Patents

Literature

30results about How to "No floating fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reinforced nylon material without floating fiber and preparation method thereof

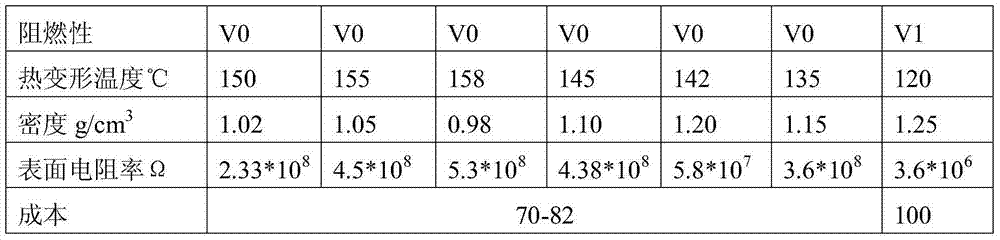

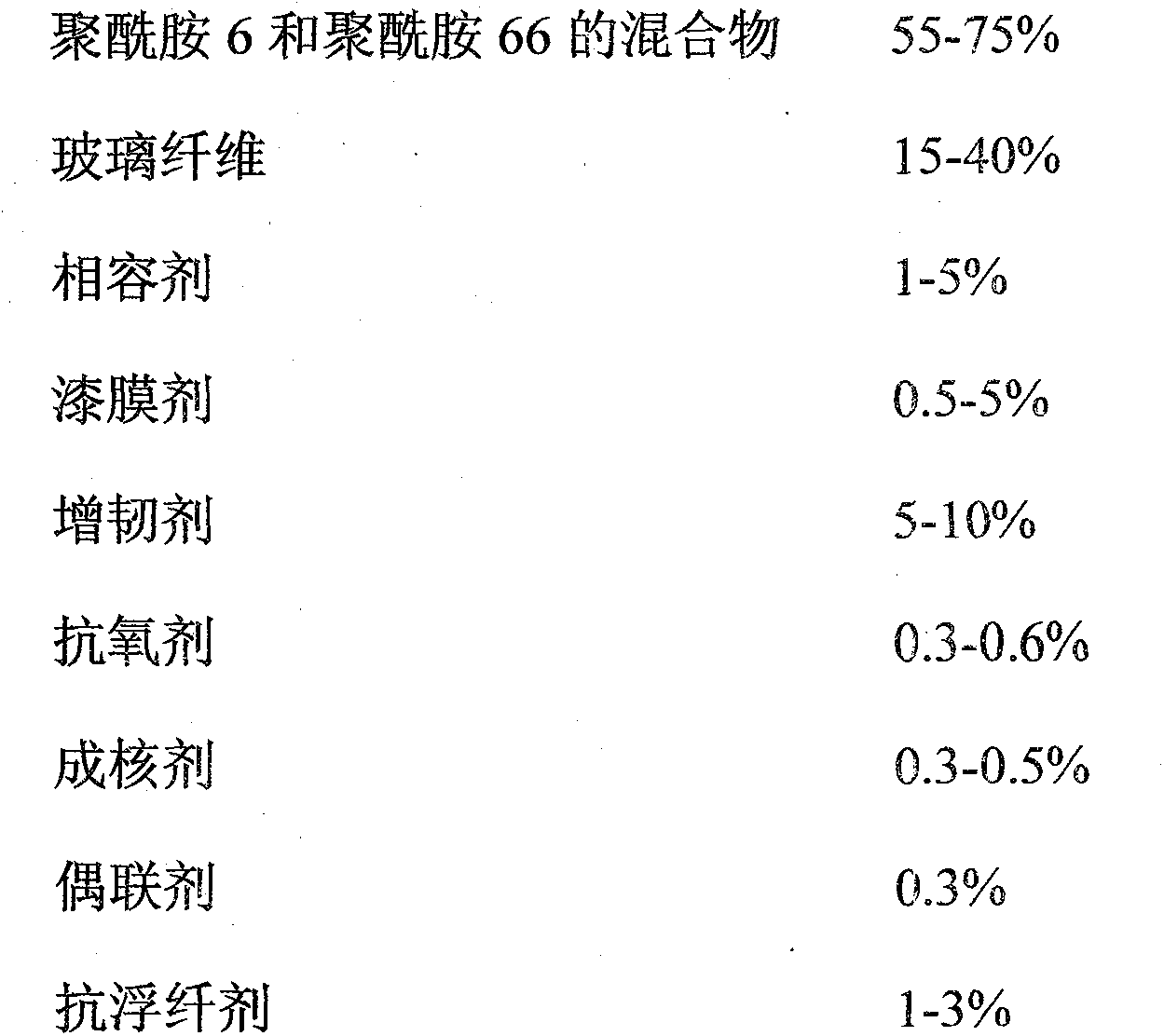

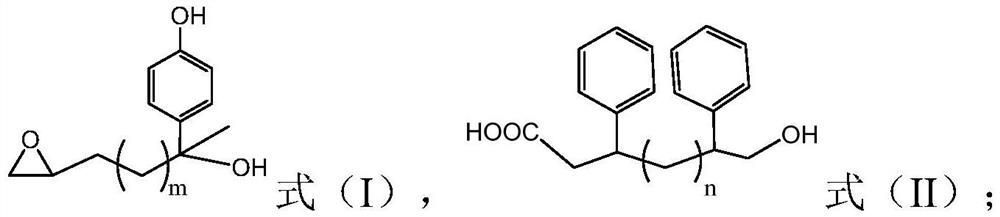

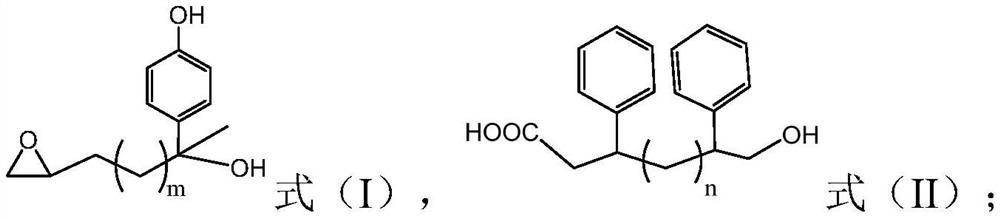

The invention discloses a reinforced nylon material without floating fiber, which is prepared from the following raw materials in percentage by weight: 42% of polyamide 6, 15% of polyamide 66, 34% of glass fiber, 1% of compatibilizer, 2% of film painting agent, 3% of toughening agent, 0.3% of antioxidant, 0.4% of nucleating agent, 0.3% of coupling agent and 2% of floating fiber resisting agent. The invention also discloses a preparation method of nylon material, which comprises the steps of drying the polyamide 6 and the polyamide 66, throwing the raw materials into a high-speed mixer for high-speed mixing, then throwing the mixed the raw materials into a double-screw extruder, and finally granulating and packaging to obtain the product via melting, mixing, extruding, cooling and drying sequentially. The high-performance reinforced nylon material without floating fiber has the characteristics of high rigidity, high toughness, high liquidity, high heat resistance, no floating fiber and the like.

Owner:SUZHOU TAIKAN MACHINERY CO LTD

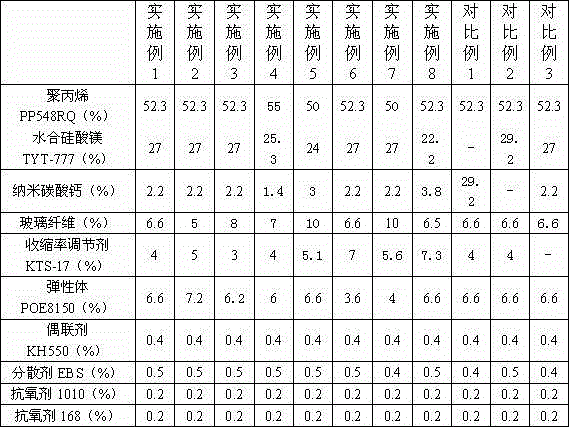

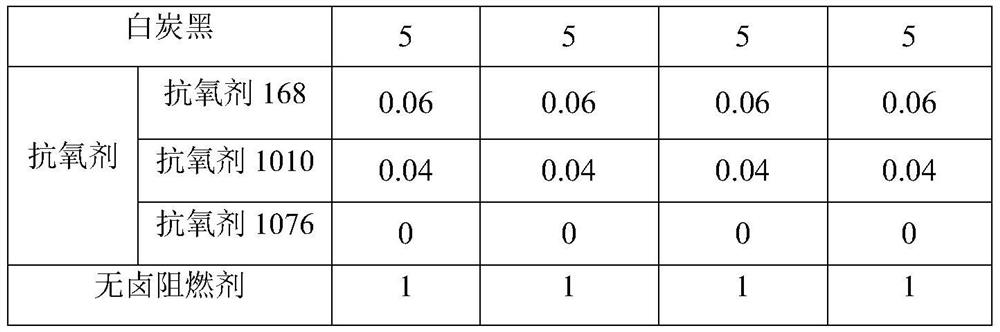

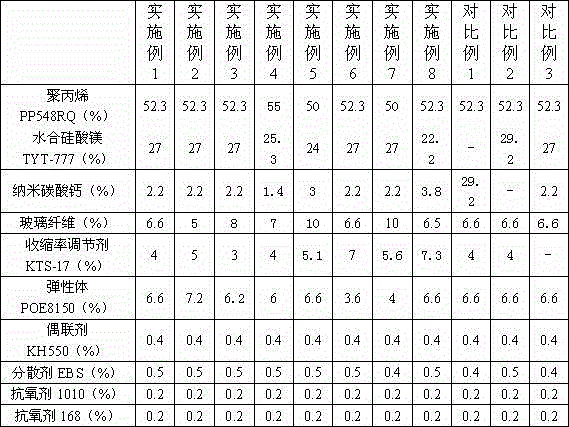

Modified polypropylene material with low molding shrinkage and without buckling deformation and preparation method of modified polypropylene material

The invention discloses a modified polypropylene material and a preparation method thereof. The modified polypropylene material comprises the following ingredients by mass percentage: 50-55% of polypropylene, 25-30% of filler, 5-10% of glass fiber, 3-8% of shrinkage regulator, 3-8% of elastomer, 0.5-1% of coupling agent, 0.4-1% of dispersing agent, and 0.2-0.5% of antioxidant. The preparation method comprises the steps of mixing weighed PP (polypropylene) resin and the coupling agent in a high speed mixer, adding the other ingredients than the glass fiber for mixing for 5-10min, fusing, mixing, extruding, cooling, drying, pelleting and packaging the mixed material and the glass fiber, and obtaining the modified polypropylene material. According to the polypropylene material and the preparation method, horizontal and vertical flow shrinkages of polypropylene are reduced to below 0.8%, the difference between the shrinkages is very small (below 0.1%), the polypropylene material has excellent processability and rigidity and balanced toughness, a product made of modified polypropylene is free from warpage, no fiber exists on the surface of the product, and the application field of the polypropylene material is expanded greatly.

