Patents

Literature

203results about How to "Reduce cost pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

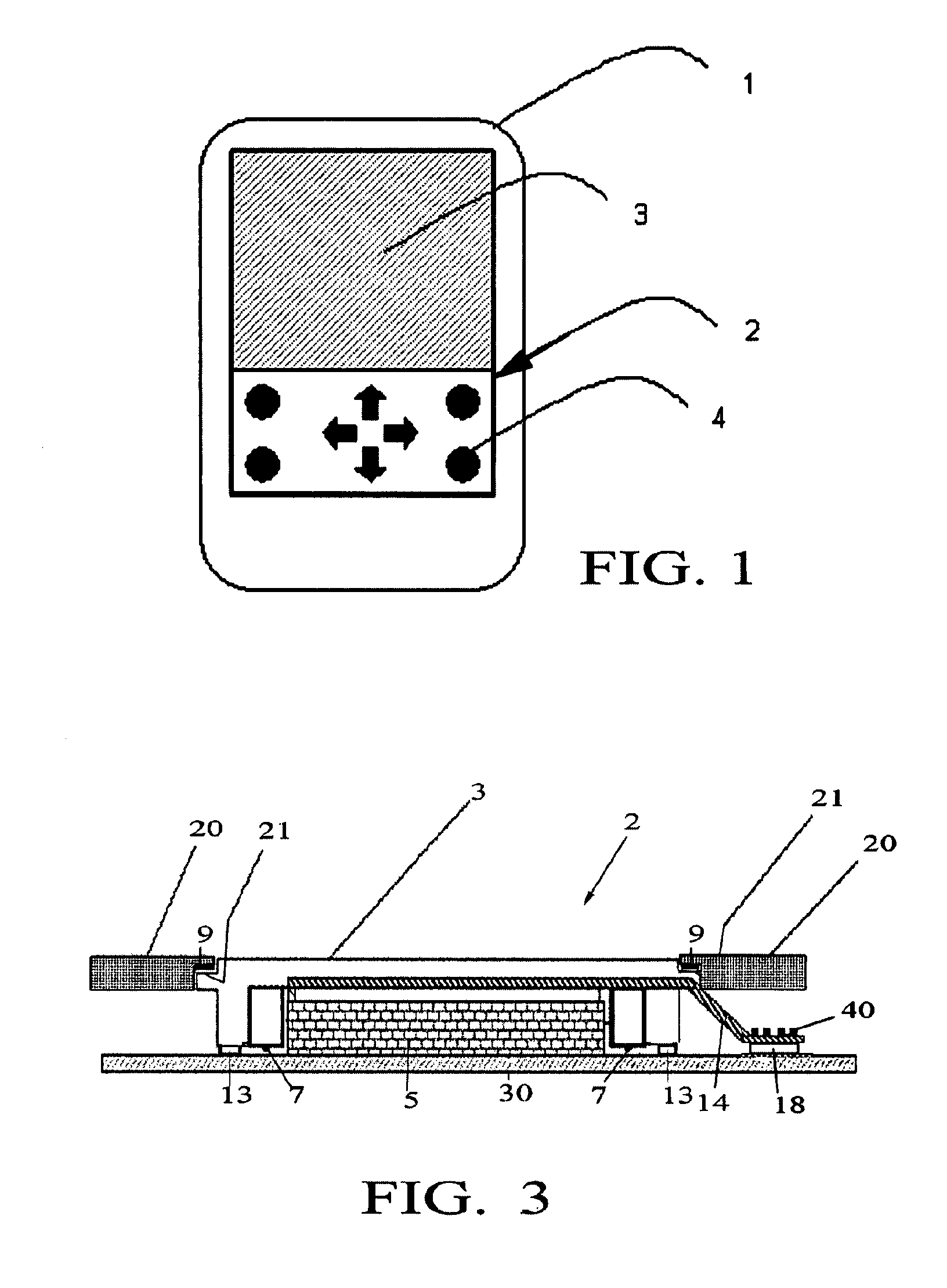

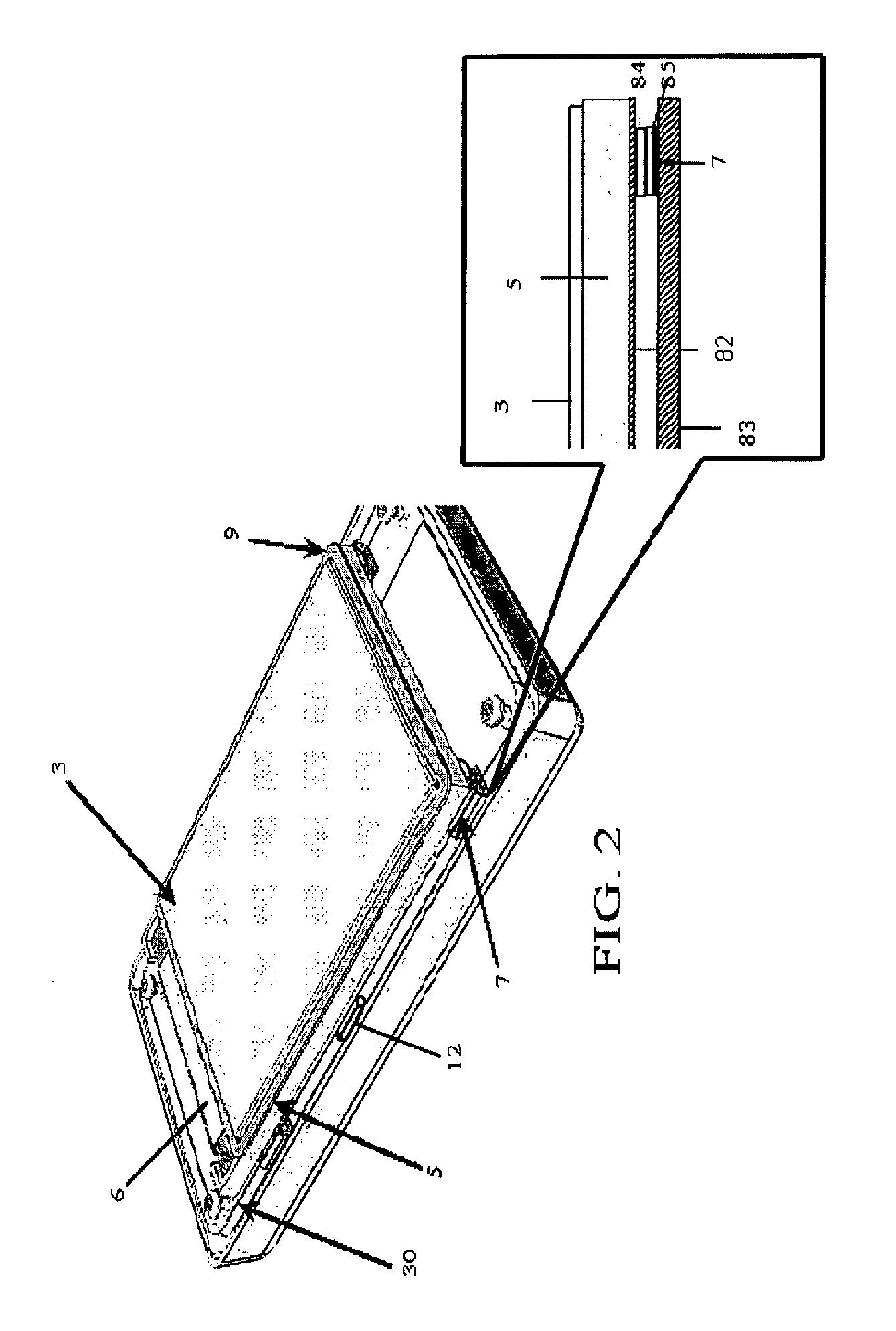

Integrated pressure sensitive lens assembly

ActiveUS20100045612A1Low costReduce cost pressureDetails for portable computersInput/output processes for data processingCamera lensData set

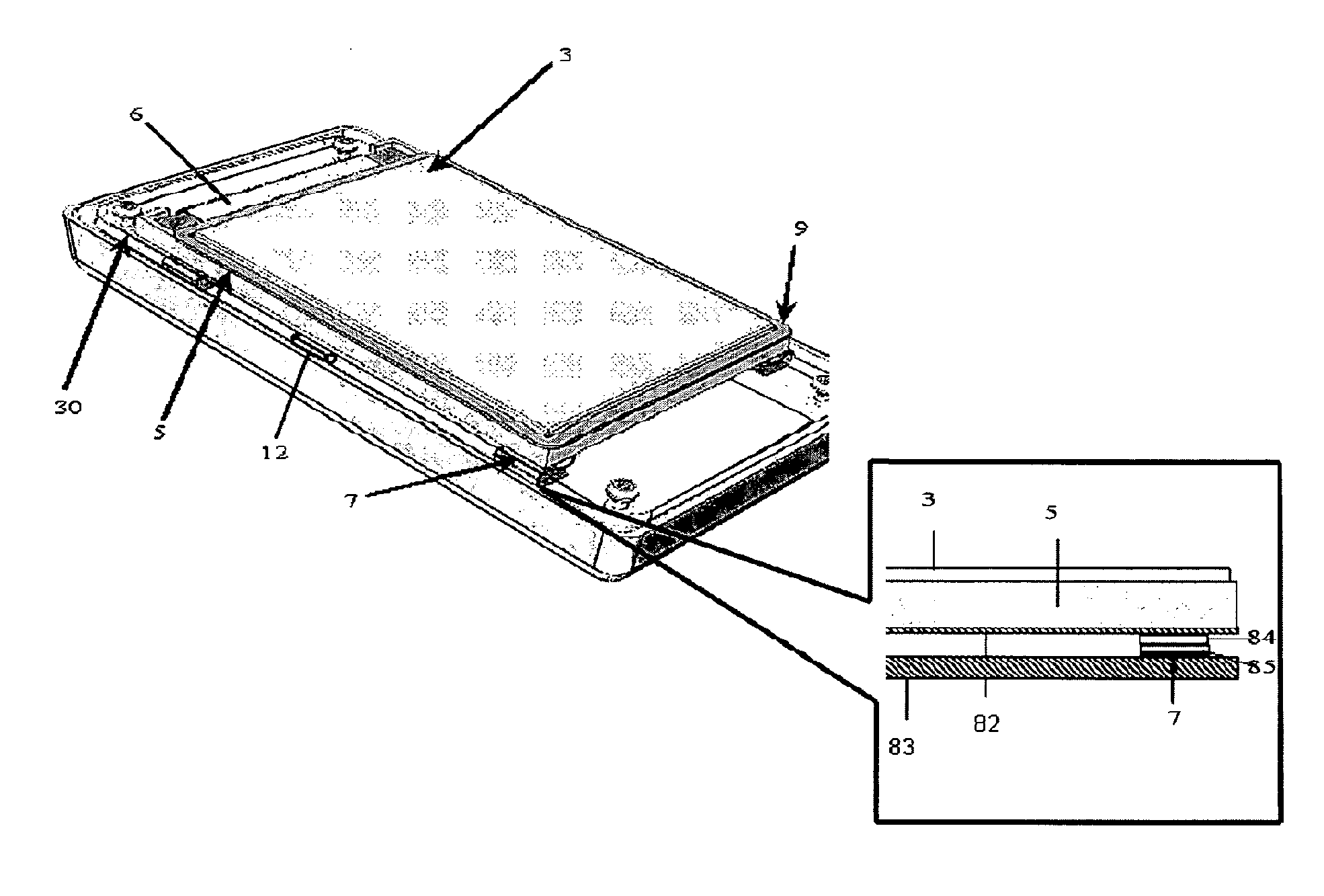

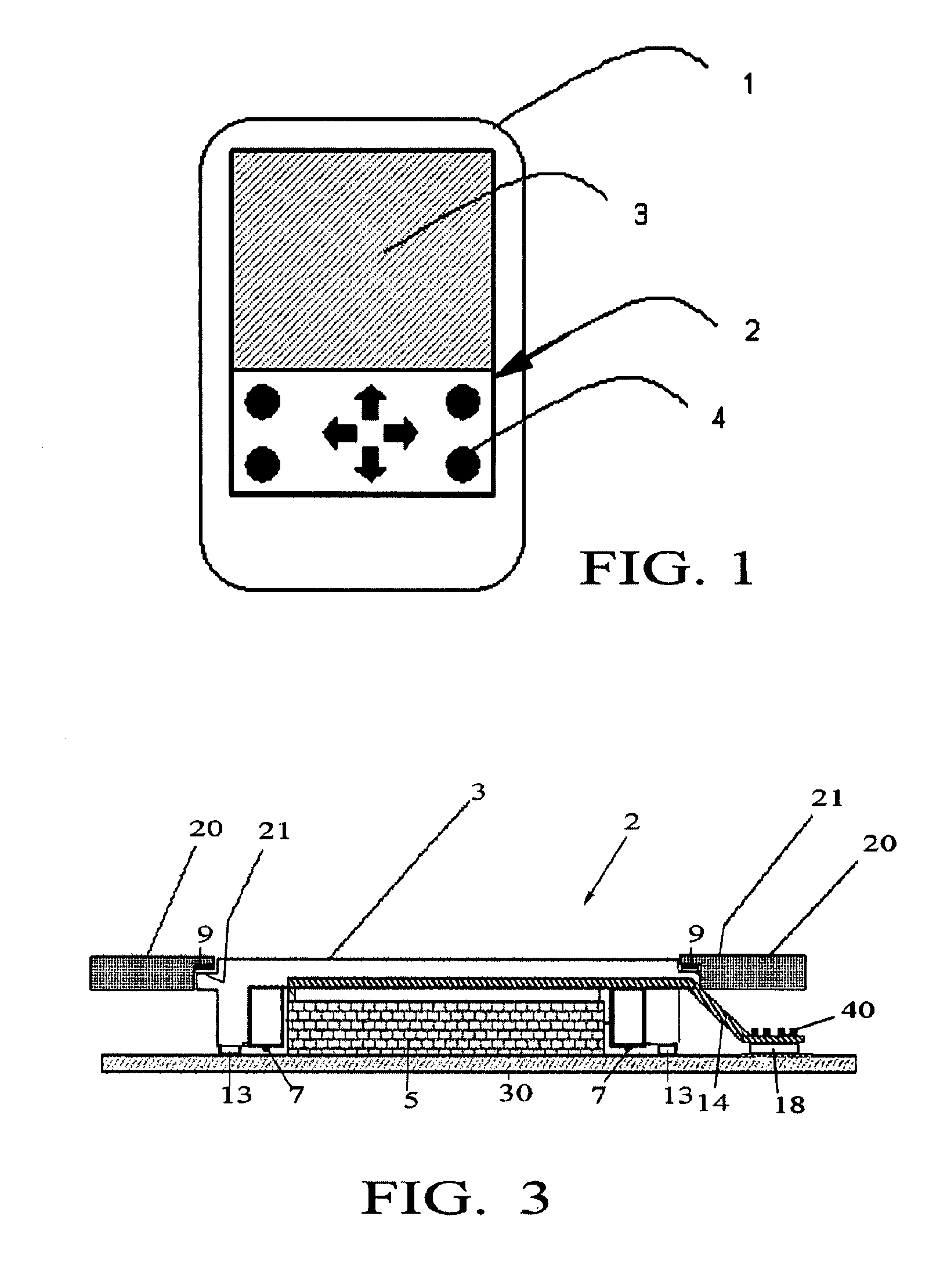

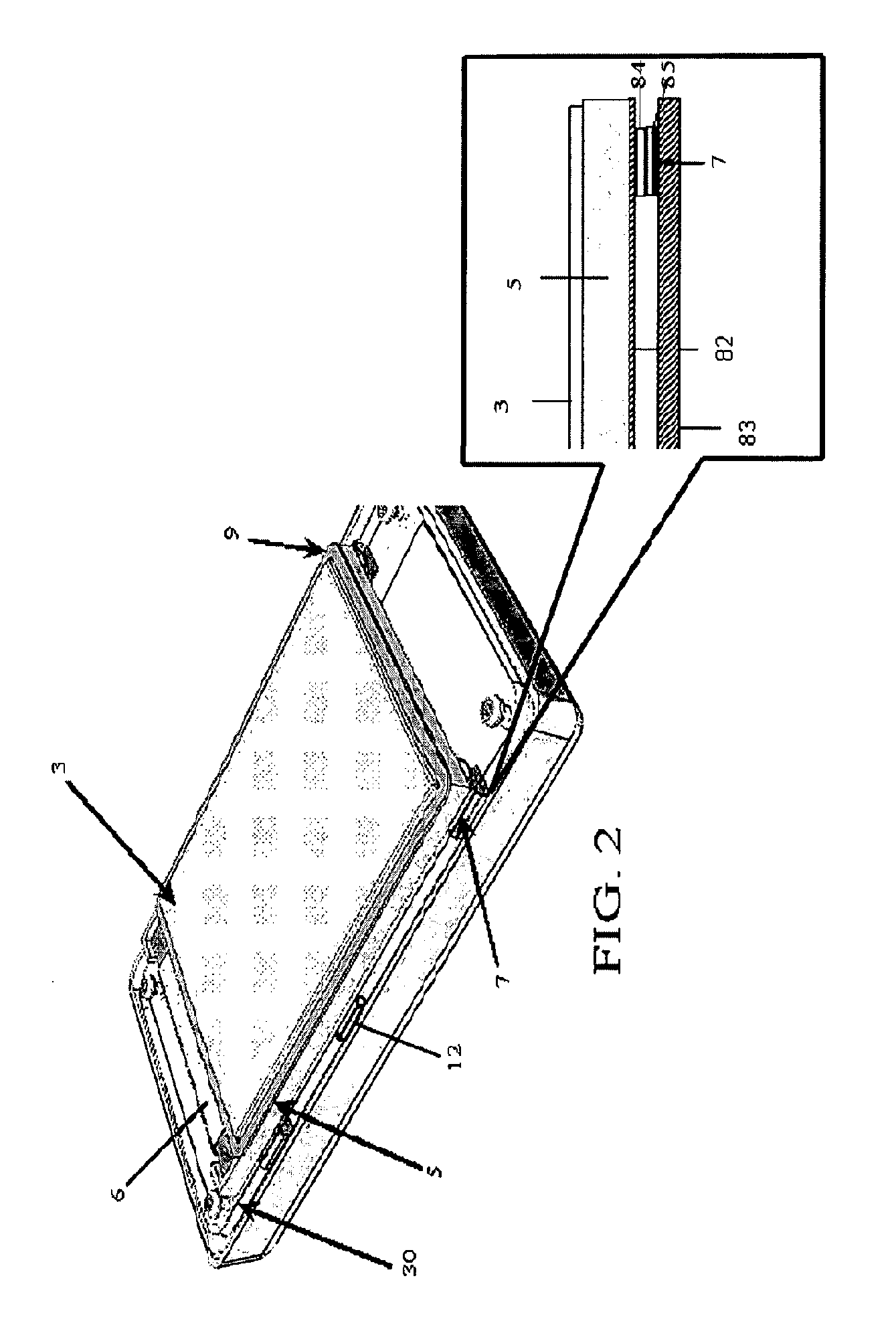

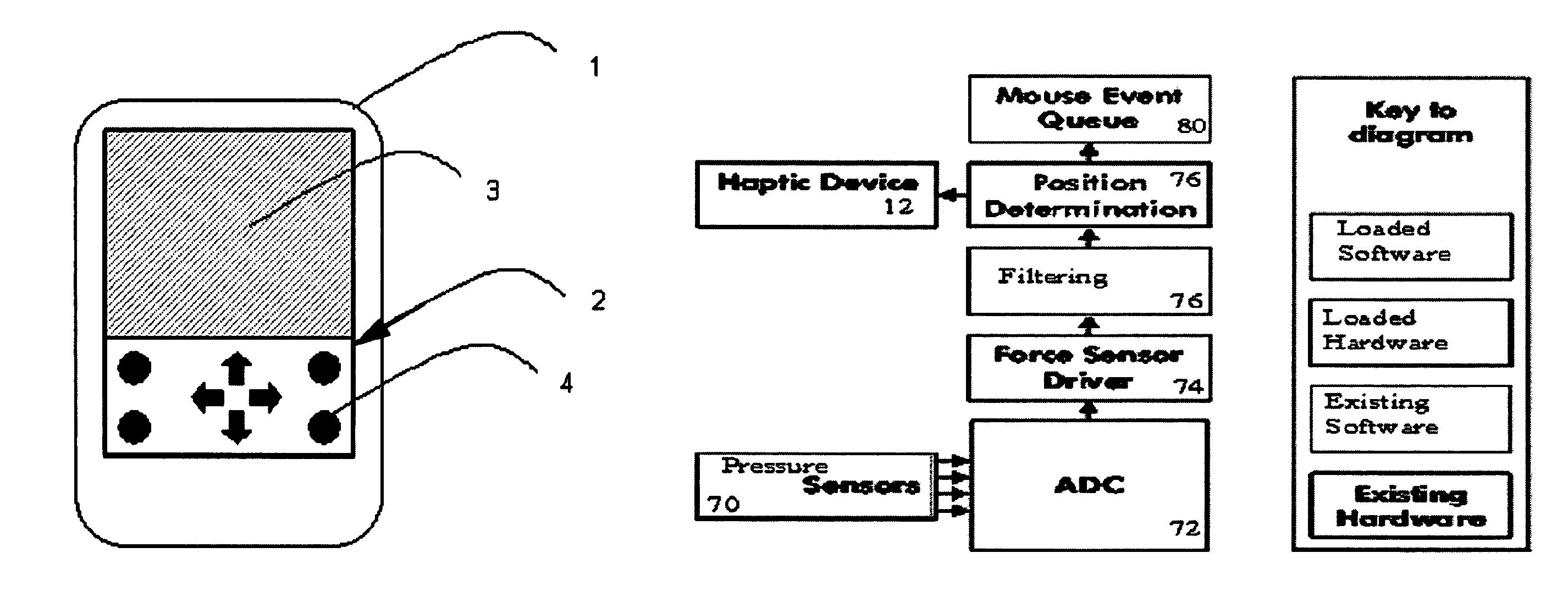

A touch screen assembly for an electronic device such as a cell phone or PDA. The touch screen assembly generally comprises a floating lens suspended over the display and, optionally, the keypad to allow a degree of freedom. An underlying thin connecting layer such as a flex film is attached beneath the floating lens, and a plurality (for example, four) differentially-mounted pressure sensors are mounted beneath the floating lens and are electrically connected to the electronic device via the flex film. The pressure sensors are differentially positioned along an x- and y-axis for registering a pressure z from a touch to the lens at each of the four positions, to provide four data sets (x1-4, y1-4, z1-4). Control software then interprets the exact touch-coordinate from the four data sets and generates a control signal. An optional haptic response generator and / or motion sensor are also contemplated. When used in a smaller electronics device such as a cell phone or PDA the touch screen sensor technology of the present invention is exceedingly thin and is capable of modular assembly for more-or-less “snap-in” construction.

Owner:APPLE INC

Integrated pressure sensitive lens assembly

ActiveUS8269731B2Reduce cost pressureDetails for portable computersInput/output processes for data processingData setControl signal

A touch screen assembly for an electronic device such as a cell phone or PDA. The touch screen assembly generally comprises a floating lens suspended over the display and, optionally, the keypad to allow a degree of freedom. An underlying thin connecting layer such as a flex film is attached beneath the floating lens, and a plurality (for example, four) differentially-mounted pressure sensors are mounted beneath the floating lens and are electrically connected to the electronic device via the flex film. The pressure sensors are differentially positioned along an x- and y-axis for registering a pressure z from a touch to the lens at each of the four positions, to provide four data sets (x1-4, y1-4, z1-4). Control software then interprets the exact touch-coordinate from the four data sets and generates a control signal. An optional haptic response generator and / or motion sensor are also contemplated. When used in a smaller electronics device such as a cell phone or PDA the touch screen sensor technology of the present invention is exceedingly thin and is capable of modular assembly for more-or-less “snap-in” construction.

