Patents

Literature

117results about How to "Simple production technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental-friendly waterproof polymer mortar

InactiveCN101560084AImprove adhesionStrong bondSolid waste managementSilicate CementConstruction aggregate

The invention relates to environmental-friendly waterproof polymer mortar, which comprises the following components in portion by weight: 50 to 230 portions of low-clinker silicate cement, 200 to 450 portions of quartz sand, 80 to 120 portions of fly ash, 1 to 18 portions of re-dispersible polyethylene vinyl acetate latex powder, 1 to 10 portions of dispersible polyvinyl acetate vinyl versatate latex powder, 0.2 to 0.6 portion of water reducing agent, 0.05 to 0.3 portion of antifoaming agent, and 0.25 to 2.25 portions of polypropylene fibers. A gel material prepared from steel slag, tailings and the fly ash replaces silicate cement and partial aggregate in the prior mortar; the modified waterproof polymer mortar has the advantages of excellent impermeability, good mechanical property and construction property, simple production technology, and easy manufacture, greatly consumes industrial and mining wastes, controls the ecological environment, and lowers the cost; and the product has reliable quality and wide market; and the environmental-friendly waterproof polymer mortar can be popularized and applied in large area.

Owner:黑龙江省学府环艺雕塑有限公司

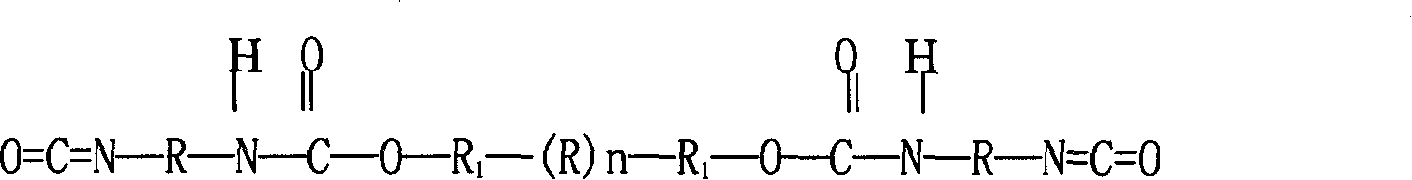

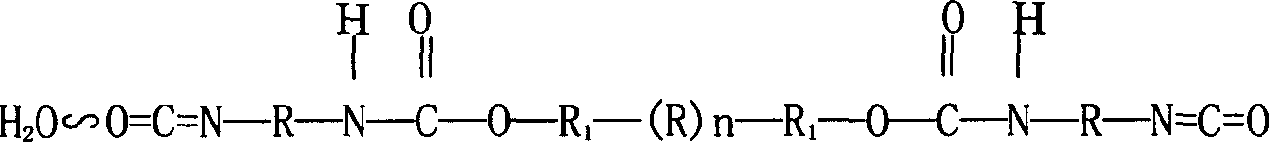

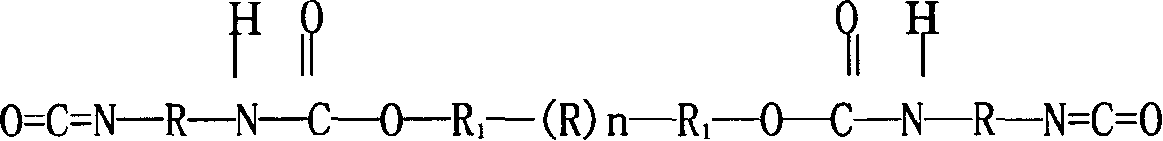

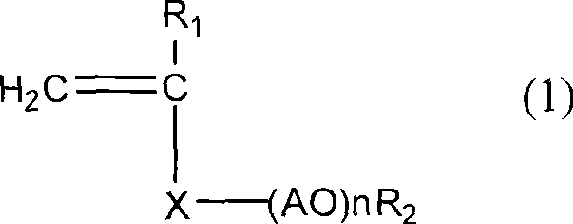

Polysiloxane-polyether copolymer modified aqueous polyurethane preparation method

InactiveCN1884335AImprove heat resistanceImprove low temperature resistanceLiquid surface applicatorsFibre treatmentCarbamateSolvent

The invention relates to a method for preparing aqueous polyurethane. It comprises following steps: employing polyisocyanates bridging agent, proceeding copolymerization with excess aqueous polyether, liquid ploydimethyl oxosilane ternary block and getting ployoxosilane-polyether polymer, introducing polyurethane and organic silicon when generating carbamate with carbamate to main chain, adding chain propagation agent for chain propagation reaction and getting preploymer containing hydrophilic group; adding mixture of polyhydroxy compound and dissolvent into reaction system for second chain propagation reaction; neutralizing by adding neutralization agent, adding water for emulsification, adding polyamine for chain propagation; distilling to remove dissolvent after reaction and getting aqueous polyurethane modified with aqueous polyurethane-polyether polymer. The product possesses characteristics of polyurethane and polysiloxane, the storage stability, mechanics property and comprehensive performance is increased and it mainly is used as pigmentum and aqueous industrial coating material.

Owner:山东圣光化工集团有限公司

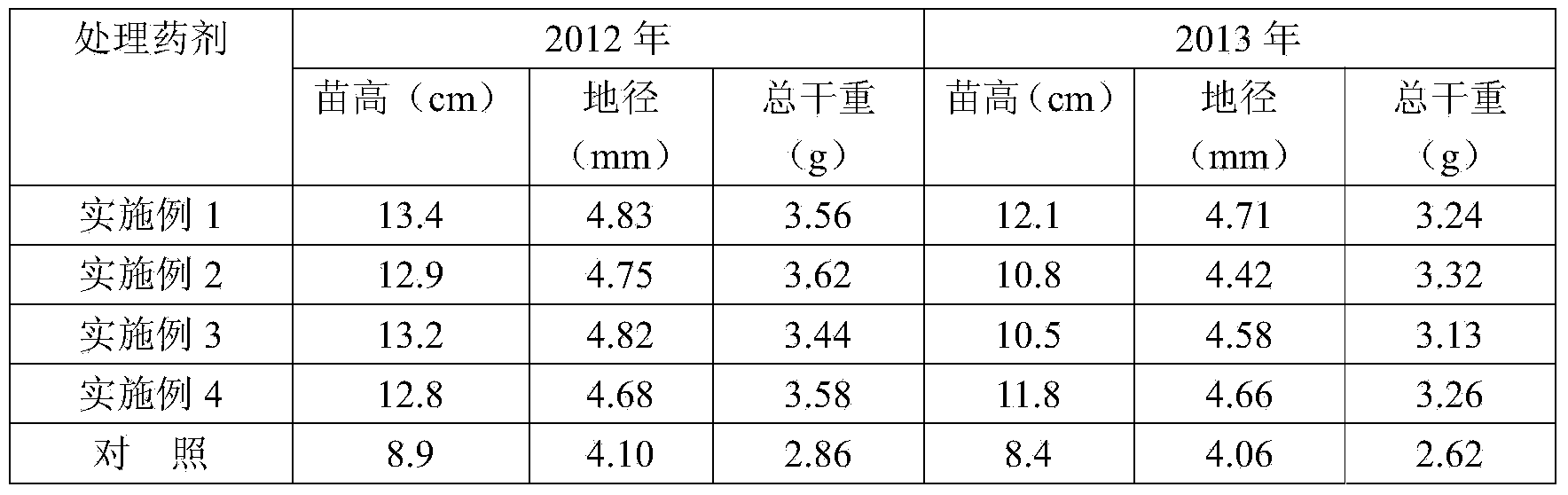

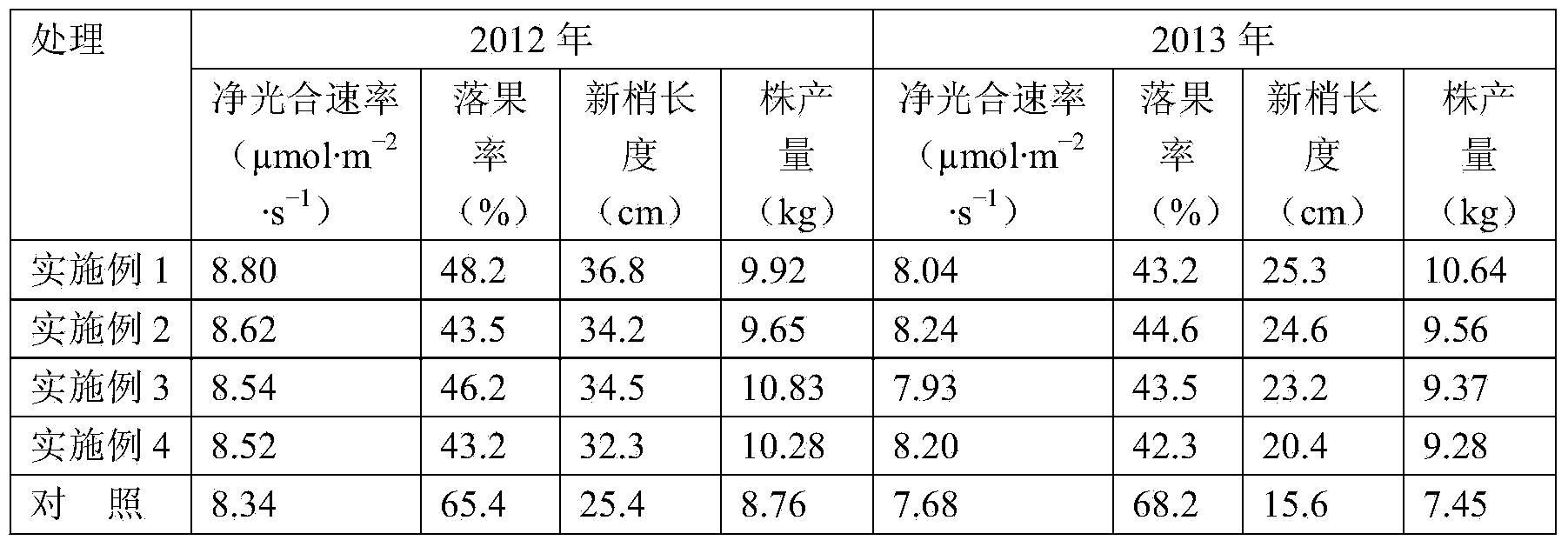

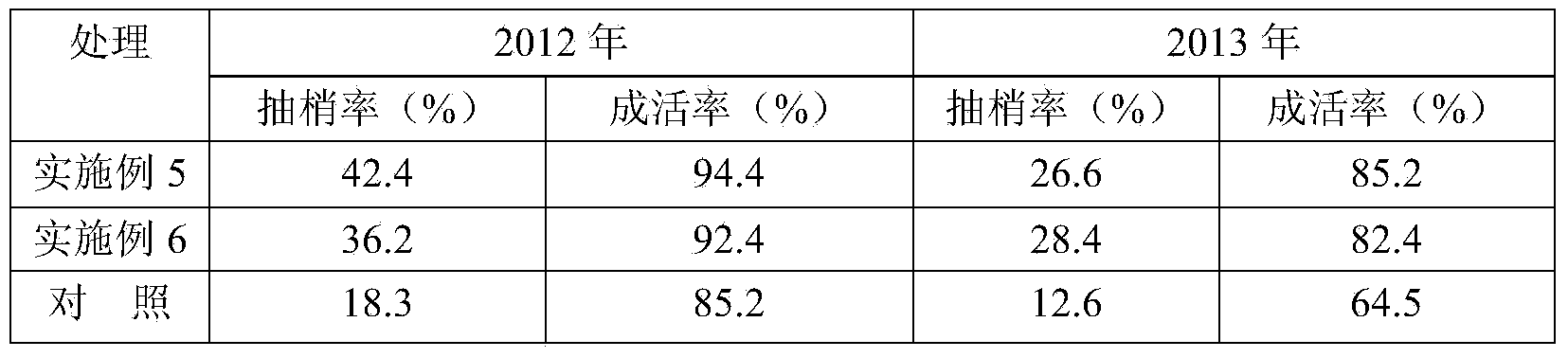

Special multifunctional foliar fertilizer for oil-tea trees, and preparation method and applications thereof

InactiveCN103848685ASimple production technologyReduce manufacturing costFertilising methodsAgriculture gas emission reductionCamellia oleiferaCuticle

The invention belongs to the field of foliar fertilizer, and relates to a special multifunctional foliar fertilizer for oil-tea trees. The special multifunctional foliar fertilizer for oil-tea trees comprises the following ingredients in parts by weight: 5-10 parts of urea, 5-8 parts of potassium dihydrogen phosphate, 3-4 parts of boric acid, 3-4 parts of magnesium chloride, 5-6 parts of calcium nitrate, 4-5 parts of glucose, 0.1-0.5 part of gibberellin, 0.5-1 part of abscisic acid, 3-5 parts of amino acid chelate, and 2-3 parts of surfactant. According to the foliage fertilization principle and aiming at the characteristics that the wax and cuticle on oil tea leaves are thick and the demand on nutrients is large and by utilizing and reasonably proportioning the main active ingredients of mineral elements, hormones, amino acid chelate, surfactant and the like, the foliar fertilizer can be effectively absorbed by the oil tea trees, and has multiple effects of promoting the seedling survival, improving the growth and fruit bearing and cultivation resilience and the like. According to the special multifunctional foliar fertilizer for oil-tea trees, the production technology of oil tea can be effectively simplified, the production cost of oil tea can be lowered, and the special multifunctional foliar fertilizer for oil-tea trees has wide application prospects.