Owner:GUANGDONG TIANBAO NEW MATERIALS CO LTD

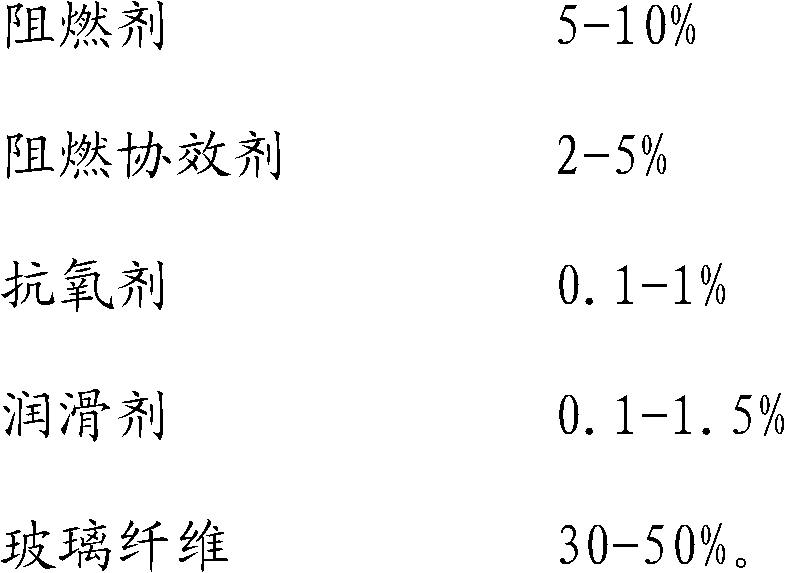

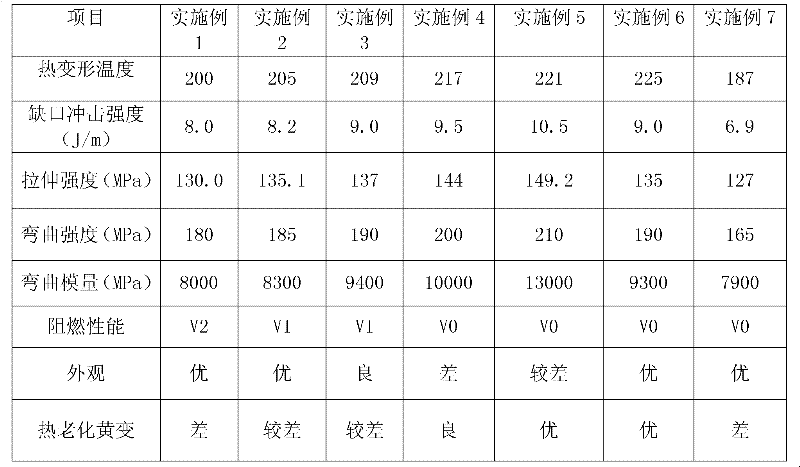

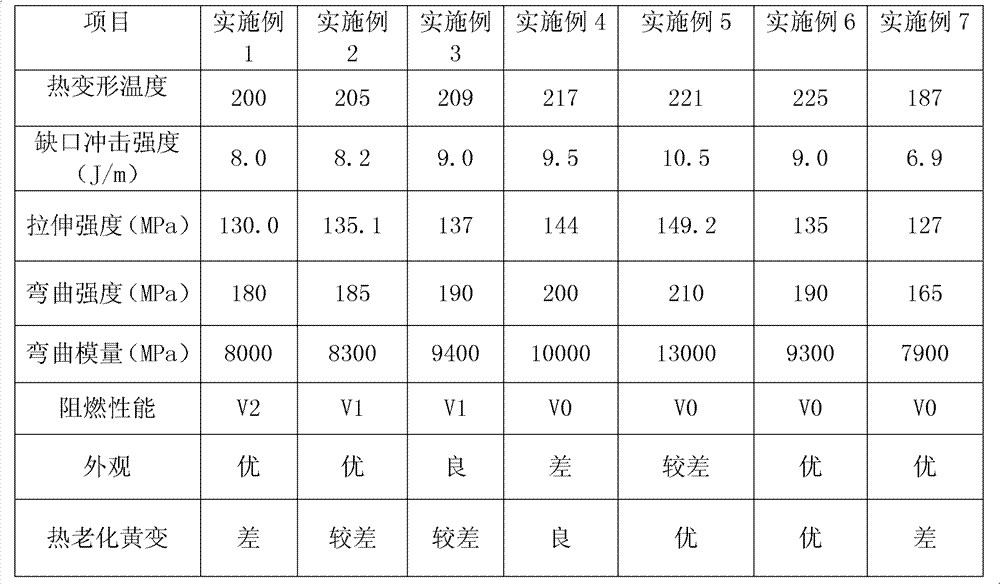

Thermal aging resistant PET modified material and its preparation method

The invention discloses a thermal aging resistant PET modified material and its preparation method. The PET modified material provided by the invention comprises the following components of: by weight, 38-62% of PET, 0.3-0.1% of a nucleating agent, 5-10% of a flame retardant, 2-5% of a flame-retardant synergist, 0.1-1% of an anti-oxidant, 0.1-1.5% of a lubricant and 30-50% of glass fibre. The thermal aging resistant PET modified material prepared in the invention has advantages of high temperature resistance, thermal aging resistance, good physical comprehensive properties and good surface glossiness without no floating fibre, and can be widely applied in the field of electronic and electrical products such as coil winders, integrated circuit packages, timer packages, relays and the like,in the field of automobile spare and accessory parts such as automobile headlight decorative loops, heatproof automobile wheel covers, midget electric motor cover casing and the like, and in the field of household electrical appliances such as straight hair device shells, electric iron pedestals, straight hair device heat spacers and the like.

Owner:SHENZHEN KEJU NEW MATERIAL

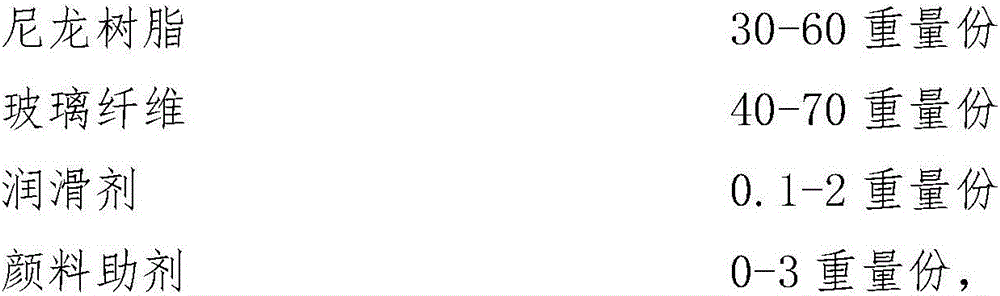

High-fiber reinforced nylon composite material

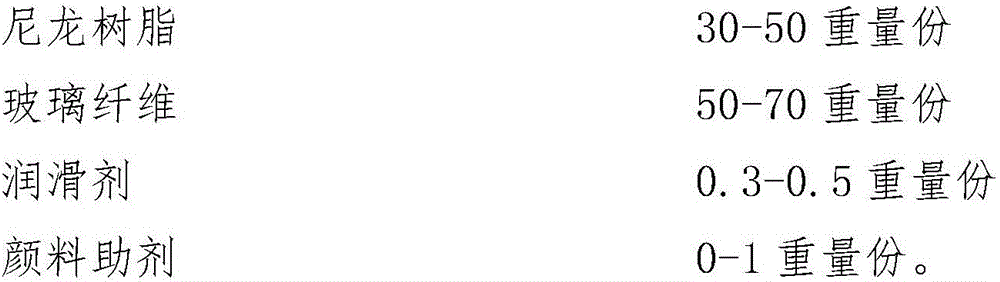

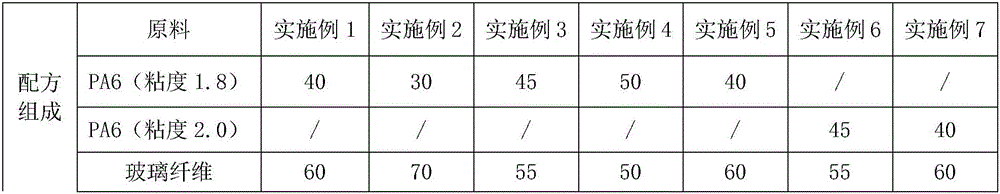

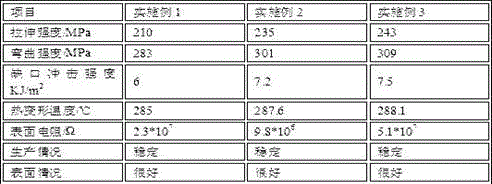

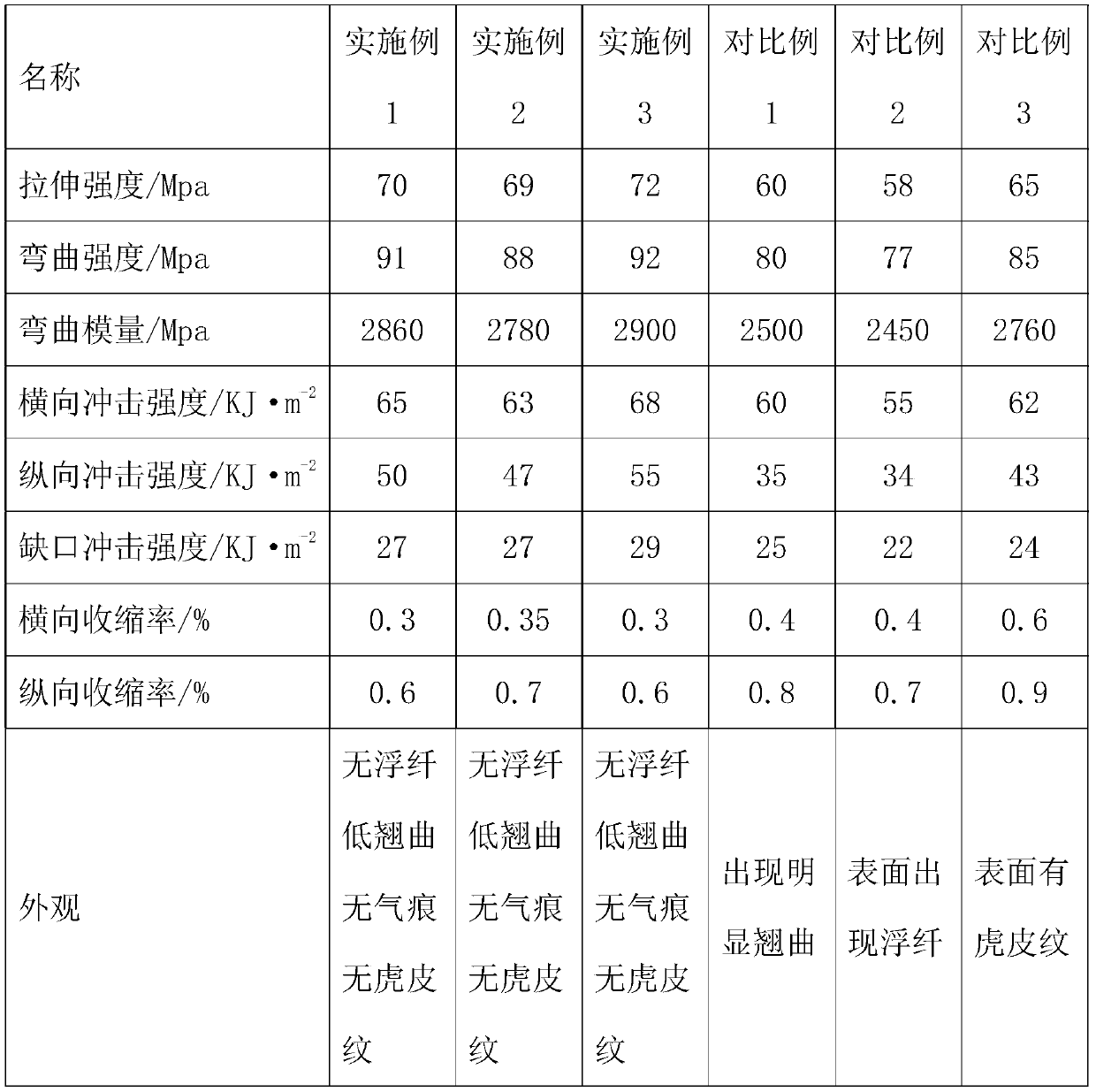

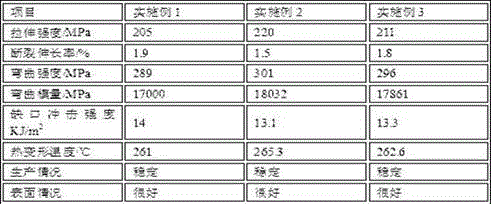

The invention belongs to the technical field of high molecular materials, and particularly relates to a high-fiber reinforced nylon composite material with high strength, high modulus and superior appearance. The high-fiber reinforced nylon composite material is prepared from the following components in parts by weight: 30 to 60 parts of nylon resin, 40 to 70 parts of glass fiber, 0.1 to 2 parts of lubricating agent, and 0 to 3 parts of pigment auxiliary. According to the high-fiber reinforced nylon composite material provided by the invention, the nylon resin with the viscosity being 1.6 to 2.1 is selected, and excellent mobility of the low-viscosity nylon resin is utilized, so that the dispersed homogeneous degree of the glass fiber in a nylon resin matrix is improved, the glass fiber can be completely coated by the resin matrix, the interface bonding of the resin matrix and the glass fiber is better, and the high-fiber reinforced nylon composite material with high glass fiber content, bright surface, no floating fiber, and superior appearance can be conveniently obtained through extruding. The nylon composite material prepared through the invention has high strength and high modulus, and the application range of the high-fiber reinforced nylon material in the application fields with high mechanical property and appearance requirements is widened.

Owner:BENSONG ENG PLASTICS HANGZHOU

Enhanced antistatic polyetheretherketone composite material and preparation method thereof

The invention discloses an enhanced antistatic polyetheretherketone composite material, which is prepared from the following components in parts by weight: 45-60 parts of polyetheretherketone, 15-40 parts of continuous fiber, 0.5-5 parts of graphene, 0.1-5 parts of coupling agent and 0.1-5 parts of processing agent. The invention also discloses a preparation method of the enhanced antistatic polyetheretherketone composite material, wherein the continuous fiber is charged from a first exhaust opening of an extruding machine under the function of a traction machine. The polyetheretherketone composite material disclosed by the invention has the advantages of high surface quality, stable production process, simplicity in operation, obviously improved mechanical performance and thermal performance, and capability of meeting antistatic requirement.