Owner:APPLE INC

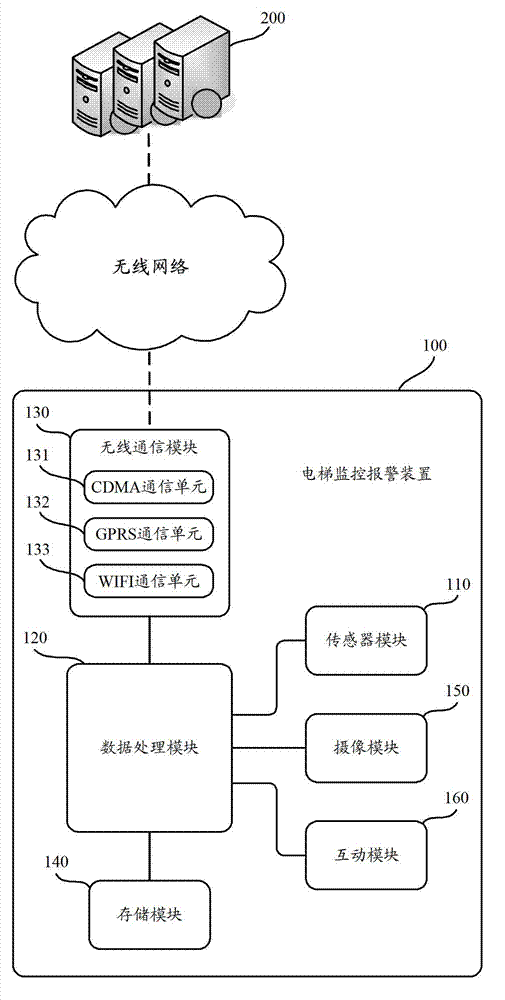

Elevator monitoring and alarming device

ActiveCN102897626AImprove efficiencyQuality improvementElevatorsWireless transmissionElevator system

The invention provides an elevator monitoring and alarming device, which is applicable to an elevator system and is arranged on a car of the elevator system. The elevator monitoring and alarming device comprises a wireless communication module, a sensor module and a data processing module, wherein the wireless communication module is used for being communicated with an elevator monitoring platform in a wireless transmission mode; the sensor module is used for acquiring running parameters of the car; and the data processing module is used for analyzing the running parameters so as to judge whether the car runs normally or not, generating a fault alarming signal if the car runs abnormally, and transmitting the fault alarming signal to the elevator monitoring platform through the wireless communication module.

Owner:四川智眼天下网络科技有限公司

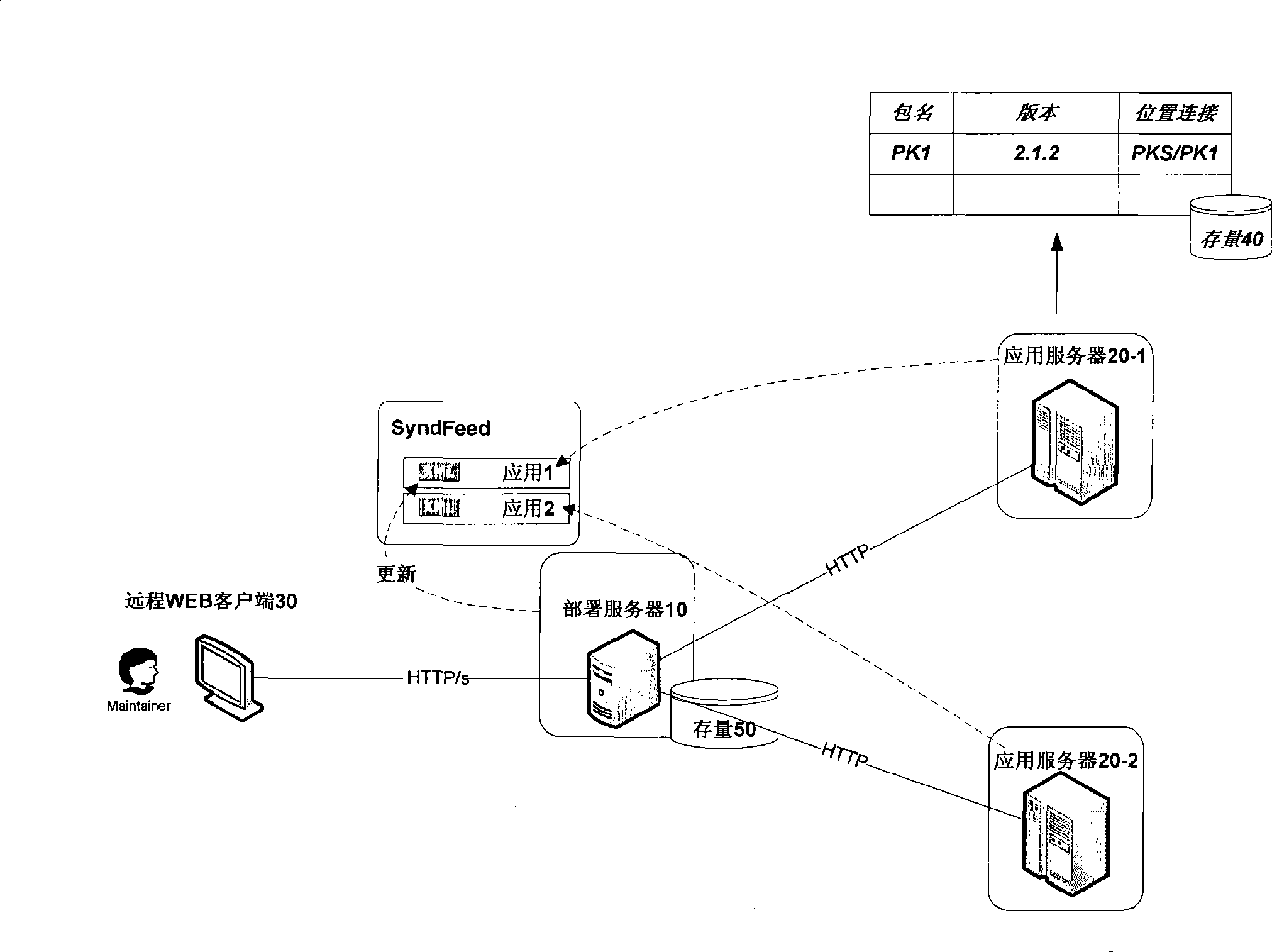

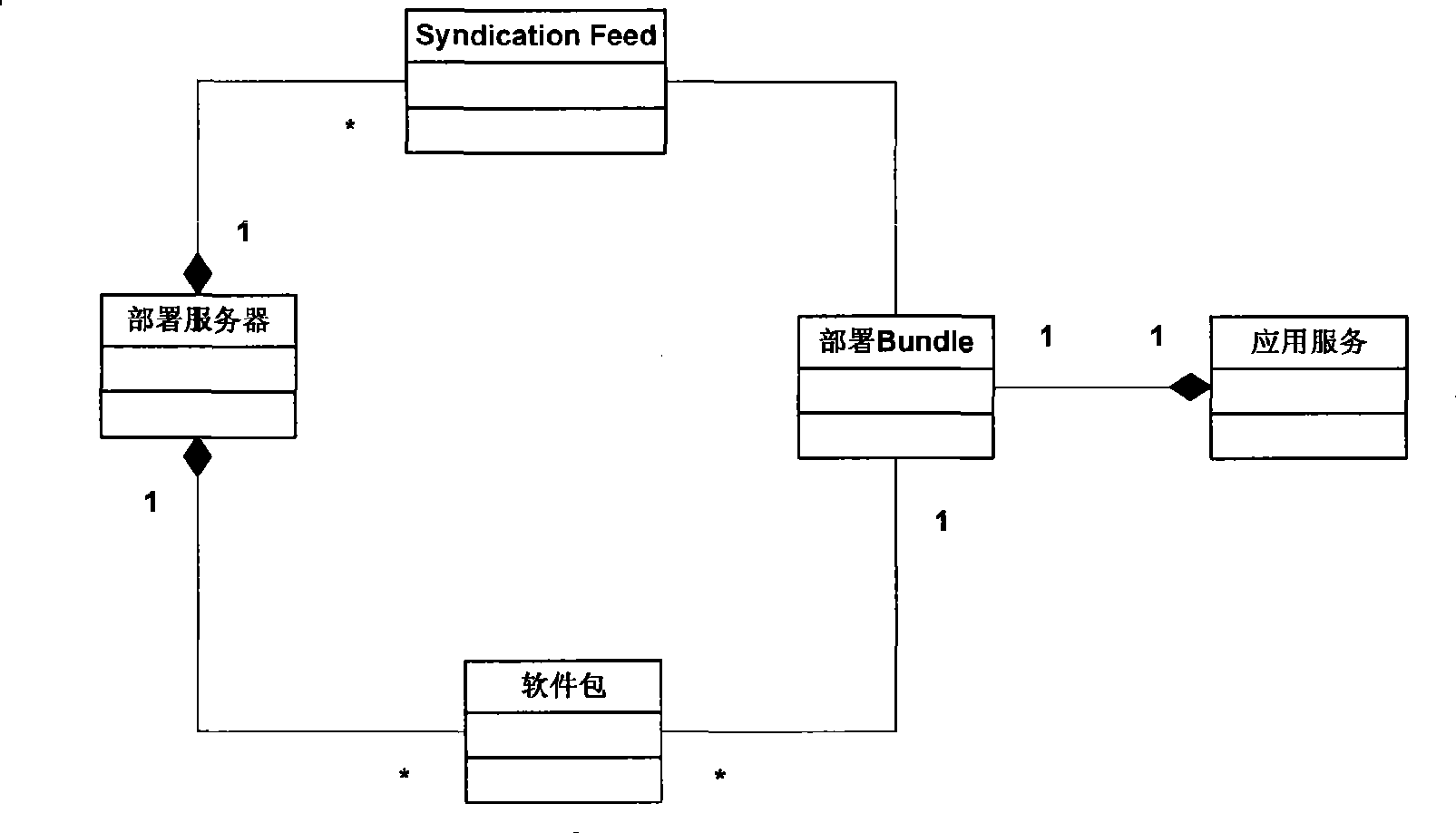

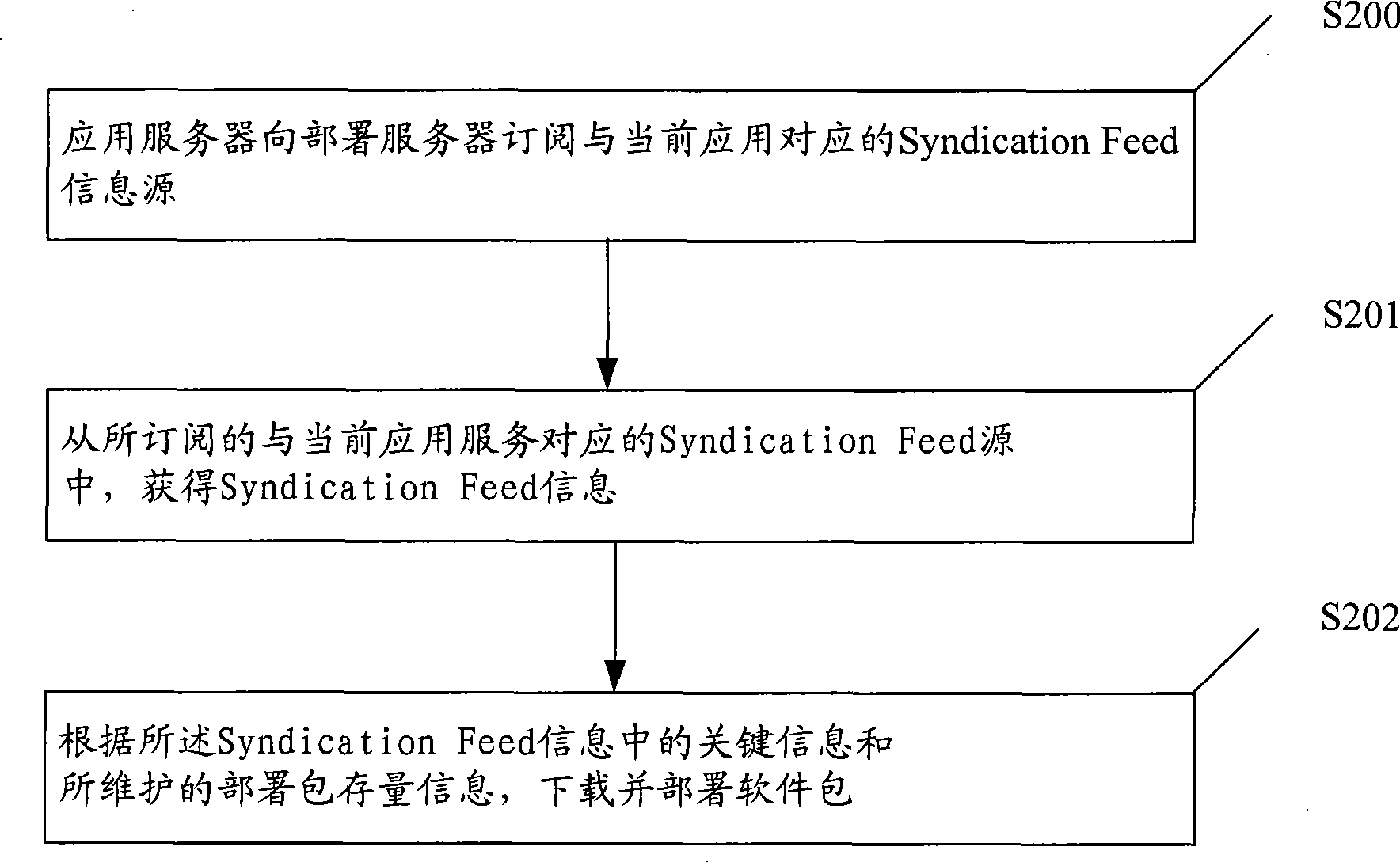

Automatic deployment method, apparatus and system for software package

InactiveCN101420325AReduce cost pressureRealize automatic upgradeProgram loading/initiatingData switching networksApplication serverSoftware engineering

The embodiment of the present invention discloses an automatic disposition method of software packages, a device and a system thereof, wherein, the automatic disposition method of software packages comprises steps of obtaining Syndication Feed information from subscribed polymerization abstract Syndication Feed information source corresponding to current application, wherein the Syndication Feed information is used for the issuance of the software packages relating to the current application; downloading and disposing software packages according to key information in the Syndication Feed information and storage information of maintained disposing packages; by using the method, an application server realizing that automatic disposition of software packages relating to the current application can be completed in the condition of manual intervention-free.

Owner:深圳市智通天下科技服务有限公司

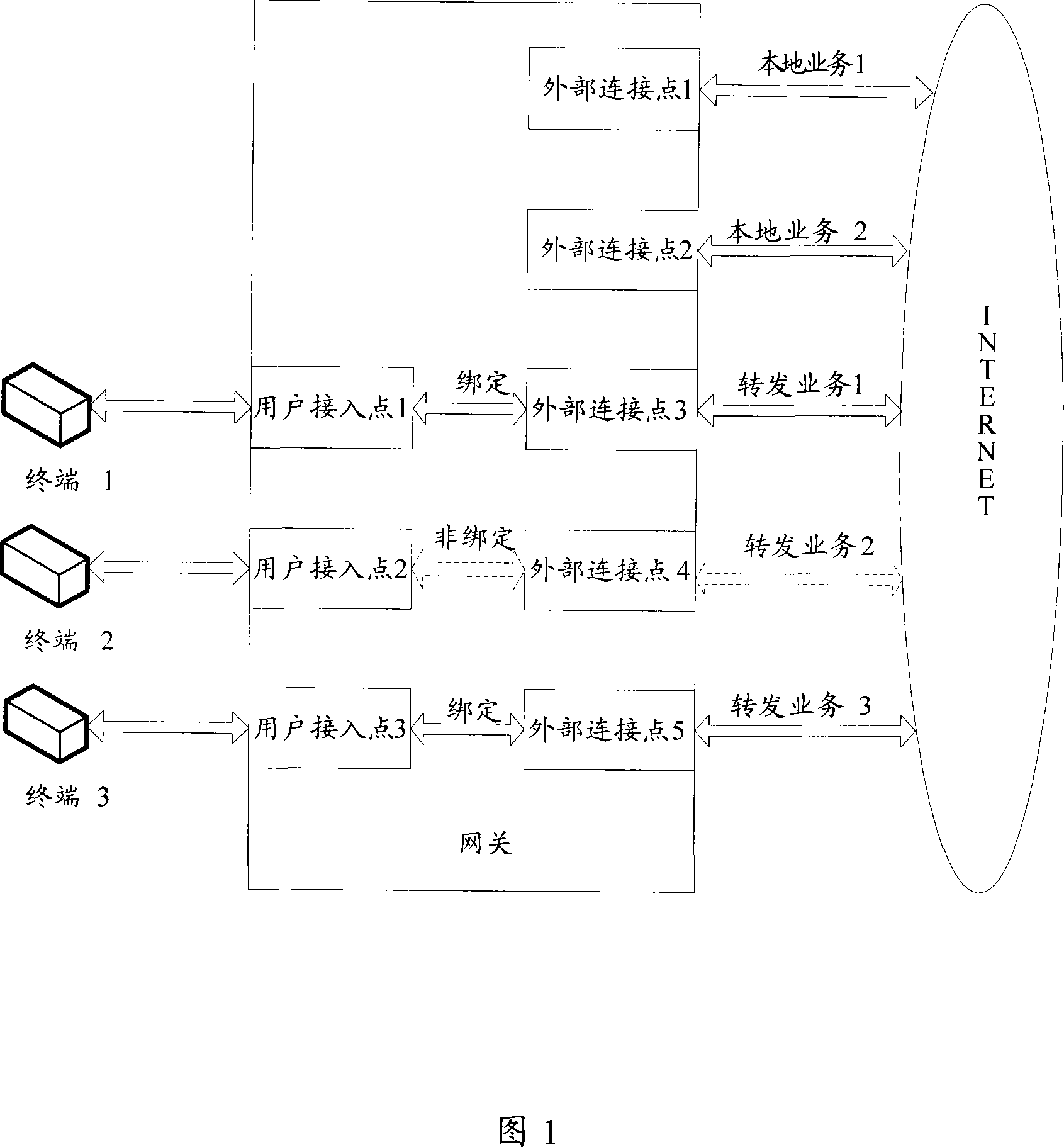

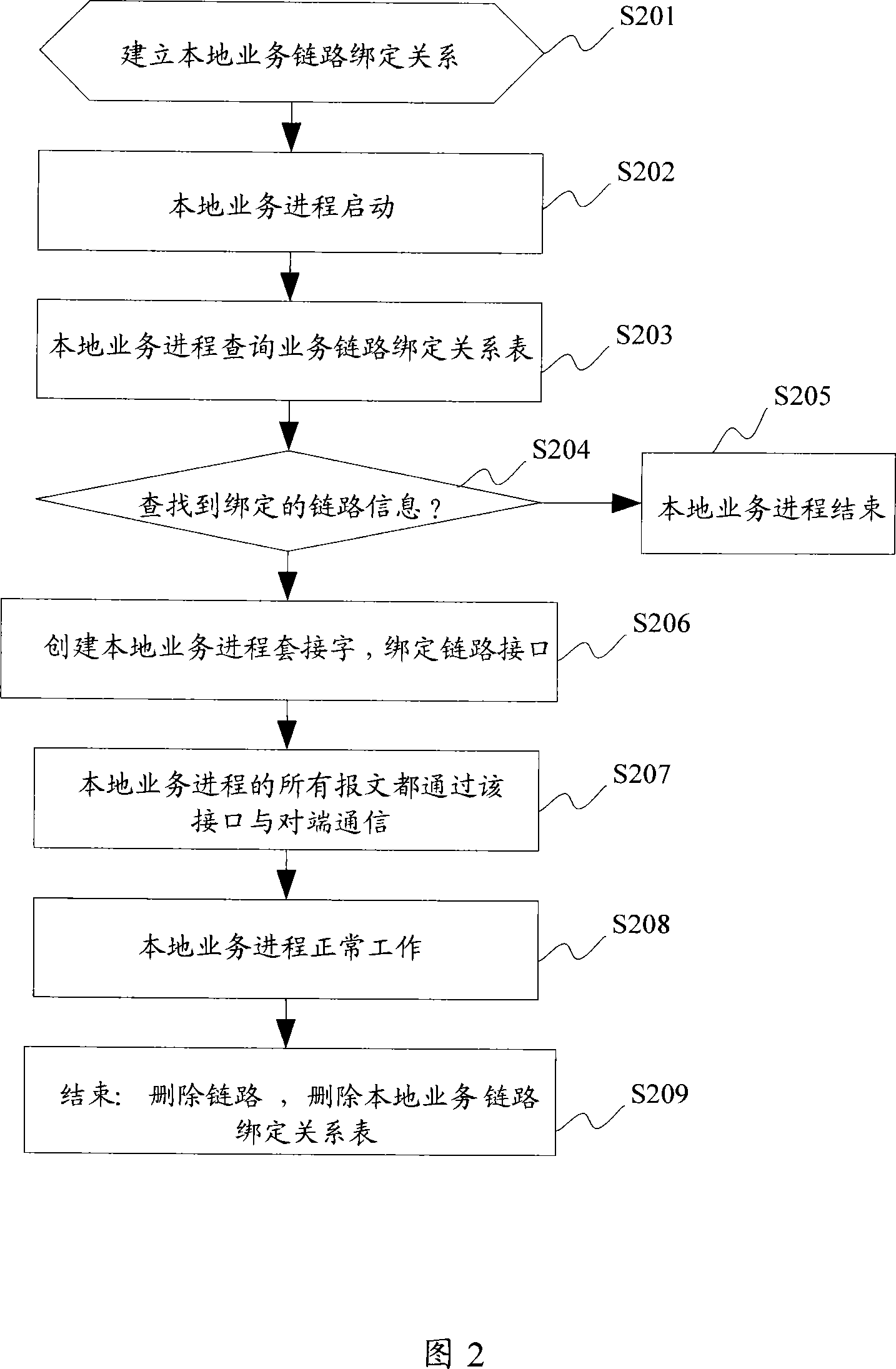

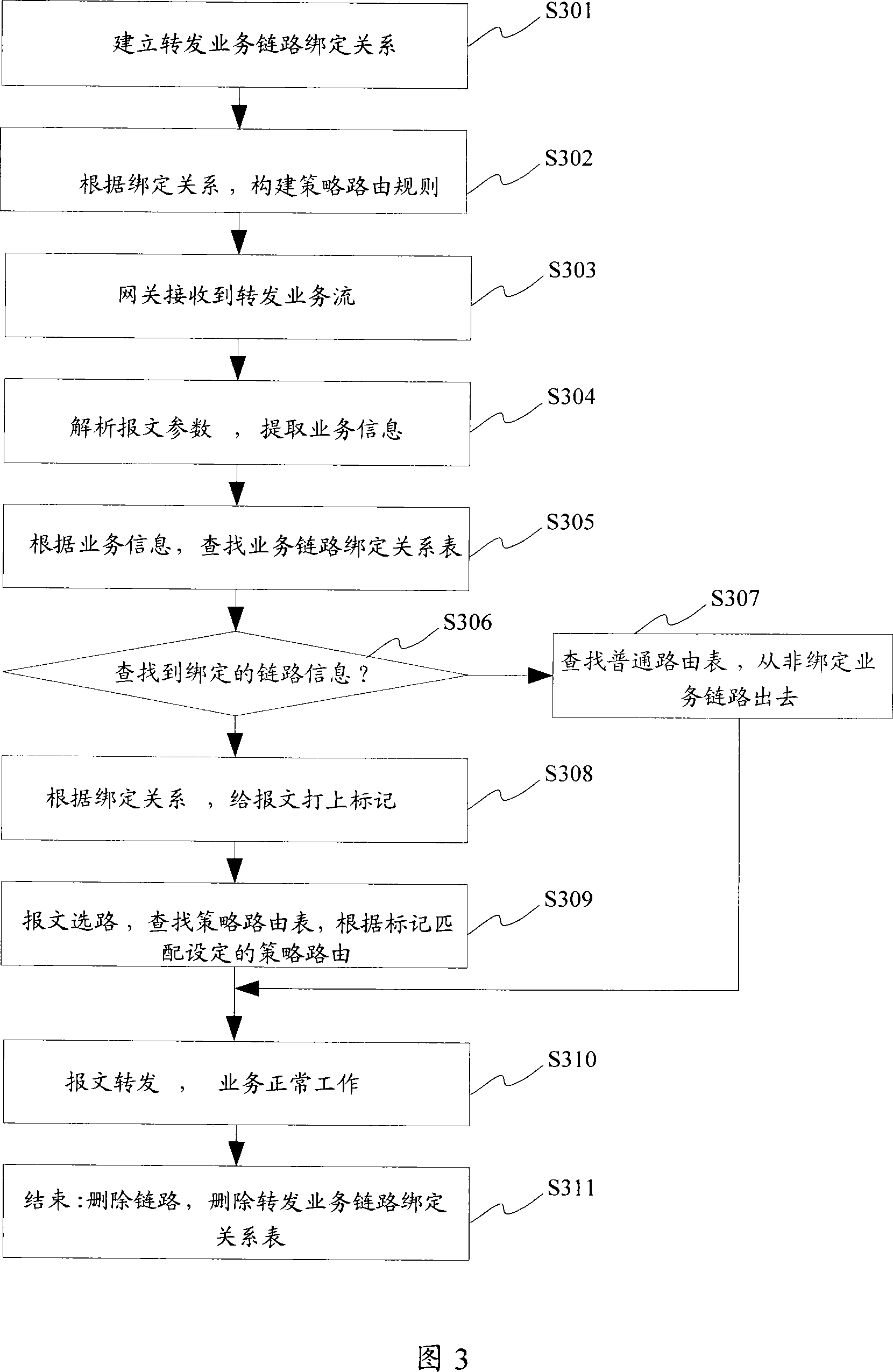

Implementing method for multi-service data flow selecting on gateway

ActiveCN101090377AStrong specificityImprove reliabilityNetwork connectionsVideo monitoringService flow

This invention discloses a realization method for selecting paths by multi-service data flows on gateway including: setting up a binding relation between service link and service kind, when a gateway receives service, it looks for a service link binded with the service kind as the transmission channel of the service to transmit it so as to realize speciality of service links from the source and increase the usability of network resources greatly by isolating service flows.

