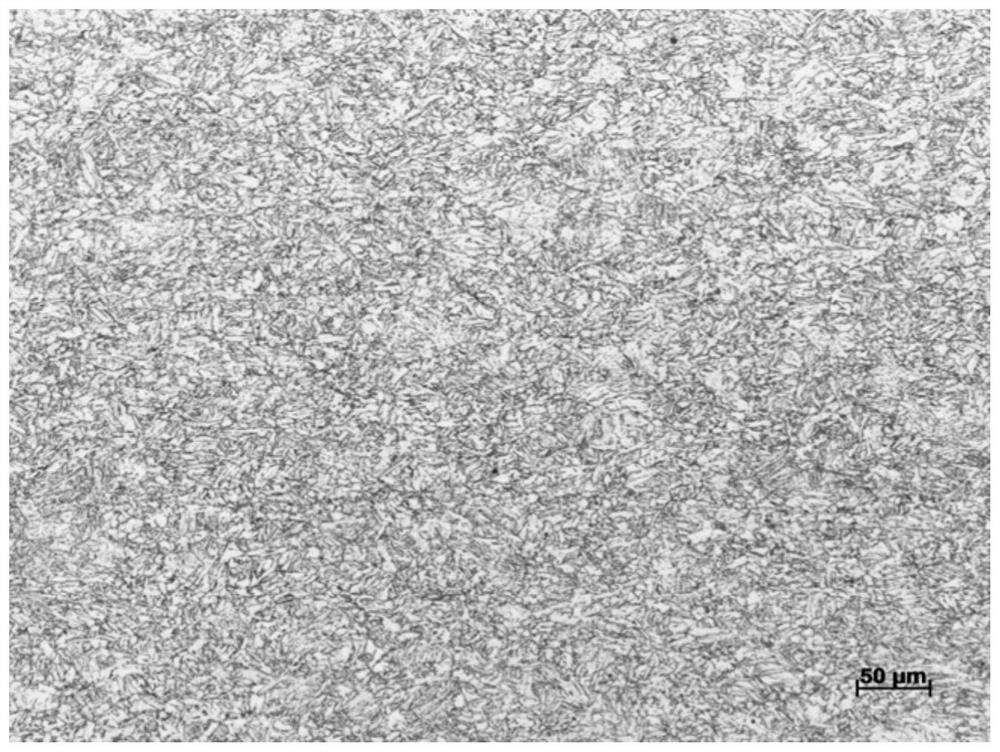

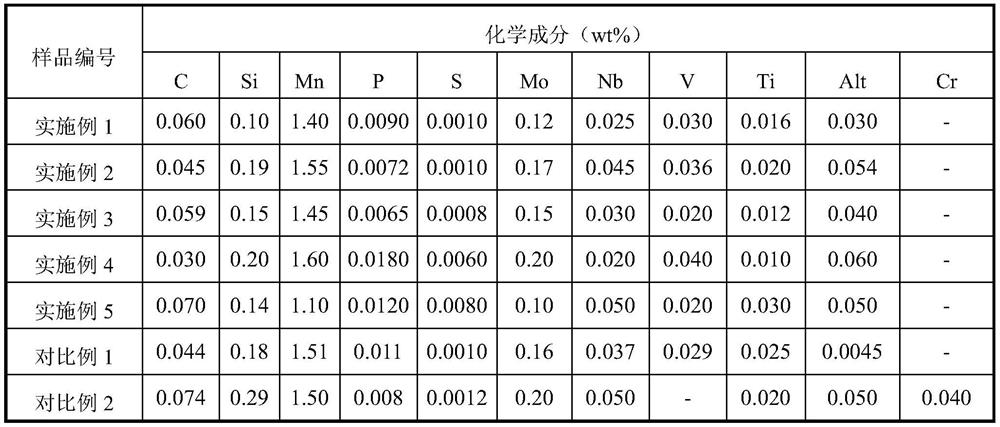

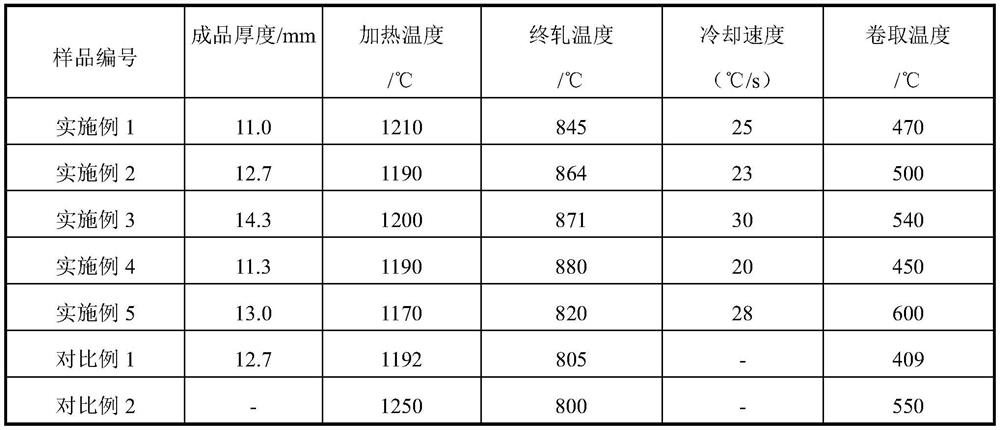

Subsea pipeline steel plate coil with excellent low-temperature CTOD performance and production process thereof

