Patents

Literature

54results about How to "Achieve productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

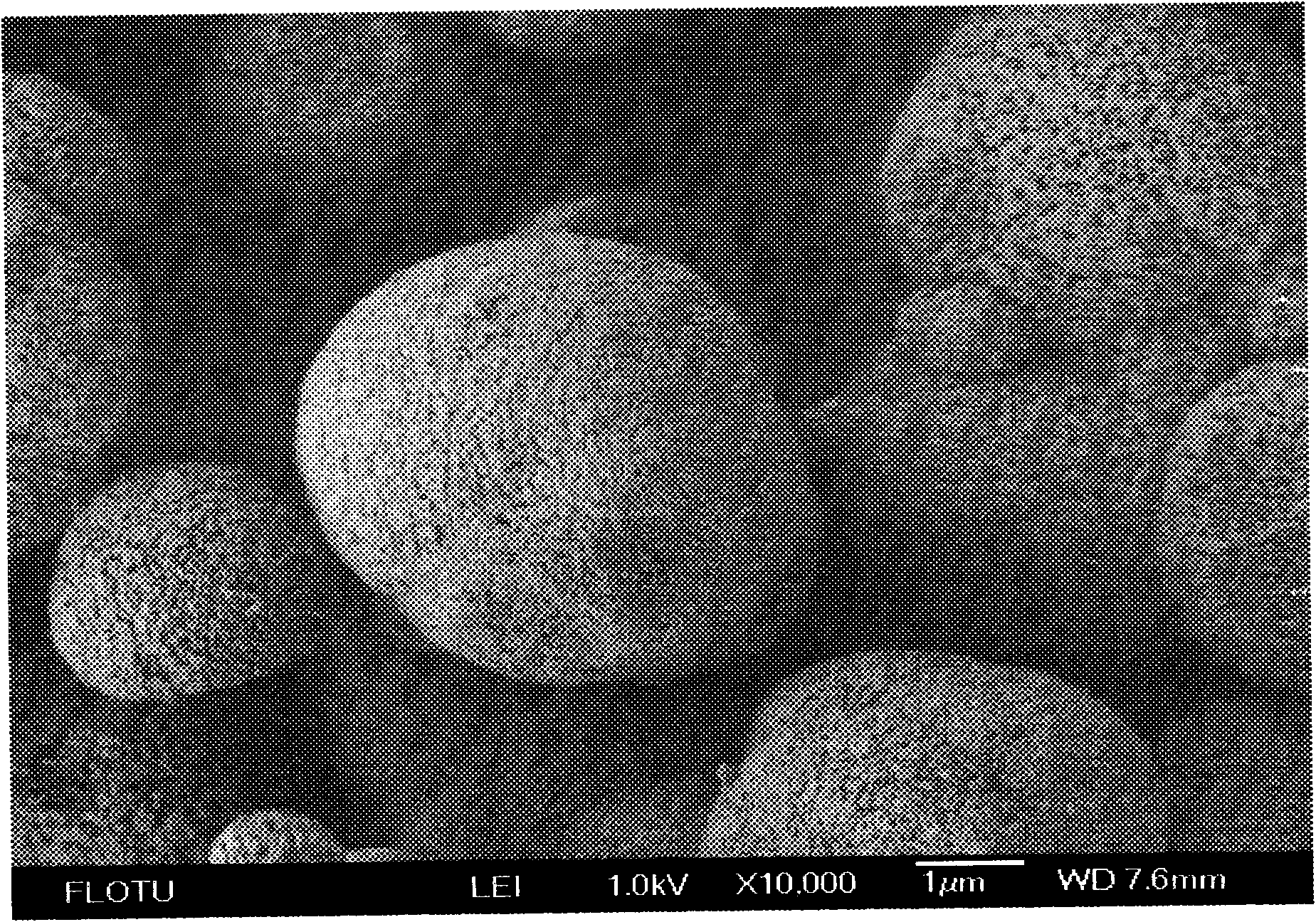

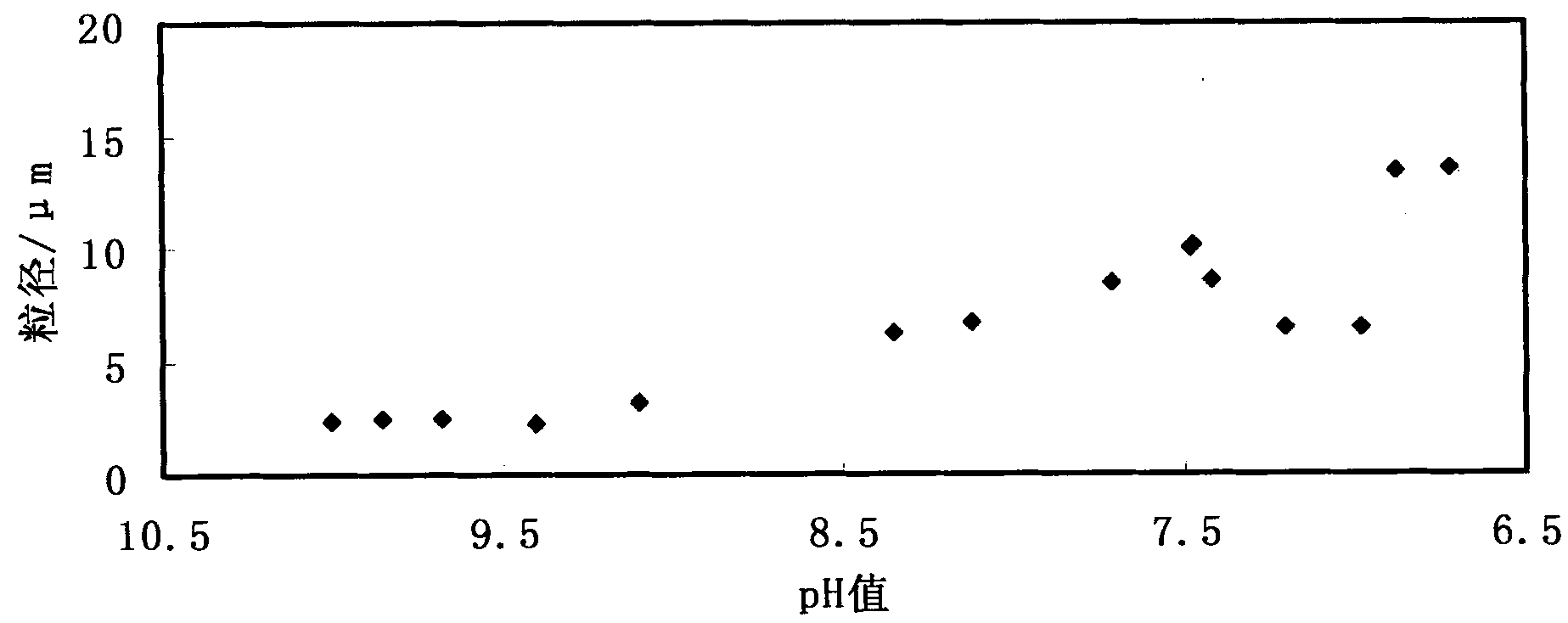

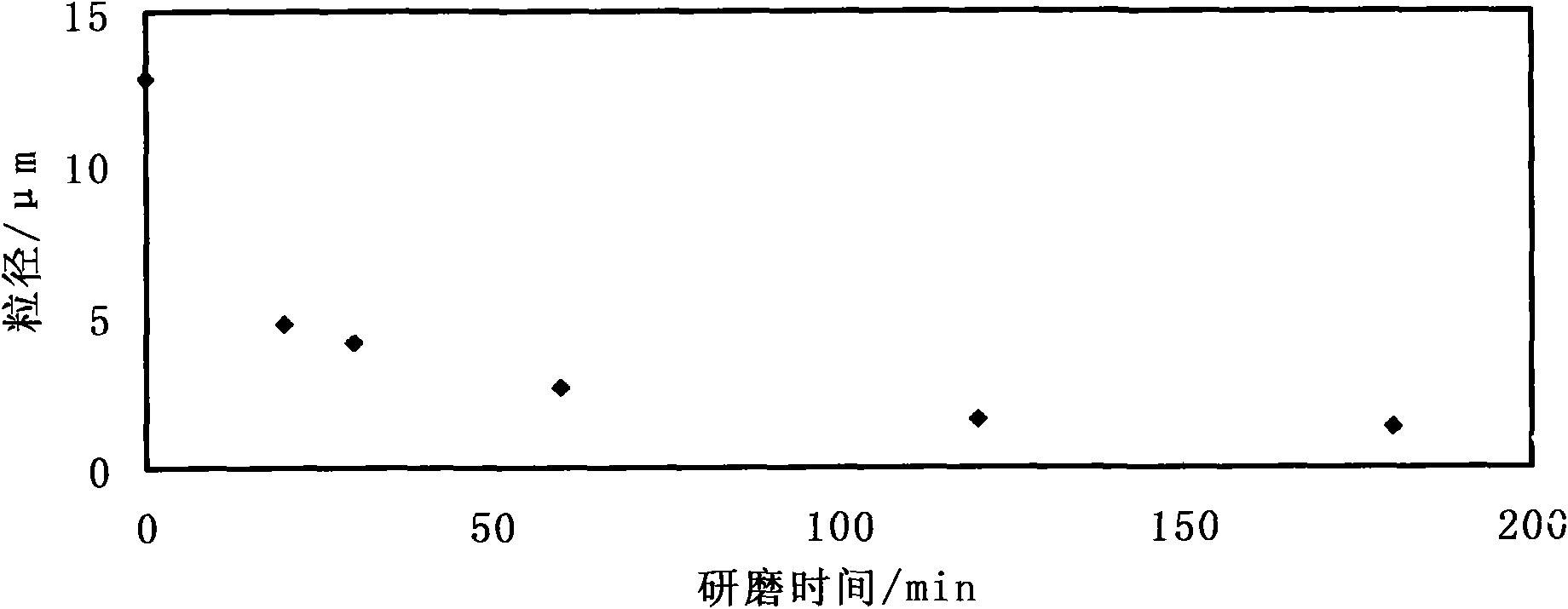

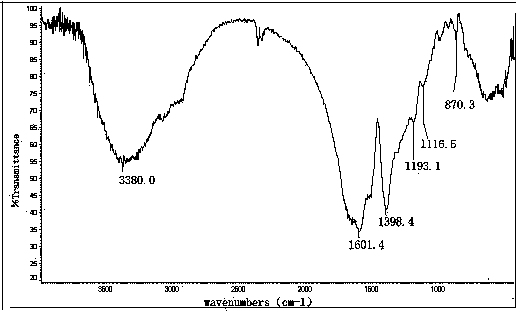

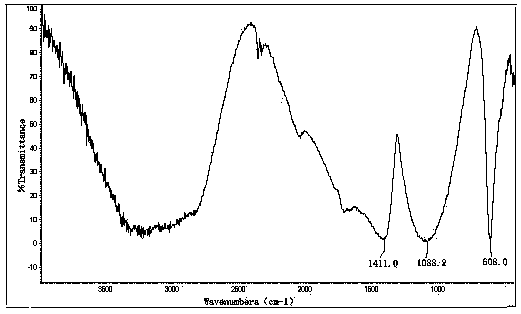

Novel method for producing superfine calcium carbonate by using carbide slag as raw material

InactiveCN101993104ASolve the possibility of industrializationRealize the possibility of industrializationCalcium/strontium/barium carbonatesCosmetic preparationsSlagCarbide

The invention relates to a method for preparing superfine calcium carbonate by adopting glycine as a dissolving agent, a modifying agent and an acid-binding agent, extracting effective calcium from calcium sources, such as carbide slag or lime, and the like and charging carbon dioxide into a reactor for calcifying, filtering and washing and application of the superfine calcium carbonate to paper making, paint production, and the like.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

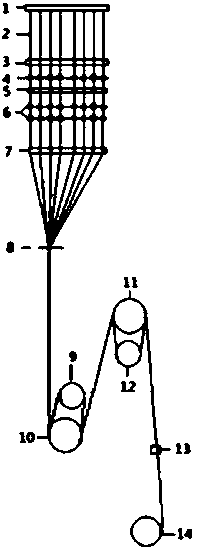

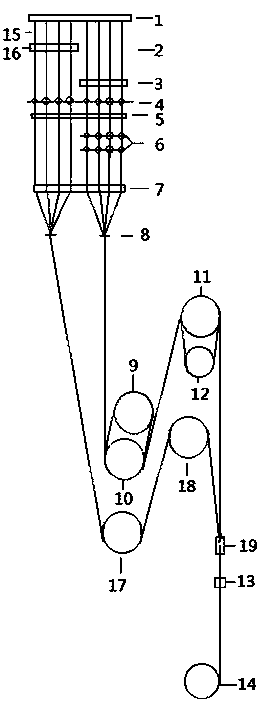

Copolyester melt direct-spinning controllable multiple differential shrinkage composite fiber and preparation method thereof

InactiveCN103526323AFull effectVersatileMonocomponent copolyesters artificial filamentMelt spinning methodsYarnPolyethylene glycol