Owner:山东赛航新材料有限公司

Glass fiber reinforced polypropylene material used for thin-wall injection molding and preparation method of glass fiber reinforced polypropylene material

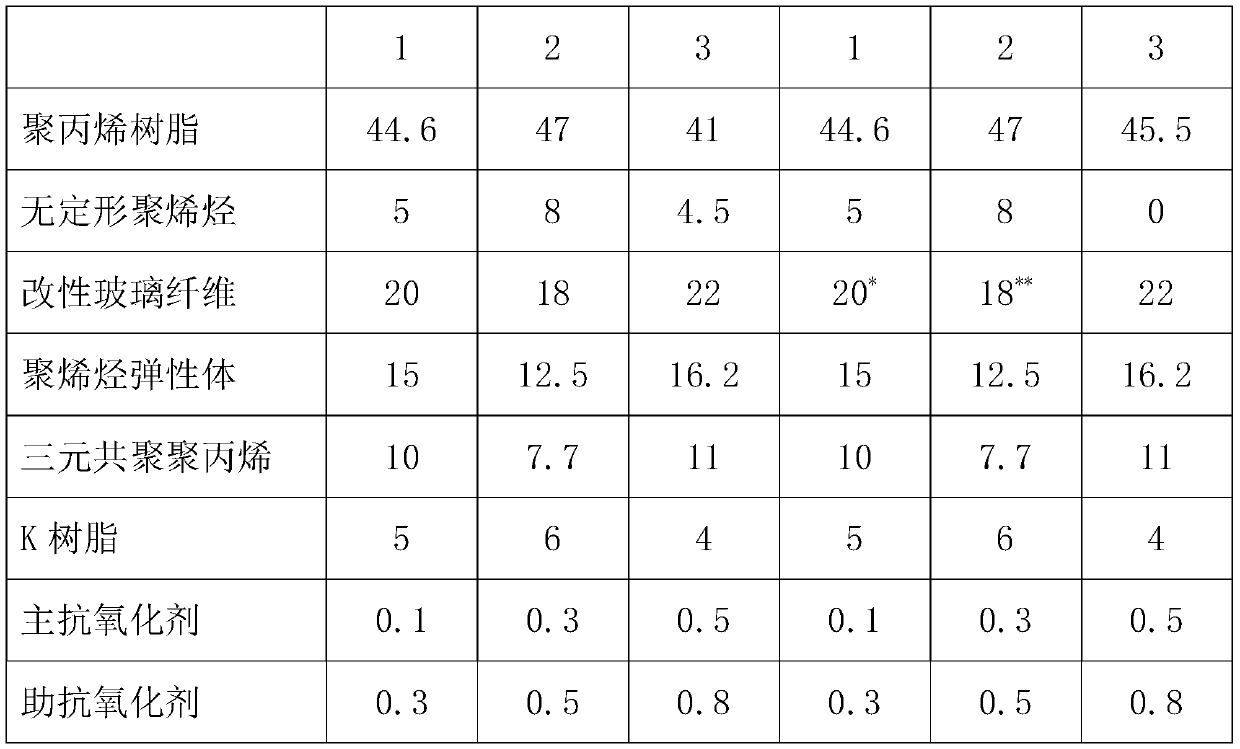

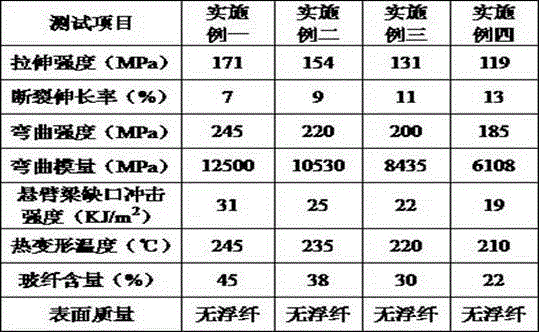

The invention relates to a glass fiber reinforced polypropylene material used for thin-wall injection molding. The glass fiber reinforced polypropylene material comprises the following components (inpercentages by mass): 41-47% of polypropylene resin, 4.5-8% of an amorphous polyolefin, 18-22% of modified glass fibers, 12.5-16.2% of a polyolefin elastomer, 7.7-11% of ternary copolymer polypropylene, 4-6% of styrene-butadiene transparent impact-resistant resin, 0.1-0.5% of a main antioxidant, and 0.3-0.8% of an auxiliary antioxidant, wherein the cross section of the glass fibers is elliptical.At the same time, the invention also relates to a method of preparing the material. The surface of a component prepared from the material provided by the invention has no floating fibers, low warpage,no gas mark and no tiger skin stripes, and the component has good mechanical properties; at the same time, the elliptical cross section of the glass fibers reduces orientation of the glass fibers andreduces anisotropy of the glass fibers, so that the problem of warpage deformation of the glass fiber reinforced polypropylene material is improved, and the mechanical properties of the material areimproved; and the glass fibers have better compatibility with the polypropylene material after being modified by hydrofluoric acid, the glass fibers and the polypropylene material are more tightly combined, so that the mechanical properties of the prepared finished product are improved.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

Polyphenylene sulfide composite material as well as preparation method and application thereof

The invention provides a polyphenylene sulfide composite material as well as a preparation method and application thereof, and belongs to the technical field of composite materials. The polyphenylenesulfide composite material provided by the invention is prepared from the following preparation raw materials in parts by weight: 100 parts of polyphenylene sulfide resin, 0.2-0.8 parts of an antioxidant, 0.1-2 parts of a blending rheological agent, 0.5-8 parts of a surface modifier, 3-15 parts of a surface active filler, 3-10 parts of a hot melt adhesive, 0.5-2 parts of carbon black and 85-165 parts of glass fibers, wherein the surface modifier is obtained by modifying organic silicon powder with a coupling agent, and the surface active filler is obtained by modifying solid glass microsphereswith a coupling agent. The polyphenylene sulfide composite material provided by the invention can meet the requirements of precise injection molding on stable boundary dimension, smooth surface, no floating fiber, high flowability, easiness in molding and the like.

Owner:宁波华腾首研新材料有限公司

Continuous-long-fiber-reinforced/toughened PPS (polyphenylene sulfide) composite material and preparation method thereof

The invention discloses a continuous-long-fiber-reinforced / toughened PPS (polyphenylene sulfide) composite material which is composed of the following components in parts by weight: 45-60 parts of polyphenyl thioether, 2-10 parts of elastomer, 15-40 parts of continuous long fiber and 0.1-5 parts of processing aid. The invention also discloses a preparation method of the continuous-long-fiber-reinforced / toughened PPS composite material. Continuous long fibers are added at the first air outlet of an extruder under the action of a tractor. The PPS composite product has high surface quality; and the production technique is stable and simple to operate, and obviously improves the mechanical properties and thermal properties.

Owner:山东赛航新材料有限公司

High heat resistance and wear resistance glass fiber enhanced nylon material for engine and preparation method

The invention provides a high heat resistance and wear resistance glass fiber enhanced nylon material for an engine and a preparation method. The material is prepared from the following materials in percentage by mass: 35%-75% of high-temperature-resistance nylon resin, 18%-50% of glass fiber, 0.5%-1% of an antioxidant, 0.5%-1% of a thermal stabilizer, 5%-15% of a maleic anhydride copolymer, 0.5%-1% of a glass fiber exposure preventer and 0.5%-2% of silicone master batch. The existing glass fiber enhanced nylon material in China hardly meets the harsh requirements of various parts of an automobile engine, particularly special components such as an engine oil bottom cover and an air intake pipe. The glass fiber enhanced nylon material provided by the invention has the advantages of high heat resistance, high wear resistance, high corrosion resistance, high strength and the like and can adapt to use environments of various peripheral parts of the automobile engine; furthermore, the use range of the glass fiber enhanced nylon material in the automobile industry is greatly expanded.

Owner:贵州凯科特材料有限公司

Glass fiber reinforced NPG-PETG transparent composite material and preparation method thereof

The invention relates to the technical field of high polymer materials, in particular to a glass fiber reinforced NPG-PETG transparent composite material and a preparation method thereof. The glass fiber reinforced NPG-PETG transparent composite material is prepared from, by weight, 50-95 parts of NPG-PETG, 5-50 parts of modified glass fiber, 0.1-3 parts of an antioxidant and 0.3-2 parts of a lubricant; the NPG-PETG used in the invention is prepared by esterification and polycondensation of three monomers of neopentyl glycol (NPG), ethylene glycol and terephthalic acid, and has good fluidity and high gloss. The modified glass fiber is blended into the NPG-PETG, so that the prepared glass fiber reinforced NPG-PETG composite material keeps transparent while having high impact strength, heatresistance, high modulus, high rigidity and high surface gloss.

Owner:腾龙特种树脂(厦门)有限公司

Engineering plastic with high surface and high performance and preparing method thereof

InactiveCN106519592AHigh surface glossImprove processing fluidityCarbon blackPolyethylene terephthalate glycol

