Patents

Literature

270results about How to "The surface of the product is smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

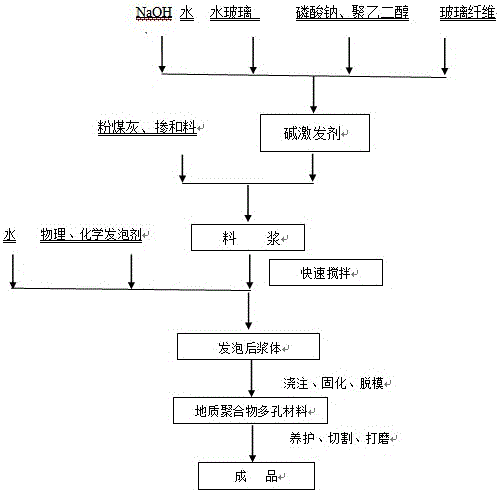

Flyash geopolymer based porous material and preparation process thereof

InactiveCN105800972APracticalSimple production processCement productionSodium phosphatesPolyethylene glycol

The invention provides a flyash geopolymer based porous material and a preparation process thereof. The porous material comprises the following components in parts by weight: 60-100 parts of flyash, 40-70 parts of alkali activator, 0-40 parts of admixtures, 0-5 parts of glass fibers, 2-8 parts of physical foaming agents and 0-0.8 part of chemical activators, wherein the alkali activator is alkaline mixed liquor containing various ions and comprises industrial water glass, sodium hydroxide, water, polyethylene glycol and sodium phosphate; the admixtures refer to levigated metakaolin, silicon micropowder and calcined coal gangue; the physical foaming agents include expired shampoo, an anionic surfactant sodium dodecyl sulfate (SDS), fatty alcohol polyoxyethylene ether sodium sulfate (AES) and disodium fatty alcohol polyoxyethylene ether monosulfosuccinate (AESS); the chemical foaming agents include aluminium powder, hydrogen peroxide, and the like. The porous material has adjustable volume density, fine and uniform pore diameter, low heat conductivity, high strength, the same life as buildings and good fireproof performance.

Owner:QINGHAI UNIVERSITY +1

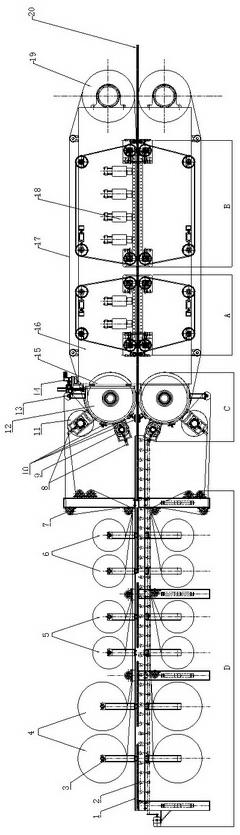

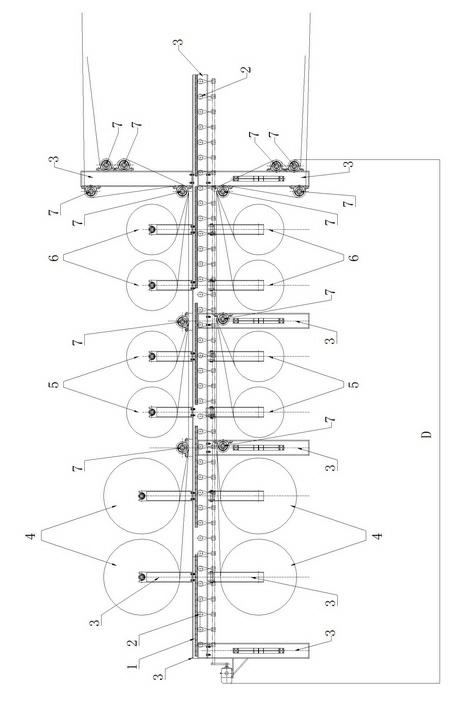

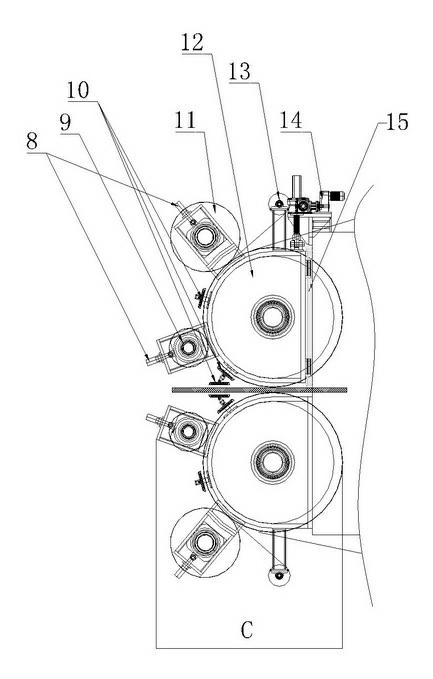

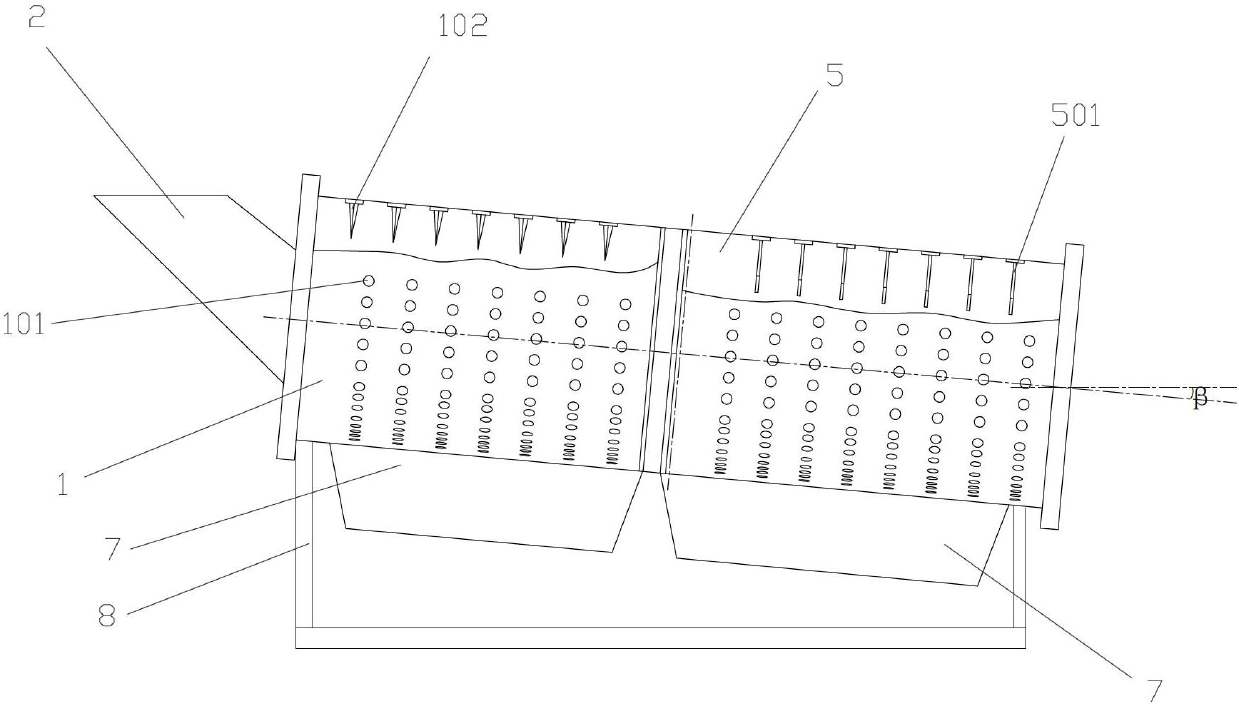

Method for producing thermoplastic composite material and double steel-belt continuous press

ActiveCN102615917AReduce area requirementsIncrease profitLaminationLamination apparatusComposite plateThermoplastic composites

The invention provides a method for producing a thermoplastic composite material and a double steel-belt continuous press. The double steel-belt continuous press mainly comprises a set of paper and board feed system D, a set of preheating and prepressurizing system C which is arranged on driven rollers at an inlet of the press, a group of driving rollers, a group of driven rollers, and steel belts which are wound on the driving rollers and the driven rollers, wherein the inner part of the press is divided into a heating section A and a cooling section B. Raw materials (core boards and paper) of a product enter the preheating and prepressurizing system C through the paper and board feed system and are combined between the two driven rollers through heating and pressurization, enter the heating section for constant-temperature setting along with the traction of the steel belts, and are cooled and molded through the cooling section to produce finished sheets and strips. The defects of the conventional production machinery for composite boards are overcome; the press has a simple structure and reliable performance, and is relatively low in cost; the finished sheets and strips are pressed by a production process that the internal gluing is not required and the raw materials are combined after being molten; and products in corresponding sizes are processed according to requirements.

Owner:DUNHUA YALIAN MACHINEY

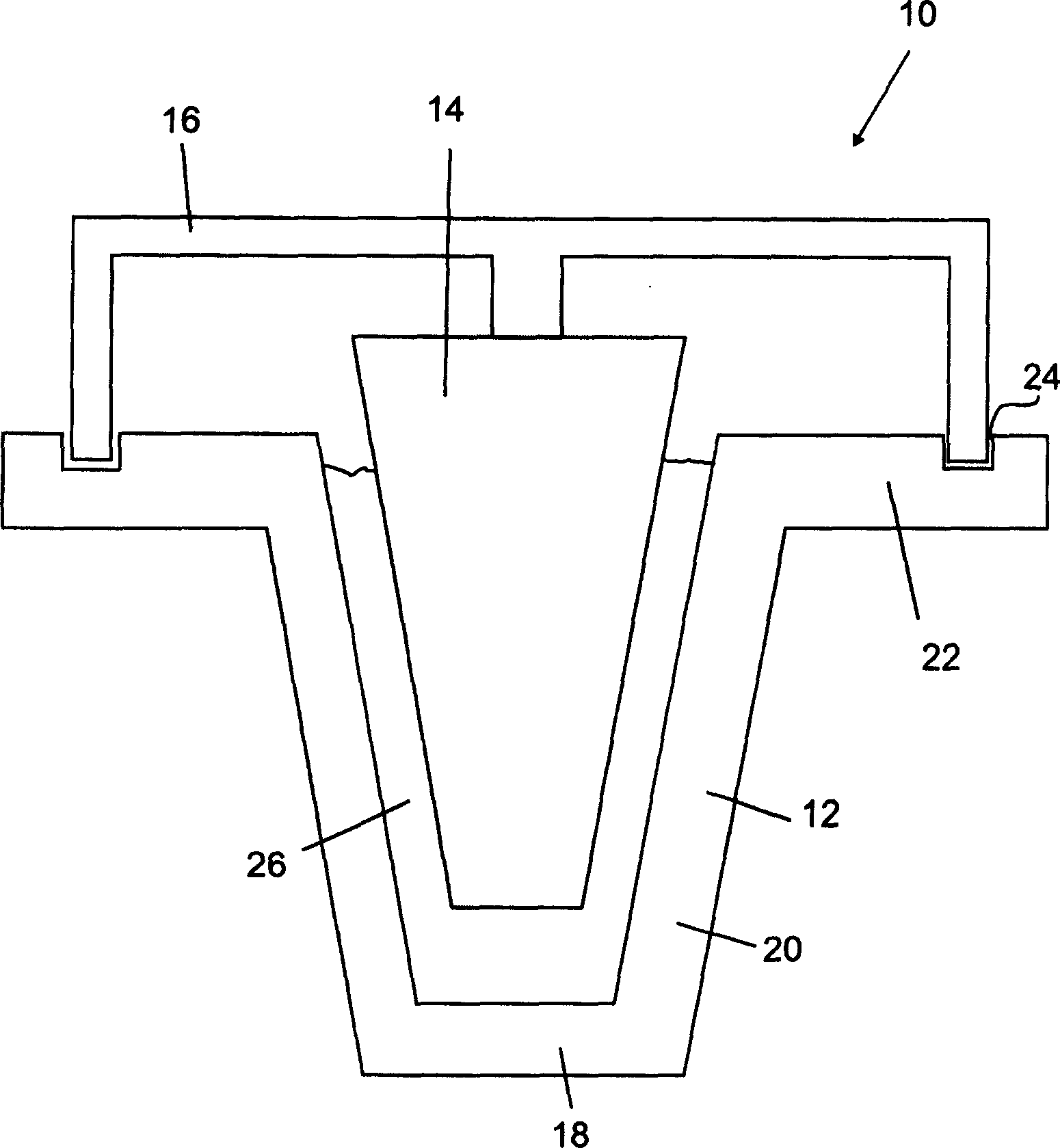

Herbst bremer goldschlaegerei

InactiveCN1789204ASimple and cheap to manufactureSmall dimensional toleranceMaterial nanotechnologyCeramic shaping apparatusCrucibleAlloy

The invention relates to a method for preparing a ceramic crucible. The following steps are proposed: providing a curable slurry; providing a casting mold (10) for a ceramic crucible, pouring the slurry into the casting mold, allowing the slurry to solidify in the mold by: (a) freezing and / or (b ) changing the pH value of the slurry to obtain a preformed body, and heat-treating the preformed body to obtain a ceramic crucible. The present invention also relates to a ceramic crucible prepared by said method and a complete set of equipment for preparing said ceramic crucible, comprising: a casting mold for a ceramic crucible, preferably a metal mold; a sol, preferably SiO2 water containing nano-ceramic particle components Sols; ceramic particles comprising particulate ceramic components; optionally metal powders consisting of metals and / or alloys and / or intermetallic compounds; optionally one or more other additives and optionally organic or inorganic binders . The invention also relates to a device for carrying out the method.