The invention discloses a subsea pipeline steel plate coil with an excellent low-temperature CTOD performance and a production process thereof, and belongs to correlation technique field of subsea oiland gas conveying pipelines. The subsea pipeline steel plate coil with the excellent low-temperature CTOD performance comprises the following chemical components in percentage by mass: 0.030 percentto 0.070 percent of C, 0.10 percent to 0.20 percent of Si, 1.10 percent to 1.60 percent of Mn, 0.020 percent to 0.050 percent of Nb, 0.020 percent to 0.040 percent of V, 0.010 percent to 0.030 percentof Ti, 0.10 percent to 0.20 percent of Mo, less than or equal to 0.06 percent of Alt, less than or equal to 0.008 percent of S, less than or equal to 0.018 percent of P, and the balance Fe and inevitable impurity elements. On the premise of meeting the performance requirements of subsea pipeline steel, through the design of corresponding technological steps and the design of relevant technological parameters, the subsea pipeline steel plate coil has the excellent CTOD performance.

Owner:MAANSHAN IRON & STEEL CO LTD

Marine ultrahigh-strength low-temperature steel with excellent fatigue performance and manufacturing method

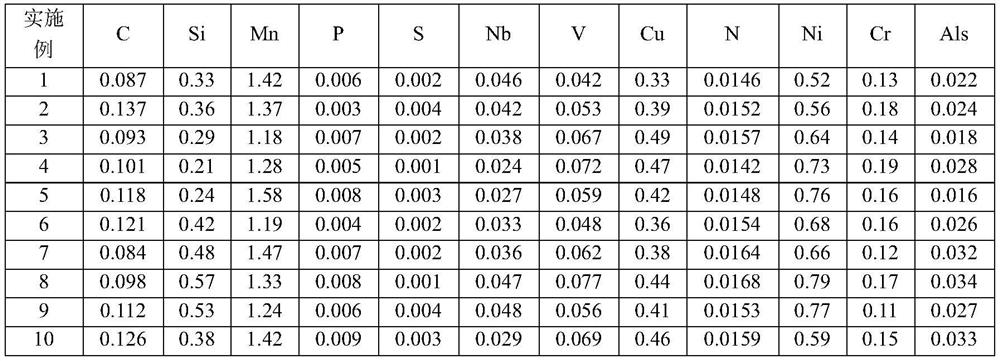

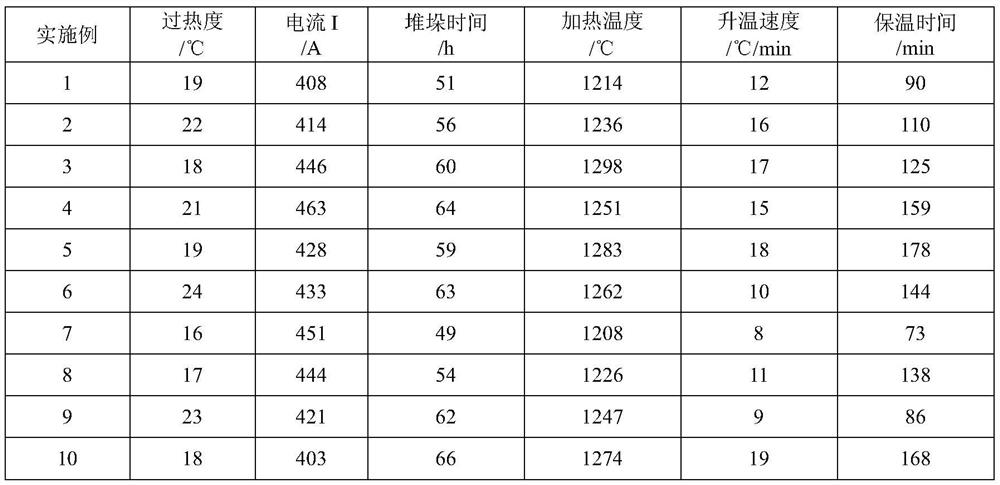

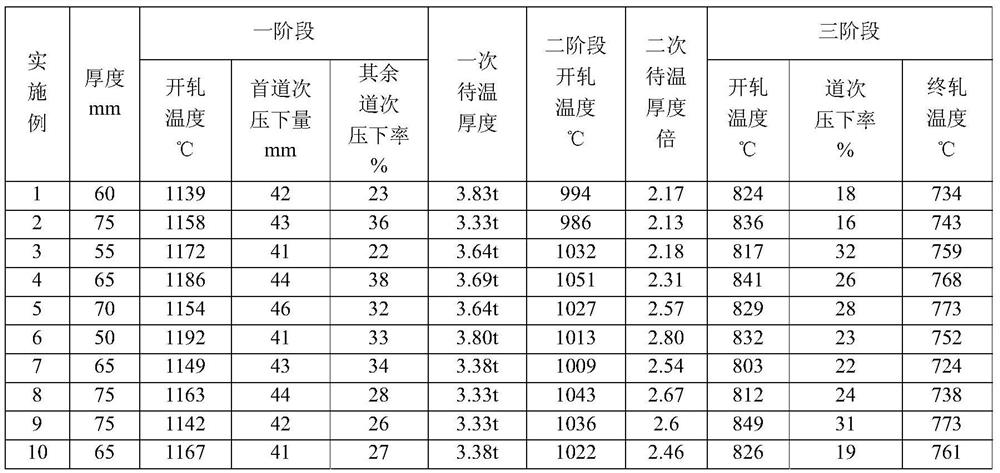

The invention provides marine ultrahigh-strength low-temperature steel with excellent fatigue performance and a manufacturing method thereof. The steel comprises the following components in percentage by weight: 0.080%-0.140% of C, 0.20%-0.60% of Si, 1.15%-1.60% of Mn, 0.020%-0.050% of Nb, 0.040%-0.080% of V, 0.30%-0.50% of Cu, 0.50%-0.80% of Ni, 0.0140%-0.057% of N, 0.10%-0.20% of Cr, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.015%-0.035% of Als and the balance of Fe and inevitable impurities. The preparation