Patents

Literature

31results about How to "Structural diversification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

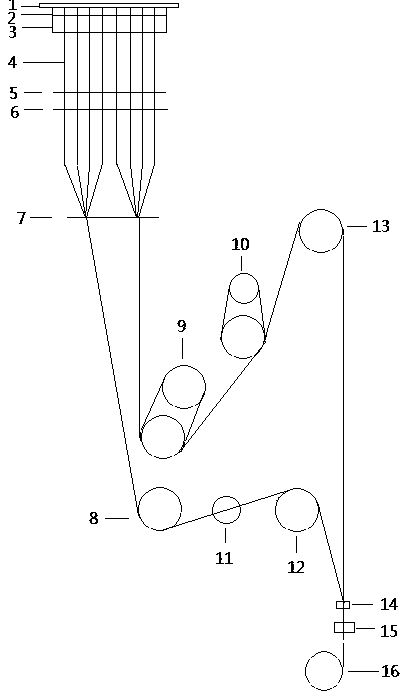

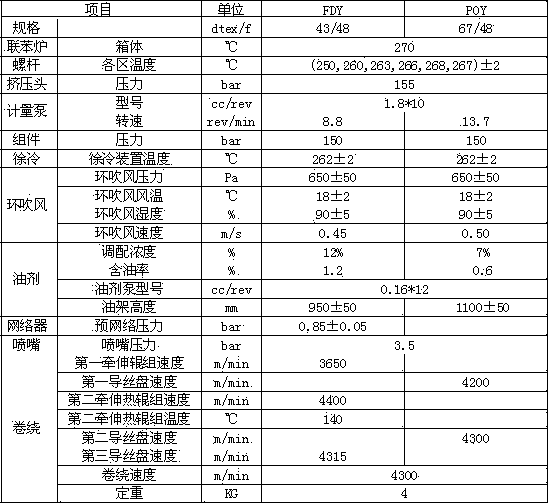

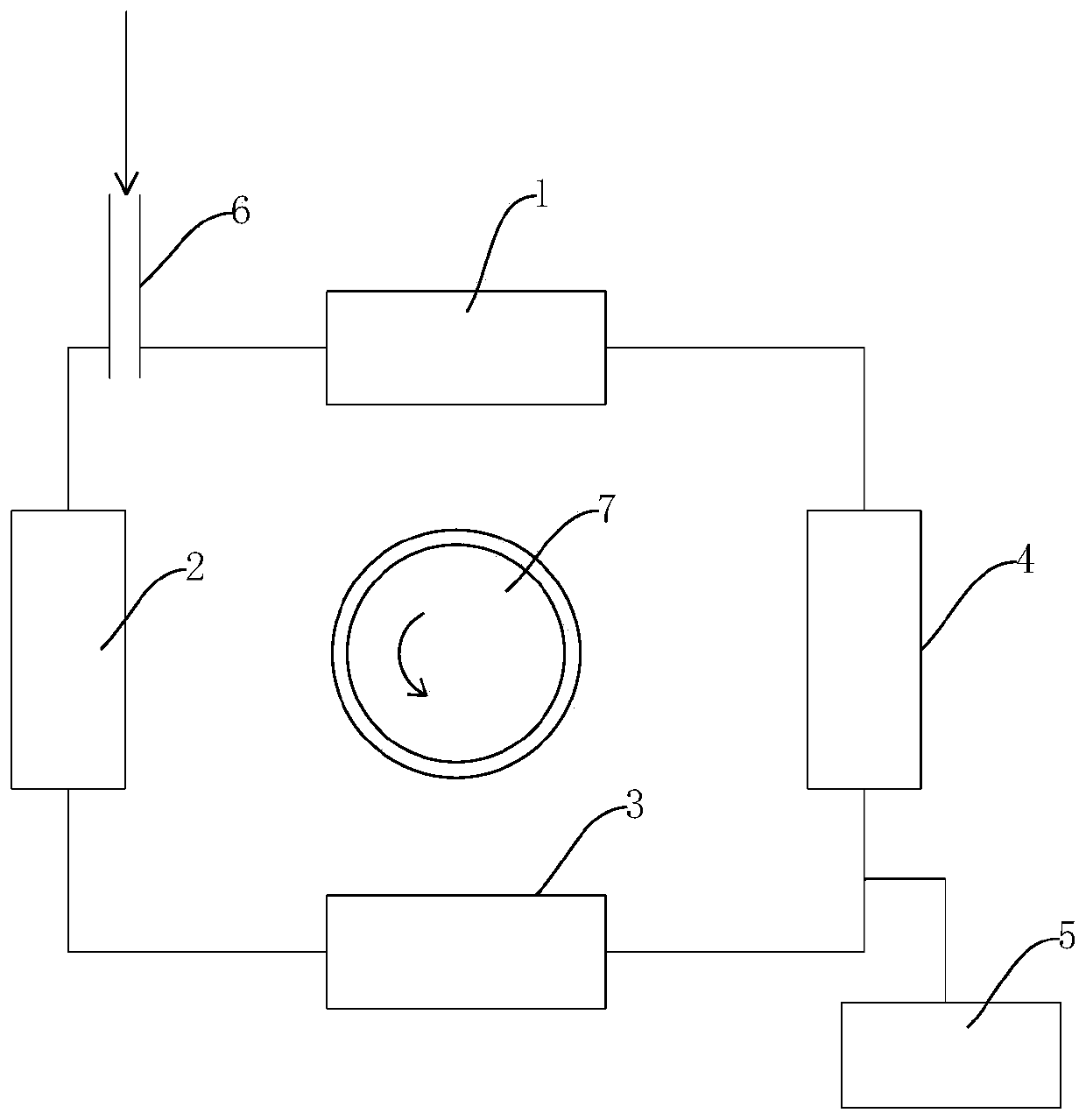

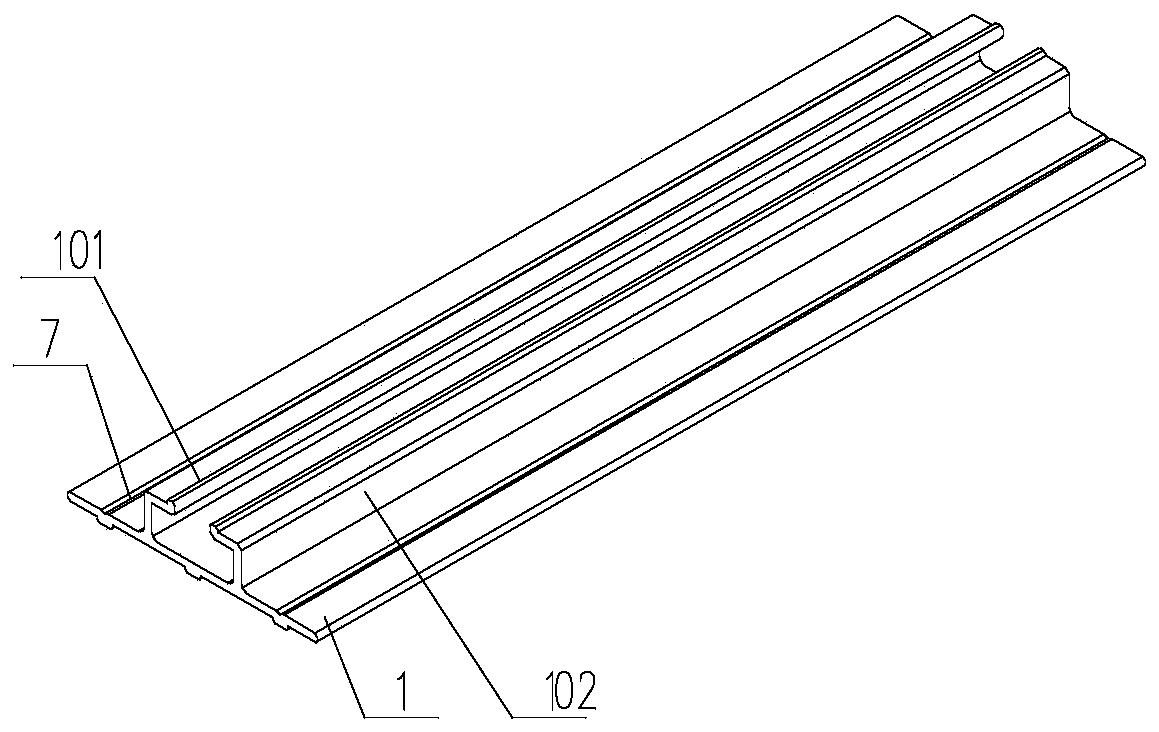

Device for producing polyamide 6POY/FDY composite fiber according to high-speed spinning and confounding one-step method

InactiveCN104032397AGood melt uniformityShort production processNew-spun product collectionSpinning head liquid feederPolyamideYarn

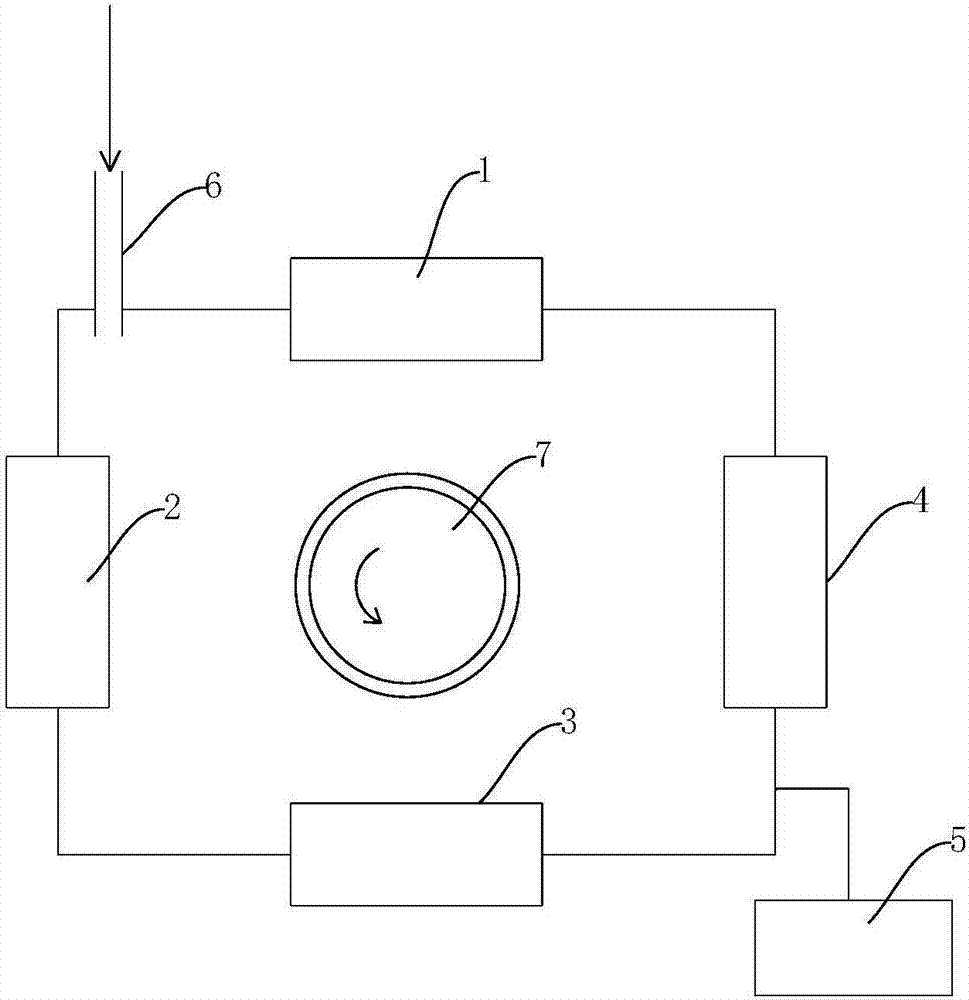

The invention discloses a device for producing polyamide 6POY / FDY composite fiber according to a high-speed spinning and confounding one-step method. A cooling device of the device is a gradually-cooling device which is arranged below a spinneret plate. A cross air blow cooling device is arranged below a heater of the gradually-cooling device, the effect of lowering the cooling speed of melt thin flow can be achieved by enabling melt extruded out of the spinneret plate to pass through the cooling device, and yarn bundle cooling is uniform and consistent. An oil spraying device is arranged below the cross air blow cooling device. A stretching heat setting device and a yarn guiding and winding device are arranged in parallel. The stretching heat setting device is used for preparing polyamide 6POY fully-drawn yarn. The yarn guiding and winding device is used for preparing polyamide 6FDY fully-drawn yarn. A winding device is used for compositing 6POY with FDY at the speed ranging from 4000m / min to 5000m / min. The device has the advantages of being short in production process, simple in procedure, low in device production cost, low in energy consumption, high in efficacy, diversified in product structure and good in quality.

Owner:SUZHOU UNIV

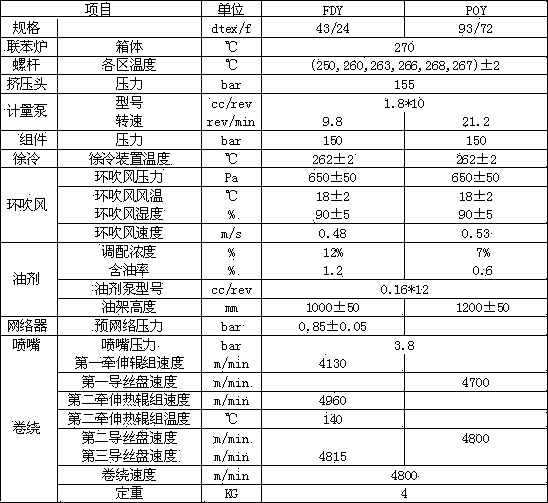

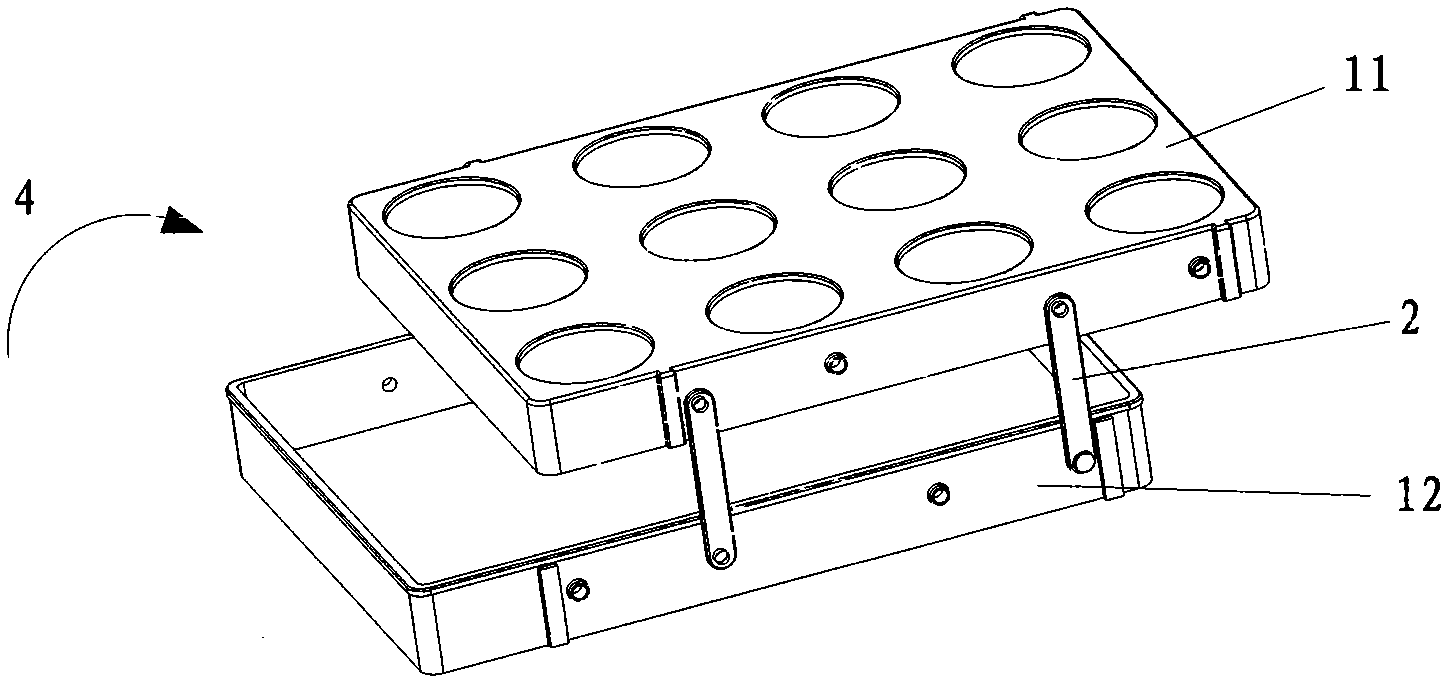

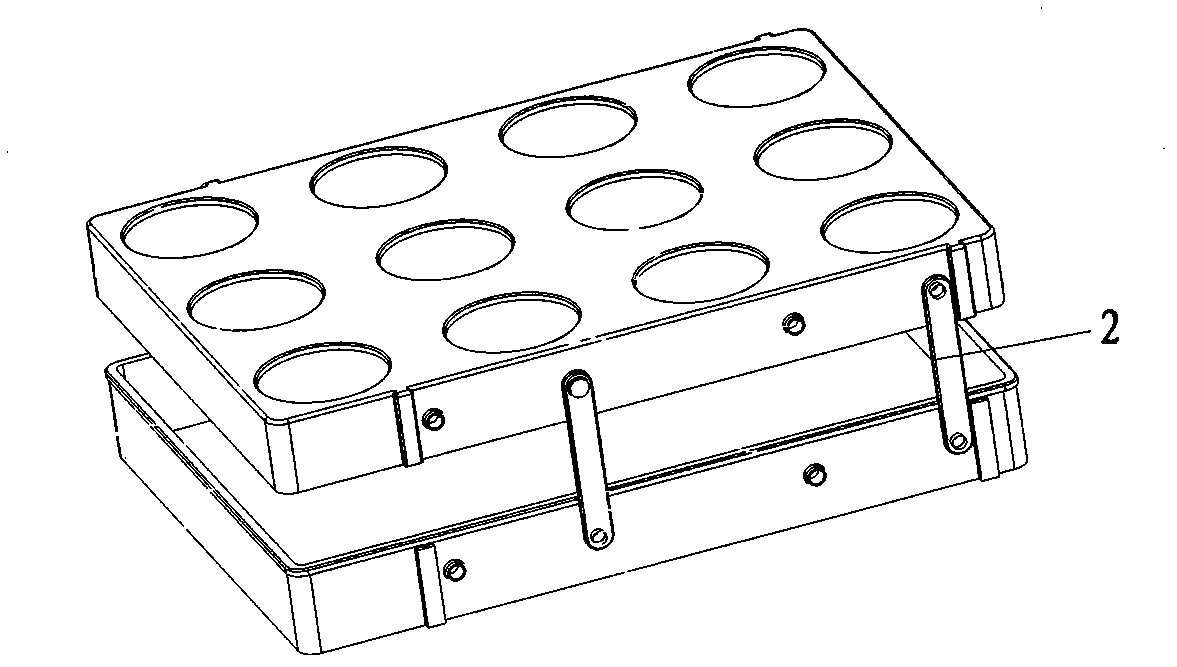

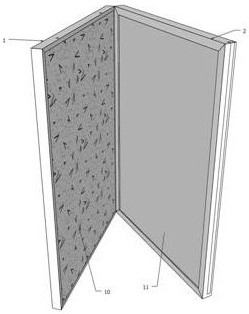

Folding storage device for refrigeration equipment and refrigeration equipment

InactiveCN102288001ASave spaceStructural diversificationLighting and heating apparatusCooling fluid circulationEngineeringRefrigeration

The invention discloses a foldable storage device for refrigeration equipment and the refrigeration equipment, wherein the foldable storage device comprises: at least two storage casings, and the storage casings are configured to be stackable with each other set; support frame, the two adjacent storage casings are connected to each other through the support frame, and among the two adjacent storage casings, the storage casing at the upper part is opposite to the storage casing at the lower part The storage case is pivotable around one end of the support frame. The foldable storage device according to the embodiment of the present invention saves space, and at the same time, the structure of the foldable storage device is diversified to meet the rich living needs of users.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