Owner:BEGO BREMER GOLDSCHLAGEREI WILH HERBST

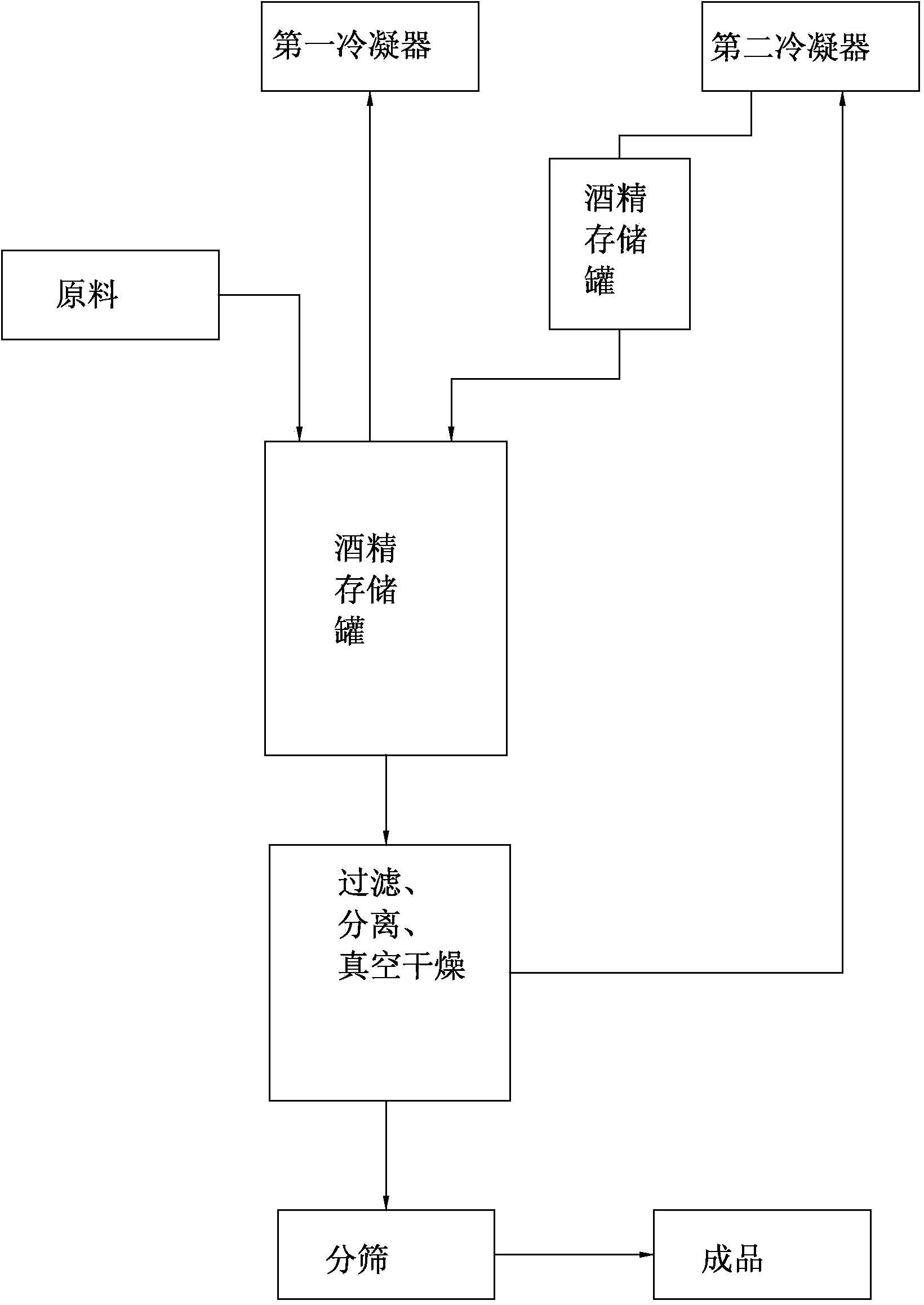

Preparation method of high-molecular nylon powder material used for 3D printing

The invention discloses a preparation method of a high-molecular nylon powder material used for 3D printing. The method comprises the following steps: 1)placing a nylon material, a nucleating agent and alcohol in a high pressure reaction vessel; 2)operating the high pressure reaction vessel for stirring, introducing nitrogen for protection, heating the material in the high pressure reaction vessel to 130-160 DEG C; 3)insulating and dissolving, insulating the reaction vessel for 2-3 hours, fully stirring, dissolving the nylon material; 4)cooling, depositing and precipitating, controlling the stirring speed of the high pressure reaction vessel, slowly cooling, and gradually completing the precipitation and moulding of the nylon powder; 5)filtering, cooling the material in the high pressure reaction vessel to less than 70 DEG C, transferring the mixture to a filter tank, separating the solvent from the solid; 6)centrifuging, transferring the filter residue to a centrifuge for removing the solvent; 7)drying under vacuum; thoroughly removing the solvent in a vacuum drying machine; and 8)sieving the dried nylon powder, and controlling the particle size of nylon powder at 35-50 mum to obtain the required material.

