A non-directional spunlace knitted fabric and its processing method

A technology for knitted fabrics and processing methods, applied in the directions of knitting, weft knitting, warp knitting, etc., to achieve the effects of reducing pollution, reducing costs, and improving feel and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

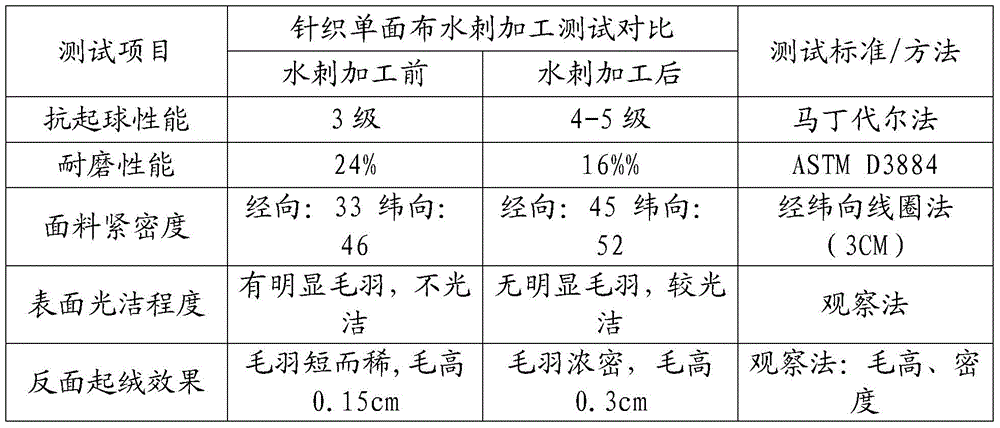

[0048] The knitted single-jersey fabric of this scheme has a single-sided structure, and the front side is smoother and smoother than the back side, and the back side is used as the next-to-body surface of clothing fabrics without special requirements.

[0049] The final processing purpose is to make the front side of the knitted single jersey tight and smooth, improve the wear resistance and anti-pilling performance, and have a velvet feeling on the back side, such as jeanette.

[0050] Cloth selection: Cotton knitted single jersey: 21Stk / 1 single yarn jersey

[0051] 1. Spunlace processing process of knitted single jersey

[0052] Fabric pretreatment----dyeing----drying----baking---spunlace processing----drying

[0053] 1.1 Fabric pretreatment, dyeing, and drying processes are produced by conventional dyeing and finishing processes;

[0054] 1.2 The softener after dyeing is made of silicon-containing softener.

[0055] 1.3 Baking, that is, the dimensional stability of the...

Embodiment 2

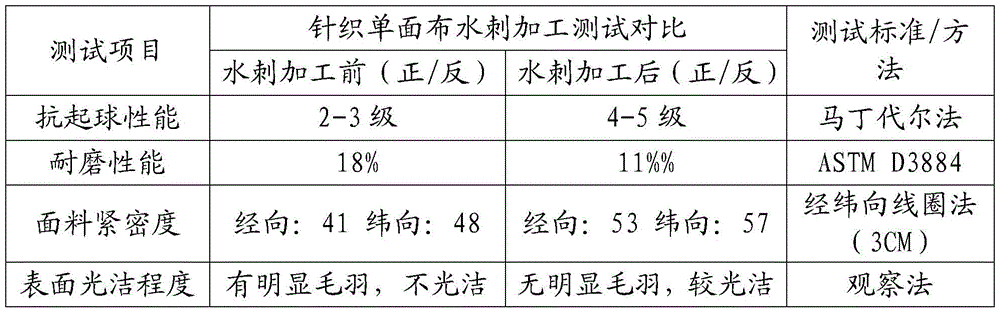

[0074] The knitted double-sided fabric of this scheme has a double-sided structure, and both the front and back sides are required to be smooth and smooth. This clothing fabric can be designed as knitted jackets and skirts, which need to be crisp and smooth. The final processing purpose is to make the front and back of the knitted double-sided fabric tight and smooth, improve the wear resistance and anti-pilling performance, and achieve the purpose of crispness, smoothness, comfort and durability.

[0075] Cloth selection: cotton knitted double-sided fabric: 32Stk / 1 cotton air layer

[0076] 1. Spunlace processing process of knitted double-sided fabric

[0077] Fabric pretreatment----dyeing----drying----baking---spunlace processing----drying

[0078] 1.1 Fabric pretreatment, dyeing, and drying processes are produced with normal dyeing and finishing processes;

[0079] 1.2 The softener after dyeing is selected to contain silicon softener;

[0080] 1.3 Baking, that is, the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com