Owner:ZTE CORP

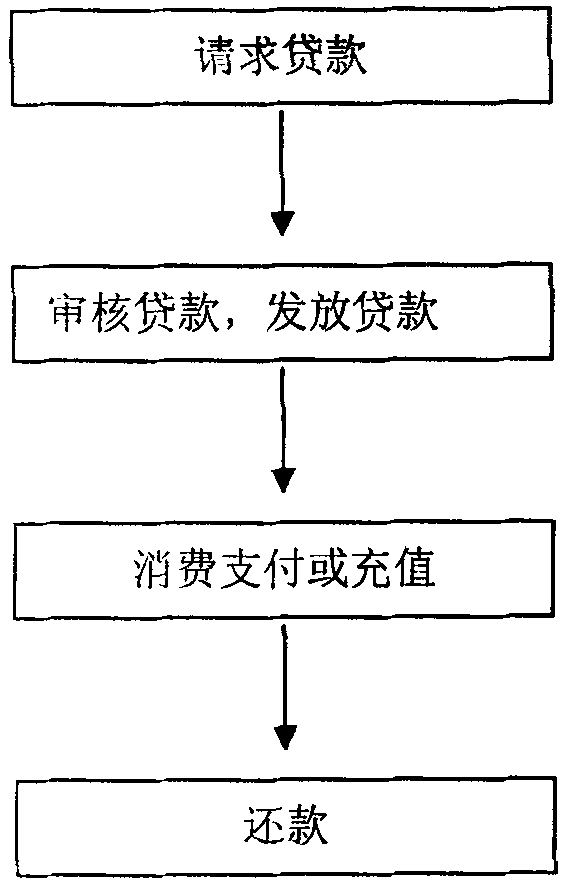

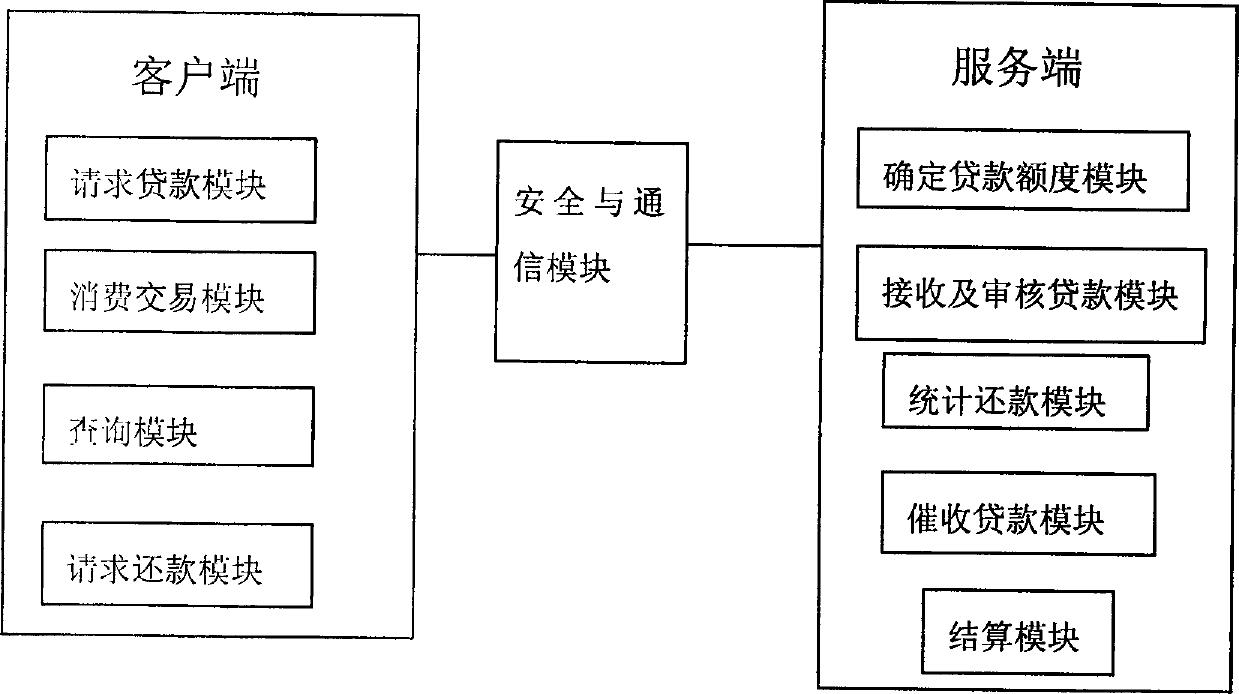

Online virtual currency third-party credit method and data processing system thereof

The invention provides an online virtual currency third-party credit method and a data processing system thereof. The online virtual currency third-party credit method includes steps of determining user credit line, user loan application, third-party credit supplier assessment and lending, user recharging or trading by loan, user repayment and payment requesting, settlement of a third-party credit supplier and a platform supplier and the like. The data processing system comprises a client and a server, the client realizes users' various service requests and the server processes the users' service requests. By the aid of the online virtual currency third-party credit method and the data processing system, value of personal online digital assets is explored, trade is promoted by means of load leverage and simple consumption payment ways, trade scale is enlarged, and the platform supplier is assisted in exploring and keeping high-quality users, and user experience is improved.

Owner:孔庆发 +1

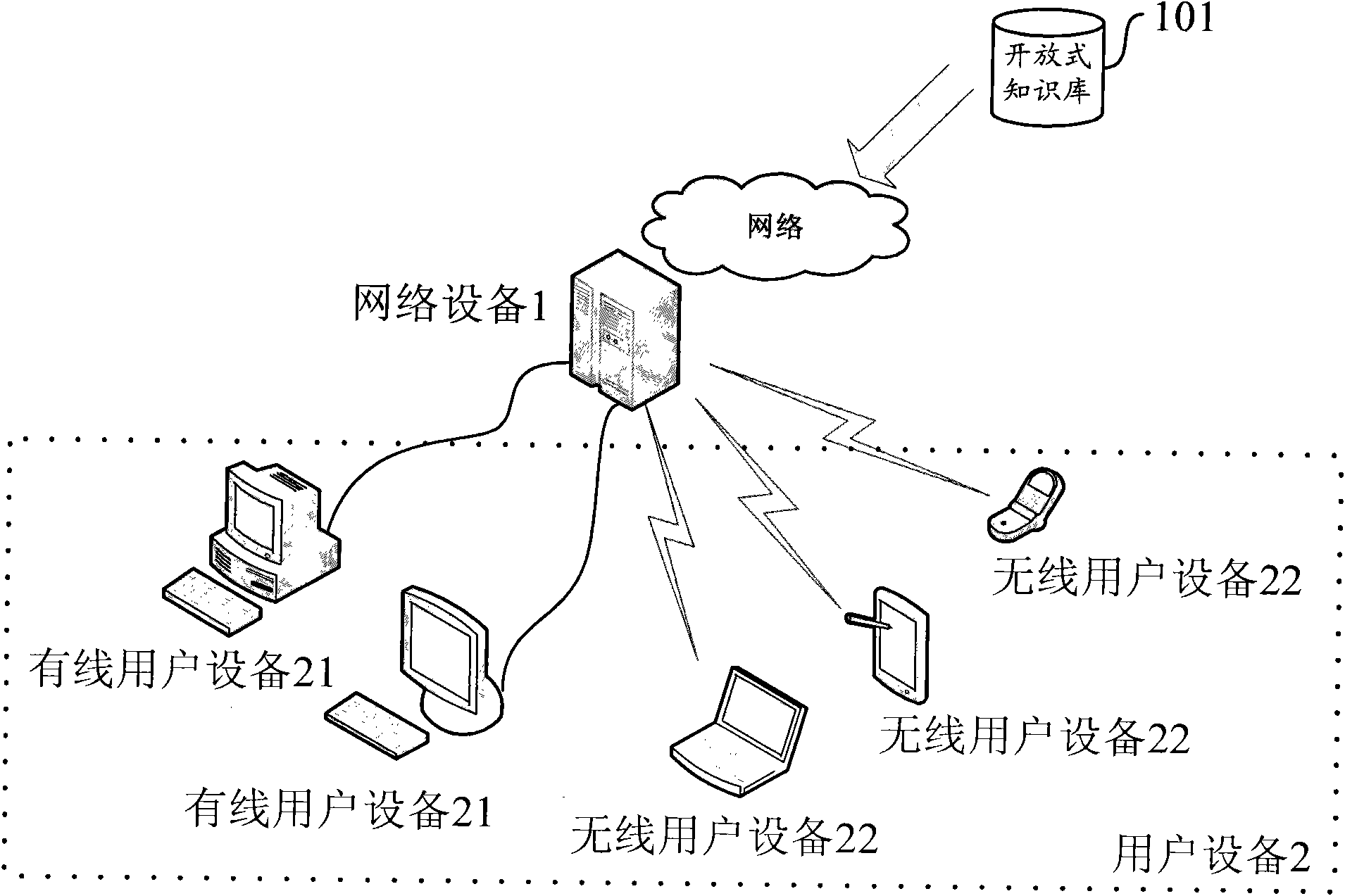

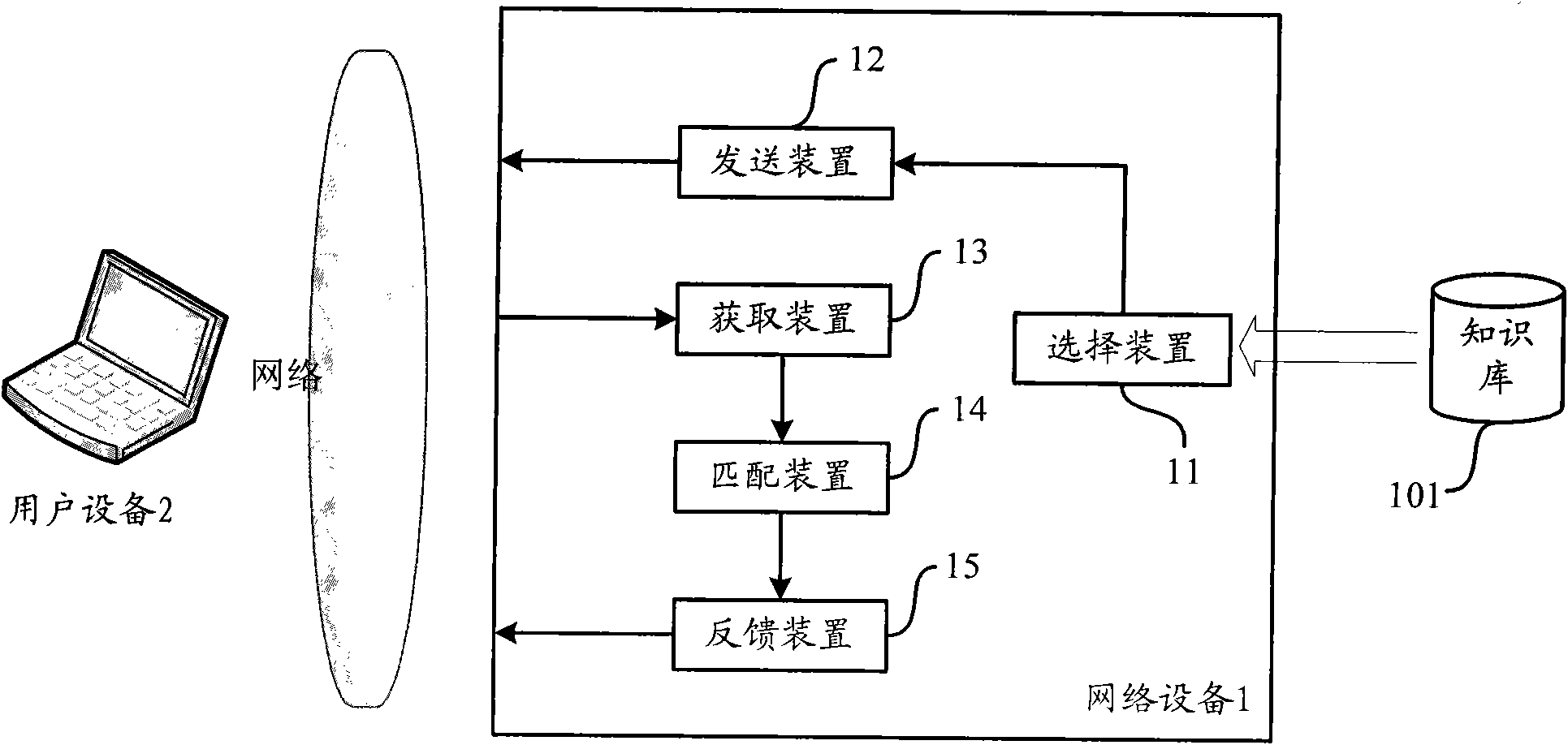

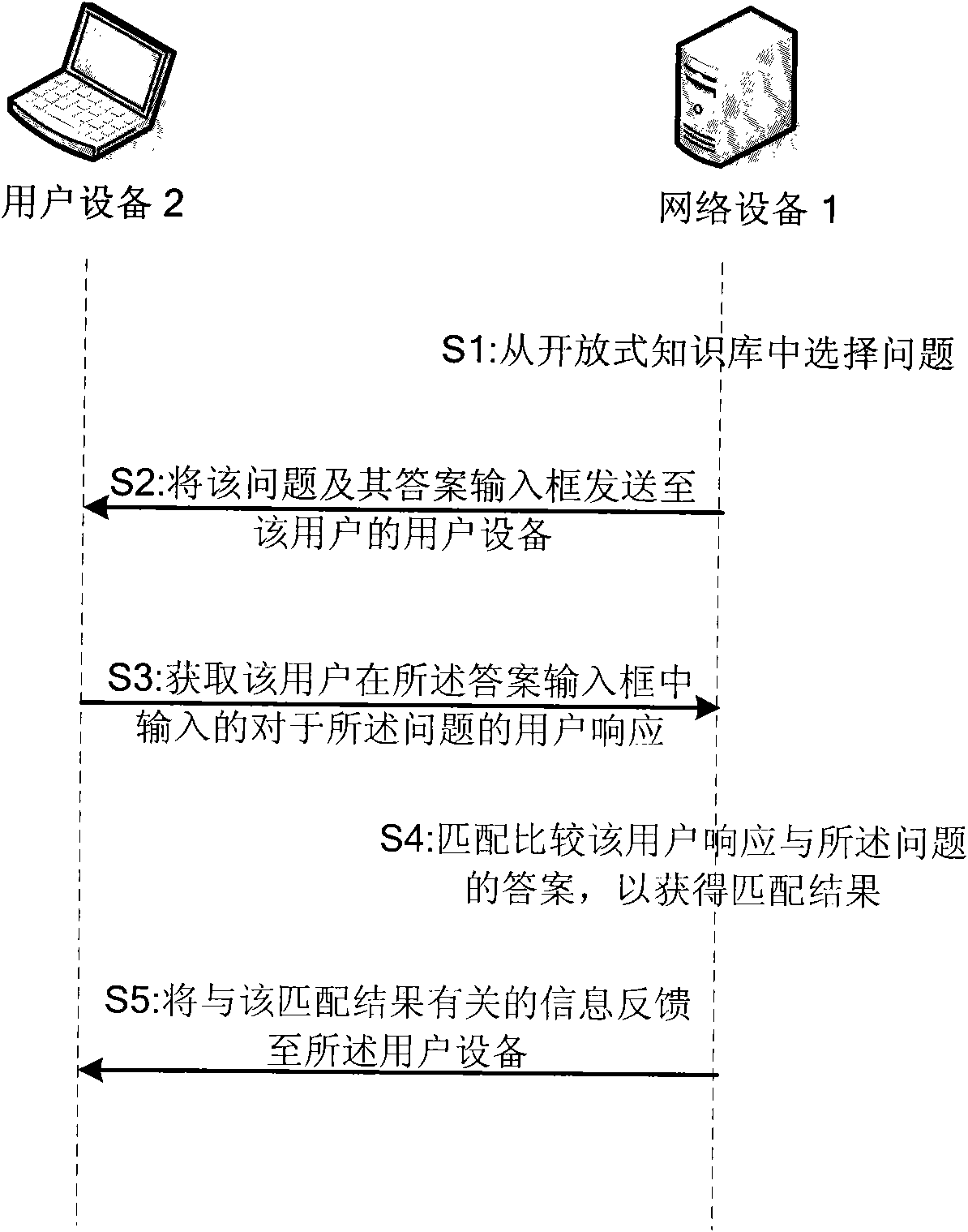

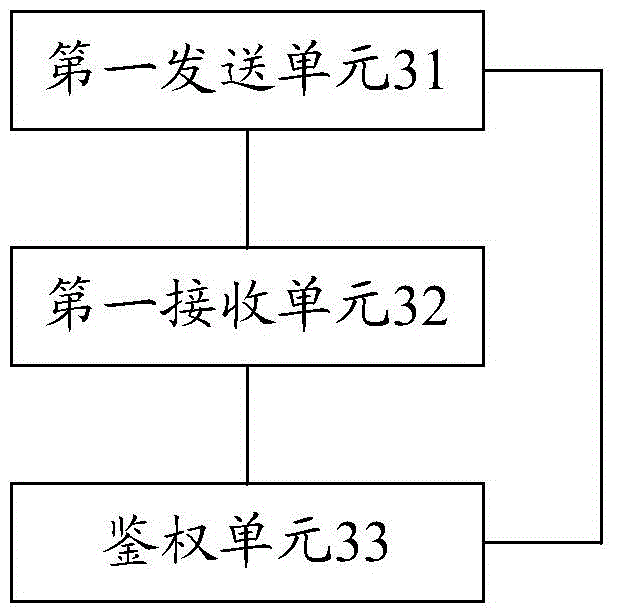

Open knowledge bases method and equipment for user authentication

InactiveCN101938466APrevent brute force crackingReduce cost pressureTransmissionSpecial data processing applicationsUser deviceService provision

The invention aims to provide open knowledge bases method and equipment for user authentication. The method comprises the following steps of: selecting a problem from the open knowledge base by the network equipment; sending the problem and an answer input frame thereof to the UE (User Equipment) of a user; acquiring a user response to the problem, wherein the user response is input in the answer input frame by the user; and matching and comparing the user response with the answer to the problem so as to acquire a matching result; and feeding back information related to the matching result to the UE. Compared with the prior art, by selecting the user authentication problem from the open knowledge base, the invention effectively avoids brutal computer cracking and relieves the cost pressure of an authentication service provider for maintaining a great amount of data so as to realize a user authentication technology with high security and high reliability in an effective cost mode.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