Owner:东莞方易达三维科技有限公司 +1

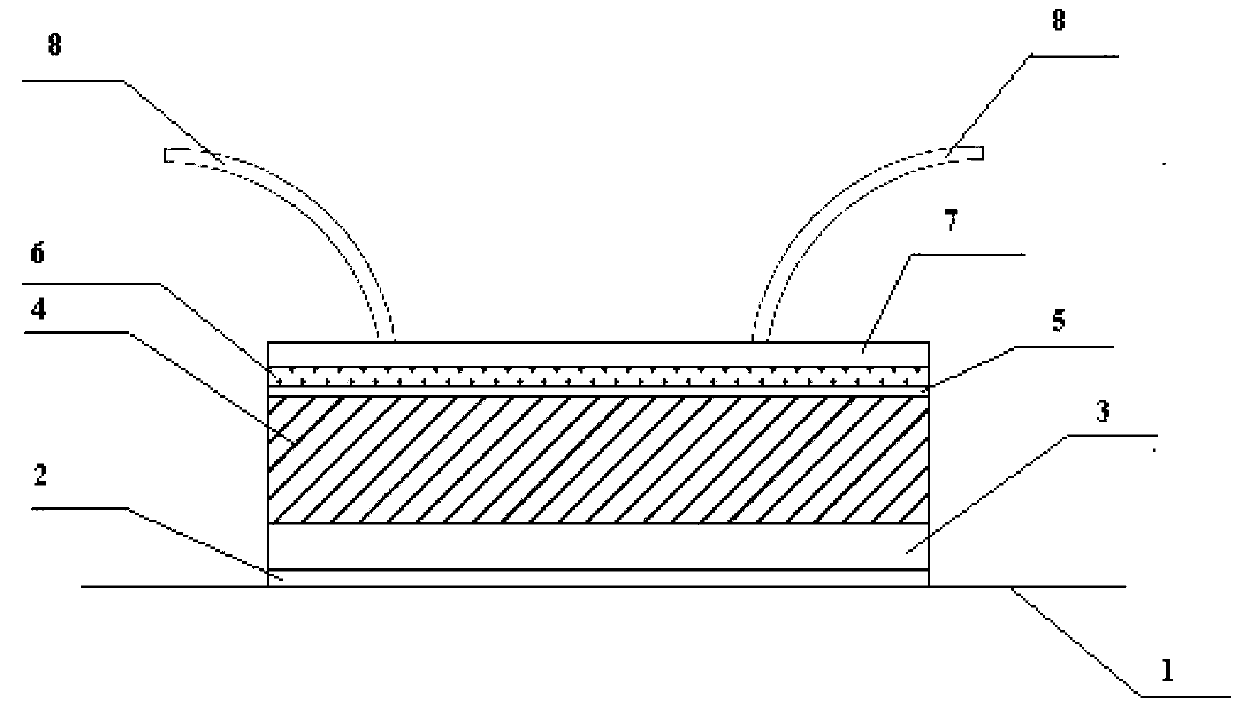

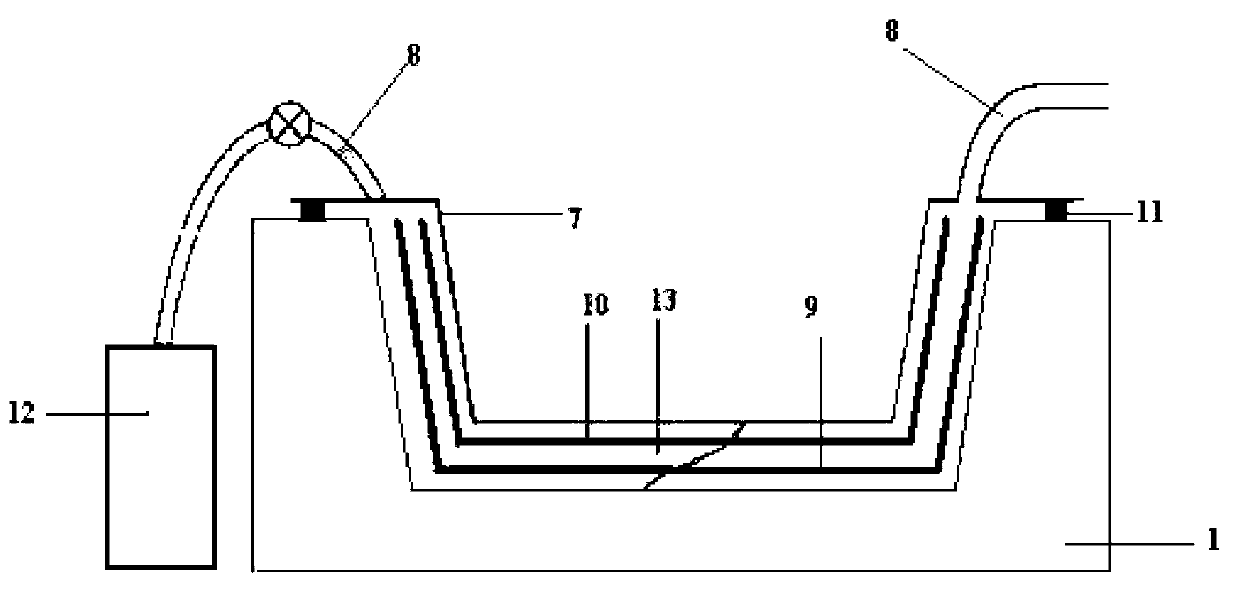

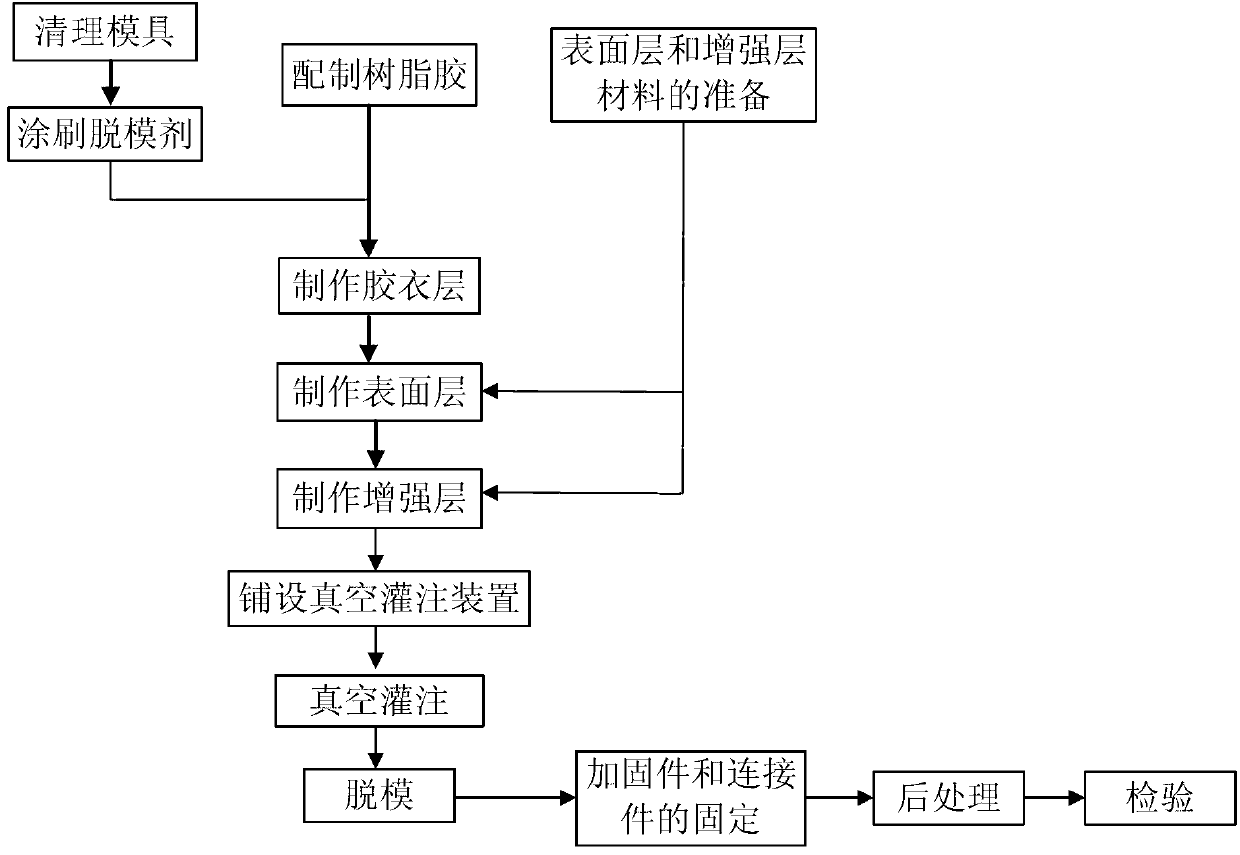

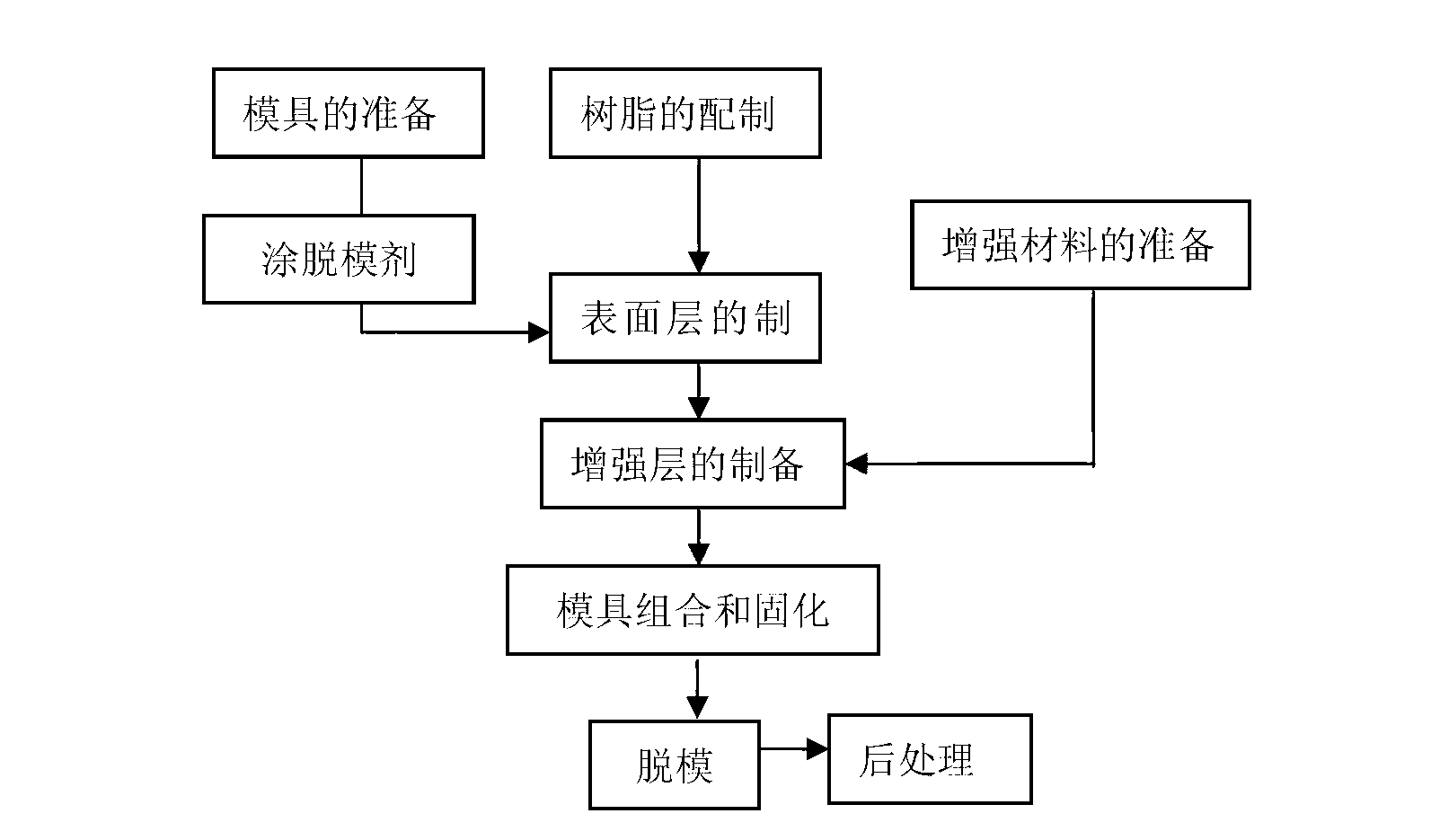

Vacuum perfusion forming method of p-aramid fiber composite material workpiece

The invention relates to a vacuum perfusion forming method of a p-aramid fiber composite material workpiece. The vacuum perfusion forming method specifically comprises the following steps of: (1) cleaning a mold; (2) painting a releasing agent; (3) respectively preparing resin glue for the gel-coat layer, resin glue for a surface layer and resin glue for perfusion; (3) manufacturing the gel-coat layer; (5) manufacturing the surface layer; (6) manufacturing a reinforcing layer which comprises p-aramid fiber cloth; (7) laying a vacuum perfusion device and sealing; (8) carrying out vacuum perfusion; (9) curing the workpiece; (10) demolding; (11) connecting a reinforcing member and a connecting piece; and (12) post-processing. The p-aramid fiber composite material prepared by the vacuum perfusion forming method provided by the invention is simple in production method and can effectively increase the ultraviolet resistance performance of the p-aramid fiber composite material workpiece; and simultaneously, p-aramid fibers and resin have a good caking property so that the composite has stable and good performances.

Owner:宁夏泰和兴材料科技有限公司

Novel floor and manufacturing method thereof

The present invention is one new type of floor board and its production process. The floor board is produced with calcite powder or limestone powder, granular waste PVC plastic, PVC resin and dibutyl ester or dioctyl ester in certain weight proportion, and through drying in a drying apparatus for 5-7 min, adding paraffin, stearic acid and other assistants in certain amount into the drying apparatus and drying for other 10-15 min, pelletizing in a pelletizer, extruding into hollow or solid floor board base in a floor board forming machine, cooling, cutting, blocking hole, tenoning, polishing, dedusting, and adhering floor film. The floor board has clear patterns, and is waterproof, fireproof and environment friendly.

Owner:吕富

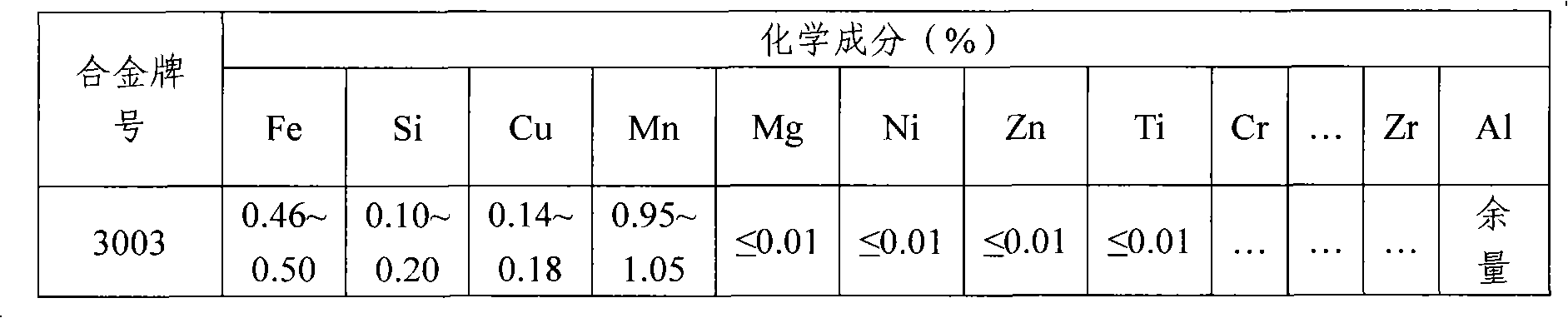

3003 reflective foil aluminum alloy

The present invention discloses a 3003 reflective foil aluminum alloy. The aluminum alloy comprises silicon, iron, copper, manganese, zinc, magnesium, titanium, and inevitable impurities, and the balance being aluminum. A processing technology includes preparing raw materials, smelting, smelting in a holding furnace, grain refinement, online degassing and deslagging, filteration deslagging, continuous casting and rolling, cold rolling, finish rolling, cutting and packing. Though configuration of the above-mentioned material composition and the processing technology arrangement, the processed aluminum foil is enabled to obtain a large amount of small, uniform, and dispersed two-phase compounds and worked structures with uniform deformation; by using the potential difference between the two-phase compounds and an Al matrix electrode, an appearance of uniform and intensive corrosion pits is achieved for increasing the specific surface area of the aluminum alloy foil through a chemical corrosion treatment; and by using worked structures with uniform deformation, that the surface of the aluminum alloy foil has a high surface quality with uniform color after the corrosion treatment is guaranteed.