Owner:辰溪县永新农林开发有限公司

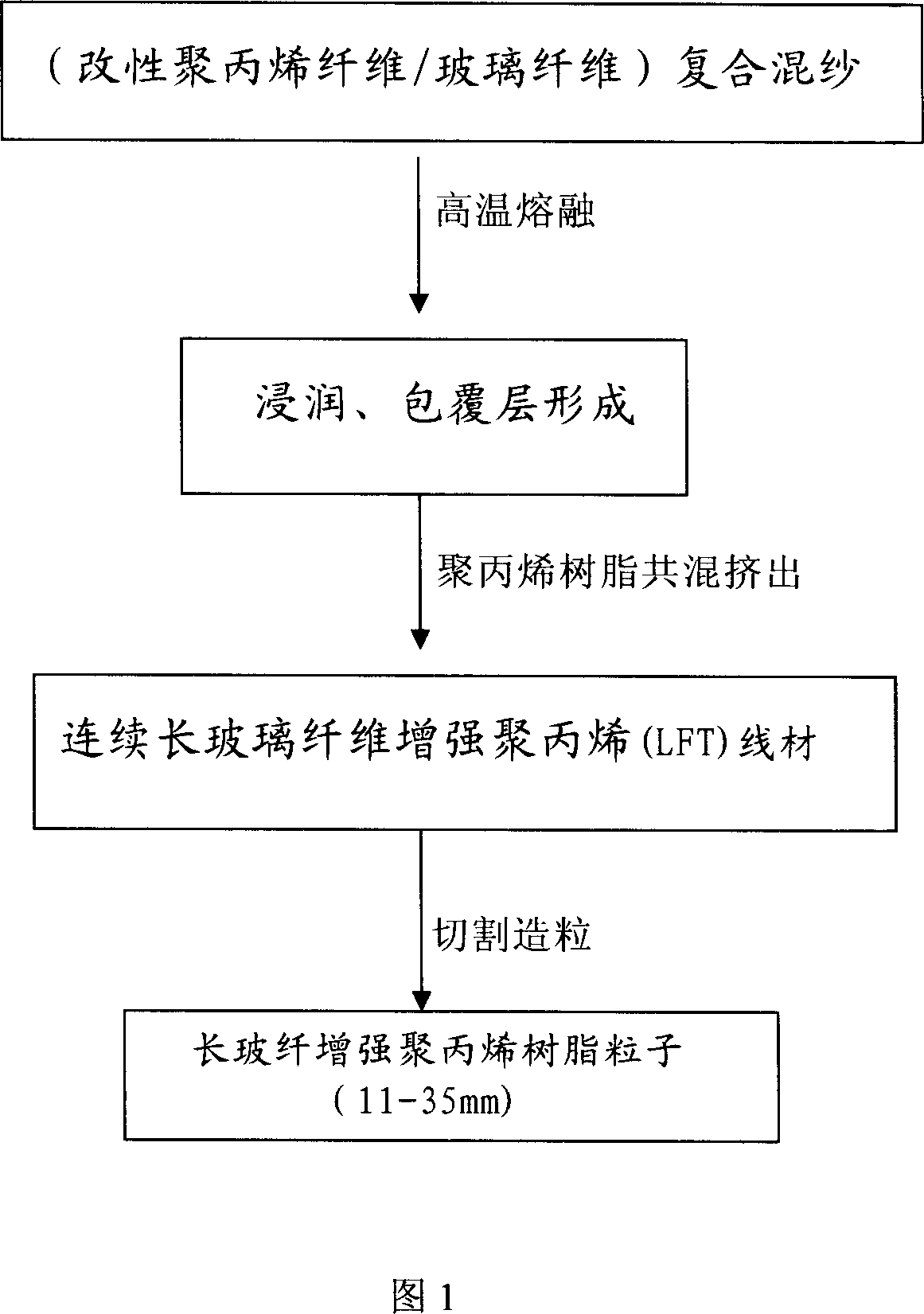

Continuous long glass fiber reinforced profax resin granular material preparation method

The invention discloses a preparing method of fiber reinforced polypropylene resin particle of continuous long-glass (LGFPP), which comprises the following steps: blending 20-80% composite yarn with glass fiber, 5-60% thermoplastic polypropylene resin and 1-15% adjuvant; heating; fusing; squeezing; graining; setting the weight rate of modified polypropylene fiber and glass fiber at 1:99-50:50 as the component of composite yarn.

Owner:TAIAN SAIGANG COMPOSITE MATERIAL

Production process of selenium-rich low-cholesterol health egg

The production process of selenium-rich low-cholesterol health egg includes the following steps: sorting and adding selenium-rich dry yeast as organic selenium source; sorting and adding conjugate linoleic acid; compounding and adding Chinese herbal medicine preparation; compounding the three kinds of powder of selenium-rich dry yeast, conjugate linoleic acid and Chinese herbal medicine preparation to form the pre-mixed material for producing selenium-rich low-cholesterol health egg; and adding the pre-mixed material to laying fowl feed and feeding with the feed. The present invention has relatively low cost in producing selenium-rich and CLA-rich egg with low cholesterol content, and the added Chinese herbal medicine preparation can promote the absorption and deposition of selenium and CLA and is beneficial to the health of the laying fowl and human body.

Owner:SHANGHAI JIAO TONG UNIV

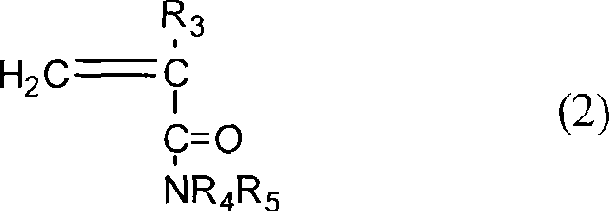

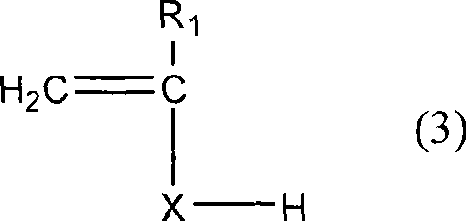

Comb-shaped graft copolymer cement dispersant

Owner:JIANGSU SOBUTE NEW MATERIALS

Inorganic modifier for historical site soil

The invention provides an inorganic modifier for historical site soil, which is prepared from the following raw materials in parts by weight: 30-50% of clay mineral material, 22-49% of inorganic cement, 15-30% of inorganic mineral powder and 1-3% of surfactant, totaling 100%. By doping the inorganic modifier into the restored soil sample, the restored soil has favorable water resistance; and the production technique of the modifier is easy to master and convenient for construction, and has the advantages of controllable quality, abundant raw material sources, favorable economical efficiency and high cost performance. The modifier has favorable compatibility with the restored soil, thereby greatly prolonging the service life of the restored soil sample. The rammed soil, adobe, clod, stack and other materials prepared from the restored soil modified by the modifier have favorable water permeability and air permeability, and completely satisfy the restoration idea for cultural relics.