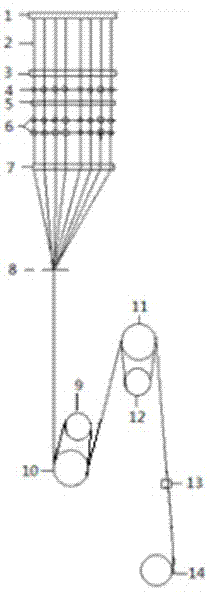

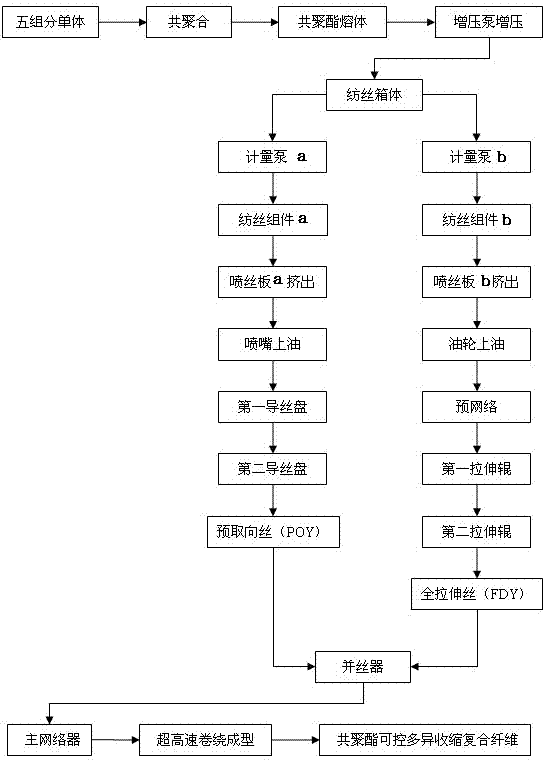

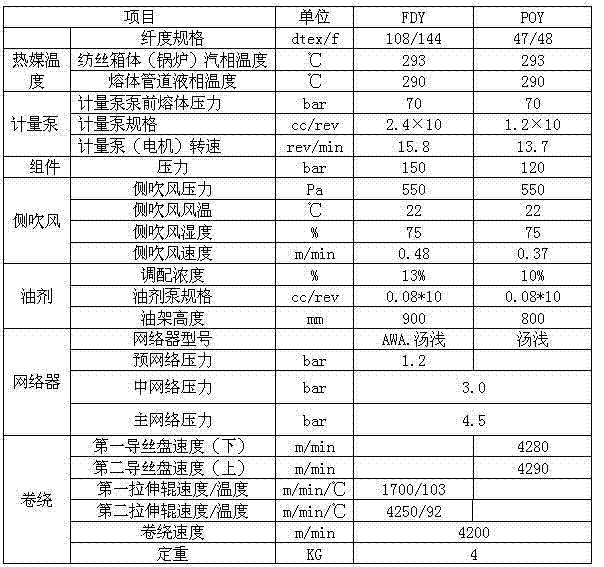

The invention relates to a copolyester melt direct-spinning controllable multiple differential shrinkage composite fiber and a preparation method thereof. Terephthalic acid and ethylene glycol serve as raw materials, a third component of polyethylene glycol, a fourth component of diethylene glycol and a fifth component of pentaerythritol are added for copolymerization, a copolyester melt is prepared, pressurized through a melt pipeline and a pressurizing pump, conveyed to a spinning box, divided into two ways through two metering pumps, sent into a spinning assembly and a spinneret plate for extrusion and cooled and solidified to form two bundles of yarn, FDY (fully drawn yarn) is obtained after oiling wheel oiling, pre-interlacing, drawing and heat setting of one of the two bundles of yarn, the other bundle of yarn is oiled through an oil spraying nozzle and then led to two yarn guiding disks to obtain POY (polyester pre-oriented yarn), the FDY and the POY are input into a yarn doubling device and a main interlacing device simultaneously for composition, and the composite fiber is obtained after ultra-high-speed winding molding. The composite fiber adopts the better fine three-dimensional multi-layer structure and is large in potential controllable hot-shrinkage rate difference, good in fluffiness, hygroscopicity, air permeability, moisture retention, chromaticity and high color rendering uniformity, multiple in product function and high in additional value.

Owner:SUZHOU UNIV

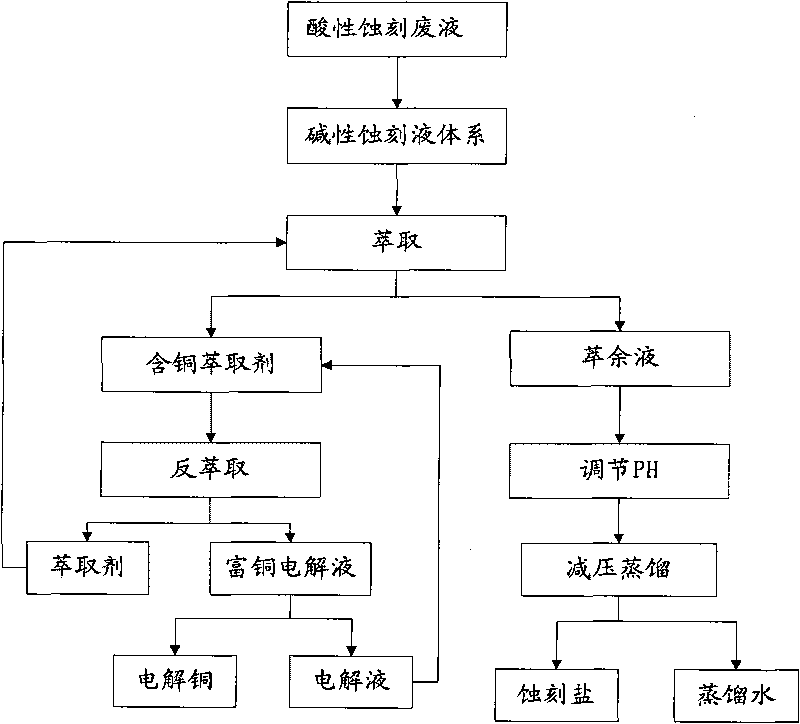

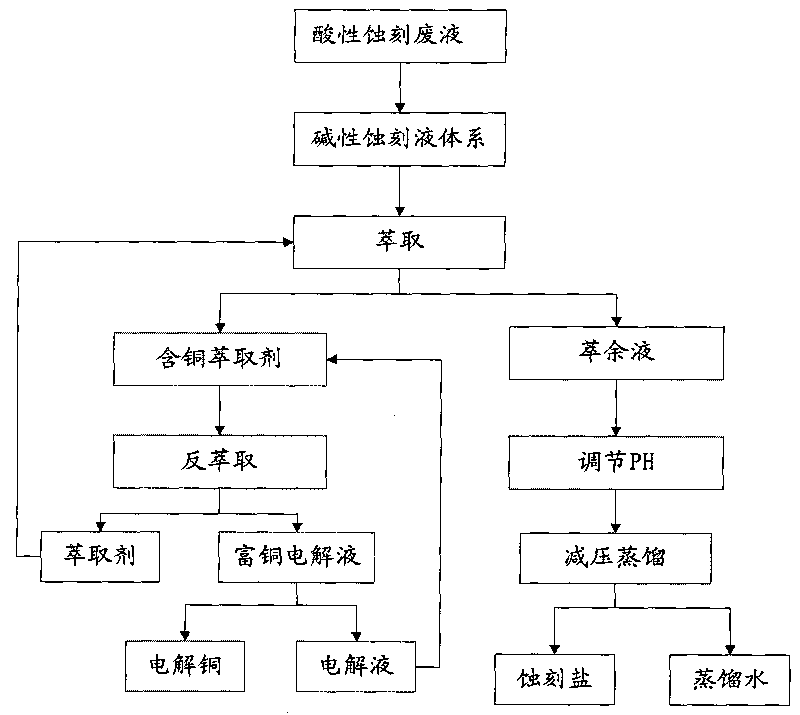

Method for processing acidic etching waste solution of printed circuit board

The invention provides a method for processing acidic etching waste solution of a printed circuit board, wherein the acidic etching waste solution comprises hydrochloric acid and copper chloride. The method comprises the following steps: adding ammoniac regulation solution in the acidic etching waste solution for converting the acidic etching waste solution into an ammoniac etching solution system with the pH value above 7.5, and then carrying out copper extraction. The processing method improves the copper extraction efficiency and ensures that the recovery rate of metallic copper can reach above 99.3 percent; the raffinate is processed to obtain ammonium chloride which can be directly reused for an etching process according to requirements, and the recovery rate of the ammonium chloride can reach above 99.9 percent, thereby not only saving resources, but also avoiding the environment pollution, and really achieving recycling economy and clean production.

Owner:SHENZHEN JECH TECH

Controllable multiple-differential-shrinkage composition fiber made from copolyester melt through ultra-fast direct spinning, and preparation method of composition fiber

InactiveCN103484967AIncrease spinning speedIncrease added valueArtificial filament heat treatmentMonocomponent copolyesters artificial filamentYarnFiber

The invention relates to a controllable multiple-differential-shrinkage composition fiber made from a copolyester melt through ultra-fast direct spinning, and a preparation method of the composition fiber. The copolyester melt, which is made from five components including terephthalic acid, ethylene glycol, poly ethylene glycol, diethylene glycol and pentaerythritol, is pressurized by a booster pump and transported through a melt pipeline into a spinning box body, and is then divided by two measuring pumps into two branches, which enter a spinning component and a spinneret respectively and finally be extruded. After cooling and curing, two yarns are formed, wherein one yarn is subject to oiling by an oil wheel, pre-entwining, stretching and thermoforming to obtain an FDY yarn, and the other yarn is subject to oiling by an oil nozzle, and is guided to two spinning discs to obtain a POY yarn; the two yarns are simultaneously input into a doubling device and a main entwining device for combination, and are formed through the ultra-fast rolling, so as to obtain the composition fiber. The composition fiber has the characteristics of relatively good micro three-dimensional morphological structure, moisture absorption property, moisture preservation property, air permeability and antistatic property, easiness in dyeing, uniform dyeing, high coloration uniformity and the like; the composition fiber is high in processing speed, high in yield, low in consumption, low in manufacturing cost, high in value added, high in product functions, good in quality, and obvious in advantage of performance price ratio.

Owner:SUZHOU UNIV

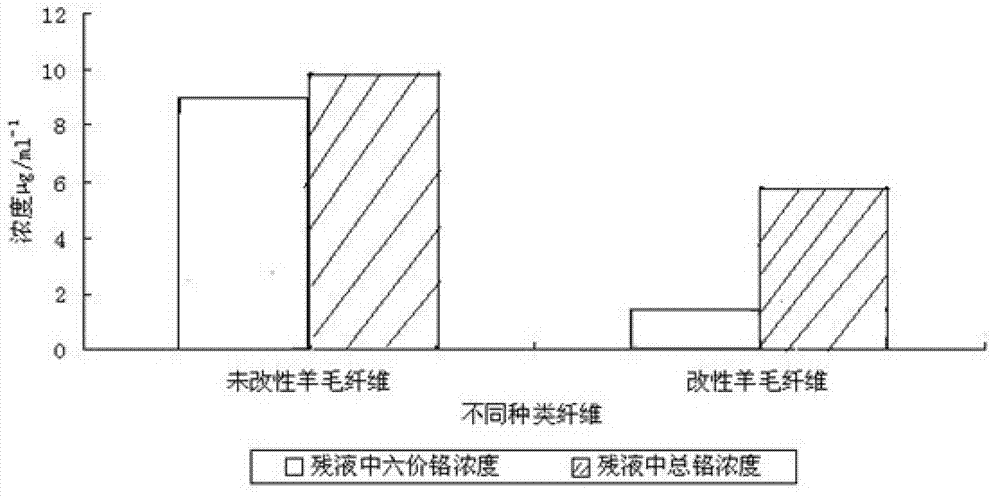

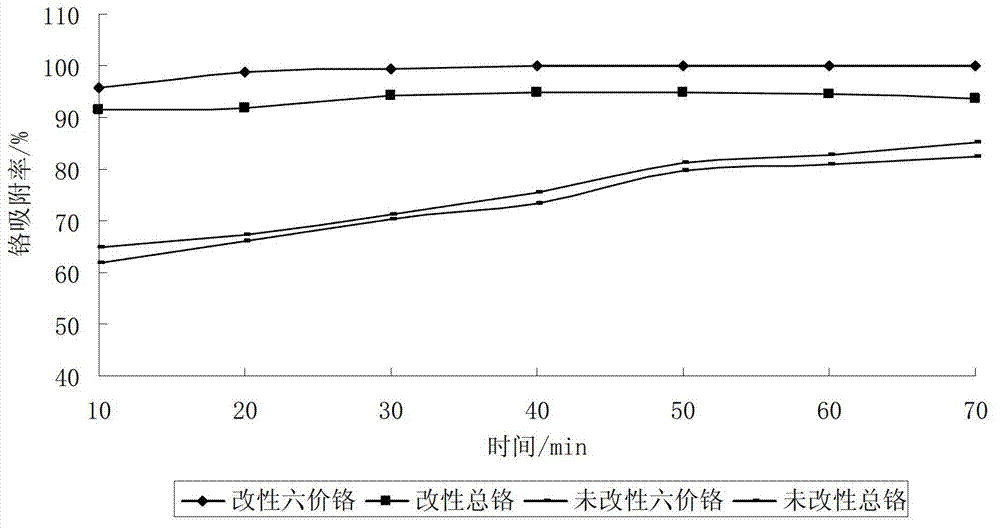

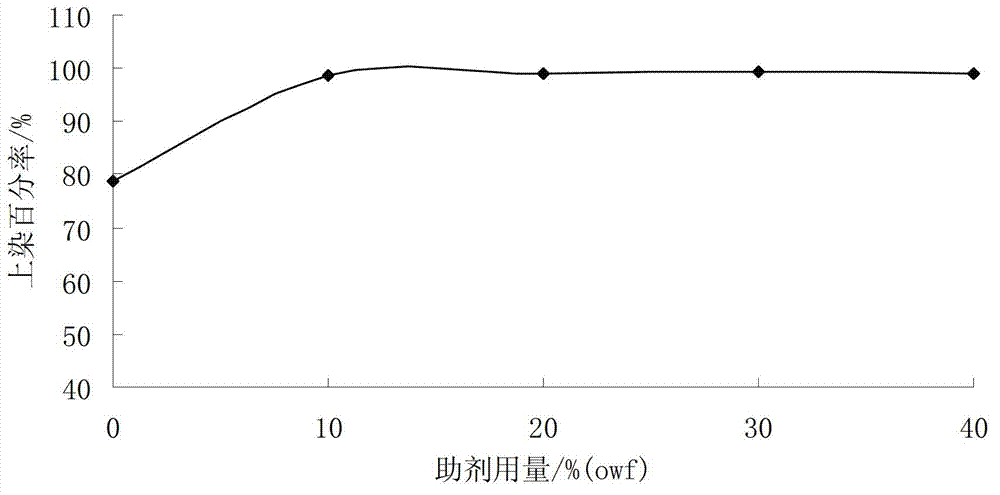

Preparation method and application method of low-temperature low-chromium dyeing auxiliary agent of acidic medium dye for wool

InactiveCN102817251AEfficient reuseReduce pollutionDepsipeptidesPeptide preparation methodsCross-linkKeratin