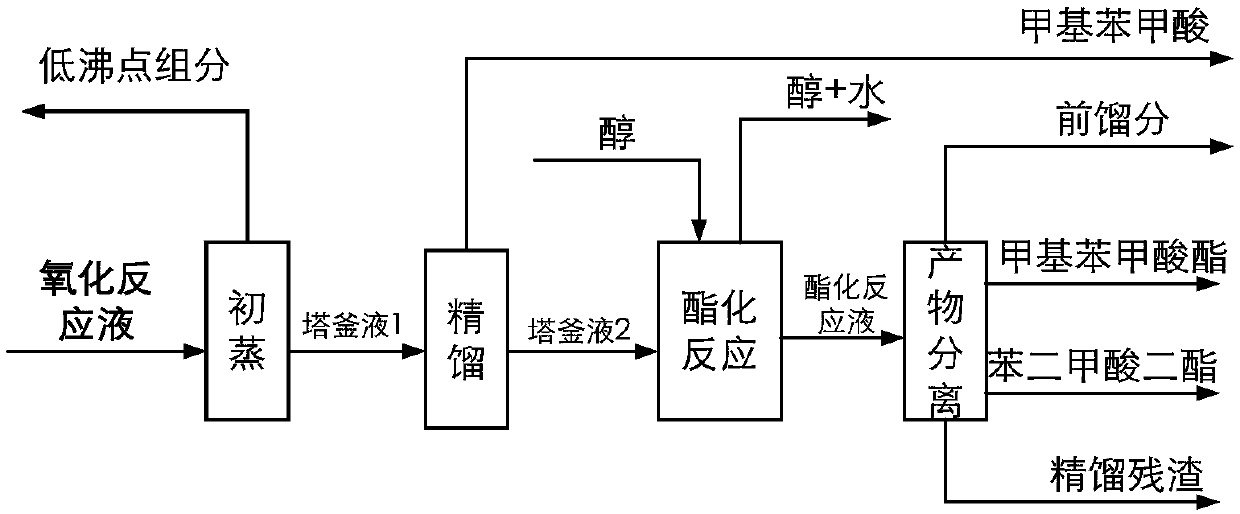

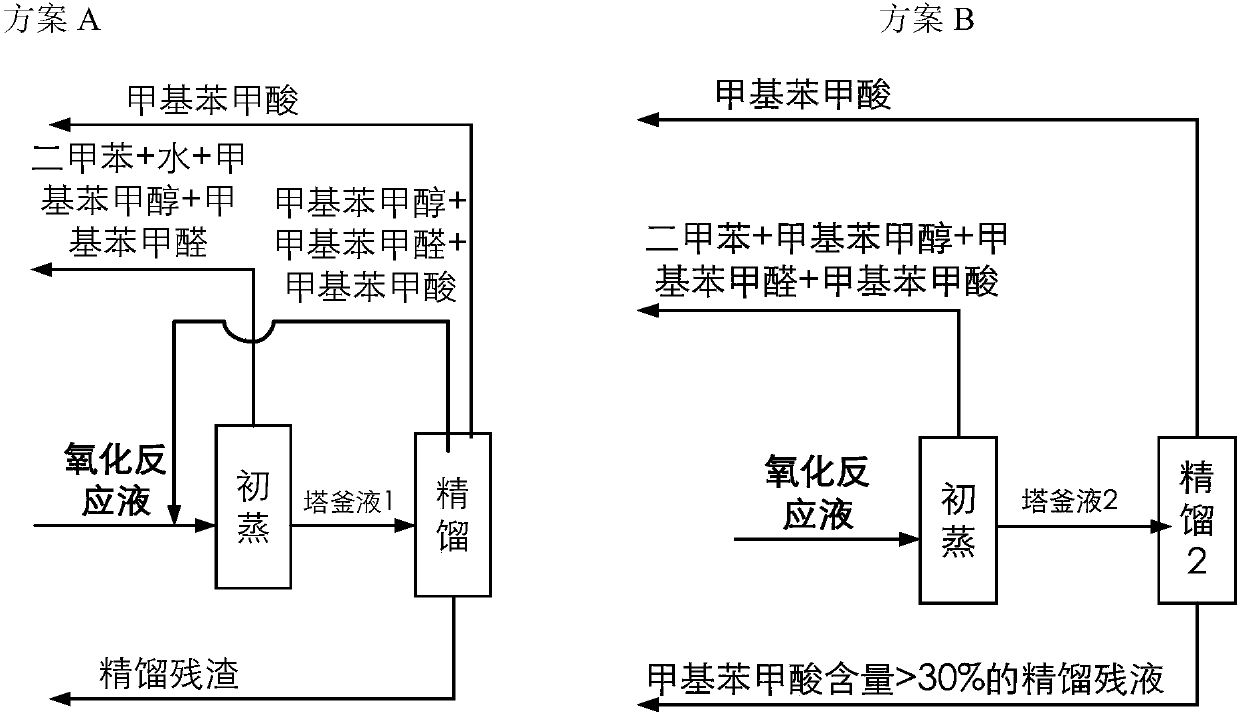

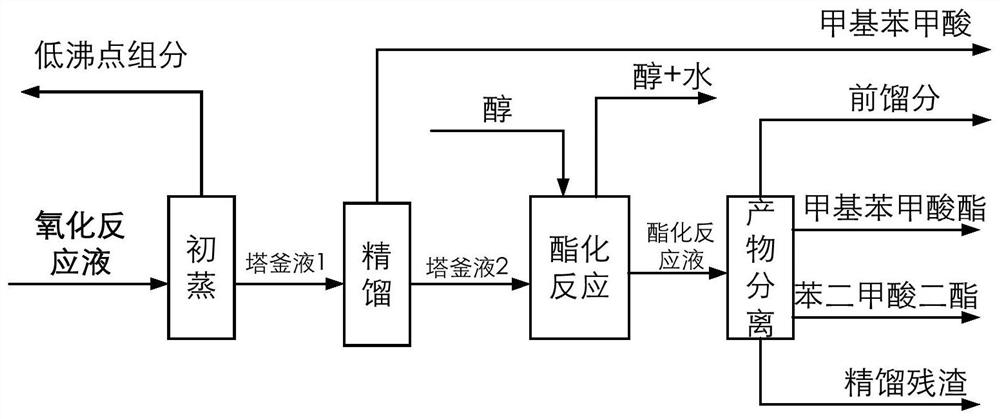

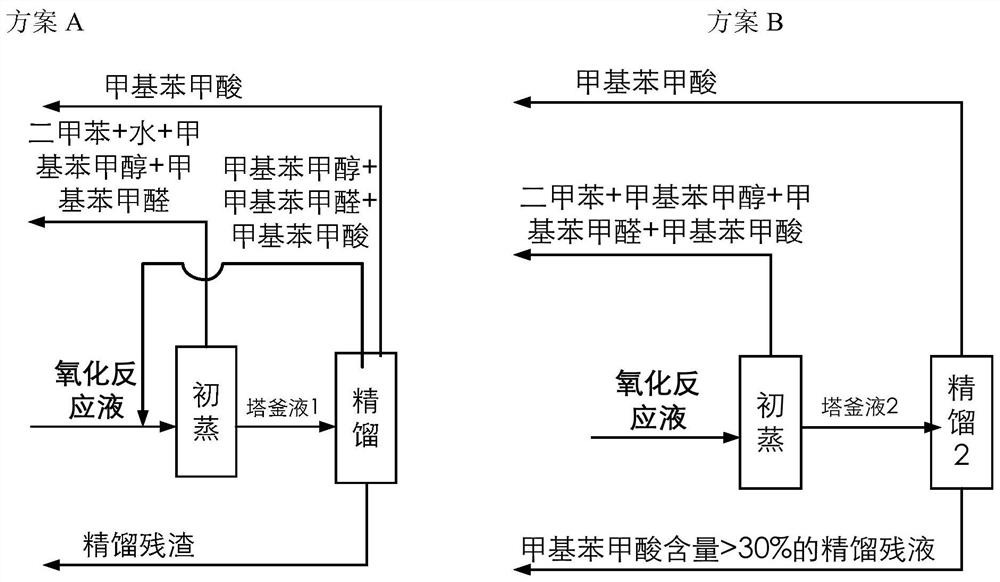

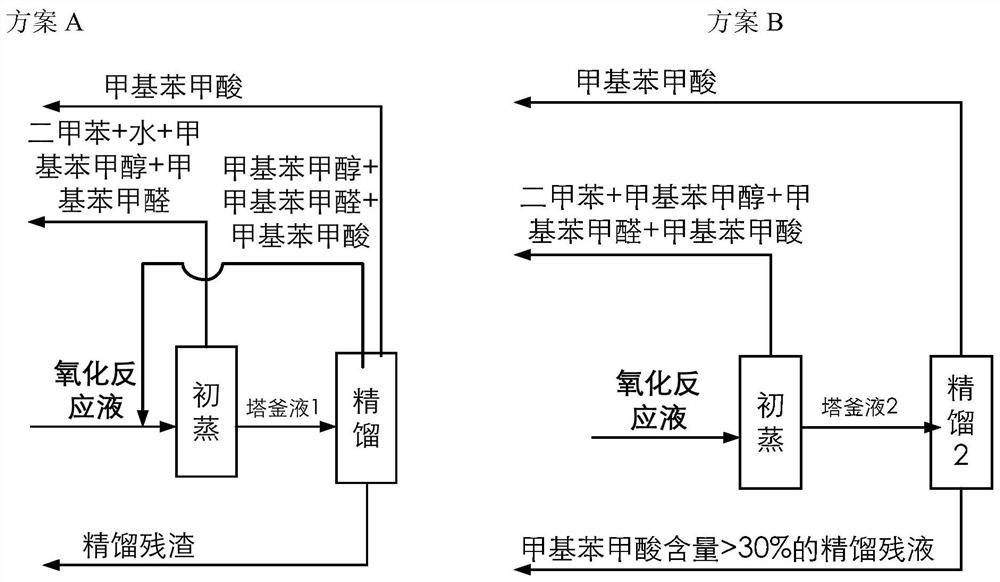

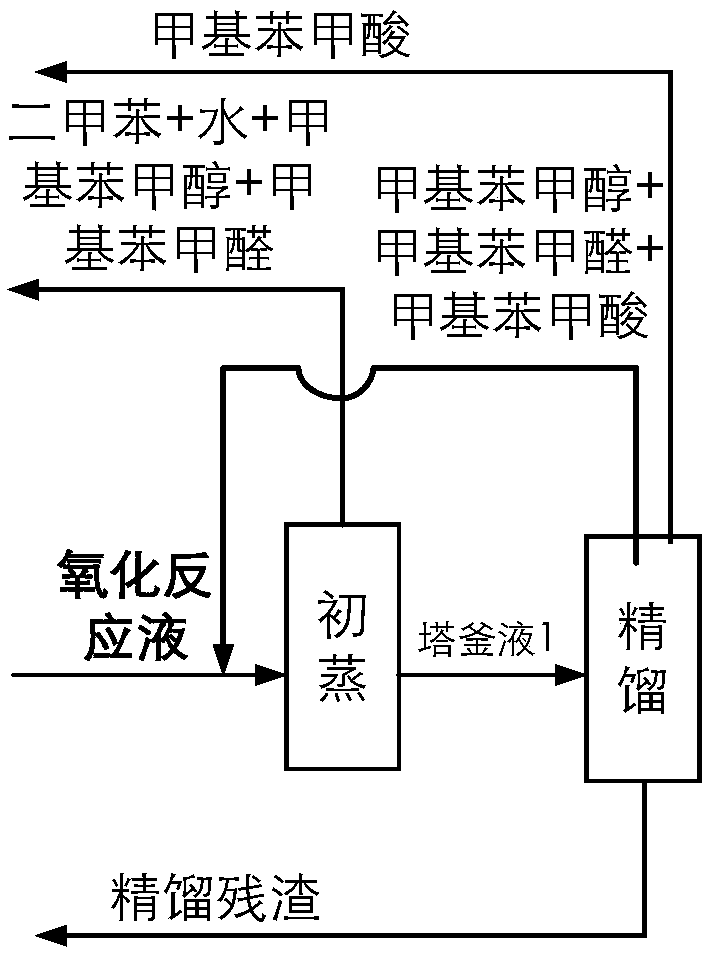

Coproduction method of methylbenzoic acid, methyl benzoate and benzenedicarboxylic acid diester

ActiveCN108047034ARaw materials are easy to getStructural diversificationOrganic compound preparationCarboxylic acid esters preparationAlcoholDistillation

The invention discloses a coproduction method of methylbenzoic acid, methyl benzoate and benzenedicarboxylic acid diester. The method comprises the following steps: (1) continuously introducing xylene, a catalyst and oxygen-containing gas into an oxidation reactor for a reaction, and controlling oxygenic concentration in the tail gas to not exceed 5% by controlling introduction amount of the oxygen-containing gas to obtain an oxidation reaction liquid; (2) feeding the obtained oxidation reaction liquid into a predistillation tower for distillation separation to obtain a low-boiling-point component and a predistillation tower bottom liquid; (3) feeding the predistillation tower bottom liquid into a distillation tower for distillation to obtain a methylbenzoic acid product and a distillationtower bottom liquid; (4) mixing the distillation tower bottom liquid and alcohol for an esterification reaction, and controlling the reaction endpoint to be lower than 0.5wt% of the content of methylbenzoic acid to obtain an esterification reaction liquid; (5) performing distillation separation on the obtained esterification reaction liquid to obtain methyl benzoate and benzenedicarboxylic acid diester products. The method has the advantages that the process is simple, equipment investment is low, and the method is environmentally friendly and has good comprehensive economic benefits.

Owner:JIANGXI KEYUAN BIOPHARM

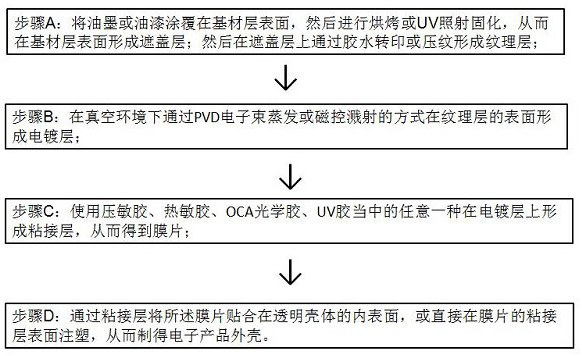

Manufacturing method of electronic product shell

PendingCN113199836ASolve the supply of materialsGuarantee material deliveryVacuum evaporation coatingSputtering coatingTransmittanceMaterial supply

The invention discloses a manufacturing method of an electronic product shell. The processed shell comprises a transparent shell and a diaphragm. The manufacturing method comprises the following specific steps: firstly, manufacturing the diaphragm of a release base material; then manufacturing the transparent shell through procedures such as injection molding, hot bending of glass or a composite board, pouring and the like; then attaching the transparent shell to the manufactured release diaphragm; and finally, conducting CNC carving on an attached product, wherein the base material can be selectively reserved or peeled off according to requirements on product characteristics. The method has no requirement on the optical property of the base material, so the base material is not limited by import, problems in material supply can be solved, and cost is greatly reduced; according to the method, the low-temperature thermal-deformation high-stretching base material is selected, so the problems of high stretching, complicated structure, crinkling, bubbles, layering, springback and the like during lamination are solved; and in addition, the middle layer of the diaphragm manufactured by the method is free of a base material, so the transmittance of the product can be directly improved by 7%-9% on an original basis, and an outer shell product is more transparent and more full and dazzling in color and texture.

Owner:曹祖铭

Method for co-producing benzoic acid, p-toluylic acid and m-methylbenzoate

ActiveCN106831392AWide variety of sourcesLow priceOrganic compound preparationCarboxylic compound separation/purificationBenzoic acidVapor–liquid separator

The invention discloses a method for co-producing benzoic acid, p-toluylic acid and m-methylbenzoate. The method comprises the following steps of (1) oxidizing: adding a xylene mixture, a catalyst and an oxygen-containing gas into an oxidation reactor to react, wherein the content of oxygen in the oxygen-containing gas in percentage by mass is no less than 15%; (2) gas and liquid separating and purifying: sending an oxidation reaction liquid into a gas and liquid separator, condensing and separating a gas phase part, circulating the condensate into the oxidation reaction liquid to continue to oxide, treating and exhausting the non-condensing gas, and performing conventional rectification on a liquid phase part, so as to obtain a low-boiling point component of which the boiling point is lower than the boiling point of benzoic acid; circulating into the oxidation reactor to continue to oxide, and performing further conventional rectification on the tower bottom component, so as to sequentially obtain the benzoic acid, m-methylbenzoate and p-toluylic acid products. The method has the advantages that the technology is simple, the cost of raw material is low, the equipment investment is little, the yield rate is high, the selectivity is good, and the economic benefit is good.