Owner:CHANGAN UNIV

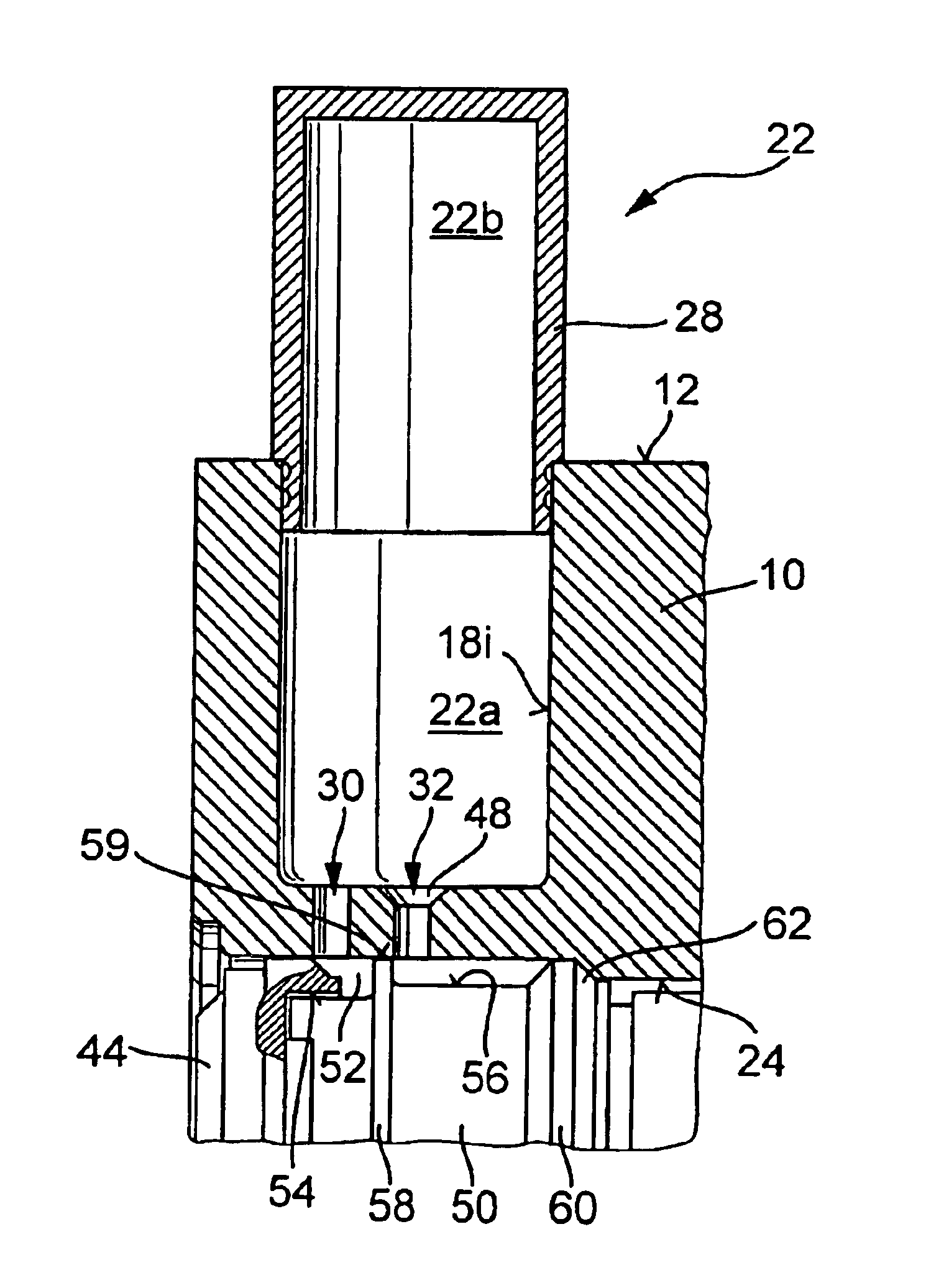

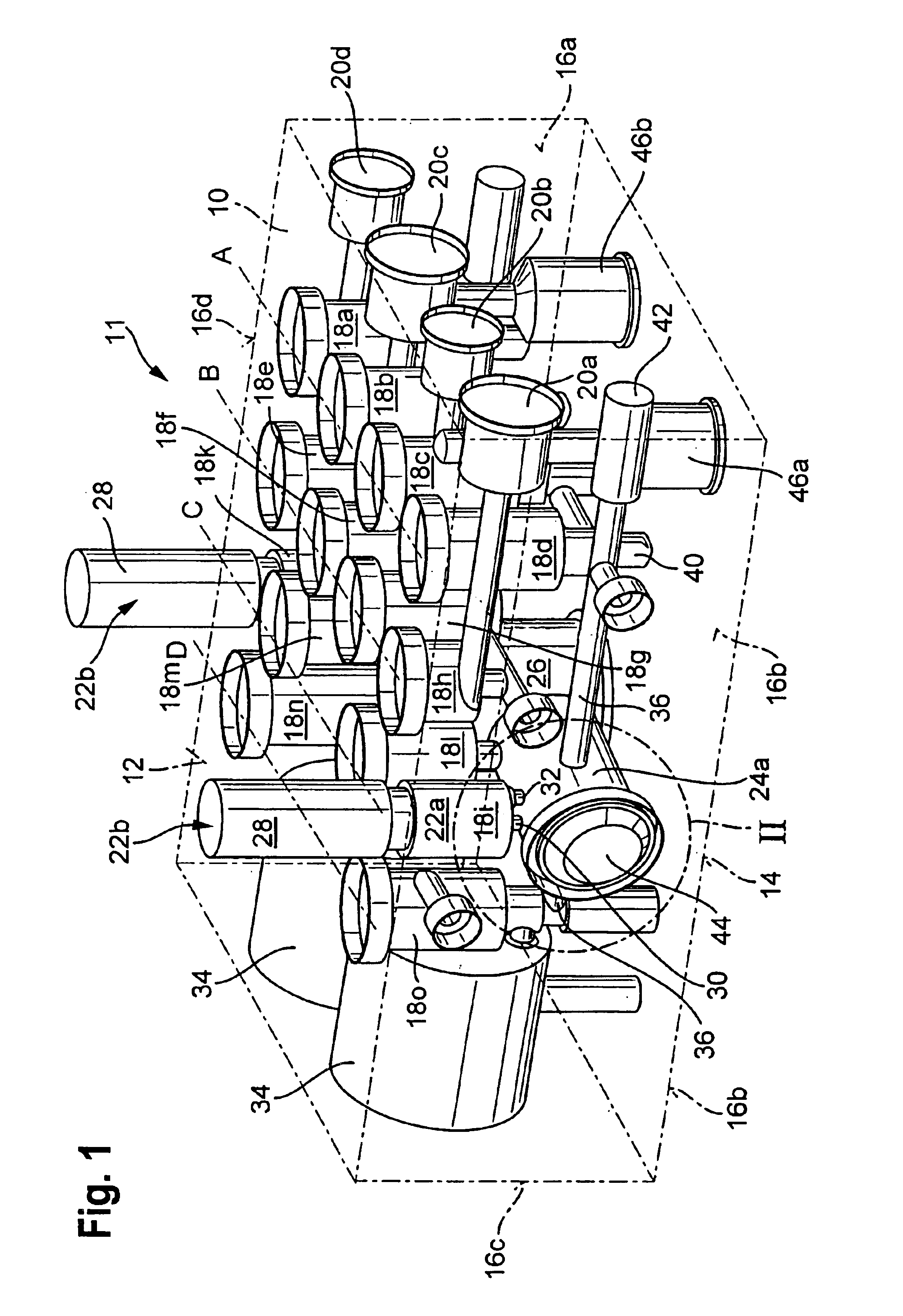

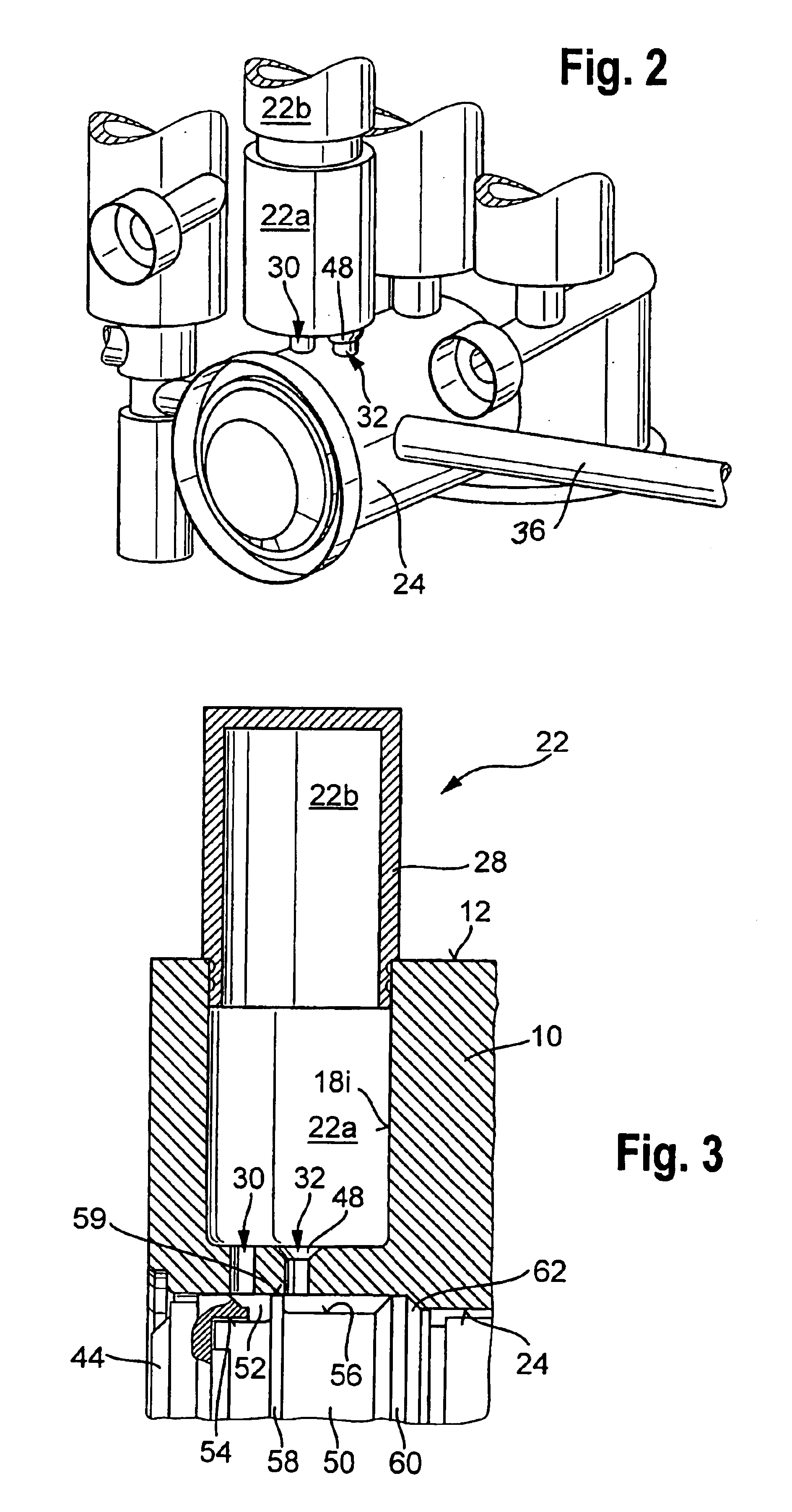

Hydraulic unit

ActiveUS6869152B2Improve adaptabilityIncrease production costPositive displacement pump componentsServomotor componentsEngineeringControl theory

A hydraulic unit for an electronically controllable brake system of a vehicle includes a housing block with mounting faces for instance for an electric motor and an electronic control unit; a plurality of connections for hydraulically contacting the block; and installation chambers, for pump elements, valves, and damping devices. These damping devices are connected hydraulically downstream to the pump elements, in order to damp operation-caused pressure pulsations and noises. Installation chambers (18i-k) for the damping devices and the installation chambers (18a-h) of the valves extend to a common mounting face of the housing block intended for mounting the electronic control unit. The damping devices protrude past this mounting face.

Owner:ROBERT BOSCH GMBH

Heat-shock and static water-pressure type method for prodn. of tetraploid of trout

InactiveCN1861017ASimple production technologyAnimal reproductionPisciculture and aquariaHeat shockTrout

A method for inducing the tetraploid salmoniform rainbow trout by hot shock or static water pressure process features that the fertilized ova of rainbow trout is treated by hot shock at 30 deg.C for 5-6 min or static water pressure under 600-650 kg / sq.cm for 5-6 min.

Owner:白宝海

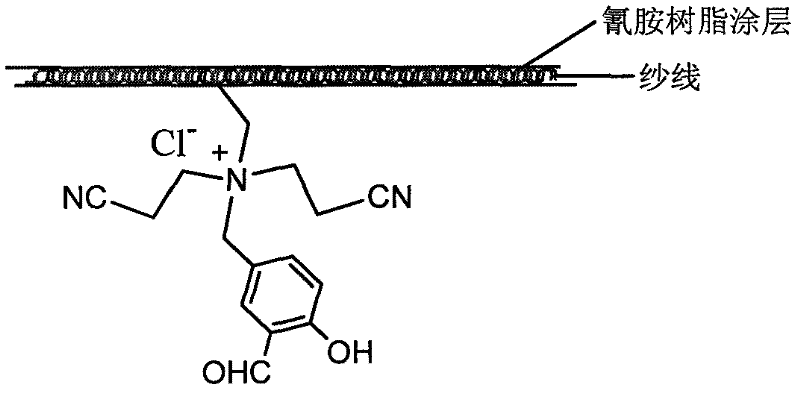

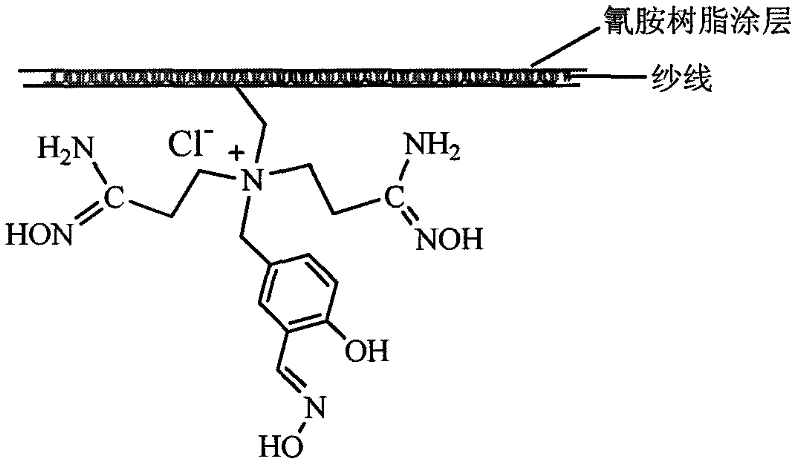

Method for preparing multifunctional chelating ion exchanging fiber

InactiveCN102409535ASimple methodImprove adsorption capacityComplex ion-exchangersVegetal fibresSalicylaldehydeIon exchange

The invention provides a method for preparing a multifunctional chelating ion exchanging fiber. The method comprises the following steps of: taking synthetic fiber or blended fiber of synthetic fiber, cotton and hemp as substrate fiber, soaking in an amino resin solution and obtaining tertiary amino group functional fiber; and then reacting the tertiary amino group functional fiber with 5-(chloromethyl) salicylaldehyde and amino-compound in turn so as to lead quaternary ammonium and salicylaldehyde shrink amino compound structure units to the functional fiber to obtain the multifunctional chelating ion exchanging fiber.

Owner:HUAIHAI INST OF TECH

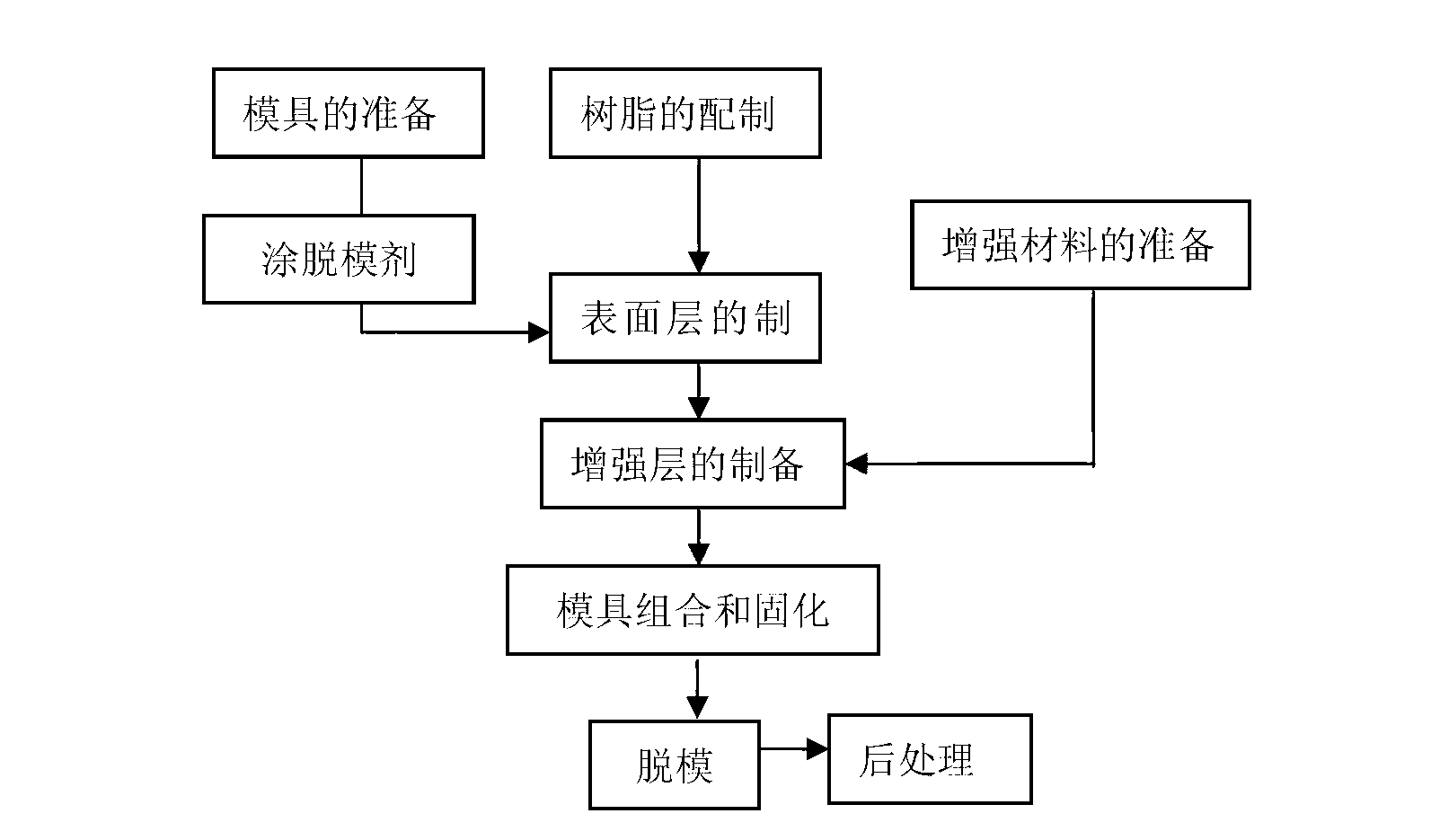

Manually-pasting molding method of para-position aramid fiber composite material

The invention relates to a manually-pasting molding method of a para-position aramid fiber composite material. The manually-pasting molding method particularly comprises the following steps of: (1) cleaning a mould; (2) coating a de-molding agent on the mould; (3) respectively preparing a resin adhesive for a gel coat layer and resin adhesives for a surface layer and an enhancement layer; (4) manufacturing the gel coat layer; (5) manufacturing the surface layer; (6) manufacturing the enhancement layer; (7) combining the mould and curing a workpiece; (8) de-molding; and (9) carrying out post-treatment on the workpiece. According to the manually-pasting molding method of the para-position aramid fiber composite material, the conventional manually-pasting molding method is improved in the manner of coating the surface layer with an ultraviolet light absorber or ultraviolet-resisting paint, and pre-treating para-position aramid fiber cloth in the enhancement layer. When the manually-pasting molding method is used for producing the para-position aramid fiber composite material, equipment is simple, the investment is less, a production technology is easy to master, and some large-sized para-position aramid fiber composite materials which are not suitable for transportation can be manufactured on site; the para-position aramid fiber composite material workpiece has good ultraviolet-resisting performance; and meanwhile, para-position aramid fibers and resin are good in cohesiveness, and thus the composite material can have various stable and good performance.