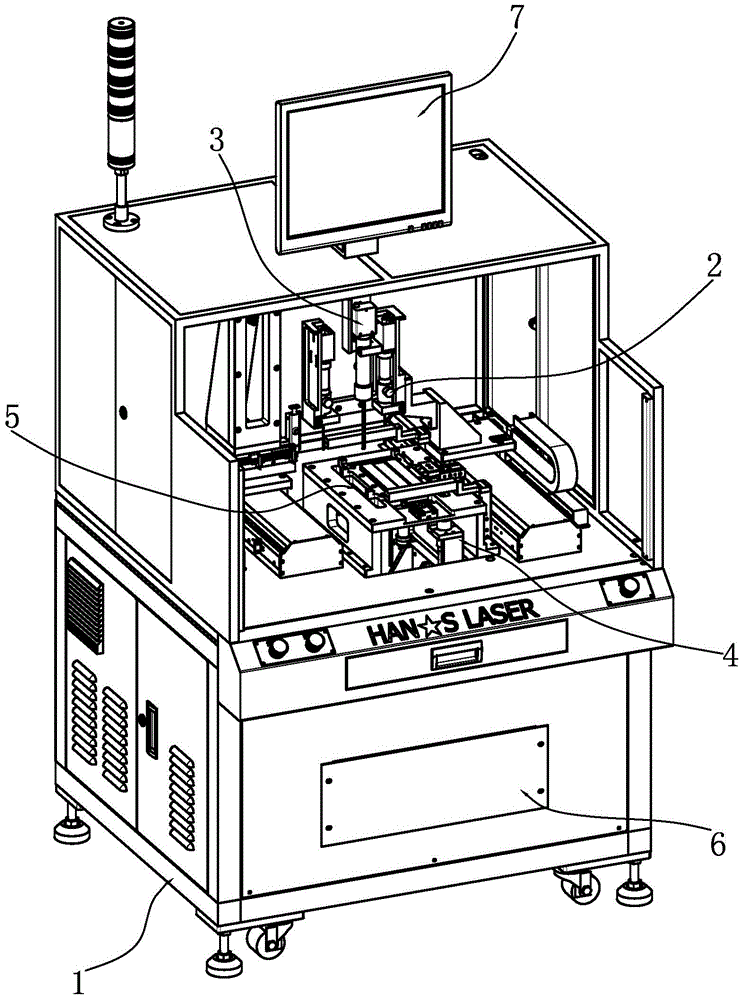

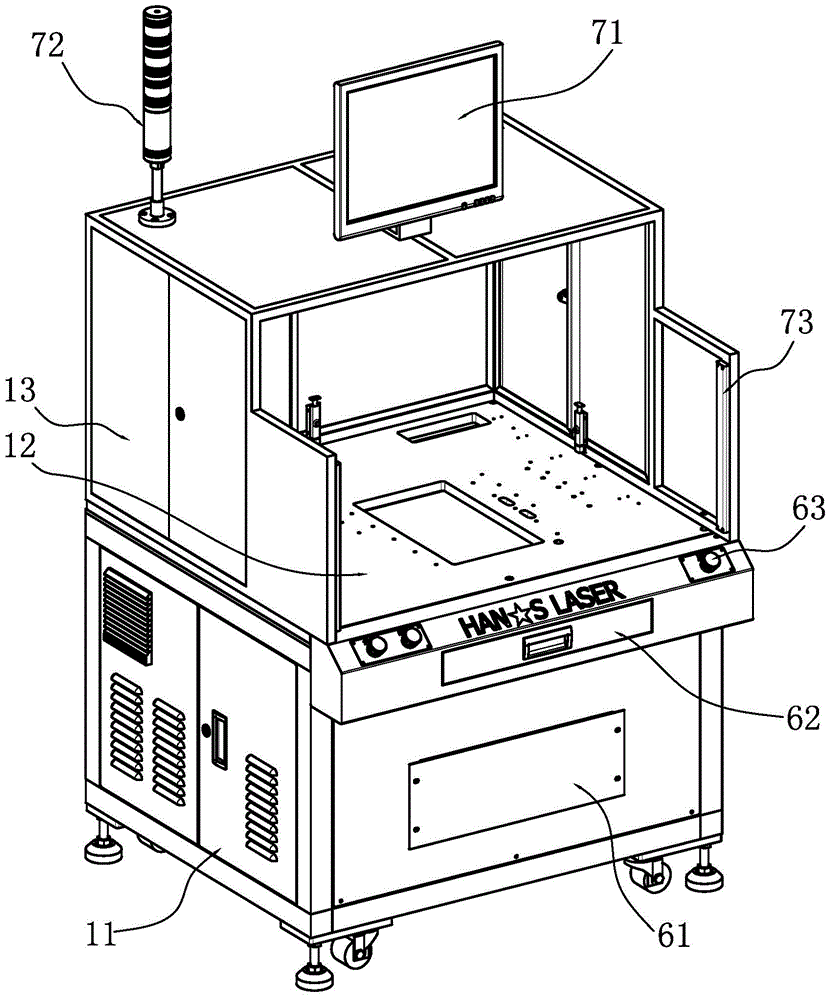

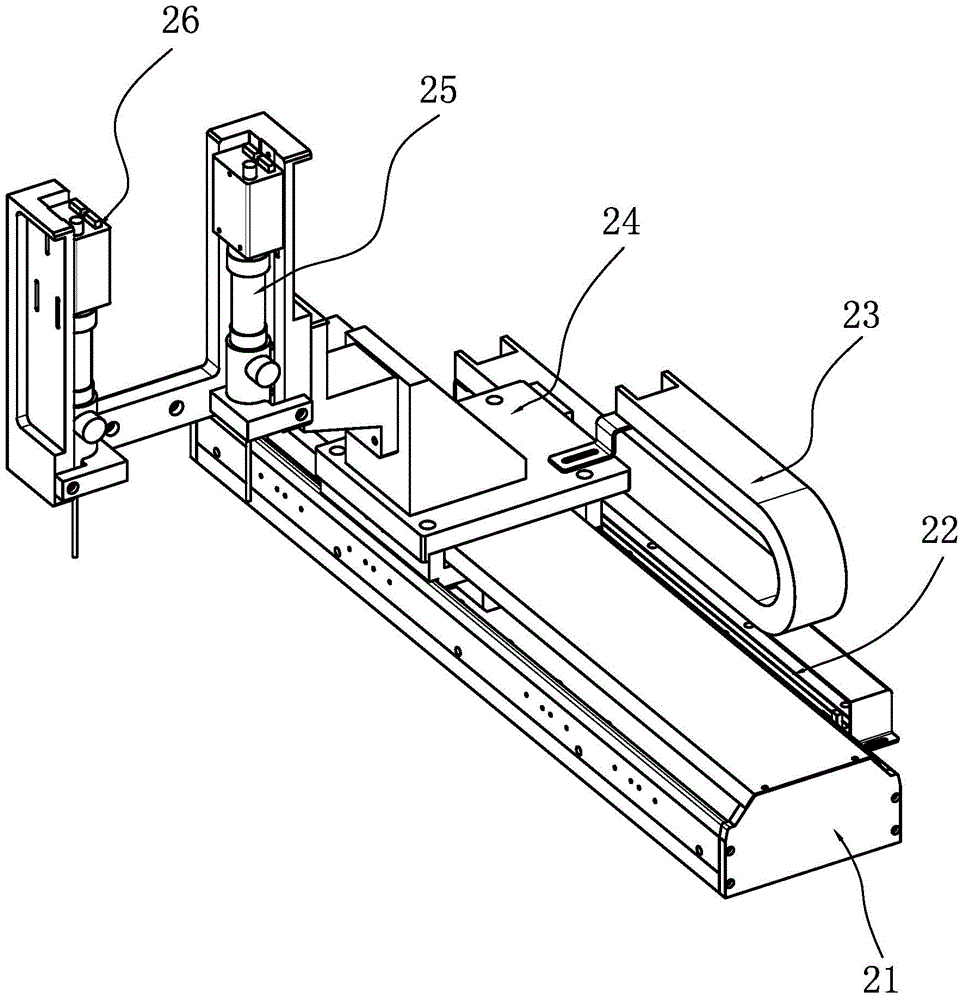

Automatic measurement equipment for profile and position of logo mounting hole

InactiveCN104482883AReduce cost pressureImprove measurement efficiencyUsing optical meansEngineering

The invention relates to the field of measurement equipment, in particular to automatic measurement equipment for the profile and the position of a logo mounting hole. The automatic measurement equipment comprises a processing device as well as three precision servo motion platforms and five cameras which are controlled by the processing device, wherein a first precision servo motion platform drives a first camera and a second camera to perform shooting scanning on two long edges of a rectangular casing of a to-be-measured product, a second precision servo motion platform drives a third camera and a fourth camera to perform shooting scanning on two short edges of the rectangular casing of the to-be-measured product, a third precision servo motion platform drives a fifth camera and a second camera to perform shooting scanning on the logo mounting hole of the to-be-measured product, and the processing device can calculate the profile and the position of the logo mounting hole according to the measurement data provided by the five cameras. The automatic measurement equipment can be well applied to the application condition of batch product manufacture.

Owner:HANS LASER TECH IND GRP CO LTD

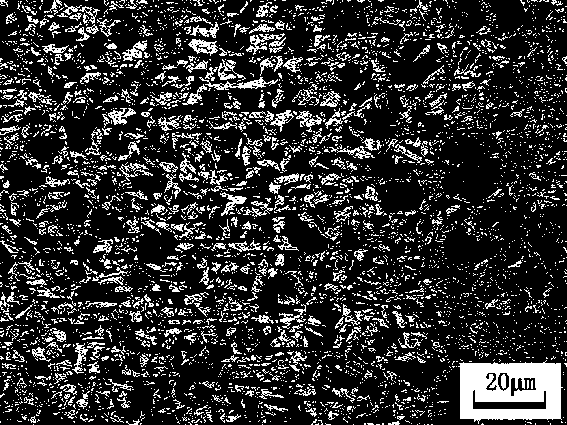

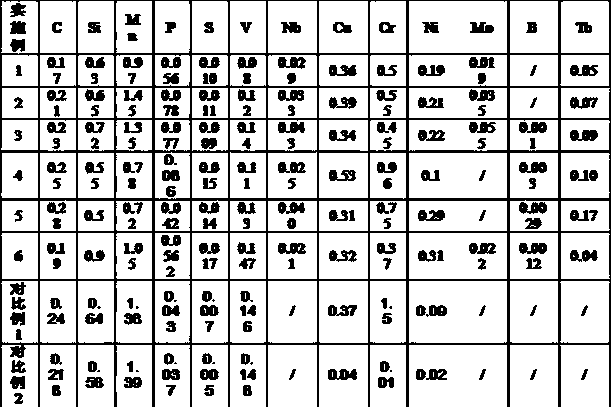

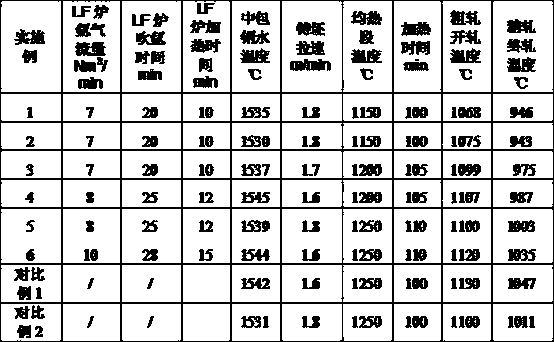

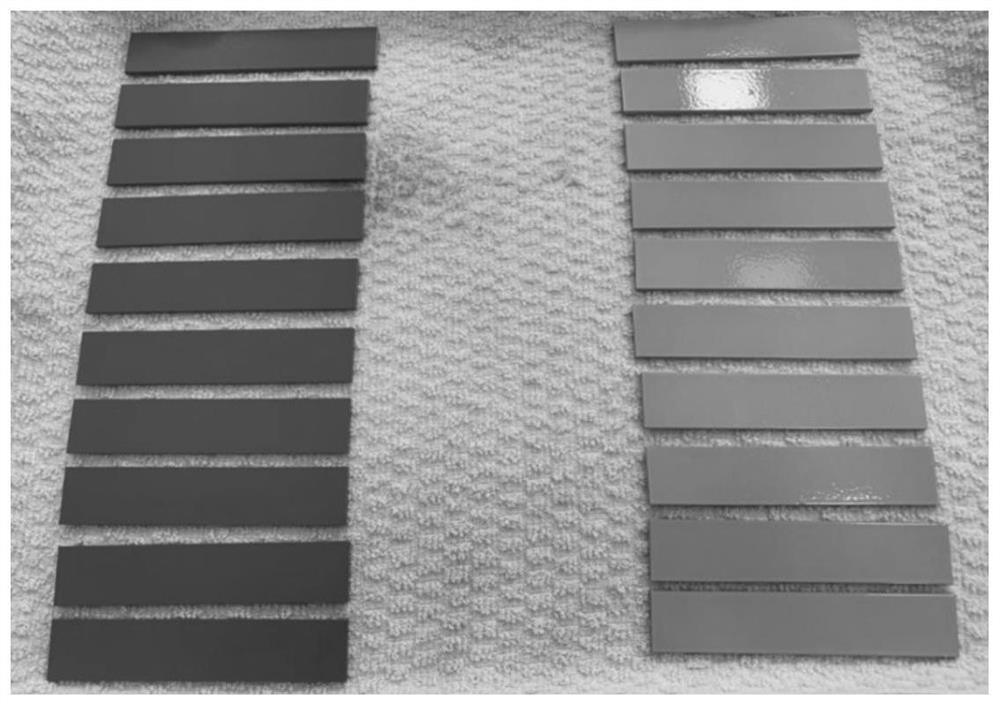

Corrosion-resistant hot-rolled ribbed steel bar with yield strength not less than 600Mpa and production method thereof

InactiveCN103451525AReduce cost pressureThere is no disadvantage of accelerated corrosion rateEpoxyFree cooling

The invention relates to a corrosion-resistant hot-rolled ribbed steel bar with yield strength not less than 600Mpa. The corrosion-resistant hot-rolled ribbed steel bar comprises the following components in percentage by weight: 0.17-0.28% of C, 0.50-0.90% of Si, 0.70-1.50% of Mn, 0.04-0.009% of P, not more than 0.015% of S, 0.08-0.15% of V and 0.025-0.045% of Nb. A production process comprises the following steps: desulfurizing molten iron; performing top and bottom combined blowing by virtue of a converter; refining by virtue of an argon station; refining by an LF (ladle furnace); performing continuous casting; stacking and cooling to a room temperature; heating a cast blank; performing rough rolling and finish rolling; naturally cooling to the room temperature. Compared with a steel bar with an epoxy resin coating, the corrosion-resistant hot-rolled ribbed steel bar has no defect of acceleration of corrosion rate caused by shedding of the coating; compared with the steel bar made of stainless steel, the corrosion-resistant hot-rolled ribbed steel bar has the advantage that the content of Cr is greatly reduced; compared with the ordinary steel bar, the corrosion-resistant hot-rolled ribbed steel bar has the advantage that the resistance to Cl ion corrosion is above 2 times higher than that of the ordinary steel bar; only the refining by virtue of the LF is additionally performed in an existing 400MPa grade steel bar process line, the increase in per ton of steel does not exceed 30 yuan, and then the production can be met.

Owner:武汉钢铁有限公司

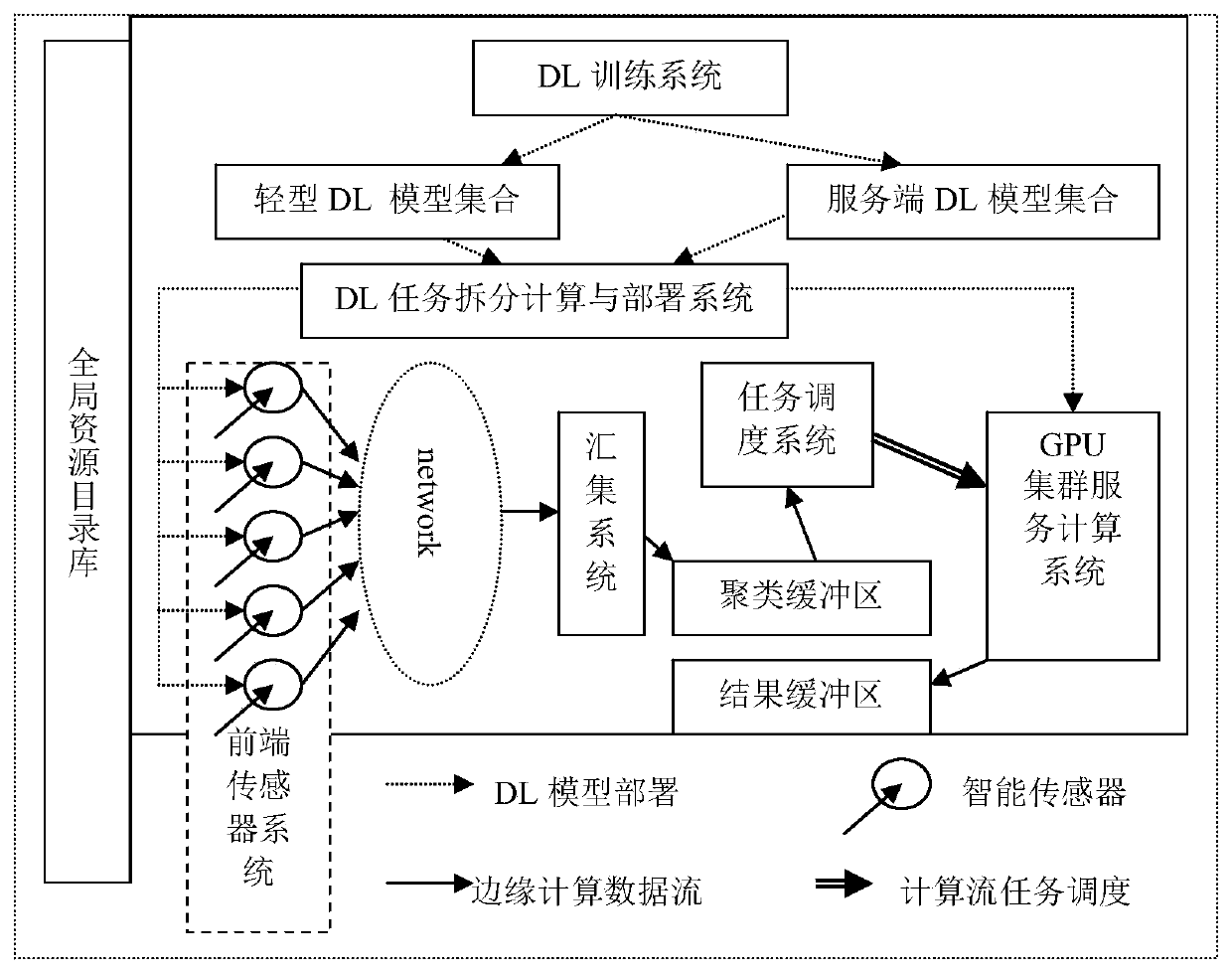

A GPU cluster deep learning edge computing system oriented to sensing information processing

ActiveCN109948428AImprove Parallel Computing EfficiencyReduce cost pressureCharacter and pattern recognitionTransmissionInformation processingRelease consistency

The invention relates to a GPU cluster deep learning edge computing system oriented to sensing information processing. pre-feature extraction is carried out on sensing information by using weak computing power of front-end intelligent sensing equipment; the quantity of original data information is greatly compressed, then the rest processing tasks are transmitted to a GPU cluster for large-scale sensing data feature clustering set processing, the computing power of front-end intelligent sensing equipment can be dynamically adapted through task splitting processing, and the cost pressure of theconsistency requirement of the front-end sensing equipment and hardware versions is reduced; The communication pressure of the edge computing network is reduced, so that the cost of constructing theedge computing network is greatly reduced; Network data feature transmission hides user privacy;, the SPMD advantages of the GPU are brought into play through the clustering operation according to thedata transmitted in the network and the stored data core characteristics, the parallel computing efficiency of edge computing is improved, and meanwhile, the large-scale parallel computing capacity of the GPU cluster and the advantages of low cost and high reliability are effectively brought into play.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Programmable general tyre pressure sensor installation system and installation method

ActiveCN101169344AChange the installation methodReduce cost pressureElectric signal transmission systemsInflated body pressure measurementPneumatic pressureProgram code

The invention relates to a programmable universal tire pressure sensor setting system and setting method, which includes a tire pressure sensing device, the tire pressure sensing device includes a sensor for sensing the air pressure and temperature inside the tire, and a sensor for receiving external signals A receiver, a storage processing group connected to the sensor and the receiver, a transmitter connected to the storage processing group; a power supply group providing power required by the tire pressure sensing device. Its setting method is to first take an unactivated tire pressure sensing device, and then select a specific activation signal by a processing device, transmit the activation signal to a program coding device, activate the tire pressure sensing device through the program coding device, and make the tire pressure The sensing device becomes a sensing device conforming to a specific coded program, which in turn communicates in telecommunication with an external specific monitoring device. The present invention not only changes the conventional installation method, makes the installation method simpler, but also greatly reduces the cost pressure on stock preparation, and obviously improves the problem of conventional products.