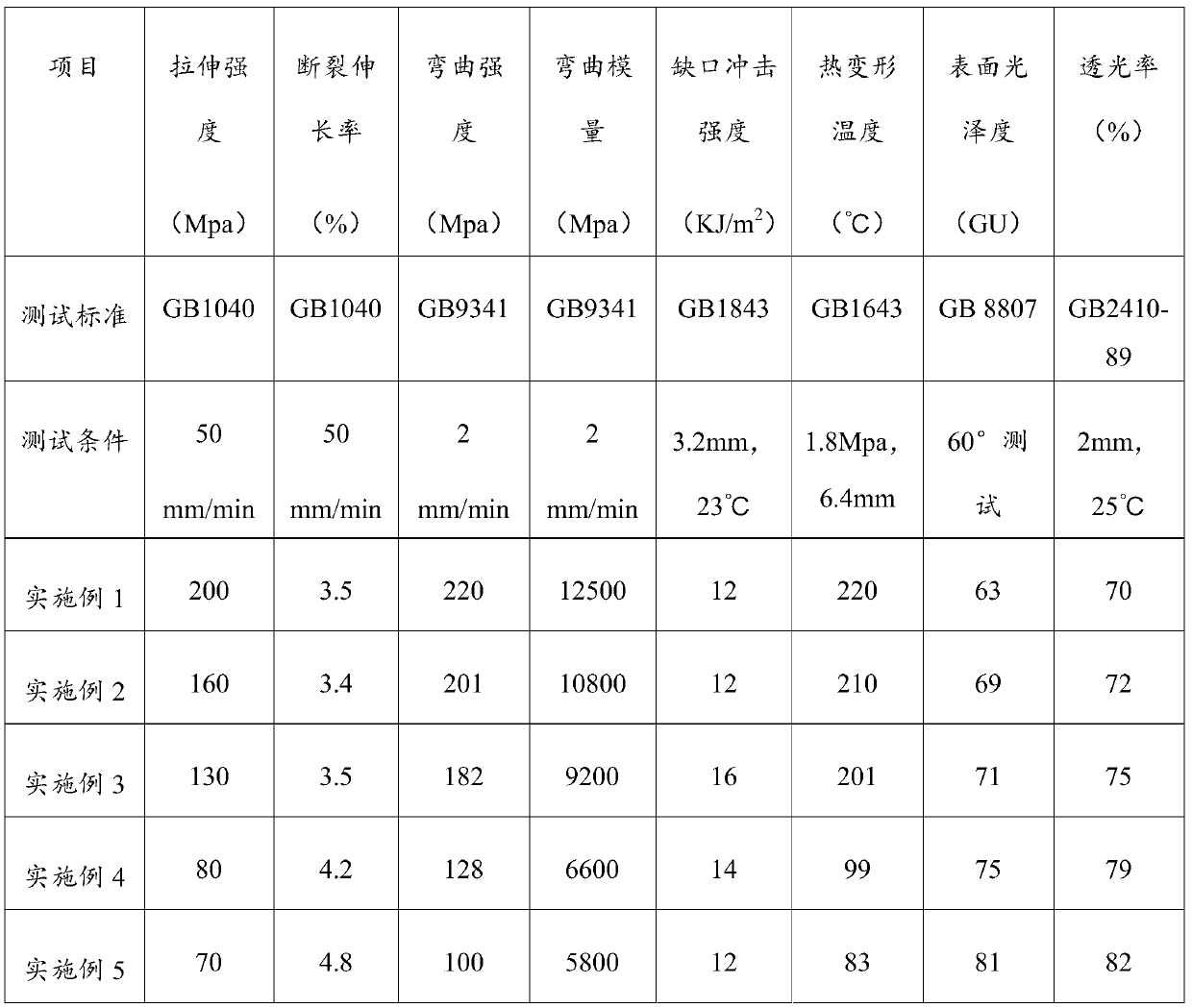

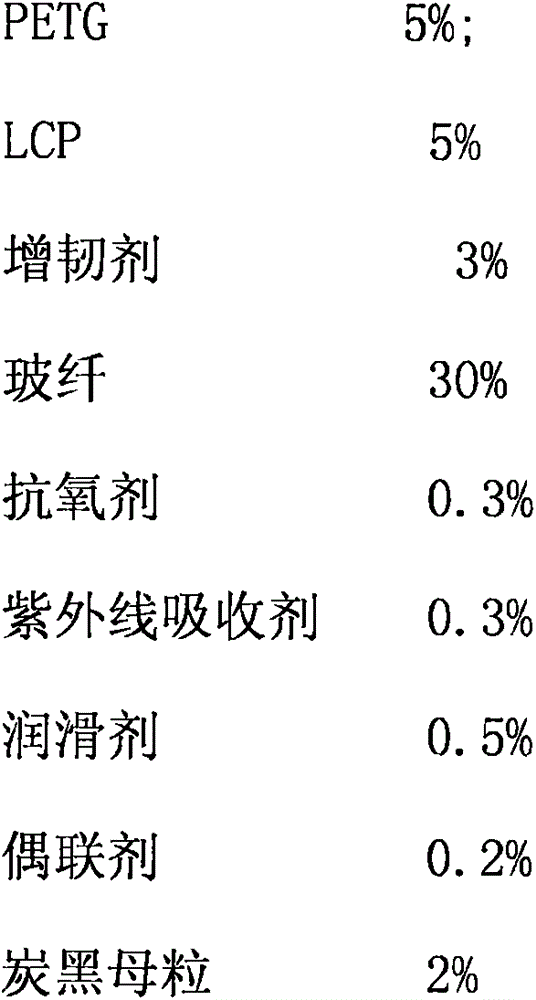

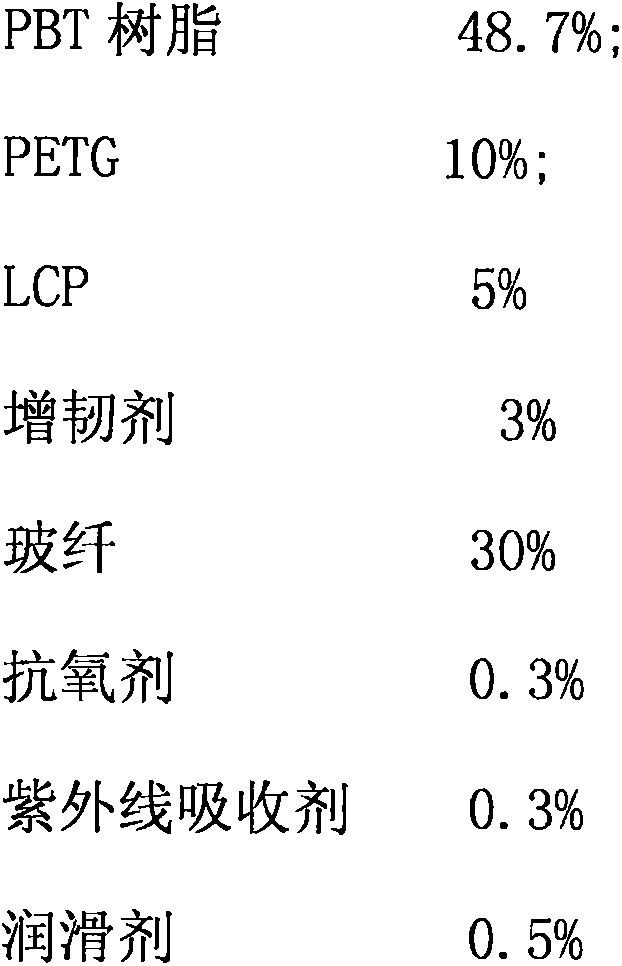

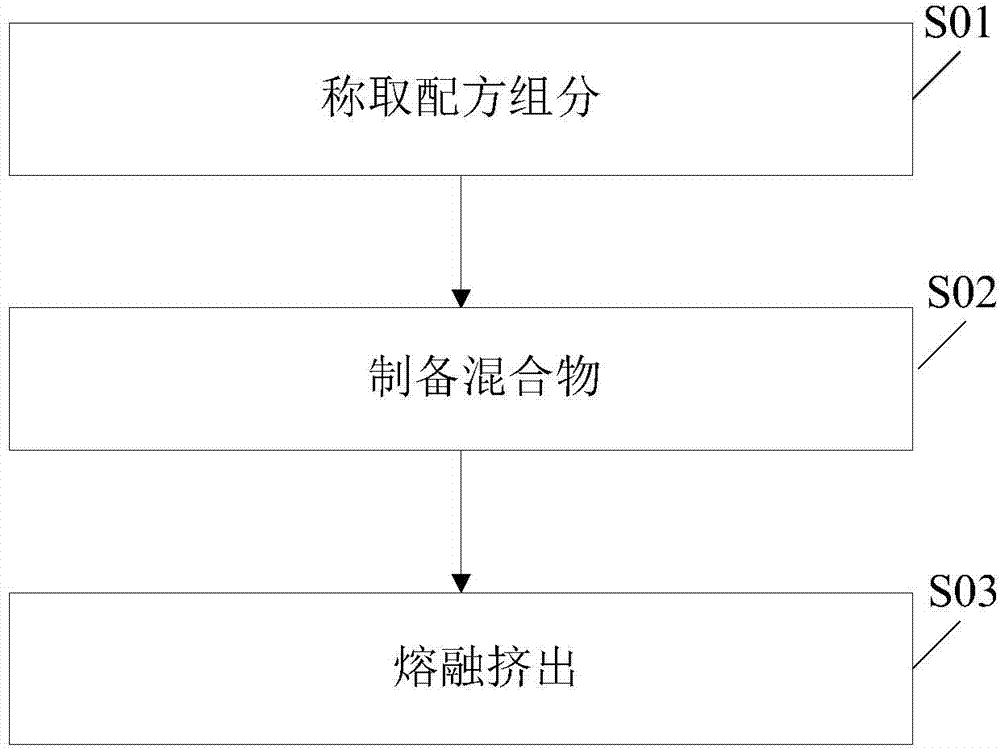

The invention relates to an engineering plastic with high surface and high performance and preparing method thereof. The composite material comprises 30%-70% of PBT (polybutylece terephthalate) resin, 5%-15% of PETG (polyethylene terephthalate glycol), 5%-10% of LCP (liquid crystal polymer), 20%-50% of alkali-free glass fiber, 1%-5% of flexibilizer, 0.1%-1% of antioxidant, 0.1%-1% of UV (ultraviolet), 0.1%-1% of lubricant, 0.1%-1% of a coupling reagent, and 1%-3% of carbon black master batches. By adding PETG (polybutylece terephthalate), the surface of the prepared material is enabled to be smooth and free of floating fibers. By adding a liquid crystal polymer, the degree of crystallinity and the heat distortion temperature of the material are increased. The preparing method comprises the steps of after putting PBT (polybutylece terephthalate), PETG (polyethylene terephthalate glycol), LCP (liquid crystal polymer) and auxiliaries according to a certain proportion into a high mixing machine to mix for 2-5 min, firstly pouring the mixture into a main feeding opening of a twin-screw extruder, then making a glass fiber enter the twin-screw extruder from a glass fiber opening or a side feeding opening, extruding the glass fiber by the twin-screw for bar stretching, and finally carrying out water cooling, air drying and grain-sized dicing, wherein the temperature in the granulation process should be controlled at 180-240 DEG C, and the screw rotation speed should be controlled at 300-400 RPM. The engineering plastic with high surface and high performance has the advantages of being good in mechanical properties, smooth in surface, free of floating fiber, resistant to heat and weather and the like, and is applicable to the fields of automobile parts and, mechanical parts and the like.

Owner:温州科力塑业有限公司

Polypropylene composite material for spinning tube and preparation method of polypropylene composite material

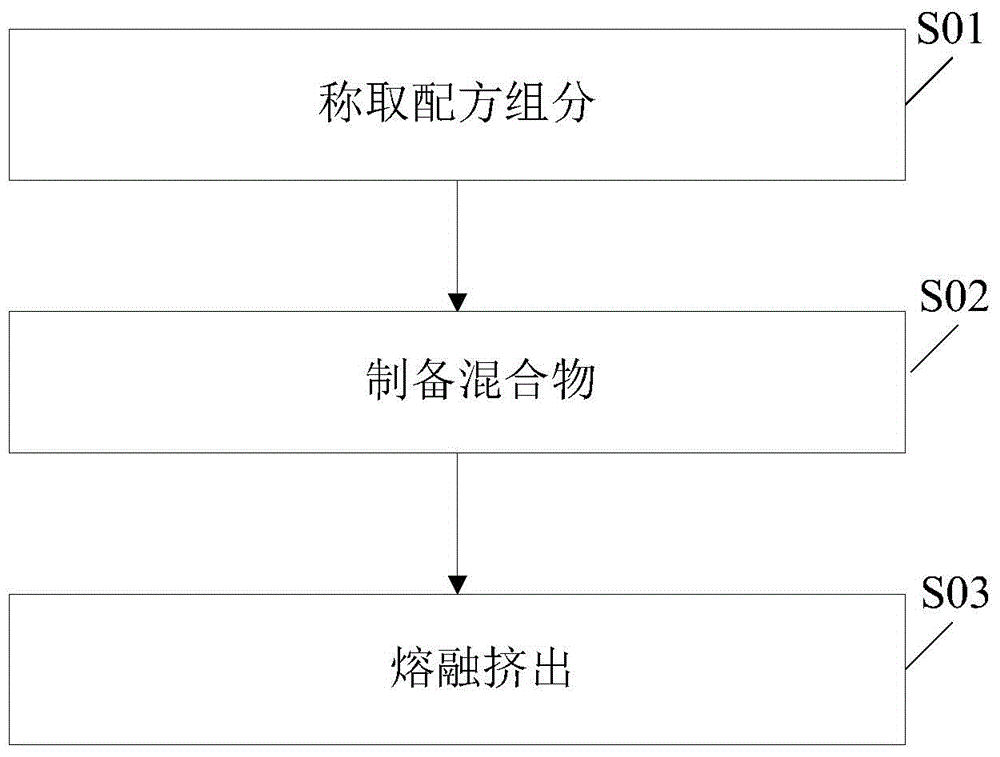

The invention belongs to the field of polymer materials and provides a polypropylene composite material for a spinning tube and a preparation method of the polypropylene composite material. The composite material comprises the following components in percentage by weight: 54.5-73.5% of polypropylene, 20-35% of glass fiber, 5-8% of active filler, 0.6-0.8% of a dispersing agent, 0.5-1.0% of a coupling agent, 0.2-0.3% of a nucleating agent and 0.2-0.4% of an antioxidant. The preparation method comprises the following steps: weighting each component according to the percentage by weight, uniformly mixing each weighted component to obtain a mixture, adding the obtained mixture into a twin screw extruder and carrying out melt extruding and granulating to obtain the polypropylene composite material for the spinning tube. The polypropylene composite material has the characteristics of high heat resistance, high strength, difficulty in deformation, no floating fiber, good surface finishing degree and the like and can be widely used in the manufacturing of various spinning tubes.

Owner:ANHUI KEJU NEW MATERIALS

Fiber-reinforced extinction flame-retardant PC/ABS alloy and preparation method thereof

The invention relates to a fiber-reinforced extinction flame-retardant PC / ABS alloy and a preparation method thereof. The fiber-reinforced extinction flame-retardant PC / ABS alloy comprises the following components in parts by weight: 40-50 parts of PC resin, 20-30 parts of ABS resin, 10-15 parts of a DOPO-based nitrogen-phosphorus fire retardant, 5-10 parts of Kevlar chopped fibers, 15-30 parts ofcalcium silicate powder, 3-6 parts of silicon dioxide extinction powder, 3-8 parts of a toughening agent, 0.5-1 part of hyperbranched resin, and 0.2-1 part of an antioxidant. The fiber-reinforced extinction flame-retardant PC / ABS alloy is good in mechanical property without a fiber floating phenomenon, good in flame retardant effect, wherein a flame retardant level reaches a level V0, and low inglossiness, and has the apparent matte effect.