Owner:山东友道化学有限公司

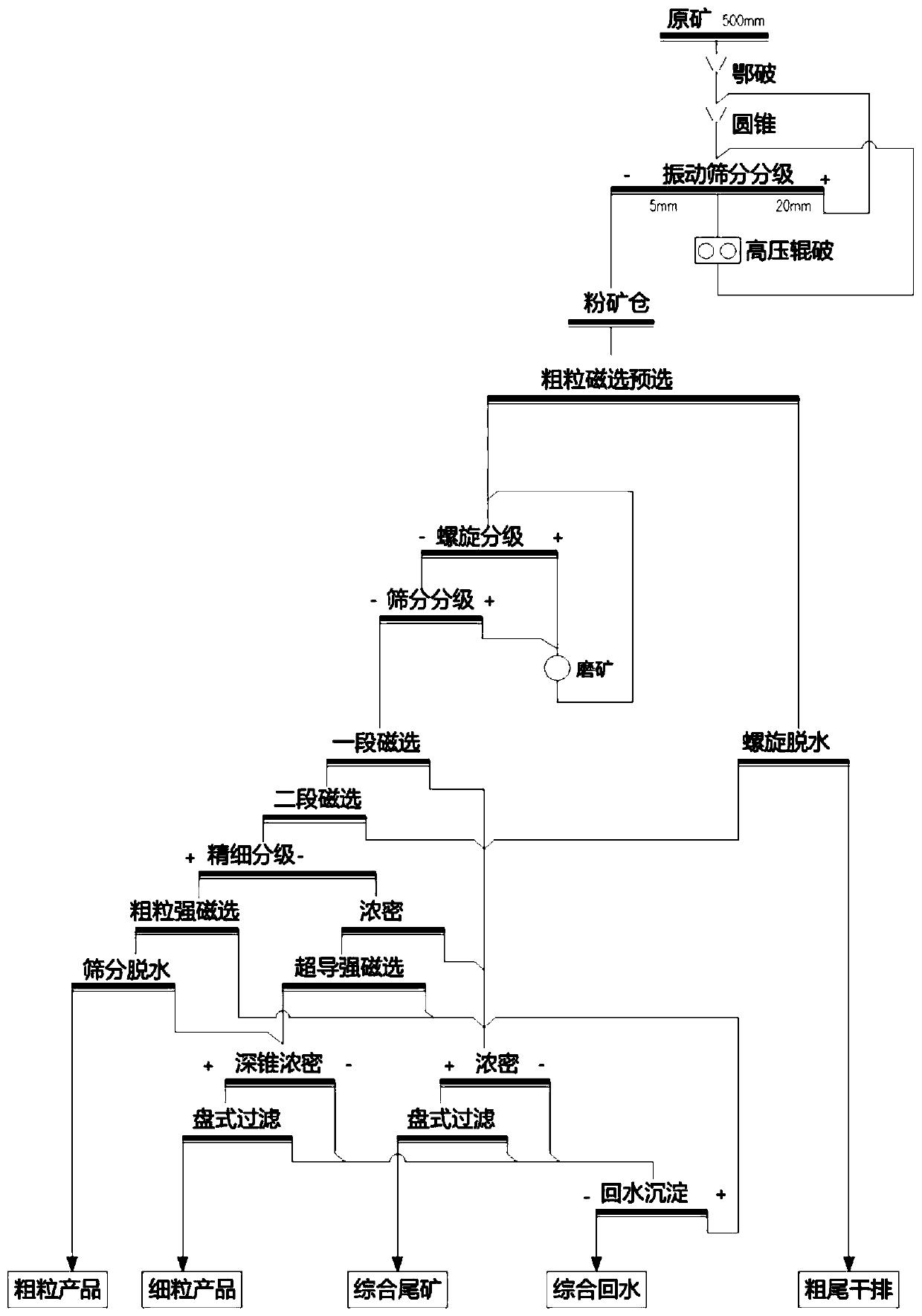

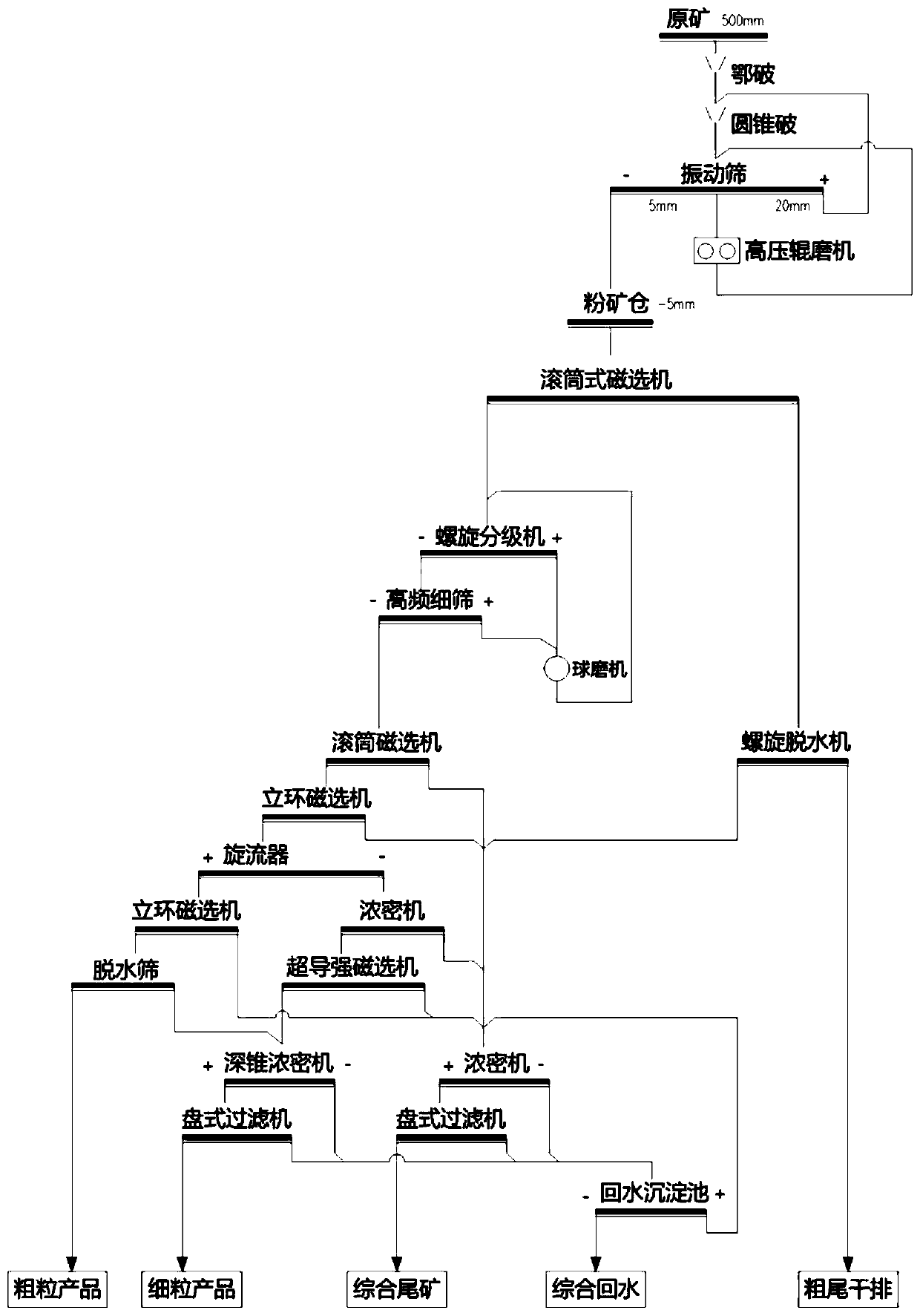

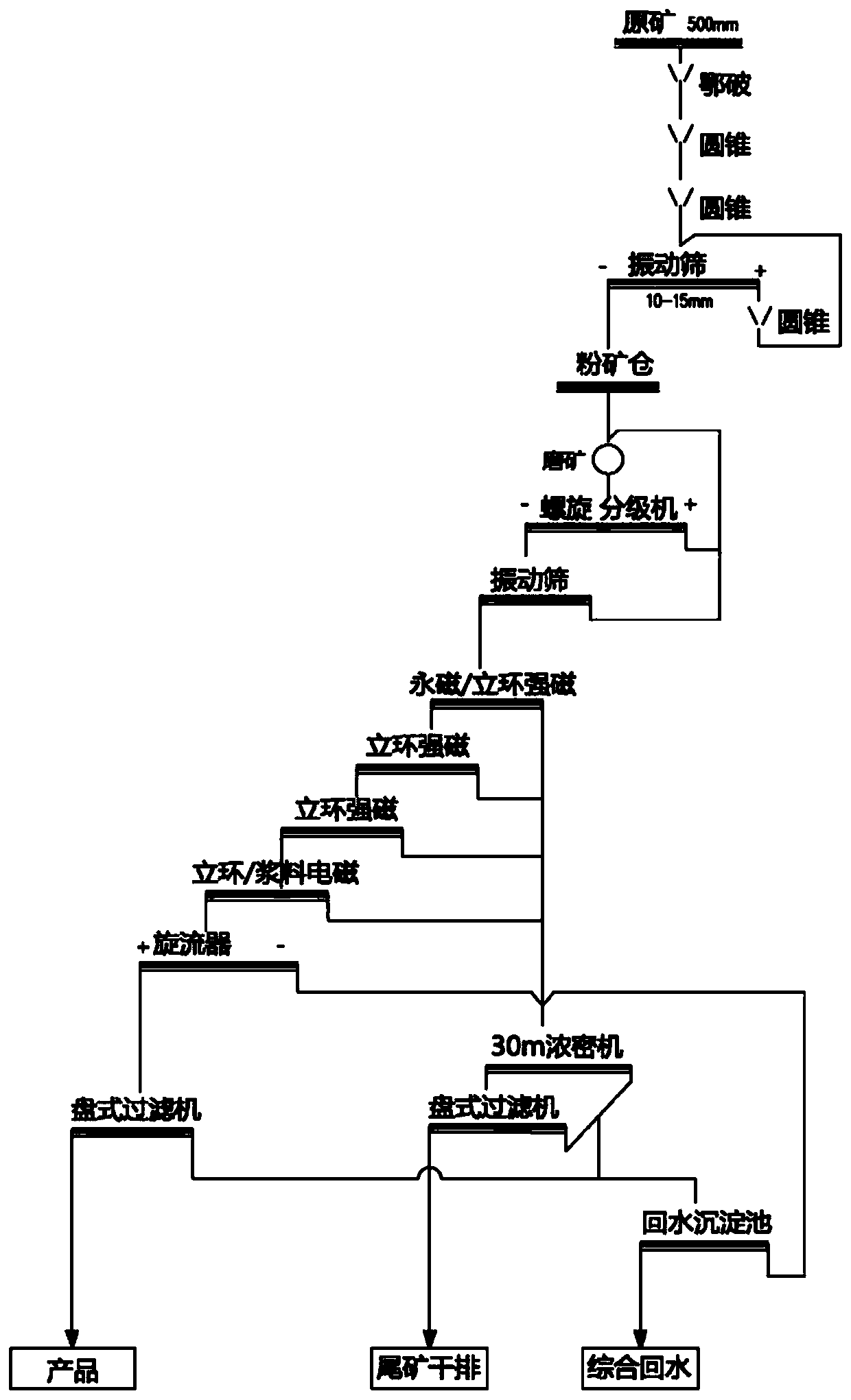

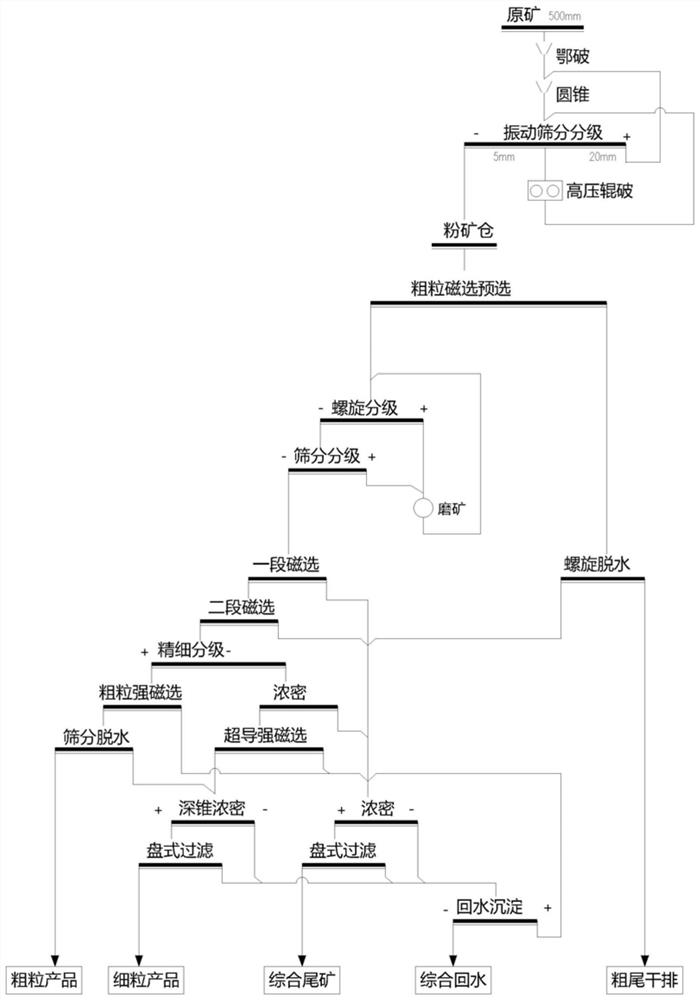

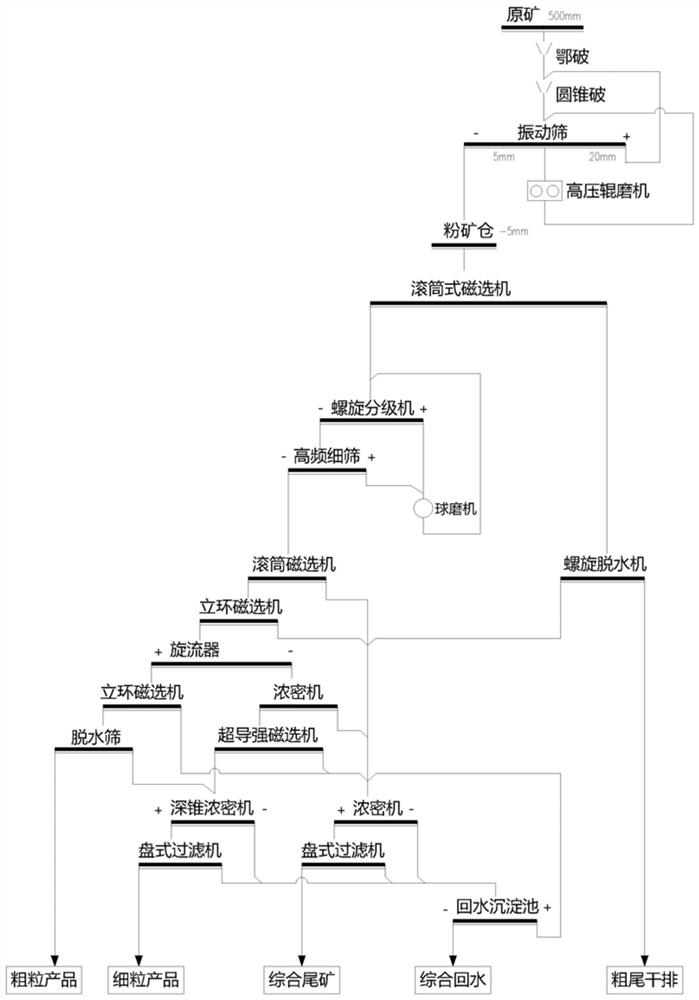

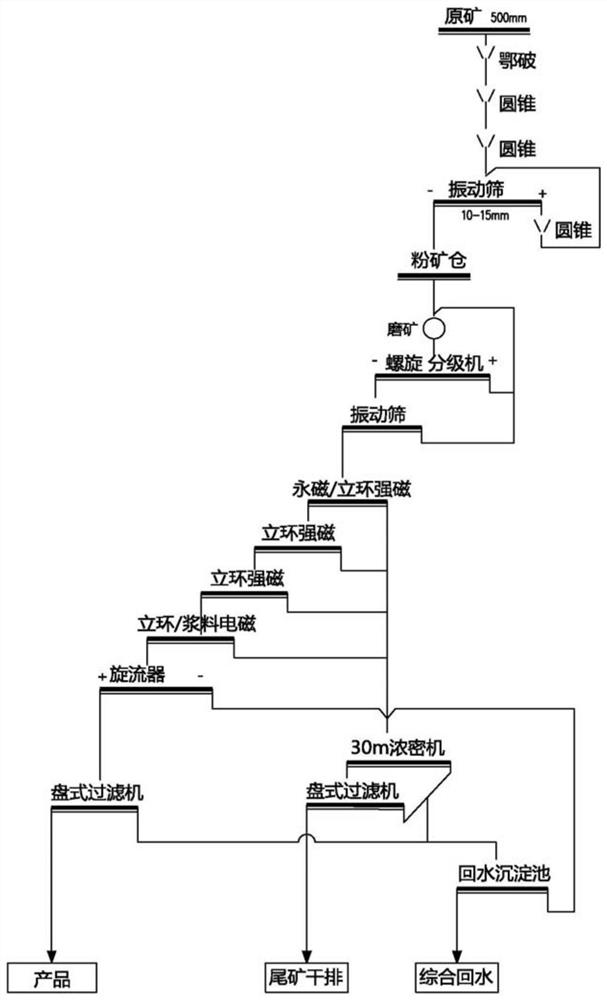

Method for improving quality, reducing cost and improving efficiency of ceramic raw materials prepared from granite stone waste rocks

ActiveCN110743684AImprovement of comprehensive technical and economic indicatorsIncrease throughputMagnetic separationGrain treatmentsMachining processGlass-ceramic

The invention provides a method for improving quality, reducing cost and improving efficiency of ceramic raw materials prepared from granite stone waste rocks. The method comprises the following steps: multi-stage crushing, laminated crushing, coarse grain pre-selection, pre-grading, partial ore grinding, multi-stage magnetic separation, grading separation, superconducting strong magnetic separation, grading dehydration and the like. The method is a pollution-free and environment-friendly physical technology in the whole process; compared with a traditional process, the comprehensive technicaland economic indexes are obviously improved, high-quality glass and ceramic raw materials with the K2O content of 6-10wt%, the Na2O content of 0.5-3.5wt%, the SiO2 content of 65-74wt% and the Fe2O3 content of 0.15wt% and the whiteness of 60-68 are obtained, the whiteness of the product is improved from 50-53 to 60-68 degrees, the yield is improved from 51-55% to 65-72%, and the treatment capacitycan be improved by 13-18%; the product structure is refined and diversified, and a proper product is provided for material homogenization, energy conservation and consumption reduction in the downstream glass and ceramic industry machining process.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Frustule asphalt modifier, frustules asphalt modifier modified composite asphalt, and preparation method of frustule asphalt modifier

InactiveCN108342090ASmall particle sizeSmaller and more uniform particle sizeBuilding insulationsCrack resistanceWaste rubber

The invention relates to a frustule asphalt modifier, a frustules asphalt modifier modified composite asphalt, and a preparation method of the frustules asphalt modifier. The frustules asphalt modifier is prepared from, by weight, 5 to 20 parts of frustule, 10 to 25 parts of waste rubber powder, 0 to 5 parts of petroleum resin or low grade asphalt, and 0 to 3 parts of a stabilizing agent. The invention also discloses a frustules composite modified asphalt, and a preparation method thereof. The frustule asphalt modifier is capable of improving the high temperature performance, the low temperature performance, the fatigue resistance, and the water stability of asphalt mixtures; the obtained frustules composite modified asphalt possesses excellent heat storage stability, and low temperature crack resistance, and is capable of prolonging the service life of road. A part of expensive SBS is replaced by cheap frustule, compared with the pavement performance of modified asphalt prepared via using of only SBS, the pavement performance is improved, and modified asphalt cost is reduced.

Owner:深圳市海绵城市科学研究院

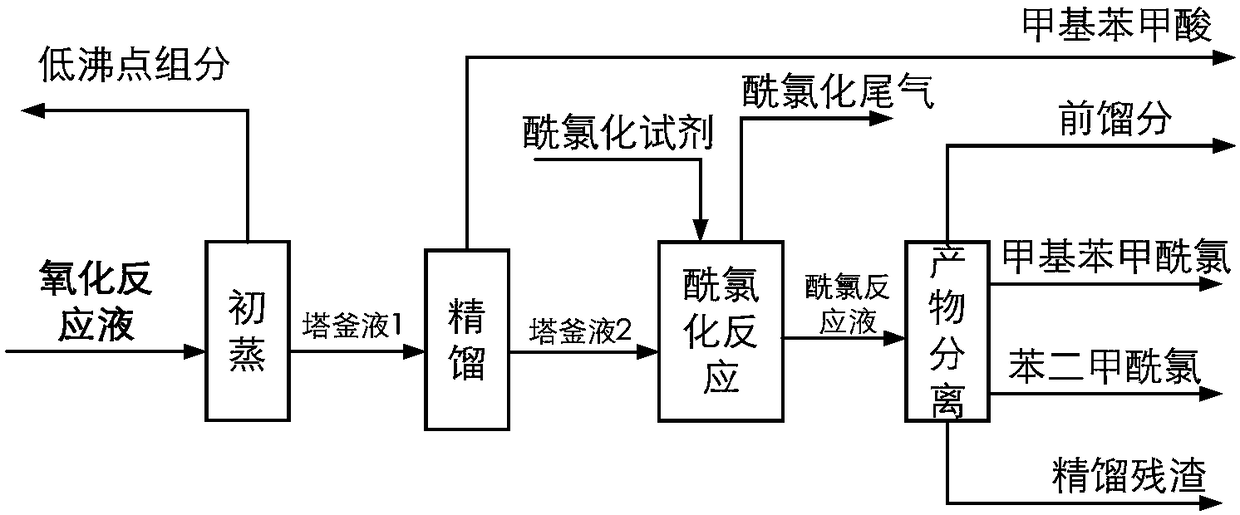

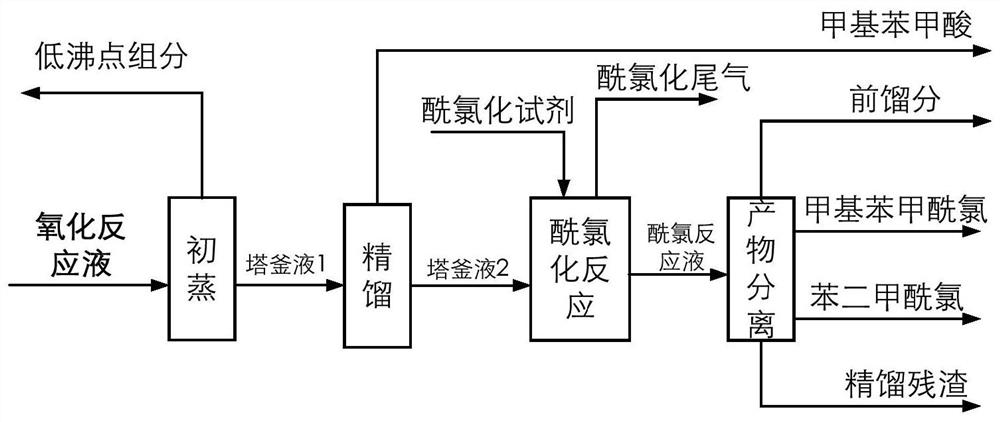

Method of co-producing methyl benzoic acid, methylbenzoyl chloride and phthaloyl dichloride

ActiveCN108117486ALow resolutionSolve the large amount of solid wasteOrganic compound preparationCarboxylic compound separation/purificationBenzoic acidBoiling point

The invention discloses a method of co-producing methyl benzoic acid, methylbenzoyl chloride and phthaloyl dichloride. The method comprises the following steps: (1) continuously introducing xylene, acatalyst and oxygen-containing gas into an oxidizing reactor to react to obtain an oxidized reaction solution; (2) rectifying and separating the oxidized reaction solution to obtain a low-boiling-point component and an initial evaporative tower bottom; (3) rectifying the initial evaporative tower bottom to obtain a methyl benzoic acid product and a tower bottom; (4) carrying out an acylating chlorination reaction on the tower bottom and an acylating chlorination reagent to obtain an acyl chloride reaction solution; and (5) rectifying and separating the acyl chloride reaction solution to separately obtain methylbenzoyl chloride and phthaloyl dichloride products. The method provided by the invention has the advantages of being simple in process, small in equipment investment, green and environment-friendly and good in comprehensive economical benefit.

Owner:JIANGXI KEYUAN BIOPHARM

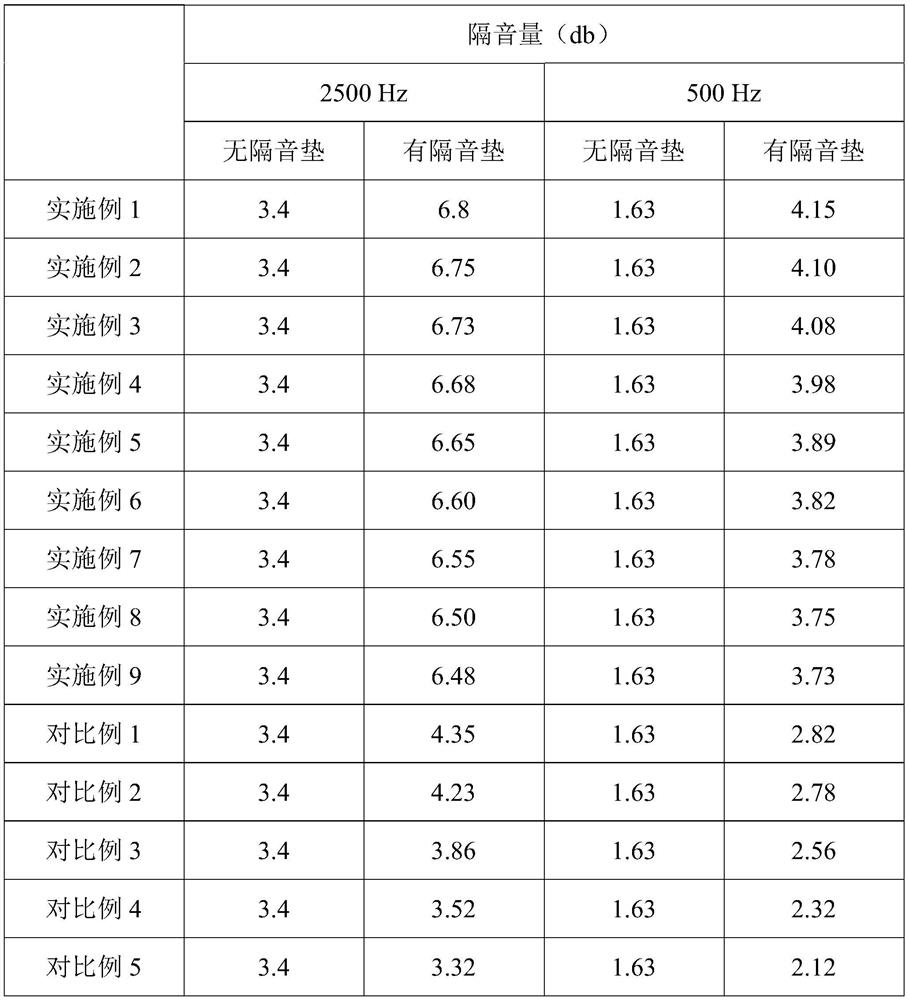

Automobile front wall inner sound insulation pad and preparation method and application thereof

PendingCN111907164ASingle solutionPlay a sound insulation effectSynthetic resin layered productsVehicle componentsEngineeringMechanical engineering

The invention provides an automobile front wall inner sound insulation pad and a preparation method and application thereof. The automobile front wall inner sound insulation pad comprises a sound insulation cotton layer, a heavy coating, a pedal cushion block and a PU foaming layer which are sequentially arranged in a stacked mode, and the preparation method comprises the following steps of dryingand pressing to form the sound insulation cotton layer for use; drying, adsorbing and forming the heavy coating, adhering the heavy coating to the pedal cushion block, then foaming, adhering the heavy coating to the pressed and formed sound insulation cotton layer, and finally cutting to obtain the automobile front wall inner sound insulation pad. The sound insulation cotton layer, the heavy coating, the pedal cushion block and the PU foaming layer are structurally adopted to solve the problem of single structure, the overall sound absorption and insulation performance is improved, meanwhile,the pedal cushion block is pre-buried during foaming, the sound insulation performance is further improved while supporting is achieved, and wide application prospects are achieved.