Owner:CUB ELECPARTS

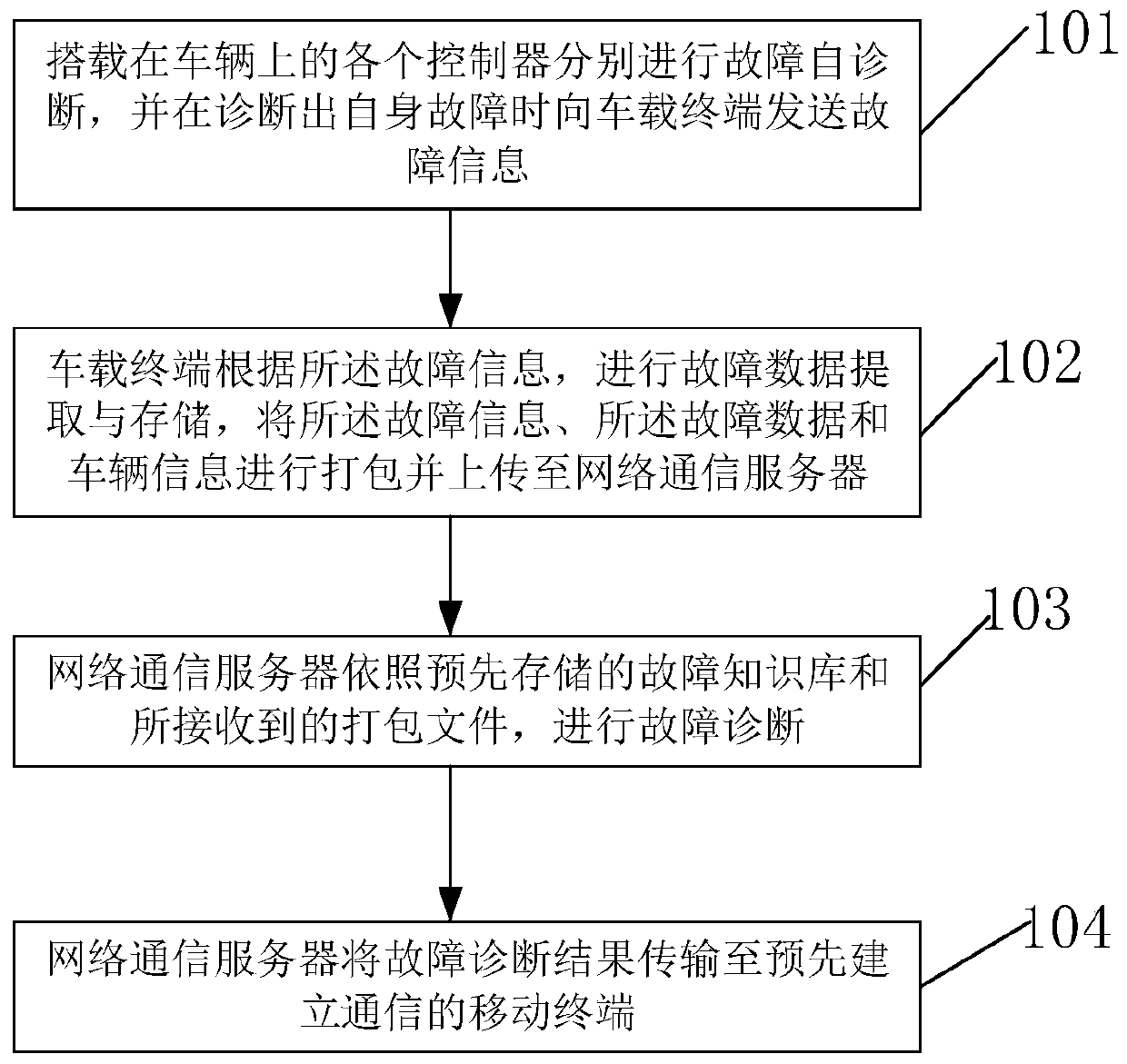

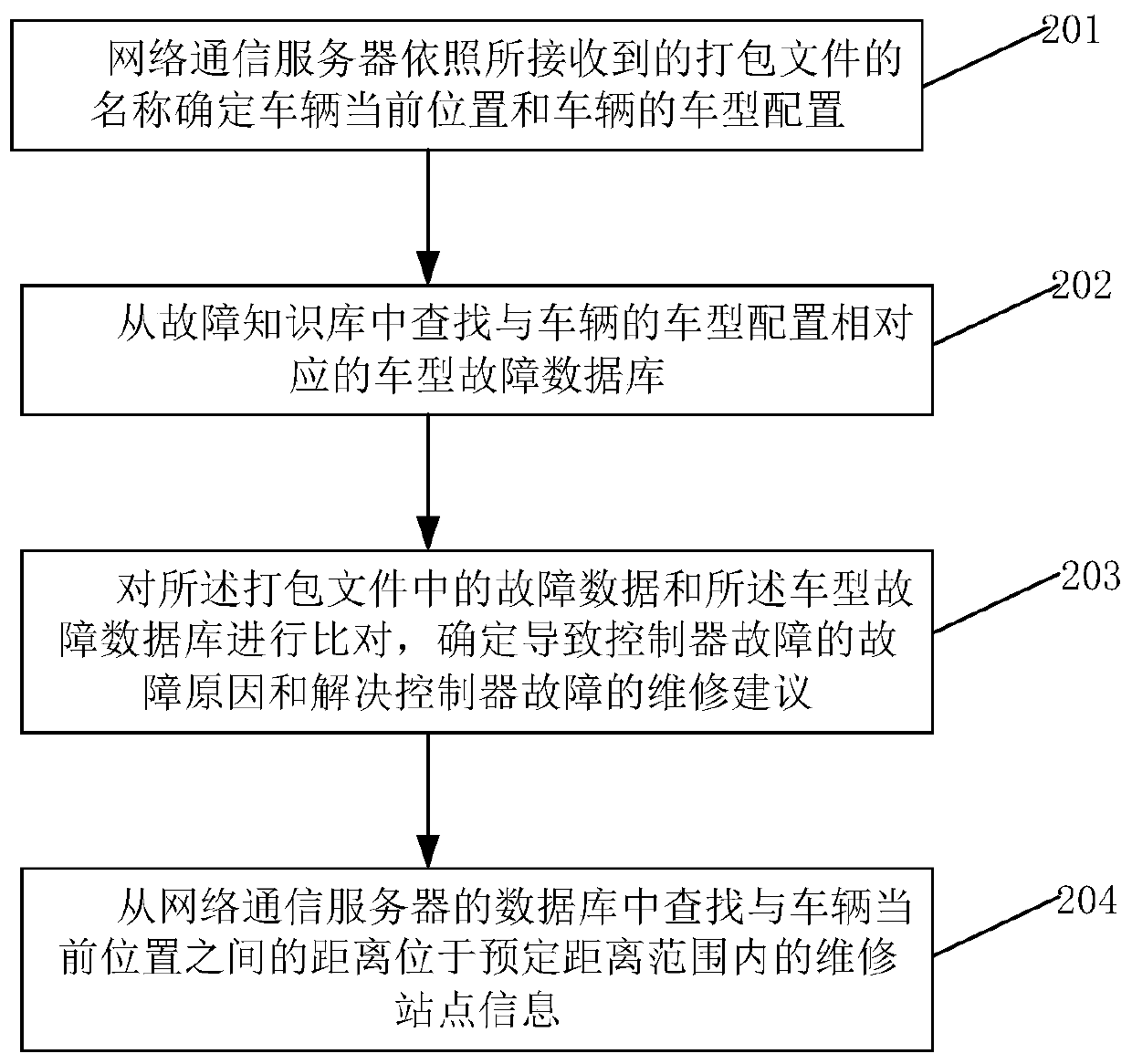

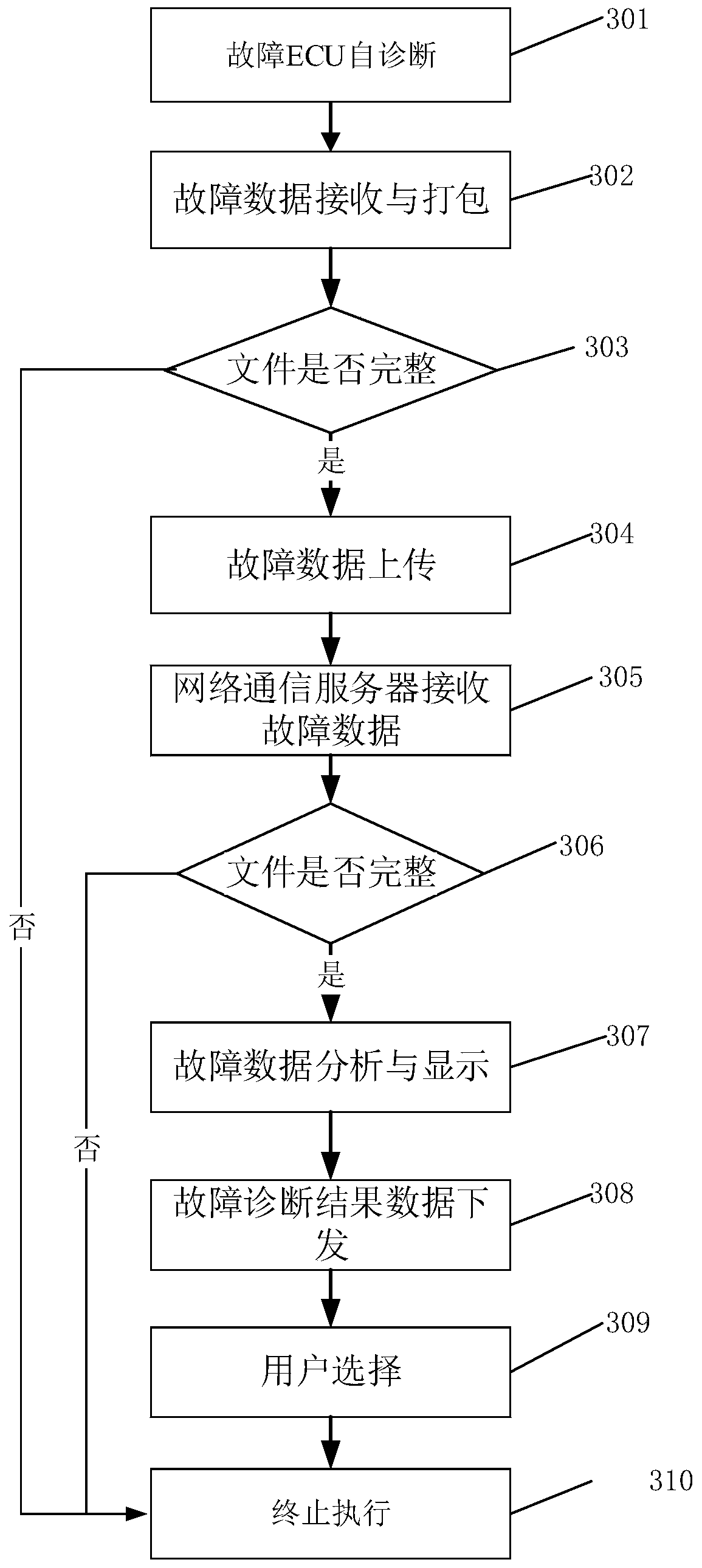

Remote fault diagnosis method and system for new energy vehicle

InactiveCN110109447AQuick repairReduce cost pressureProgramme controlElectric testing/monitoringNew energyDiagnosis methods

The invention relates to a remote fault diagnosis method and system for a new energy vehicle. Specific data at the fault occurring moment are collected, packed, uploaded and analyzed so as to solve the problems of unclear fault positioning and low positioning efficiency in the prior art; and by pushing fault suggestions and maintenance sites, the problem that the new energy vehicle cannot feed vehicle faults and a maintenance scheme back to a user in time is solved. The remote fault diagnosis method for the new energy vehicle comprises the steps that all controllers carried on the vehicle conduct fault self-diagnosis and send fault information to a vehicle-mounted terminal when the faults of the vehicle are diagnosed; the vehicle-mounted terminal extracts and stores fault data according tothe fault information, and the fault information, the fault data and vehicle information are packed and uploaded to a network communication server; and the network communication server conducts faultdiagnosis according to a pre-stored fault knowledge base and a received package file; and the network communication server transmits a fault diagnosis result to a mobile terminal pre-establishing communication with the network communication server.

Owner:深蓝汽车科技有限公司

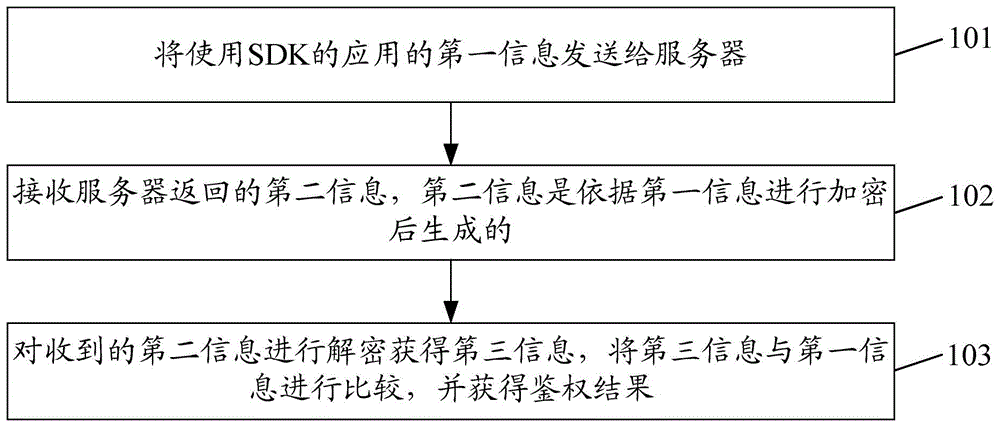

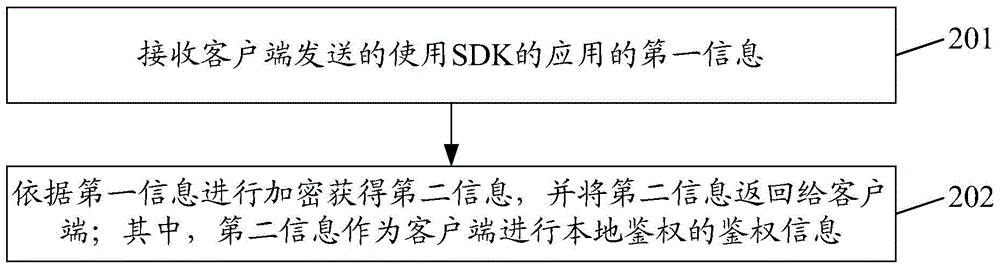

Information processing method, client, and server

ActiveCN104836784AShorten the timeReduce uncertaintyTransmissionInformation processingSoftware development

The invention discloses an information processing method, a client, and a server. The information processing method is characterized in that first information adopting a software development kit (SDK) can be transmitted to the server; second information returned by the server can be received, when the first information is defined as legal, and the second information can be generated after the encryption of the first information; third information can be acquired by decrypting the received second information according to a decryption key from the server, and by comparing the third information with the first information, the authentication result can be acquired.

Owner:TENCENT TECH (BEIJING) CO LTD

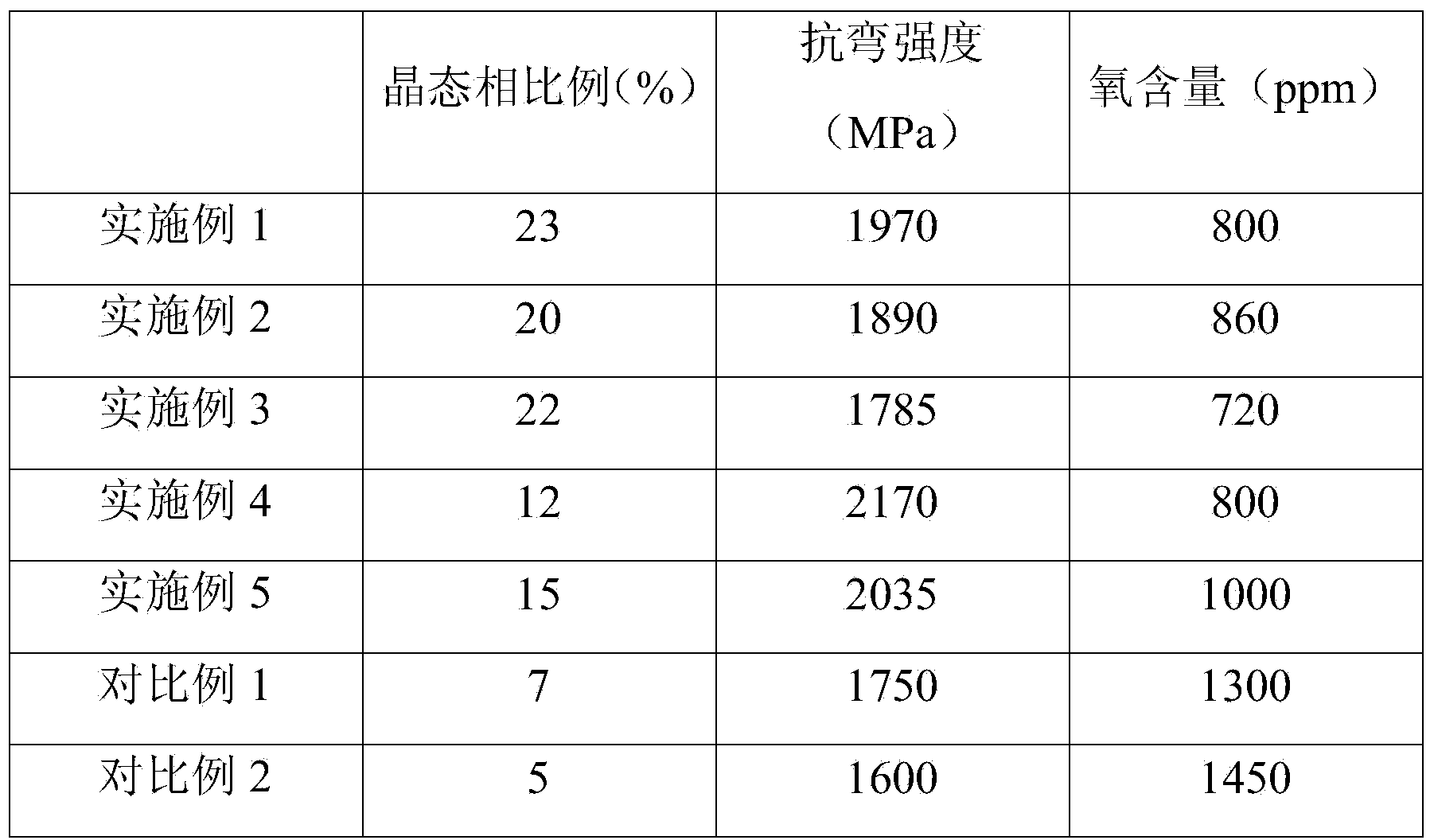

Zirconium-based amorphous alloy and preparation method thereof

ActiveCN103484800ALow preparation requirementsOverall performance will not be affectedMetallic materialsCritical dimension

Owner:METASTABLE TECH INVESTMENT CO LTD

Taihu sheep feed and production method thereof

The present invention discloses Taihu sheep (raised in Taihu River Basin, China) feed and a production method thereof. The feed is characterized in that the feed comprises the following raw materials in parts by weight: fodder 70-80 parts, cassava residues 15-20 parts, corn 1-3 parts, soybean meal 1-3 parts, wheat bran 0.1-0.5 part, table salt 0.1-0.5 part, calcium powder 0.1-0.3 part, molasses 0.1-0.3 part, Chinese medicinal herb 0.1-0.3 part, trace element 0.1-0.3 part, multi-vitamin powder 0.01-0.05 part, sodium humate 0.01-0.05 part, cod liver oil 0.001-0.003 part, beneficial bacteria 0.01-0.05 part and heavy metal removal agent 0.01-0.05 part. The feed has characteristics of high efficiency and environmental protection, good palatability, normal growth and development promotion, immunity enhancement, low cost, simple production, etc.

Owner:谢向萌

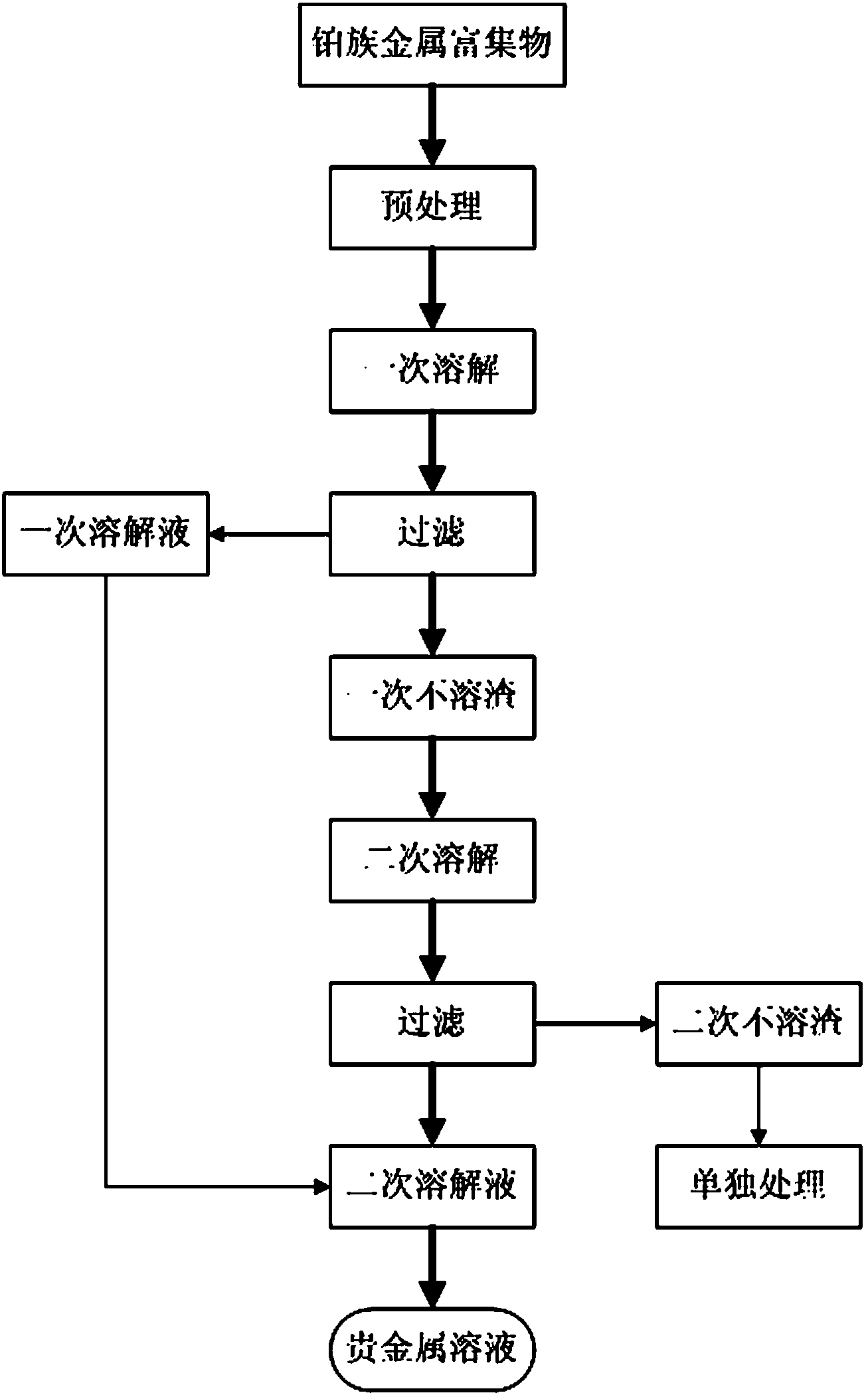

Method for dissolving platinum group metals in automobile spent catalyst enrichment

InactiveCN103526033AReduce cost pressureReduce pressure on environmental protectionProcess efficiency improvementPre treatmentEnvironmental chemistry

The invention relates to a method for recovering platinum group metals from automobile spent catalysts and in particular relates to a method for dissolving platinum group metals in automobile spent catalyst enrichment. The method comprises the following steps: after pretreating the enrichment which contains platinum group metals and is obtained by enriching the automobile spent catalysts, adding oxidants to hydrochloric acid media so that the platinum group metals are fully and quickly dissolved and transferred to a solution, and treating insoluble substances after being filtered. The method has the advantages of high platinum group metal recovery rate, short flow, low environmental protection pressure, low cost and the like.

Owner:昆明贵研催化剂有限责任公司

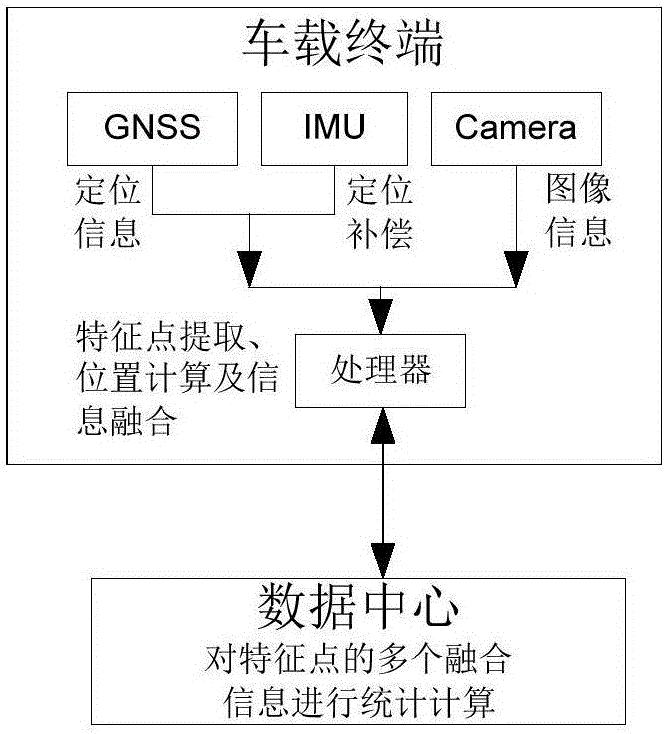

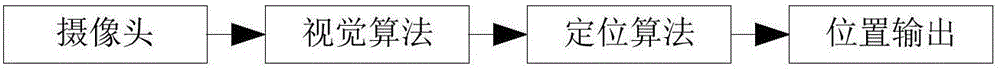

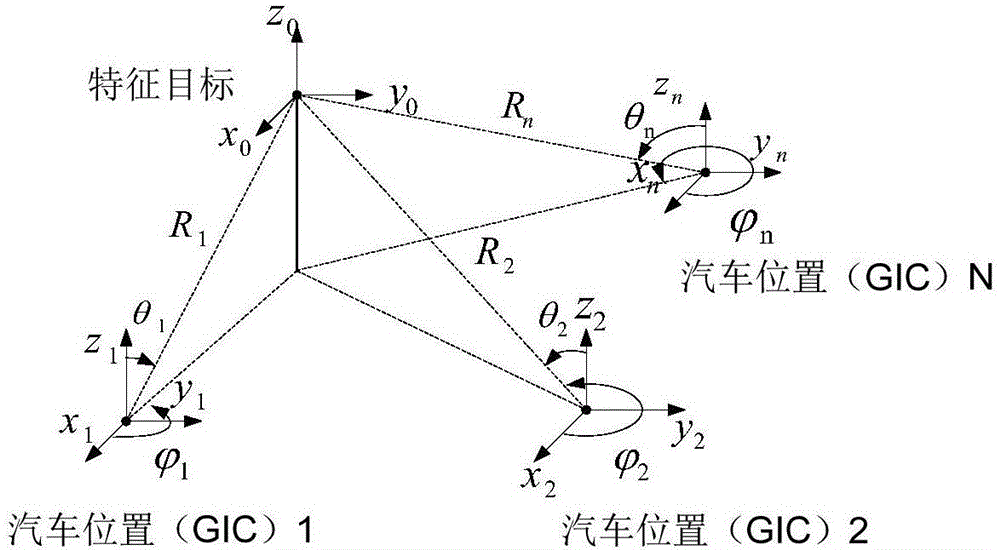

Method for high-precision positioning of automobile through scene recognition

InactiveCN106643690AReduce cost pressureLow costNavigation by speed/acceleration measurementsSatellite radio beaconingData centerData transmission

The invention provides a method for high-precision positioning of an automobile through scene recognition. The method comprises steps as follows: a car captures a driving environment characteristic target in different positions through a car-mounted terminal, calculates the characteristic points (certain positions like geometrical center) of the characteristic target and uploads the characteristic points to a data center, the data center calculates the accurate position of the characteristic target based on different capturing positions of the same characteristic target, and the accurate position of the car is calculated according to the accurate position of the characteristic target. The car-mounted terminal integrating a camera, an inertia unit and a satellite positioning unit is used for acquiring the driving characteristic target of the car, image characteristic point extraction and information integration are performed, the position of the car can be calculated according to the position of the characteristic point, the position of the characteristic point is calculated by the data center, and data transmission between a car-mounted module and a data service center is realized. The car-mounted terminal is mounted above the middle of front windshield glass of the car.