The invention discloses a preparation method and an application method of a low-temperature low-chromium dyeing auxiliary agent of an acidic medium dye for wool. The preparation method comprises the steps that: 1, protein powder is prepared by using waste duck feather, wherein (1) the duck feather is subjected to pretreatment; (2) the suck feather is subjected to a dissolving treatment; and (3) duck feather protein powder is prepared; 2, a sodium hydroxide solution is prepared, and the sodium hydroxide solution is used for dissolving the duck feather protein powder; 3, sodium hydroxide, triethanolamine, and epichlorohydrin are adopted for preparing a cationic quaternary ammonium salt cross-linking modification agent WLS; and 4, the low-temperature low-chromium dyeing auxiliary agent for the acidic medium dye is prepared. The auxiliary agent can be used as a wool modification agent. After wool fibers are modified, wool fiber dyeing properties of acidic medium dyes are greatly improved, dye uptake percentage rate can be improved, mordant absorption performance of the dye is improved, chromium pollution in dye wastewater is reduced, wool fiber low-temperature low-chromium dyeing is realized, and waste duck feather keratin is effectively utilized. After modification, the wearability of wool products is improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

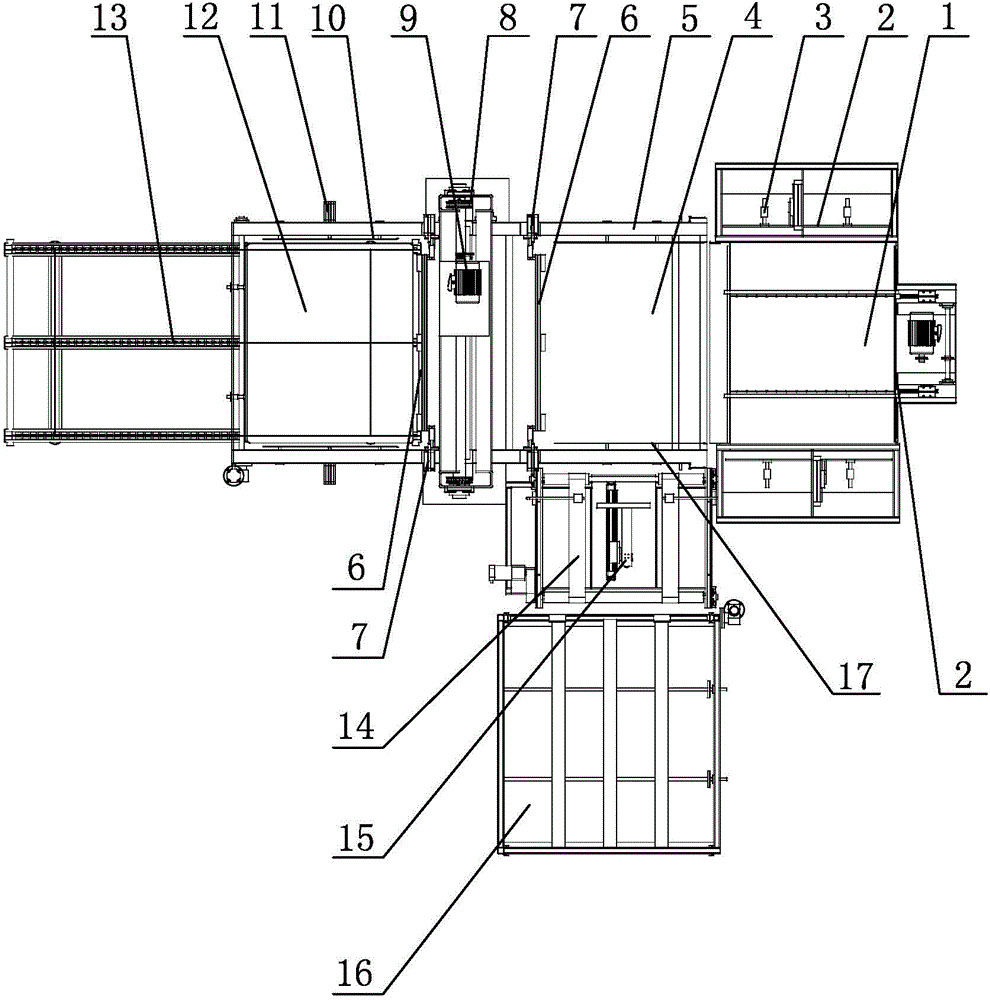

Horizontal pushing stacking system of medicinal glass bottles

ActiveCN104554896ACompact and reasonable structureReduce labor requirementsWrappingPackaging automatic controlBottleSystem structure

The invention relates to a horizontal pushing stacking system of medicinal glass bottles. The horizontal pushing stacking system comprises an alignment bottle-collection mechanism, a lifting stacking mechanism, a film coating mechanism and a conveying transmission mechanism which are arranged in turn; one side of the lifting stacking mechanism is provided with a cushion plate separating mechanism; the alignment bottle-collection mechanism comprises a bottle collection table; each side of the bottle collection table is provided with an alignment device; the bottle collection table is provided with a material pushing device; the lifting stacking mechanism comprises a stacking platform and a stacking workstation tray; the stacking platform is connected with a motor through a transmission device; a bottle blocking plate is arranged above the stacking platform and the stacking workstation tray; the bottle blocking plate is connected with a bottle blocking cylinder; the cushion plate separating mechanism comprises a cushion plate frame; a guide groove and a pushing plate frame are arranged between the cushion plate frame and the stacking platform of the lifting stacking mechanism; the pushing plate frame is connected with a pushing plate cylinder. According to the horizontal pushing stacking system of the medicinal glass bottles, the structure is compact and reasonable, the stacking process is stable, the horizontal pushing stacking system is suitable for various sizes, the manpower is saved, and the working efficiency is improved.

Owner:SHANDONG PHARMA GLASS

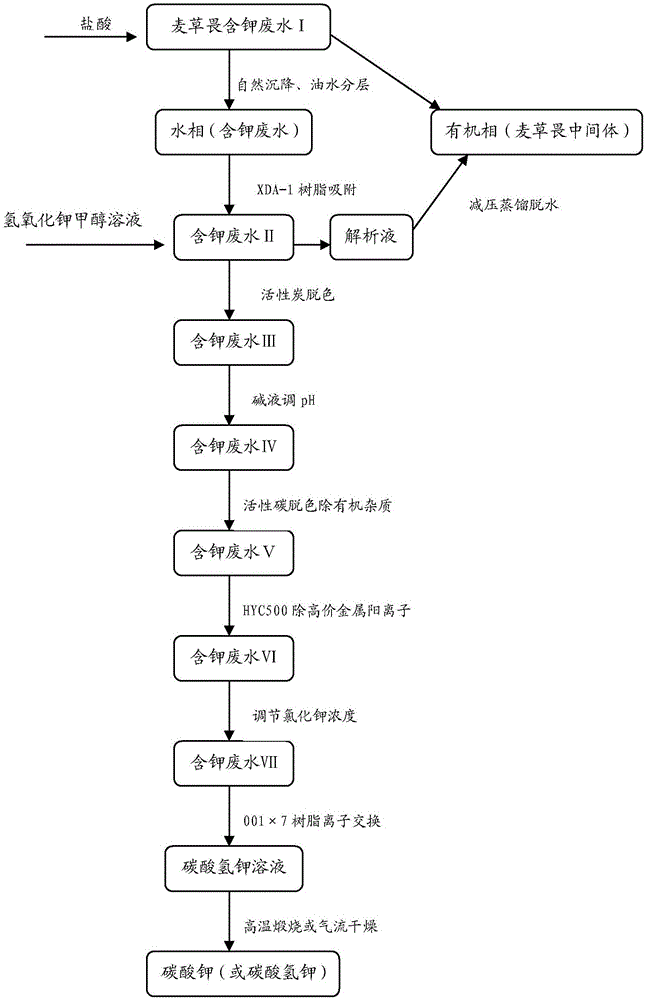

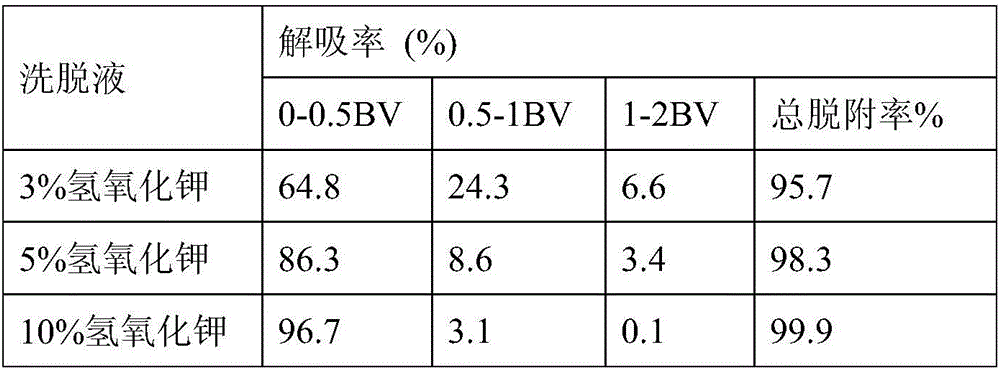

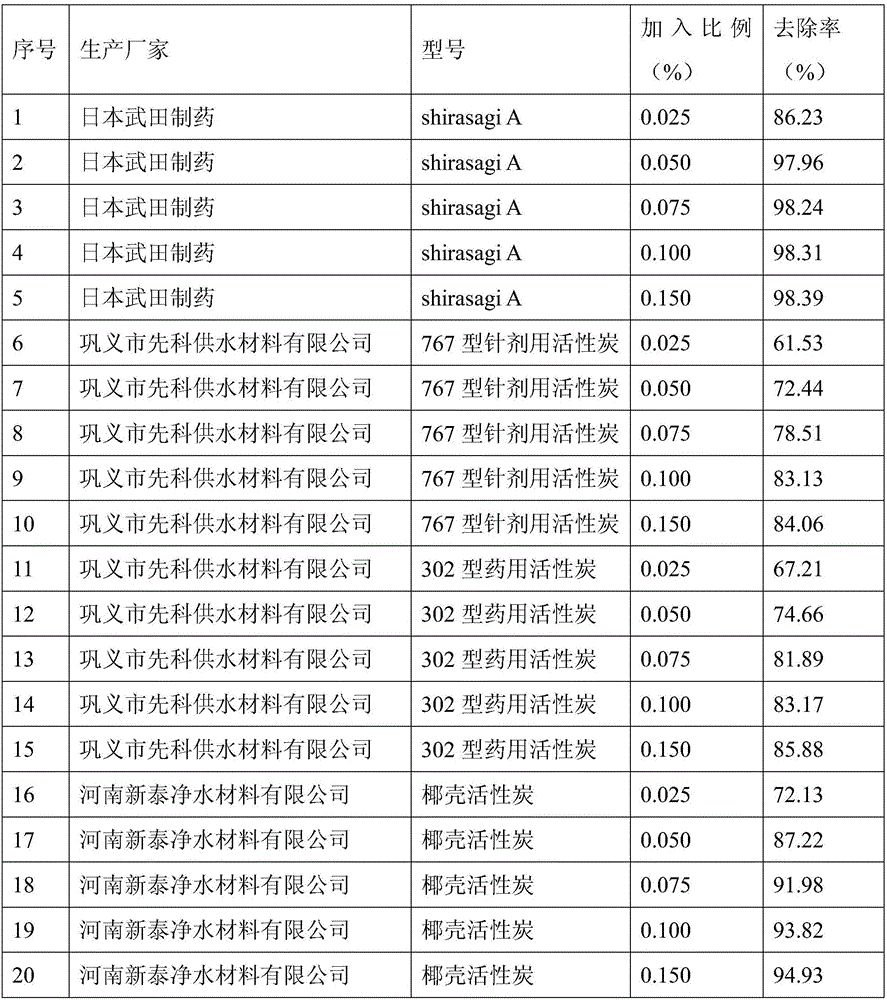

Comprehensive recycling utilization method of potassium-containing wastewater generated in synthesis process of dicamba

ActiveCN106830478ARealize the big cycleImprove competitive advantageTreatment involving filtrationOxygen compounds purification/separationIon exchangePotassium

The invention discloses a comprehensive recycling utilization method of potassium-containing wastewater generated in a synthesis process of dicamba. The comprehensive recycling utilization method comprises the following steps: adding acid into potassium-containing wastewater I generated in the synthesis process of the dicamba, and naturally depositing; conveying a water layer obtained by layering into a macroporous adsorption resin bed through a pump; adsorbing and recycling dicamba intermediates, namely 2,5-dichlorophenol and 3,6-dichlorosalicylic acid, in the water layer through the macroporous adsorption resin bed; adding active carbon and stirring and filtering; adding alkali liquid to adjust the pH (Potential of Hydrogen); adding active carbon into potassium-containing wastewater IV; stirring and filtering; conveying the wastewater into a chelating resin bed through the pump; removing high-valent metal cations in the alkaline potassium-containing wastewater IV through ion exchange; conveying the wastewater into a cation exchange resin bed through the pump; carrying out the ion exchange to obtain a potassium hydrogen carbonate solution and an ammonium chloride solution respectively; and drying an obtained potassium hydrogen carbonate wet product to obtain potassium hydrogen carbonate, or calcining the potassium hydrogen carbonate wet product at a high temperature to obtain potassium carbonate.

Owner:ZHEJIANG DAYANG BIOTECH GROUP

Method for preparing sulphur black dye and sodium thiosulfate from sulphur dye waste water

InactiveCN101633495ASolve processing problemsAchieve governanceThiosulfates/dithionites/polythionitesMultistage water/sewage treatmentWastewaterSulphur dye

The invention relates to a method for preparing sulphur black dye and sodium thiosulfate from sulphur dye waste water, which comprises the following steps: heating sulphur dye waste water, then mixing the sulphur dye waste water with 2,4-dinitrochlorobenzol, adjusting the PH value of the mixed solution with alkali, and carrying hydrolysis reaction; mixing and stirring the sulphur dye waste water, the sodium thiosulfate and sulfur, and heating the mixture for carrying out polysulfide reaction; mixing the mixed solution of the hydrolysis reaction and the mixed solution of polysulfide reaction for sulfofication reaction, and after the reaction is finished, introducing air for oxidation reaction to obtain mixed mother solution; filtering the mixed mother solution to obtain sulphur black dye grains, and drying, grinding and blending the sulphur black dye grains to obtain commercial sulphur black dye grains; and condensing, decoloring, crystallizing, drying and screening the filtered mixed mother solution to obtain the sodium thiosulfate. The method can effectively treat sulphur dye waste water, not only solve the problem of sewage treatment, but also save large amount of clean water.