method comprises the steps of smelting, continuous casting, heating, rolling and cooling. The microscopic structure of the low-temperature steel produced through the method is a complex-phase structure of superfine ferrite, bainite and a small amount of martensite, the room-temperature high-cycle fatigue ultimate strength is 320 MPa or above, the fatigue ratio is larger than or equal to 0.52, and the-20 DEG C high-cycle fatigue ultimate strength is 350 MPa or above; according to the low-temperature steel, the yield strength is 500 MPa or above, the tensile strength is 620 MPa or above, the percentage elongation after fracture is 23.0% or above, the impact absorption energy at the temperature of-40 DEG C is larger than or equal to 260 J, and the impact absorption energy at the temperature of-60 DEG C is larger than or equal to 230 J.

Owner:ANGANG STEEL CO LTD

A modified polycarbonate material applied to 3D printing

ActiveCN108034217BAvoid crackingNo warpingAdditive manufacturing apparatusPolymer sciencePolycarbonate

The invention relates to a modified polycarbonate material applied to 3D printing. The modified polycarbonate material is prepared from the following components in parts by weight: 100 parts of polycarbonate, 0 to 10 parts of a thermotropic liquid crystal polymer, 10 to 25 parts of polycaprolactone, 8 to 15 parts of a flexibilizer, 0 to 2 parts of hydrophobic fumed silica, 0.2 to 0.5 part of a hindered phenol antioxidant and 0.2 to 0.5 part of a phosphite antioxidant. The modified polycarbonate material applied to 3D printing can be printed and molded at a temperature of 260 DEG C, and is highin mechanical property, relatively high in tensile strength and notch impact strength and has low probability of thermal degrading; a printed product has no warping and deformation, has low probability of cracking and has a smooth and flat surface.