Owner:WUXI GISSING AUTO PARTS CO LTD

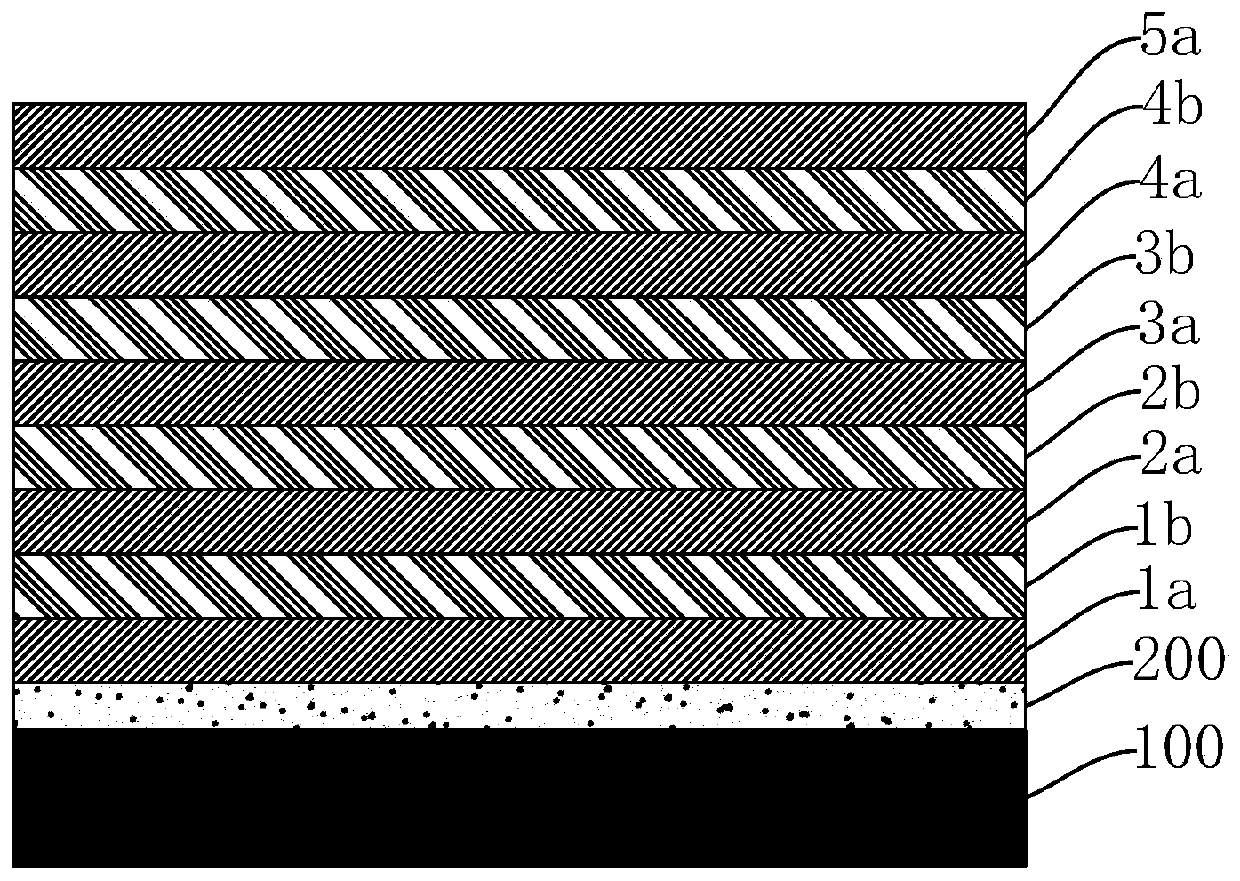

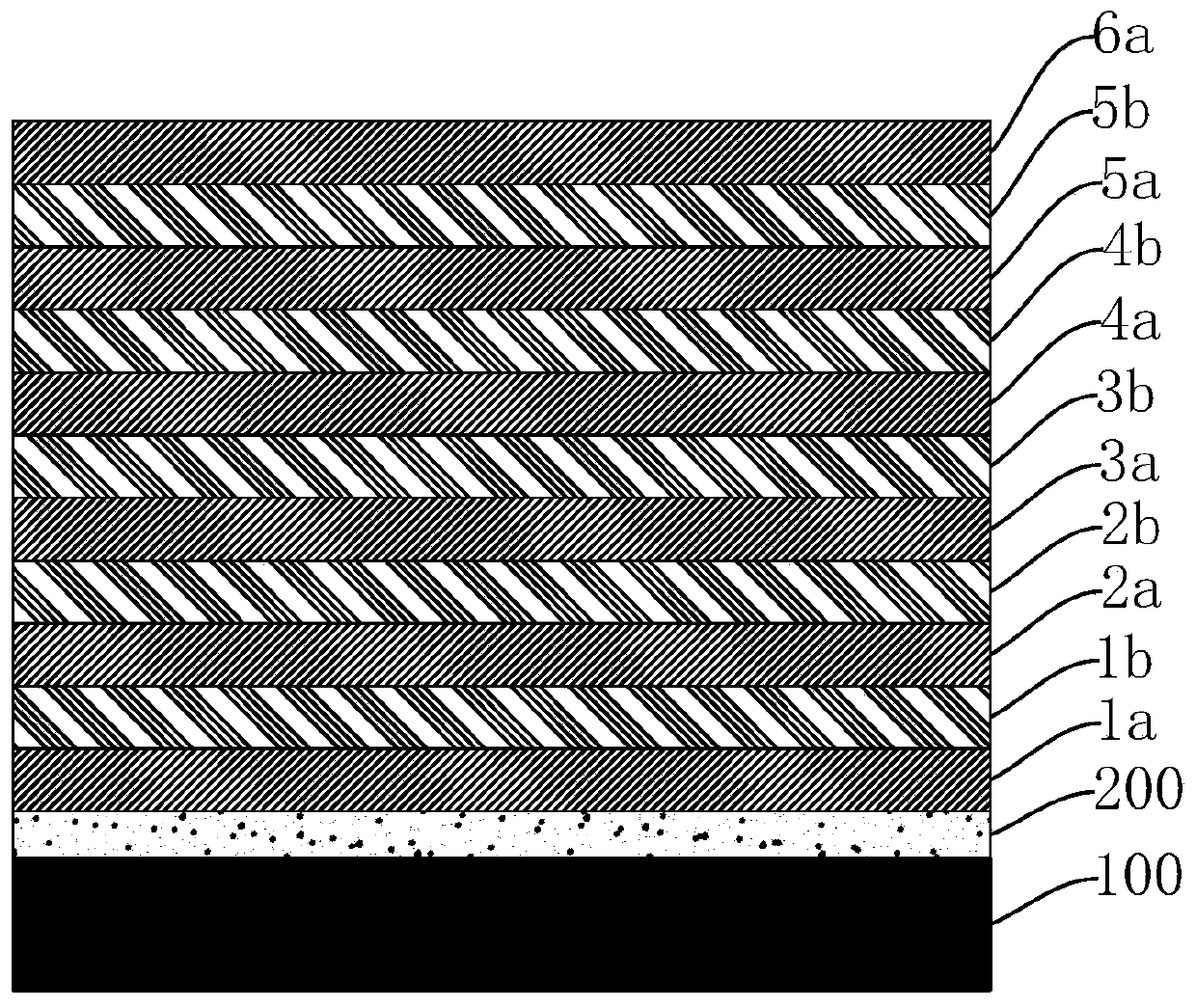

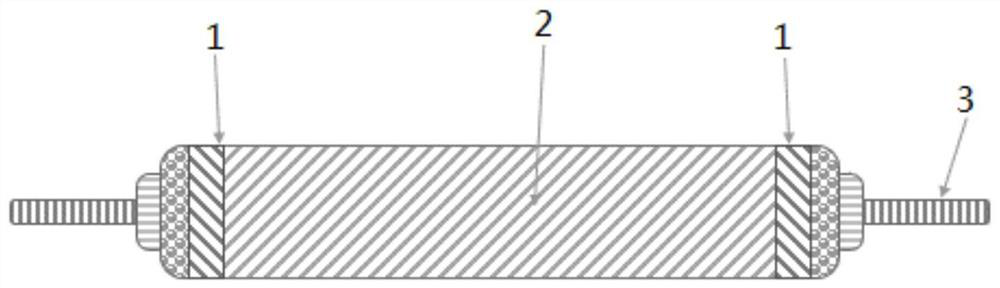

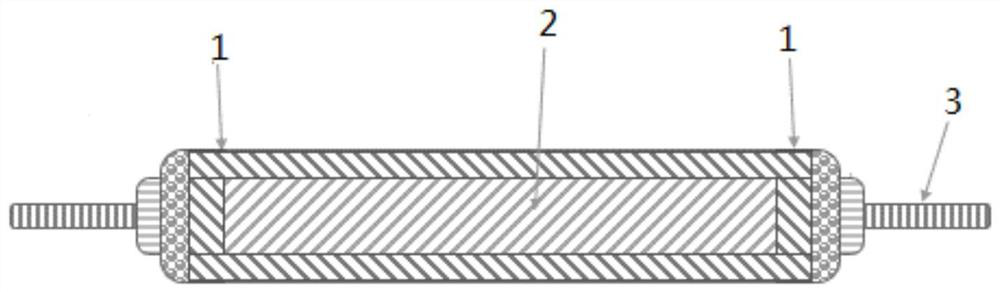

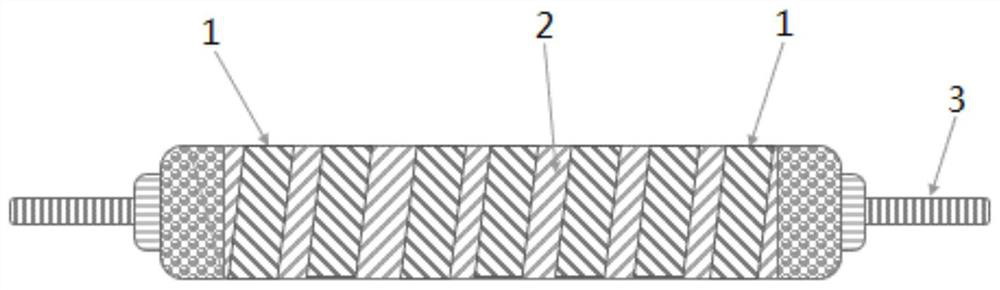

Self-lubricating composite coating, coating preparation method and product with coating

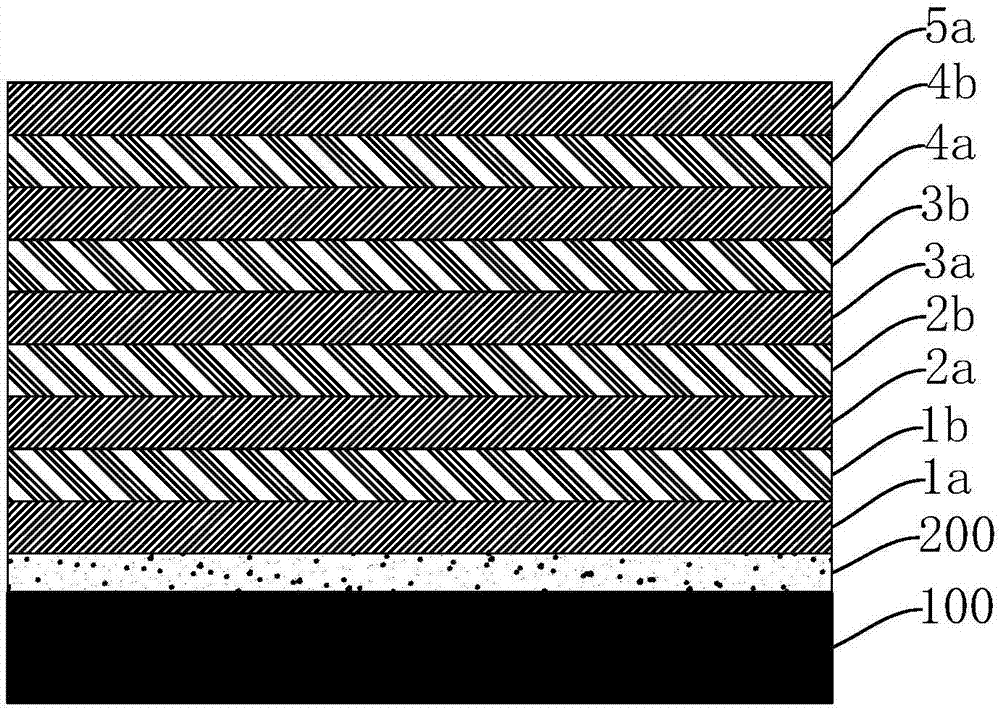

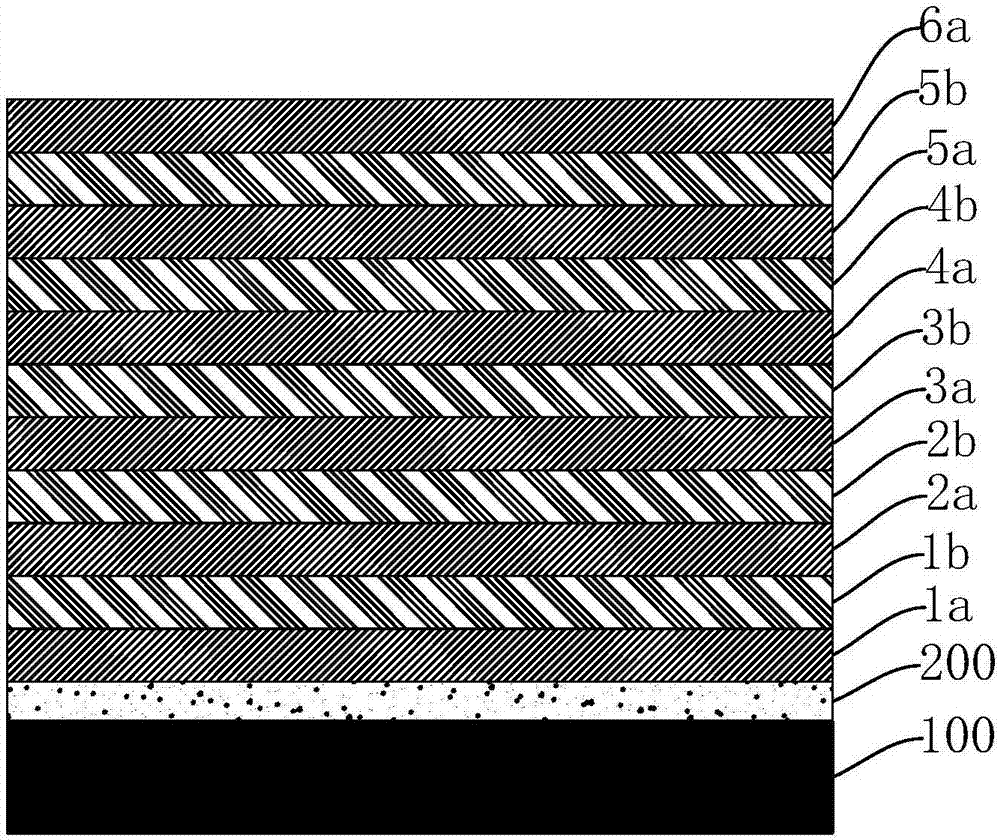

ActiveCN107513684AReduce stressImprove the binding force of membrane baseVacuum evaporation coatingSputtering coatingTribologyMaterials science

The invention discloses a self-lubricating composite coating, a coating preparation method and a product with the coating. The self-lubricating composite coating comprises a plurality of AlSn20Cu layers and a plurality of MoS2 layers which are arranged alternately. According to the self-lubricating composite coating, the MoS2 lubricating layers are introduced into the original AlSn20Cu coatings, so that the coating is diversified in component and structure, the stress of the coating can be effectively reduced, and film-base binding force is increased; and additionally, through introduction of a MoS2 phase, the tribological performance of the coating in the oil-lack and dry-friction environments can be greatly improved while the original lubricating performance of the AlSn20Cu coatings is not changed.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

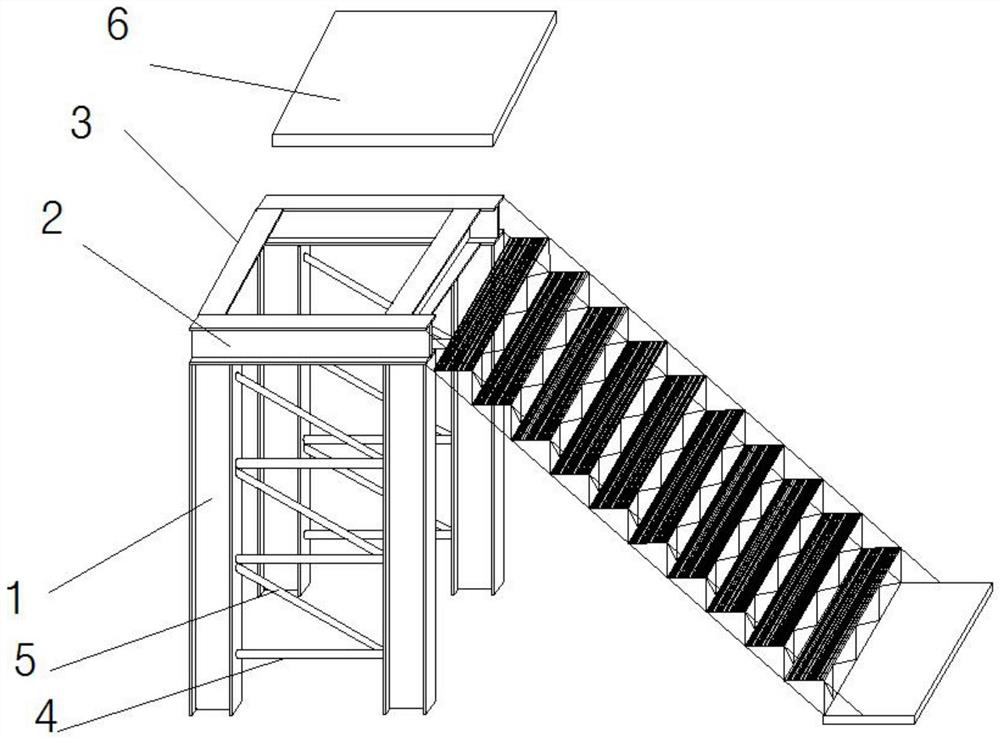

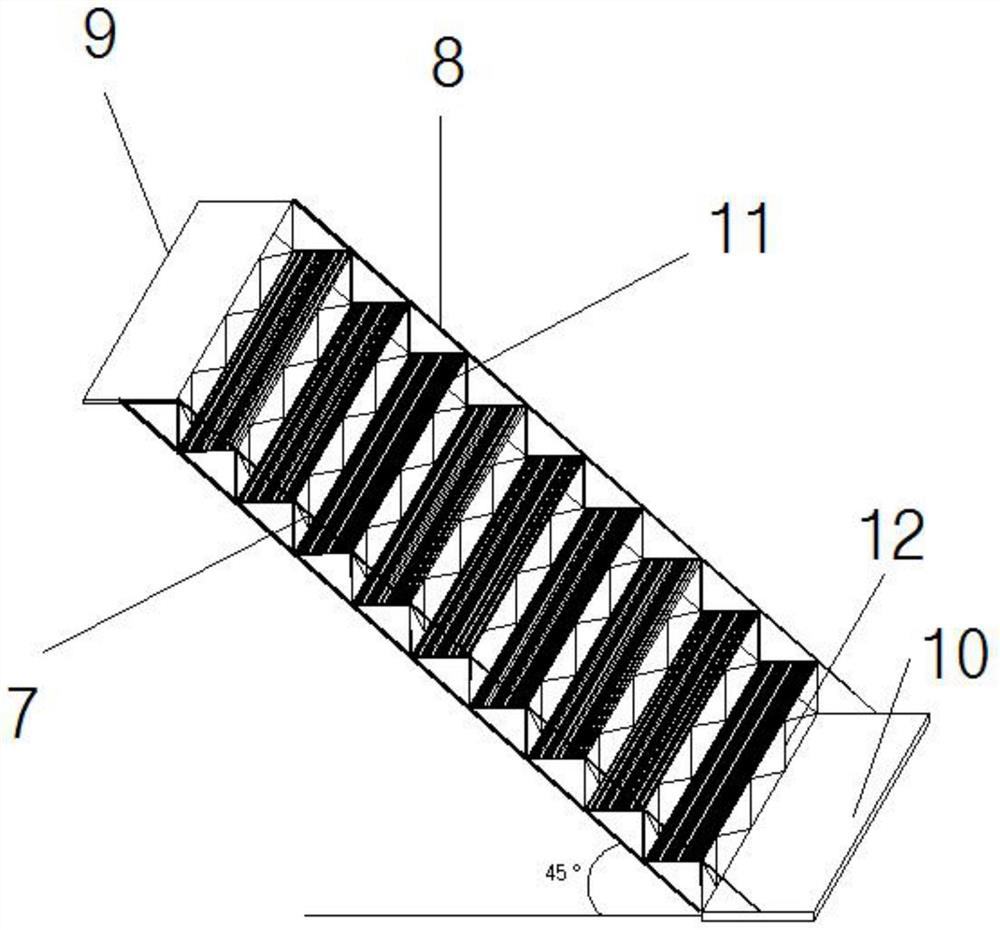

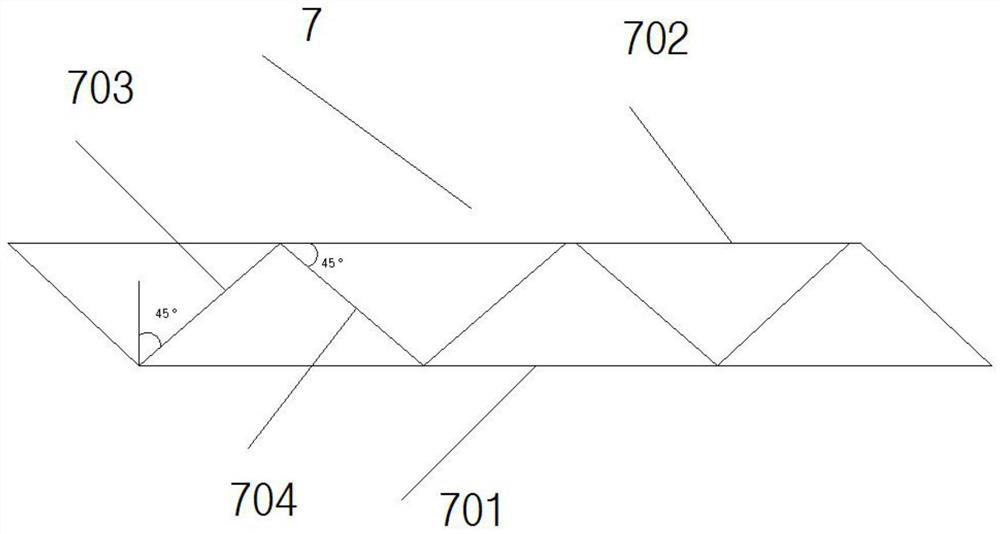

Truss type steel structure stair

The invention relates to a truss type steel structure stair which structurally comprises I-shaped steel main beams and is characterized in that the I-shaped steel main beams are sequentially and vertically fixed on a floor; the number of the I-shaped steel main beams is four; i-shaped steel cross beams are welded to the front end and the rear end of the top face of the I-shaped steel main beam in a horizontal alignment mode, I-shaped steel longitudinal beams are welded to the left end and the right end of the top face of the I-shaped steel main beam in a horizontal alignment mode, and the I-shaped steel cross beams and the I-shaped steel longitudinal beams form a rectangular structure. A platform is installed on the rectangular top face, cross rods are welded to the I-shaped steel main beams at equal intervals of the height, inclined rods are welded to the cross rods in a diagonal mode, and first connecting plates are welded to the tail portions of the right sides of the I-shaped steel cross beams in a horizontally-aligned mode, and the truss type steel structure stair is convenient to install, high in construction efficiency and diversified in structure.

Owner:福建省川工建设工程有限公司

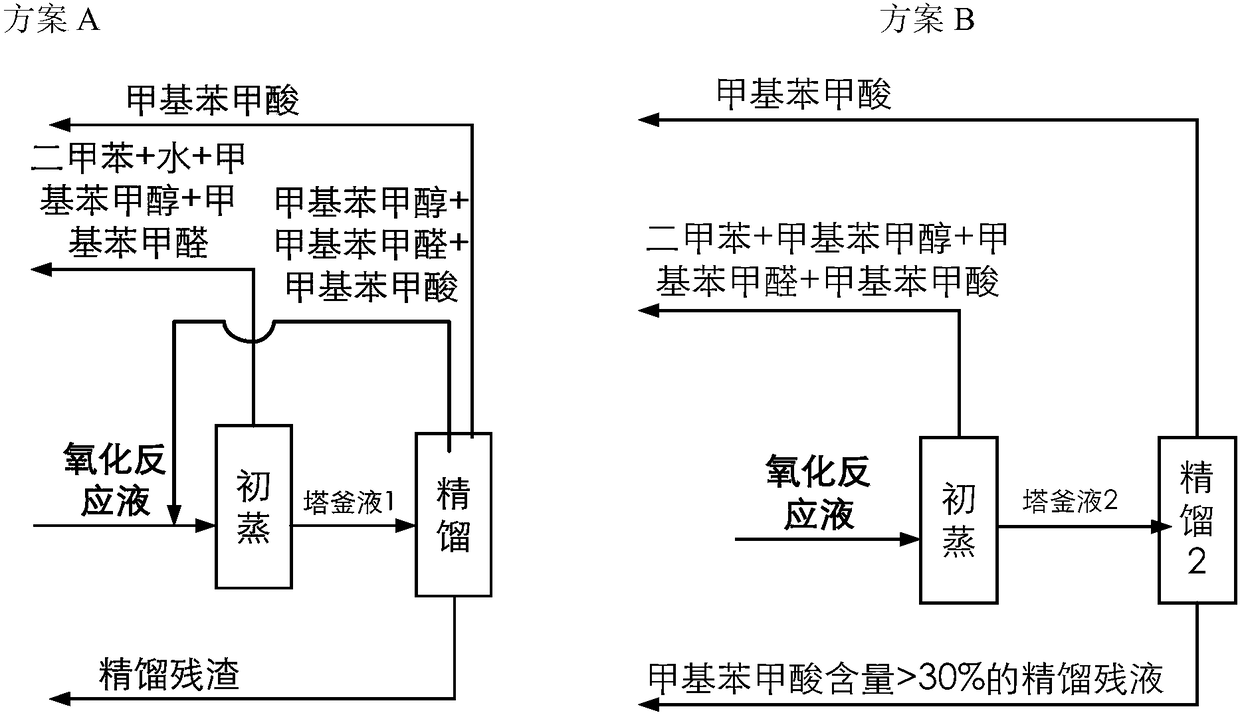

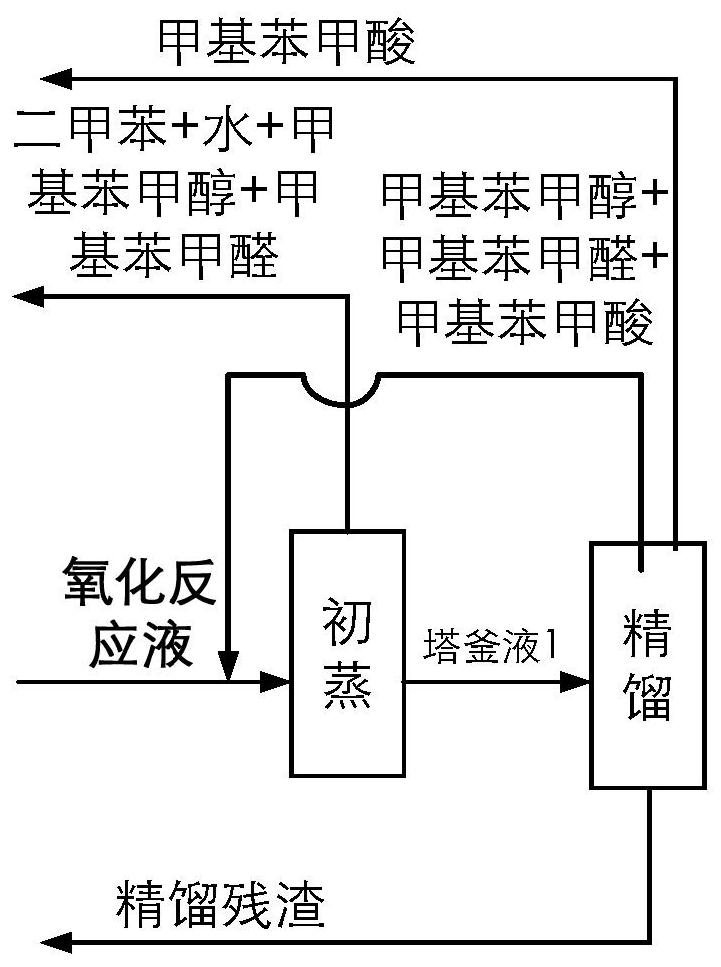

A method for co-producing methylbenzoic acid, methylbenzoic acid ester and phthalic acid diester

ActiveCN108047034BRaw materials are easy to getStructural diversificationOrganic compound preparationCarboxylic acid esters preparationBenzoic acidXylylene

The invention discloses a method for co-producing methyl benzoic acid, methyl benzoate and phthalic acid diester, comprising: (1) continuously feeding xylene, a catalyst and an oxygen-containing gas into an oxidation reactor to carry out reaction, by controlling the amount of oxygen-containing gas to control the tail oxygen concentration to be no more than 5%, to obtain an oxidation reaction liquid; (2) enter the obtained oxidation reaction liquid into an initial distillation tower for rectification separation, to obtain low boiling point components and initial (3) enter the rectifying tower still liquid into the rectifying tower for rectification to obtain toluic acid product and rectifying tower still liquid; (4) mix the rectifying tower tower liquid with alcohol , carry out the esterification reaction, control the reaction end point to be that the content of toluic acid<0.5wt%, obtain the esterification reaction solution; (5) carry out rectification separation with the esterification reaction solution obtained, obtain methyl benzoic acid ester respectively and diester phthalate products. The invention has the advantages of simple process, less equipment investment, environmental protection and good comprehensive economic benefits.

