Low-temperature-resistant impact-resistant PC composite material, preparation thereof and application thereof in air conditioner shell

A composite material and impact-resistant technology, which is applied in the field of low-temperature-resistant and impact-resistant PC composite materials and its preparation and application in air-conditioning shells, can solve the impact of PC resin on impact performance, low-temperature resistance to impact strength reduction, unfavorable PC composite materials, etc. Problems, to achieve excellent low temperature resistance and impact resistance and other mechanical properties, excellent impact resistance, and excellent overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0043] The toughening agent used in the present invention obtains through following treatment operation to metallocene ethylene-octene copolymer:

[0044] Add the commercially available metallocene ethylene-octene copolymer into the ozone generator, and control the gas flow in the ozone generator to be 0.1m 3 / h, the ozone concentration is 55mg / L, the molar ratio of ozone to metallocene ethylene-octene copolymer is 1.3:1, and the treatment is 100min to obtain the toughening agent metallocene ethylene-octene copolymer after ozonation reaction treatment. Wherein, the molar ratio of ozone to the metallocene ethylene-octene copolymer can also be 1:1, 2:1, etc., mainly to ensure that the molar amount of ozone is not less than that of the metallocene ethylene-octene copolymer.

[0045] White carbon black among the present invention is the white carbon black through pretreatment, and concrete treatment operation is:

[0046] Commercially available white carbon black and silane coupl...

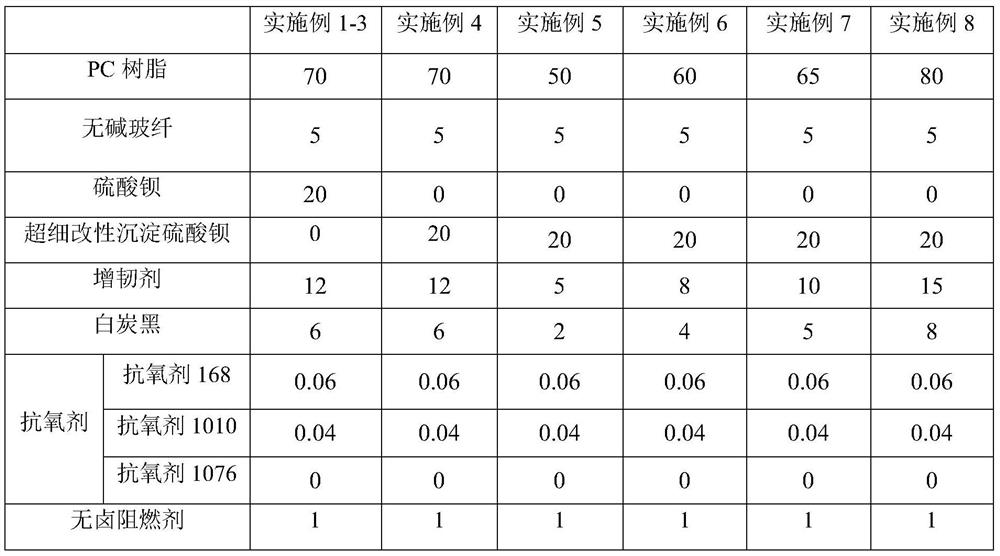

Embodiment 1

[0050] A low-temperature-resistant and impact-resistant PC composite material, which is prepared by the following operations:

[0051] (1) According to the dosage shown in Table 1, add PC resin, toughening agent and white carbon black into the mixer and mix them, and mix them at 225°C for 45 minutes to obtain material A;

[0052] (2) Add barium sulfate and alkali-free glass fiber to material A, stir evenly, obtain material B;

[0053] (3) Add antioxidant and halogen-free flame retardant to material B, melt and mix at 230°C for 5 minutes to obtain material C;

[0054] (4) Add material C to the twin-screw extruder, control the temperature of the front section of the barrel to 240°C, the temperature of the middle section to 230°C, the temperature of the rear section to 220°C, the temperature of the mold to 90°C, and the speed of the main engine to 350r / min. Pelletizing to obtain low temperature and impact resistant PC composite materials.

Embodiment 2

[0056] A low-temperature-resistant and impact-resistant PC composite material, which is prepared by the following operations:

[0057] (1) According to the dosage shown in Table 1, add PC resin, toughening agent and white carbon black into the mixer and mix them, and mix them at 235°C for 45 minutes to obtain material A;

[0058] (2) Add barium sulfate and alkali-free glass fiber to material A, stir evenly, obtain material B;

[0059] (3) Add antioxidant and halogen-free flame retardant to material B, melt and mix at 238°C for 5 minutes to obtain material C;

[0060] (4) Add material C to the twin-screw extruder, control the temperature of the front section of the barrel to 240°C, the temperature of the middle section to 230°C, the temperature of the rear section to 220°C, the temperature of the mold to 90°C, and the speed of the main engine to 350r / min. Pelletizing to obtain low temperature and impact resistant PC composite materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com