Owner:宁夏泰和兴材料科技有限公司

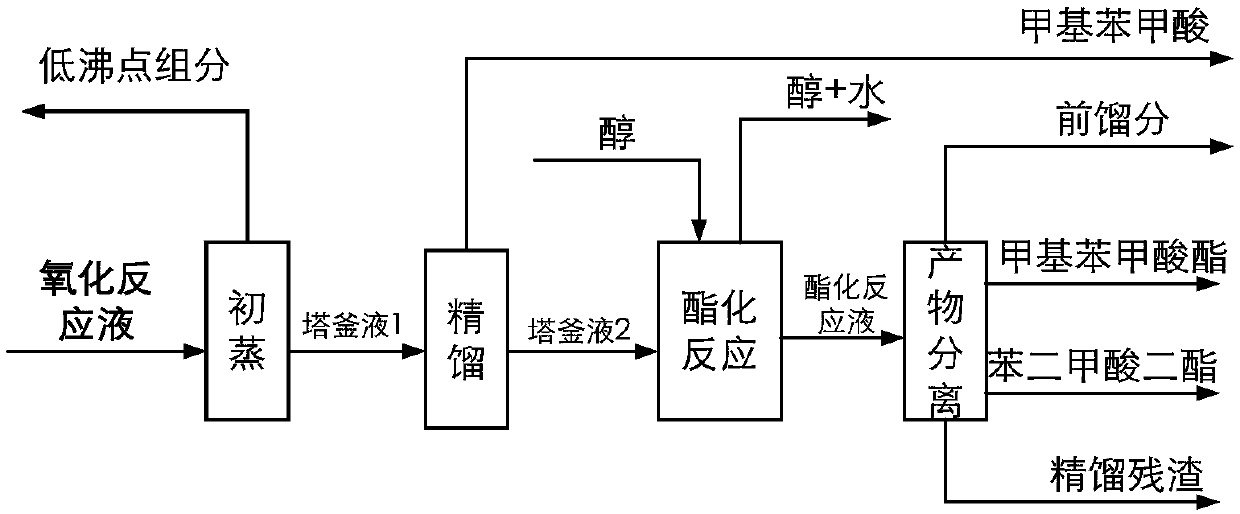

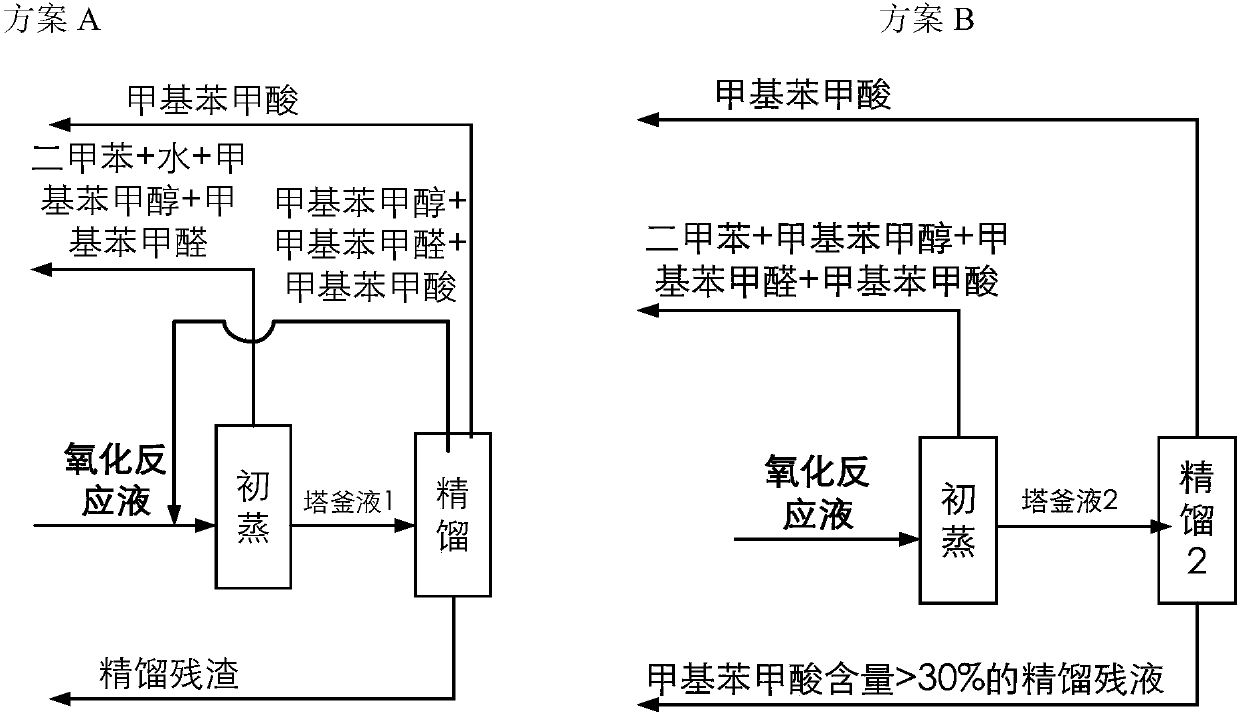

Coproduction method of methylbenzoic acid, methyl benzoate and benzenedicarboxylic acid diester

ActiveCN108047034ARaw materials are easy to getStructural diversificationOrganic compound preparationCarboxylic acid esters preparationAlcoholDistillation

The invention discloses a coproduction method of methylbenzoic acid, methyl benzoate and benzenedicarboxylic acid diester. The method comprises the following steps: (1) continuously introducing xylene, a catalyst and oxygen-containing gas into an oxidation reactor for a reaction, and controlling oxygenic concentration in the tail gas to not exceed 5% by controlling introduction amount of the oxygen-containing gas to obtain an oxidation reaction liquid; (2) feeding the obtained oxidation reaction liquid into a predistillation tower for distillation separation to obtain a low-boiling-point component and a predistillation tower bottom liquid; (3) feeding the predistillation tower bottom liquid into a distillation tower for distillation to obtain a methylbenzoic acid product and a distillationtower bottom liquid; (4) mixing the distillation tower bottom liquid and alcohol for an esterification reaction, and controlling the reaction endpoint to be lower than 0.5wt% of the content of methylbenzoic acid to obtain an esterification reaction liquid; (5) performing distillation separation on the obtained esterification reaction liquid to obtain methyl benzoate and benzenedicarboxylic acid diester products. The method has the advantages that the process is simple, equipment investment is low, and the method is environmentally friendly and has good comprehensive economic benefits.

Owner:JIANGXI KEYUAN BIOPHARM

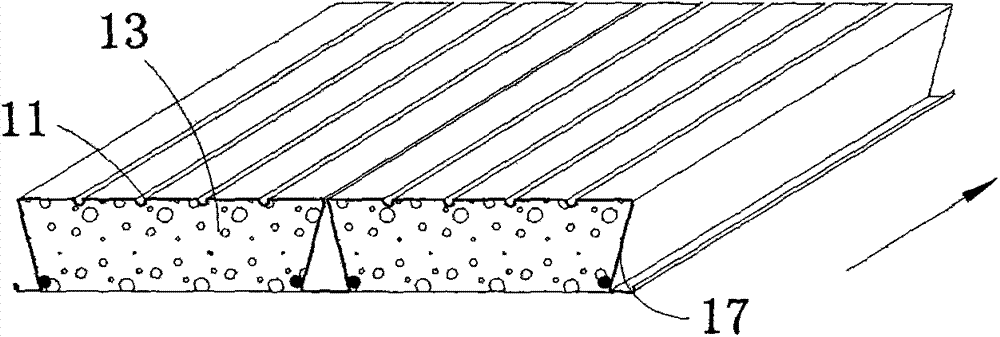

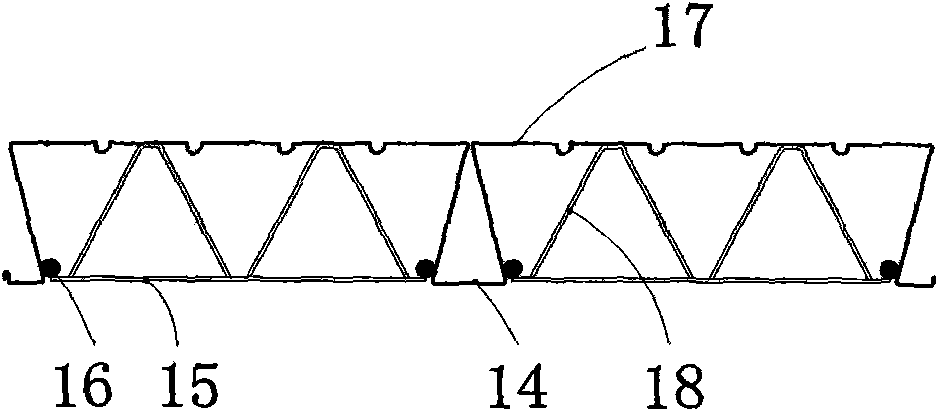

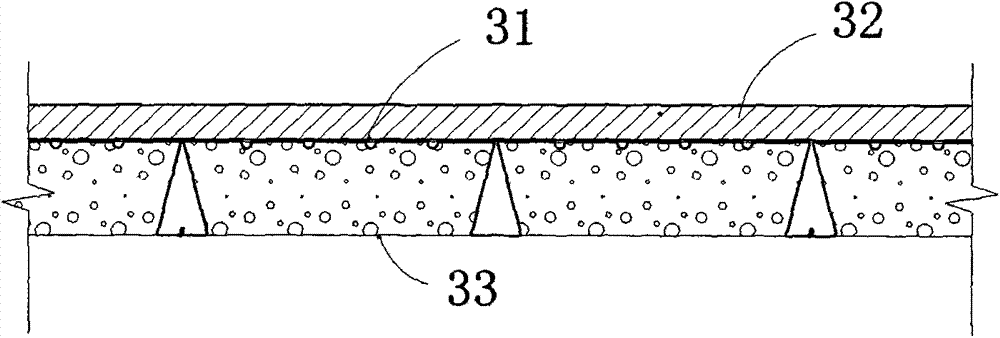

Profiled steel sheet composite board as well as roofing board, floor board or wall panel with composite boards

InactiveCN104120824AImprove applicabilitySimple production technologyRoof covering using slabs/sheetsFloorsFloor slabSheet steel

The invention relates to a profiled steel sheet composite board as well as a roofing board, a floor board or a wall panel with the composite boards. The profiled steel sheet composite board comprises a profiled steel sheet and a filler, wherein the profiled steel sheet is a ribbed plate; the profiled steel sheet serves as the force-bearing main body of the composite board; a cavity at the lower part of the profiled steel sheet is filled by the filler; an auxiliary steel material is welded on one side or the bottom of the vertical plate rib; a steel wire mesh piece is attached and welded on the lower open surface of the profiled steel sheet; the profiled steel sheet at the closed surface of the profiled steel sheet is used for resisting pressure, while the auxiliary steel material is used for bearing tension, and the two components work cooperatively by use of the plate rib to resist the bending moment. The composite board is low in weight and high in strength; under the same span and load, the dead weight of the composite board is about 1 / 5 of that of the traditional profiled steel sheet concrete floor board, and therefore, product support is provided for the realization of a large-span beamless space.