Owner:JIANGXI KEYUAN BIOPHARM

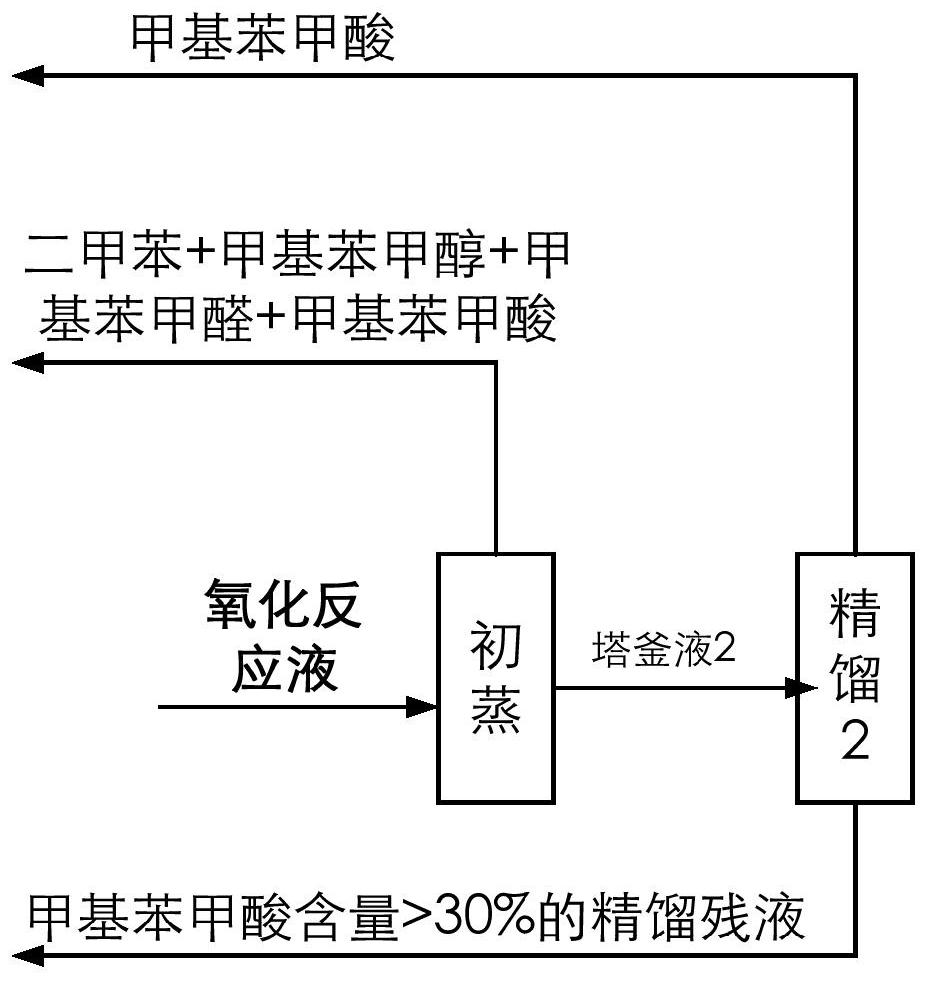

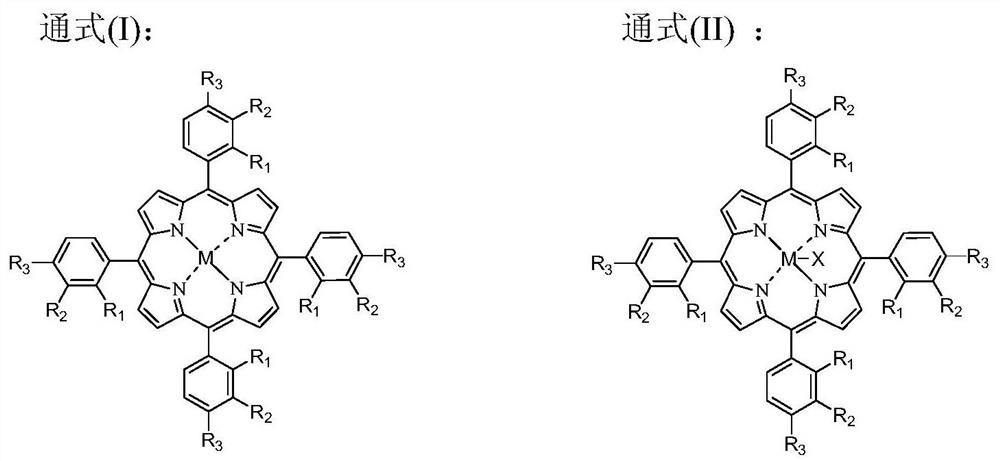

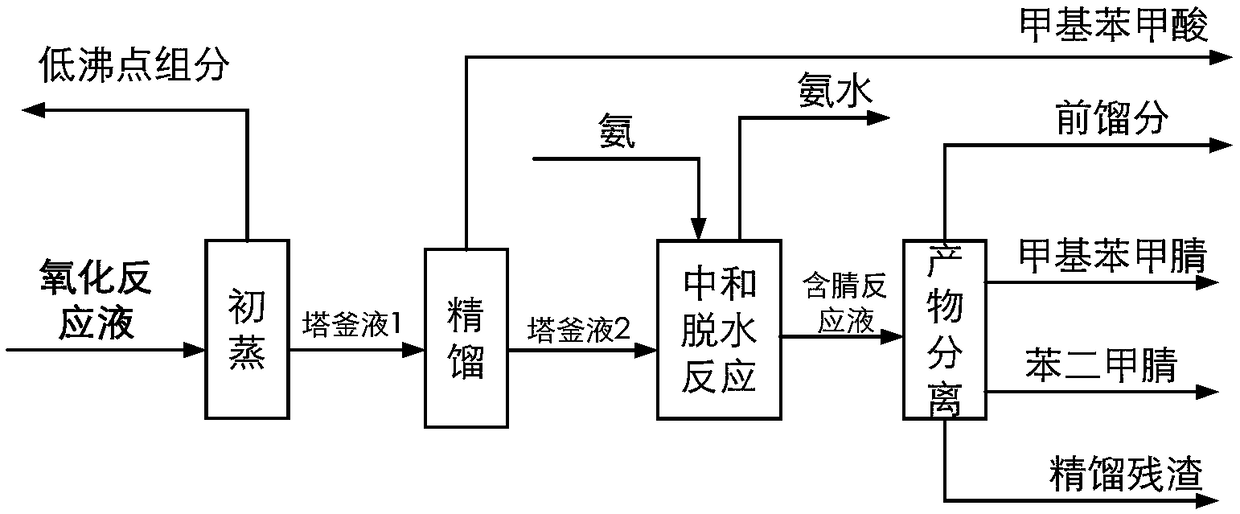

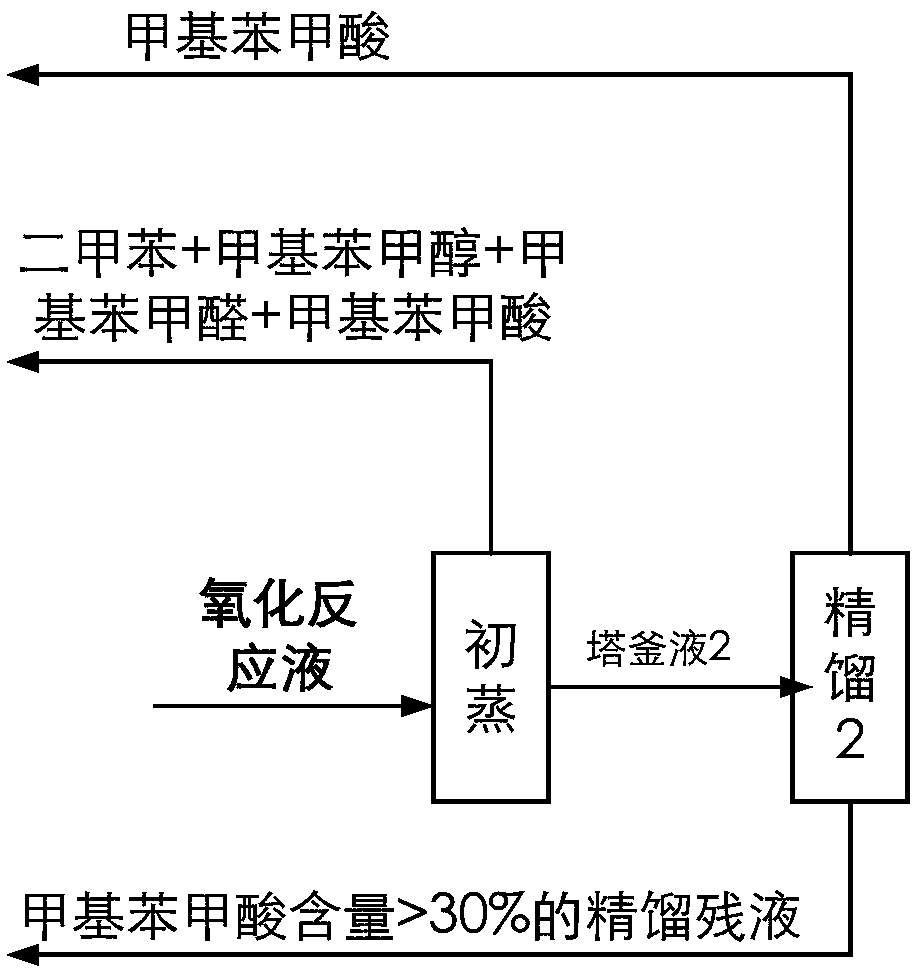

A kind of co-production methyl benzoic acid, methyl benzonitrile and phthalonitrile method

ActiveCN108863757BHigh concentration of production industryImprove concentrationOrganic compound preparationPreparation by ammonia-carboxylic acid reactionBenzoic acidPtru catalyst

The invention discloses a method for co-producing methylbenzoic acid, methylbenzonitrile and phthalonitrile, comprising: (1) continuously feeding xylene, a catalyst and an oxygen-containing gas into an oxidation reactor for reaction, Obtain the oxidation reaction liquid; (2) enter the oxidation reaction liquid into the initial distillation tower and carry out rectification separation, stop the rectification when the methyl benzyl alcohol content reaches 0.01~0.15wt% in the initial distillation tower bottom liquid, obtain low boiling point component and (3) enter the rectification tower with the initial distillation tower still liquid; (3) stop rectification when toluic acid content reaches 30~90wt% in the rectifying tower tower still liquid, obtain formosan (4) mixing the rectifying tower and tower liquid with ammonia to obtain a nitrile-containing reaction liquid; (5) carrying out rectification and separation of a nitrile-containing reaction liquid to obtain methylbenzene respectively Carbonitrile and phthalonitrile products. The invention has the advantages of simple process, less equipment investment, environmental protection and good comprehensive economic benefits.

Owner:JIANGXI KEYUAN BIOPHARM

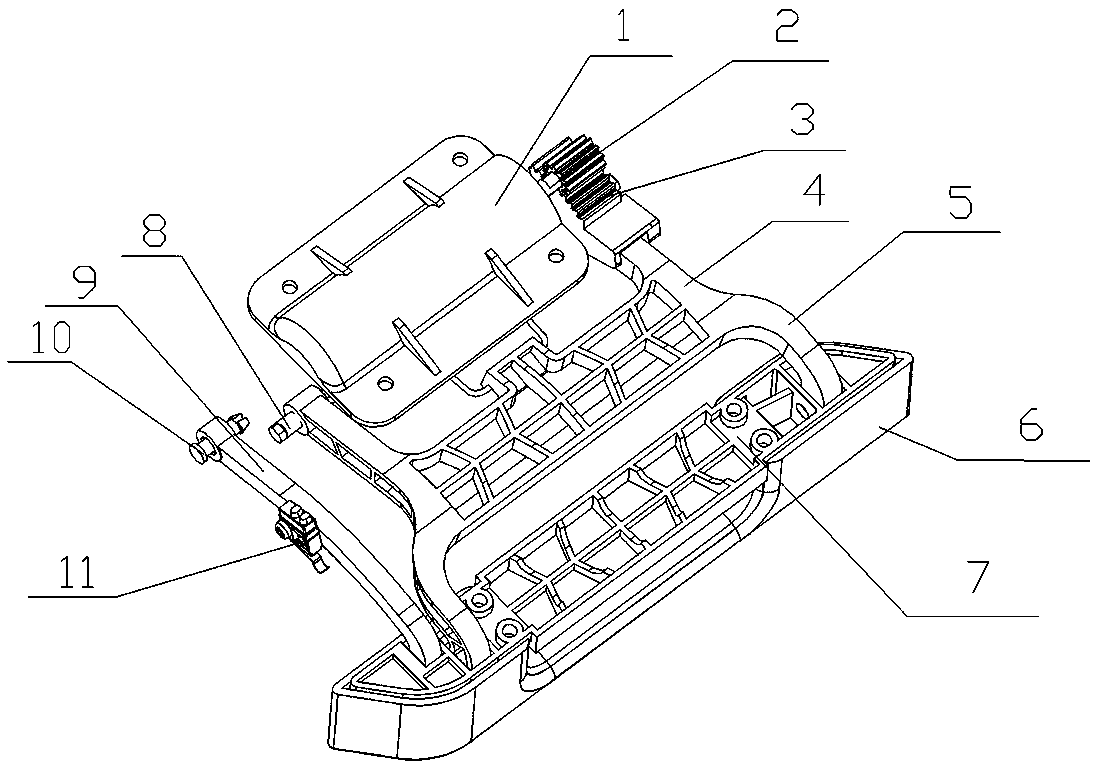

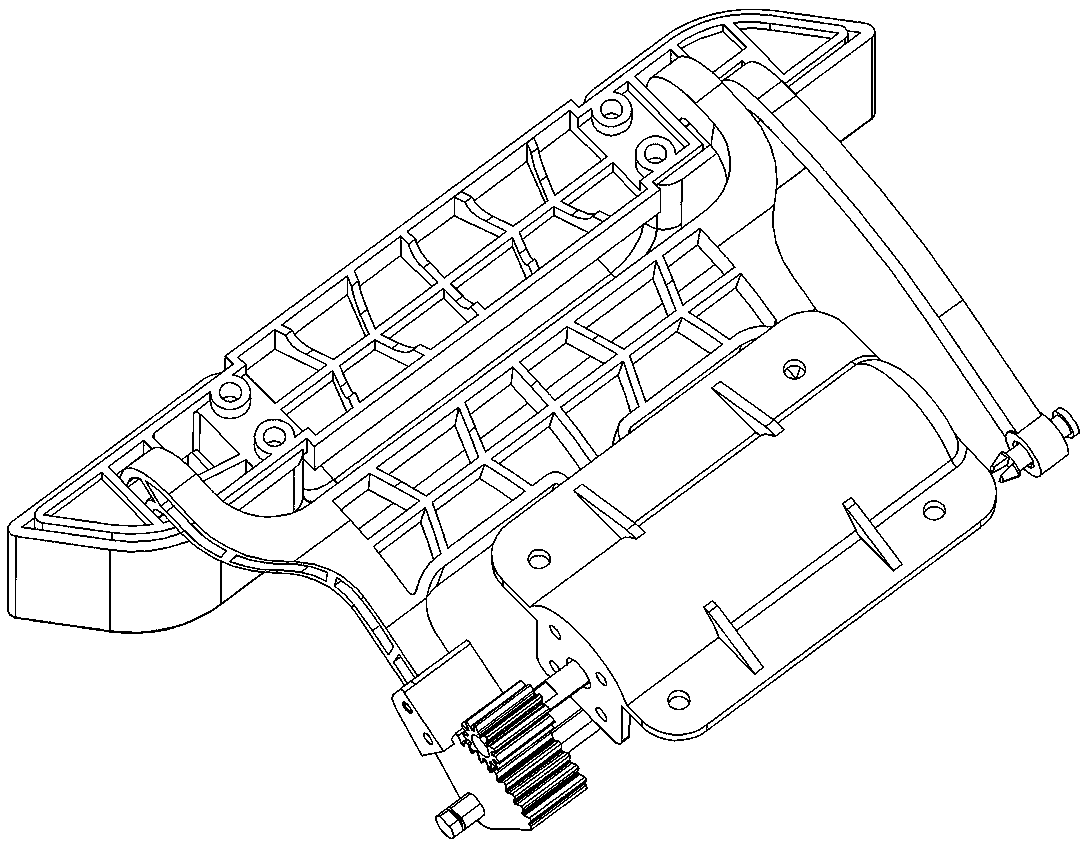

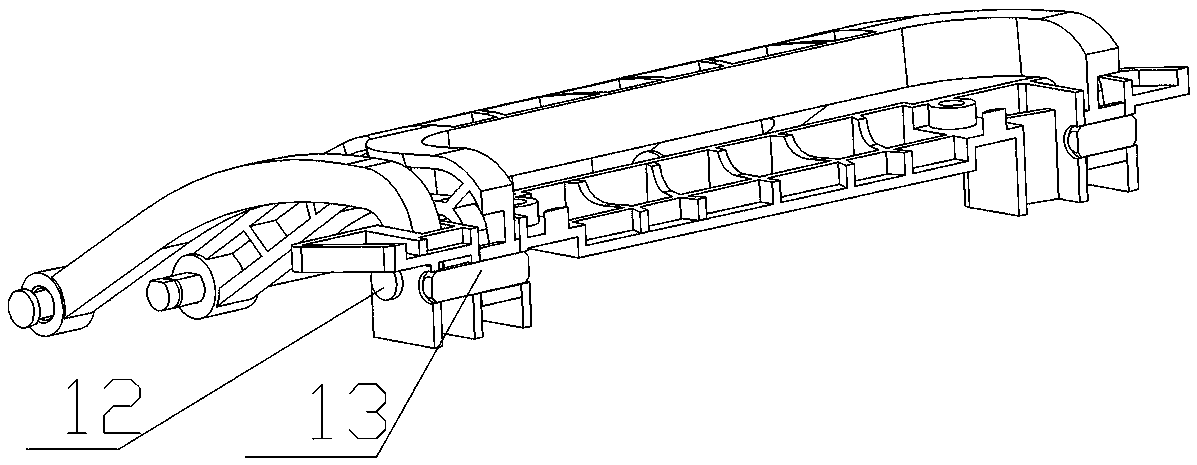

Parallel pop-up type hidden type outer pull handle

The invention relates to a parallel pop-up type hidden type outer pull handle. The outer pull handle comprises an outer pull handle body hidden in outer sheet metal, a base is fixed in the outer sheet metal, and the outer handle body is installed on the base through a handle connecting rod which is fixedly connected with the outer handle body; the base is hinged to one end of a main connecting rod through a main connecting rod pin shaft, and the other end of the main connecting rod is hinged to one side of a handle connecting rod through a first pin shaft; one end of an auxiliary connecting rod is hinged to the base through an auxiliary connecting rod pin shaft, the other end of the auxiliary connecting rod is hinged to the handle connecting rod through a second pin shaft, and the secondpin shaft is deviated from the first pin shaft; the main connecting rod is in transmission connection with the output end of a motor and is driven by the motor to rotate around the main connecting rodpin shaft, and the auxiliary connecting rod is driven to move along the auxiliary connecting rod pin shaft; and the handle connecting rod is relatively fixed with the second pin shaft through the first pin shaft and do parallel pop-up motion with radian. According to the outer pull handle, the handle is reasonably arranged, so that the handle is integrally popped up in parallel after a signal isobtained, and structure is more diversified.