Owner:苏州市同发塑业有限公司

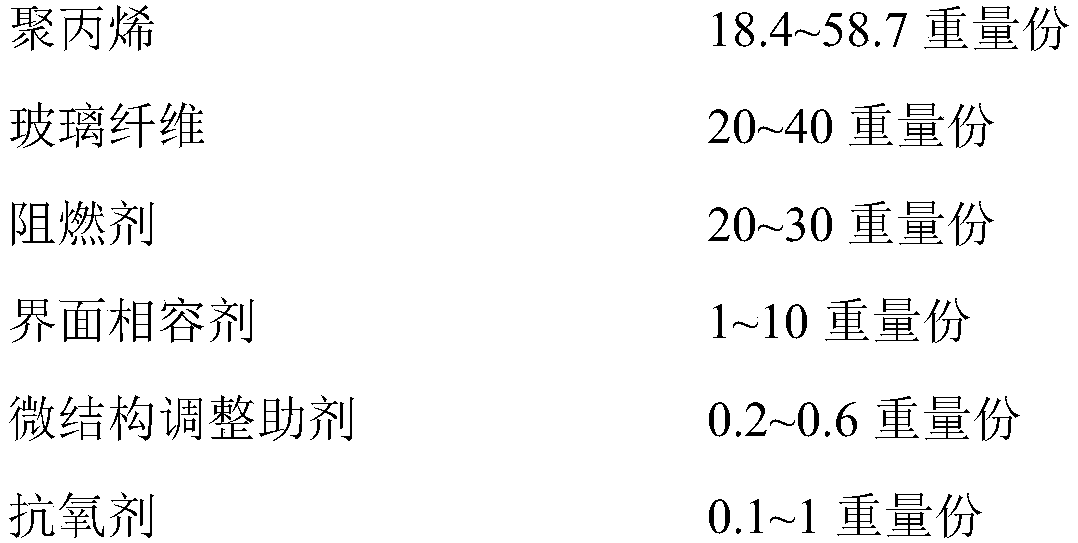

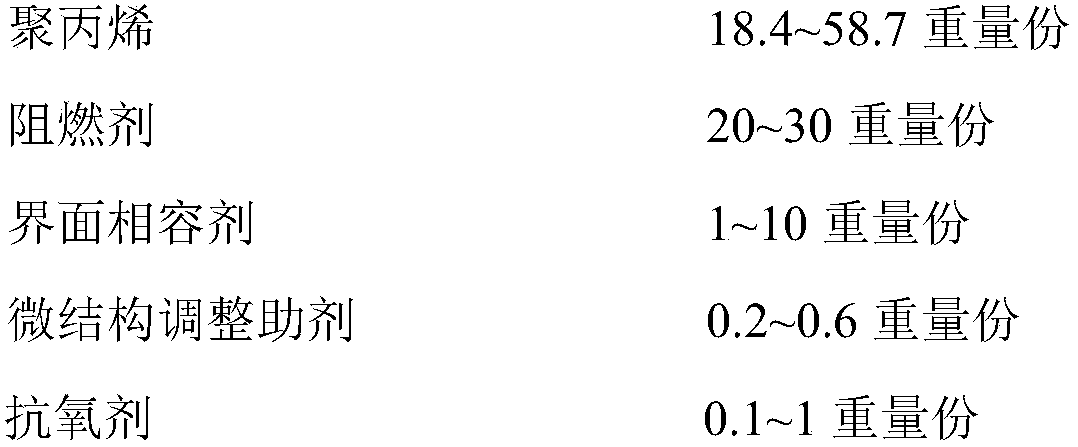

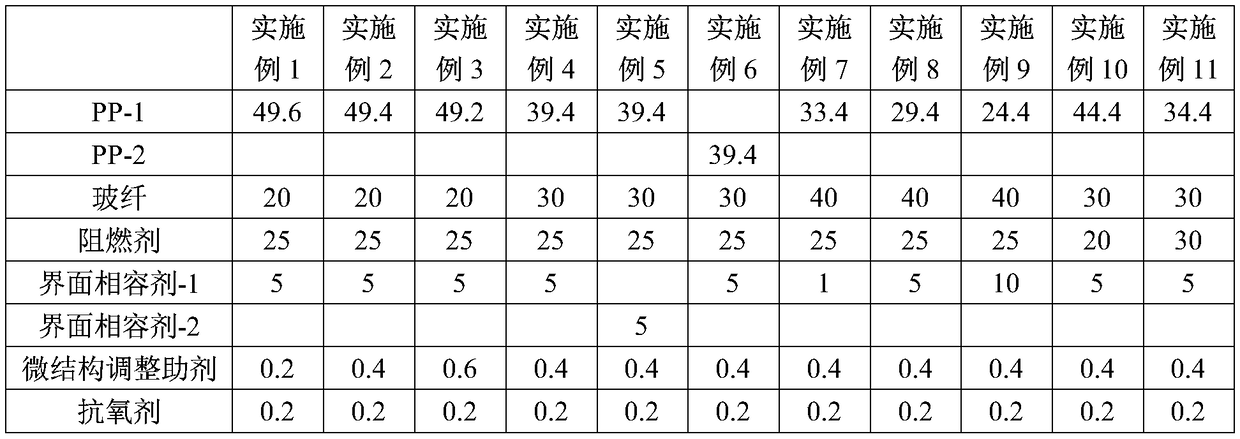

Glass fiber enhanced flame retardant polypropylene composite material for upper cover of battery pack and preparation method thereof

ActiveCN109181101AControl performanceExtrusion granulation difficult problem solvingCell component detailsManufacturing cost reductionGlass fiber

Owner:中广核俊尔(上海)新材料有限公司

Weather-resistant matte-type high-strength PA6 and ASA alloy material and preparation method thereof

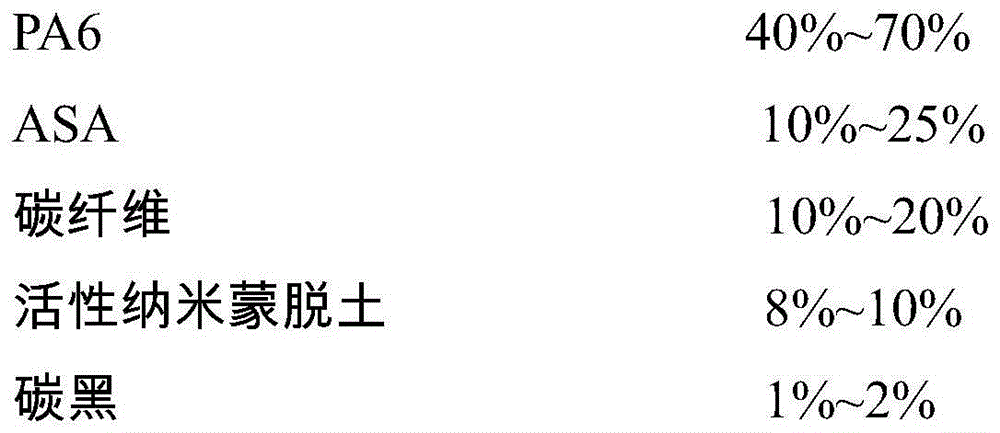

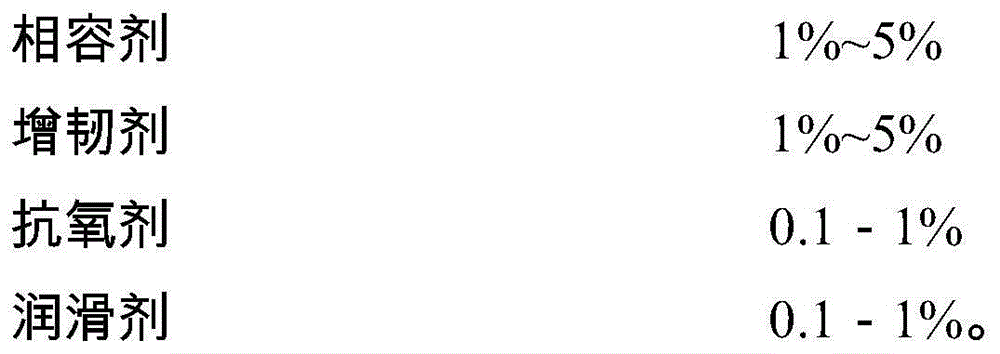

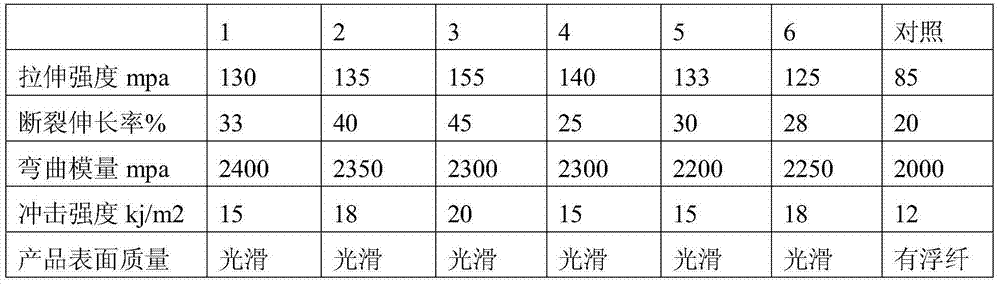

The invention belongs to the field of polymer materials and provides a weather-resistant matte-type high-strength PA6 and ASA alloy material and a preparation method thereof. The PA6 and ASA alloy material comprises the following components: 40%-70% of PA6, 10%-25% of ASA, 10%-20% of carbon fiber, 8%-12% of nano-montmorillonite, 1%-5% of a compatibilizer, namely, ABS grafted maleic anhydride, 1%-5% of a toughener, namely, POE grafted maleic anhydride, 0.1%-1% of an antioxidant, 0.1%-1% of a lubricant and 1%-2.5% of carbon black. By adopting the PA6 and ASA alloys, an incompatible system of the PA6 and ASA alloys in a sea-island structure forms slightly rough surfaces of the surface and thus matte delustering-grade surface is formed, the nano-montmorillonite is added to further homogenize the distribution of the slightly rough surfaces and meanwhile, carbon fiber is added to achieve a reinforcement effect, the compatibilizer is added so that the phenomenon that two resins are severely separated and the material is layered and peeled are not caused, and carbon black is added such that the UV aging resistance of the material can be effectively improved, therefore, the weather-resistant matte-type high-strength PA6 and ASA alloy material disclosed by the invention is a matte-grade interior / exterior material which has very excellent overall performance.

Owner:ANHUI KEJU NEW MATERIALS

Light high-strength flame retardant composite material for high-speed train compartment and preparation method thereof

The invention discloses a light high-strength flame retardant composite material for a high-speed train compartment and a preparation method thereof. The light high-strength flame retardant composite material for the high-speed train compartment is composed of the following components in parts by weight: 30-45 parts of glass fibers, 50-65 parts of homopolymerized PP (Poly Propylene) resin, 10-15 parts of carbon fibers, 1-3 parts of a silane coupling agent, 3-5 parts of maleic anhydride grafted PP (Poly Propylene), 3-5 parts of phenoxytetrabromo-bisphenol A-polycarbonate oligomer, 5-8 parts of corundum, 0.2-1.5 parts of phosphite antioxidant 168, 1-3 parts of stearate, 0.2-0.5 part of cerium oxide and 0.2-0.3 part of a hindered amine light stabilizer. The light high-strength flame retardant composite material has the advantages of good compatibility, no fiber emergence on the surface and low cost; the preparation process is simple and the production process is controllable.

Owner:广州市新稀冶金化工有限公司

Reinforced nylon material without floating fiber and preparation method thereof

The invention discloses a reinforced nylon material without floating fiber, which is prepared from the following raw materials in percentage by weight: 42% of polyamide 6, 15% of polyamide 66, 34% of glass fiber, 1% of compatibilizer, 2% of film painting agent, 3% of toughening agent, 0.3% of antioxidant, 0.4% of nucleating agent, 0.3% of coupling agent and 2% of floating fiber resisting agent. The invention also discloses a preparation method of nylon material, which comprises the steps of drying the polyamide 6 and the polyamide 66, throwing the raw materials into a high-speed mixer for high-speed mixing, then throwing the mixed the raw materials into a double-screw extruder, and finally granulating and packaging to obtain the product via melting, mixing, extruding, cooling and drying sequentially. The high-performance reinforced nylon material without floating fiber has the characteristics of high rigidity, high toughness, high liquidity, high heat resistance, no floating fiber and the like.

Owner:SUZHOU TAIKAN MACHINERY CO LTD

Hyperbranched ester compound and nylon fiber-added composite material and preparation method thereof

The invention belongs to the technical field of polymer composite materials, and discloses a hyperbranched ester compound, a nylon fiber-added composite material and a preparation method of the hyperbranched ester compound and the nylon fiber-added composite material. The nylon fiber-added composite material contains nylon 66, modified glass fiber, a hyperbranched ester compound, an anti-warping agent, a compatible flexibilizer, a highlight lubricant and an antioxidant. The weight ratio of the nylon 66 to the modified glass fiber to the hyperbranched ester compound is 1: (0.25-0.8): (0.01-0.04); the modified glass fiber is glass fiber with the surface treated by a silane coupling agent. The nylon fiber-added composite material provided by the invention has excellent apparent mass and few or even no floating fibers on the surface under the condition of keeping high-strength mechanical properties, and the application field of the nylon 66 fiber-added composite material is widened.

Owner:厦门德丰行塑胶工业有限公司

Continuous fiber bundle reinforced composite material as well as preparation method and application thereof

ActiveCN114274638AGood lookingNo floating fiberSynthetic resin layered productsLaminationFiber bundleWeather resistance

The invention discloses a continuous fiber bundle reinforced composite material as well as a preparation method and application thereof. The continuous fiber bundle reinforced composite material comprises a strip layer, an upper film layer and a lower film layer, the upper film layer and the lower film layer are arranged on the upper side and the lower side of the strip layer, the strip layer contains continuous fiber bundles, and the upper film layer and the lower film layer do not contain the continuous fiber bundles. According to the continuous fiber bundle reinforced composite material, an impregnating compound does not need to be added, the compatibility between the reinforced material and matrix resin is good, the problem of poor interface bonding does not exist, and good weather resistance and aging resistance are achieved.