Owner:SHAANXI HAOXING HOUSES ENG

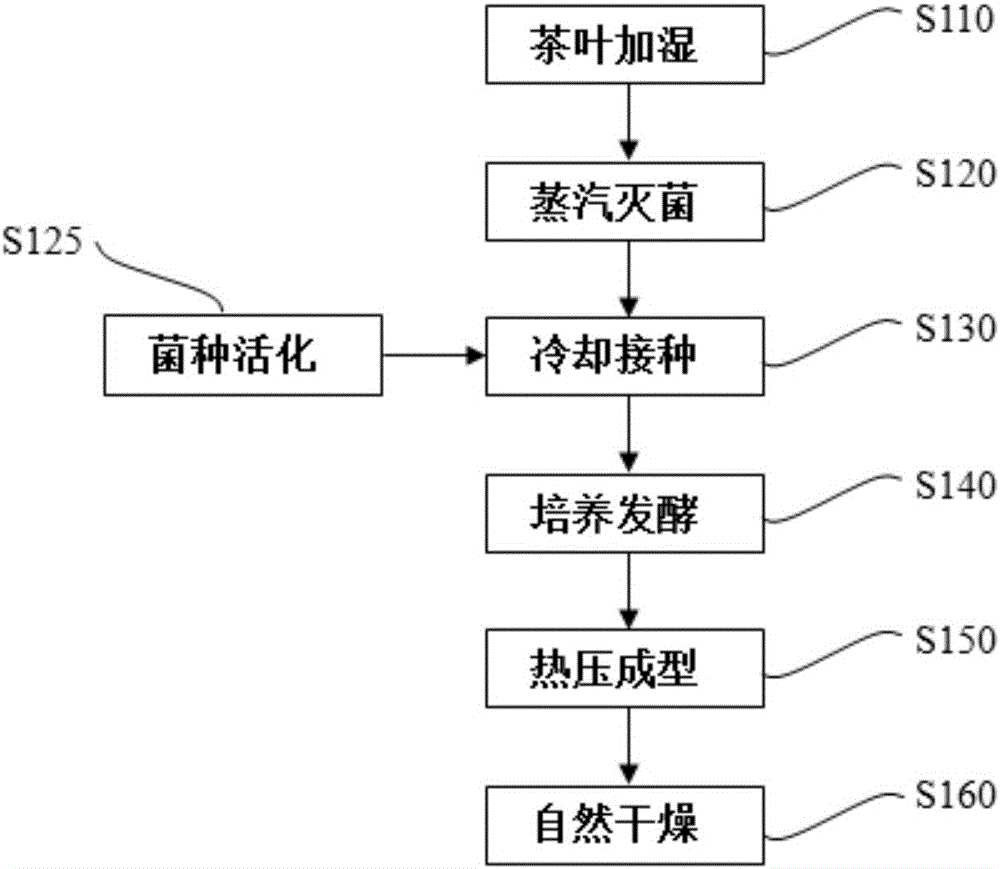

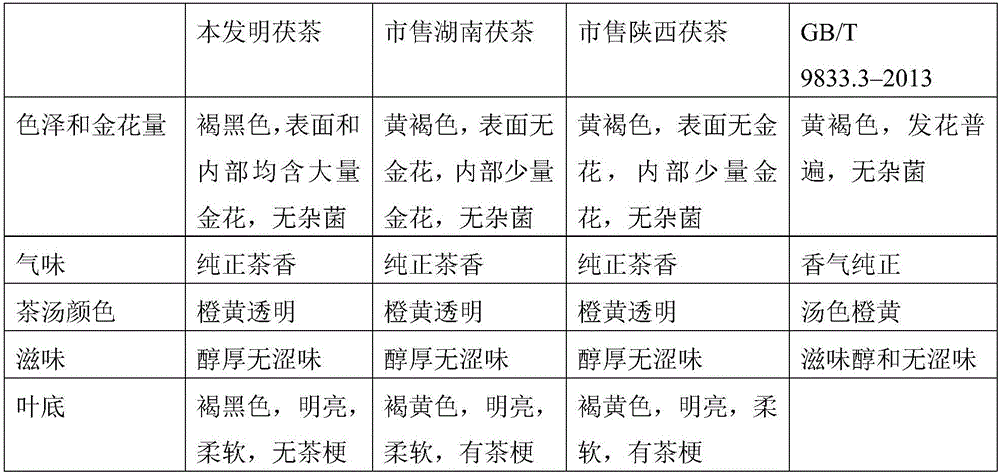

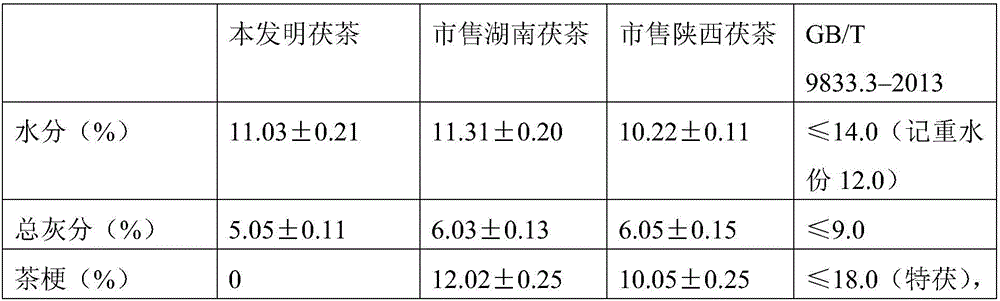

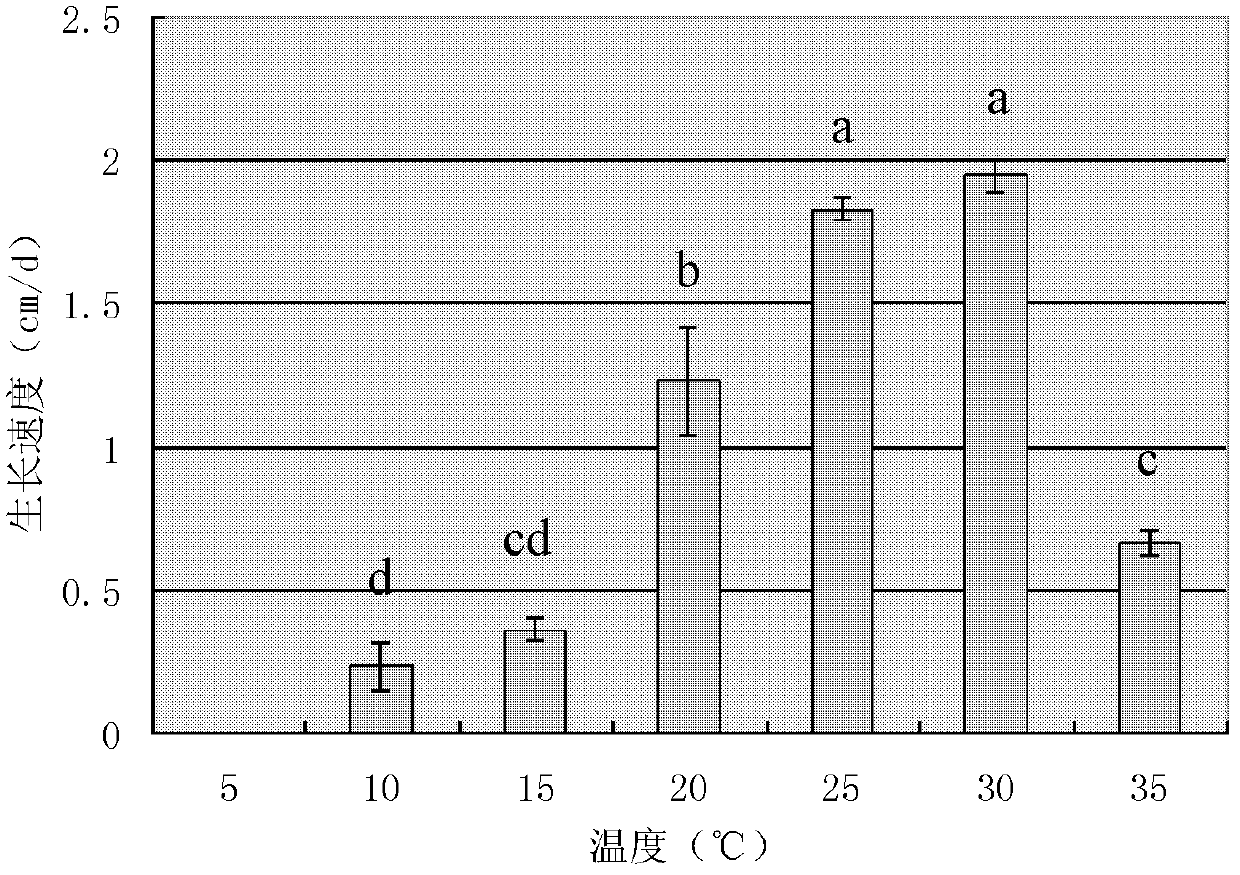

Method of producing Fu tea from artificial fermentation tea leaves and bacterial strain

InactiveCN105746756ASimple production technologyBreak the technical barriers of the industryFungiPre-extraction tea treatmentBacterial strainFermentation

The invention discloses a method of producing Fu tea by means of artificial fermentation. Themethod comprises the following steps in sequence: humidifying dry tea leaves to enable water content of the tea leaves to be 30-40%; sterilizing the humidified tea leaves at a temperature of 110-120 DEG C; cooling the sterilized tea leaves to a temperature below 40 DEG C, artificially inoculating activated eurotium cristatum under a sterile condition, and mixing uniformly; fermenting the tea leaves for 20-30 days in a sterile and air-permeable container at a temperature of 20-30 DEG C; hot-pressing and forming the tea leaves; drying the tea leaves naturally. The invention further discloses an eurotium cristatum bacterial strain with the preservation number of CGMCC No.3.15516. According to the invention, the method has the advantages of simplicity in operation, relatively low cost and no limitation from raw materials and geographical conditions. As a sterile culture technology is employed, sundry bacteria contamination is avoided, and high product quality and product safety are realized.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

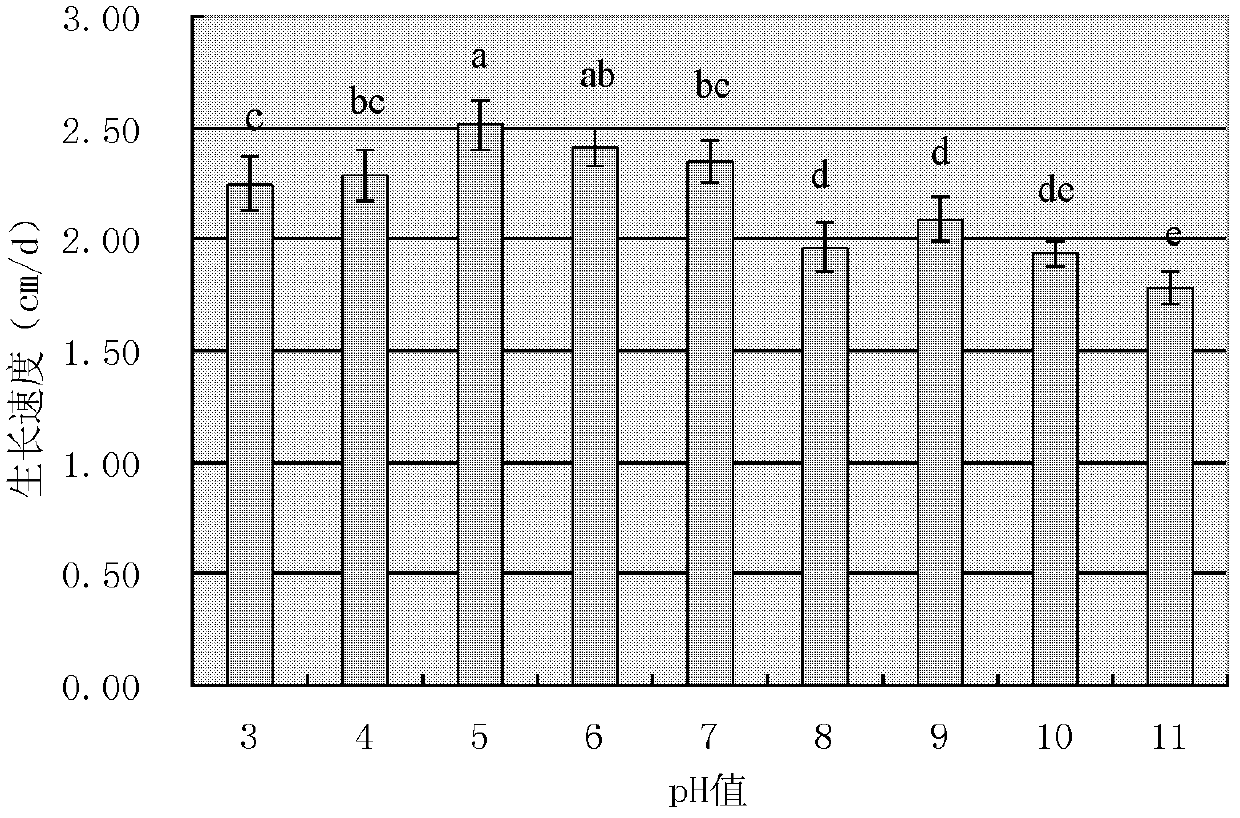

Trichoderma harzianum Sch234 bacterial strain as well as preparation method and application thereof

InactiveCN103374527AStrong parasitic effectSimple production technologyBiocideFungiBiotechnologySoil treatment

The invention discloses trichoderma harzianum Sch234 bactericide as well as a preparation method and an application thereof. The preparation method of the trichoderma harzianum Sch234 bactericide comprises the following steps of: (1) firstly activating a trichoderma harzianum bacterial strain Sch234 on a PDA flat plate, then inoculating the trichoderma harzianum bacterial strain Sch234 on a PDA inclined plane to be cultured, adding deionized water for sterilization, preparing spore suspension, adding tween-20 until final concentration of the tween-20 in the spore suspension is 0.025%, and adjusting the concentration of the spore suspension to be 1.5*10<6> / ml; (2) mixing dry substrate oatmeal with rice husk uniformly, adding water, and carrying out high-pressure steam sterilizing; and (3) inoculating the prepared spore suspension with substrate in ratio of 10ml per bag, cultivating, and drying in the air and grinding, thus the trichoderma harzianum Sch234 bactericide is obtained. The trichoderma harzianum bacterial strain Sch234 has a strong parasitic effect on rice sheath blight disease and hypha and sclerotium of sclerotinia sclerotiorum, control effect of antibiological inoculant to rice sheath blight disease under field cultivation condition is 83%, an application method in soil treatment is simple, labour force is saved, and the trichoderma harzianum bacterial strain Sch234 can be used for producing biopesticide and is safe to people and livestock.

Owner:HUAZHONG AGRI UNIV

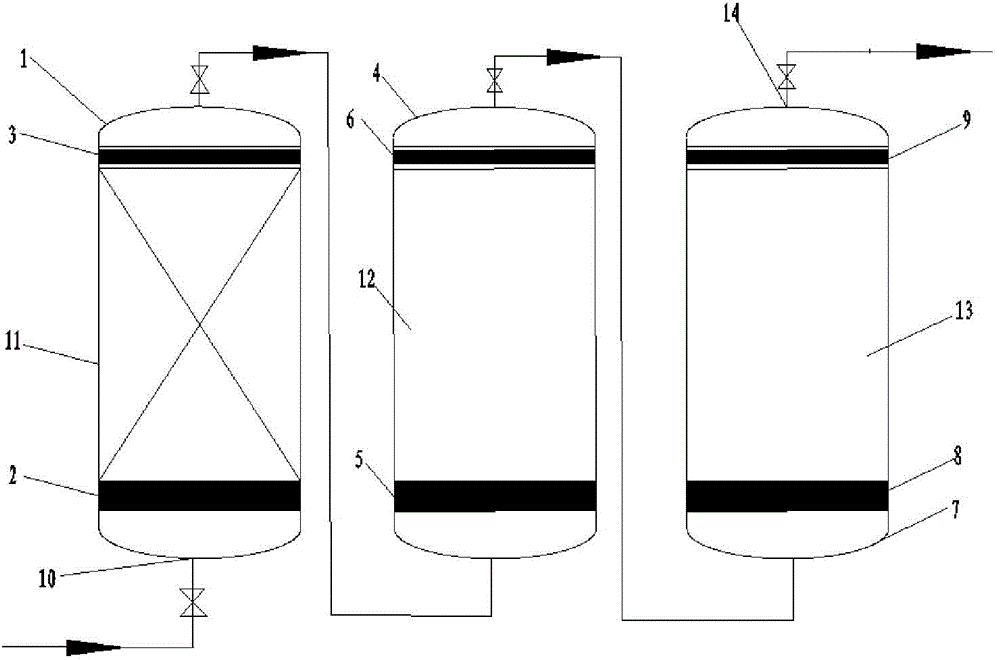

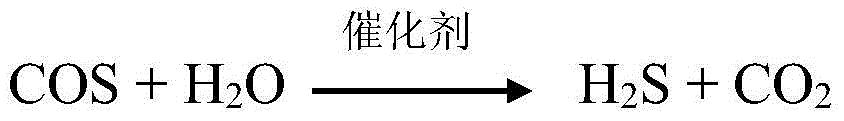

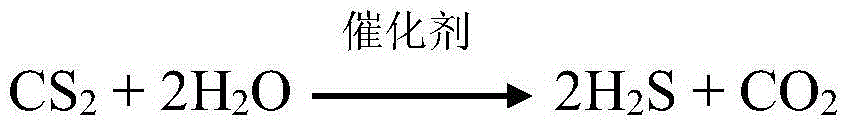

Liquefied gas desulfurizing agent

InactiveCN104524973AGood compatibilityGood synergyDispersed particle separationGaseous mixture working upSilicon oxideLiquid gas

The invention relates to a liquefied gas desulfurizing agent and belongs to the technical field of liquefied gas refining. The liquefied gas desulfurizing agent comprises the following components in percent by weight: 35-50% of ZnO, 35-50% of MnO2, 5-15% of CaO and the balance being a carrier, wherein the carrier comprises the components in percent by weight: 40-65% of aluminum oxide and 35-60% of silicon oxide. The liquefied gas desulfurizing agent has the advantages that the desulfurization rate is high, the removal rate for hydrogen sulfide reaches more than or equal to 99%, the sulfur capacity is more than or equal to 25%, and the removal rate of disulfide converted by an organic-sulfur conversion catalyst is more than or equal to 50%; the compatible and synergistic effects with the organic-sulfur conversion catalyst are good, and the protective effect is stable.