Owner:新疆天展新材料科技有限公司

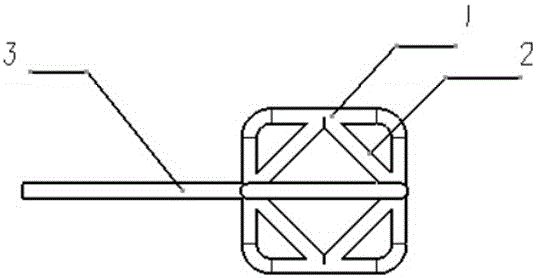

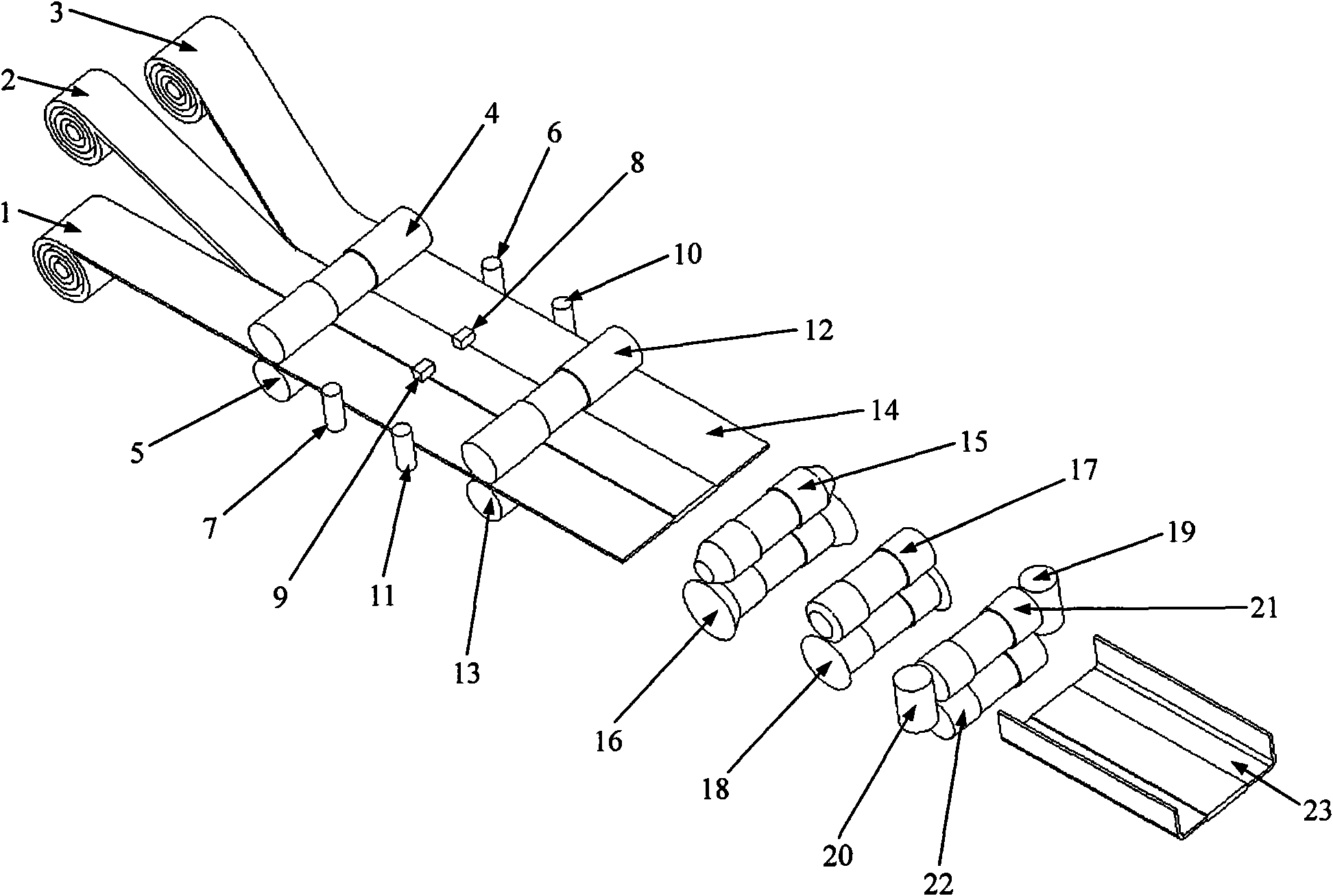

Tailor-welded blank roll bending formation device and method thereof

InactiveCN101664879ARealize online continuous productionIncrease productivityMetal-working feeding devicesWelding/cutting auxillary devicesPunchingEngineering

The invention relates to a tailor-welded blank roll bending formation device and a method thereof, belonging to the roll bending formation technology and equipment field. The tailor-welded blank rollbending formation device comprises before-welding upper and lower locating rollers, before-welding left and right locating rollers, after-welding welding device, after-welding left and right locatingrollers, after-welding upper and lower locating rollers and a formation roller bank. By adopting the device, two or more than blanks with different thickness, performance, material and surface coatingare welded together by the before-welding upper and lower locating rollers, the before-welding left and right locating rollers and the welding device, and then carry out roller bending formation through the after-welding left and right locating rollers, after-welding upper and lower locating rollers and the formation roller bank. Compared with the existing punching technology, the device can continuously produce tailor-welded blanks with any cross section in a high-efficiency and high-quality way.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

150 DEG C high-flame-retardant halogen-free red phosphorus-free modified material

A 150 DEG C high-flame-retardant halogen-free red phosphorus-free modified material comprises the following components by weight: 100 parts of a vinyl polymer, 10 parts of a grafting agent, 10-30 parts of an inorganic flame retardant, 20-40 parts of an organosilicon flame retardant, 60-90 parts of a nitrogen and phosphorus flame retardant agent, 5-15 parts of a smoke suppressor, 2-5 parts of an antioxidant, 2-5 parts of a light stabilizer, 2-5 parts of a lubricant, 3-5 parts of a crosslinking agent and 5 parts of color masterbatch. The modified material provided by the invention can be applied to production of heat shrink tubing and crosslinking cable for wide usage in the fields of locomotive, ship, spaceflight, nuclear power and war industry.

Owner:长园科技集团股份有限公司 +1

Manufacturing technology of ceramic water tap housing

InactiveCN101201132AWill not polluteAvoid pollutionValve housingsParaffin waxManufacturing technology

The invention relates to a manufacture art for a housing of a ceramics tap, which is prepared according to the following steps: firstly 10 to 20 portions of raw talcum, 60 to 70 portion of ripe talcum, 10 to 15 portion of clay, 5 to 10 portion of TiO or BaCO3 or the mixture of the two to carry through mixing are prepared and mixed together; then the original mixed raw materials can be calcined to 1320 to 1390 degrees, rubbed for 28 to 36 hours and then sifted to get ultrafine powder with 250 to 300 meshes; then the powder can be added into a paraffin liquid, the weight of which is 15 to 20 percent of that of the powder to make slurry; then the slurry can be shaped into a roughcasts of tap shells in required shape through an injection moulding technics forming technology; then roughcasts can be calcined, dewaxed, polished and glazed; finally roughcasts can be calcined to 1280 to 1350 degrees and cooled naturally. The invention can not generate any pollution during the manufacture and using processes and the product has the advantages of high temperature resistance, abrasion resistance, rust resistance and light weight, etc.

Owner:闽清中瓷卫浴有限公司

Polyphenyleneoxide-based composite resin composition for IC tray

InactiveCN1392892AImprove shrinkageGood dimensional stabilitySemiconductor/solid-state device manufacturingPackagingPolyetherimidePolystyrene

The present invention relates to polyphenylene-based composite resin composition for IC TRAY, which comprises polyphenyleneoxide or polyphenylene ether at the amount of 20 to 98 wt% of total composition weight; one or more resins selected from the group consisting of polystylene, polyphenylene sulfide, polyetherimide, polycarbonate and polyethylene (including HDPE, LDPE, LLDPE, VLDPE) at the amount of 1 to 40 wt% of total composition weight; and glass fiber or inorganic fillers at the amount of 1 to 40 wt% of total composition weight. In addition, the composition of the present invention has excellent mechanical strength, dimensional stability, low linear fever expansion coefficient, and a good outlook for a product. The composition of the present invention is appropriate for IC TRAY in view that it does not deflect due to contraction, linear expansion coefficient and heat, thus having excellent dimensional stability.

Owner:GE POLYMERLAND

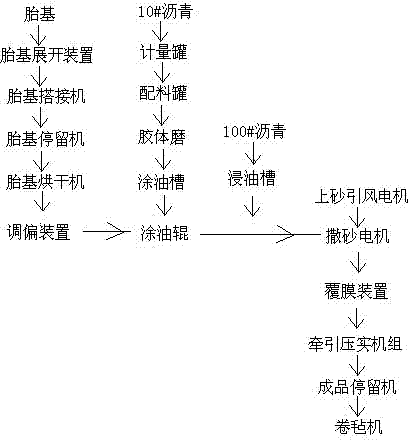

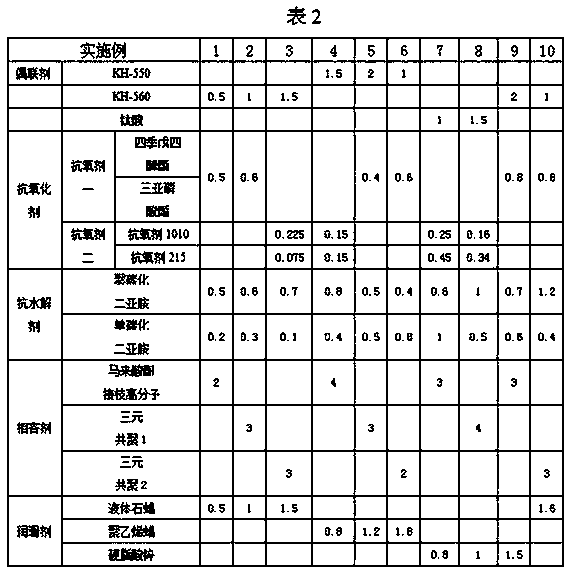

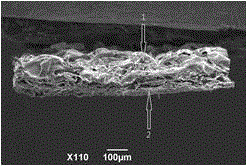

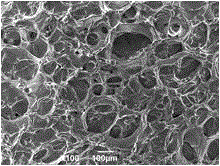

Elastomer modified asphalt waterproof coiled material as well as production technology and equipment thereof

ActiveCN103483837ASimple ingredientsImprove performanceBuilding insulationsBituminous layered productsColloid millBituminous waterproofing

The invention discloses an elastomer modified asphalt waterproof coiled material as well as a production technology and equipment thereof. The coiled material is prepared by the following raw materials in parts by weight: 20 parts of 10# asphalt, 40 parts of 100# asphalt, 11 parts of machine oil, 12 parts of elastomer and 17 parts of talcum powder. The technology comprises the steps of ingredient stirring, base feeding, oil dip coating, sanding, film coating, traction compaction and the like. The equipment comprises a metering tank, a batching tank, a colloid mill and an oil coating groove, wherein the oil coating groove is provided with an oil coating roll; a base unfolding device, a base overlapping machine, a base retention machine and a base dryer are sequentially arranged at an inlet end of the oil coating roll; and an oil soaking groove and a film coating device are sequentially arranged at an outlet end of the oil coating roll and connected with the oil coating roll. The coiled material has the advantages that the coiled material has simple components, is higher in property, simple and practicable in technology and easy to control; the surface of the coiled material is level and free from holes, chipped edges, gaps and pimples; mineral particles are uniform and consistent in particle size and are adhered to the surface of the coiled material tightly; and the coiled material is wide in using temperature range and aging-resistant.

Owner:潍坊英凯防水材料有限公司

PLA (polylactic acid) modified material for 3D (three-dimensional) printing and preparation method thereof

InactiveCN107686638AHigh strengthHigh elongation at breakAdditive manufacturing apparatusResource utilizationPollution

The invention relates to a high-intensity high-toughness PLA (polylactic acid) modified material for 3D (three-dimensional) printing and a preparation method thereof in the technical field of a 3D printing material. The high-intensity high-toughness PLA modified material for 3D printing is characterized by being prepared from the following ingredients in parts by mass: 100 parts of PLA, 10 to 30 parts of inorganic filling materials, 5 to 10 parts of toughening agents, 6 to 10 parts of anti-impact modifying agents and 4 to 10 parts of other auxiliary agents. The modified and prepared PLA modified material achieves an environment-friendly effect and is nontoxic; the printing is smooth; no odor exists; no pollution exists; the safety coefficient is high; a printing finished product has the excellent characteristics of bright and clean surface, beautiful appearance, uniformity, stable dimension, shrinkage difficulty and the like; the PLA modified material is suitable for being used by an FDM 3D printer; waste materials can be completely recovered and recycled; the cost is reduced; the resource utilization rate is also improved. The product manufacturing technological process is short;the equipment requirements are simple; the manufacturing process is simple and convenient; the operation is convenient; the severe chemical process operation is omitted; the preparation method is verysuitable for large-scale industrial production.