Owner:CYBRID TECHNOLOGIES INC

Low temperature and impact resistant PC composite material and its preparation and application in air conditioner shell

Owner:宁波德伟电器有限公司

A kind of glass fiber reinforced npg-pet transparent composite material and preparation method thereof

Owner:腾龙特种树脂(厦门)有限公司

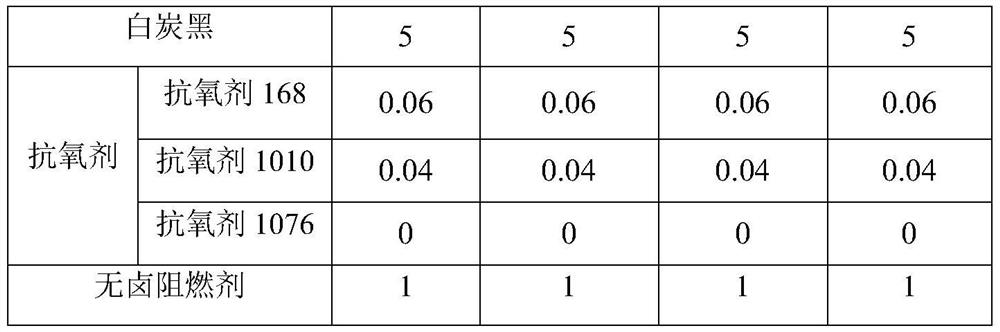

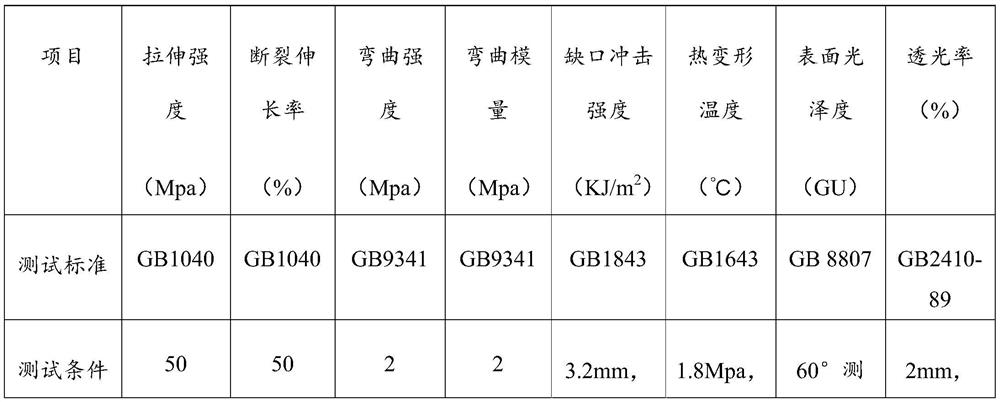

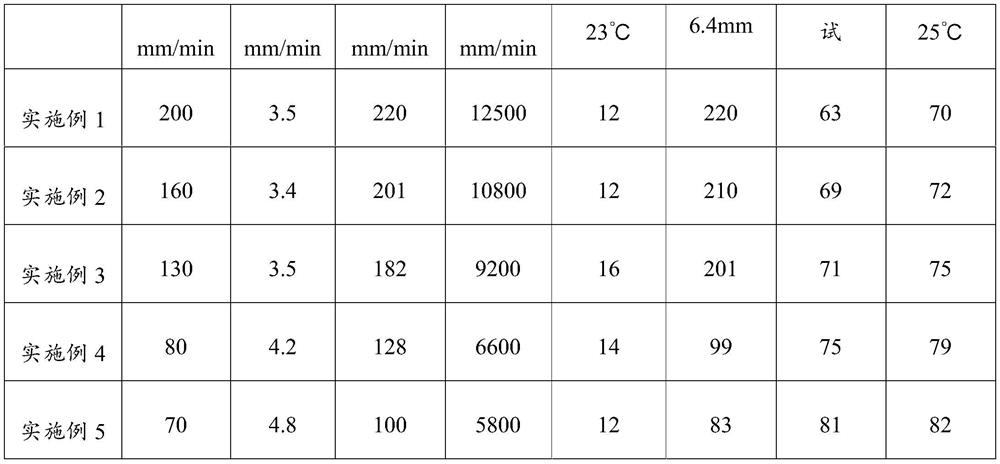

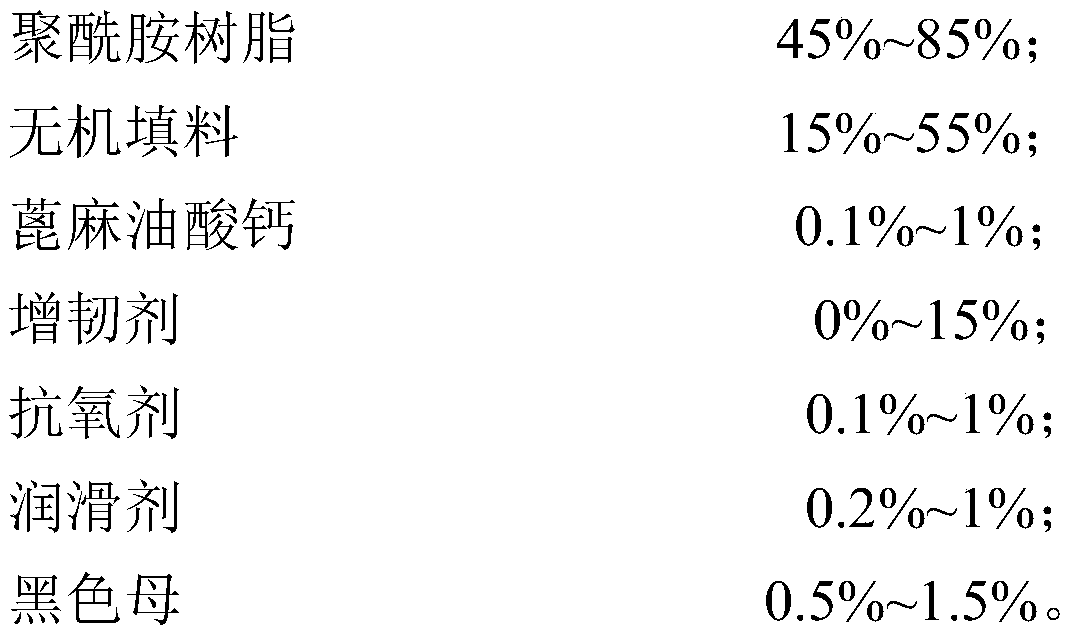

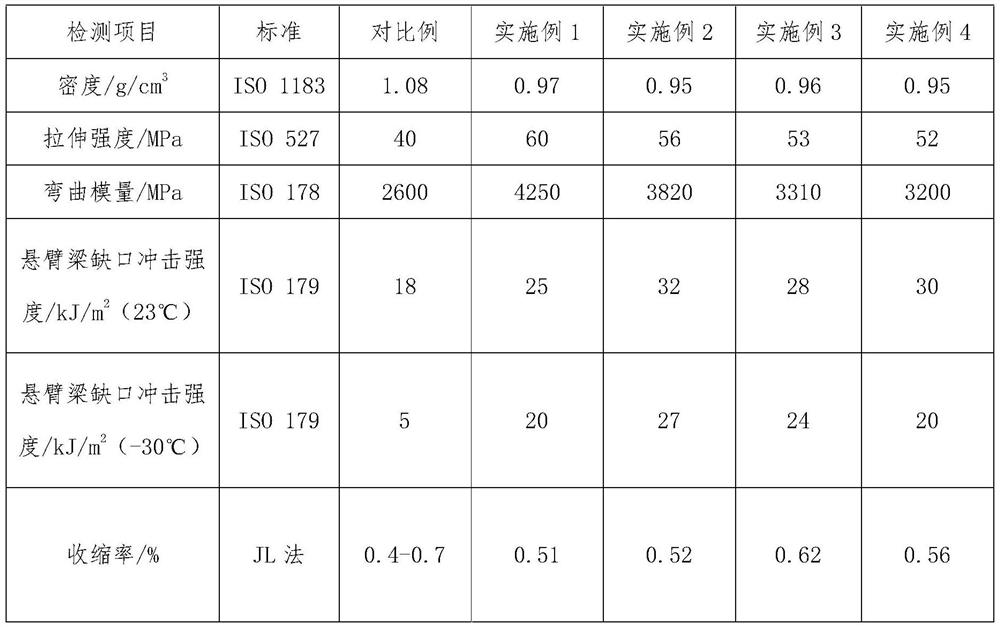

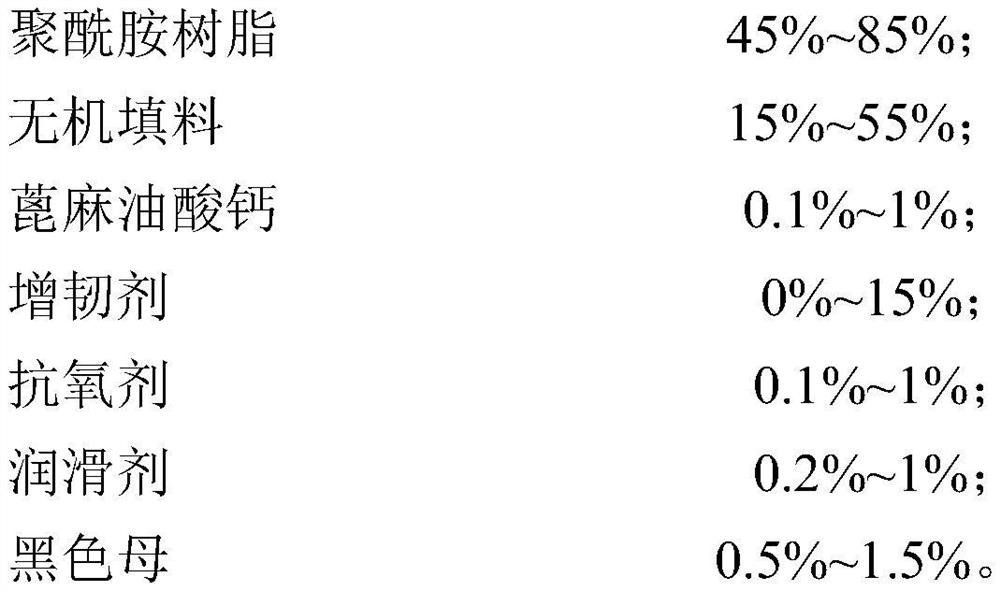

High-performance high-flow polyamide composite material and preparation method thereof

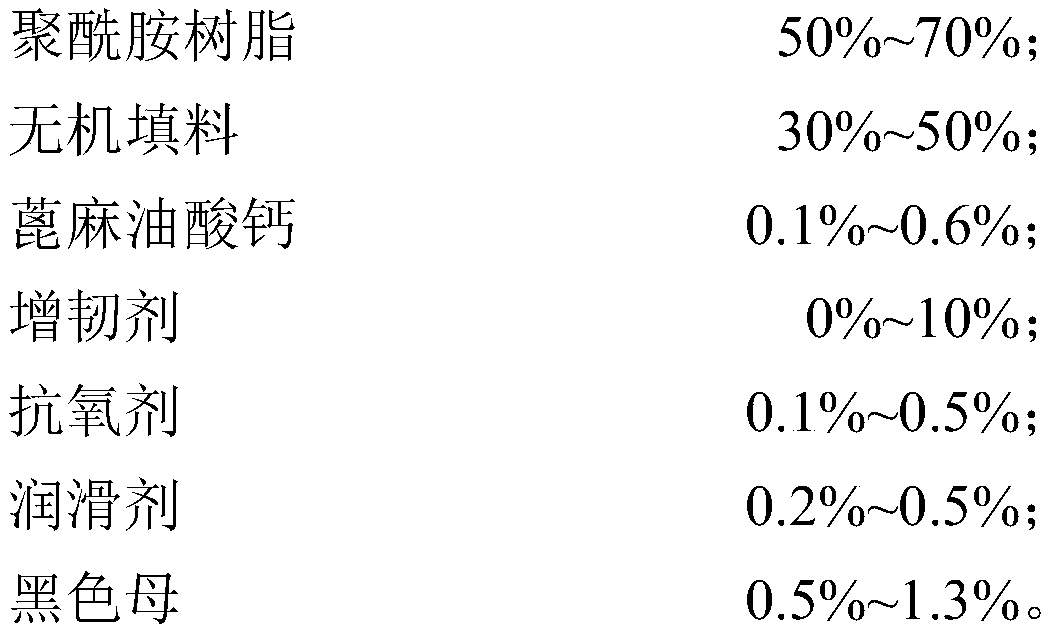

The invention discloses a high-performance high-flow polyamide composite material. The high-performance high-flow polyamide composite material comprises the following raw materials: polyamide resin, an inorganic filler, and calcium ricinoleate. The invention also provides a preparation method for the high-performance high-flow polyamide composite material. The preparation method comprises the following steps: uniformly mixing all the raw materials except the inorganic filler, then feeding the formed mixture into a twin-screw extruder from a main feed hopper, then adding the inorganic filler into the twin-screw extruder from a side feed hopper, carrying out extrusion via the twin-screw extruder, and then performing water cooling, pelletizing and drying to obtain the high-performance high-flow polyamide composite material. According to the invention, the inorganic filler is utilized to enhance polyamide, and calcium ricinoleate is used for improving the fluidity of the material, so the fluidity of the material is greatly increased and the gloss of the surface of an injection molded part is improved under the premise of ensuring mechanical properties.