Owner:CHINA FIRST AUTOMOBILE

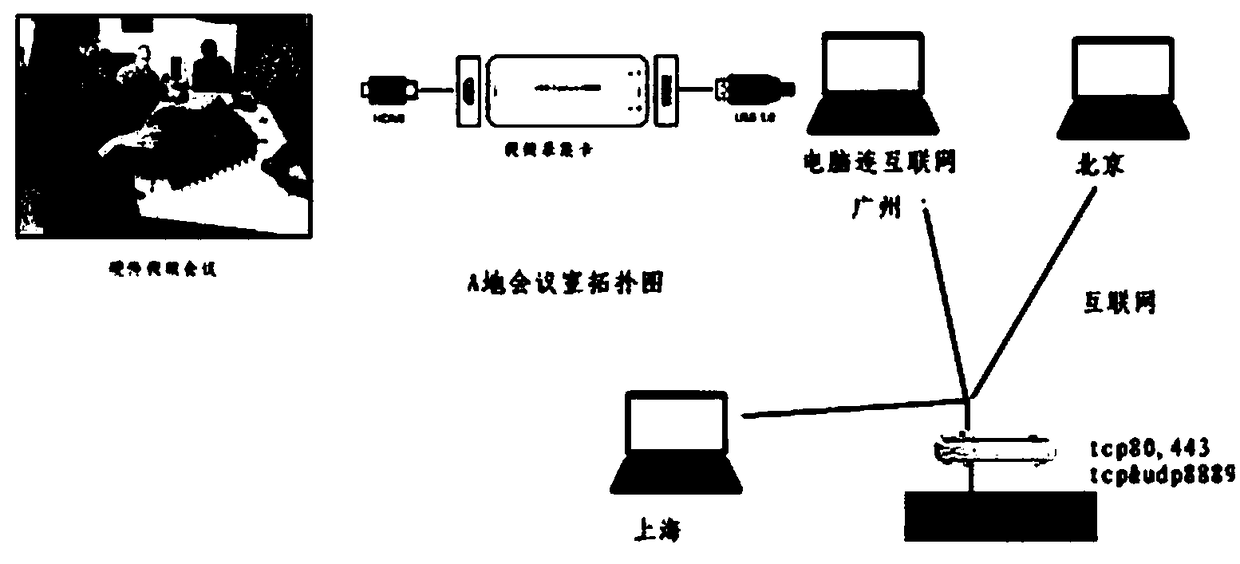

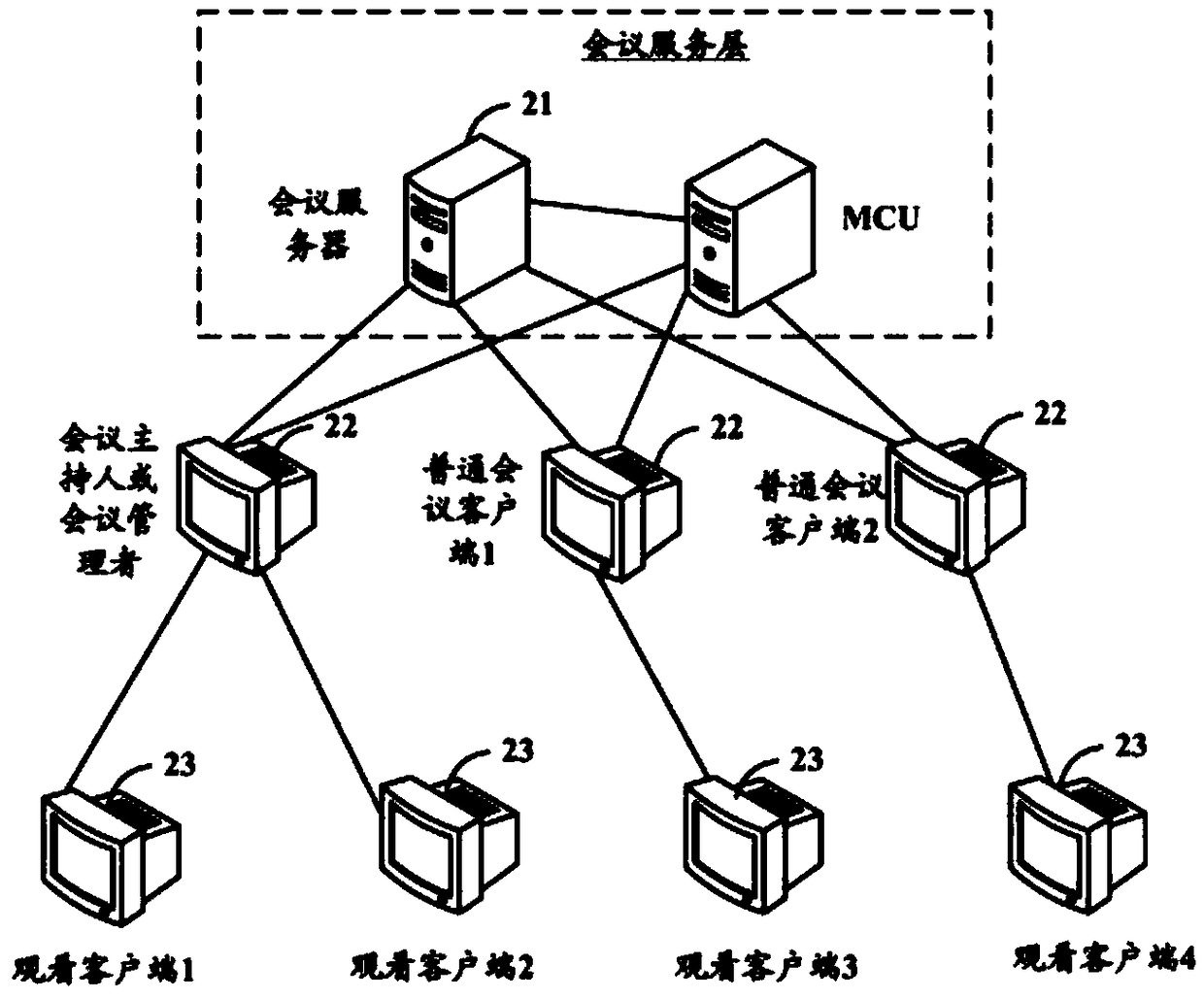

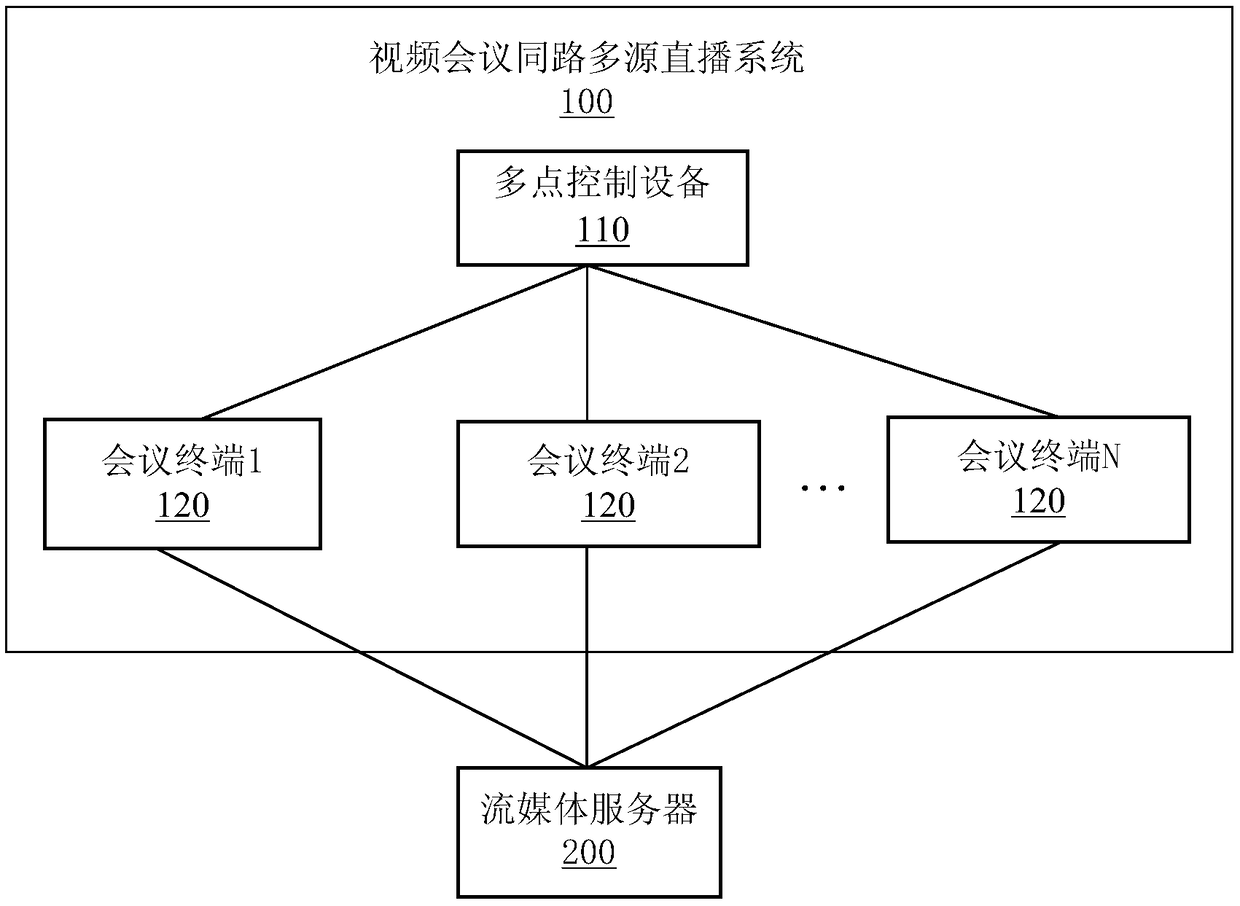

Video conference co-channel multi-source live broadcast method and system

InactiveCN109361893AReduce complexityReduce the difficulty of operationTelevision conference systemsTwo-way working systemsComputer terminalMedia server

The invention provides a video conference co-channel multi-source live broadcast method and system. The video conference co-channel multi-source live broadcast system comprises a multipoint control device and at least two conference terminals; the multipoint control device establishes a video conference live connection for each conference terminal, receives streaming push capability information from each conference terminal, and sends the received streaming push capability information of each conference terminal to all conference terminals; and each conference terminal determines a conferenceterminal that has the best streaming push capability information in all conference terminals according to the received streaming push capability information of each conference terminal, and the conference terminal with the best streaming push capability information performs live broadcast and streaming push on the audio and video information of the video conference site to a streaming server. Theinvention uses the existing equipment and the own capability of the video conference, and realizes the method for same source multi-channel intelligent autonomous switching of live video conference through each conference terminal; therefore, the investment of other director or external devices is saved, the complexity and operation difficulty of the live broadcast system are reduced, and the invested cost and bandwidth pressure are reduced.

Owner:SHANGHAI AVCON INFORMATION TECH

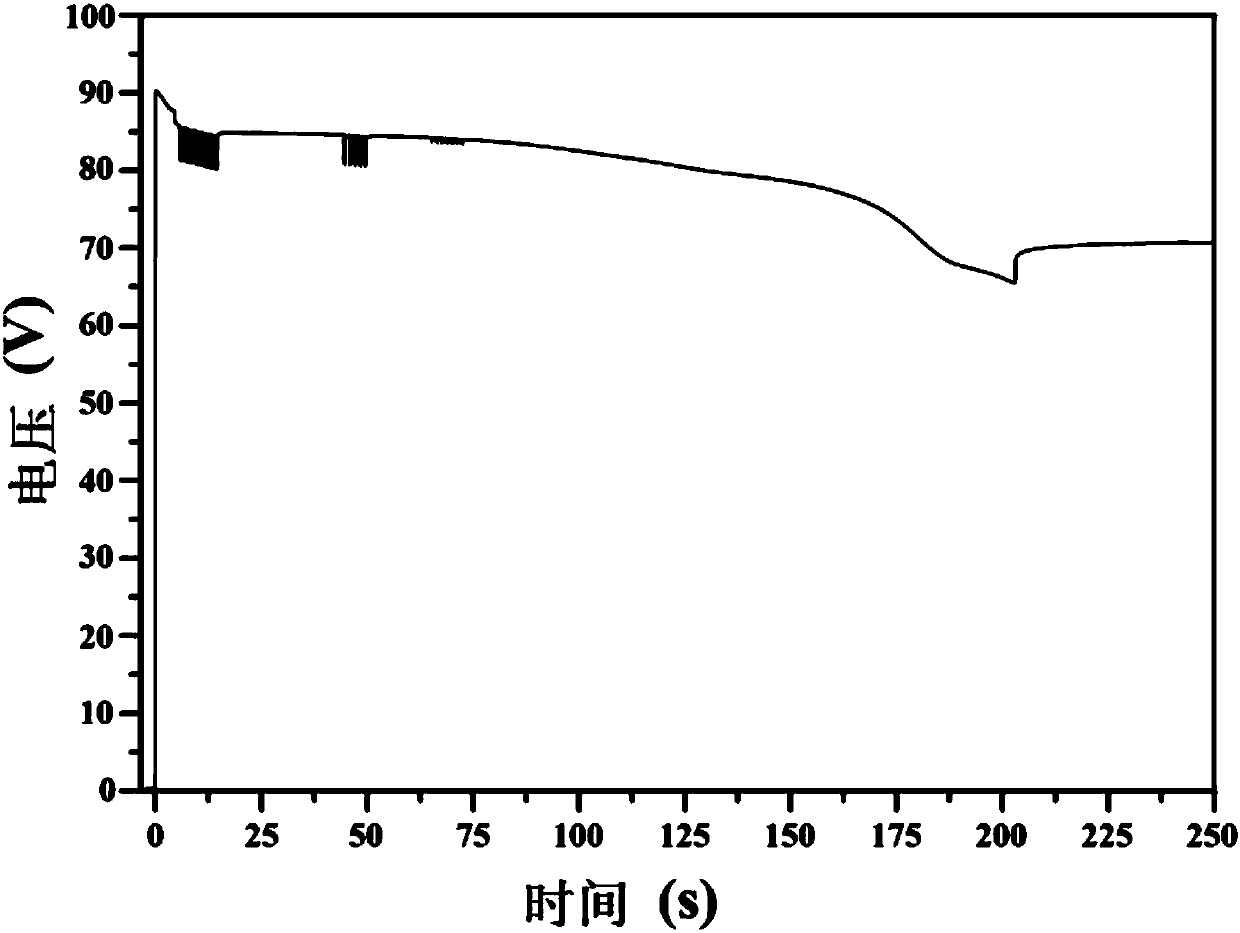

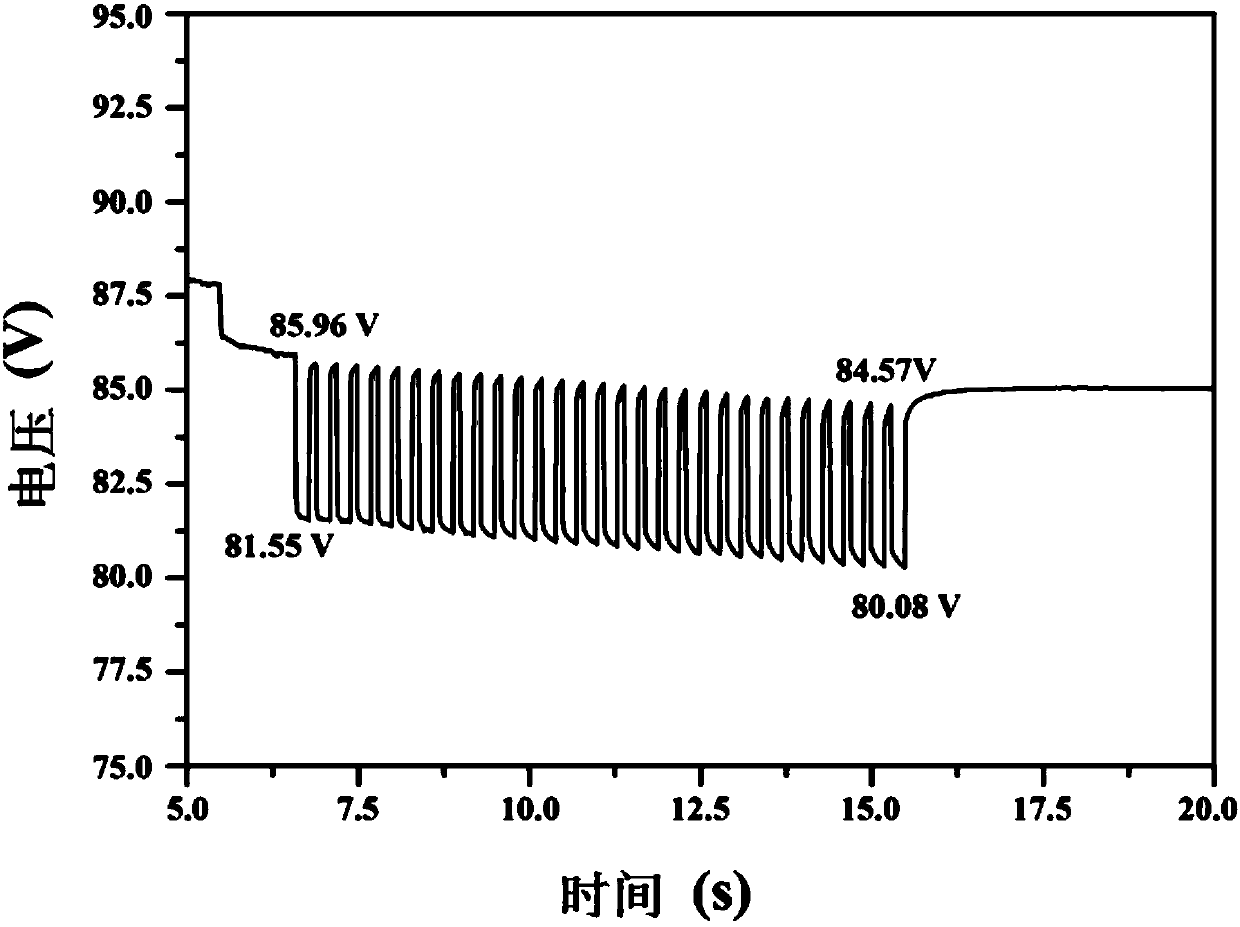

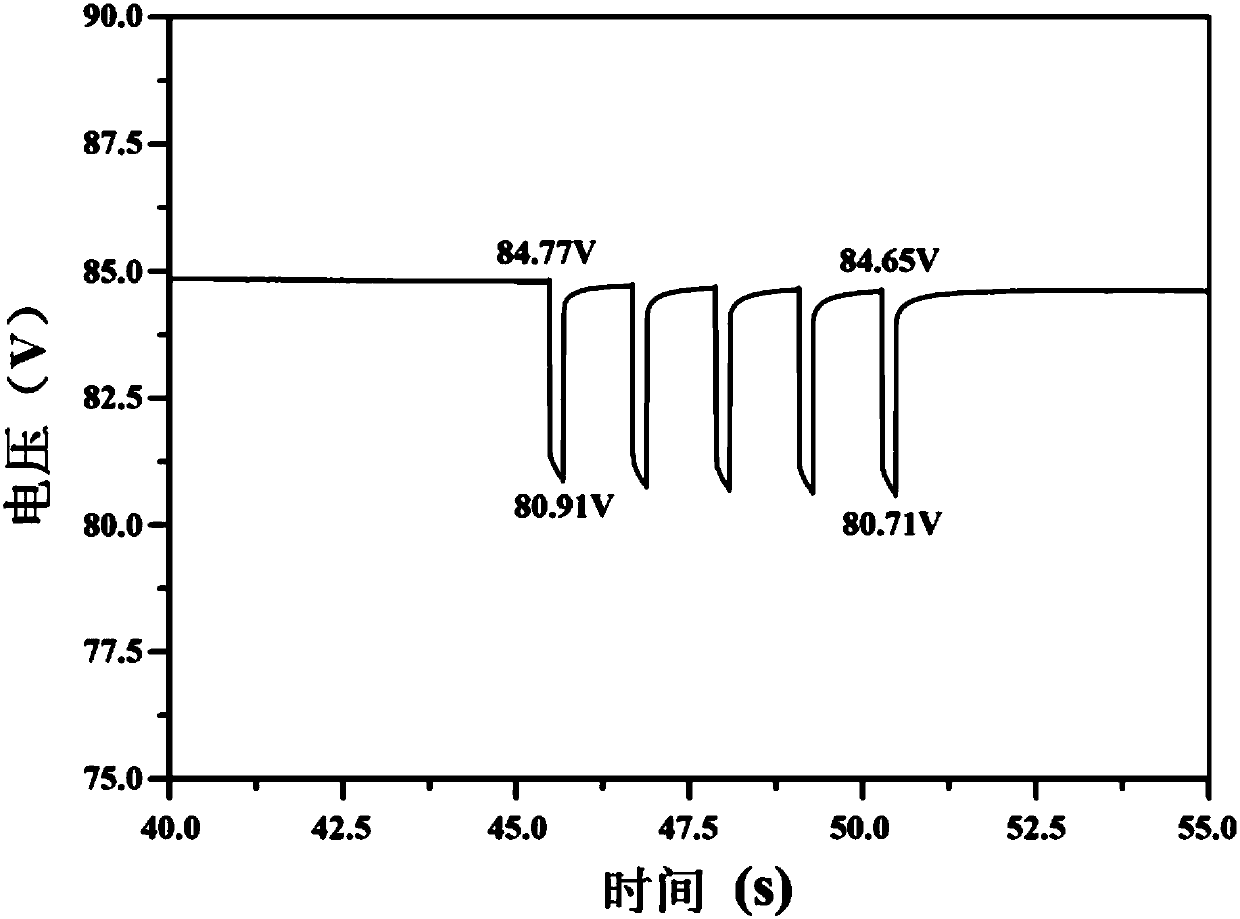

Battery cell of thermal battery for carrier rocket

ActiveCN107732268AGuaranteed adsorption effectGuaranteed reliable performanceDeferred-action cellsSorbentRocket

The invention discloses a battery cell of a thermal battery for a carrier rocket. The battery cell of the thermal battery for the carrier rocket comprises an isolating powder, a heating powder, a positive electrode powder and a negative electrode powder, wherein the isolating powder consists of LiF-LiCi-LiBr ternary all-lithium electrolyte molten salt and a molten salt adsorbent; the molten salt adsorbent accounts for 50-65% of the total mass of the isolating powder. A performance characteristic that the pulse voltage drop change rates of the thermal battery in three working time periods of 5-20s, 45-55s and 65-75s are lower than 2% is achieved, and the performance reliability of load equipment on the rocket is guaranteed. Raw materials and a component preparation technology of the batterycell of the thermal battery provided by the invention are the same as those of the conventional thermal battery, so that large-scale production can be carried out under the premise of not restructuring the conventional production line and the production process is high in universality; the cost pressure is low and the economic benefits are good while model development and production tasks of a new-generation solid carrier rocket are met.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

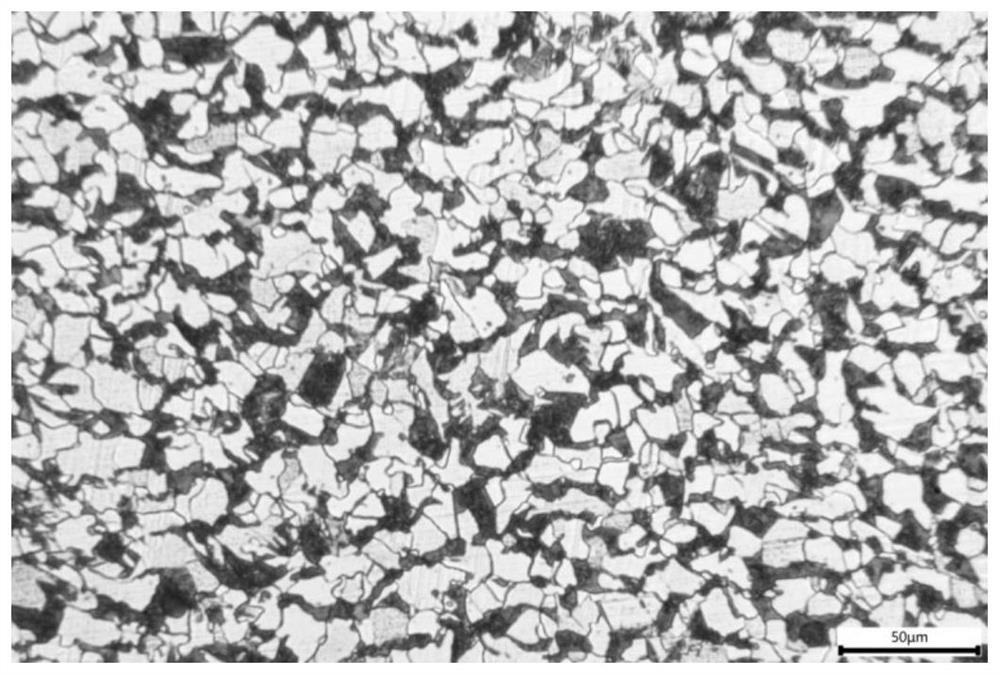

Low-alloy high-strength corrosion-resistant steel bar and preparation method thereof