Owner:NINGXIA KOCEL MOLD

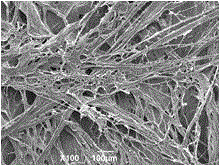

Biological repair membrane and preparation method thereof

The invention provides a biological repair membrane and a preparation method thereof. In the prior art, the existing biological repair membrane has the following disadvantages that the mechanical strength is poor, the suture point has the cerebrospinal fluid leakage risk, the tissue regeneration and repair promoting performance is weakened, the residual toxicity exists after the degradation, the biocompatibility is poor, and the adhesion between the repair material and the brain tissue is easily caused, and other complications are easily induced. According to the present invention, the animal-derived membrane tissue is subjected to cell removing and antigen removing, and a natural polymer material coating capable of being adsorbed and providing bleeding stopping effect is coated on the treated animal-derived membrane tissue so as to solve the problems in the prior art; the method specifically comprises: pretreatment, degreasing with an organic reagent, cell removing and antigen removing with an alkali liquid, coating preparation, vacuum compression and freeze-drying, packaging, and sterilization so as to complete the preparation of the biological repair membrane; and the biological repair membrane has advantages of bleeding stopping, antibacterial property, adhesion, natural three-dimensional space structure retaining, good mechanical property, good biocompatibility, good tissue growth induction, degradation non-toxicity, wide raw material source, low price, and easy mass-production.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

Soft-pellet creep feed and preparation method thereof

ActiveCN103416591AImprove palatabilityEliminate lossAnimal feeding stuffAdditive ingredientBlood plasma

The invention discloses a soft-pellet creep feed and a preparation method thereof, and belongs to the field of feed formulation design and feed processing techniques. The preparation method comprises the following steps: mixing and bacillus subtilis and pickled vegetables fermentation liquor, performing fermentation in sequence to form fermented soybean meal and rice which are taken as main raw materials; adding steam fish meal, blood plasma powder, soybean meal and the like in a matched manner; utilizing a soft pelletizer to prepare pellet materials through ultramicro smashing; utilizing a syrup spray device to uniformly spray syrup on the surfaces of the pellet materials. The creep feed provided by the invention is full and balanced in nutrition, is easy to digest and intake, has stable quality, and is subjected to multiple fermentation. Moreover, feed inducing performance, soft protection performance and nutrition full value performance are improved, as a process of combining a soft manufacturing system and the syrup spray system is adopted; the incidence of hardening of medium-sized pellet feed during the preservation process is reduced; compared with a dry pellet feed, the loss of nutritional ingredient during the granulating heating and drying process is avoided, and the palatability of soft pellet feed is kept well.

Owner:LIAONING WELLHOPE AGRI TECH

High-strength and high-tenacity polypropylene composite materials and preparation method thereof

The invention discloses high-strength and high-tenacity polypropylene composite materials. The high-strength and high-tenacity polypropylene composite materials solve the problems that existing polypropylene is poor in tenacity and poor in strength. The high-strength and high-tenacity polypropylene composite materials are formed by the following components, by weight, 35-75% of polypropylene, 10-40% of calcium carbonate, 8-25% of calcium sulfate whisker masterbatch, 0.1-2% of coupling agents, 2-8% of compatilizer, 0.3-4% of lubricating agents and 0.2-0.8% of antioxygen. The invention further provides a preparation method of the high-strength and high-tenacity polypropylene composite materials. According to the preparation method of the high-strength and high-tenacity polypropylene composite materials, through the mode that calcium sulfate whiskers are made into masterbatch, the calcium sulfate whisker masterbatch is added to plastics to carry out co-extrusion mixing with the plastics and the like, thus, compared with powdery whiskers, material preparation can be evener and controllable, the problem that material preparation of the calcium sulfate whiskers is difficult is solved, meanwhile, the calcium sulfate whiskers are made to have better dispersity in plastic substrate, and the surfaces of products are smoother.

Owner:四川万润非金属矿物材料有限公司

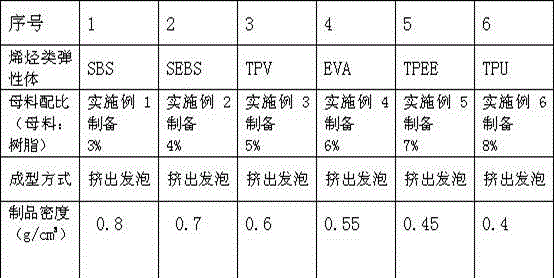

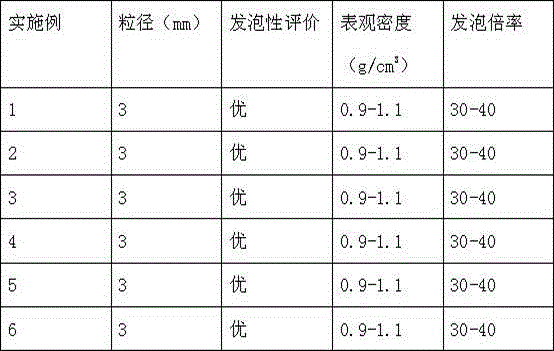

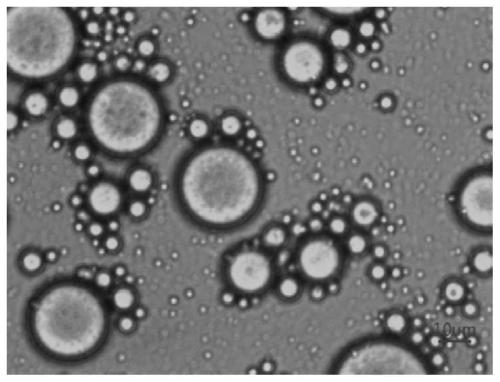

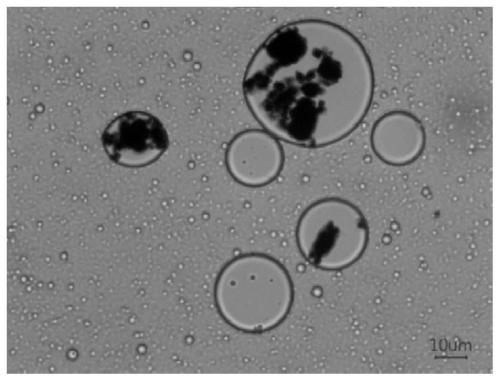

TPE (thermoplastic elastomer) foamed master batch and preparation method thereof

The invention relates to TPE (thermoplastic elastomer) foamed master batch and a preparation method thereof and belongs to the field of new chemical materials. The TPE foamed master batch is prepared from raw materials in parts by weight as follows: 10-30 parts of a styrene-butadiene block copolymer, 10-30 parts of an ethylene-octylene block copolymer, 30-80 parts of white oil, 20-80 parts of a microsphere foaming agent, 10-50 parts of a chemical foaming agent, 1-3 parts of a lubricating agent and 1-3 parts of a dispersing agent. The prepared TPE foamed master batch has high modulus, fine and uniform foam holes and adjustable density.

Owner:FUZHOU HAOWANG MATERIALS TECH CO LTD

Cathode water-soluble electrophoretic paint

InactiveCN104371497AImprove performanceReasonable ratioPaints for electrolytic applicationsEpoxy resin coatingsEpoxyCorrosion

The invention provides a cathode water-soluble electrophoretic paint which comprises 1 part of emulsion and 3-4 parts of color paste. The emulsion is prepared from the following raw materials in percentage by mass: 25-40% of epoxy resin, 20-30% of curing agent, 2-4% of fatty amine, 1-2% of nontoxic drying agent and 25-40% of deionized water. The color paste is prepared from the following raw materials in percentage by mass: 25-35% of epoxy resin, 5-15% of carbon black, 15-30% of titanium white, 2-6% of anti-stratifying agent, 2-4% of emulsifier and 20-30% of deionized water. The cathode water-soluble electrophoretic paint has the advantages of reasonable proportioning and lower cost. The produced product has the advantages of smooth surface, high safety, environment protection, favorable corrosion resistance, high combination degree, high reaction speed and higher conversion rate. Thus, the electrophoretic paint has favorable properties.

Owner:GUANGDE RUIBANG PAINT

Boil-proof health-care konjak starch vermicelli

InactiveCN1341382AGood cooking resistanceUnique health functionFood preparationFood processingStarch

The present invention relates to a food processing method, in particular it relates to a boil-proof health-care konjak starch vermicelli. It is made up by adding konjack fine flour and other auxiliary material in the market starch with various types through the vermicelli production process. As compared with traditional high-quality starch vermicelli said invented product is smooth in surface, transparent and uniform in fineness, boil-proof and possesses a certain health-care function.

Owner:天津市金利保健食品有限公司

Method for preparing honeydew dendrobium flower tea

The invention provides a method for preparing honeydew dendrobium flower tea. The honeydew dendrobium stem flower tea is prepared by utilizing the vacuum impregnating and freezing drying technology, which is improved on the basis of the conventional sun shining, baking, heating and drying process, the vacuum impregnation and vacuum accelerated freeze-drying are finished under an closed environment, so that the medicinal properties of dendrobium flower can be fully exerted, the active ingredients of the dendrobium flower can be protected maximally during the preparation process of the honeydew dendrobium flower tea, and the pollution of microorganisms to the product can be avoided. The bee honey and the dendrobium flower are combined, so that the natural preservative, namely, bee honey is dissolved into the flower, the prepared dendrobium flower tea is easy to preserve and store, the whole shape of the flower is well kept, and the made flower tea has faint scent, sweet taste. The honeydew dendrobium flower tea is convenient to carry, easy to store; and the flower is flat and dry.

Owner:杨军

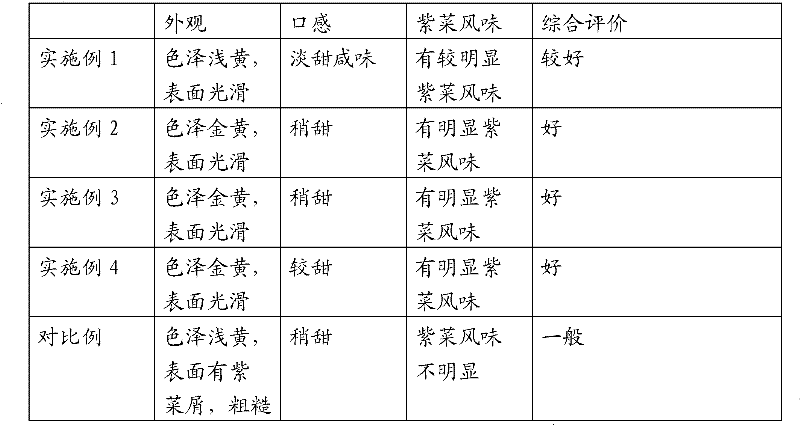

Process for making agar biscuits

The invention discloses a process for making agar biscuits. The process mainly comprises the following steps of: (1) coarsely crushing a clear and dry agar raw material to grains of 20-30 meshes, carrying out a micronization treatment on the grains to obtain micro-grains with the grain size of 120-150 meshes; (2) mixing various raw materials and auxiliary materials with flour and kneading a dough at 38-40 DEG C for 50-60min, and standing for 15-20min; (3) rolling and pressing dough to be thin sheets, and baking after printing modeling formation; and (4) naturally cooling finished-products, and sealing and packing the finished products. According to the process for making the agar biscuits, the agar undergoes the micronization treatment so that the nutrients of the agar are easier to be absorbed by human bodies; and the finished-products have smooth surfaces and have pure and remarkable agar flavor.