Owner:中广核俊尔(浙江)新材料有限公司 +1

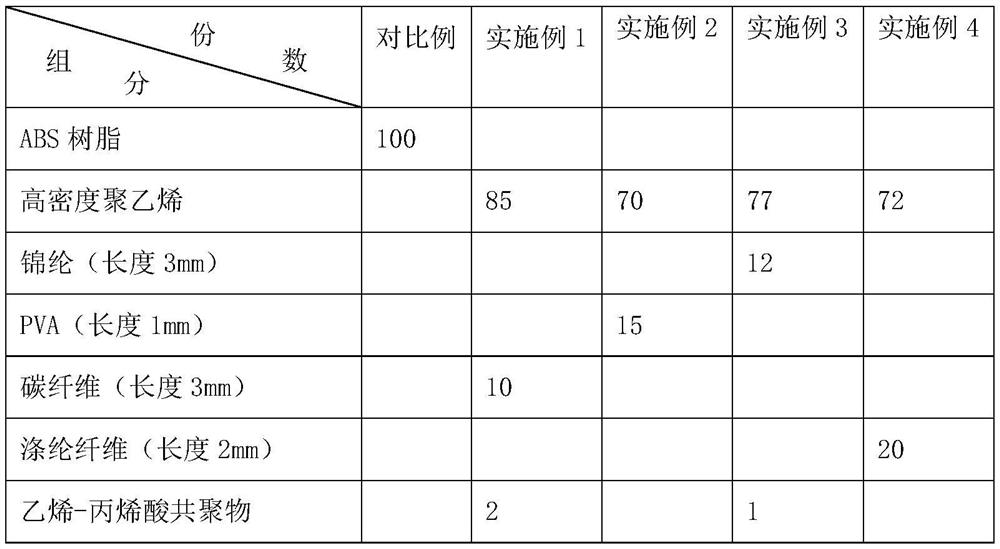

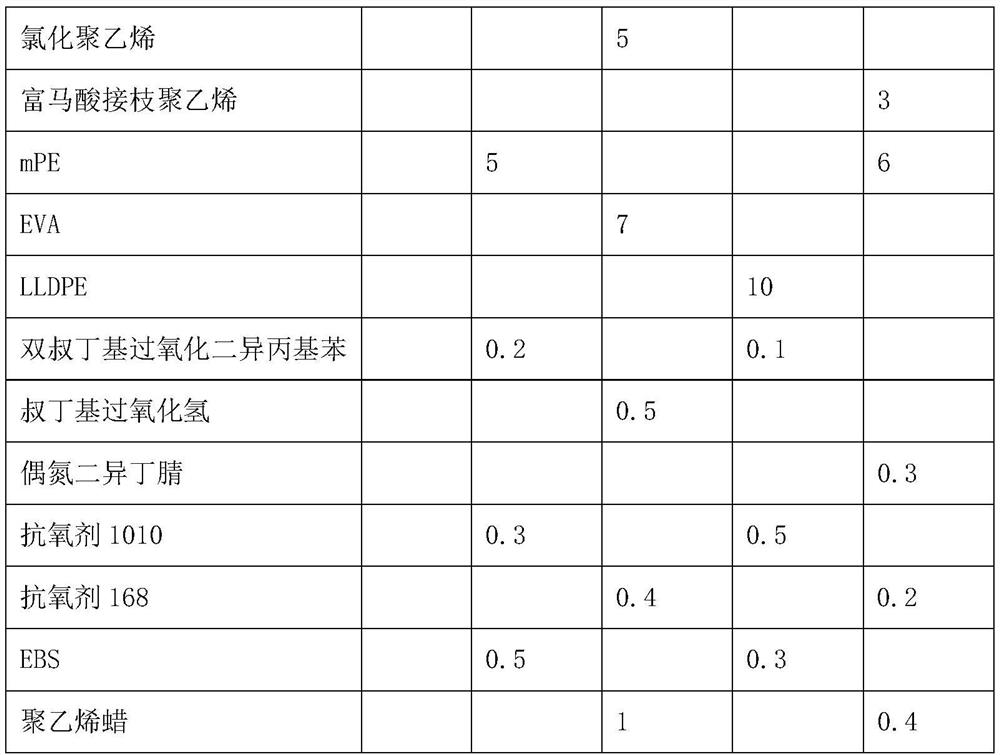

A kind of lightweight ski helmet material and preparation method thereof

The invention relates to a helmet material and a preparation method thereof and particularly relates to a light ski helmet material and a preparation method thereof. The light ski helmet material comprises, by weight, 70 to 85 parts of high density polyethylene, 10 to 20 parts of reinforced fibers, 3 to 10 parts of a toughening agent, 1 to 5 parts of an accelerator, 0.1 to 0.5 parts of a curing agent, 0.2 to 0.5 parts of an antioxidant and 0.3 to 1 part of a lubricant. Through use of the high-density polyethylene base with lower density as a base and high strength organic fibers as reinforcingbodies, the light, high strength, high toughness and high cold resistance polyethylene composite material is obtained. Through the curing agent, the heat resistance of the material is further improved and the light ski helmet material used at high and low temperatures for a long time is prepared.

Owner:NANJING JULONG SCI&TECH CO LTD +1

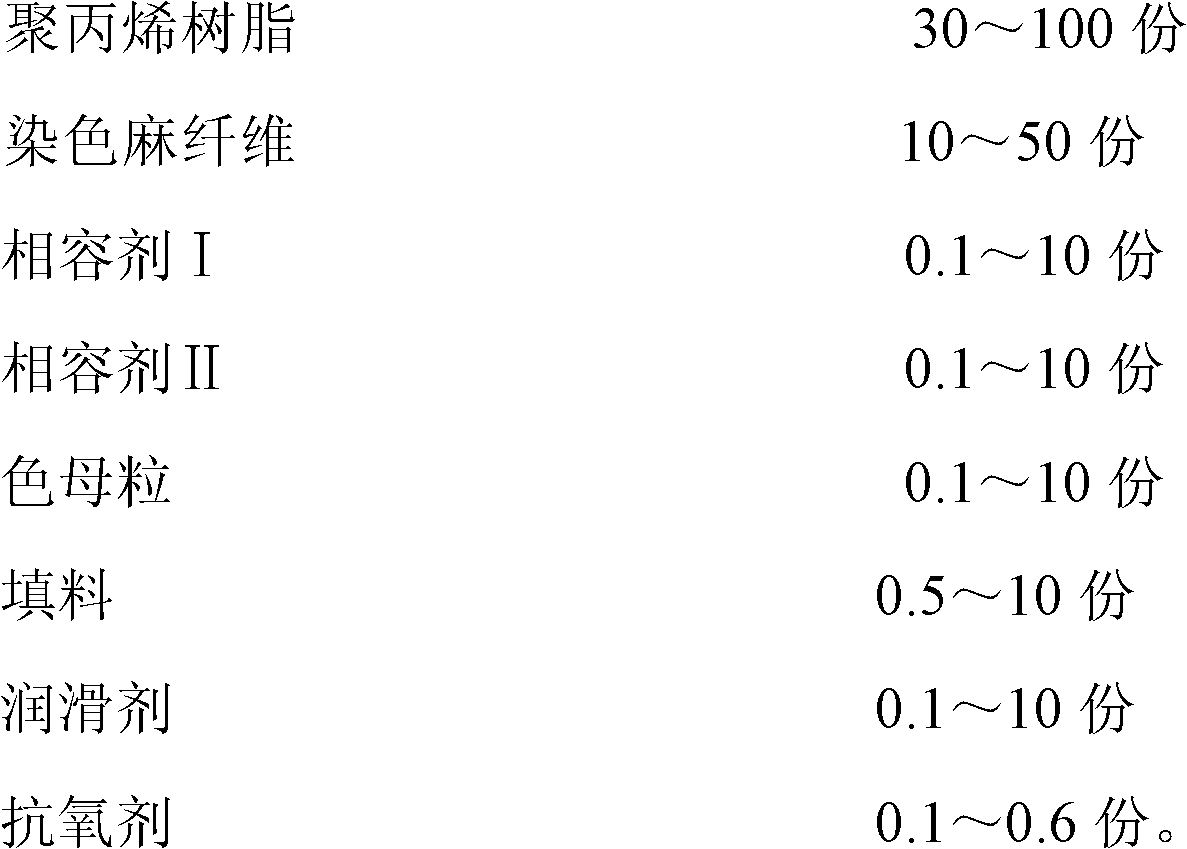

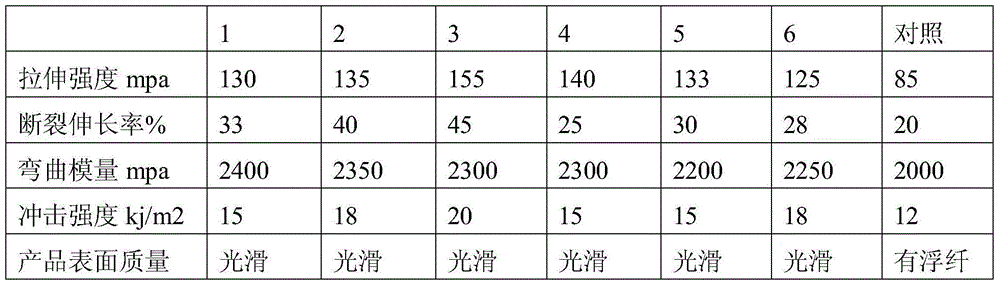

Dyeing bastose and modified polypropylene particle prepared from same

The invention discloses a dyeing bastose and a modified polypropylene particle prepared from the same. The bastose comprises the following components in parts by weight: 100 parts of chopped bastose, 0.1-5 parts of dye and 0.1-5 parts of coupling agent. The dyeing bastose prepared by the invention is tarnishproof and fadeless, has good compatibility with plastic and can be used for preparing high-performance short bastose / plastic composite materials. The modified polypropylene particle prepared from the bastose comprises the following components in parts by weight: 30-100 parts of polypropylene resin, 10-50 parts of dyeing bastose, 0.1-10 parts of compatilizer I, 0.1-10 parts of compatilizer II, 0.1-10 parts of masterbatch, 0.5-10 parts of filler, 0.1-10 parts of lubricating agent and 0.1-0.6 part of antioxidant. The bastose modified polypropylene (PP) prepared from the dyeing bastose has the advantages of light surface, vivid color, no obvious floating fiber and good performance.

Owner:BILIC FORTUNE TECH

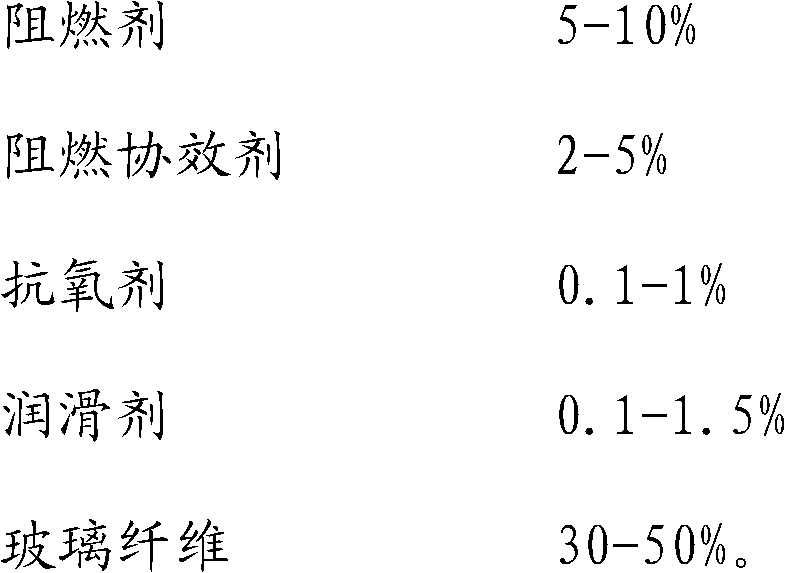

Thermal aging resistant PET modified material and its preparation method

The invention discloses a thermal aging resistant PET modified material and its preparation method. The PET modified material provided by the invention comprises the following components of: by weight, 38-62% of PET, 0.3-0.1% of a nucleating agent, 5-10% of a flame retardant, 2-5% of a flame-retardant synergist, 0.1-1% of an anti-oxidant, 0.1-1.5% of a lubricant and 30-50% of glass fibre. The thermal aging resistant PET modified material prepared in the invention has advantages of high temperature resistance, thermal aging resistance, good physical comprehensive properties and good surface glossiness without no floating fibre, and can be widely applied in the field of electronic and electrical products such as coil winders, integrated circuit packages, timer packages, relays and the like,in the field of automobile spare and accessory parts such as automobile headlight decorative loops, heatproof automobile wheel covers, midget electric motor cover casing and the like, and in the field of household electrical appliances such as straight hair device shells, electric iron pedestals, straight hair device heat spacers and the like.

