Comprehensive recycling utilization method of potassium-containing wastewater generated in synthesis process of dicamba

A dicamba and wastewater technology, applied in the preparation of organic compounds, separation/purification of carboxylic acid compounds, purification/separation of oxygenated compounds, etc., can solve the problems of inability to effectively remove heavy metal pollutants, long reaction time, and operating costs High-level problems, to achieve the effect of reducing the cost of environmental protection and emission pressure, reducing processing costs and energy consumption, and improving the competitive advantage of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

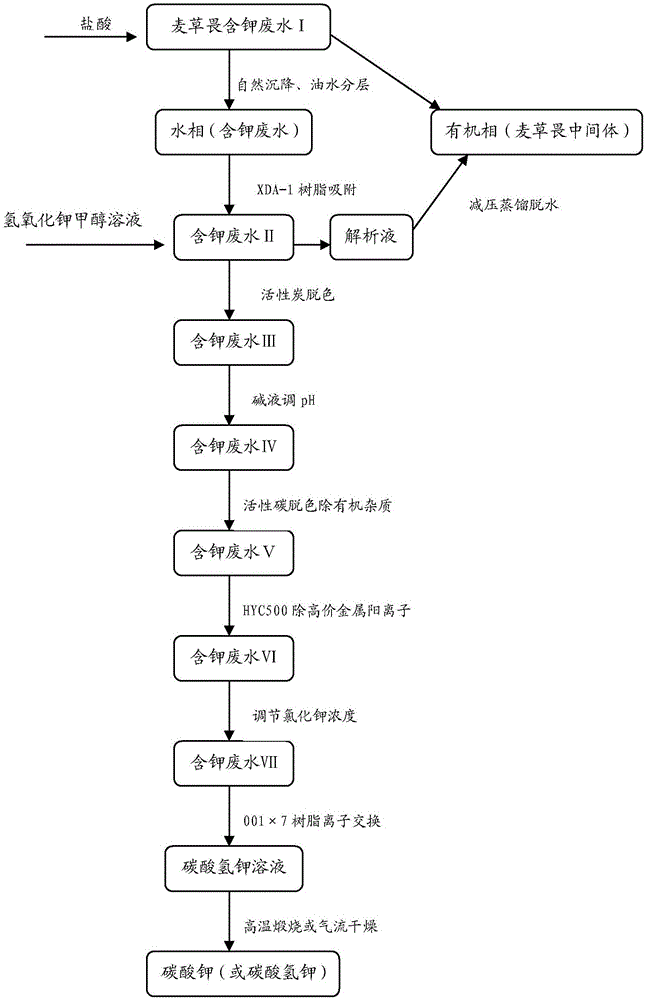

Method used

Image

Examples

Embodiment 1

[0125] Embodiment 1, a method for the comprehensive recycling of potassium-containing waste water produced by synthesizing dicamba, comprises the following steps successively:

[0126] 1), take 100 liters of potassium-containing wastewater I produced by synthesizing dicamba, add 30% (mass %) hydrochloric acid to adjust the acidity until the pH is 2, consume about 3.6 liters of hydrochloric acid, then naturally settle for 1 hour, and the oil and water are separated , separate 120 ml of organic layer and 103 liters of aqueous phase.

[0127] The potassium-containing waste water I composition produced by the above-mentioned synthesis of dicamba is as follows:

[0128] pH 9.82, potassium chloride 19.46%, potassium bicarbonate 2.37%, sodium chloride 0.16%, potassium sulfate 0.036%, calcium 0.013%, magnesium 0.036%, iron 0.0045%, nickel 0.0021%, cadmium 0.0016%, lead 0.0012% , 0.048% of 2,5-dichlorophenol, 0.036% of 3,6-dichlorosalicylic acid, 0.062% of toluene, and 0.024% of xylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com