Owner:诺思贝瑞新材料科技(苏州)有限公司

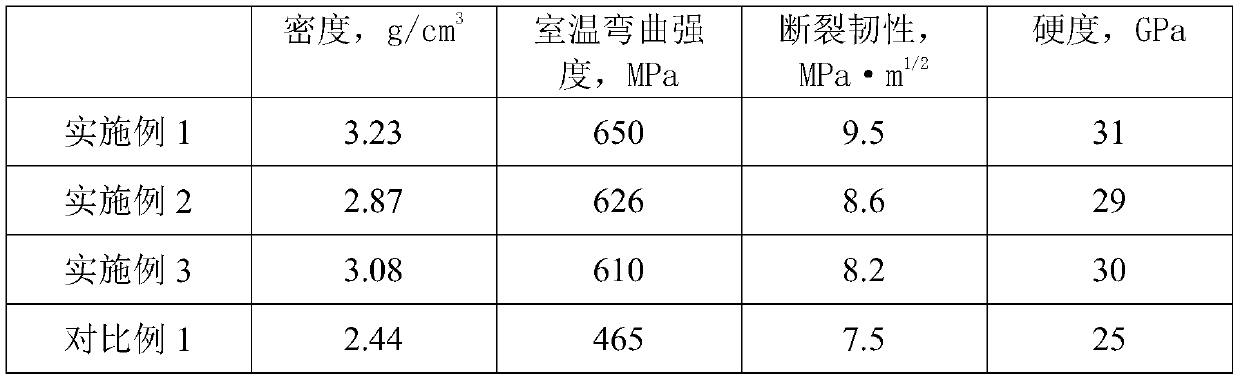

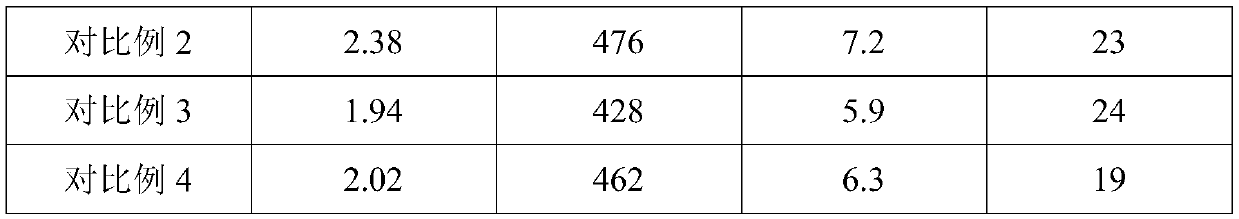

Toughened silicon carbide ceramic and preparation method thereof

InactiveCN111410538AGood hardnessOvercoming uneven quality of ceramicsAluminium oxideLanthanum oxide

The invention discloses toughened silicon carbide ceramic and a preparation method thereof, belongs to the technical field of ceramic materials, silicon carbide micro-powder, boron carbide micro-powder, carbon black, flaky aluminum oxide, magnesium fluoride, lanthanum oxide, carbon nanotubes, reinforced fibers and Ti-Si-Fe alloy powder are used as raw materials, are fully mixed after two-stage ball milling, spherical powder is obtained while the raw materials are refined, the flowability of the powder is enhanced, and subsequent compression molding of the powder is facilitated; the toughened silicon carbide ceramic material prepared by the invention has excellent hardness, density, strength and toughness, can still maintain most of properties under a high-temperature condition, and overcomes the problem of non-uniform ceramic quality caused by difficult uniform mixing of whiskers and fibers with very high length-diameter ratio in the prior art, so that the silicon carbide ceramic material has excellent properties.

Owner:WEIFANG BUSINESS VOCATIONAL COLLEGE +1

A kind of sintered zirconium corundum refractory raw material and preparation method thereof

InactiveCN105967706BImprove thermal shock resistanceGood thermal shock resistanceMagnesium saltCerium

Owner:WUHAN UNIV OF SCI & TECH

PVC pipe material having high toughness, thermal stability and stainless steel effects

The invention relates to a PVC pipe material having high toughness, thermal stability and stainless steel effects, which includes, by weight, 100 parts of PVC, 15-30 parts of stainless steel powder, 8-15 parts of a dispersant, 8-18 parts of crystal whiskers, 5-15 parts of butadiene styrene rubber powder, 1-3 parts of a coupling agent, 1.5-3 parts of a thermal stabilizer, and 0.5-1.5 parts of a lubricant. The PVC pipe material has excellent stainless steel effects, wherein due to the added butadiene styrene rubber powder and crystal whiskers, the PVC pipe material has good toughness, thus avoiding a problem of further reduction of the toughness of the PVC pipe material due to addition of the stainless steel powder. A rare earth stabilizer and a sulfo-ester anti-oxidant are compounded to prepare a thermal stabilizer, so that the PVC pipe material has excellent thermal stability.

Owner:SUZHOU SHUIBOSHI BUILDING MATERIAL TECH CO LTD

Sintered fused alumina zirconia refractory raw material and preparation method thereof

InactiveCN105967706AImprove thermal shock resistanceGood thermal shock resistanceCerous chlorideMagnesium salt

The invention relates to a sintered fused alumina zirconia refractory raw material and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps: placing alumina powder into a ball forming mill, and spraying ball forming liquid to obtain blank balls being 18-28mm in diameters, wherein the mass ratio of the alumina powder to the ball forming liquid is 1:(0.16-0.22); introducing the blank balls into a drying chamber of a high-temperature shaft kiln, drying at the temperature of 450-650 DEG C for 70-100 minutes, introducing the dried blank balls into a burning chamber of the high-temperature shaft kiln, preserving heat at the temperature of 1,850-1,900 DEG C for 25-45 minutes, cooling along with the kiln, smashing, sieving and packaging to obtain the sintered fused alumina zirconia refractory raw material. A preparation method of the ball-forming liquid comprises the following steps: preparing 86-92 percent by weight of zirconium oxychloride, 4-9 percent by weight of calcium salt or magnesium salt, 1-6.5 percent by weight of yttrium chloride and 0.5-3 percent by weight of cerium chloride to serve as raw materials; adding water into the raw materials in a solid-liquid ratio of 40-120g / L; stirring till clarification. The sintered fused alumina zirconia refractory raw material is low in cost, is suitable for industrial production, is uniform in structure and has superior thermal shock stability.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of PPR (polypropylene random copolymer) pipe with copper metal effect

