Manually-pasting molding method of para-position aramid fiber composite material

A composite material, para-aramid fiber technology, which is applied in the field of preparation of para-aramid fiber composite material parts, can solve the problems of affecting life, low interlaminar shear strength of composite materials, poor adhesion of aramid fiber materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] A hand lay-up method process for flat para-aramid composite parts:

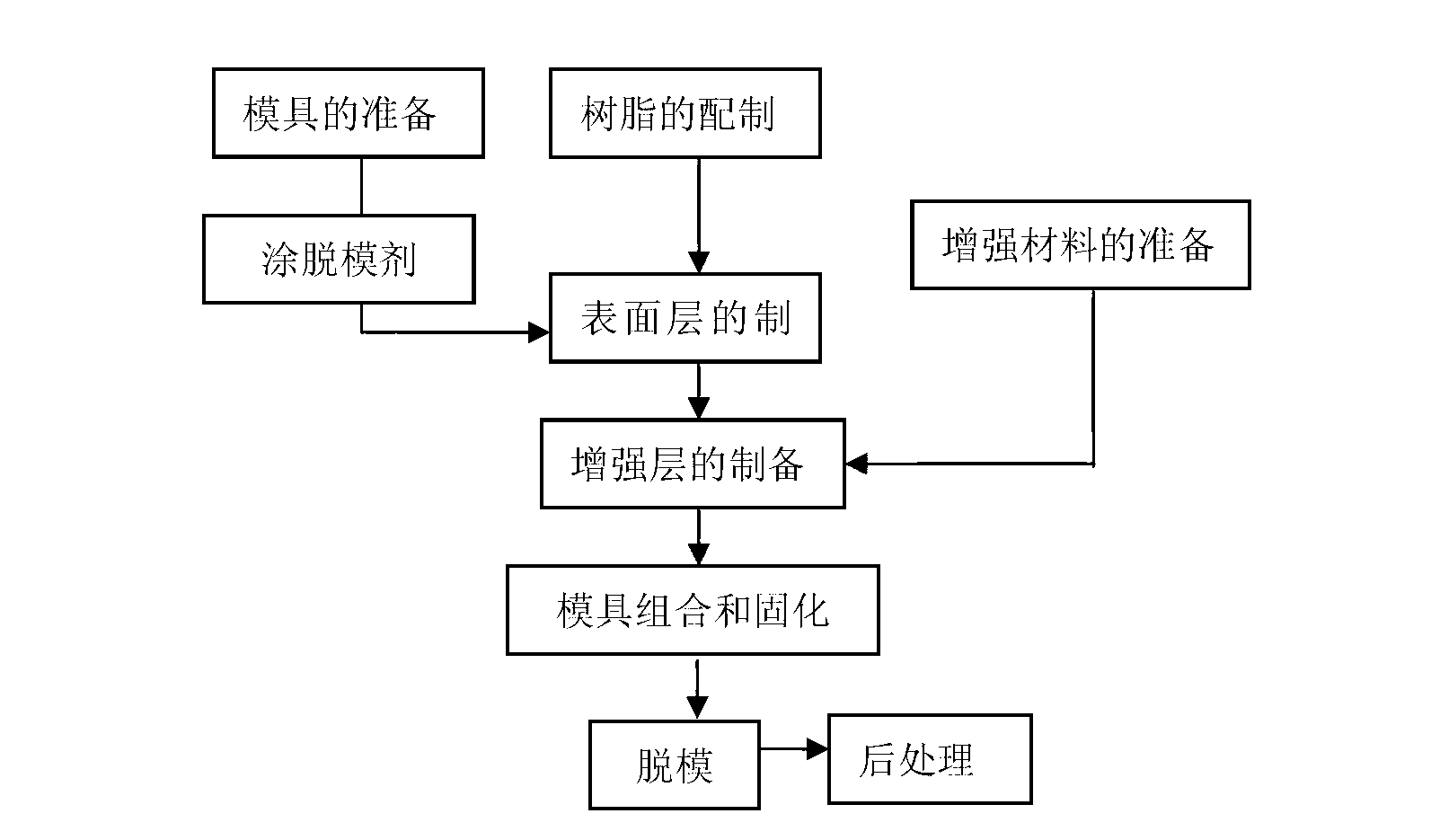

[0088] figure 1 Flowchart of the hand lay-up method. Specifically include the following steps:

[0089] 1. Clean the mold

[0090] A composite mold made of stainless steel is adopted, including a relative female mold and a male mold, and the prepared para-aramid composite material is a rectangular plate-shaped workpiece. The mold is stuck with the residual glue left over from the last demoulding, carefully remove it with a flat shovel without damaging the surface; wash the release agent with water, dry it and set it aside.

[0091] 2. Brushing release agent

[0092] Heat 45 parts of water to 60~70°C, add 5 parts of polyvinyl alcohol (low molecular powder, average molecular weight 16000~20000), keep stirring until completely dissolved, then cool to room temperature, then add 50 parts of ethanol dropwise with stirring to complete Filter to remove particles and impurities. Finally, add 1 part of def...

Embodiment 2

[0121] A hand lay-up method process for cuboid-shaped para-aramid composite parts:

[0122] figure 1 Flowchart of the hand lay-up method. Specifically include the following steps:

[0123] 1. Clean the mold

[0124] A composite mold made of stainless steel is adopted, including a relative female mold and a male mold, and the prepared para-aramid composite material is a rectangular shaped workpiece. The mold is stuck with the residual glue left over from the last demoulding, carefully remove it with a flat shovel without damaging the surface; wash the release agent with water, dry it and set it aside.

[0125] 2. Brushing release agent

[0126] Heat 45 parts of water to 60~70°C, add 5 parts of polyvinyl alcohol (low molecular powder, average molecular weight 16000~20000), keep stirring until completely dissolved, then cool to room temperature, then add 50 parts of ethanol dropwise with stirring to complete Filter to remove particles and impurities. Finally, add 1 part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com