Owner:蔡瑞琳 +1

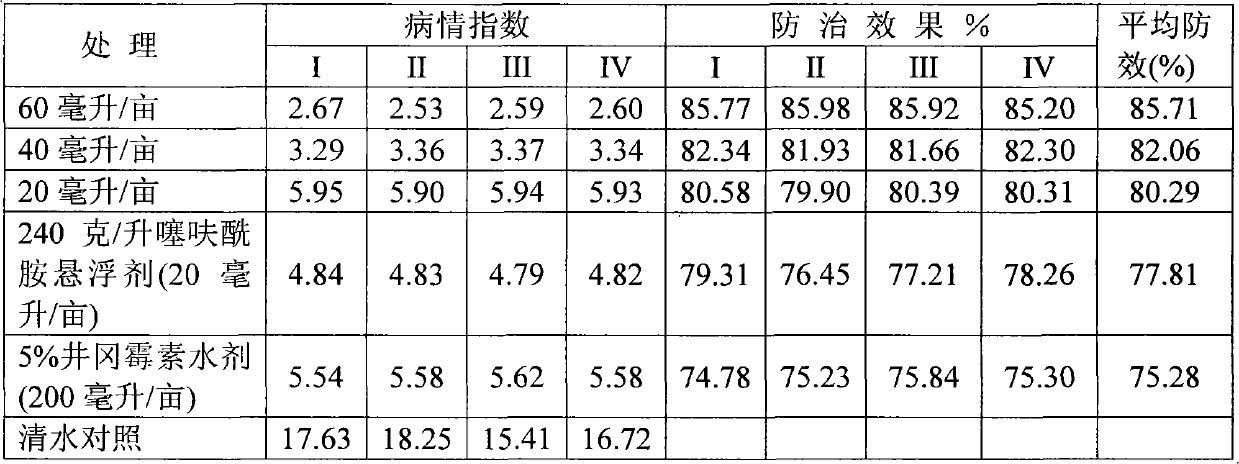

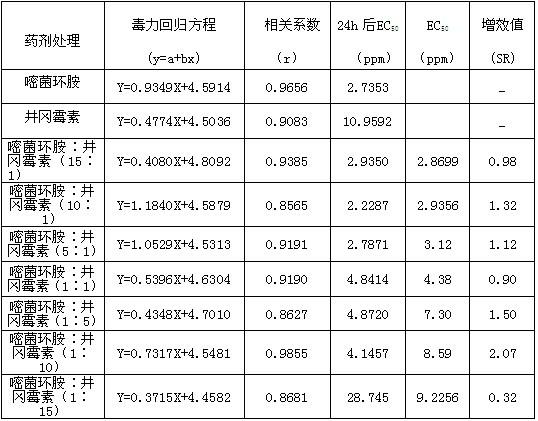

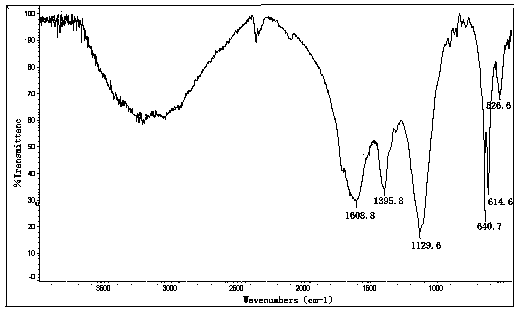

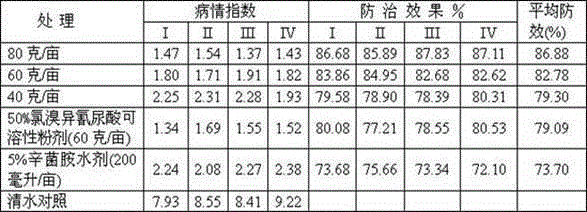

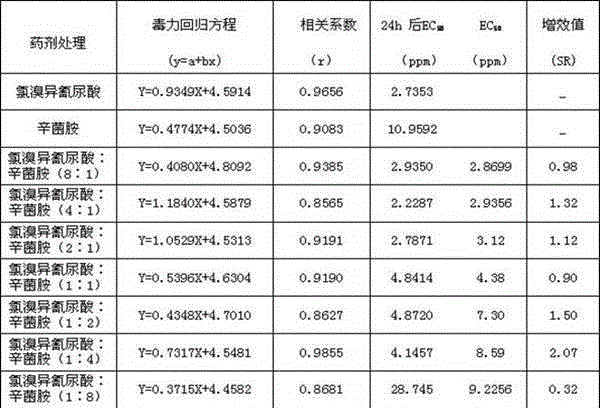

Biologically-chemically synergistic bactericidal suspension and preparation method thereof

InactiveCN101946779ABroad-spectrum germicidalGood control effectBiocideFungicidesSuspending AgentsBULK ACTIVE INGREDIENT

The invention discloses a biologically-chemically synergistic bactericidal suspension, which relates to the technical field of biologically-chemically synergistic bactericide compositions. The biologically-chemically synergistic bactericidal suspension comprises the active ingredients of jingangmycin and thifluzamide, and further comprises a dispersion wetting agent, an antifreeze agent, a thickening agent, an antifoaming agent and a filler, wherein the content of the jingangmycin is 2 to 20 percent based on the total mass of the suspension; and the content of the thifluzamide is 1 to 30 percent based on the total mass of the suspension. A jingangmycin and thifluzamide-containing bactericide in form of wettable powder or suspension can be prepared by adding the raw materials into an enamel stirred tank for uniform mixing and then performing jet-milling or grinding. Due to the compounding of the jingangmycin and the thifluzamide, the bactericidal suspension has the characteristics of low toxicity, less residue, broad insecticidal spectrum, high persistence, low cost, and particularly pollution-free prevention and control, and is a relatively more ideal pesticide for preventing and controlling various diseases of rice.