The invention relates to a preparation method of a PPR (polypropylene random copolymer) pipe with a copper metal effect. The method comprises the following steps: raw materials in parts by weight including 100 parts of PPR, 15-30 parts of granular copper powder, 1-5 parts of flaky copper powder, 10-15 parts of a dispersant, 8-18 parts of carbon fibers, 1-3 parts of a coupling agent, 5-15 parts ofa soft-core and hard-shell type copolymer toughening agent and 1.3-3 parts of an antioxidant are prepared; the coupling agent is dispersed to the surfaces of the carbon fibers, and modified carbon fibers are obtained; the granular copper powder and the flaky copper powder are added to a dispersant solution, and a modified copper solution is obtained; PPR, the soft-core and hard-shell type copolymer toughening agent and the antioxidant in the preparation raw materials are mixed and sprayed into the modified copper solution, the solution is dried, and a premixed raw material is obtained; the premixed raw material and the modified carbon fibers are added to an extruder for extrusion and granulation, and the PPR pipe is obtained. The prepared PPR pipe has good copper texture and is good in low-temperature toughness and heat resistance.

Owner:江西陈氏科技集团股份有限公司

A kind of preparation method of modified polycarbonate material for 3D printing

ActiveCN108164961BAvoid crackingNo warpingAdditive manufacturing apparatusPolymer sciencePolycarbonate

The invention relates to a preparation method of a modified polycarbonate material for 3D printing. The method comprises the following steps: weighing, by weight, 100 parts of polycarbonate, 0-10 parts of a thermotropic liquid crystal polymer, 10-25 parts of polycaprolactone, 8-15 parts of a toughening agent, 0-2 parts of hydrophobic fumed silica, 0.2-0.5 part of a hindered phenolic antioxidant and 0.2-0.5 part of a phosphite antioxidant, mixing above raw materials, adding the obtained mixture into a twin-screw extruder, performing extruding granulation, drying obtained pellets, adding the dried pellets into a single-screw extruder, performing extrusion to obtain a plastic melt, and performing hot water treatment, cold water cooling setting and air drying on the plastic melt to obtain a wire. The method is convenient and economical, and is suitable for mass production, the prepared modified polycarbonate material for 3D printing has the advantages of realization of printing at a temperature of 260 DEG C or less, high tensile strength, high notched impact strength, and no thermal degradation, and products printed by using the material do not warp and have a smooth surface.

