Comb-shaped graft copolymer cement dispersant

A technology of graft copolymer and cement dispersant, which is applied in the field of concrete admixture in building materials, can solve the problems that affect the wide application of existing products, the quality of aggregates varies greatly in different regions, and it is difficult to ensure the quality of freshly mixed concrete. Effects of reducing sensitivity, strong adaptability, and cement adaptability

Active Publication Date: 2009-07-08

JIANGSU SOBUTE NEW MATERIALS

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Although the excellent dispersibility and good slump retention ability of the new polycarboxylate admixture have been widely recognized by the industry, there are still concerns on the mineral composition of cement (mainly C 3 A and alkali content), cement fineness, gypsum form and content, admixture addition amount and addition method, mix ratio, water consumption, concrete mixing process and ambient temperature have extremely high sensitivity (R.Magarotto, F. Moratti, N. Zeminian. Influence of sulfates c

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Login to View More

Abstract

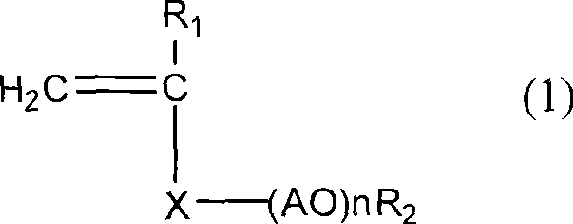

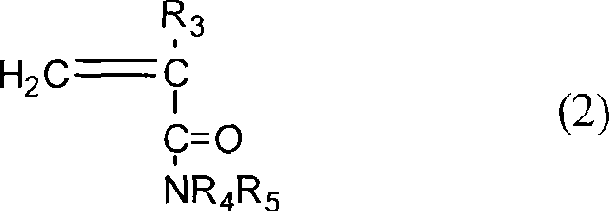

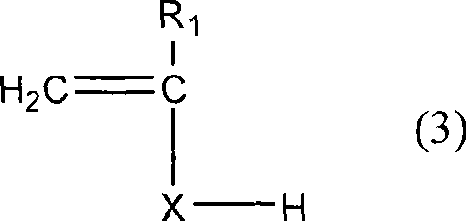

The invention relates to a comb-shaped grafted copolymer cement dispersing agent. The comb-shaped grafted copolymer cement dispersing agent has the advantages of simple production technology, low mixing amount and high adaptability. The comb-shaped grafted copolymer cement dispersing agent is prepared through the following steps: preparing the comb-shaped grafted copolymer cement dispersing agent through the free radical copolymerization reaction of monomers A shown by a general formula (1) and monomers B shown by a general formula (2) in an aqueous medium; and setting the mol ratio of A to B to be 1:2 to 1:10. Amide nonionic base groups are introduced into the backbone of the grafted copolymer and are taken as the absorption base groups, thereby reducing the sensitivity of the grafted copolymer absorption characteristic to the variety and content of ions in the cement slurry, and consequently improving the adaptability of the grafted copolymer dispersing agent in the building engineering. The comb-shaped grafted copolymer cement dispersing agent has the advantages of simple production process, low mixing amount and high cement adaptability.

Description

technical field [0001] The invention belongs to the technical field of concrete admixtures in building materials, and in particular relates to a comb-shaped graft copolymer cement dispersant. Background technique [0002] Cement production not only consumes a lot of resources and energy, but also emits a lot of CO 2 and other harmful gases. At the same time, with the development of social economy, the discharge of solid waste such as slag, fly ash and coal gangue is increasing day by day, which not only occupies land, pollutes the environment, but also causes a huge waste of energy and resources. Reducing the amount of cement, maximizing the use of industrial waste, and prolonging the service life of concrete structures can not only effectively reduce environmental pollution, but also save land, energy and resources, which is conducive to the implementation of sustainable strategies. [0003] The development and application of high-performance admixtures is the most effect...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F283/06C04B24/26

CPCC04B2103/006C04B24/2658C04B2103/408

Inventor 刘加平冉千平缪昌文周栋梁毛永琳杨勇张志勇

Owner JIANGSU SOBUTE NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com