Owner:JIANGSU DONGBAO AGROCHEM

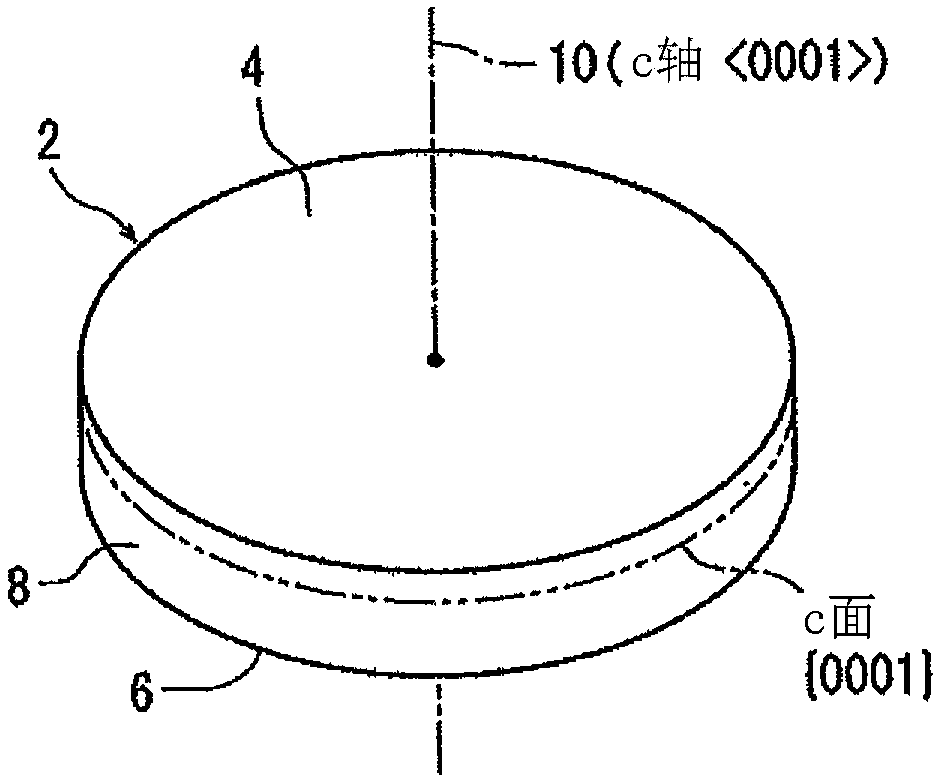

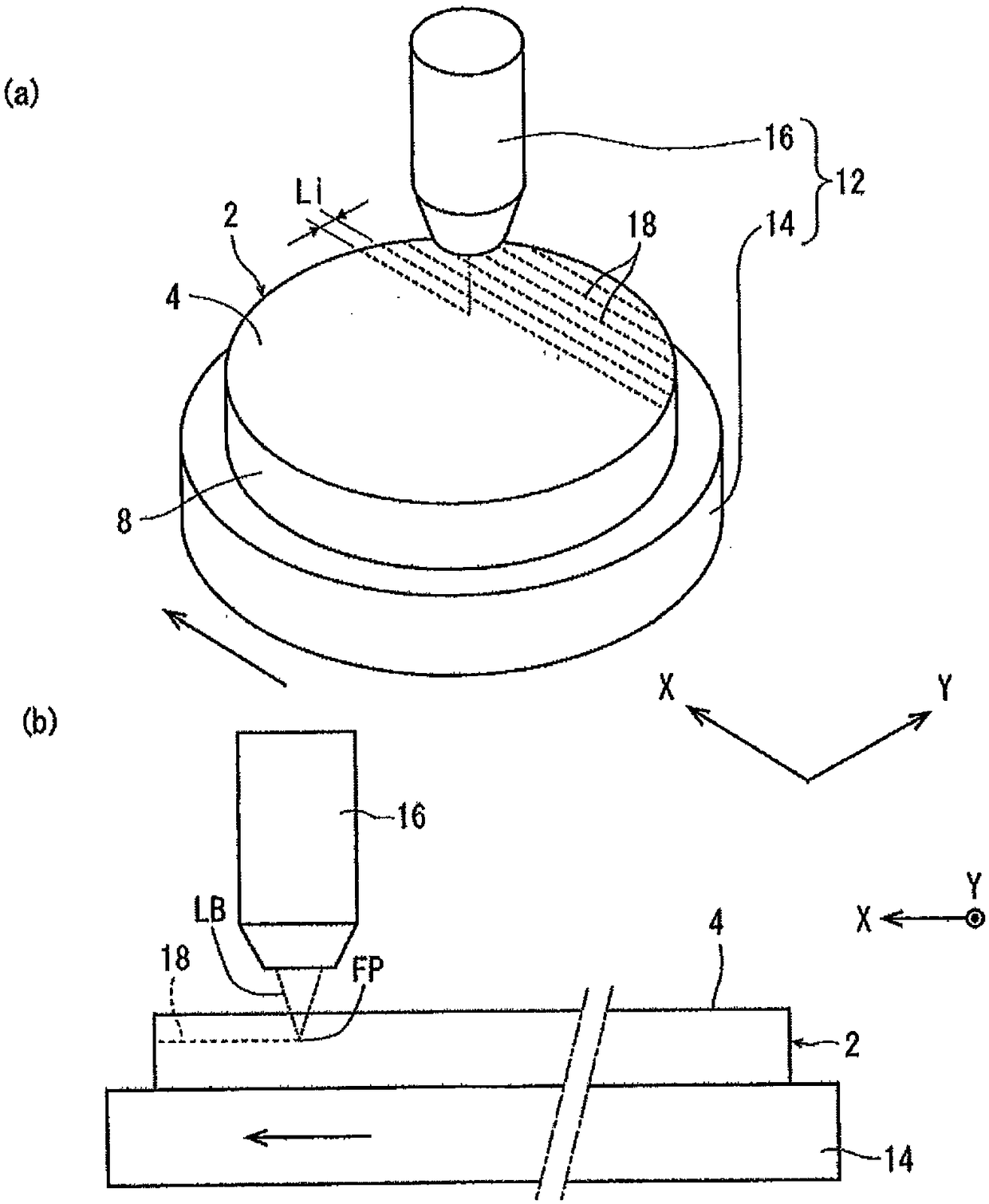

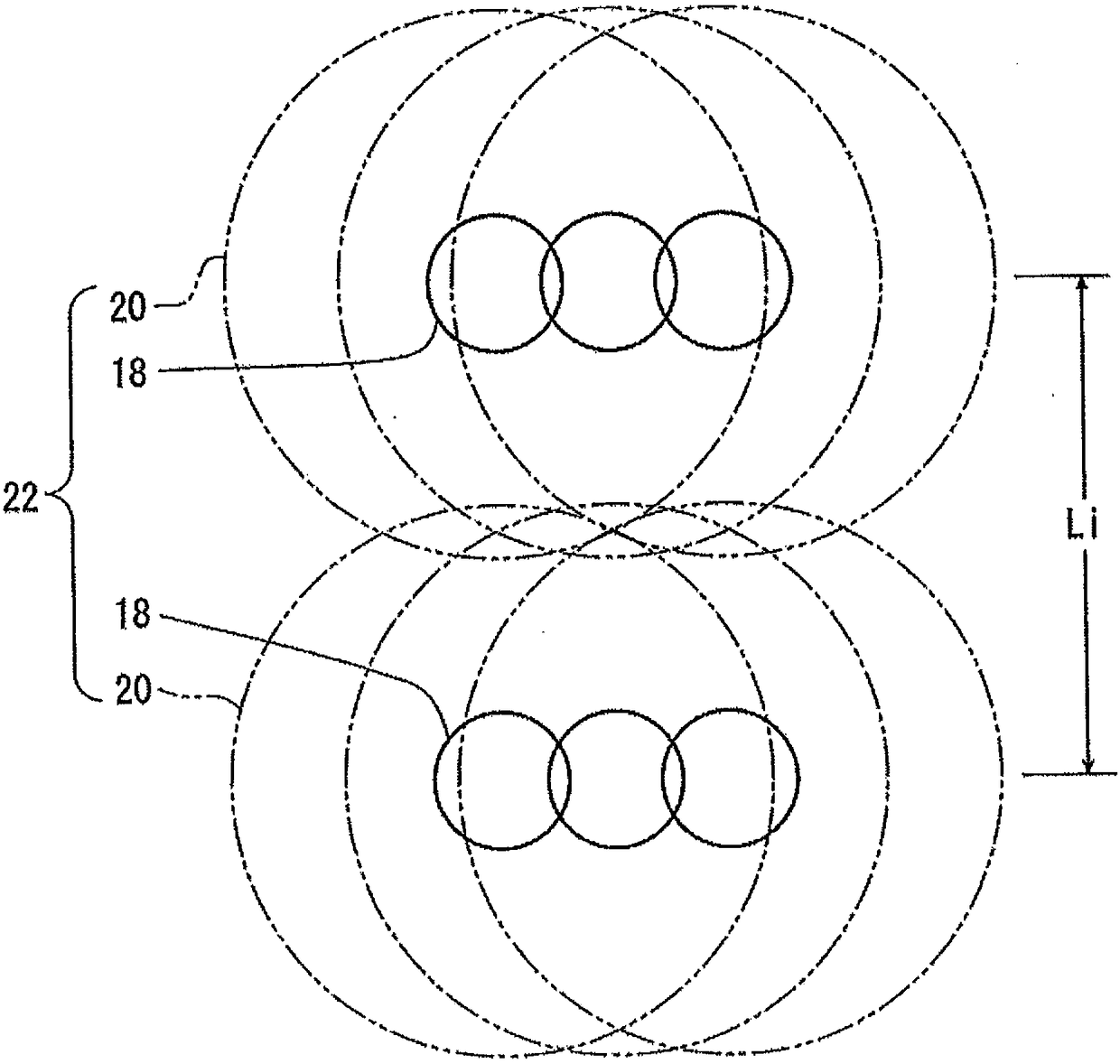

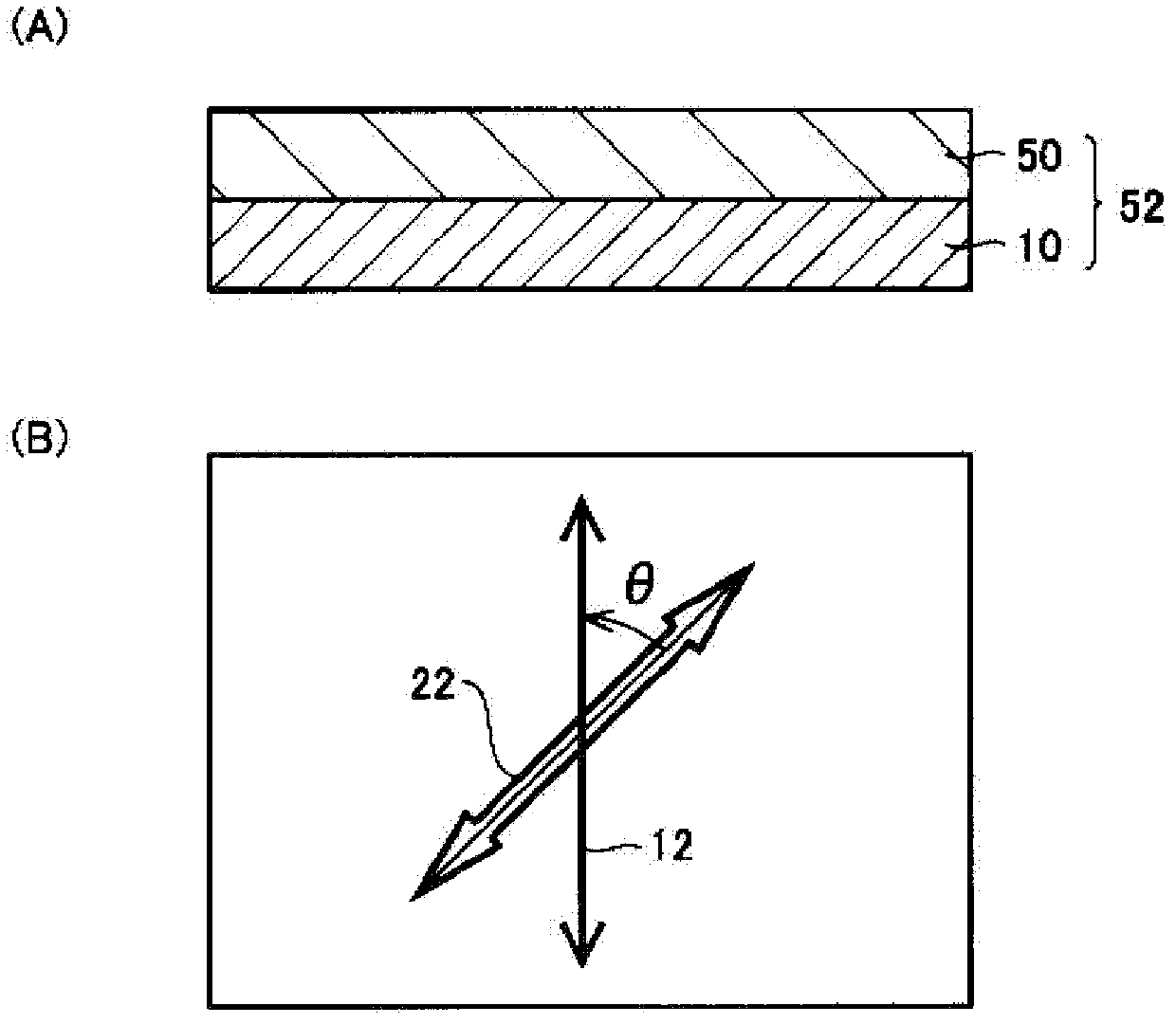

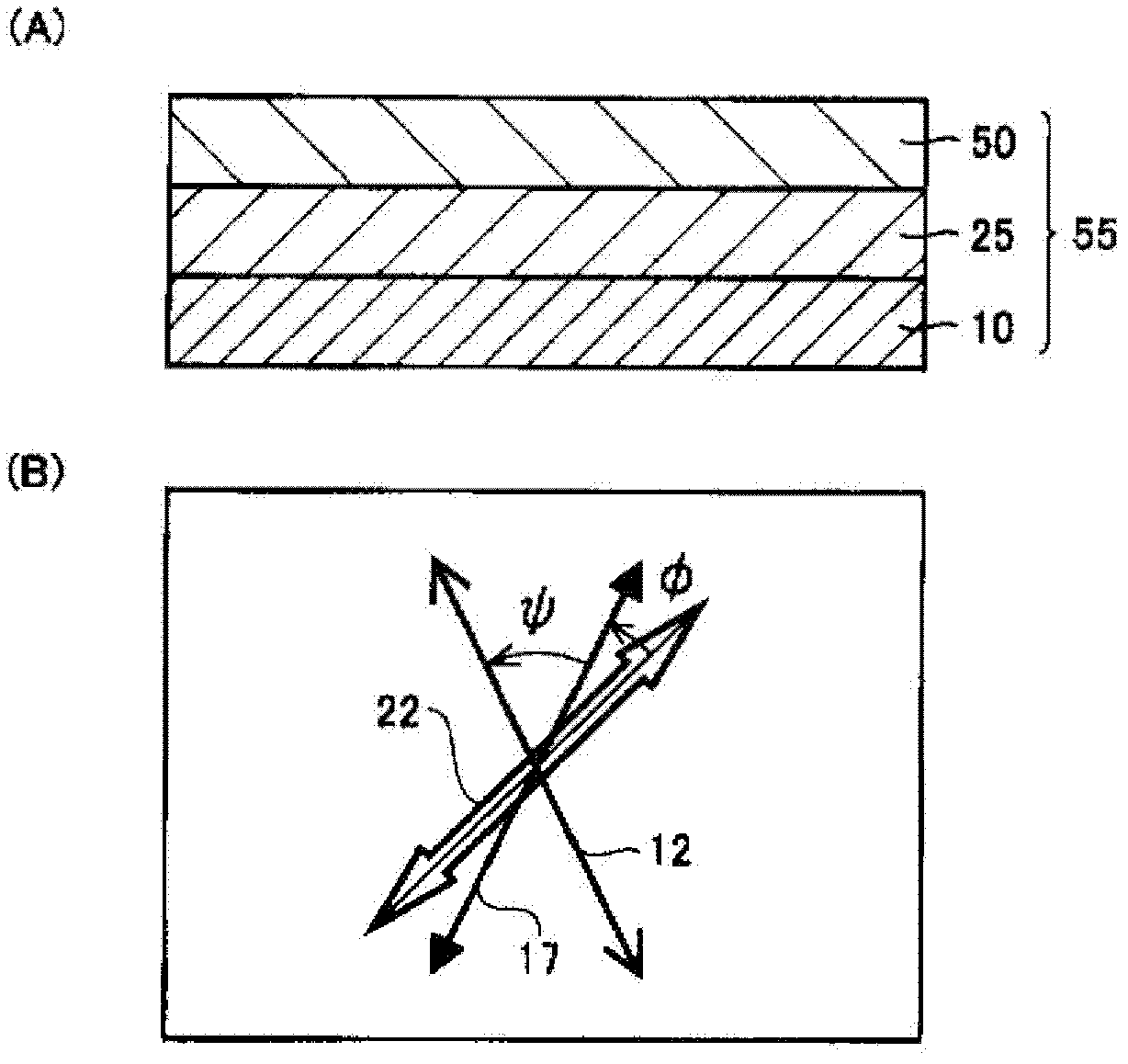

Method for producing wafer

PendingCN108447769AAchieve productivityEfficient strippingSemiconductor/solid-state device manufacturingLaser beam welding apparatusPhysicsSingle crystal

The present invention provides a method for producing a wafer capable of effectively stripping the wafer from a single crystal SiC crystal ingot. The method at least comprises the following steps of:a stripping layer formation process: locating a focus (FP) of a laser light (LB) having a wavelength of permeability about the single crystal SiC at the depth having a thickness of a wafer to be generated far away from a first surface (4) (end face) of the crystal ingot (2) to perform radiation of the laser light (LB) for the crystal ingot (2) to form a stripping layer (22), wherein the strippinglayer (22) is formed by an improvement portion (18) of separating the SiC into Si and C and cracks (20) formed in a isotropy mode at a c surface from the improvement portion (18); a stripping open endformation process configured to perform further radiation of the laser light (LB) to one part of all of the periphery area of the periphery area of the stripping layer (22) to allow the cracks (20) to grow to form the stripping open end (23); and a wafer generation process configured to steep the crystal ingot (2) into the liquid (26) to give ultrasonic waves having frequency larger than the frequency being similar to the natural vibration frequency of the crystal ingot (2) so as to strip one part of the crystal ingot (2) to generate the wafer (34) by taking the stripping layer (22) as an interface.

Owner:DISCO CORP

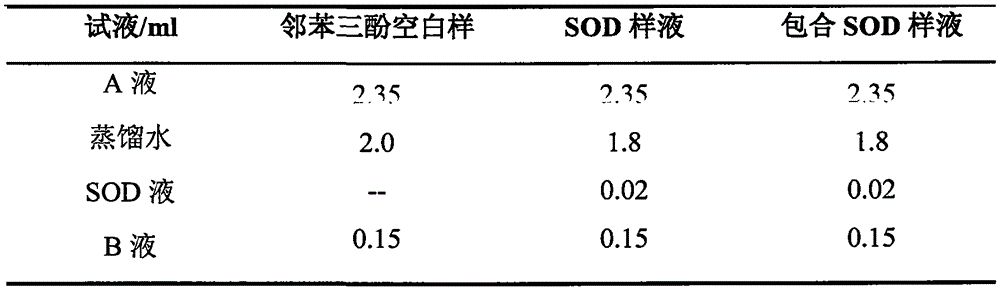

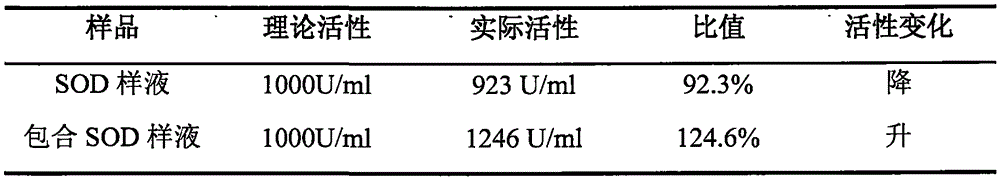

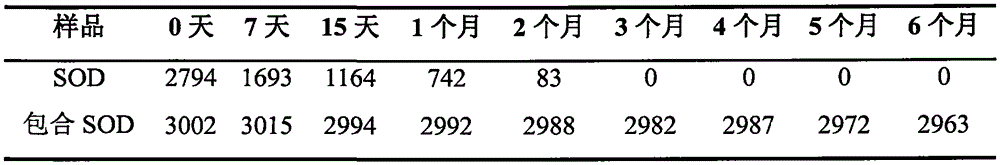

Superoxide dismutase microcapsule powder and preparation method thereof

InactiveCN105288652AImprove stabilityLong validity periodCosmetic preparationsPeptide/protein ingredientsSUPEROXIDE DISMUTASE 3Lactose

The invention discloses superoxide dismutase microcapsule powder and a preparation method thereof. The superoxide dismutase microcapsule powder is prepared from, by weight, 15-35 parts of hydroxypropyl-beta-cyclodextrin, 3-35 parts of superoxide dismutase and 20-40 parts of lactose or mycose. The superoxide dismutase is added into a hydroxypropyl-beta-cyclodextrin saturated solution for even mixing, wherein the weight ratio of the superoxide dismutase to the hydroxypropyl-beta-cyclodextrin is 1:(0.2-1), then the lactose or mycose is added as a protective agent, even mixing and freeze-drying are carried out, and finally the superoxide dismutase microcapsule powder is obtained. The SOD activity and stability of the superoxide dismutase microcapsule powder are obviously improved, and therefore the bioavailability of the superoxide dismutase microcapsule powder is increased.

