Polysiloxane-polyether copolymer modified aqueous polyurethane preparation method

A technology of polyether copolymer and waterborne polyurethane, which is applied in the field of polysiloxane-polyether copolymer modified waterborne polyurethane, can solve the problem of high price of terminal hydroxyalkyl siloxane, low value of industrial promotion, and influence on coating In order to achieve the effects of improving moisture permeability, excellent storage stability, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

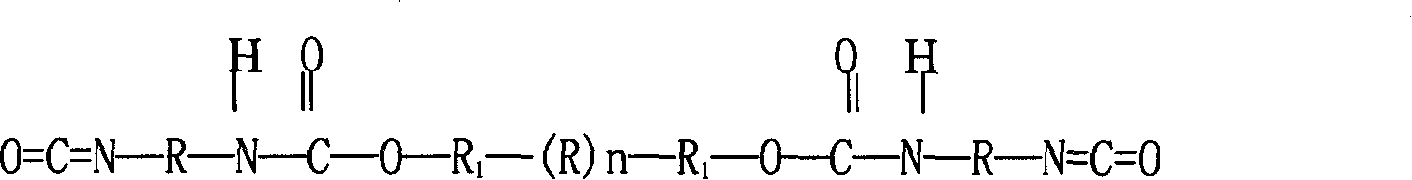

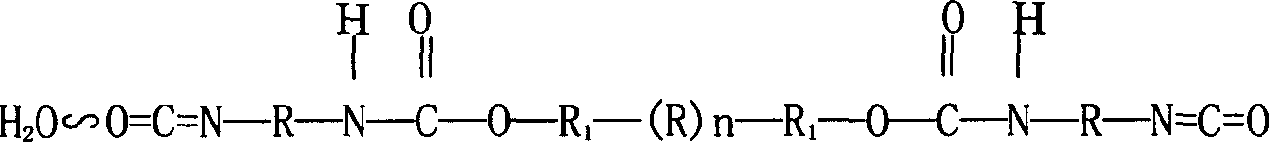

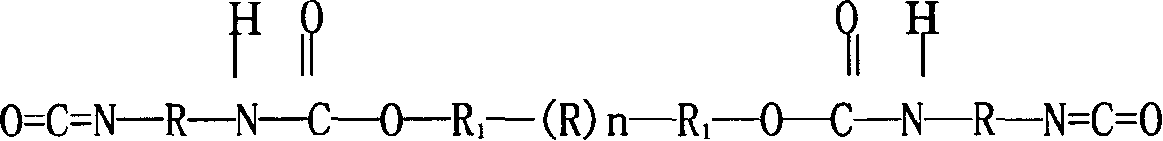

[0044] α-ω dihydroxy polydimethylsiloxane liquid: 3.5 kg, TDI: 0.6 kg into the reactor, react at 98°C for 1 hour, add polyether polyol: 9 kg, react at 105°C for 2- After 4 hours (NCO is 0), after the polysiloxane-polyether copolymer is prepared, add TDI: 11.8 kg, react at 85°C for 2-3 hours (NCO% is 9.8%), add dimethylolpropane Acid: 2.5 kg, react at 82°C for 1-2 hours (NCO% is 5.1%), add 1,4-butanediol: 2 kg and acetone: 16 kg of blended dispersion, at 65°C Reaction 2-4 hour, (NCO% is 0.81%) obtains polyurethane resin, and its structural formula is I, and polyurethane resin is added mixing tank, and the rotating speed is controlled at 900 revs / min, adds triethylamine under the condition of room temperature 3 ℃: 1.8 kilograms , distilled water: 51.6 kg, isophorone diamine: 1.2 kg, stir and disperse for 2-30 minutes to obtain a polyurethane emulsion, its structural formula is II, add the polyurethane emulsion to the precipitation kettle, and remove it under the conditions of 55...

Embodiment 2

[0051] Polyether polyol: add 16 kg to the reaction kettle, heat up to 68°C, dehydrate for 0.6 hours under the condition of vacuum degree 0.09Mpa, add IPDI: 2.3 kg, α-ω dihydroxy polydimethylsiloxane liquid: 8.5 kg The blended dispersion liquid was reacted at 98°C for 2-4 hours (NCO is 0) to obtain polysiloxane-polyether copolymer, adding IPDI: 23 kg, and reacted at 82°C for 2-3 hours (NCO % is 11.1%), add dimethylolpropionic acid: 3.1 kg, react at 82°C for 1-2 hours (NCO% is 4.9%), add ethylene glycol: 2.6 kg and acetone: 31 kg of blend Dispersion, react at 65°C for 2-4 hours (NCO% is 0.75%) to obtain polyurethane resin, its structural formula is I, add polyurethane resin to the mixing tank, rotate at 1000 rpm, stir and disperse at room temperature at 15°C , add triethylamine: 2.9 kg, distilled water: 108.8 kg, isophorone diamine: 1.8 kg, stir and disperse for 2-30 minutes to obtain a polyurethane emulsion, its structural formula is II, add the polyurethane emulsion to the sol...

Embodiment 3

[0054] Hydroxyl-terminated polydimethylsiloxane liquid: 6.5 kg, TDI: 1.2 kg into the reactor, react at 98°C for 1 hour, add polyether polyol: 13.5 kg, react at 105°C for 2-4 hours (NCO is 0), polysiloxane-polyether copolymer is obtained, add MDI: 18.2 kilograms, react 2-3 hours under the condition of 83 ℃ (NCO% is 11.6%), add dimethylolpropionic acid: 3.4 kg, react at 83°C for 1-2 hours (NCO% is 6.3%), add 1,4-butanediol: 2.8 kg and acetone: 23 kg of blended dispersion, and react at 63°C for 2- 4 hours (NCO% is 0.69%), obtained polyurethane resin, and its structural formula is 1, and polyurethane resin is added mixing barrel, and rotating speed is controlled at 1200 revs / min, adds triethylamine under the condition of 20 ℃ of room temperature: 2.5 kilograms, distilled water: 77.3 kg, diethylenetriamine: 1.6 kg, stirring and dispersing for 2-30 minutes to obtain a polyurethane emulsion, its structural formula is II, adding the polyurethane emulsion to the solvent removal kettle,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com