Owner:NINGBO HUADE AUTOMOBILE PARTS

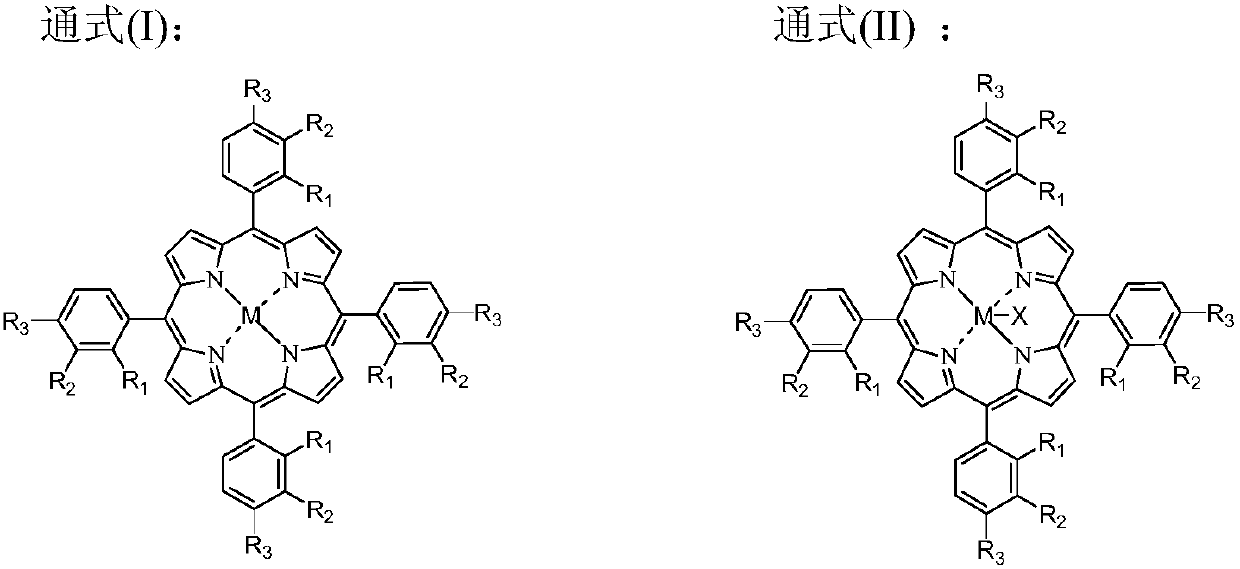

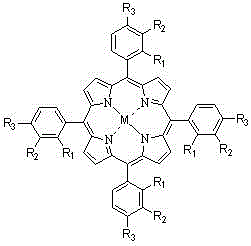

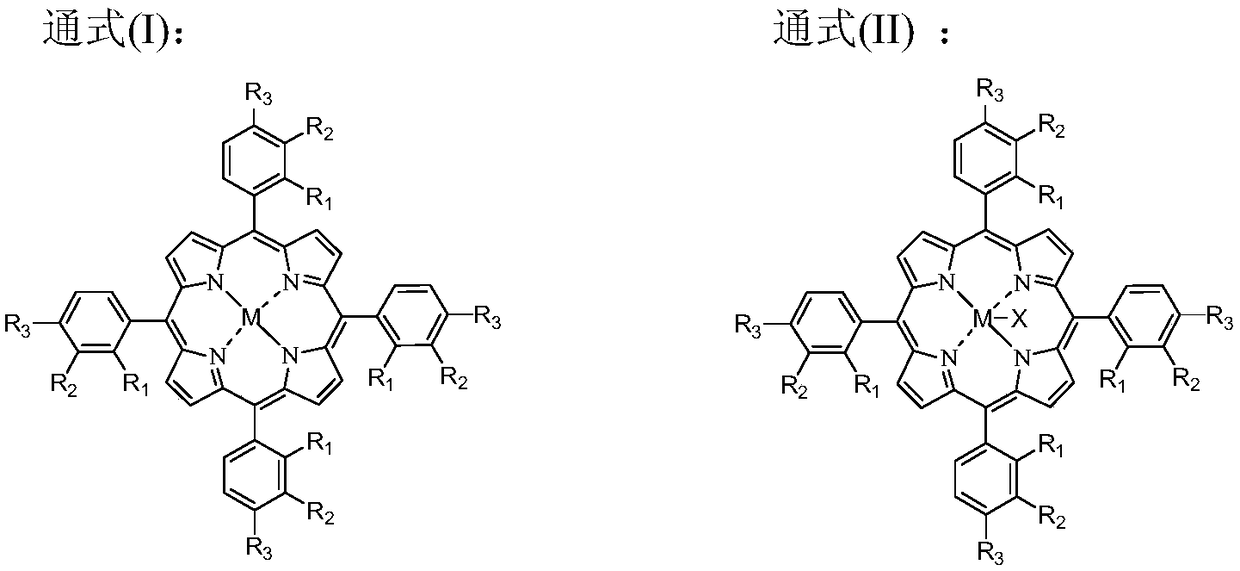

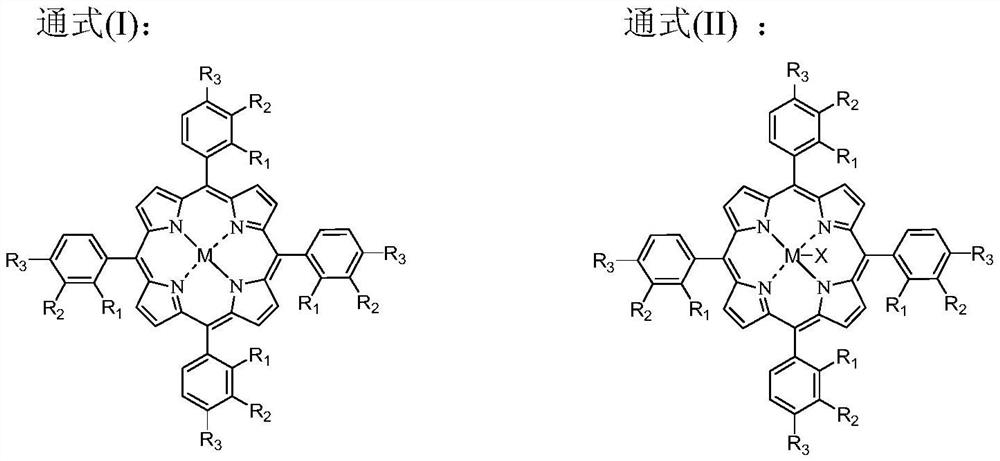

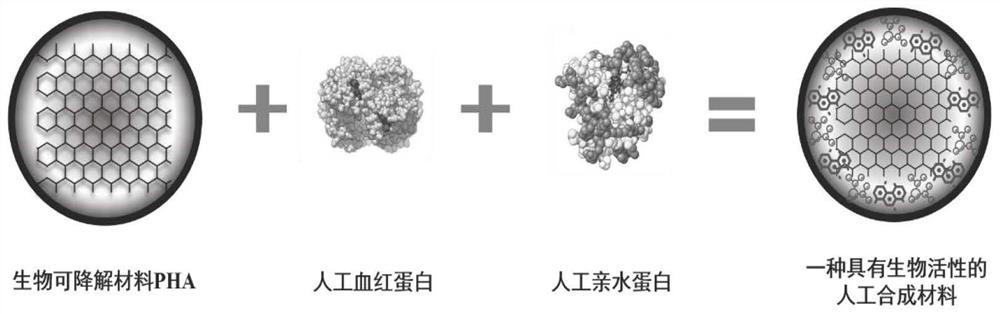

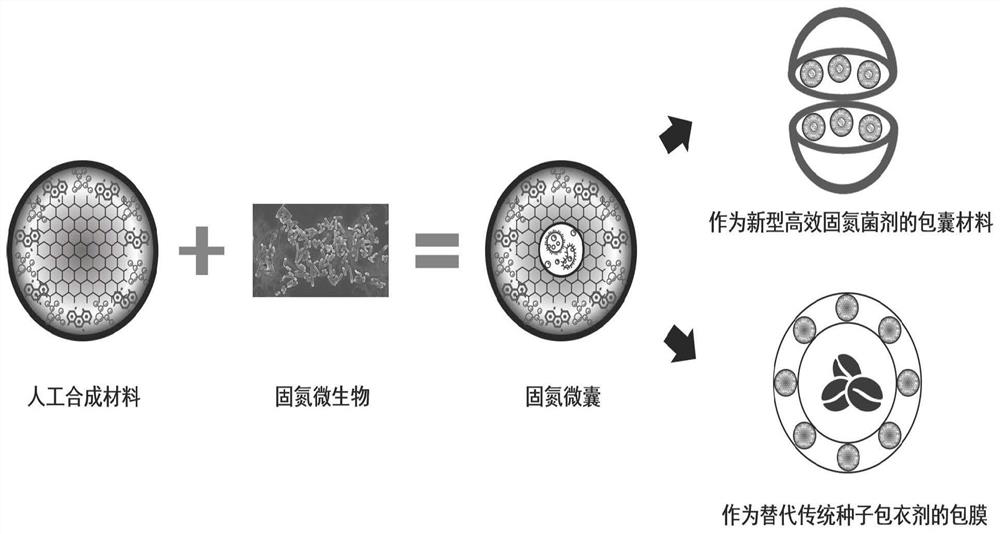

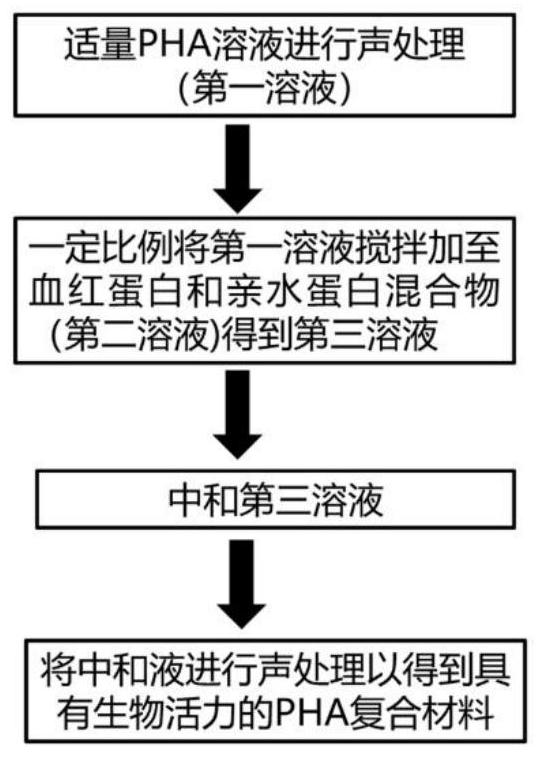

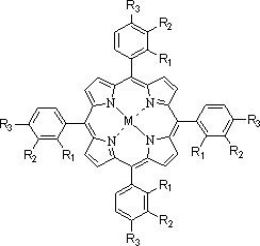

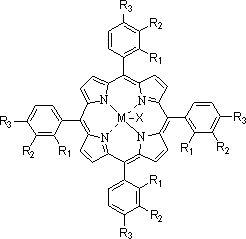

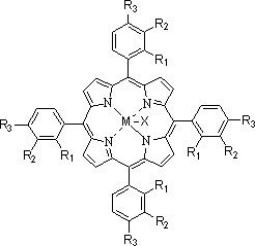

Artificial synthetic material with biological activity and agricultural application thereof

PendingCN113896786ABiodegradableBiologically activeBiocidePlant growth regulatorsBiotechnologyDrip irrigation

The invention provides an artificial synthetic material with biological activity and is applied to agriculture. The artificial synthetic material contains artificial hydrophilic protein, artificial hemoglobin and polyhydroxyalkanoate (PHA) which are designed and synthesized in the invention. The material can be used for preparing micron-sized active artificial micro-capsules, wrapping agricultural microbial excellent strains with the characteristics of nitrogen fixation, phosphorus and potassium solubilization, disease and pest resistance, growth promotion and the like to form a novel bacterial fertilizer, and can also be used in the agricultural fields of preparation of novel crop seed active coating agents and the like. The material has the unique properties of keeping thallus activity, directionally combining with root surface, accurately and efficiently fertilizing and the like, and is suitable for modern agricultural production modes such as mechanical seeding, water and fertilizer integrated drip irrigation, soilless culture and the like.

Owner:北京绿氮生物科技有限公司

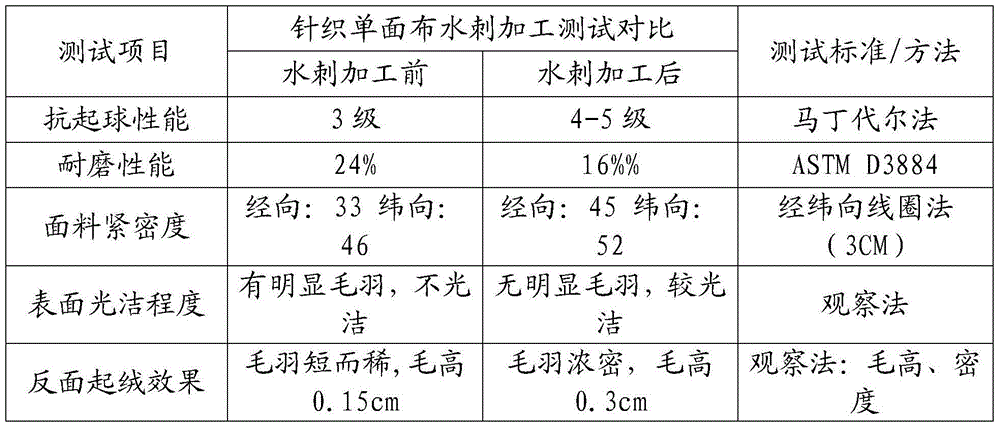

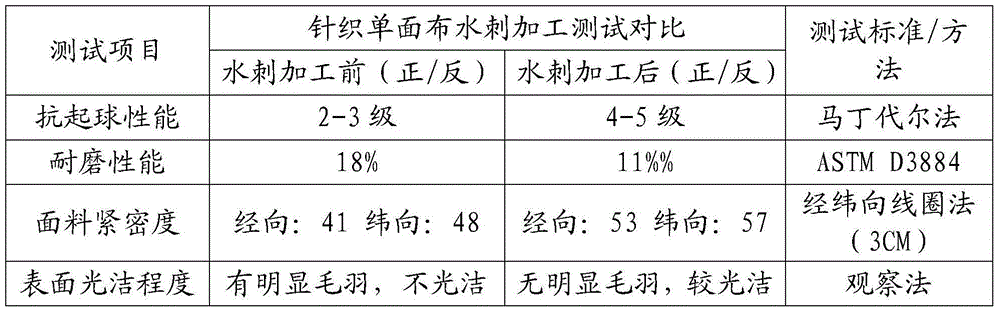

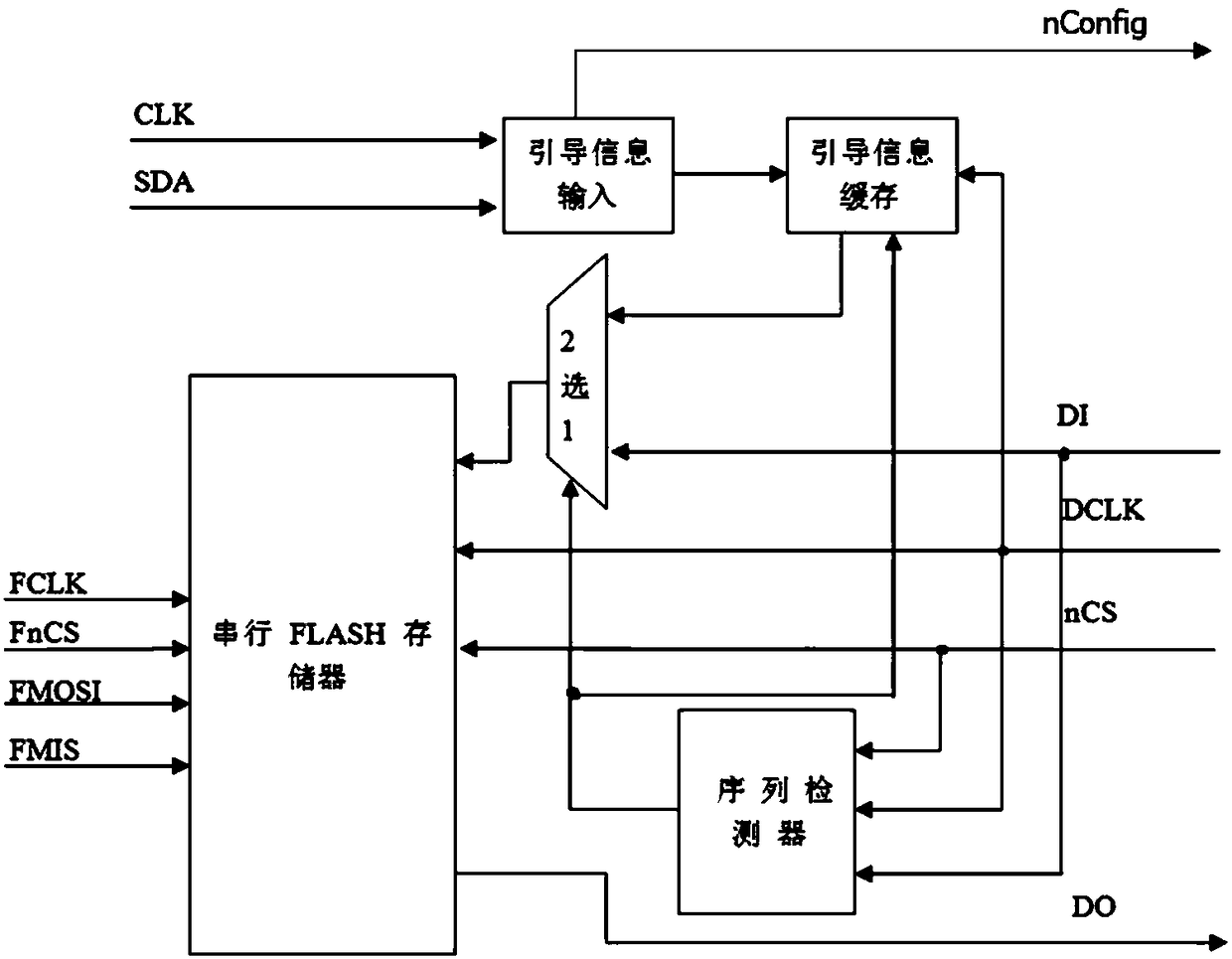

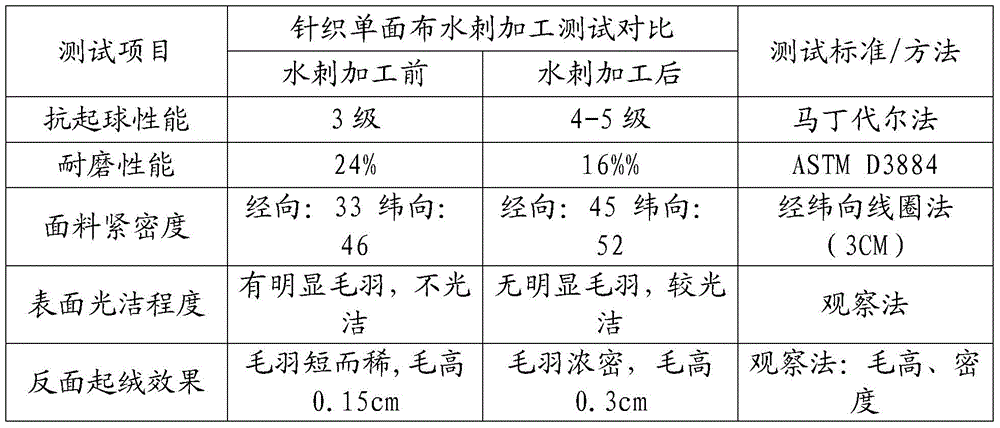

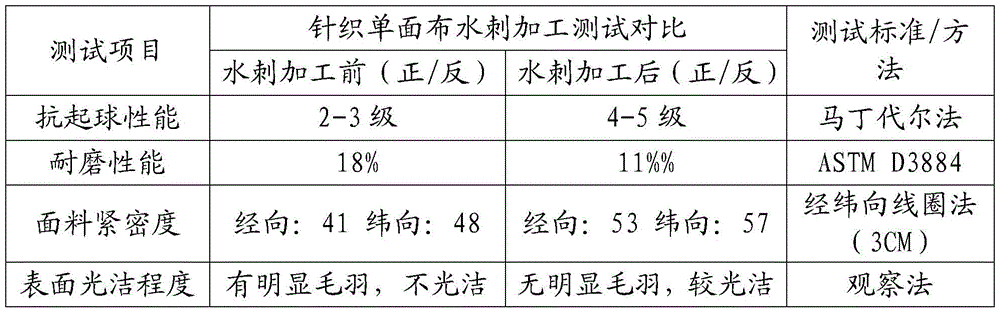

Non-oriented spunlace knitted fabric and machining method thereof

ActiveCN104631024AStructural diversificationReduce wasteWeft knittingFibre treatmentStructure propertyAfter treatment

The invention provides a non-oriented spunlace knitted fabric. The non-oriented spunlace knitted fabric is characterized in that a woven knitted fabric is subjected to after-treatment by using a spunlace machining method. The spunlace method is combined; aiming at a diversified structure property of the knitted fabric and being different from a warp and weft structure of the woven fabric, the spunlace method is researched and a non-oriented spunlace machining process is carried out on the knitted fabric, so that the physical performances of the knitted fabric are improved; and the yarn strength, the moisture absorption property, the hand feeling and the appearance of the knitted fabric are greatly improved. Meanwhile, the cost is lowered and the pollution to the environment is alleviated.

Owner:SHANGHAI JIALE

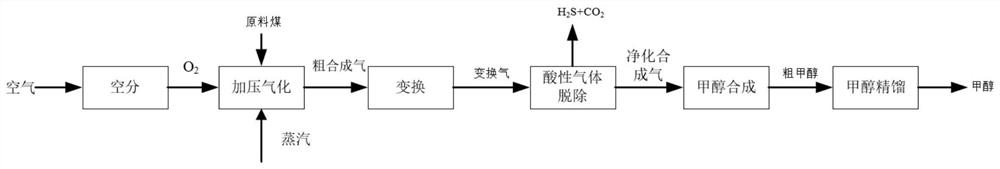

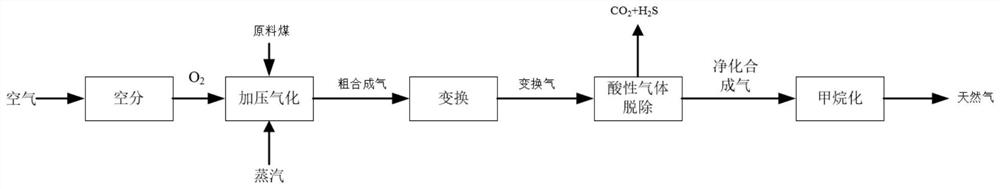

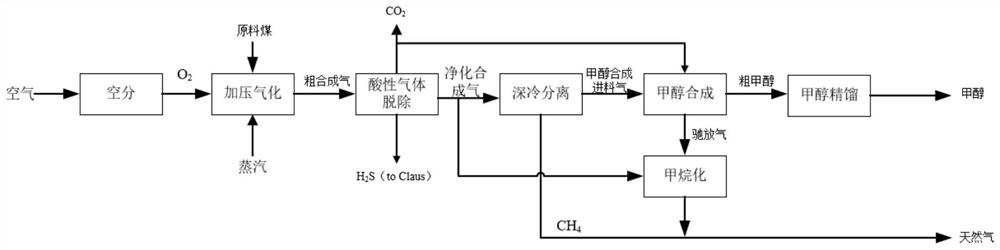

A system and method for coal-to-natural gas co-production of methanol

ActiveCN110862839BIncrease profitDeal effectively with volatilityOrganic compound preparationGaseous fuelsThermodynamicsMethanation

The invention belongs to the technical field of coal chemical industry, and in particular relates to a system and method for coal-to-natural gas co-production of methanol. The system includes air separation unit, coal gasification unit, acid gas removal unit, cryogenic separation unit, methanation unit, methanol synthesis unit and methanol rectification unit. This method uses the carbon dioxide discharged from the acid gas removal unit as the raw material gas for methanol synthesis, which can not only ensure the optimal hydrogen-carbon ratio of the methanol synthesis unit, increase the output of methanol, but also reduce CO 2 emissions; supplementing the hydrogen-rich purge gas from the methanol synthesis unit to the methanation unit can not only ensure the optimal hydrogen-carbon ratio of the methanation unit, increase the production of SNG, but also reduce the purge gas emissions. The method improves the utilization rate of carbon element and hydrogen element by coproducing natural gas and methanol, wherein the utilization rate of carbon element can reach more than 50%, and the utilization rate of hydrogen element can reach more than 65%. The amount of natural gas and methanol output can be adjusted according to changes in market prices.