Owner:珠海雅莎生物科技股份有限公司

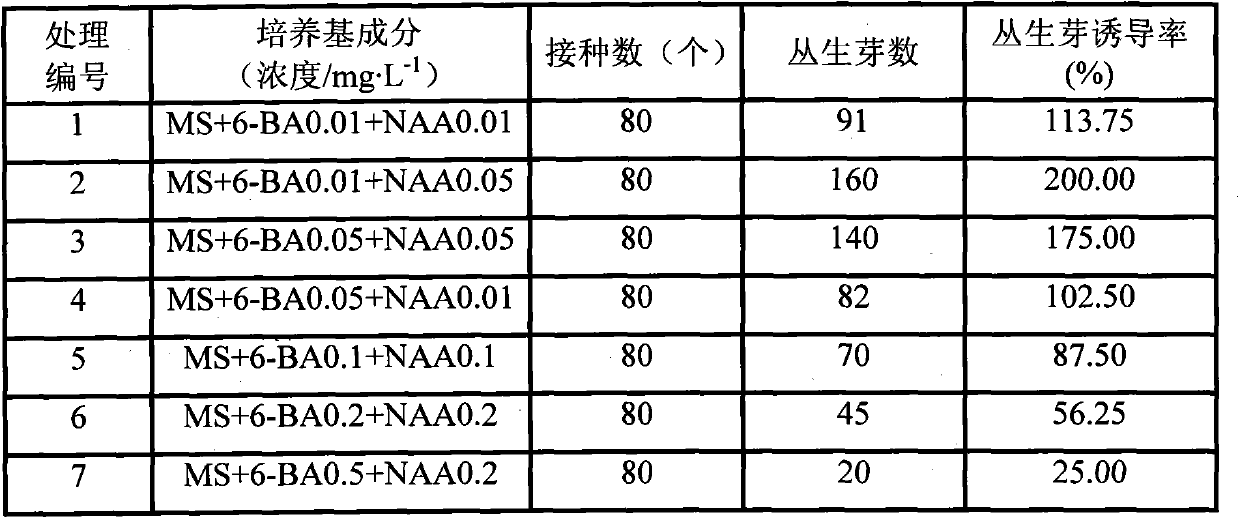

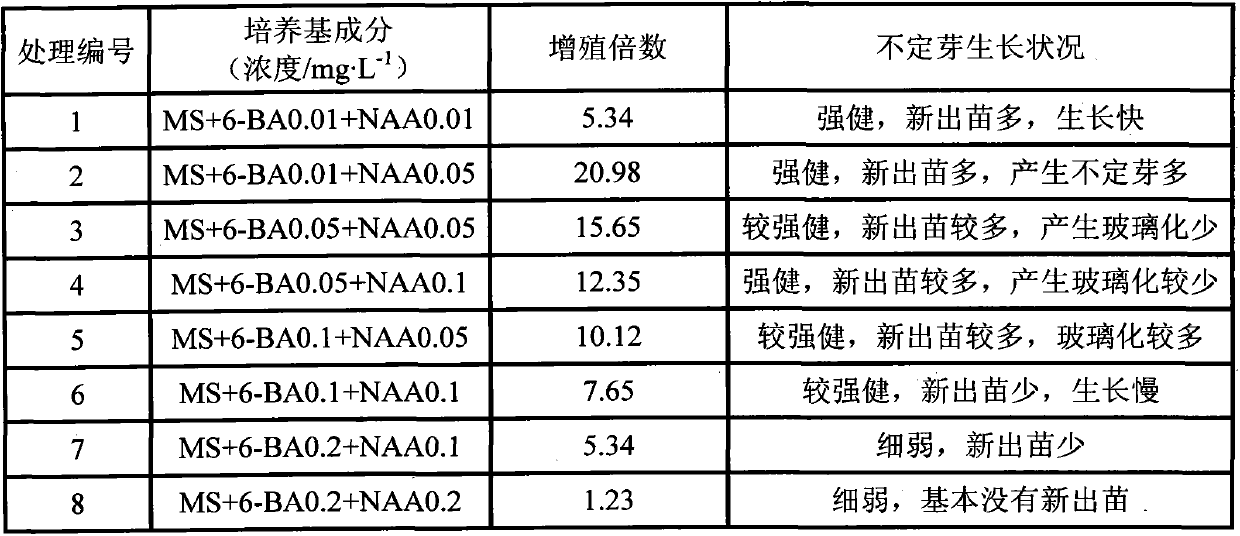

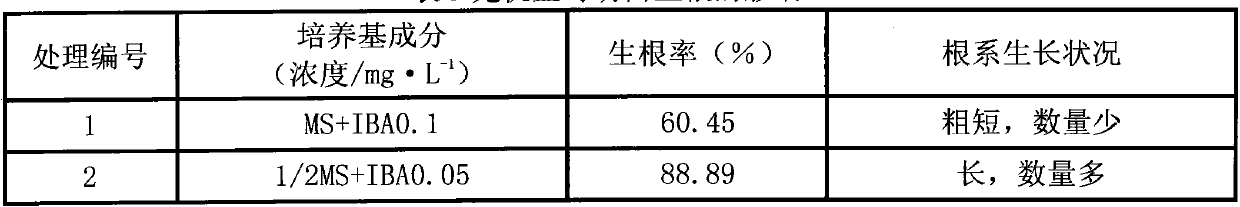

Culture mediums for tissue culturing of maiden pink

ActiveCN103718962AMeet nutritional needsMeet growth and developmentPlant tissue cultureHorticulture methodsPhases of clinical researchButyric acid

The invention relates to culture mediums for tissue culturing of a maiden pink. The optimal culture mediums for different stages in the tissue culturing of the maiden pink are screened; and the matching proportions of various hormones in the culture mediums are determined, so that the culture mediums prepared according to a formula provided by the invention can meet the nutritional requirement and the growing development requirement of the maiden pink in all stages. The culture media respectively comprise: an initial induction culture medium formed by MS, 0.01mg / L of 6-BA and 0.05mg / L of NAA (Naphthalene Acetic Acid), a mulitiplication culture medium formed by the MS, 0.01mg / L of 6-BA and 0.05mg / L of NAA, and a rooting culture medium formed by 1 / 2 of MS and 0.05mg / L of IBA (Indole Butyric Acid). The culture mediums are particularly suitable for the tissue culturing of the maiden pink.

Owner:INNER MONGOLIA M GRASS ECOLOGY & ENVIROMENT GRP CO LTD +1

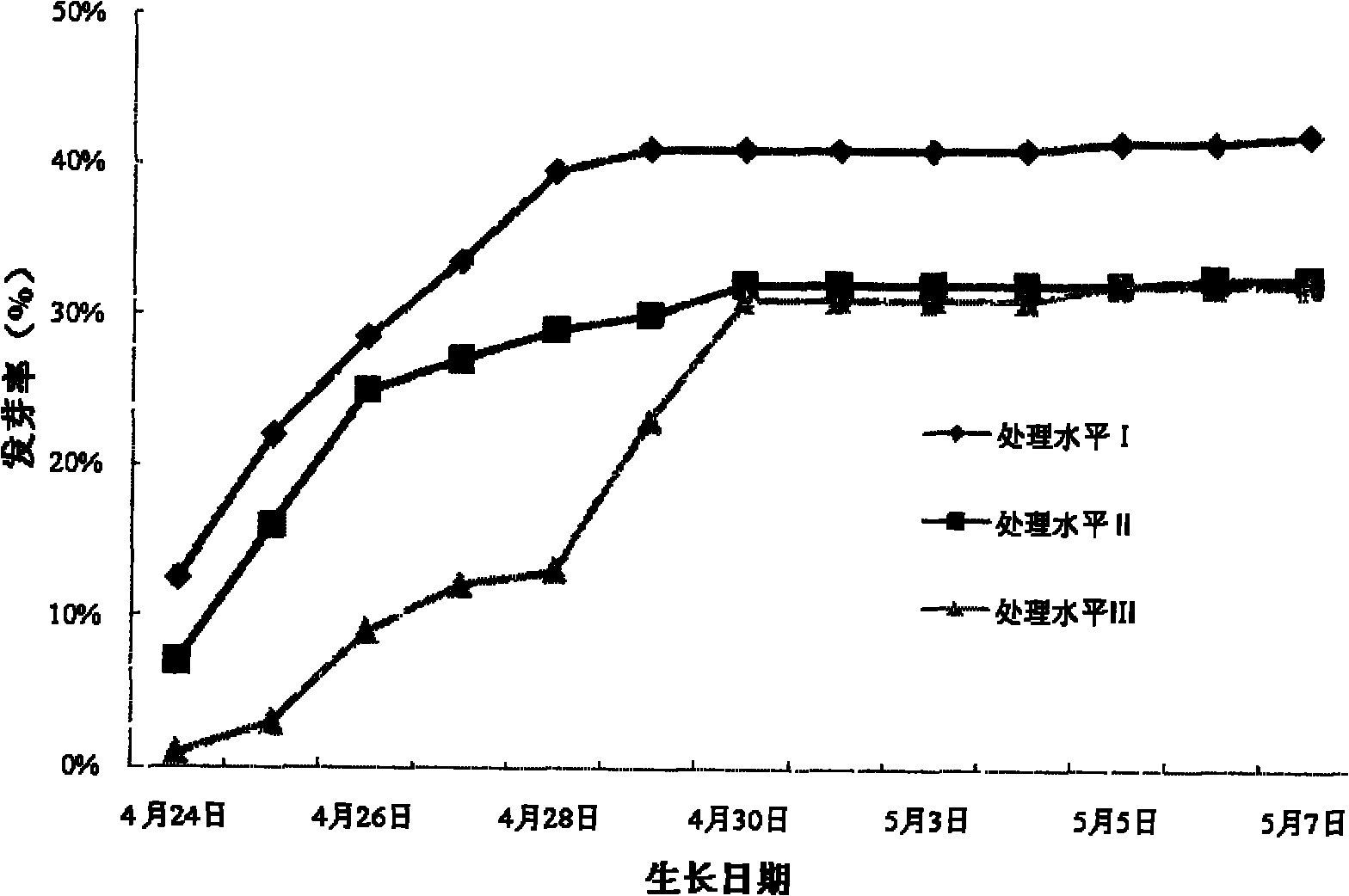

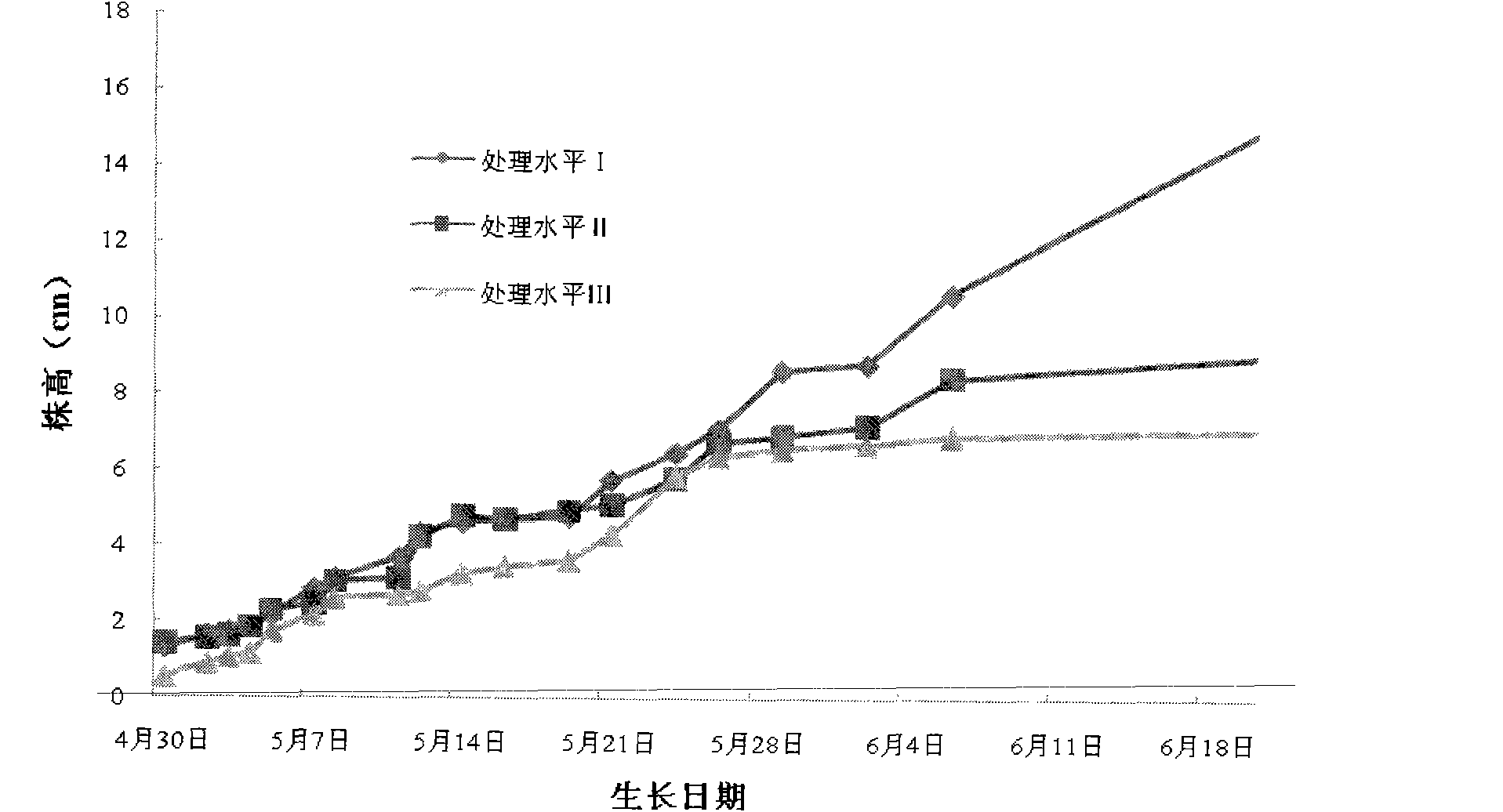

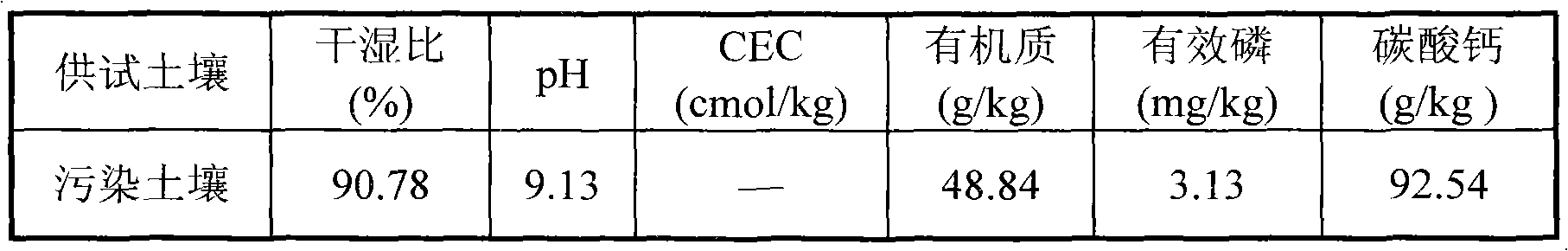

Method for repairing nitrobenzene compound contaminated soil by utilizing flax

InactiveCN102151692ADrought tolerantResistant to barrennessContaminated soil reclamationSulfateNitrobenzene

The invention relates to a method for repairing nitrobenzene compound contaminated soil by utilizing flax, which comprises the following steps: firstly, mixing and homogenizing soil contaminated by red water and a mixture of sierozem and municipal sewage sludge pro rata to obtain mixed soil; secondly, adding wheat bran in the mixed soil; admixing ferrous sulfate, so that the pH value of the mixed soil is neutral; and then cultivating the flax in the open on the mixed soil; and thirdly, managing the flax in a conventional planting manner and cradling the flax when the growth period of the flax is over. The method is economical and green, is free from secondary pollution, is easy to accept by the masses, can be suitable for the large-area nitrobenzene compound contaminated soil and also can achieve the purpose of producing while repairing.