The invention relates to a low-alloy high-strength corrosion-resistant steel bar composed of Al, Ti, Cr and other elements and a preparation method of the low-alloy high-strength corrosion-resistant steel bar, and belongs to the technical field of steel preparation. The low-alloy high-strength corrosion-resistant steel bar comprises the following components in percentage by weight: 0.05-0.2% of C,0.1-1.0% of Si, 0.8-1.5% of Mn, 0.5-1.5% of Cr, 0.005-0.15% of Ti, 0.005-0.60% of Al, 0.005-0.05% of V, 0.01-0.03% of Nb, less than or equal to 0.045% of S, less than or equal to 0.045% of P and thebalance of iron and inevitable impurity elements. The preparation method comprises the following steps that smelting is carried out in a converter to obtain crude molten steel, the crude molten steelenters an LF (ladle furnace) to be refined to obtain refined molten steel, the refined molten steel is continuously cast into small square billets, the small square billets are heated and soaked in aheating furnace, and rolled into steel bars with target specifications on a bar rolling mill, and the structure of the obtained corrosion-resistant steel bar is ferrite and pearlite. Compared with other corrosion-resistant steel bars, the production process is simple, and the obtained corrosion-resistant steel bars are high in yield strength and tensile strength and good in corrosion resistance.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

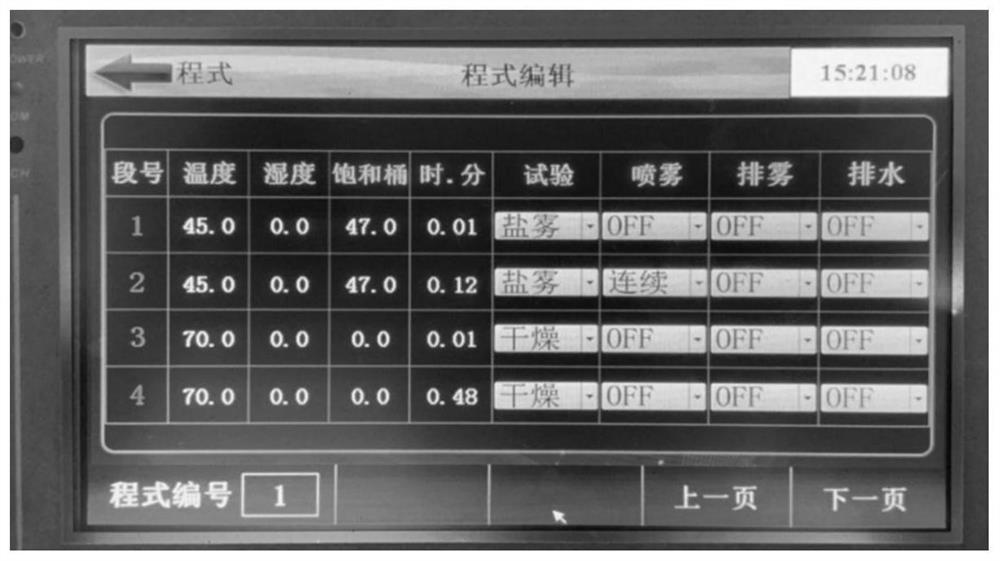

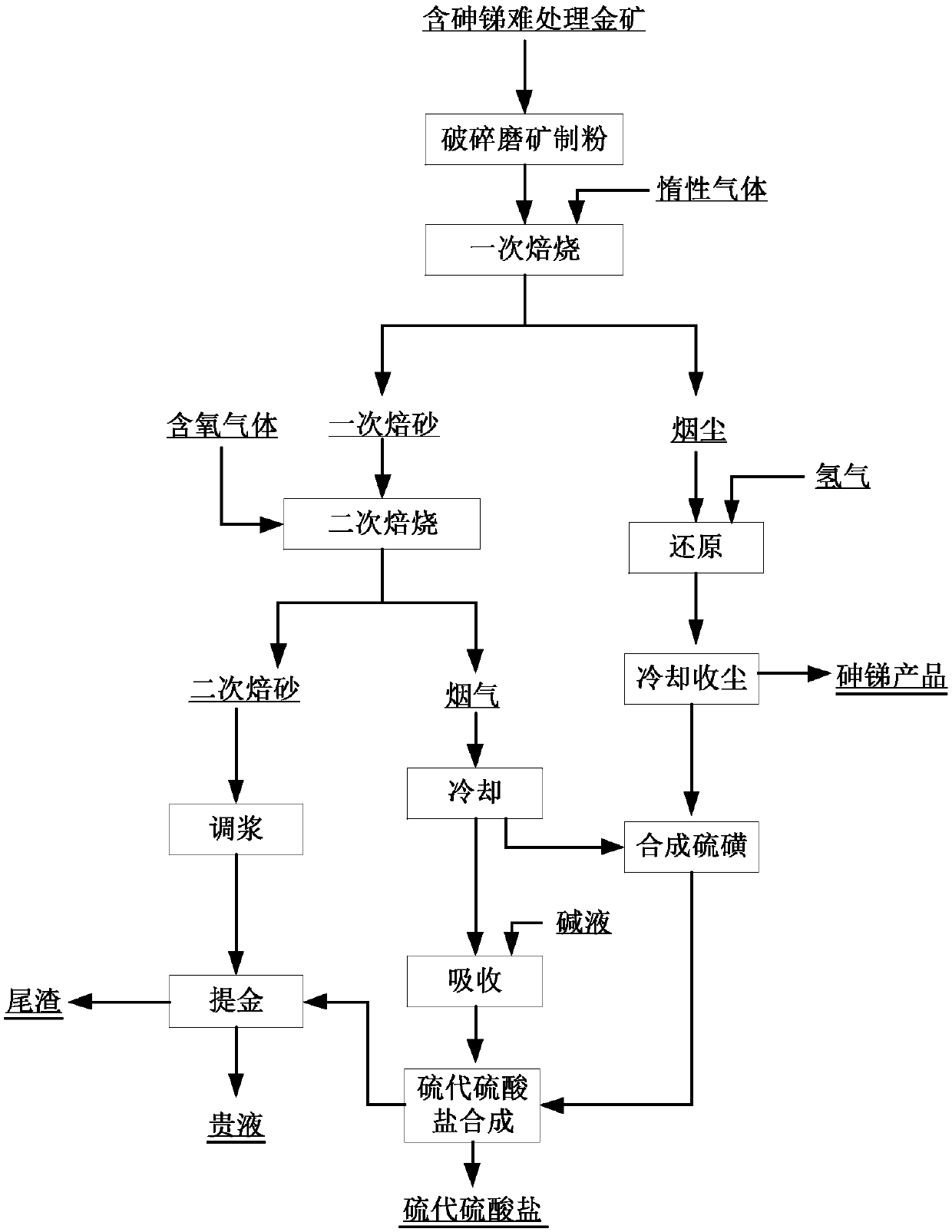

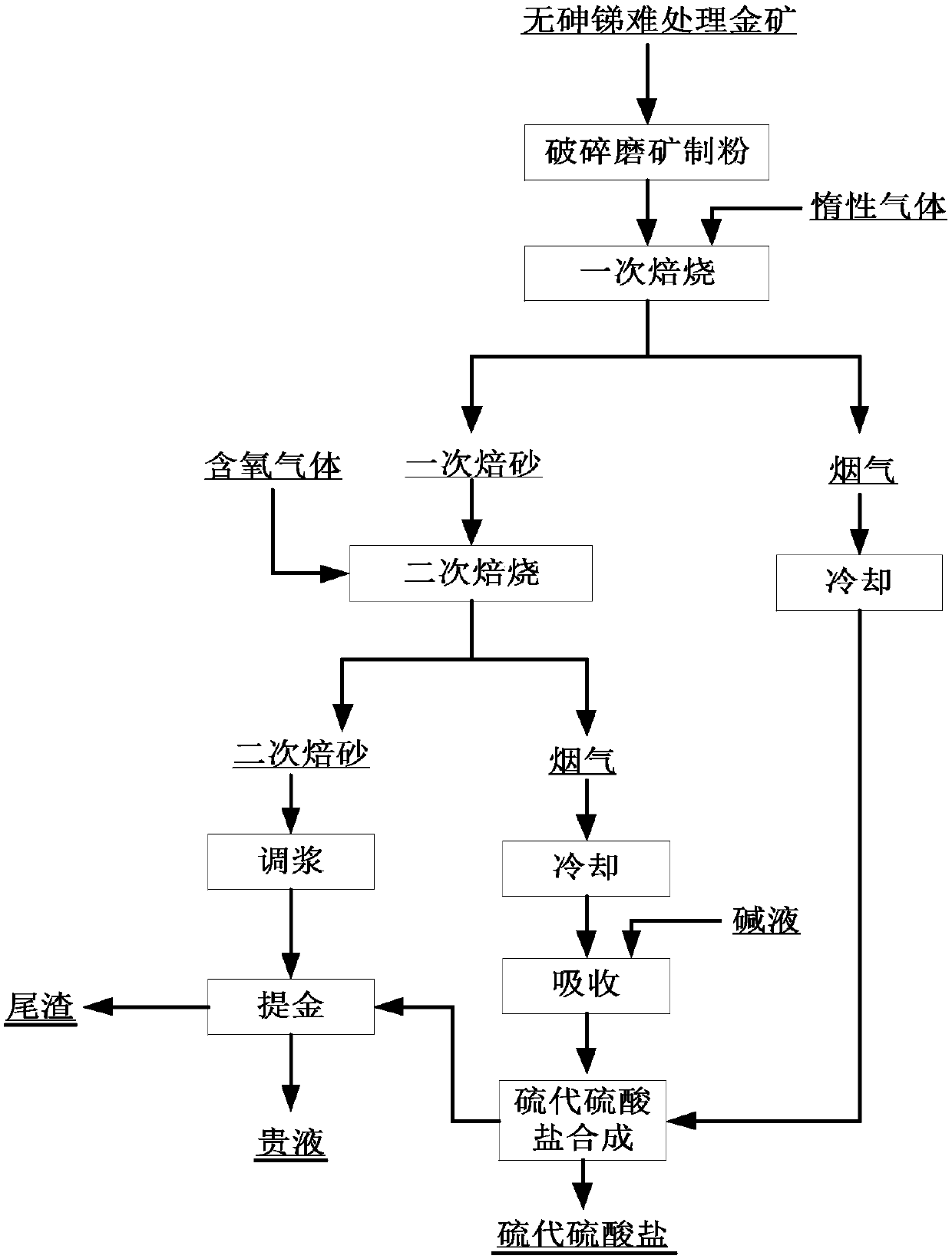

Technology for preparing thiosulfate on site and extracting gold from refractory gold ore

ActiveCN107893160AReduce consumptionLow costThiosulfates/dithionites/polythionitesOxygenSulfur containing

The invention relates to a technology for preparing thiosulfate on site and extracting gold from refractory gold ore. The technology comprises the following steps: crushing sulfur-containing refractory gold ore, and powdering by ball milling; roasting the powdered gold ore in one time under inert gas to obtain primary roasted ore and smoke A; roasting the primary roasted ore for the second time inair or oxygen-containing oxide mixed gas so as to obtain secondary roasted ore and gas B; cooling the gas B and charging into an alkaline solution for absorbing, so as to obtain a solution C; mixingthe smoke A and excessive hydrogen, and reacting to obtain a gas product D; reacting the cooled and dedusted gas D and B to generate sulphur; reacting sulphur and the solution C to obtain a thiosulfate solution. In case of gold ore without arsenic antimony, the technology comprises the following steps: cooling the smoke A, and reacting with the solution C to prepare thiosulfate solution; cooling and performing size mixing on the secondary roasted ore; and adding the thiosulfate solution to extract gold. The technology has the advantages of being green, environmentally friend, extracting gold without cyanogen, low in energy consumption, low in cost, high in economic benefit, high in social benefit, and high in environmental benefit.

Owner:NORTHEASTERN UNIV

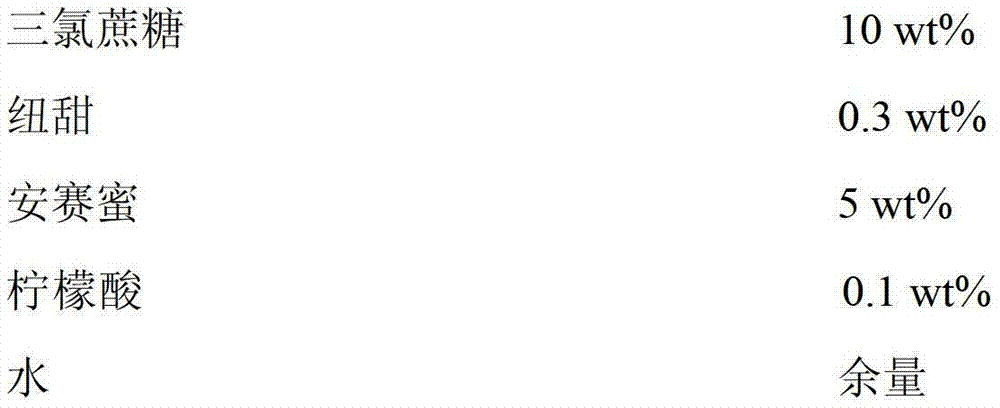

Liquid composite high-intensity sweeter and preparation method thereof

The invention discloses a liquid composite high intensity sweeter comprising sweet substances and a solvent. Based on the weight of the sweeter, the sweet substances are one or a plurality of the following components: 0.1-3wt% of aspartame, 0.1-30wt% of sucralose, 0.1-30wt% of acesulfame potassium and 0.01-10wt% of neotame. In addition, the invention further discloses a method for preparing the liquid composite high intensity sweeter. The liquid composite high intensity sweeter is obtained by dissolving the sweet substances into the solvent, not only has the similar sweet taste to sucrose and several times to thousandfold higher sweetness than sucrose, is mixed uniformly, and has no particles remained; the product quality and the convenience in use are beneficially improved, and the actual requirements of production and consumption are well satisfied; and meanwhile, the method for preparing the sweeter provides an effective guarantee for the quality and the edible safety of sweeter products.

Owner:TECHNO (FUJIAN) FOOD INGREDIENTS CO LTD

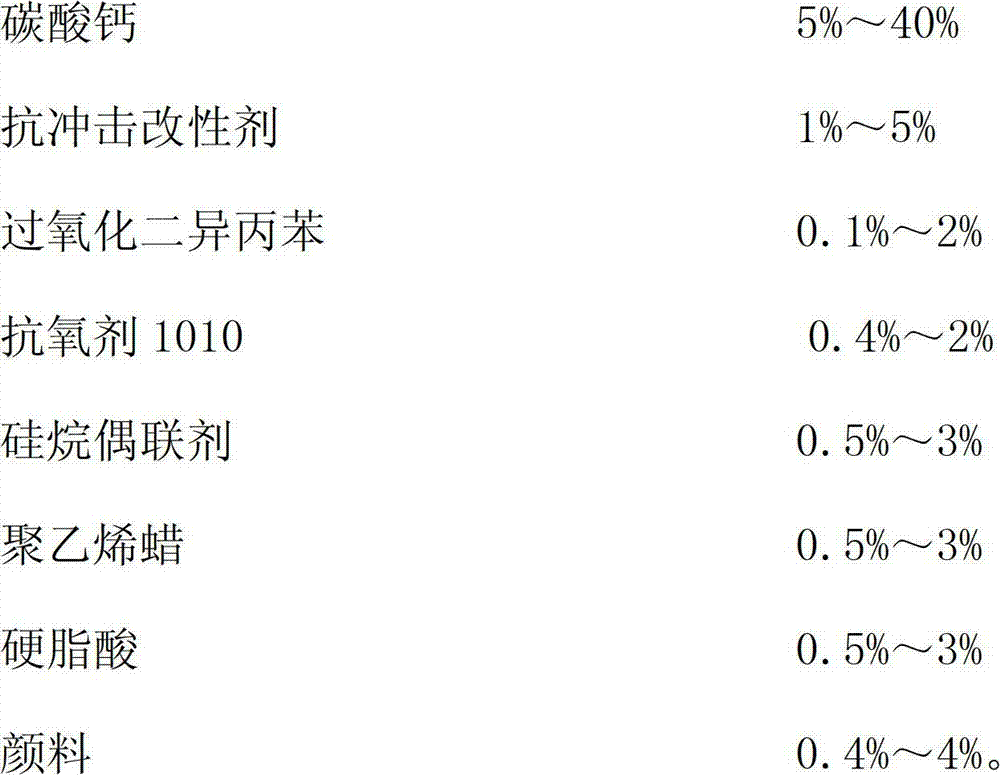

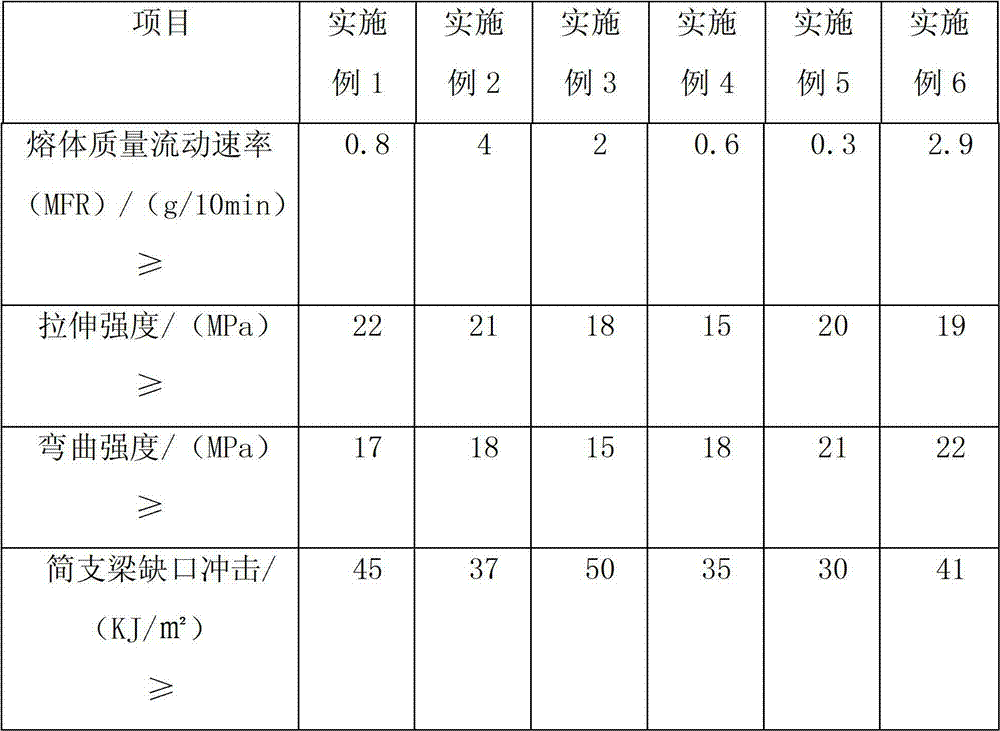

Special modified recycled polyethylene material for cables and preparation method of special modified recycled polyethylene material

ActiveCN102863678AMitigation raw materialReduce cost pressurePlastic/resin/waxes insulatorsDicumyl peroxidePOLYETHYLENE WAX

The invention discloses a special modified recycled polyethylene material for cables and a preparation method of the special modified recycled polyethylene material, so that the problem of high production cost due to the fact that existing special modified polyethylene materials for cables are prepared from new polyethylene and the problem of raw material and cost pressure of existing polyethylene are solved. The special modified recycled polyethylene material for the cables mainly comprises, by weight, 7%-69% of polyethylene, 10%-70% of recycled polyethylene, 5%-20% of toughening agents, 5%-40% of talcum powder, 5%-40% of calcium carbonate, 1%-5% of impact modifiers, 0.1%-2% of dicumyl peroxide, 0.4%-2% of antioxidants 1010, 0.5%-3% of silane coupling agents, 0.5%-3% of polyethylene wax, 0.5%-3% of calcium stearate and 0.4%-4% of pigment. Waste polyethylene can be recycled and reused effectively, and the special modified recycled polyethylene material for the cables and the preparation method have the advantages of resource saving, environmental protection, cost reduction and the like.

Owner:四川塑金科技有限公司

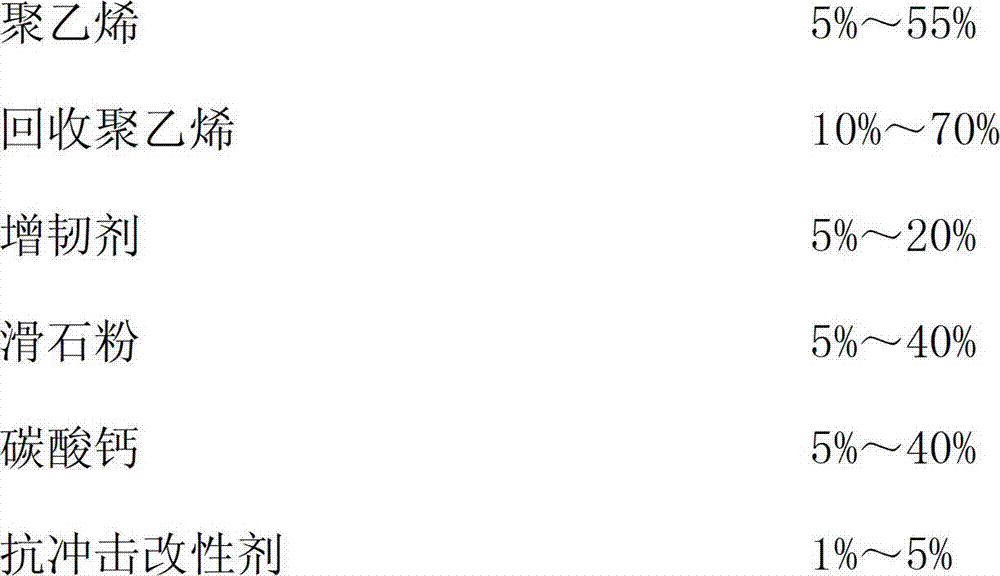

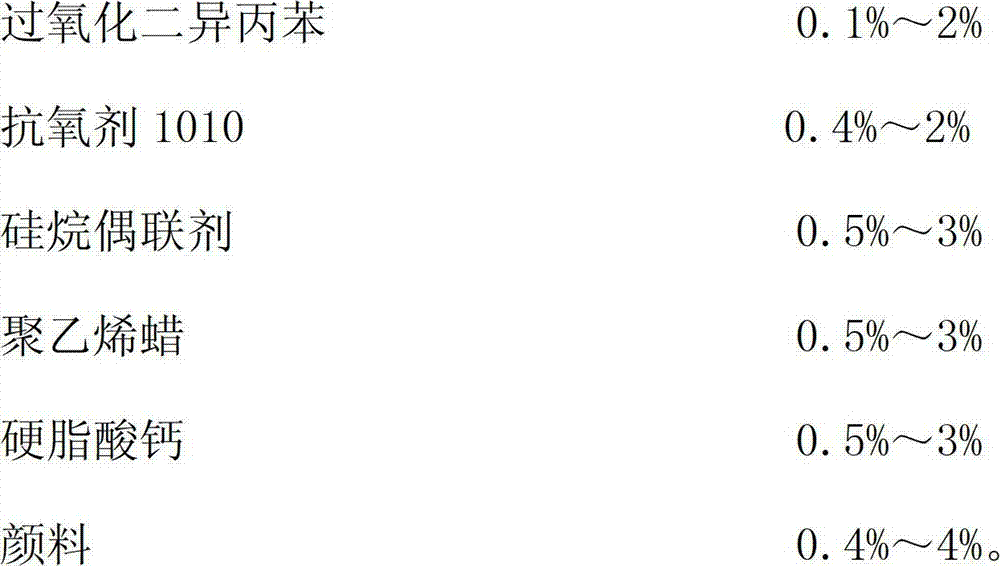

Special modified recycled polyethylene material for pipes and pipe fittings and preparation method of special modified recycled polyethylene material

The invention discloses a special modified recycled polyethylene material for pipes and pipe fittings and a preparation method of the special modified recycled polyethylene material, so that the problems of higher new polyethylene consumption and higher production cost of an existing special modified polyethylene material for pipes and pipe fittings are solved. The special modified recycled polyethylene material mainly comprises, by weight, 5%-55% of polyethylene, 10%-70% of recycled polyethylene, 5%-20% of toughening agents, 5%-40% of talcum powder, 5%-40% of calcium carbonate, 1%-5% of impact modifiers, 0.1%-2% of dicumyl peroxide, 0.4%-2% of antioxidants 1010, 0.5%-3% of silane coupling agents, 0.5%-3% of polyethylene wax, 0.5%-3% of calcium stearate and 0.4%-4% of pigment. Waste polyethylene is recycled and reused effectively, and the special modified recycled polyethylene material for the pipes and the pipe fittings and the preparation method have the advantages of resource saving, environmental protection, cost reduction and the like.