Owner:FUJIAN BEICHILE FOOD

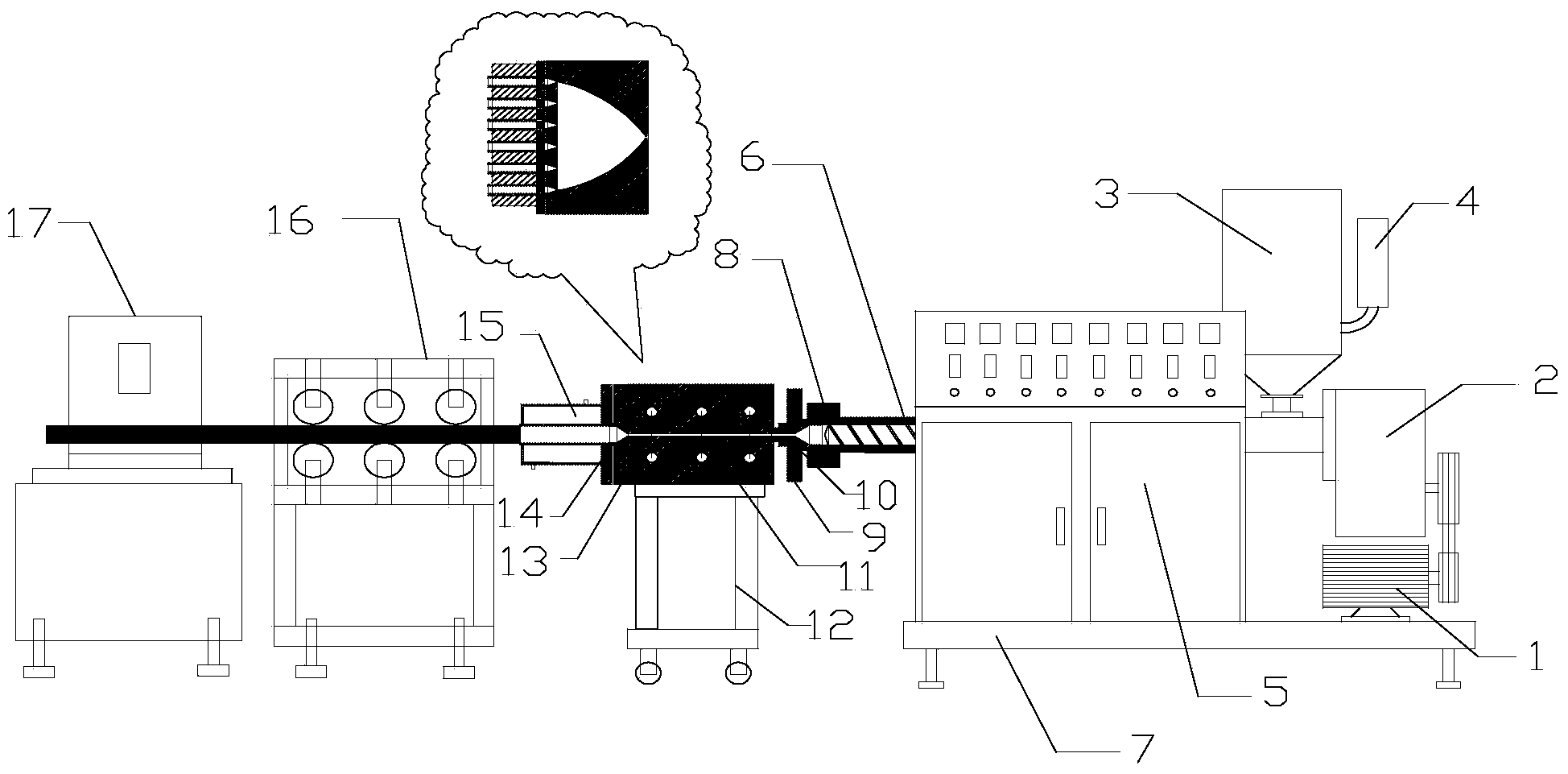

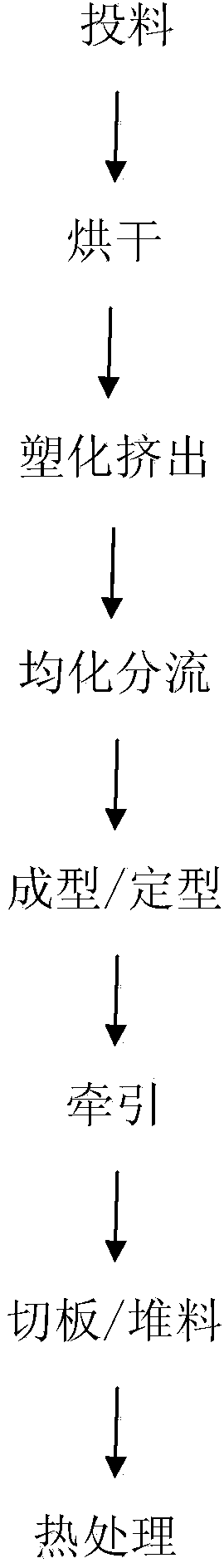

PEEK plastic rod production device and process

InactiveCN103722718AReduced flow marks and scratchesMeet the mechanical propertiesPolyether ether ketoneCompression device

The invention discloses a PEEK plastic rod production device and process. The PEEK plastic rod production device comprises a main machine and an auxiliary machine. The main machine is an extruder and comprises an extruding system, a rotating system and a control system, wherein the extruding system is a gun barrel screw; the rotating system comprises a motor and a reduction box; the control system comprises an electric appliance instrument and an actuating mechanism; the auxiliary machine comprises a mold, a traction machine, an oil temperature machine, a cutting machine and an oven; the mold comprises a main mold, a guide plate, a heat insulation ring, a forming shaping barrel and a cooling water tank; the oil temperature machine is installed on a shaping section of a forming pipe; the traction machine mainly comprises a transmission device, a roller compression device and a brake device, and is installed behind a heat preserving device; the cutting machine is installed behind an outlet of the mold; the oven is a closed box body. The process comprises the steps of charging, drying, plasticizing extruding, homogenizing distributing, forming / shaping, pulling, cutting / stacking and thermal processing.

Owner:深圳市恩欣龙特种材料股份有限公司

Light environment-friendly brick prepared from waste brick powder, and preparation method for light environment-friendly brick

InactiveCN102515691ASolve the problem of foaming rate controlUniform foamingSolid waste managementBrickFoaming agent

The invention discloses a light environment-friendly brick prepared from waste brick powder, and a preparation method for the light environment-friendly brick. The light environment-friendly brick prepared by the method comprises the following raw materials in percentage by weight: 50 to 60 percent of polishing brick waste mud, 10 to 15 percent of waste brick powder, 10 to 15 percent of Qidao clay, 10 to 15 percent of aluminum ore, 5 to 10 percent of mung bean mud, 0.3 percent of foaming agent, 0.5 percent of water reducing agent and 0.08 percent of green body intensifier, wherein the polishing brick waste mud is waste mud which is wasted when a polishing brick is produced; and the waste brick powder is brick powder which is wasted when a common brick is produced. The problems about control over foaming rate and flatness of a product in a drying and calcination process can be solved, the prepared finished product is smooth and flat in surface, and closed air holes in the brick are ideal. Meanwhile, the waste brick powder and the waste mud in a ceramic production enterprise are used as raw materials, so industrial waste is treated, production cost is saved, environment is protected, and energy consumption is reduced.

Owner:SICHUAN BAITA XINLIANXING CERAMIC GROUP

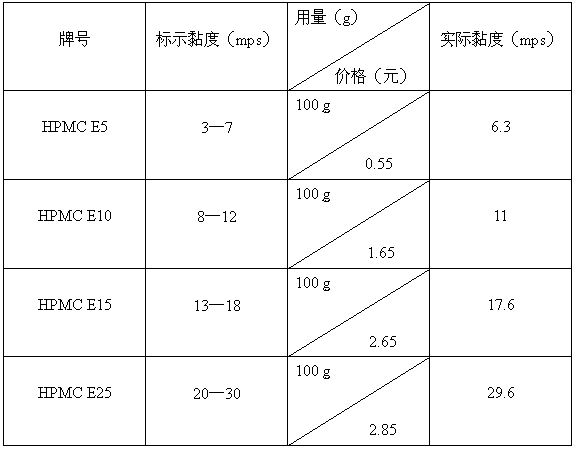

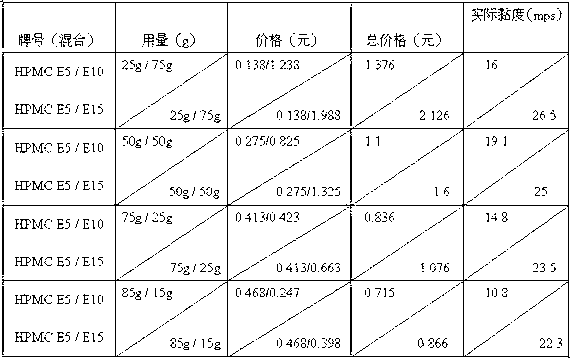

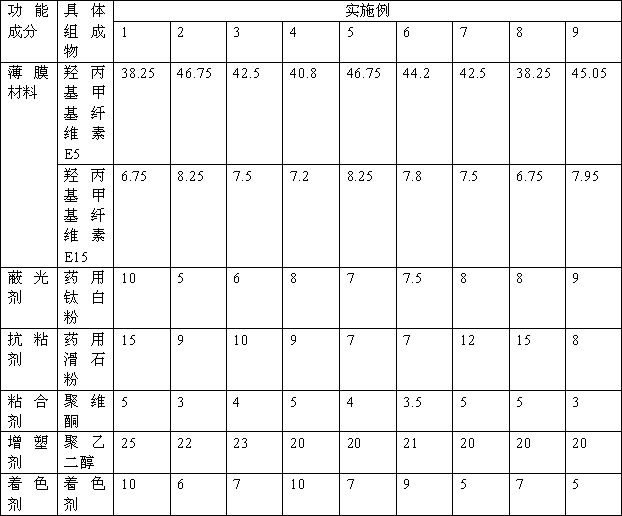

Film coating medicine and preparation method thereof

ActiveCN102935234ACost efficient to manufactureThe surface of the product is smoothPharmaceutical delivery mechanismPharmaceutical non-active ingredientsPlasticizerMethyl cellulose

The invention discloses a film coating medicine and a preparation method thereof and relates to the technical field of film coating for tablets. The active ingredients of the film coating medicine are prepared from the following raw materials in percentage by weight: 45%-55% of hydroxyl propyl methyl cellulose E5 and hydroxyl propyl methyl cellulose E15, 5%-10% of light screen agent, 7%-15% of antisticking agent, 3%-5% of bonding agent, 20%-25% of plasticizer and 5%-10% of coloring agent. Compared with the prior art, the produced product has smooth surface and good moisture resistance, and the production cost can be effectively lowered.