Owner:CHONGQING DIZHIJING TECH

Method for preparing male non-testicular-sourced protein-induced autologous-reproduction stem cells, kit, the stem cells and application

InactiveCN104419658ASimple production technologyYield advantageDead animal preservationMammal material medical ingredientsSomatic cellReproduction

The invention provides a method for preparing male non-testicular-sourced protein-induced autologous-reproduction stem cells. The method comprising following steps: (1) cultivating somatic cells in a cell culture fluid A for 1-3 days, cultivating the somatic cells in a cell culture fluid B for 1-6 days and then cultivating the somatic cells in a cell culture fluid C for 1-6 days; and (2) collecting the male non-testicular-sourced protein-induced autologous-reproduction stem cells. The invention also provides a kit used for preparing the male non-testicular-sourced protein-induced autologous-reproduction stem cells. The method and the kit are advantaged in yield, purity, and producing speed of the production of the protein-induced autologous hematopoietic stem cells.

Owner:深圳百年干细胞技术研究院有限公司

Earthen archaeological site crack repairing agent and application thereof

The invention provides an earthen archaeological site crack repairing agent and an application thereof. The earthen archaeological site crack repairing agent consists of the following raw materials in percentage by weight: 70-79% of an inorganic gel material, 18-27% of inorganic mineral powder, 0.1-0.3% of an inhibiting agent, 2-3% of a surfactant, and 0.2-0.4% of a thickening agent, wherein the total weight percentage of the raw materials is 100%. The repairing agent is doped into a repaired soil sample, and the mixing amount of the earthen archaeological site crack repairing agent in archaeological site soil is 20-40wt% to ensure that a grouting material doped with the repairing agent has good durability, water resistance, mechanical properties and micro-expansibility, and the effect of repairing archaeological site cracks is greatly improved; and a production technology of the earthen archaeological site crack repairing agent is relatively easy to grasp, and the earthen archaeological site crack repairing agent is easily-controlled in quality, is convenient to construct, is rich in raw material source, and has good economical efficiency and performance price. The crack repairing agent has good compatibility with repaired soil, so that the service life of the repaired soil sample is greatly prolonged.

Owner:CHANGAN UNIV

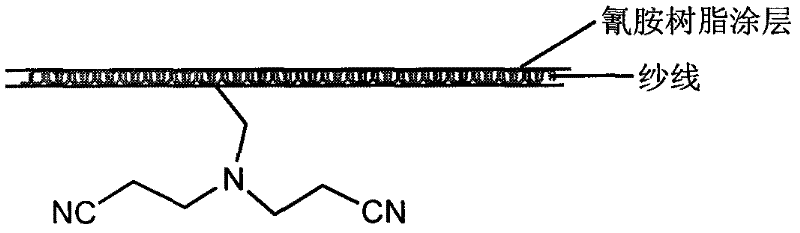

Super chelating ion exchange fiber

InactiveCN102500432AImprove mechanical propertiesMechanical properties (improved breaking strengthComplex ion-exchangersPolyesterEmulsion

The invention provides a super chelating ion exchange fiber which adopts one of cotton fiber, hemp fiber, wood fiber, bamboo fiber, grass fiber, polypropylene fiber, polyacrylonitrile fiber, vinylon, polyester or spandex or the blend fiber composed of more than two above fibers as fiber substrate; the fiber substrate is impregnated in cyanamide resin emulsion to obtain a cyanamide resin emulsion coated functional fiber which then reacts with 5-(chloromethyl)salicylaldehyde and hydroxylamine hydrochloride in turn, so that the functional fiber is introduced with quaternary ammonium group, salicylaldoxime and amidoxime and becomes the super chelating ion exchange fiber.

Owner:上海紫临实业有限公司

Tobacco stem field stacking and retting fermentation method and product

ActiveCN103274812AReduce the amount of applicationProtect environmentBio-organic fraction processingOrganic fertiliser preparationEcological environmentSoil fertility

The invention provides a tobacco stem field stacking and retting fermentation method. After tobaccos are matured and harvested, tobacco stems are collected on the spot and are broken according to a certain size; and then stacking and retting fermentation is performed on the tobacco stems by mixing the tobacco stems with water, soil, cow dung, phosphatic fertilizer, a ferment activator and lime according to proper proportions. The invention also provides a compost product produced by the tobacco stem field stacking and retting fermentation method. A using method for the compost product obtained by tobacco stem stacking and retting fermentation is characterized in that the compost product is fertilized every two crop planting periods preferably; the fermented compost product is used as a base fertilizer; and a ditch is formed, and the compost product is fertilized into the deep ditch. According to the tobacco stem field stacking and retting fermentation method, the application amount of chemical fertilizers can be reduced, a soil ecological environment is protected, the soil is improved, the soil fertility is improved, and the tobacco stem field stacking and retting fermentation method is safe and ecological. By the method, raw materials are readily available, convenient to collect, easy to operate, environmentally-friendly, sanitary and low in cost, and tobacco farmers can easily master the method; the cost is low, the expense is low, the production technology is simple ad can be easily popularized and applied in a large tobacco area; the quality of a product is stable; and the economical and ecological benefits are outstanding.

Owner:HUBEI CHINA TOBACCO IND

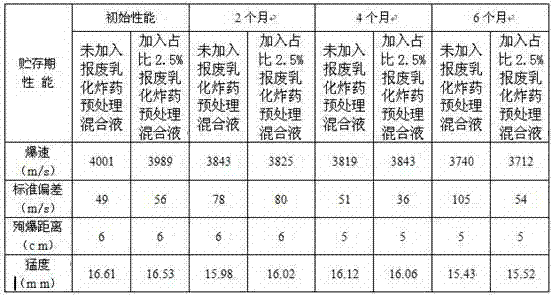

Method for recycling waste emulsion explosive in rock powder emulsion explosive

InactiveCN103396272ASimple production technologyImprove efficiencyExplosive working-up apparatusNon-explosive/non-thermic compositionsEmulsion explosiveMaterials science

The invention provides a method for recycling a waste emulsion explosive in a rock powder emulsion explosive. The method comprises the following steps of pre-treating the waste emulsion explosive to form a mixed solution; then, mixing the mixed solution and rock powder emulsion explosive water and oil according to a specific proportion; and carrying out vacuum drying at negative pressure to obtain the rock powder emulsion explosive, wherein the mixed solution obtained through pre-treating the waste emulsion explosive accounts for 1.0-5.0% of the mass of the prepared rock powder emulsion explosive product, the added rock powder emulsion explosive water accounts for 92.0-95.0% of the mass of the prepared rock powder emulsion explosive product, and the rock powder emulsion explosive oil accounts for 3.0-6.0% of the mass of the prepared rock powder emulsion explosive product. Compared with the traditional other waste emulsion explosive treating technologies, the method has the advantages that the production process is simple, the product is stable and reliable in quality as well as economic and environment-friendly, and the problems of raw material waste and environment pollution which are caused by waste emulsion explosive destruction are avoided.

Owner:SICHUAN YAHUA IND GRP

Oligochitosan oral cavity cleaning agent

InactiveCN101849893AConvenient sourceEasy to useCosmetic preparationsToilet preparationsSide effectIrritation

The invention discloses oligochitosan oral cavity cleaning agent and a preparation method thereof. The oligochitosan oral cavity cleaning agent is made from oligochitosan, lower polyxylose, sorbitol, magnesium stearate, sweetening agent and essence, and is eatable. When in use, the oligochitosan oral cavity cleaning agent can be directly swallowed without needing to spit and gargle after orally taking or chewing; is convenient as sugar; can achieve the aims of sterilizing, halitosis removing, dental plaque removing, curing the ulcer, the periodontitis, the gingivitis and the pericoronitis, and cleaning the oral cavity; and removing the peculiar smell of the oral cavity by eating stimulating foods. The invention is simple and convenient in use, can be used at any place and any time, has no toxic side effect, can be used for diabetics, is harmless after being used for a long time, and is environment-friendly.

Owner:苗辉

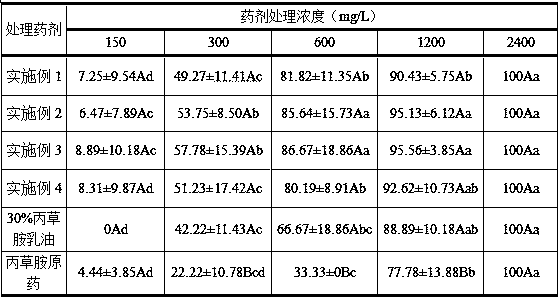

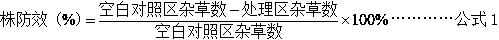

Pretilachlor microcapsule suspension and preparation method thereof

The invention discloses a pretilachlor microcapsule suspension and a preparation method thereof. The pretilachlor microcapsule suspension comprises following components in percentage by weight: 10 to30% of pretilachlor, 2 to 6% of capsule wall material, 1.5 to 5% of emulsifier, 1 to 5% of dispersant, 2.5 to 8% of solvent, 0 to 0.3% of thickening agent, and the balance being water. Pretilachlor isthe effective component, isocyanate and matched dispersant and emulsifier are taken as the auxiliary materials; and the prepared high quality pretilachlor microcapsule suspension has the advantages of high encapsulation rate, high dispersibility, and high suspension rate, has a long-lasting and stable effect on killing weeds in rice fields such as barnyard grass, is safe for the paddy rice, can effectively protect crops, and kills multiple weeds in fields such as barnyard grass.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

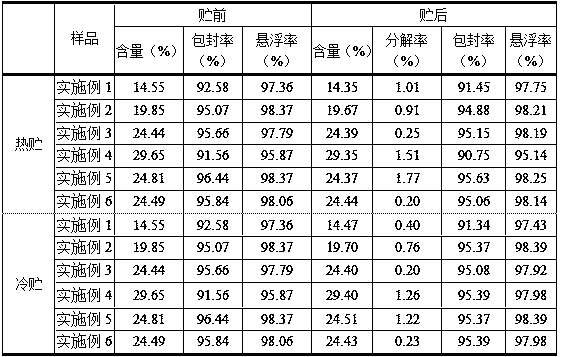

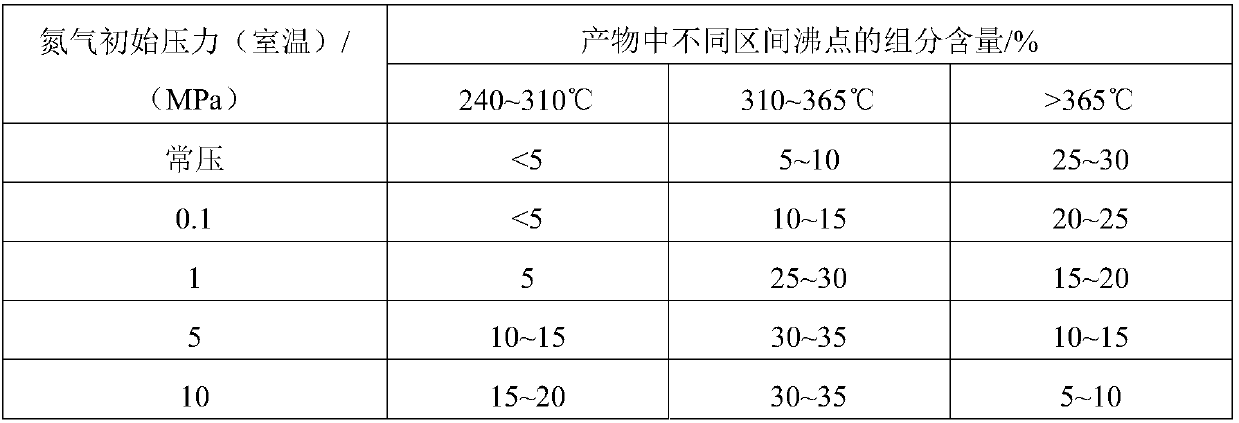

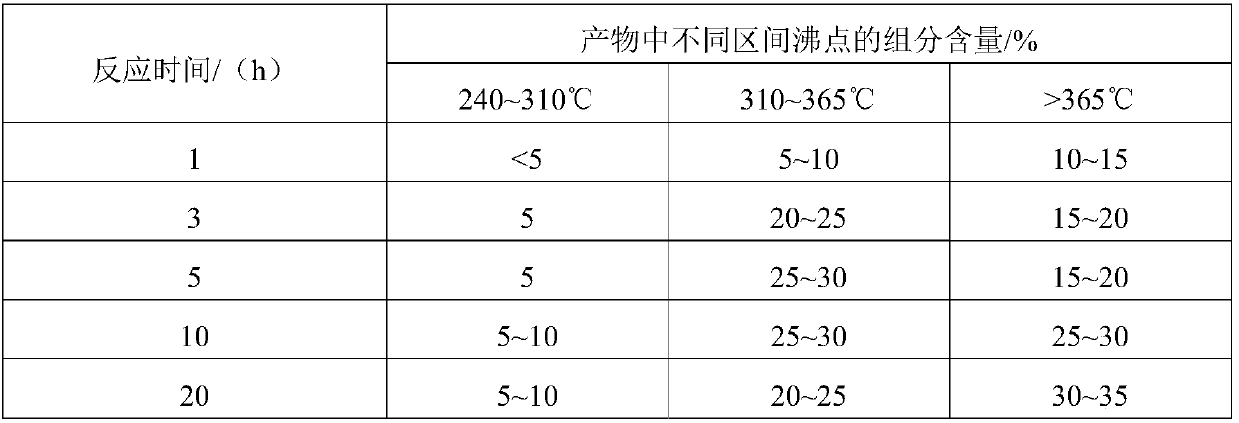

Method for preparing high-boiling aromatics used as heat carrier oil from heavy aromatics

InactiveCN107903938AImprove utilization efficiencyEasy accessLiquid hydrocarbon mixtures productionHydrocarbon oils treatment productsLiquid productHeat carrier

The present invention provides a method for preparing high-boiling aromatics used as heat carrier oil from heavy aromatics. According to the method, monocyclic aromatic hydrocarbons or bicyclic and polycyclic aromatic hydrocarbons obtained from whole fractions of heavy aromatics or by rectification of heavy aromatics are respectively used as raw materials to be stirred with an olefin in a closed reaction kettle or to undergo a flowing reaction with an olefin in a fixed-bed reactor, a liquid inorganic acid or solid acid catalyst or a mixed acid catalyst is employed, at a reaction temperature of60 DEG C or more and under the condition that the nitrogen initial pressure at room temperature is normal pressure or above, one-step catalytic conversion is performed, so that alkylation of the aromatic hydrocarbon with the olefin is achieved to prepare the high-boiling aromatic hydrocarbon used as the heat carrier oil. Compared with existing industrial synthetic routes of mineral heat carrier oil, the method of the invention has the advantages of wide range of sources of raw materials for reaction, low cost, highly efficient use of fossil resources, less waste and reduction of environmentalpollution, and has a wide range of reaction catalyst sources, mild reaction conditions, separation easiness between a liquid product and the catalyst.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Production process of selenium-rich low-cholesterol health egg

The production process of selenium-rich low-cholesterol health egg includes the following steps: sorting and adding selenium-rich dry yeast as organic selenium source; sorting and adding conjugate linoleic acid; compounding and adding Chinese herbal medicine preparation; compounding the three kinds of powder of selenium-rich dry yeast, conjugate linoleic acid and Chinese herbal medicine preparation to form the pre-mixed material for producing selenium-rich low-cholesterol health egg; and adding the pre-mixed material to laying fowl feed and feeding with the feed. The present invention has relatively low cost in producing selenium-rich and CLA-rich egg with low cholesterol content, and the added Chinese herbal medicine preparation can promote the absorption and deposition of selenium and CLA and is beneficial to the health of the laying fowl and human body.