Owner:LANZHOU UNIVERSITY

Synergistic weedicide composition containing clodinafop-propargyl and tribenuron-methyl and preparation method thereof

InactiveCN101703062AGood broad spectrum weed controlGood for weed controlBiocideAnimal repellantsTribenuron-methylDrug resistance

The invention discloses a synergistic weedicide composition containing clodinafop-propargyl and tribenuron-methyl and a preparation method thereof and relates to a composition for preventing and controlling weeds in wheat paddocks. The synergistic weedicide composition comprises clodinafop-propargyl, tribenuron-methyl and additives. By mixing the clodinafop-propargyl and the tribenuron-methyl, the invention keeps the advantages of broad weeding spectrum and good control effect on weeds of the clodinafop-propargyl and the tribenuron-methyl, overcomes the existing disadvantages, reduces the poison to other living things, enhances the quick action, extends the lasting period, broadens the weeding spectrum and reduces the cost. The composition is different from other existing weedicides and can defer the generation of weedicide resistance. In addition, the composition has a small residual quantity which ensures the environmental safety, so that goals of increasing agricultural yields and revenues and ensuring safe production of food are achieved. The synergistic weedicide composition is a comparatively ideal agricultural chemical for preventing and controlling weeds in wheat paddocks.

Owner:扬州市苏灵农药化工有限公司

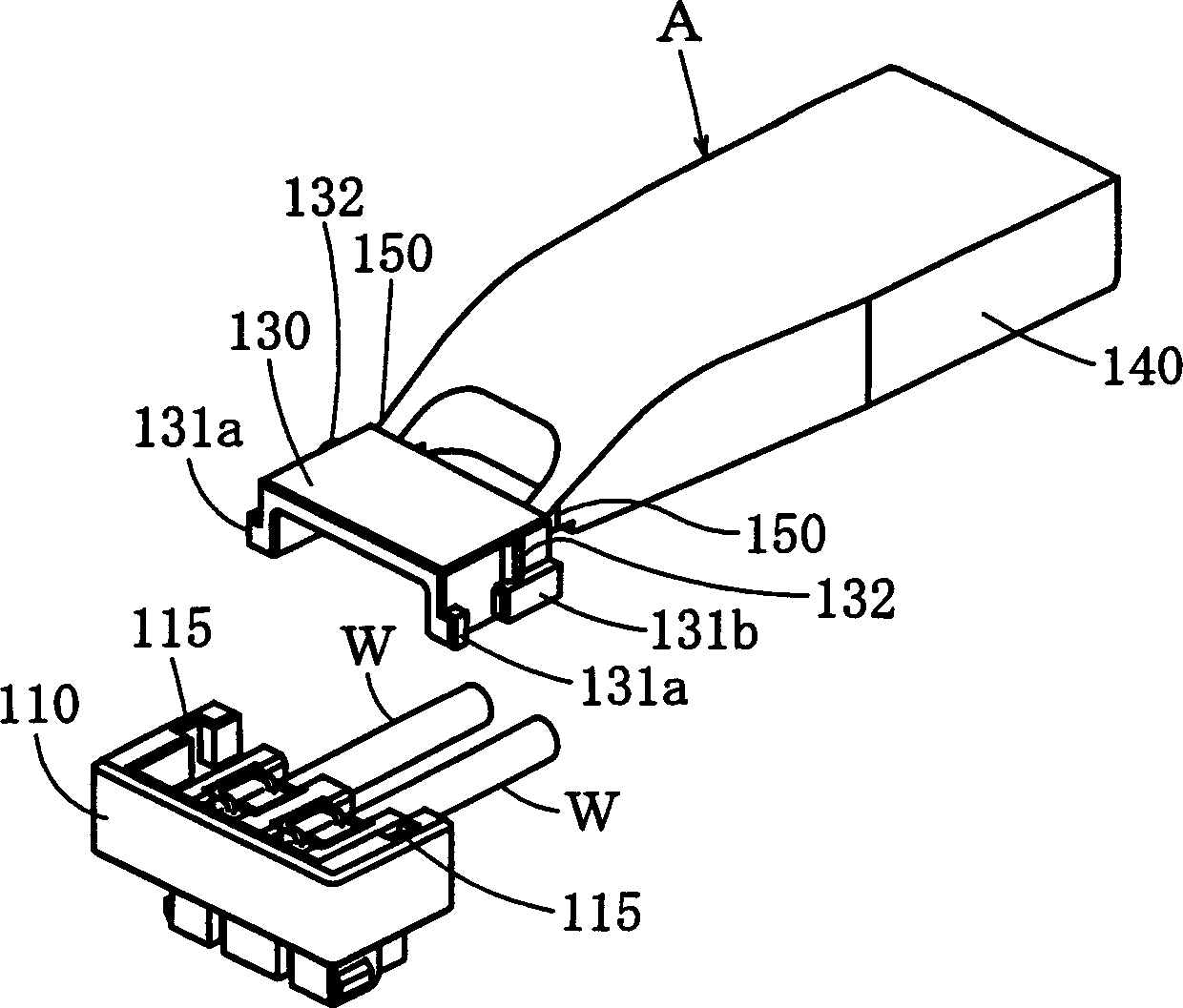

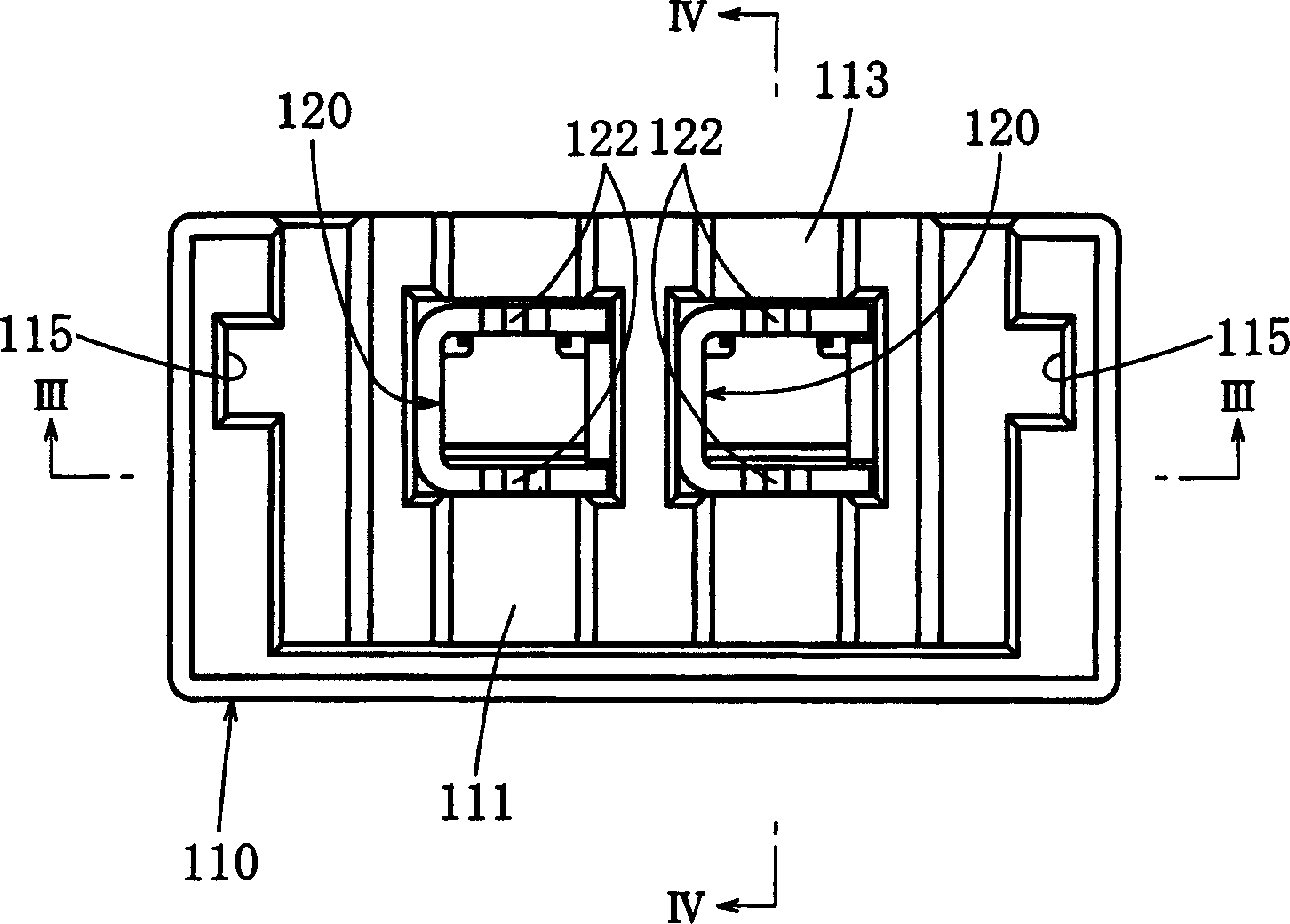

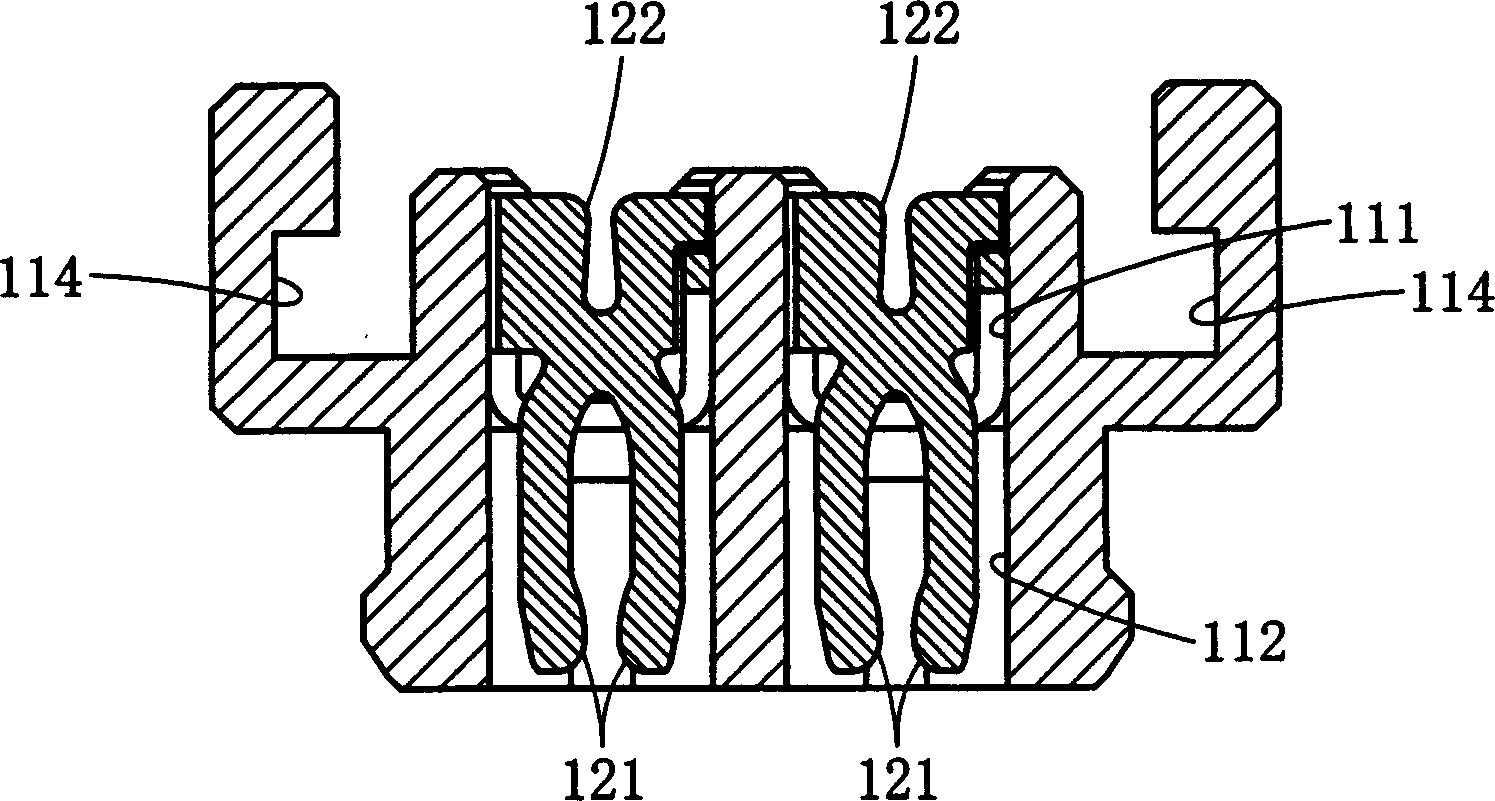

A connector housing assembly and an electric connector assembly

InactiveCN1614826AAchieve productivityEasy to operateCoupling contact membersCouplings bases/casesEngineeringElectrical and Electronics engineering

A connector housing assembly and an electrical connector assembly. The purpose of the present invention is to simplify the operation of fitting the cover on the main body of the connector housing, improve the productivity of the electronic connector, and reduce the production cost. It includes: a connector housing main body (110) provided with an accommodation chamber (111) open to the outside; contacts (120) accommodated in the connector housing main body (110) so as to be able to contact contacts on the opposite side and fit on the cover (130) of the housing chamber (111) on the connector housing main body (110), which is configured to connect the electric wire (W) of the contact (120) from the connector housing main body (110) and Between the covers (130) is drawn out to the outside. A connector housing main body (110) and a cover assembly part (A) formed by connecting an auxiliary part (140) to a cover (130) via a cutable connection part (150) are combined.