Owner:GUANGXI JIAJIN PHARMA

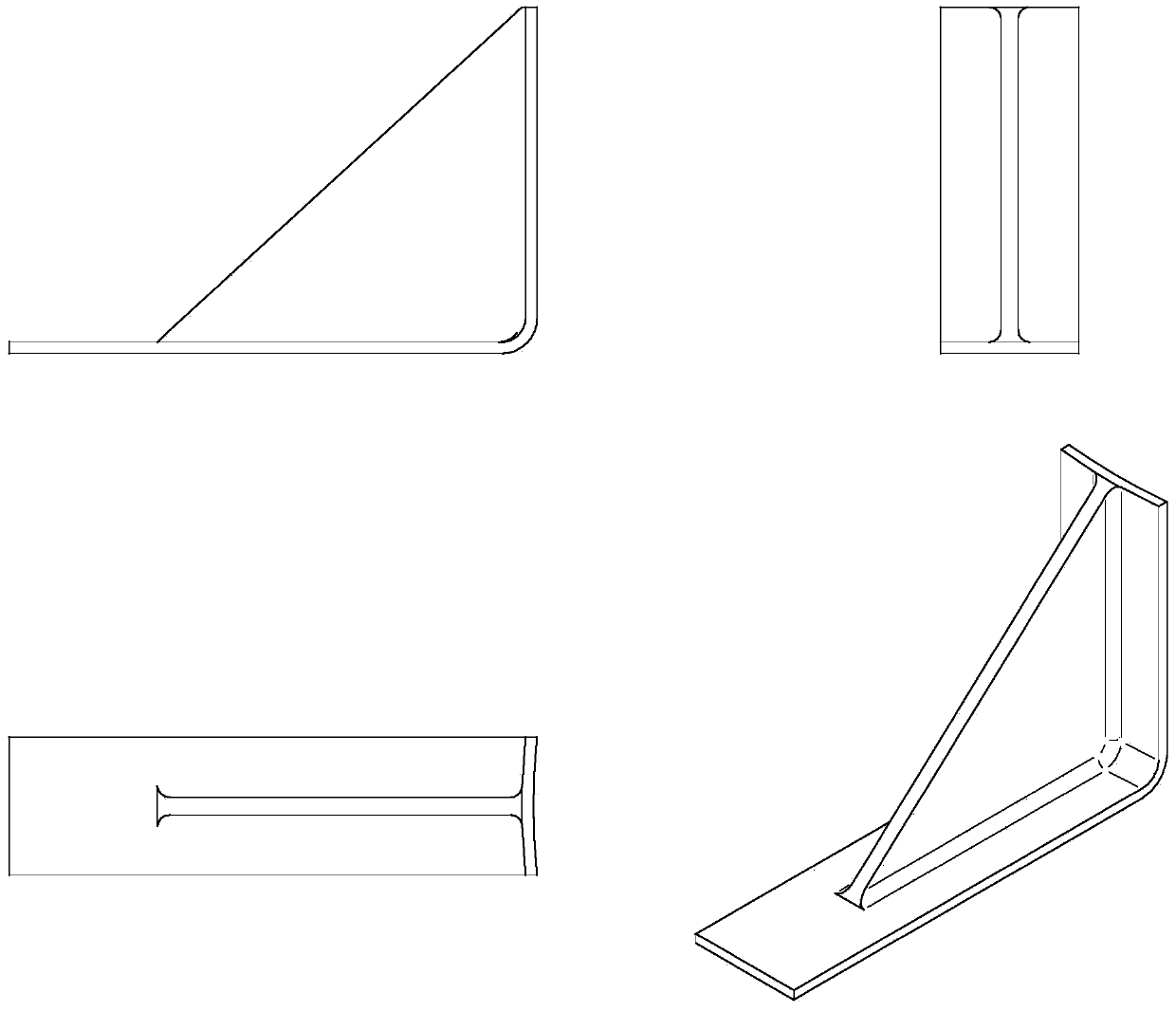

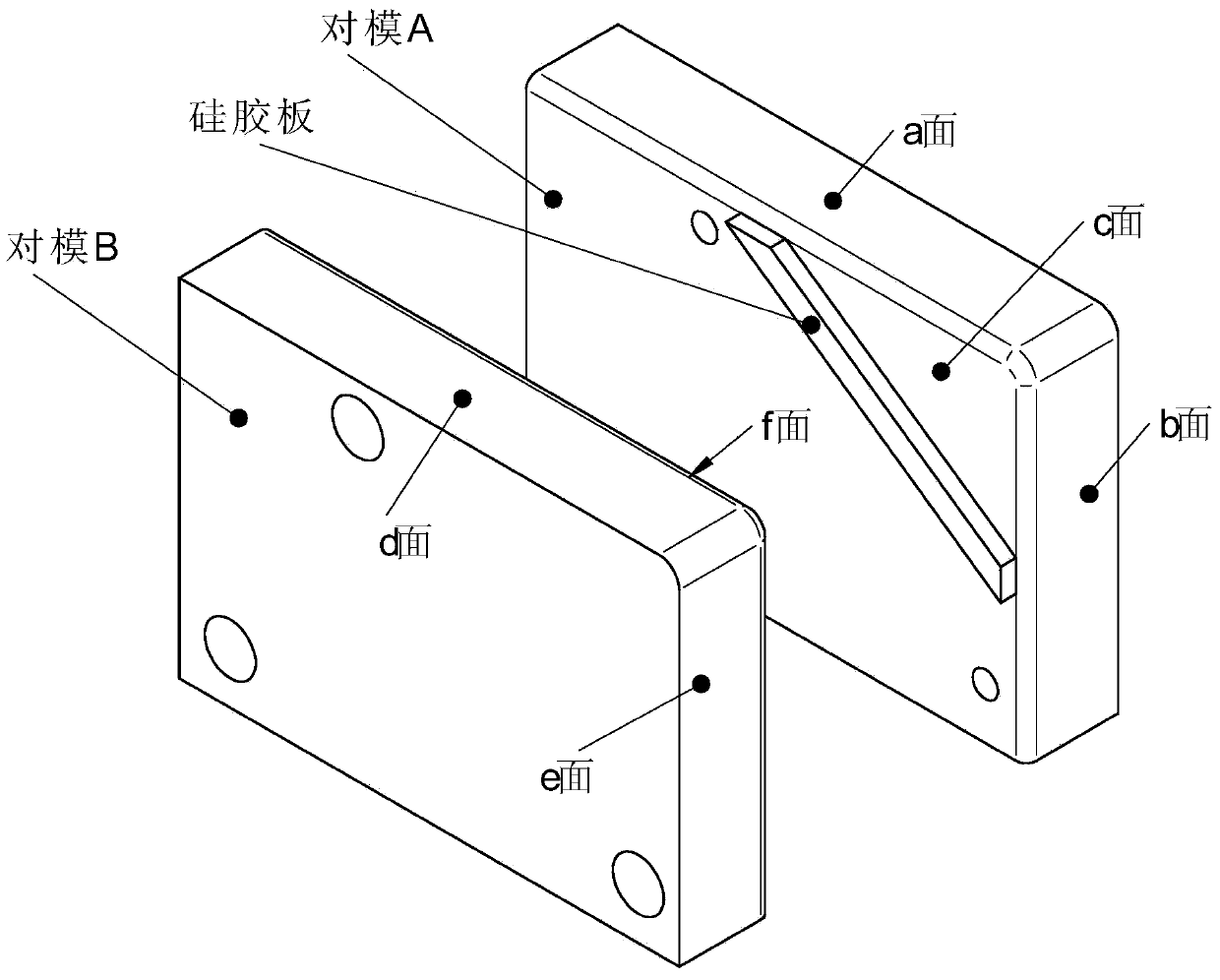

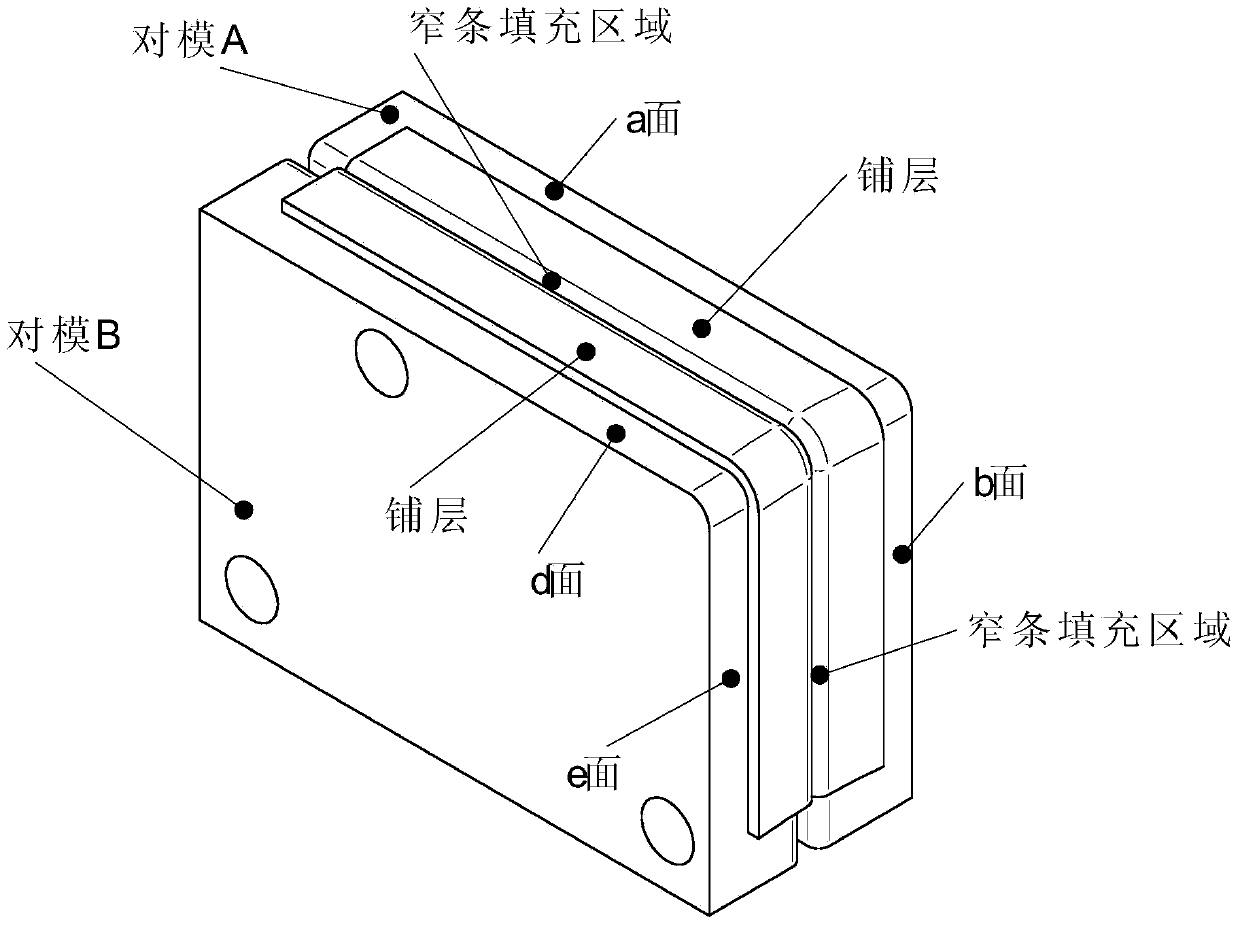

Forming method of resin matrix composite reinforcing ribs

The invention belongs to the technical field of formation of carbon fiber reinforced resin matrix composite structures, and relates to a forming method of resin matrix composite reinforcing ribs, which is particularly suitable for reinforcing ribs with maximum overall dimension smaller than 500mm. The forming method of the resin matrix composite reinforcing ribs, disclosed by the invention, is simple, convenient and easy to carry out; a used forming die is simple and easy to obtained, and has adaptive capability to different product sizes, and the appearance of obtained products is smooth and elegant; the method is particularly suitable for formation of serial reinforcing ribs, and the advantages are more prominent when the number of the reinforcing ribs is greater; multiple identical die assemblies can be manufactured continuously, meanwhile the method can be used for forming multiple reinforcing ribs with different structures, and different demands of the same structure system can be met quickly.

Owner:BEIJING SATELLITE MFG FACTORY

Manually-pasting molding method of para-position aramid fiber composite material

The invention relates to a manually-pasting molding method of a para-position aramid fiber composite material. The manually-pasting molding method particularly comprises the following steps of: (1) cleaning a mould; (2) coating a de-molding agent on the mould; (3) respectively preparing a resin adhesive for a gel coat layer and resin adhesives for a surface layer and an enhancement layer; (4) manufacturing the gel coat layer; (5) manufacturing the surface layer; (6) manufacturing the enhancement layer; (7) combining the mould and curing a workpiece; (8) de-molding; and (9) carrying out post-treatment on the workpiece. According to the manually-pasting molding method of the para-position aramid fiber composite material, the conventional manually-pasting molding method is improved in the manner of coating the surface layer with an ultraviolet light absorber or ultraviolet-resisting paint, and pre-treating para-position aramid fiber cloth in the enhancement layer. When the manually-pasting molding method is used for producing the para-position aramid fiber composite material, equipment is simple, the investment is less, a production technology is easy to master, and some large-sized para-position aramid fiber composite materials which are not suitable for transportation can be manufactured on site; the para-position aramid fiber composite material workpiece has good ultraviolet-resisting performance; and meanwhile, para-position aramid fibers and resin are good in cohesiveness, and thus the composite material can have various stable and good performance.