Owner:SHANGHAI JIAO TONG UNIV

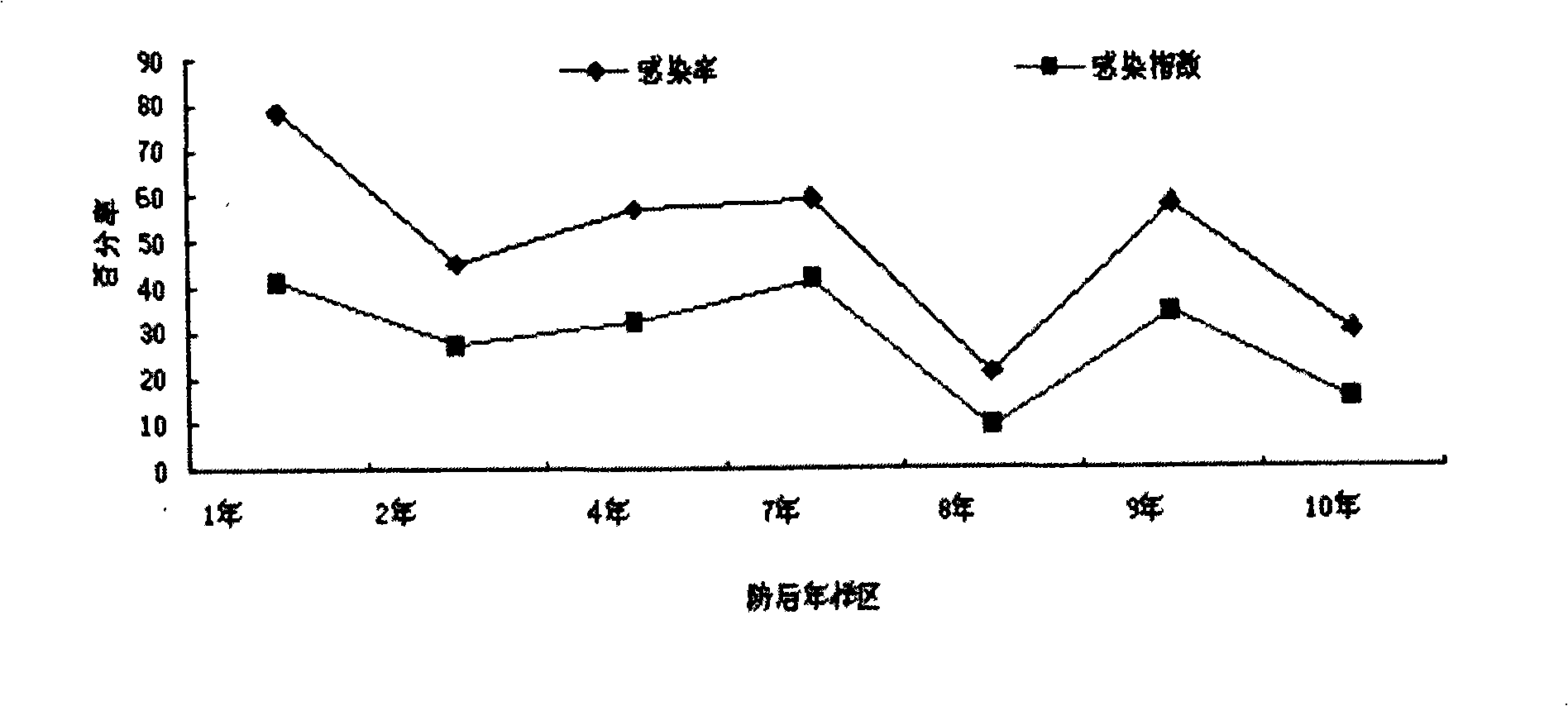

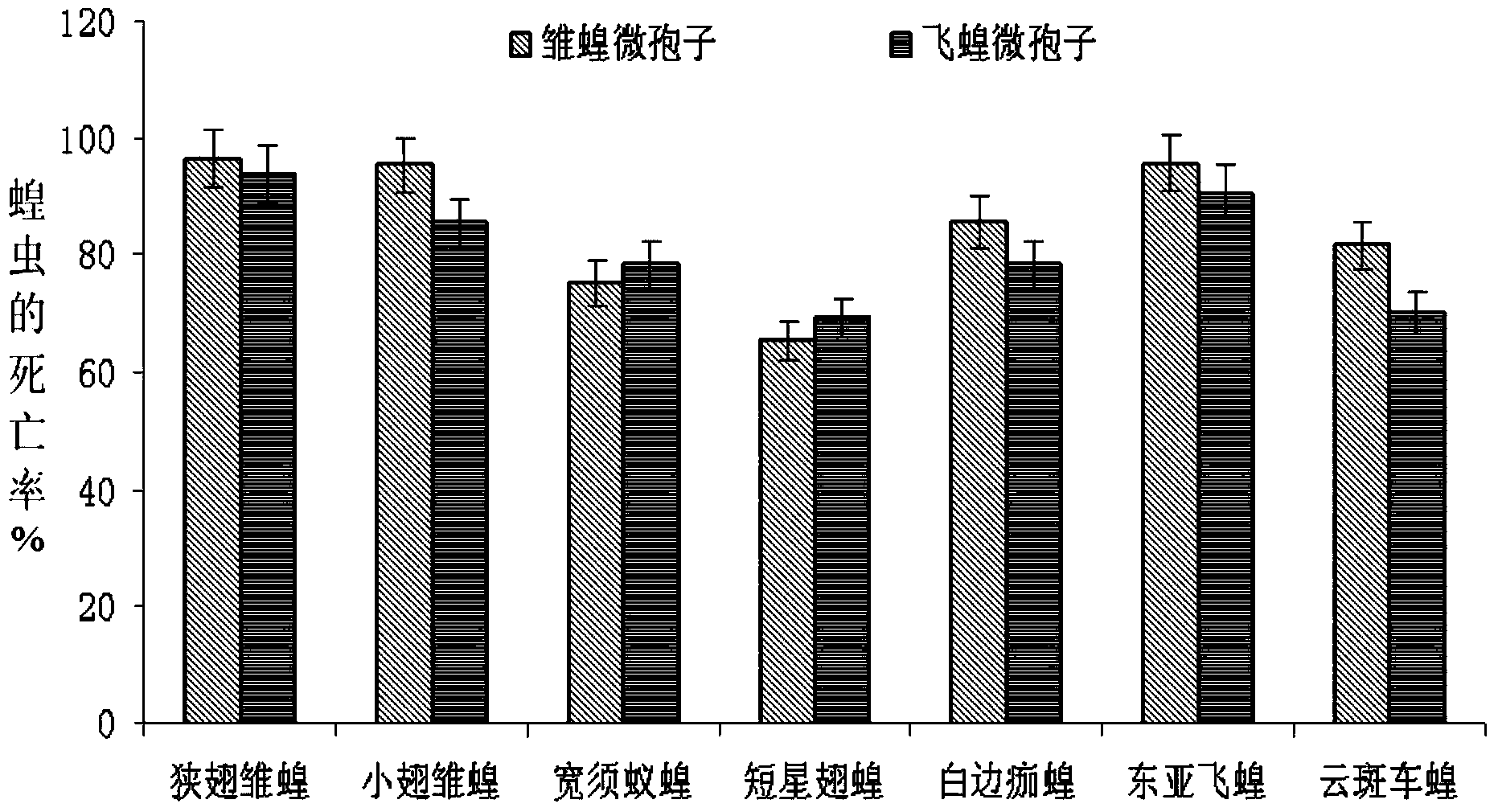

Microspore strain and use thereof

The invention provides a microspore strain extracted from gastrimargus and an application thereof. The strain has quite strong specificity and has specific action of killing grassland locusts and farmland migratory locusts, and the killing effect is relatively good. The microspore strain extracted from the gastrimargus of the invention can be used to control tens of locusts such as farmland migratory locusts, grassland locusts, gastrimargus, bamboo locusts and rice locusts, etc.