Owner:SOUTH CHINA UNIV OF TECH

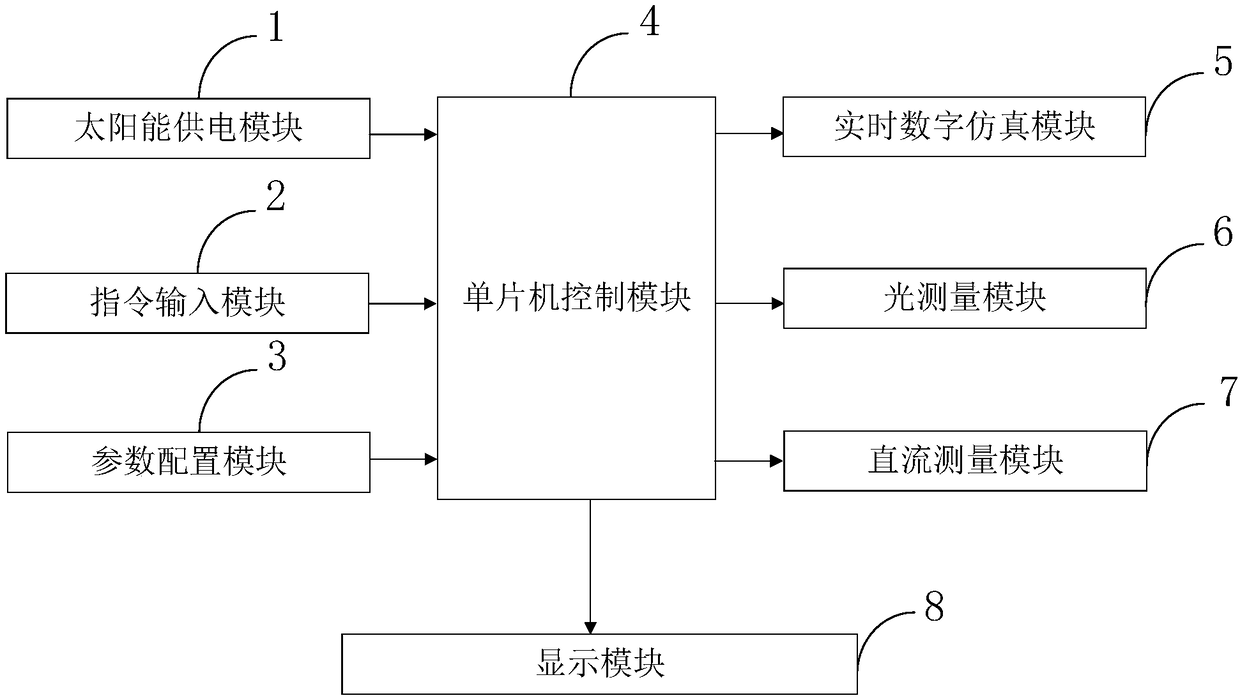

Intelligent electrical engineering measurement system

InactiveCN108319783AAvoid outagesSave energyProgramme controlComputer controlMicrocontrollerSolar power

The invention, within the technical field of electrical measurement, discloses an intelligent electrical engineering measurement system. The system comprises a solar power supply module, command inputmodule, parameter configuration module, single chip control module, real-time digital simulation module, light measurement module, fault measurement module, display module. The system can obtain clean and efficient solar energy through the solar power supply module, save energy, and be economical and environmentally friendly. The system can be permanently powered to avoid interruptions during electrical engineering measurements; at the same time, the measurement by the fault measurement module is more comprehensive, and the troubleshooting efficiency is improved.

Owner:LUDONG UNIVERSITY

A non-directional spunlace knitted fabric and its processing method

ActiveCN104631024BStructural diversificationReduce wasteWeft knittingFibre treatmentAfter treatmentStructure property

The invention provides a non-oriented spunlace knitted fabric. The non-oriented spunlace knitted fabric is characterized in that a woven knitted fabric is subjected to after-treatment by using a spunlace machining method. The spunlace method is combined; aiming at a diversified structure property of the knitted fabric and being different from a warp and weft structure of the woven fabric, the spunlace method is researched and a non-oriented spunlace machining process is carried out on the knitted fabric, so that the physical performances of the knitted fabric are improved; and the yarn strength, the moisture absorption property, the hand feeling and the appearance of the knitted fabric are greatly improved. Meanwhile, the cost is lowered and the pollution to the environment is alleviated.

Owner:SHANGHAI JIALE

A method for co-producing methylbenzoic acid, methylbenzoyl chloride and phthaloyl chloride

ActiveCN108117486BHigh concentration of production industryRaw materials are easy to getOrganic compound preparationCarboxylic compound separation/purificationBenzoic acidXylylene

The invention discloses a method of co-producing methyl benzoic acid, methylbenzoyl chloride and phthaloyl dichloride. The method comprises the following steps: (1) continuously introducing xylene, acatalyst and oxygen-containing gas into an oxidizing reactor to react to obtain an oxidized reaction solution; (2) rectifying and separating the oxidized reaction solution to obtain a low-boiling-point component and an initial evaporative tower bottom; (3) rectifying the initial evaporative tower bottom to obtain a methyl benzoic acid product and a tower bottom; (4) carrying out an acylating chlorination reaction on the tower bottom and an acylating chlorination reagent to obtain an acyl chloride reaction solution; and (5) rectifying and separating the acyl chloride reaction solution to separately obtain methylbenzoyl chloride and phthaloyl dichloride products. The method provided by the invention has the advantages of being simple in process, small in equipment investment, green and environment-friendly and good in comprehensive economical benefit.

Owner:JIANGXI KEYUAN BIOPHARM

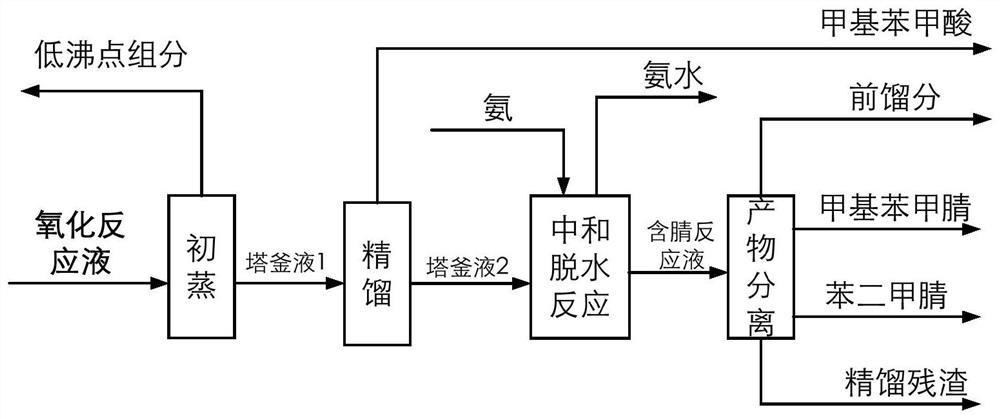

Method for coproducing methylbenzoic acid, methyl benzonitrie and phthalonitrile

ActiveCN108863757AAvoid Rectification BottomsLess wasteOrganic compound preparationPreparation by ammonia-carboxylic acid reactionPhthalonitrileChemistry

The invention discloses a method for coproducing methylbenzoic acid, methyl benzonitrie and phthalonitrile. The method comprises the following steps: (1) continuously introducing xylol, a catalyst andoxygen-containing gas into an oxidation reactor and reacting to obtain an oxidation reaction solution; (2) conveying the oxidation reaction solution into a primary evaporation tower and carrying outrectification separation; when the content of methylbenzyl alcohol in a tower kettle solution of the primary evaporation tower reaches 0.01 to 0.15 weight percent, stopping rectification, so as to obtain a low-boiling-point component and the tower kettle solution of the primary evaporation tower; (3) conveying the tower kettle solution of the primary evaporation tower into a rectification tower and carrying out rectification; when the content of the methylbenzoic acid in a tower kettle solution of the rectification tower reaches 30 to 90 weight percent, stopping rectification, so as to obtaina methylbenzoic acid product and the tower kettle solution of the rectification tower; (4) mixing the tower kettle solution of the rectification tower and ammonia to obtain a nitrile-containing reaction solution; (5) carrying out rectification separation on the nitrile-containing reaction solution to obtain methyl benzonitrie and phthalonitrile products. The method disclosed by the invention has the advantages of simple technology, few equipment investment, greenness and environment protection and good comprehensive economic benefits.

Owner:JIANGXI KEYUAN BIOPHARM

A method for co-producing benzoic acid, p-toluic acid and m-toluic acid

ActiveCN106831392BWide variety of sourcesLow priceOrganic compound preparationCarboxylic compound separation/purificationBenzoic acidXylylene

The invention discloses a method for co-producing benzoic acid, p-toluylic acid and m-methylbenzoate. The method comprises the following steps of (1) oxidizing: adding a xylene mixture, a catalyst and an oxygen-containing gas into an oxidation reactor to react, wherein the content of oxygen in the oxygen-containing gas in percentage by mass is no less than 15%; (2) gas and liquid separating and purifying: sending an oxidation reaction liquid into a gas and liquid separator, condensing and separating a gas phase part, circulating the condensate into the oxidation reaction liquid to continue to oxide, treating and exhausting the non-condensing gas, and performing conventional rectification on a liquid phase part, so as to obtain a low-boiling point component of which the boiling point is lower than the boiling point of benzoic acid; circulating into the oxidation reactor to continue to oxide, and performing further conventional rectification on the tower bottom component, so as to sequentially obtain the benzoic acid, m-methylbenzoate and p-toluylic acid products. The method has the advantages that the technology is simple, the cost of raw material is low, the equipment investment is little, the yield rate is high, the selectivity is good, and the economic benefit is good.

Owner:山东友道化学有限公司

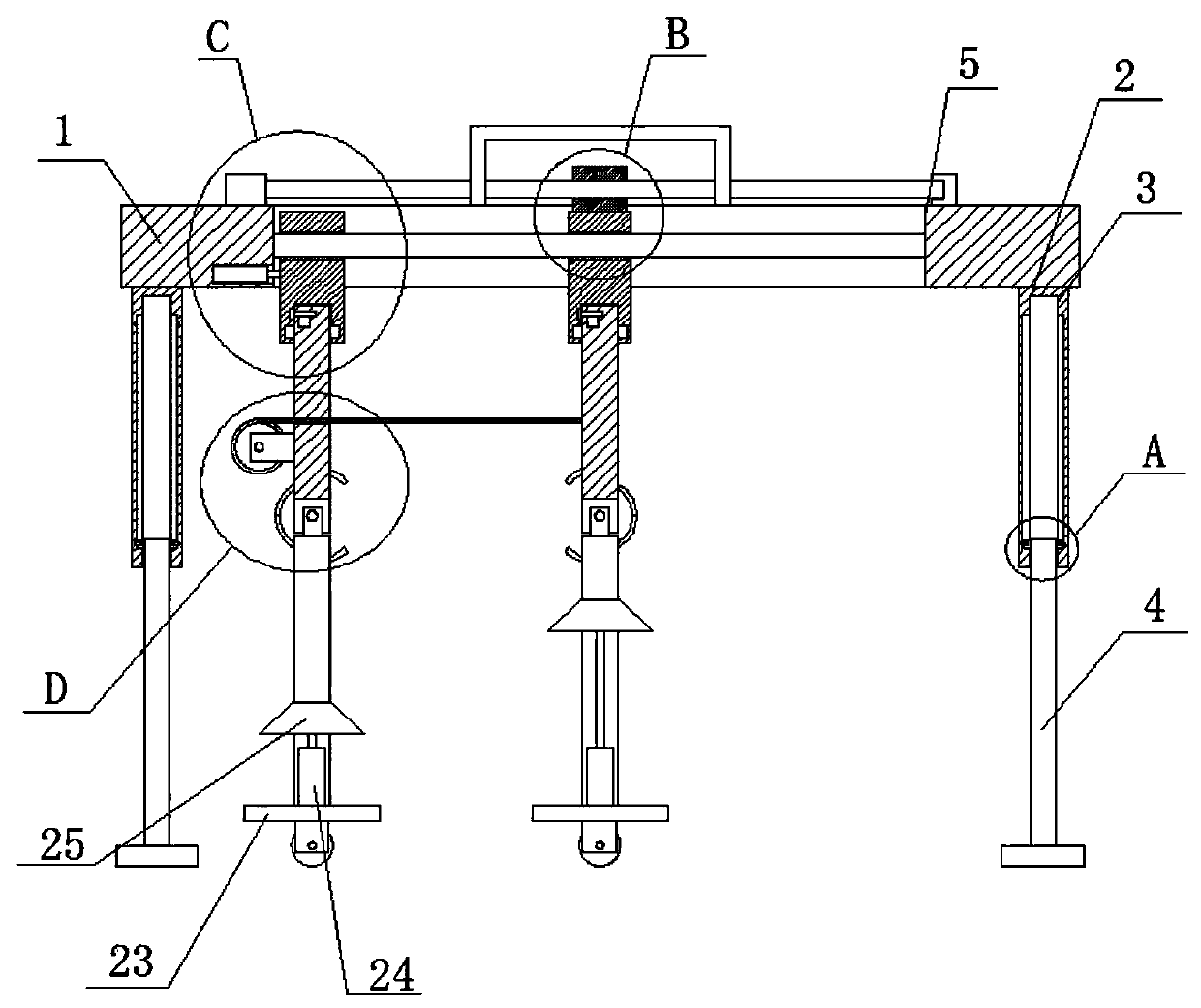

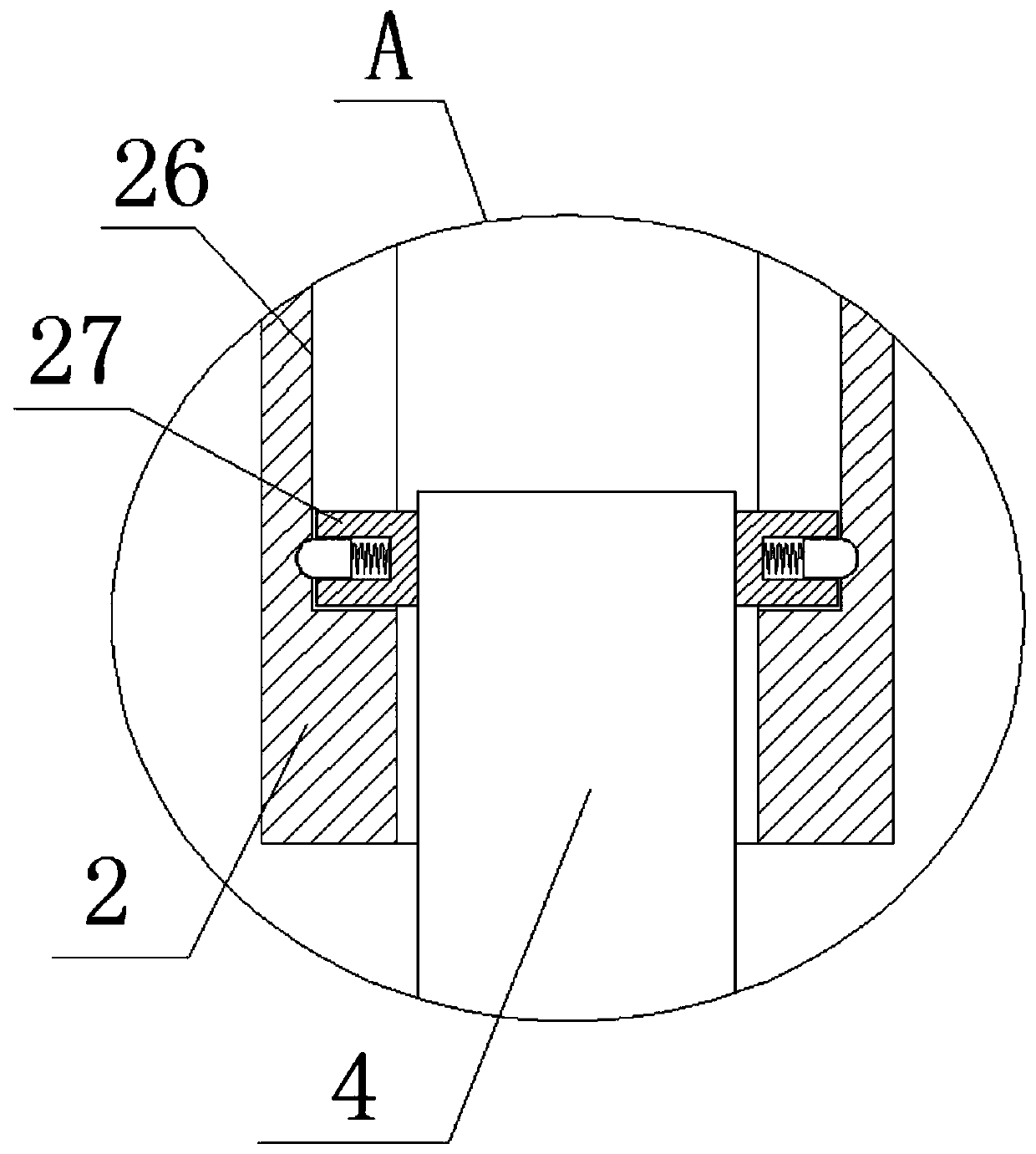

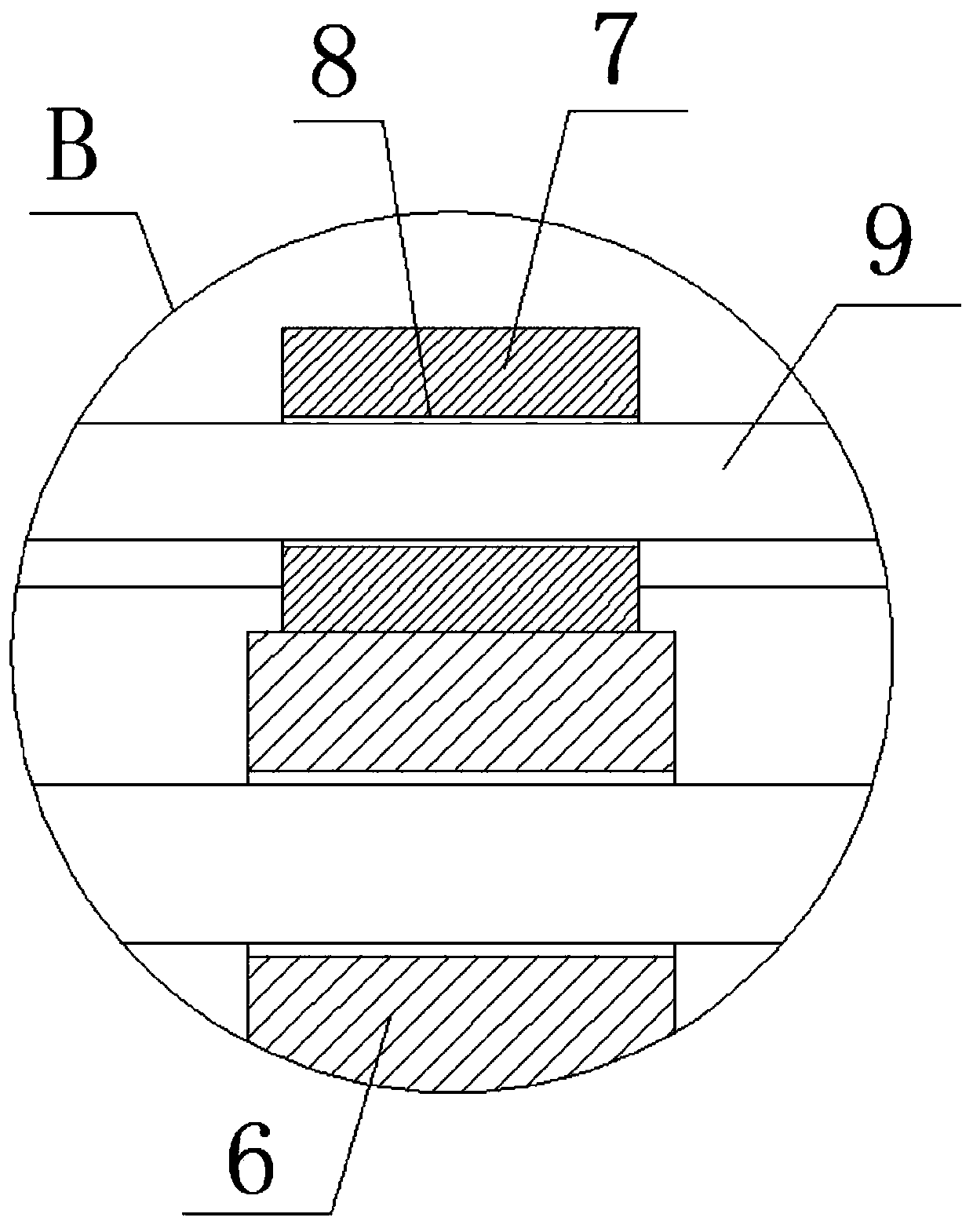

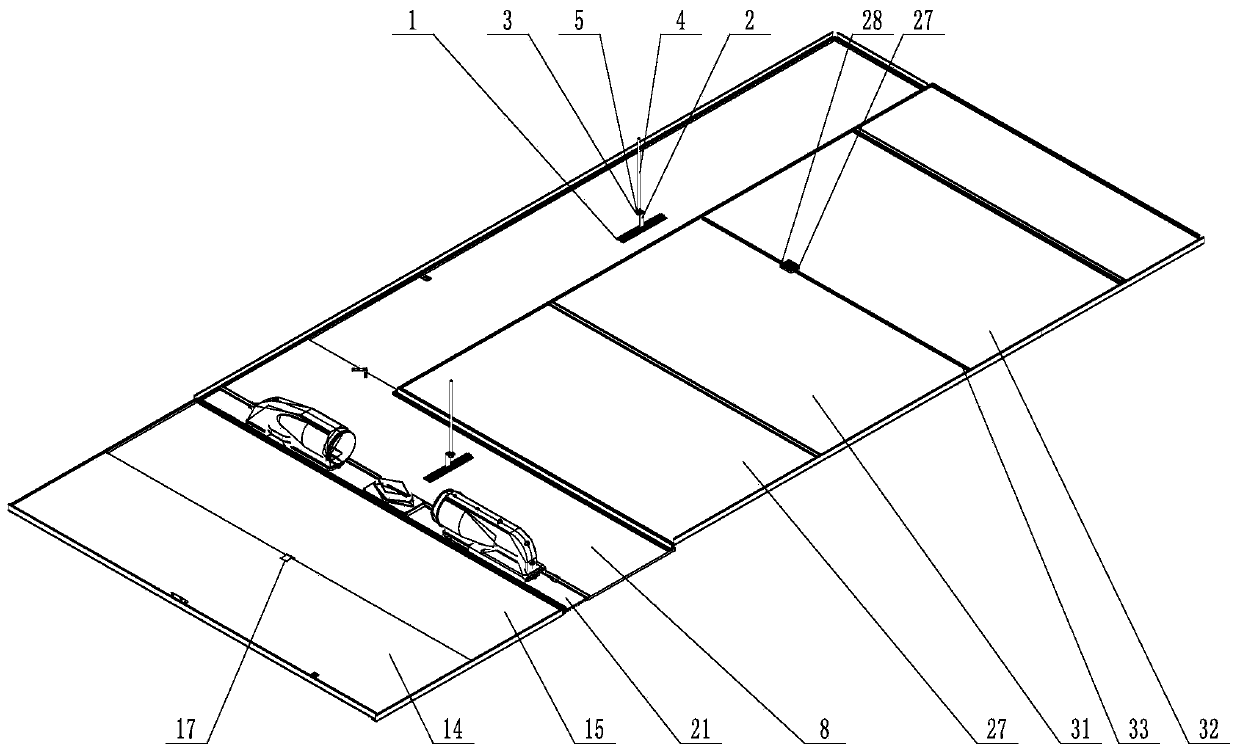

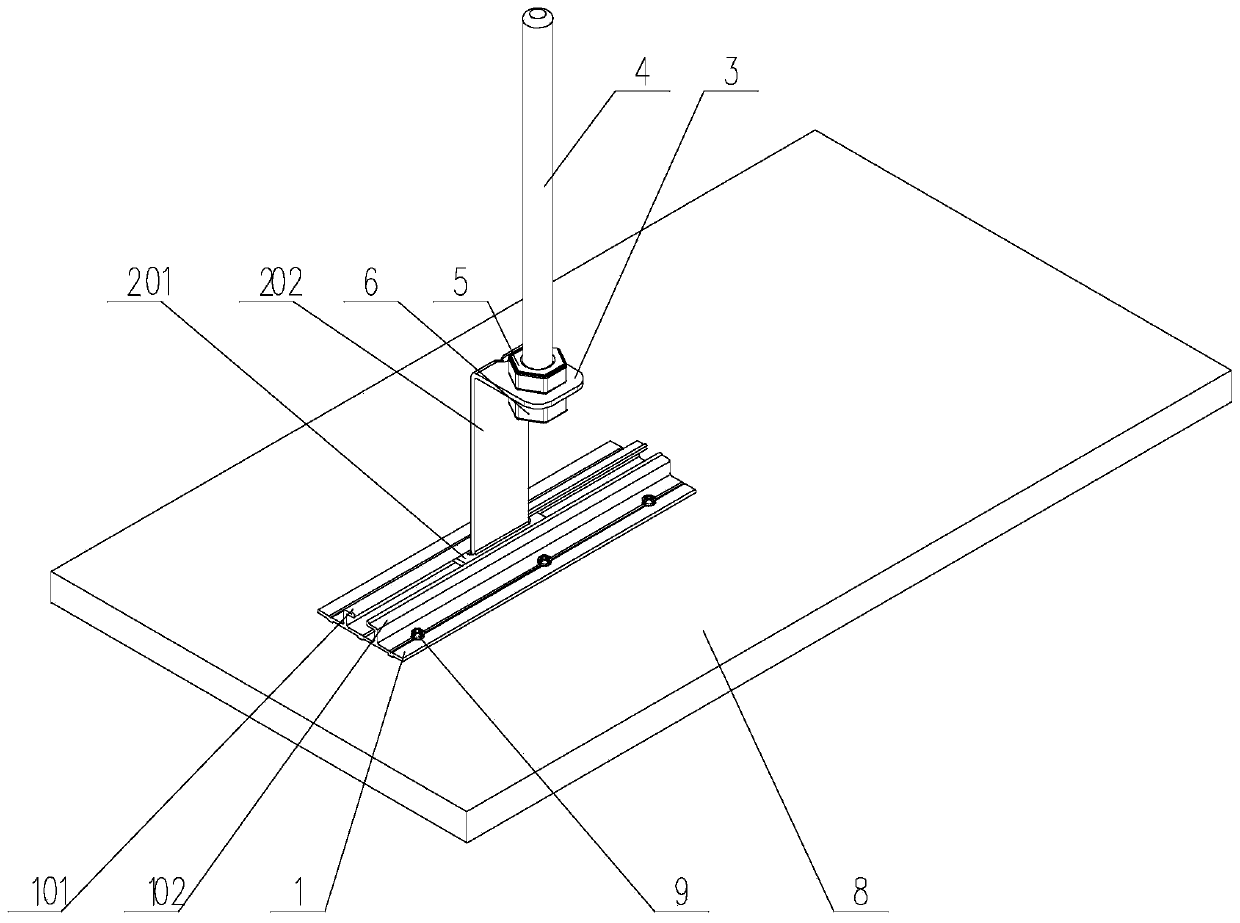

A device for measuring vehicle dimensions

ActiveCN109612421BEasy to carry and useStructural diversificationMeasurement devicesElectric machineryScrew thread

