Micro-concave roller gap engraving process

A concave roll and gap technology, which is applied in the field of micro-concave roll gap engraving technology, can solve problems such as difficulty in meeting the design requirements of diaphragm coatings, and achieve the effect of broadening the scope of use, broadening the scope of application, and reducing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

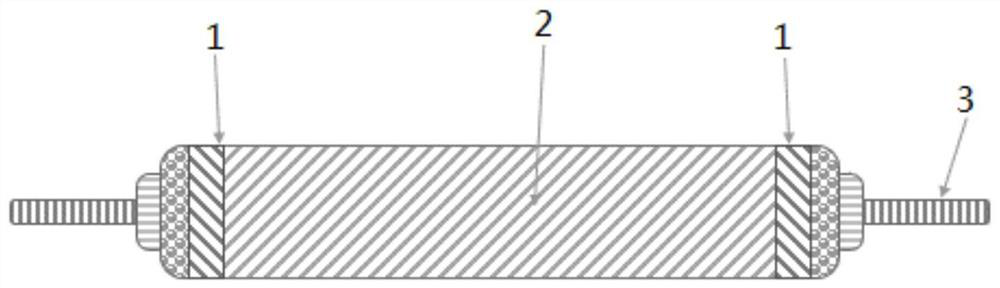

[0035] Please refer to figure 1 As shown, in the micro-gravure roller gap engraving process in this embodiment, the middle part of the roller surface of the micro-gravure roller is a blank area and does not need to be engraved, only the engraving area is engraved, and the engraving area is two strip-shaped areas. The pit depth of the engraving area is 80 μm, the line speed is designed to be 120 lines, the width of the coating area is 2 mm, and the spacing is 285 mm. Bottom-coated primer diaphragm, the width of this diaphragm is 289mm, and there are 2mm areas at both ends of the edge with ceramic coating, and the coating thickness is 4μm, this diaphragm can be applied to 322 size power cells.

Embodiment 2

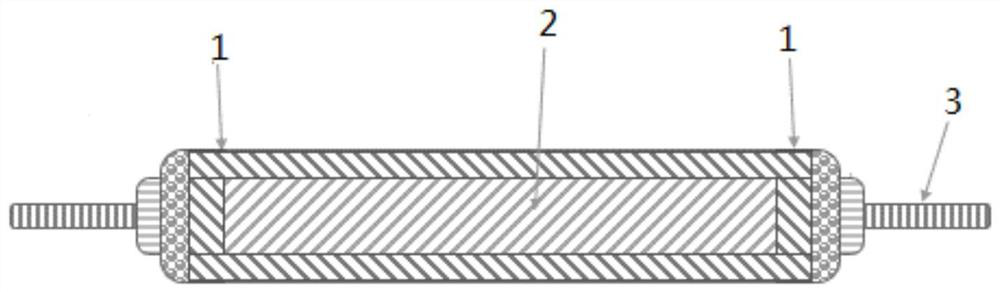

[0037] Please refer to figure 2 As shown, in the engraving process of the micro-gravure roller gap in this embodiment, the engraving area of the roller surface of the micro-gravure roller is 4 strip-shaped areas, 2 vertical bearings, 2 parallel bearings, and the part other than the engraving area is a blank area. Sculpture. The pit depth of the engraving area is 100μm, the line speed is designed to be 160 lines, the width of the engraving area is 2mm, the spacing of the strip area of the vertical bearing is 285mm, and the spacing of the strip area of the parallel bearing is 93mm. Coating the ceramic slurry with a viscosity of 80mpa s at room temperature, the edge-coated diaphragm with only edge coating can be obtained directly after coating and slitting. With a coating thickness of 3μm, this diaphragm can be applied to 322 size power cells.

Embodiment 3

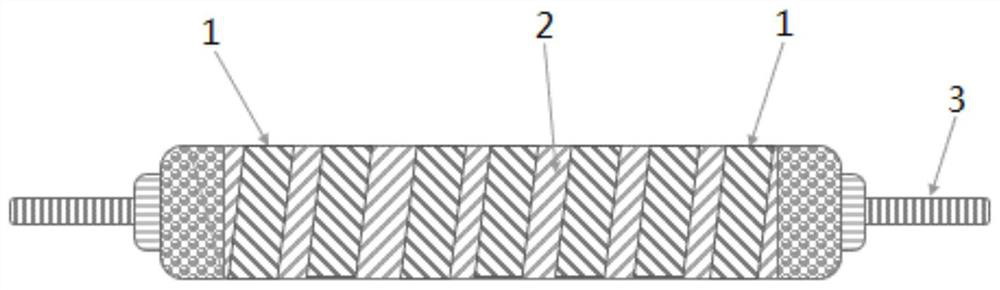

[0039] Please refer to image 3 As shown, in the micro-gravure roller gap engraving process of this embodiment, the engraving area of the roller surface of the micro-gravure roller is several strip-shaped areas, and the part other than the engraving area is a blank area without engraving. The area ratio of the engraving area to the blank area should be less than 3:1, the strip engraving area and the bearing direction should be 60° to 80°, parallel to each other, the pit depth of the engraving area is 100 μm, and the line speed is designed to be 160 lines. Coating the ceramic slurry with a viscosity of 200mpa s at room temperature, the edge-coated diaphragm with only edge coating can be directly obtained after coating and slitting. With a coating thickness of 3μm, this diaphragm can be applied to 322 size power cells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com