Owner:宁夏泰和兴材料科技有限公司

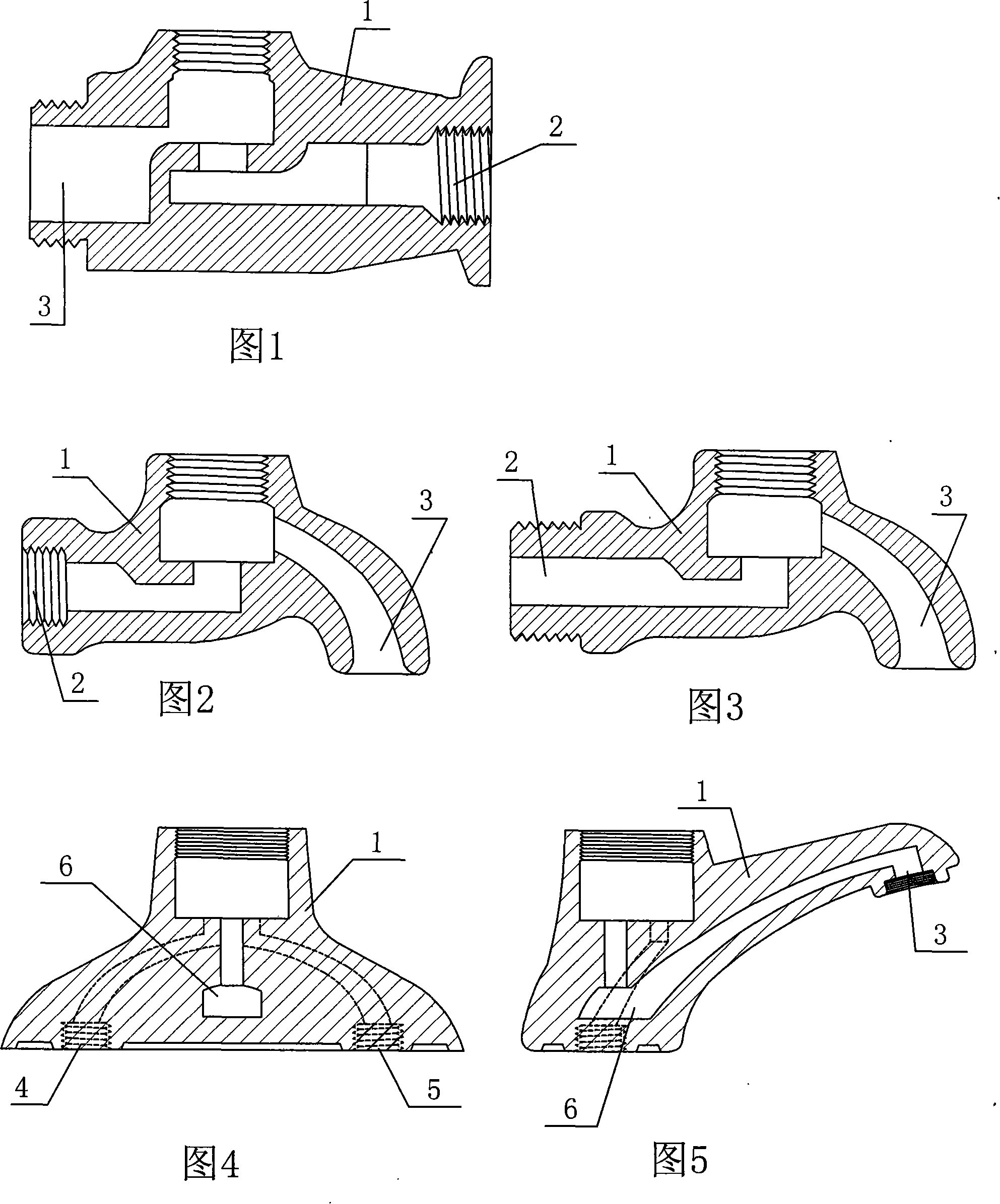

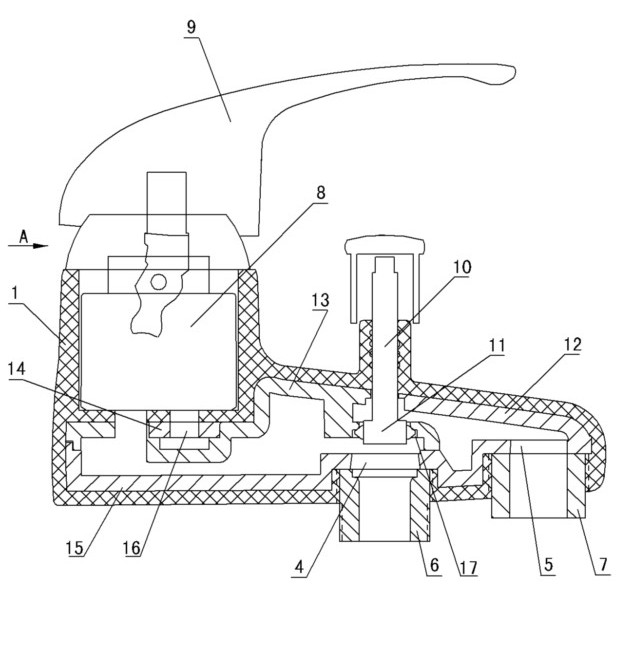

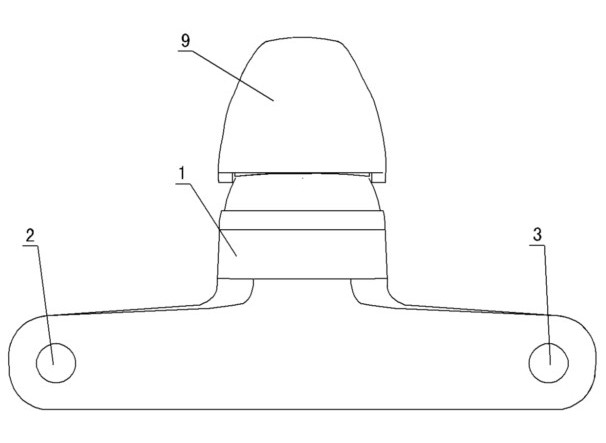

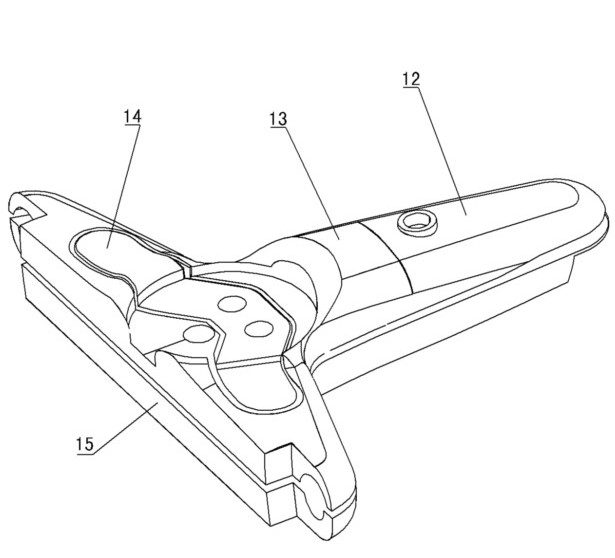

Triple bathtub water faucet and processing method

The invention discloses a triple bathtub water faucet, which comprises a water faucet body, wherein the rear part of the body is provided with a cold water port and a hot water inlet which are respectively connected with a cold water pipe and a hot water pipe; a shower joint and a falling water port are arranged below the front part of the body; a valve rod is arranged above the shower joint, and a valve head is arranged on the head of the valve rod; a valve core is arranged in the body, and a water passage is formed in the body; a handle is arranged on the valve core; the water passage is communicated with each inlet and each outlet; the water passage comprises a water passage front cover, a water passage main body upper cover, a cold and hot water inlet passage upper cover and a water passage main body lower cover which are molded by injecting plastic materials and welded through ultrasonic; a falling water outlet is formed in the water passage front cover, a main body upper cover water outlet is formed in the water passage main body upper cover, a cold and hot water passage water outlet is formed in the cold and hot water inlet passage upper cover, and a shower outlet is formed in the water passage main body lower cover; and the cold and hot water passage water outlet is matched with the valve core, the lower part of the valve head is matched with the shower outlet, the upper part of the valve head is matched with the main body upper cover water outlet, and the main body upper cover water outlet is communicated with the falling water outlet.

Owner:台州卓泰工贸有限公司

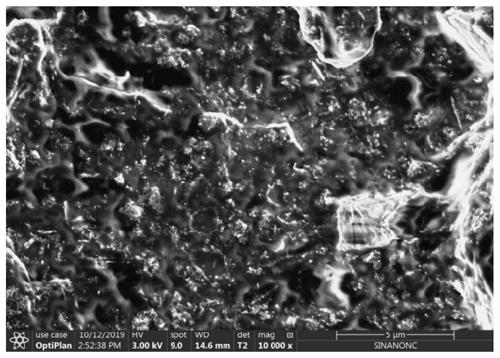

Easy-to-disperse carbon nanotube master batch as well as preparation method and application thereof

The invention belongs to the field of carbon nanotubes, and relates to an easy-to-disperse carbon nanotube master batch, and a preparation method and an application thereof. The master batch specifically comprises white oil, an emulsifier, an antioxidant, carbon nanotubes and powdered polyolefin. The process comprises the following steps: carrying out shearing emulsification on the white oil, theemulsifier and the deionized water to prepare white oil emulsion; then adding carbon nanotubes, and carrying out infiltration, shearing and dispersion to obtain a carbon nanotube wetting dispersion; and adding powdered polyolefin, uniformly mixing the components, concentrating and drying the mixture, and carrying out screw melt extrusion granulation to obtain the carbon nanotube master batch. Herein, the white oil emulsion is used as an infiltration carrier, carbon nanotubes are uniformly dispersed in white oil emulsion bundles through high-speed shearing under the auxiliary action of an emulsifier, micelle particles are stabilized under the action of hydrophilic-hydrophobic force, and re-agglomeration of the dispersed carbon nanotubes is avoided; the fully dispersed carbon nanotubes are used to obtain the easily-dispersed carbon nanotube master batch taking polyolefin as a carrier. The master batch is used as a conductive master batch, and has the advantages of low addition amount, easy dispersion, no flying dust and the like.

Owner:JIANGXI COPPER TECHNOLOGY RESEARCH INSTITUTE CO LTD

Plastic wood prepared from mixed plastic in domestic garbage and wood powder, and preparation method of plastic wood

Owner:四川川润环保能源科技有限公司 +1

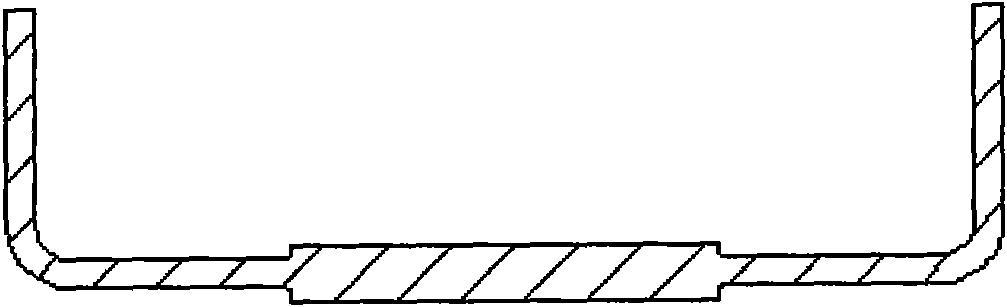

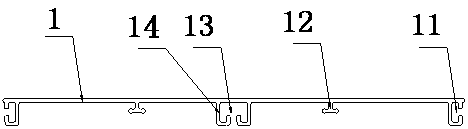

Combined PVC (Poly Vinyl Chloride) building template

InactiveCN102359266AImprove impact resistance and pressure resistanceImprove weather resistanceForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEarthquake resistantSurface plate

Owner:HUAJUN PLASTIC BUILDING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com