Owner:BEIJING MAMMOTH SEED

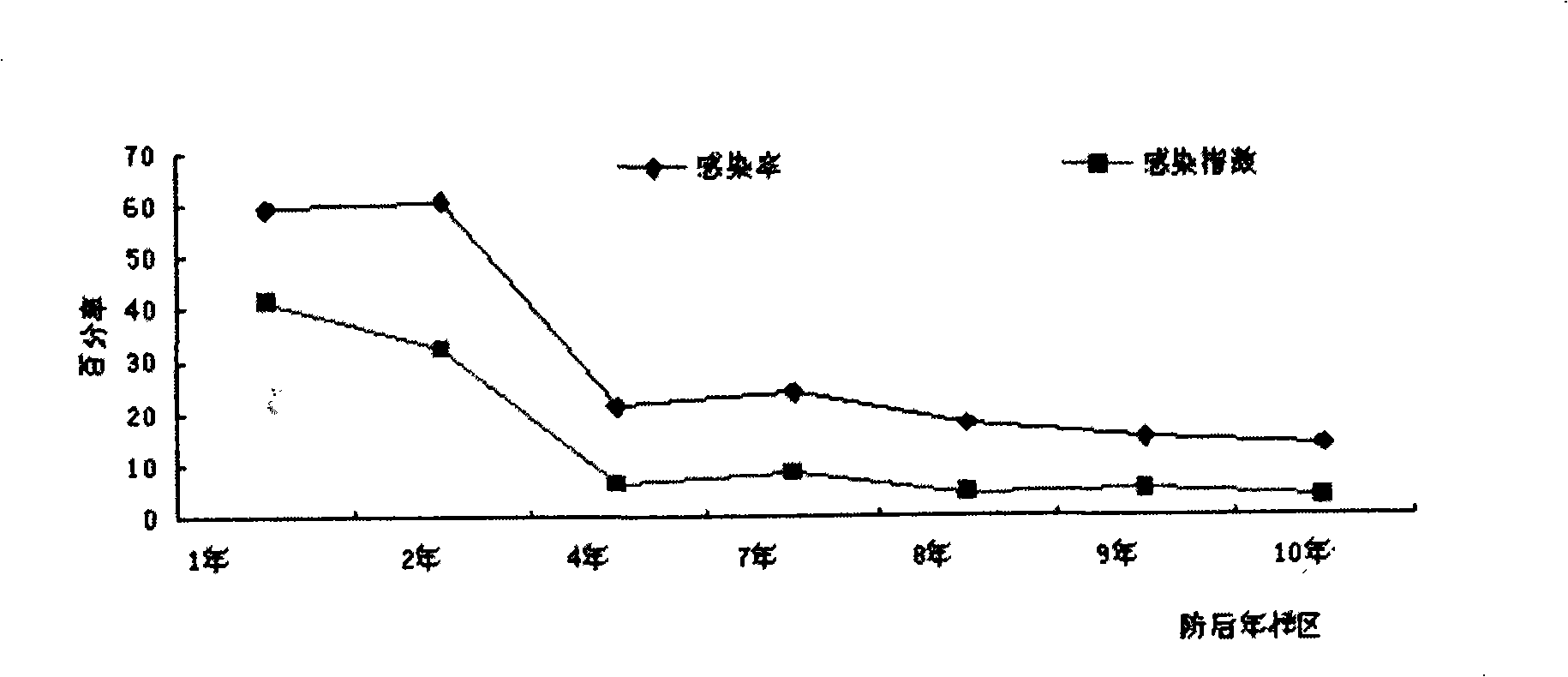

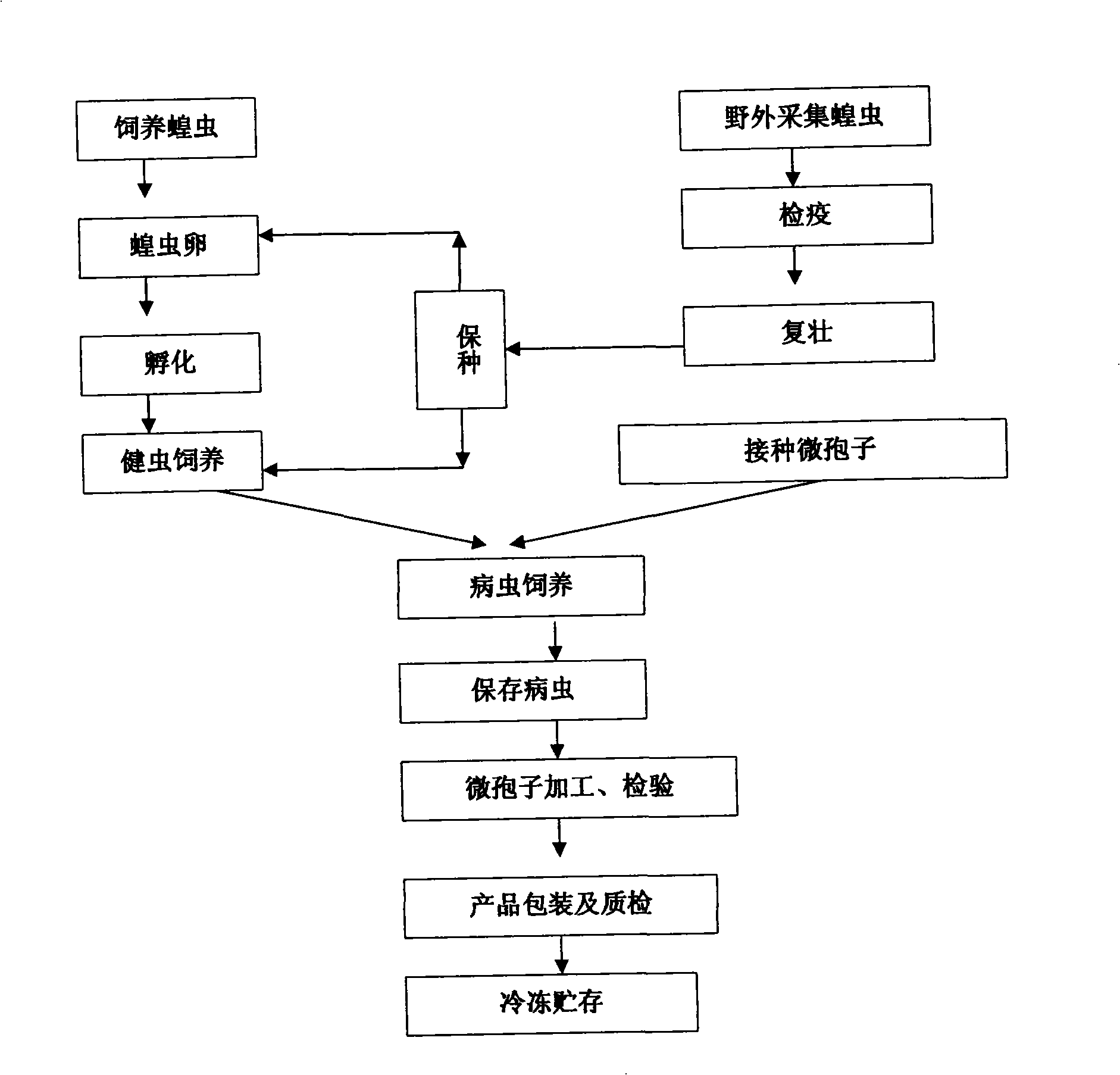

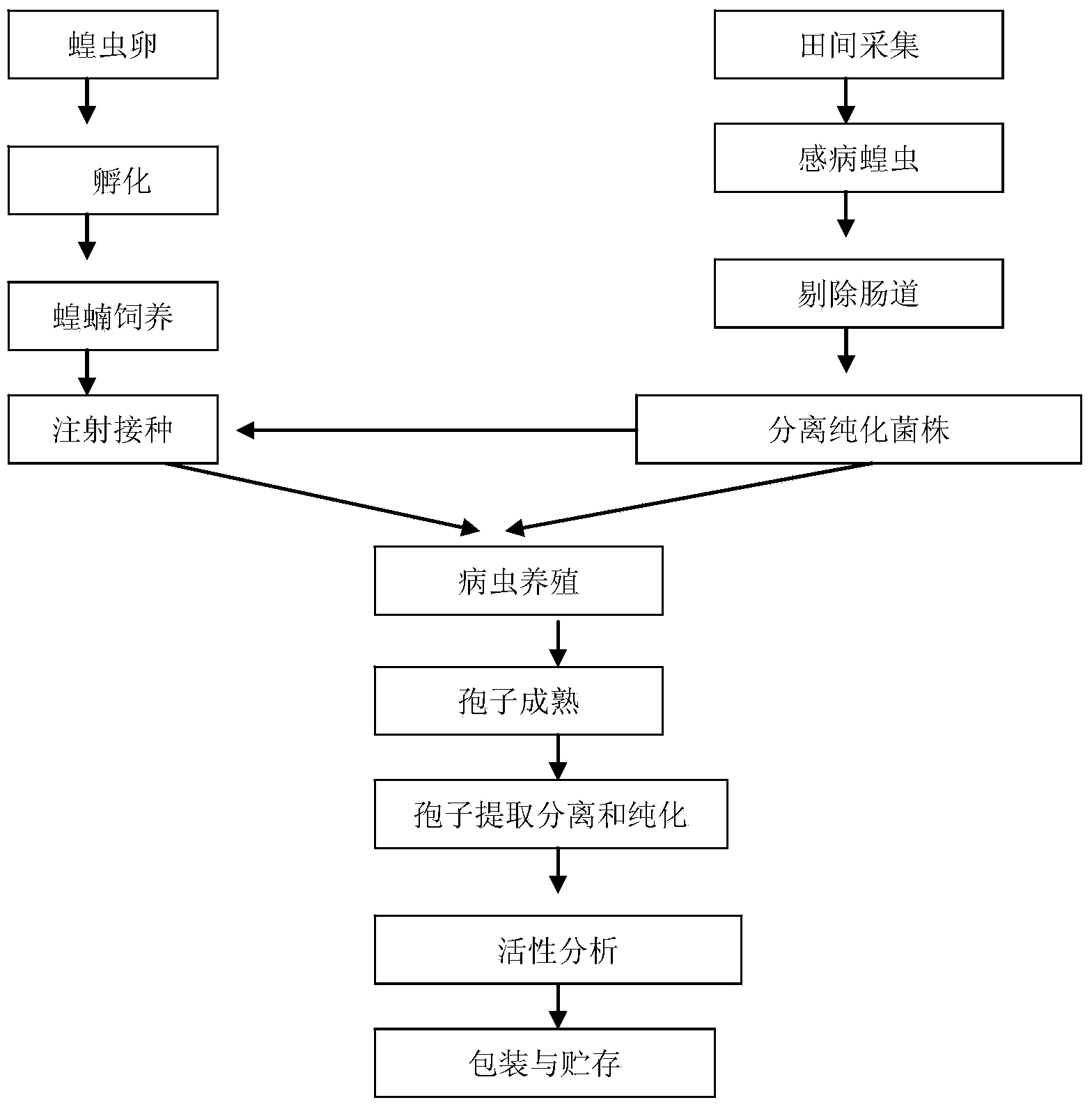

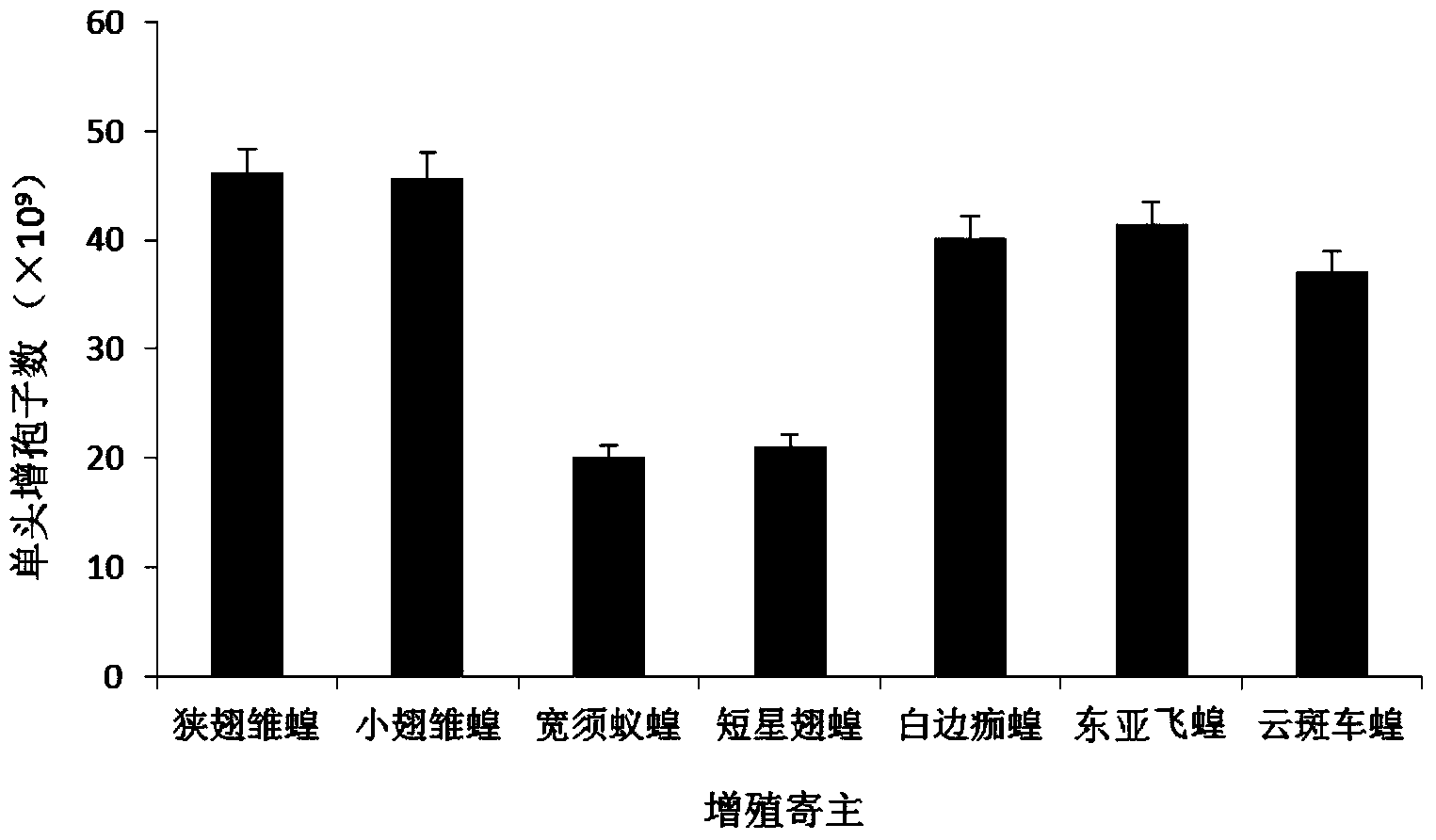

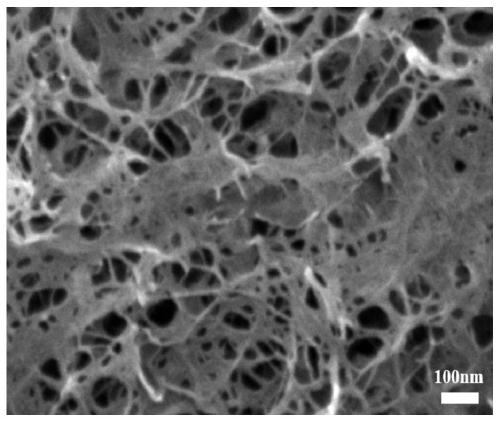

Locust microspore chorthippus strain and applications thereof

ActiveCN103451100ASimple production technologyGreat lethal effectBiocideProtozoaSpore germinationUltraviolet lights

The invention discloses a chorthippus microspore strain and applications thereof. The chorthippus microspore strain disclosed by the invention is paranosema acridophagus PA-201301 with the preservation number of CGMCC No.7757 in the China General Microbiological Culture Collection Center. The paranosema acridophagus PA-201301 CGMCC No.7757 disclosed by the invention has the advantages of obvious lethal effect to chorthippus dubius, chorthippus fallax, myrmeleotettix palpalis, calliptamus abbreviatus, bryodema luctuosum, oriental migratory locust and gastrimargus marmoratus than that of an existing locust microspore, and stress resistance, in particular strong ultraviolet resistance, wherein the germination rate of spores is still more than 80% after a spore solution is irradiated by the ultraviolet light for one hour; in addition, the production technology of microspores of the chorthippus microspore strain is simple, and propagation hosts are easily obtained; after homogenating, separation is performed at the centrifugal force of about 6000g; the chorthippus microspore strain disclosed by the invention is conductive to mass production and applications.

Owner:HEBEI SHENGPU BIOLOGICAL SCI & TECH CO LTD

Sulfur positive electrode material with functional intermediate layer and preparation and application thereof

ActiveCN111416121ARich in amide functional groupsImprove heat resistanceSecondary cellsPositive electrodesLithium–sulfur batteryElectrical battery

The invention relates to a sulfur positive electrode material with a functional intermediate layer and preparation and application thereof, and the sulfur positive electrode material with the functional intermediate layer is prepared by taking commercial Kevlar fibers and a transition metal salt solution as raw materials. Compared with the modification of other lithium-sulfur batteries, due to a fact that the raw materials come from aramid fibers produced by Dupont Company and the production technology is mature, the material can be produced in a large scale, and the dissolving and compoundingsteps are simple; the preparation is easy, the sulfur positive electrode material with the functional middle layer obtained after coating and drying is applied to the lithium-sulfur battery, the cycle performance and the rate capability are greatly improved, the battery can also normally operate at the high temperature of 70 DEG C, and the applicable temperature interval of the lithium-sulfur battery is widened; the preparation method is simple, low in cost, excellent in performance and suitable for production of large-scale commercial batteries.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method for breeding purple chicory

InactiveCN101084735ASuitable for growthEasy to cultivatePlant genotype modificationAngiosperms/flowering plantsCataphyllSonchus arvensis

A method for breeding purple endive comprises performing intergeneric crossing with lettuce as female parent and wild endive as male parent, performing selfing, and breeding a new type endive with purple leaf, convenient artificial cultivation, and high yield. The invention gathers the features of lettuce and endive, and has the advantages of good taste, purple leaf, high yield, realizable aquaculture, and simple production technology.

Owner:陈振志 +1

Sulpride dispersion tablets prepn. method

InactiveCN1723892AGood disintegrationEasy to takeNervous disorderDigestive systemCarboxymethyl starchAlcohol

A dispersive tablet of surpiride for treating psychosis is prepared proportionally from surpiride, carboxymethyl starch sodium, microcrystalline cellulose and dextrin through mixing, adding the alcohol solution of polyvinyl pyrrolidone, mixing, wet granulating, drying, adding carboxymethyl starch, talc powder, SDS and magnesium stearate, stirring and tablet pressing.

Owner:任巧玲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com