Owner:诺思贝瑞新材料科技(苏州)有限公司

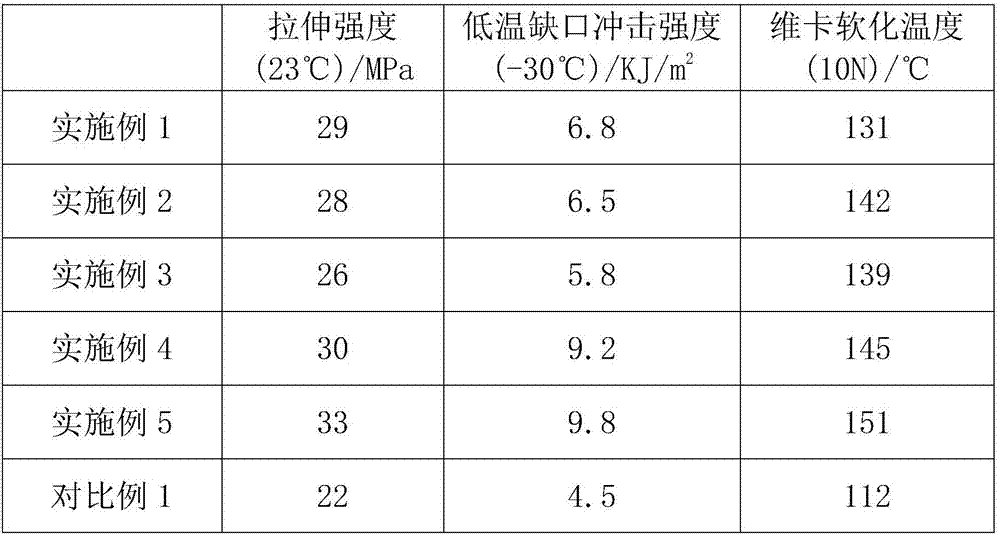

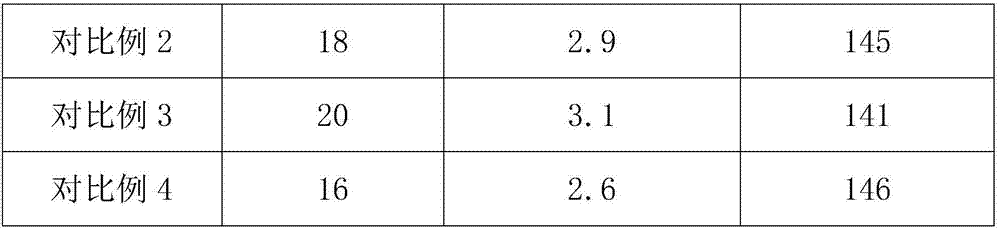

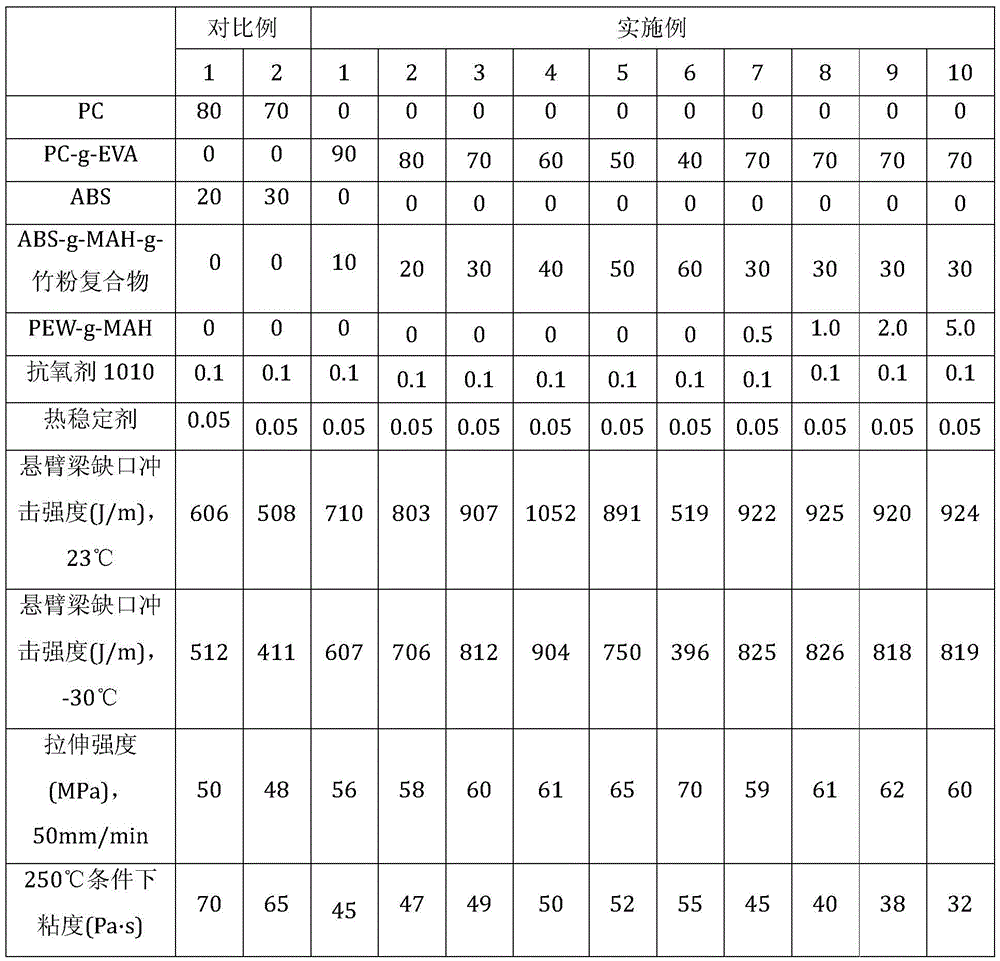

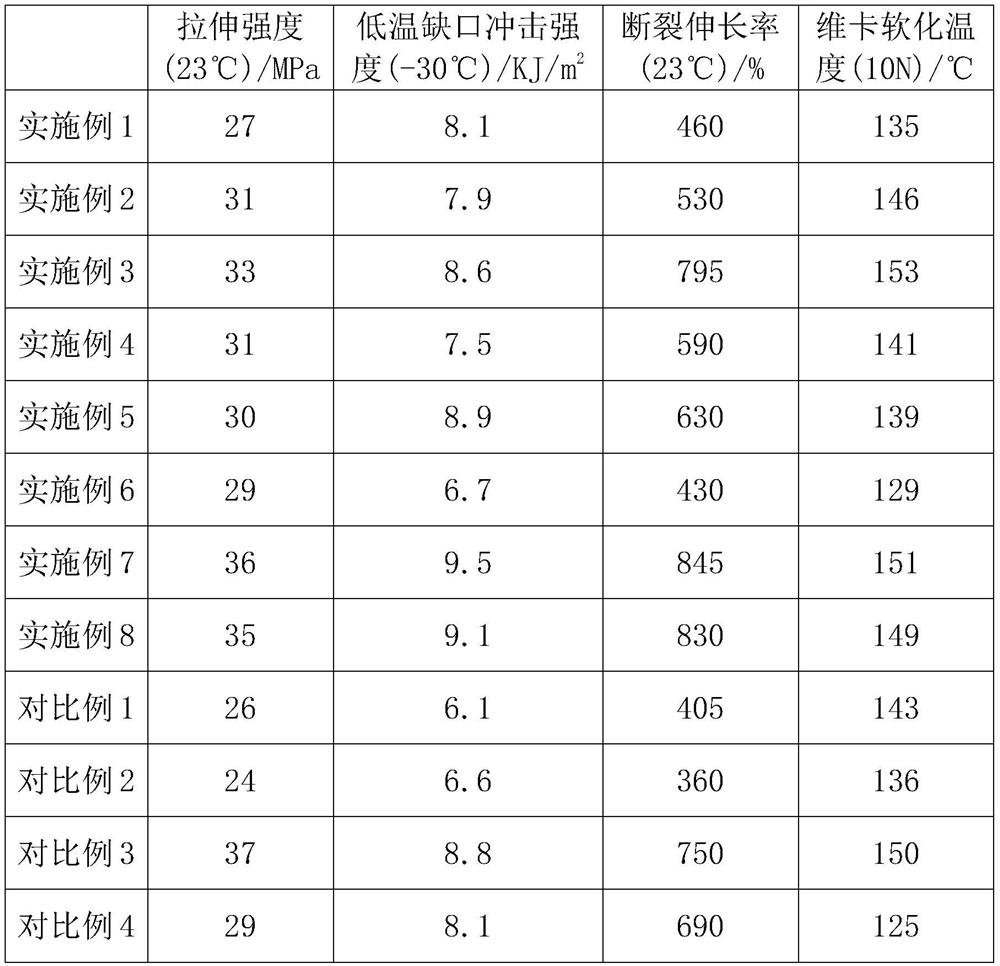

Based on modified bamboo powder pc/abs alloy and preparation method thereof

ActiveCN104804400BImproved impact characteristicsReduce processing viscosityFiberAcrylonitrile butadiene styrene

The invention relates to a manufacturing method of a modified bamboo powder-based PC / ABS (Poly carbonate / Acrylonitrile Butadiene Styrene) alloy in the field of high polymer materials. The manufacturing method comprises the following steps: carrying out blending and internal mixing on bamboo powder, ABS-g-MAH (Maleic Anhydride), a fiber pre-dispersing agent and a coupling agent to obtain an ABS-g-MAH-g-bamboo powder composite; blending the ABS-g-MAH-g-bamboo powder composite, PC-g-EVA (Ethylene Vinyl Acetate) and PEW (polyethylene wax)-g-MAH at high speed and carrying out melt blending to obtain the modified bamboo powder-based PC / ABS alloy. The alloy material manufactured by the method disclosed by the invention not only has superhigh normal-temperature impact tenacity and low-temperature impact tenacity, but also has low viscosity property, is easy for molding processing of larger products, and has relatively high tensile strength, relatively low cost and an environment-friendly effect as well as a wide market value.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

A kind of preparation method of ppr pipe with copper metal effect

The invention relates to a preparation method of a PPR (polypropylene random copolymer) pipe with a copper metal effect. The method comprises the following steps: raw materials in parts by weight including 100 parts of PPR, 15-30 parts of granular copper powder, 1-5 parts of flaky copper powder, 10-15 parts of a dispersant, 8-18 parts of carbon fibers, 1-3 parts of a coupling agent, 5-15 parts ofa soft-core and hard-shell type copolymer toughening agent and 1.3-3 parts of an antioxidant are prepared; the coupling agent is dispersed to the surfaces of the carbon fibers, and modified carbon fibers are obtained; the granular copper powder and the flaky copper powder are added to a dispersant solution, and a modified copper solution is obtained; PPR, the soft-core and hard-shell type copolymer toughening agent and the antioxidant in the preparation raw materials are mixed and sprayed into the modified copper solution, the solution is dried, and a premixed raw material is obtained; the premixed raw material and the modified carbon fibers are added to an extruder for extrusion and granulation, and the PPR pipe is obtained. The prepared PPR pipe has good copper texture and is good in low-temperature toughness and heat resistance.