Owner:SHENZHEN KEJU NEW MATERIAL

Lightweight high-strength flame-retardant composite material for high-speed train carriage and preparation method thereof

Owner:广州市新稀冶金化工有限公司

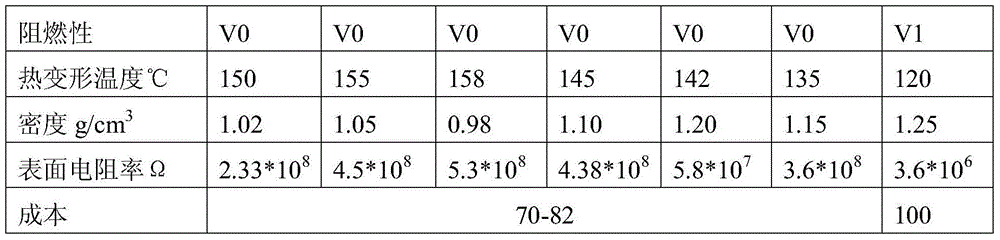

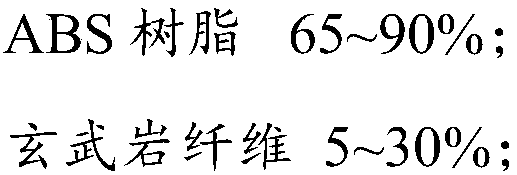

Chopped basalt fiber reinforced abs resin composite material and its preparation method and application

Owner:惠州市沃特新材料有限公司

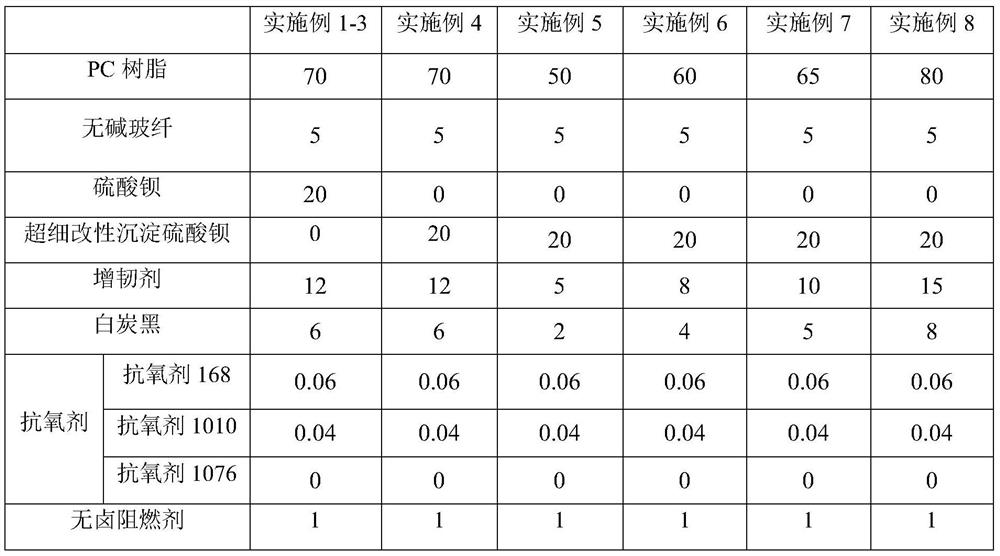

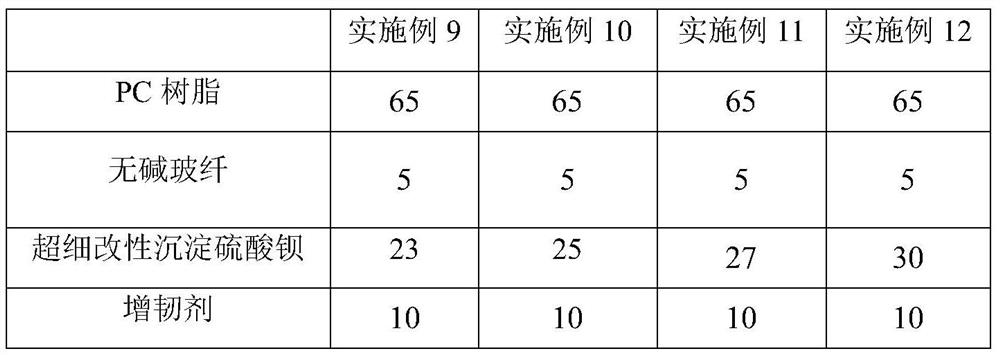

Low-temperature-resistant impact-resistant PC composite material, preparation thereof and application thereof in air conditioner shell

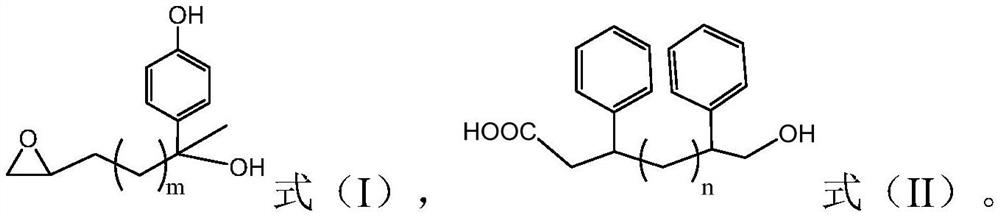

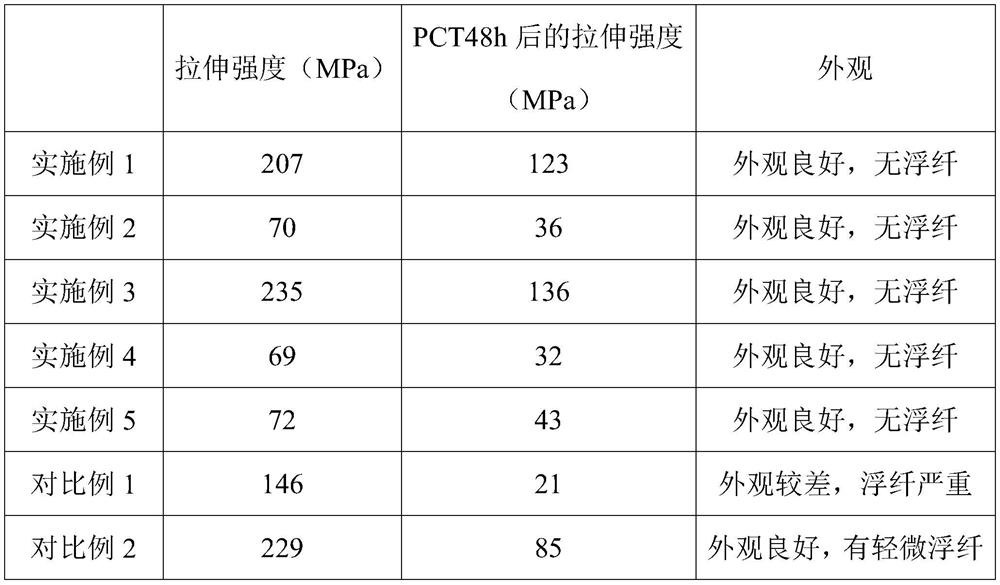

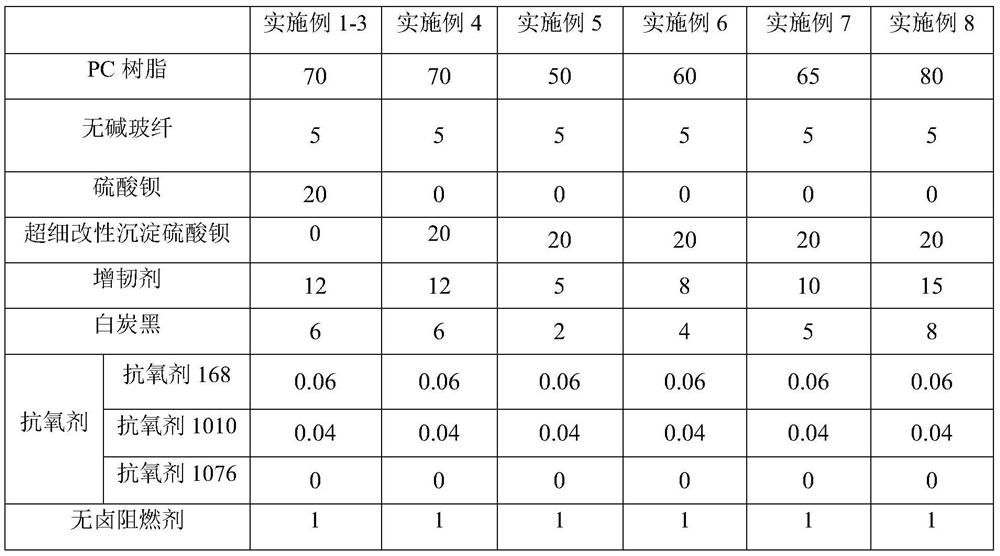

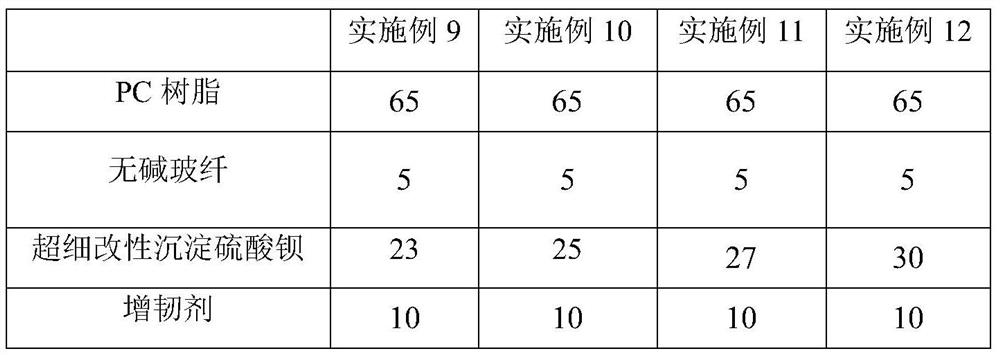

The invention relates to the technical field of modified plastics for electric appliance shells. The invention relates to a PC composite material,, and especially relates to a low-temperature-resistant impact-resistant PC composite material and preparation and application thereof in an air conditioner shell. The low-temperature-resistant impact-resistant PC composite material is prepared from, byweight: 50-80 parts of PC resin, 5-20 parts of alkali-free glass fibers, 20-30 parts of barium sulfate, 5-15 parts of a toughening agent, 2-8 parts of white carbon black, 0.1-0.8 part of an antioxidant and 1-5 parts of a halogen-free flame retardant, wherein the toughening agent is a metallocene ethylene-octene copolymer; the material has the advantages of no floating fiber on the surface, low temperature resistance, impact resistance and good flame retardant property.

Owner:宁波德伟电器有限公司

Modified polypropylene material with low molding shrinkage and without buckling deformation and preparation method of modified polypropylene material

The invention discloses a modified polypropylene material and a preparation method thereof. The modified polypropylene material comprises the following ingredients by mass percentage: 50-55% of polypropylene, 25-30% of filler, 5-10% of glass fiber, 3-8% of shrinkage regulator, 3-8% of elastomer, 0.5-1% of coupling agent, 0.4-1% of dispersing agent, and 0.2-0.5% of antioxidant. The preparation method comprises the steps of mixing weighed PP (polypropylene) resin and the coupling agent in a high speed mixer, adding the other ingredients than the glass fiber for mixing for 5-10min, fusing, mixing, extruding, cooling, drying, pelleting and packaging the mixed material and the glass fiber, and obtaining the modified polypropylene material. According to the polypropylene material and the preparation method, horizontal and vertical flow shrinkages of polypropylene are reduced to below 0.8%, the difference between the shrinkages is very small (below 0.1%), the polypropylene material has excellent processability and rigidity and balanced toughness, a product made of modified polypropylene is free from warpage, no fiber exists on the surface of the product, and the application field of the polypropylene material is expanded greatly.

Owner:GUANGDONG TIANBAO NEW MATERIALS CO LTD

High-performance high-flow polyamide composite material and preparation method thereof

The invention discloses a polyamide composite material with high performance and high flow. The raw material composition includes polyamide resin, inorganic filler and calcium ricinoleate. The present invention also provides a method for preparing the high-performance and high-fluidity polyamide composite material, comprising: uniformly mixing all raw materials except inorganic fillers, and then feeding them into a twin-screw extruder from a main feeding hopper, Then, the inorganic filler is added into the twin-screw extruder from the side feeding hopper, extruded by the twin-screw extruder, and then water-cooled, pelletized and dried to obtain the high-performance and high-fluidity polyamide composite material. The present invention utilizes inorganic fillers to reinforce polyamide, and simultaneously utilizes calcium ricinoleate to improve the fluidity of the material, thereby greatly increasing the fluidity of the material and improving the glossiness of the surface of injection molded parts under the premise of ensuring mechanical properties.

Owner:中广核俊尔(浙江)新材料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com