Owner:广西微车检智能科技有限公司

Self-lubricating composite coating, coating preparation method and article with the coating

ActiveCN107513684BReduce stressImprove bindingVacuum evaporation coatingSputtering coatingMaterials scienceTribology

The invention discloses a self-lubricating composite coating, a coating preparation method and products with the coating. The self-lubricating composite coating of the present invention comprises several AlSn20Cu layers and several MoS 2 layer, AlSn20Cu layer with MoS 2 Layers are set alternately. The self-lubricating composite coating provided by the present invention introduces MoS into the original AlSn20Cu coating 2 The lubricating layer makes the coating composition and structure diversified, which can effectively reduce the stress of the coating and improve the bonding force of the film base. In addition, MoS 2 The introduction of phases can greatly improve the tribological properties of AlSn20Cu coatings in oil-poor and dry friction environments without changing the original lubricating properties of AlSn20Cu coatings.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

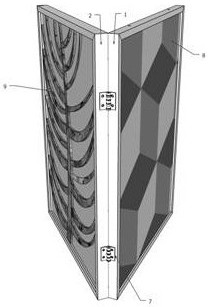

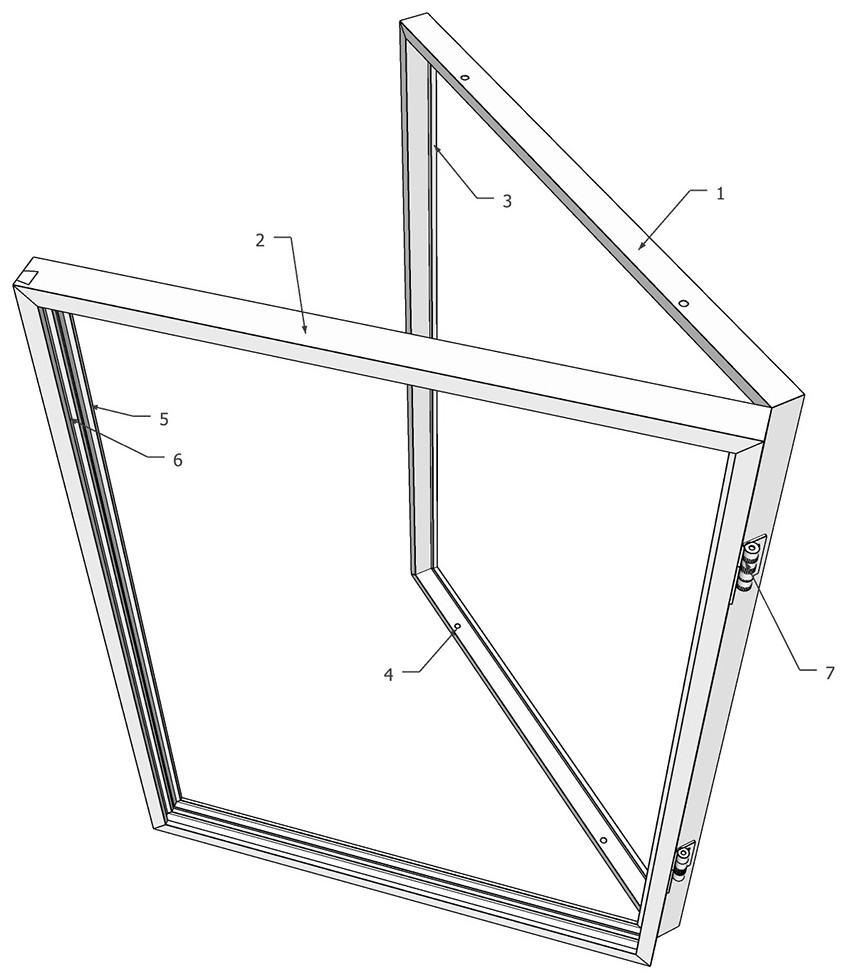

Four-side display combined frame

InactiveCN112167908AStructural diversificationFreedom of expressionPicture framesDomestic mirrorsComputer graphics (images)

Owner:深圳市待秀君科技有限公司

High-sulfur light distillate and organic heat-carrier raw oil mixing process

InactiveCN109266381AImprove the economic efficiency of the deviceSimple production processHydrocarbon oils treatmentRefining to eliminate hetero atomsHeat carrierChemistry

The invention discloses a high-sulfur light distillate and organic heat-carrier raw oil mixing process and belongs to the technical field of oil hydrogenation. The process is characterized by proportionally mixing high-sulfur light distillate and organic heat-carrier raw oil to produce lubricant base oil and light white oil; hydrogenation conditions for a first reactor and a second reactor: hydrogen partial pressure ranges from 15 MPa to 17.2 MPa, content of H2S of recycle gas ranges from 100 ppm to 500 ppm, airspeed ranges from 0.78 h<-1> to 0.83h<-1>, volume ratio of hydrogen to oil ranges from 500 to 600, and reaction temperature ranges from 300 / 280 DEG C to 306 / 285 DEG C; products of hydrogenation reaction are separated to obtain the lubricant base oil and the light white oil. According to the technology, different raw oil such as the high-sulfur light distillate and the organic heat-carrier are mixed proportionally, and then are used for producing two different products, namely the lubricant base oil and the light white oil, through the same device and the same catalyst.

Owner:山东齐胜工贸股份有限公司

Integrated decorative suspended ceiling

PendingCN111042425AEliminate fit gapsGuaranteed synchronicityCeilingsStructural engineeringMechanical engineering

The invention discloses an integrated decorative suspended ceiling, which comprises a suspended ceiling module, a decorative plate staggered overlapping module and a decorative plate flat connecting module, wherein the suspended ceiling module comprises a suspended ceiling plate parallel to a horizontal plane and a suspended ceiling fastener for fixing the suspended ceiling plate below the ceiling, two sides of the suspended ceiling plate are respectively connected with the decorative plate flat connecting module and the decorative plate staggered overlapping module, and the lower surface of the suspended ceiling plate is a decorative surface. The ceiling module, the decorative plate staggered overlapping module and the decorative plate flat connecting module are combined to form the novelintegrated decorative ceiling, so that the ceiling structure is diversified and more three-dimensional, and the aesthetic feeling of the ceiling is improved.

Owner:成都劲启家居有限公司

Method for preparing ceramic raw material from waste granite stone

ActiveCN110743684BImprove economic indicatorsComprehensive utilization to improve quality and efficiencyMagnetic separationGrain treatmentsGlass-ceramicMagnetic separation

The present invention proposes a method for preparing ceramic raw materials from granite stone waste rock, which includes multi-stage crushing, laminated crushing, coarse grain pre-selection, pre-grading, partial grinding, multi-stage magnetic separation, classification and separation, and superconducting strong magnetic separation And graded dehydration and other processes. The present invention is a pollution-free and environmentally friendly physical technology for the whole process; the comprehensive technical and economic indicators are significantly improved compared with the traditional technology, and K 2 O: 6‑10wt%, Na 2 O:0.5‑3.5wt%, SiO 2 :65‑74wt%, Fe 2 o 3 <0.15wt%, high-quality glass and ceramic raw materials with a whiteness of 60-68, the whiteness of the product is increased from 50-53 to 60-68 degrees, the yield is increased from 51-55% to 65-72%, and the processing capacity can be increased by 13% ‑18%; the product structure is refined and diversified, and suitable products are provided for material homogenization and energy saving and consumption reduction in the downstream glass and ceramic industries.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Micro-concave roller gap engraving process

PendingCN114571088AExpand the scope of useReduce difficultyMetal working apparatusLaser beam welding apparatusDiaphragm structureCarving

The invention discloses a micro-concave roller gap engraving process, and belongs to the technical field of production of lithium electronic diaphragms. The method comprises the following steps that the roller surface of the micro-concave roller is divided into a carving area and a blank area, and the carving area is carved; according to the invention, the conventional micro-concave roller reticulate pattern design is abandoned, and the reticulate pattern roller is designed according to the diaphragm to be coated in a clearance carving manner, so that the difficulty of special coating is solved in a targeted manner, the diaphragm coating is not limited by the reticulate pattern carved by the micro-concave roller in a full-width manner any more, and the coated diaphragm structure is more diversified.

Owner:华鼎国联四川动力电池有限公司

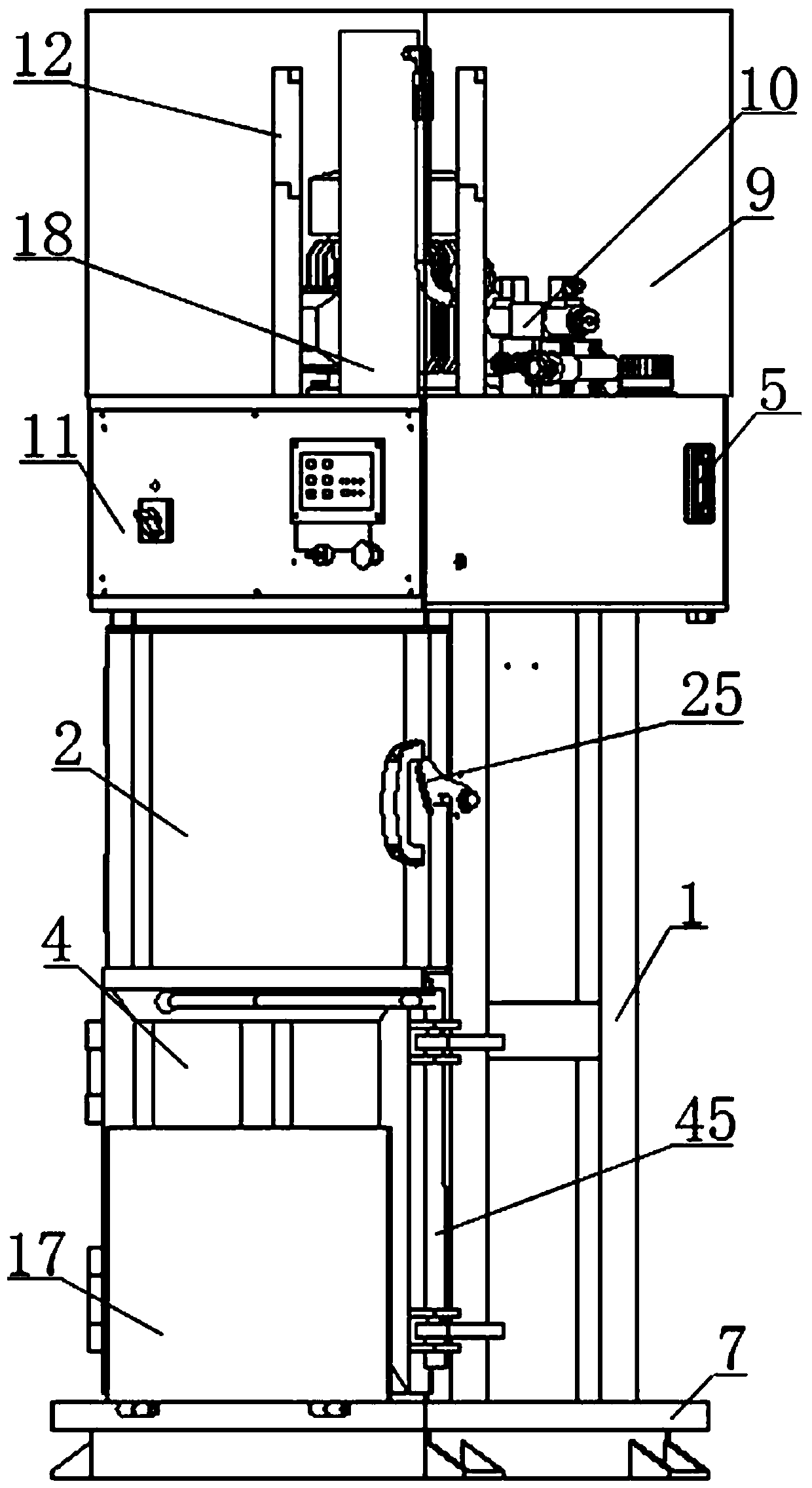

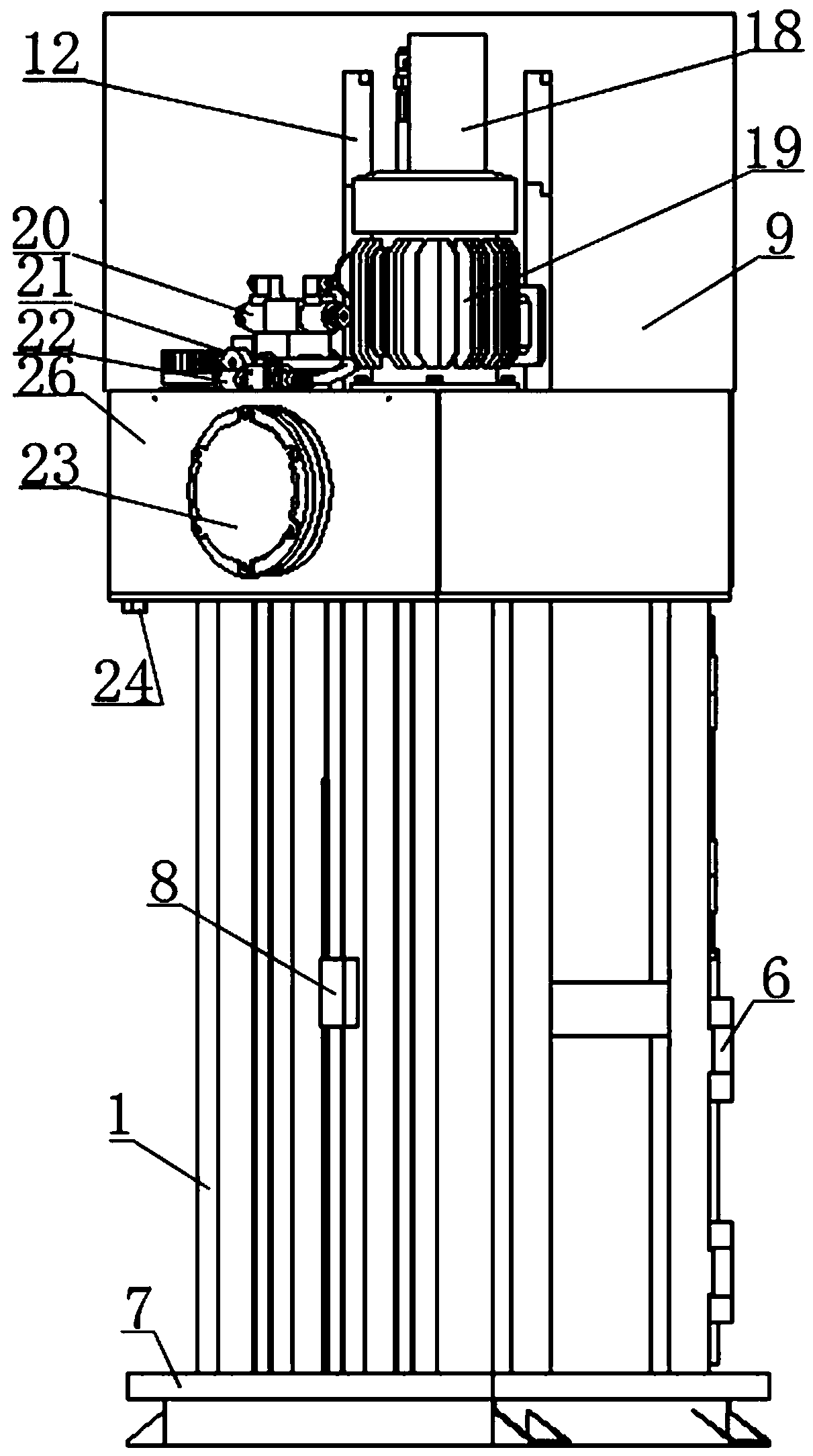

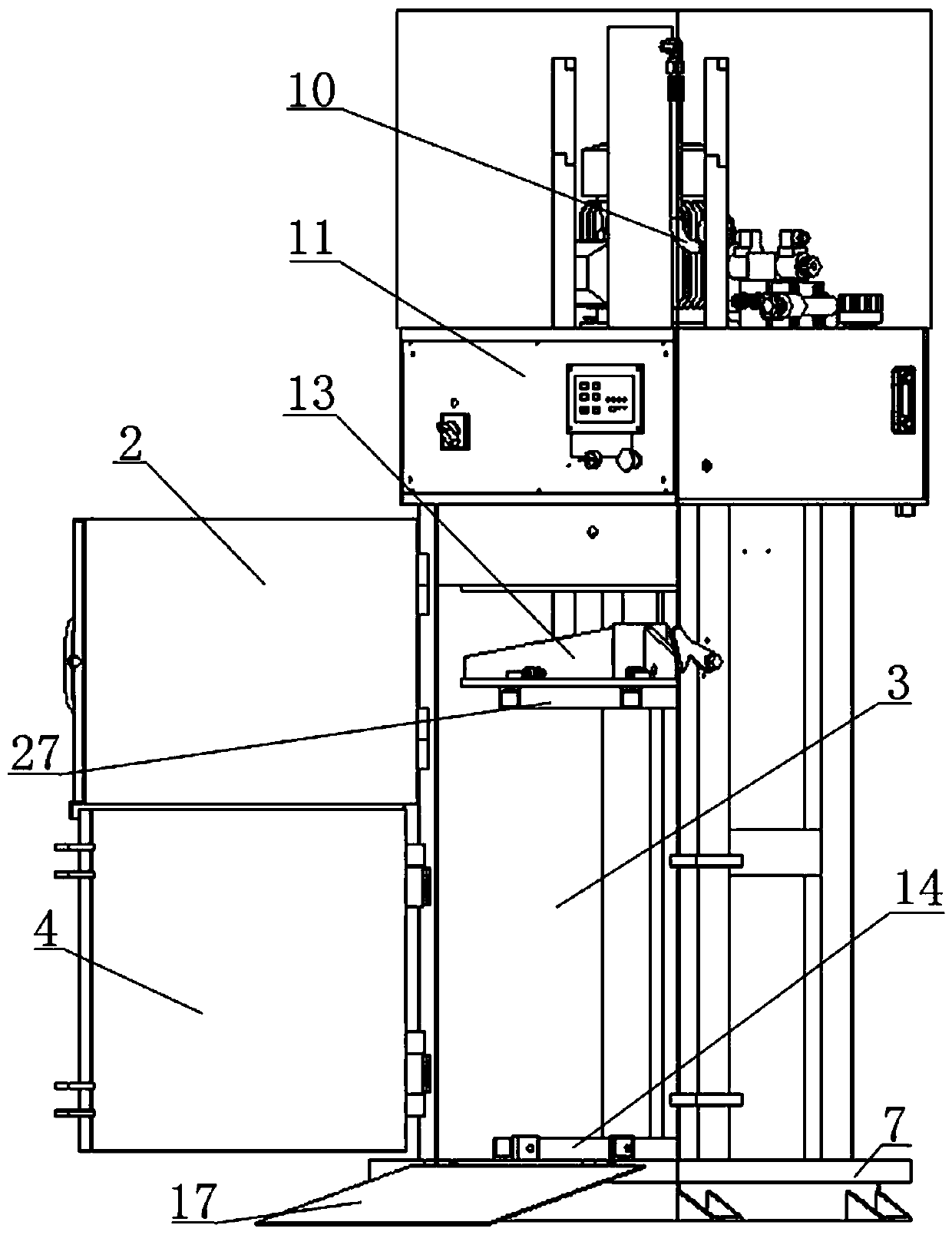

Multifunctional hydraulic baler and its baling method

The invention relates to a multifunctional hydraulic packaging machine and a packaging method thereof. The packaging machine comprises a machine body frame, a safety protection door, a compression bin, a compression bin door, a door clamping device, a hinge, a water receiving groove, a package turning check block, a protection cover, a hydraulic system, an electric control system, a guide rod, an extrusion plate, a package turning system, a dustbin and a compression platform; the water receiving groove and the compression bin are arranged on the lower portion of the machine body frame, the package turning system is arranged at the bottom of the compression bin, the compression bin door and the safety protection door are hinged to the machine body frame through the hinge, an inclined panel is hinged to the opening position of the lower portion of the compression bin through the hinge, the compression bin door and the machine body frame are locked through the door clamping device, and the safety protection door and the machine body frame are locked through the door clamping device; and the multifunctional hydraulic packaging machine and the packaging method have the beneficial effects that design is simple and ingenious, the structure is reasonable and compact, use is convenient, the structure is diversified, one machine has multiple purposes, and the compression problem of different types of materials in the actual production life is solved.

Owner:南通建恒机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com