Owner:四川塑金科技有限公司

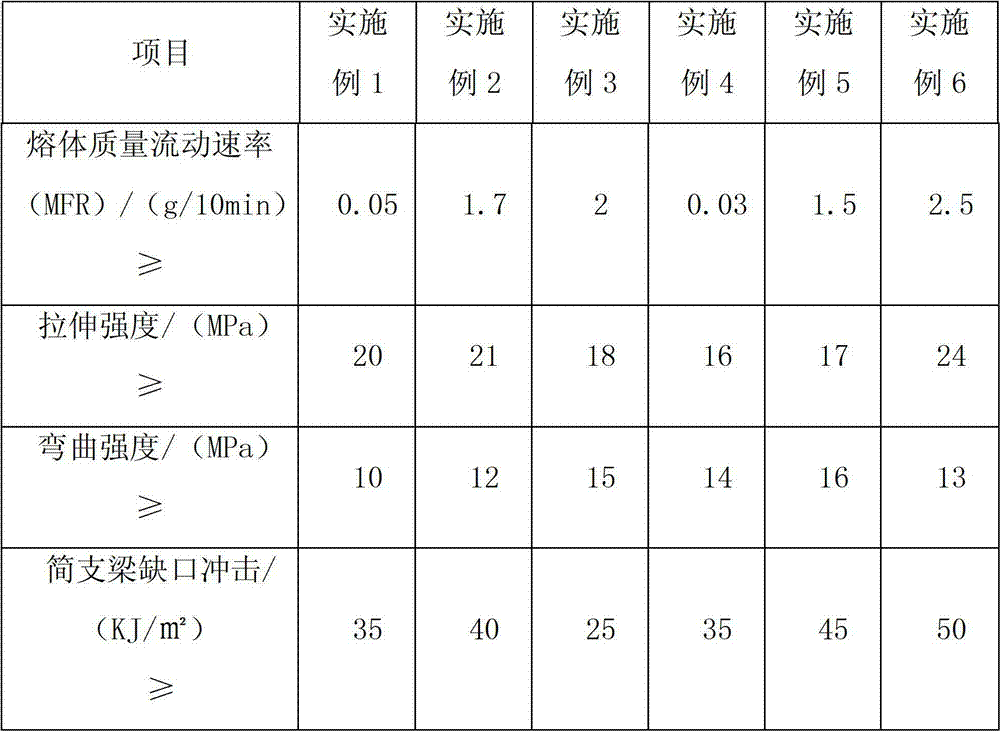

Process for using specific desulphurization mixed bacterium for high sulfur coal mine biological desulfurization

ActiveCN104745497AEfficient removalSolve the problem of low removal efficiencyBacteriaMicroorganism based processesGas compositionSulfur

A process for using specific desulphurization mixed bacterium for high sulfur coal mine biological desulfurization is as follows: ore is crushed to-25mm for heap construction, the heap height is 8-10m, temperature and gas composition induction devices are embedded during heap construction; then spray operation is performed, the spraying intensity is 10-15L / (M<2>.H), the spray solution contains 107-108cfu / mL of specific desulphurization mixed bacterium CGMCC NO.8336, the oxidation reduction potential of the spray solution is more than 700mV (SCE), the spray operation is performed according to the mode of spraying for 7 days and resting for 5 days or spraying for 7 days and resting for 7 days, the in-heap temperature is controlled at 45 to 60 DEG C, and the leaching system pH value is 1.5 to 1.8. The process has the advantages of short process, simple equipment, small investment, low cost, no pollution, larger or smaller production scale, and capability of processing high sulfur coal mine resources which cannot be processed by traditional mineral processing and metallurgical technology, and can expand the resource utilization scope and improve the comprehensive recovery level of the coal mine resources.

Owner:有研资源环境技术研究院(北京)有限公司

Method for synthesizing trimellitic triesters

ActiveCN106008204AReduce generationReduce cost pressureOrganic compound preparationPreparation by transesterificationEconomic benefits2-Ethylhexanol

The invention discloses a method for synthesizing trimellitic triesters. The method comprises the following steps: carrying out a methyl esterification reaction on trimellitic anhydride light and heavy components and methanol used as raw materials under the catalysis of a catalyst to generate trimethyl trimellitate, rectifying the trimethyl trimellitate to obtain high-purity and low-color number trimethyl trimellitate, and carrying out ester exchange on trimethyl trimellitate and 2-ethylhexanol, and purifying the obtained ester exchange product to obtain a tri(2-ethylhexyl) trimellitate product. The method has the advantages of effective recycling of the trimellitic anhydride light and heavy components, reduction of generation of pollutants, increase of economic benefits, reduction of the product cost and the environmental protection pressure, low requirements of the content and the color number of the raw material trimellitic anhydride, and realization of high content and low color number of obtained trihexyl ester, and allows the quality of the trihexyl ester to be better than the quality of trihexyl ester obtained through direct esterification of trimellitic anhydride and 2-ethylhexanol.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +2

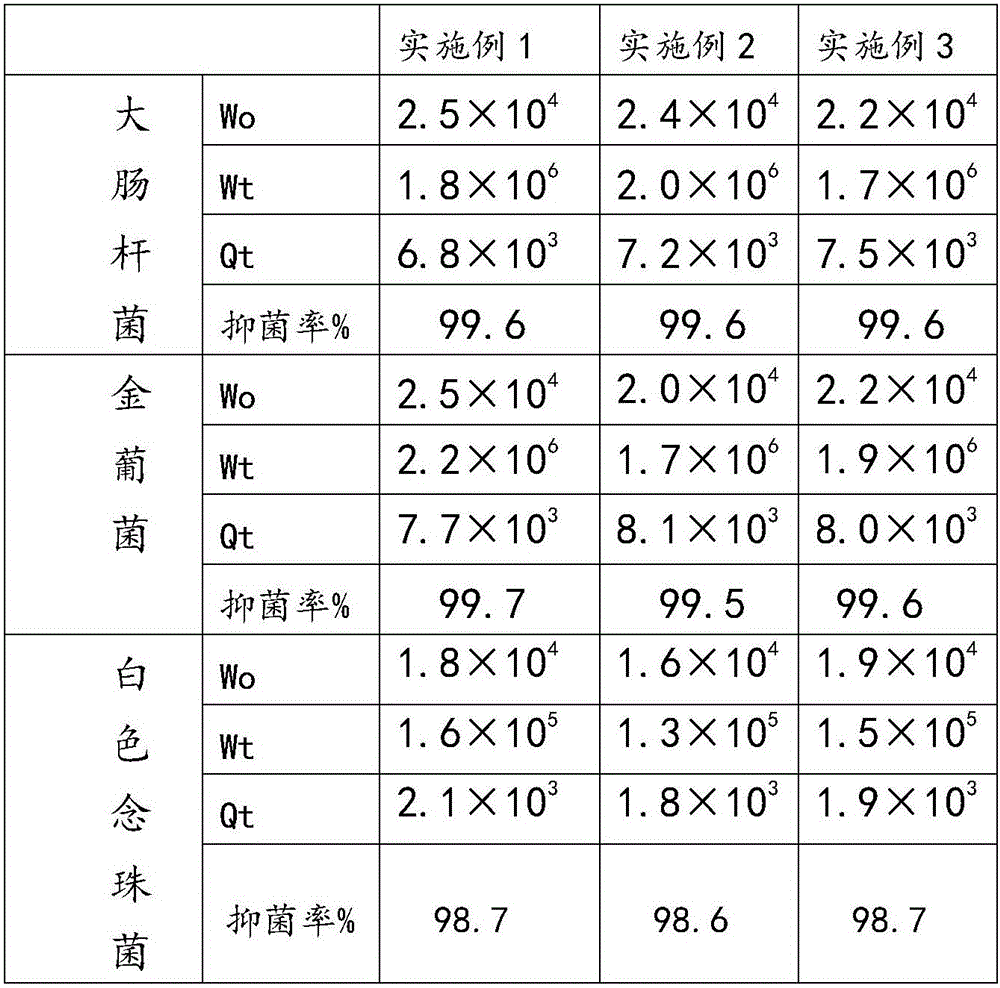

Method for preparing natural color bamboo fiber high-water absorption lining paper for production of hygienic products

ActiveCN106835793AMeet needsWin word of mouthReinforcing agents additionPaper/cardboardEscherichia coliFiber

The invention discloses a method for preparing natural color bamboo fiber high-water absorption lining paper for production of hygienic products. According to the method, bamboo is adopted as a raw material, and with the combination of physical and chemical methods, a product which is excellent in comprehensive quality and small in environment pollution is prepared. The physical property indexes of the natural color bamboo fiber high-water absorption lining paper are that the longitudinal tensile index is 12-15N-m / g, the transverse tensile index is 3-5N-m / g, the longitudinal wet tensile strength is 30-50N / m, the transverse wet tensile strength is 10-20N / m, the transverse water-absorbing quality is 45-65mm / 100s, the fixed quantity is 10-40g / m<2>, the whiteness is 35-50% ISO, the pentosan is 8% or less, the ash content is 1.0% or less, the bulkiness is 5.5-6.5cm<3> / g, the softness is 250mN or less, the bacteriostasis rate of staphylococcus aureus and escherichia coli is 99% or above, and the bacteriostasis rate of candida albicans is 98% or above.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

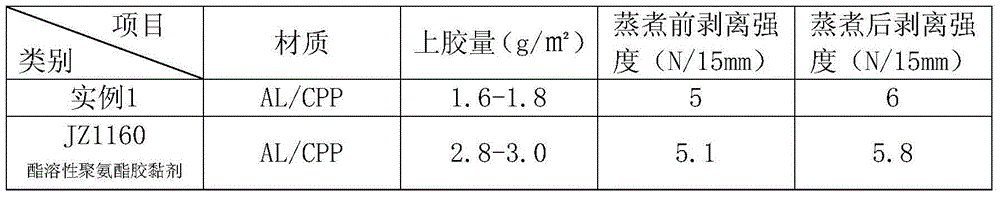

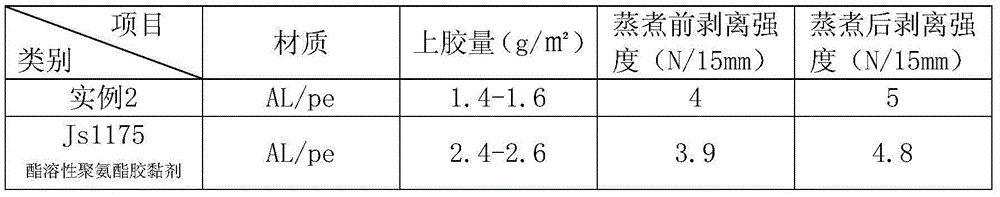

Composite bi-component polyurethane adhesive capable of resisting 121 DEG C thermophilic digestion as well as preparation method and using method of adhesive

ActiveCN104312518AGood adhesionReduce dependencePolyureas/polyurethane adhesivesEnvironmental resistancePolyurethane adhesive

The invention provides a composite bi-component polyurethane adhesive capable of resisting 121 DEG C thermophilic digestion as well as a preparation method and a using method of the adhesive. The polyurethane adhesive comprises a component A and a component B, wherein the component A comprises isocyanate, polyester with a molecular weight of 1500 and PPG2000; and the component B comprises castor oil, glycol, neopentyl glycol, glycerinum and sebacic acid. As the molecular chain has an isocyanate group, a carbamic acid ester group and castor oil, the polyurethane adhesive shows high flexibility, polarity and relatively good adhesion; and by importing the plant oil, the dependency to the petroleum is reduced. Compared with the prior art, the degradable solvent-free polyurethane adhesive is extensive in use, has good adhesion in the aluminum / plastic and plastic / plastic composition, is capable of resisting 121 DEG C thermophilic digestion in plastic-plastic composite materials, has better peel strength than common solvent-free adhesives, and is low in application cost, environment-friendly, sanitary and safe.

Owner:MEGABOND HUANGSHAN ADHESIVE

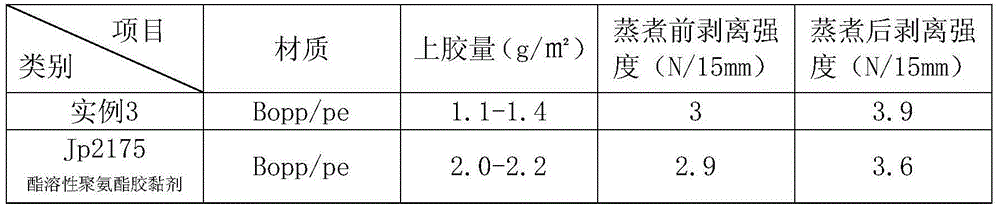

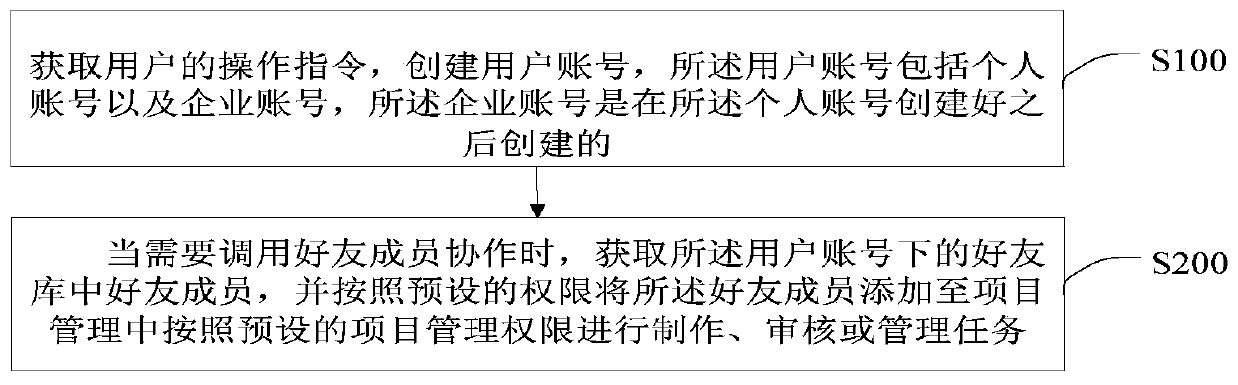

Multi-element stacked data cooperative processing method and system, storage medium and intelligent terminal

ActiveCN110852723AReduce uncontrollable risksImprove production efficiencyOffice automationBusiness enterpriseData collaboration

The invention discloses a multi-element stacked data cooperative processing method and system, a storage medium and an intelligent terminal, and the method comprises the steps: obtaining an operationinstruction of a user, and creating user accounts which comprise a personal account and an enterprise account, and the enterprise account is created after the personal account is created; and when friend members need to be called for cooperation, obtaining the friend members in the friend library under the user account, adding the friend members to project management according to a preset permission, and making, auditing or managing a task according to the preset project management permission. According to the invention, the project package sender, the project intermediate party, the project producer, the individual designer, the individual artistic effect auditor and the individual project manager in different regions can be quickly connected under one project to cooperate with one another, and each user account can play a plurality of roles based on one platform, so that the applicability is improved.

Owner:象和文化科技(深圳)有限公司

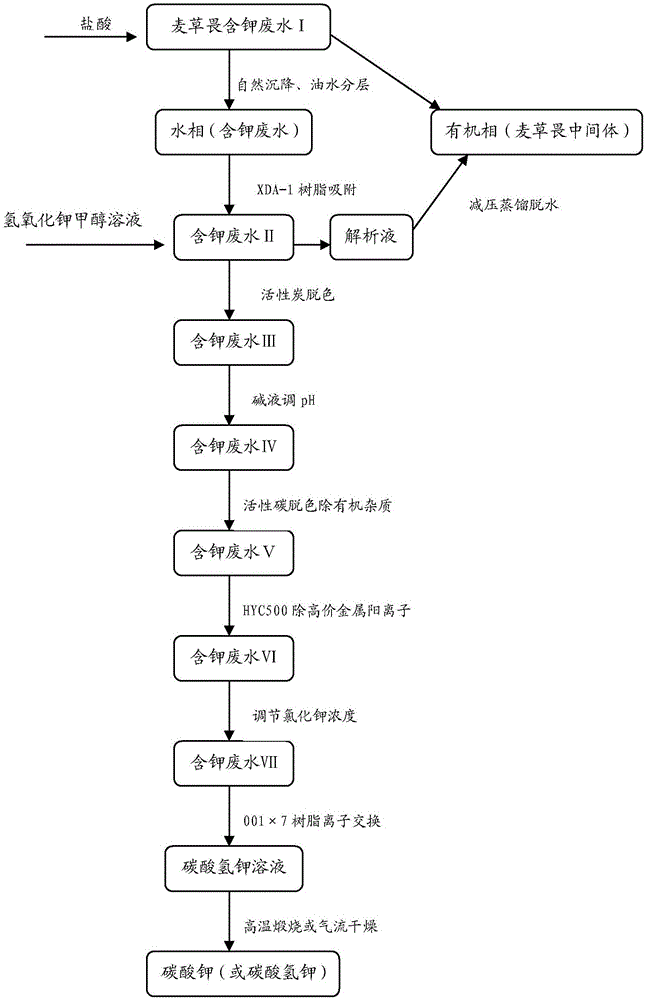

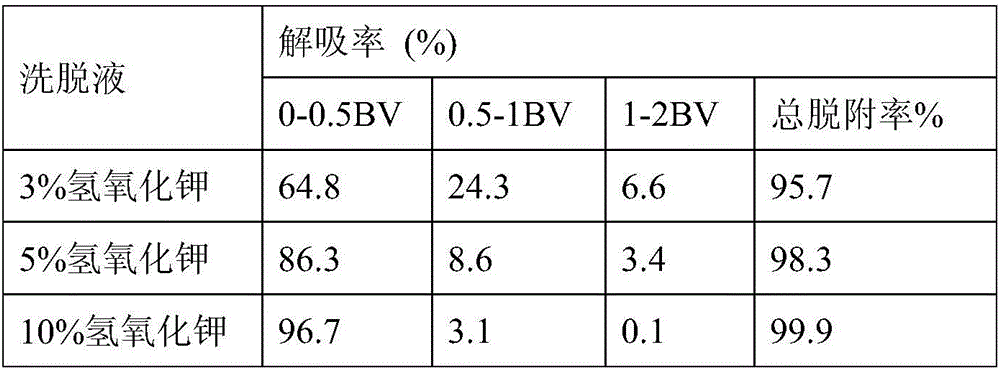

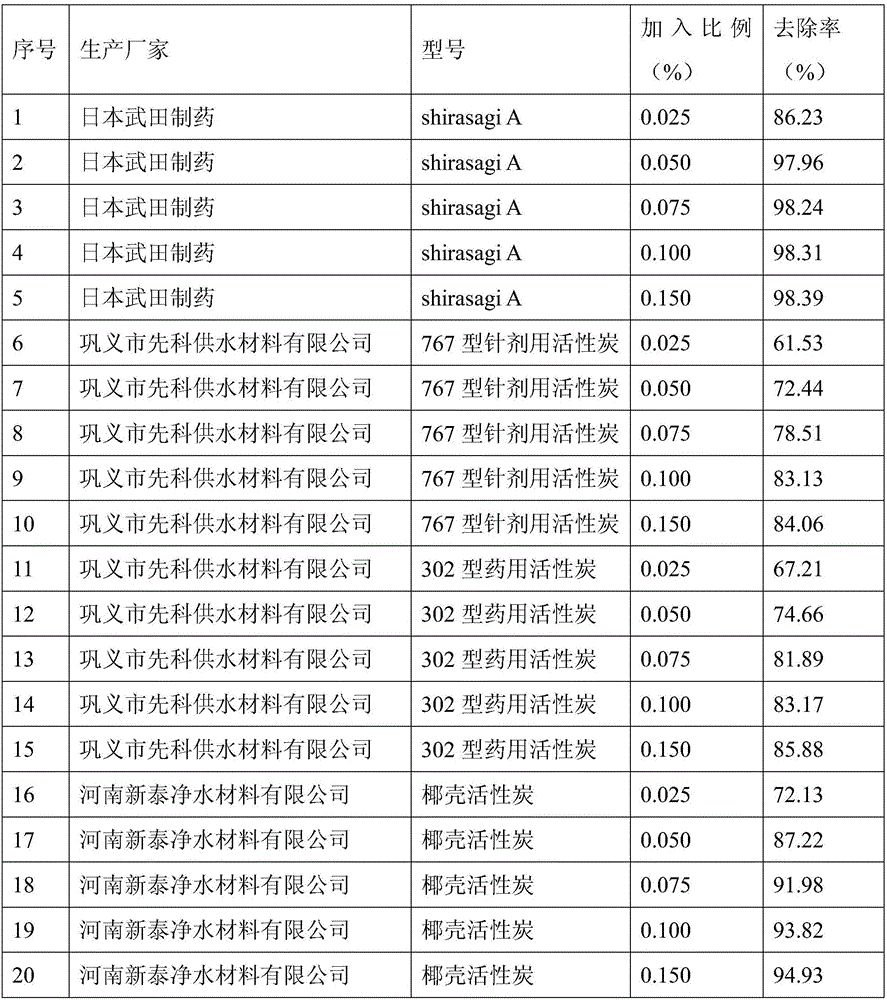

Comprehensive recycling utilization method of potassium-containing wastewater generated in synthesis process of dicamba

ActiveCN106830478ARealize the big cycleImprove competitive advantageTreatment involving filtrationOxygen compounds purification/separationIon exchangePotassium

The invention discloses a comprehensive recycling utilization method of potassium-containing wastewater generated in a synthesis process of dicamba. The comprehensive recycling utilization method comprises the following steps: adding acid into potassium-containing wastewater I generated in the synthesis process of the dicamba, and naturally depositing; conveying a water layer obtained by layering into a macroporous adsorption resin bed through a pump; adsorbing and recycling dicamba intermediates, namely 2,5-dichlorophenol and 3,6-dichlorosalicylic acid, in the water layer through the macroporous adsorption resin bed; adding active carbon and stirring and filtering; adding alkali liquid to adjust the pH (Potential of Hydrogen); adding active carbon into potassium-containing wastewater IV; stirring and filtering; conveying the wastewater into a chelating resin bed through the pump; removing high-valent metal cations in the alkaline potassium-containing wastewater IV through ion exchange; conveying the wastewater into a cation exchange resin bed through the pump; carrying out the ion exchange to obtain a potassium hydrogen carbonate solution and an ammonium chloride solution respectively; and drying an obtained potassium hydrogen carbonate wet product to obtain potassium hydrogen carbonate, or calcining the potassium hydrogen carbonate wet product at a high temperature to obtain potassium carbonate.

Owner:ZHEJIANG DAYANG BIOTECH GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com