Owner:江西陈氏科技集团股份有限公司

A method for preparing a high-toughness thermally conductive functional composite material

ActiveCN103435998BGive full play to the toughening effectAchieve paddingHeat-exchange elementsElastomerEngineering plastic

The invention relates to a method for preparing a high-toughness heat-conducting functional composite material. This method is based on the basic principle of core-shell structure toughening, and the heat-conducting filler is designed as the core, and the elastomer is designed as the shell, so as to achieve high filling and give full play to the toughening effect of the elastomer. The specific implementation method is to firstly prepare heat-conducting composite material master batches from heat-conducting fillers, elastomer compatibilizers, and processing aids, and then melt and blend them with a certain proportion of engineering plastics. The high-toughness and heat-conducting functional composite material prepared by the method of the present invention has functions such as high toughness, high thermal conductivity and good processing fluidity, and can be applied to molding processes such as extrusion and injection. It has good application prospects, and its production process is simple and easy to operate. The control is convenient, the quality is stable, the production efficiency is high, and it has broad industrialization and market prospects.

Owner:SICHUAN UNIV

Metakaolin-based inorganic composite cementitious material and its toughening modifier

The invention discloses a metakaolin-based inorganic composite cementing material and a toughening modifier of the metakaolin-based inorganic composite cementing material. The toughening modifier can effectively improve the toughness and the bearing capacity of the metakaolin-based inorganic composite cementing material and has the advantages of being simple in preparation process and low in production cost. The metakaolin-based inorganic composite cementing material and the toughening modifier of the metakaolin-based inorganic composite cementing material comprise the following components in parts by weight: 60 to 80 parts of fiber and 20 to 40 parts of fiber suspending agent.

Owner:江苏博拓新型建筑材料股份有限公司

A ppr pipe with copper texture

Owner:江西陈氏科技集团股份有限公司

A kind of polystyrene resin matrix composite material and preparation method thereof

The invention provides a polystyrene-resin-based composite material and a preparation method thereof and belongs to the field of materials. The polystyrene-resin-based composite material is prepared from polystyrene resin serving as a base body, a graphene sheet functionally modified by a silane coupling agent and serving as filler and elastomer POE-g-MAH serving as flexibilizer through a melt blending method. The elastic strength, the tensile strength and the elasticity modulus of the polystyrene-resin-based composite material are remarkably improved compared with polystyrene resin.

Owner:黑龙江昆和新材料科技有限公司

Preparation method of polylactic acid bamboo nanocellulose whisker ultrafine bamboo charcoal composite film

InactiveCN106009570BSolve the problem of poor tensile toughnessImprove brittle defectsOrganic solventSolvent evaporation

The invention discloses a method for preparing a polylactic acid, bamboo nano-cellulose whisker and ultrafine bamboo charcoal composite material film. The method comprises the following steps: (1) performing surface modification treatment on bamboo nano-cellulose whiskers to obtain modified bamboo nano-cellulose whiskers; (2) performing surface modification treatment on ultrafine bamboo charcoal particles to obtain modified ultrafine bamboo charcoal particles; (3) conducting a solution pouring-solvent evaporation method: adding an organic solvent into polylactic acid, heating and stirring till polylactic acid is completely dissolved, then adding the modified bamboo nano-cellulose whiskers and the modified ultrafine bamboo charcoal particles, performing dispersion treatment to obtain a blend system, pouring the blend system in a die to manufacture a film, and drying to obtain the polylactic acid, bamboo nano-cellulose whisker and ultrafine bamboo charcoal composite material film. The method provided by the invention can endow a composite material with favorable tensile strength and tensile modulus of elasticity while toughening the polylactic acid composite material.

Owner:ZHEJIANG UNIV

A kind of high toughness matt modified polylactic acid material for 3D printing and preparation method thereof

ActiveCN109575539BImprove poor toughnessImprove anti-agingAdditive manufacturing apparatusElastomerMethacrylate methyl

Owner:诺思贝瑞新材料科技(苏州)有限公司

A kind of method for preparing ppr pipe with aluminum metal effect

The invention relates to a method for preparing a PPR (polypropylene) tube with an aluminum metal effect. The method comprises the following specific steps: preparing the following raw materials in parts by weight: 100 parts of PPR, 10-25 parts of aluminum powder, 8-18 parts of a dispersing agent, 3-8 parts of a core-shell copolymer with a soft core and a hard shell, 5-10 parts of styrene-butadiene rubber, 5-10 parts of carbon fiber, 3-8 parts of aciform wollastonite fiber, 1-3 parts of a coupling agent and 1.5-3 parts of an antioxidant; distributing a weakly acidic coupling agent solution onthe surface of the carbon fiber and the surface of the aciform wollastonite fiber; adding the aluminum powder into an alkaline dispersing agent solution; stirring and mixing the PPR, the core-shell copolymer with the soft core and the hard shell, the styrene-butadiene rubber and the antioxidant, and simultaneously, spraying modified aluminum powder mixed liquid to obtain a premixed raw material; and adding the premixed raw material, the modified carbon fiber and the modified aciform wollastonite fiber to an extruding machine to be extruded and granulated to obtain the PPR tube. The PPR tube prepared by the method provided by the invention has the advantages of uniform aluminum metal effect, good low-temperature flexibility and good heat resistance.

Owner:江西陈氏科技集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com