Owner:JST MFG CO LTD

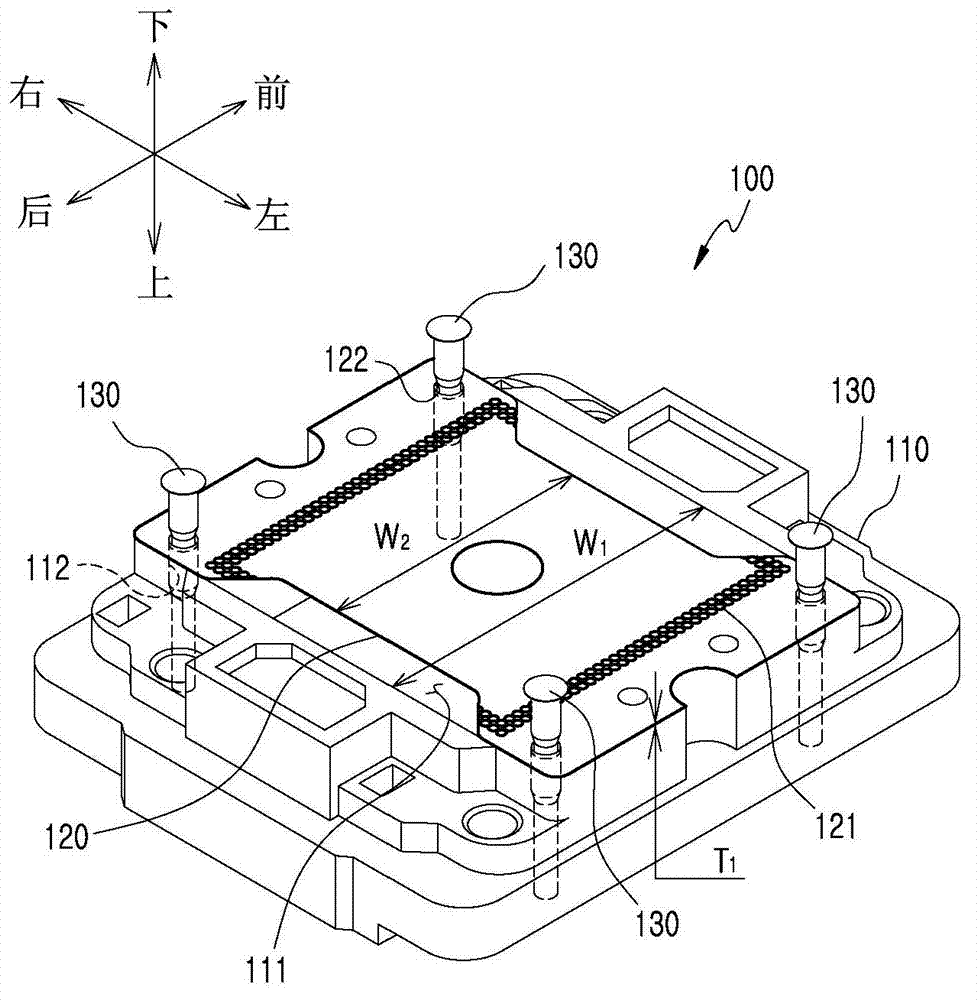

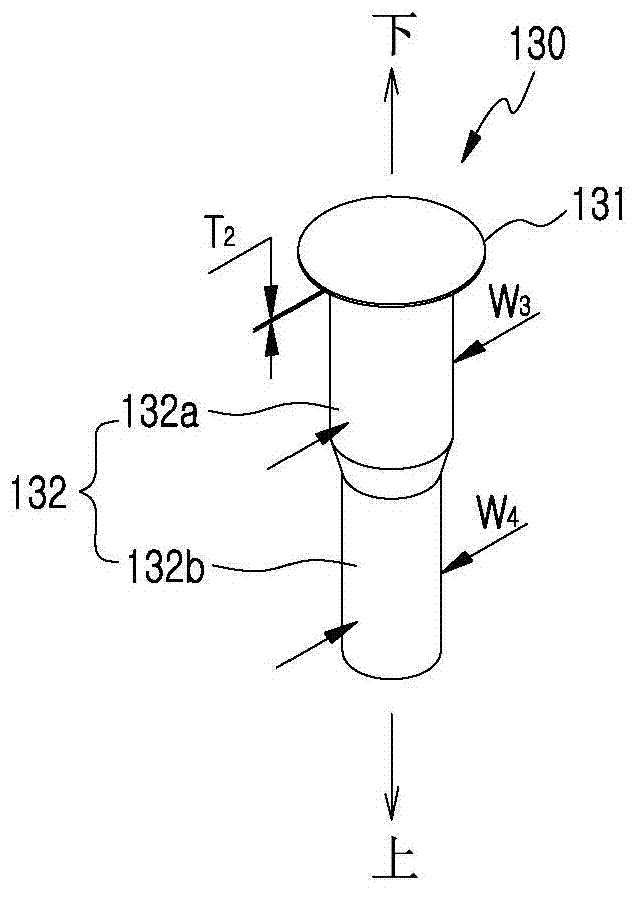

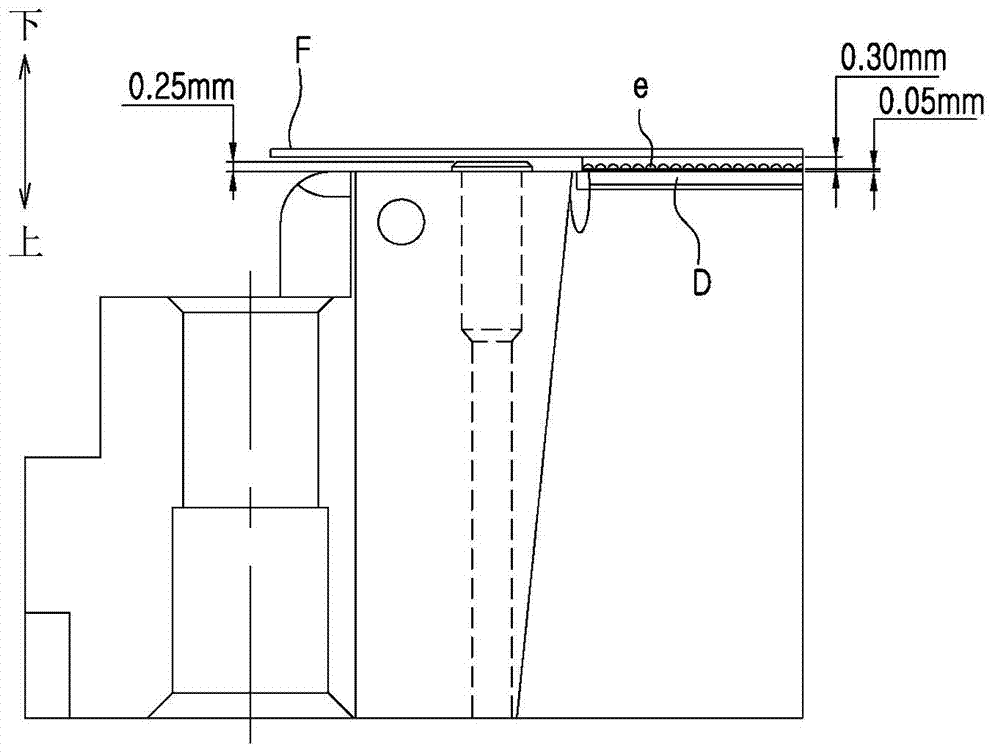

Plug-in used for test sorter

The invention relates to a plug-in used for a test sorter. The invention discloses a technique that enables a supporting part to be fixed to a plug-in main body through interference insertion or fusion welding, so that an extrusion portion used for extruding the supporting part toward the side of the plug-in main body is minimized in thickness.

Owner:TECHWING CO LTD

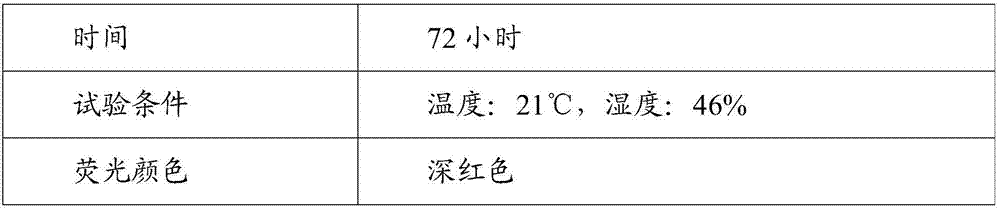

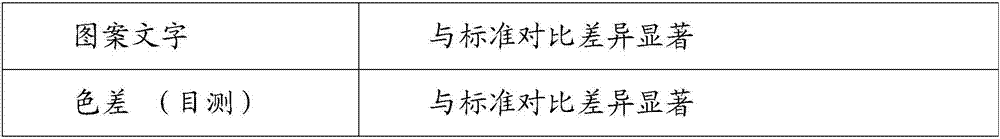

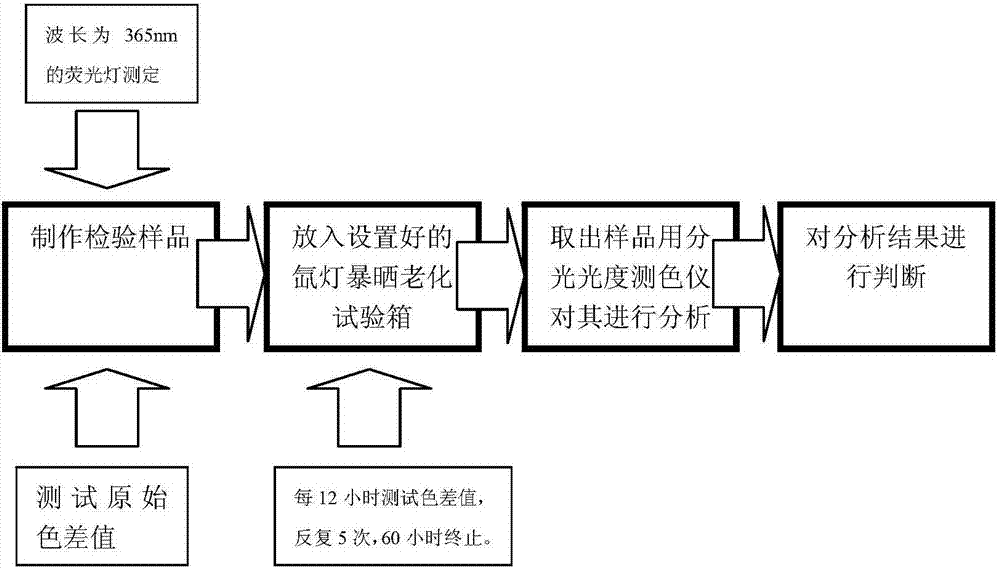

Qualitative detection method for attenuation rate of anti-counterfeiting information of cigarette fluorescent anti-counterfeiting tear line

InactiveCN107462554AEliminate hidden dangers of illegal infringementGuaranteed qualityFluorescence/phosphorescenceUltrasound attenuationFluorescence

Owner:CHINA TOBACCO YUNNAN IND

Qualitative detection method of anti-forgery information attenuation rate of cigarette fluorescent anti-forgery stay wire

InactiveCN103712920AEliminate hidden dangers of illegal infringementGuaranteed qualityColor/spectral properties measurementsUltrasound attenuationFluorescence

The invention discloses a qualitative detection method of anti-forgery information attenuation rate of cigarette fluorescent anti-forgery stay wire. The method utilizes a sunshine imitation cabinet to simulate different sunlight exposure environments under different temperatures and time periods so as to observe the change of a product under different environments; and then carries out detection on the fluorescent strength by using a spectrophotometric color photometer so as to determine the attenuation of the cigarette fluorescent anti-forgery stay wire. The qualitative detection method fills the technical blank in the field of attenuation rate detection of fluorescent anti-forgery materials at present, the detection results can represent recessive anti-forgery information attenuation period, so the qualitative detection method has a positive meaning for early warning in production and scientific using of anti-forgery materials. The method is simple and practicable, the detection result is objective and scientific, and the method is easy to popularize.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Biological-chemical synergistic bactericide composition and preparation method thereof

InactiveCN102630674ABroad-spectrum germicidalGood control effectBiocideFungicidesBiologyWettable powder

The invention discloses a biological-chemical synergistic bactericide composition and a preparation method thereof. The preparation method comprises the following steps of: adding jinggangmycin, cyprodinil and additives into an enamel stirring kettle for uniform mixing, then performing airflow crushing or grinding, and then preparing into the bactericide composition containing the jinggangmycin and the cyprodinil, which is of wettable powder or suspension concentrate. The jinggangmycin and the cyprodinil are compounded for use, thus the bactericide composition has the characteristics of low toxicity, low residue, broad insecticidal spectrum, good lasting effect and low cost, in particular to nuisanceless control, and further becomes a relatively ideal pesticide variety for controlling rice sheath blight.

Owner:JIANGSU DONGBAO AGROCHEM

Adhesive layer-attached retardation film, and elliptical polarizing plate and liquid crystal display device each utilizing same

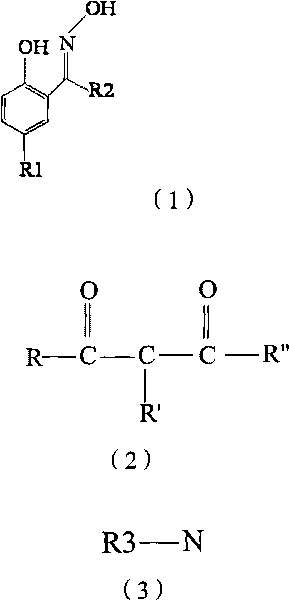

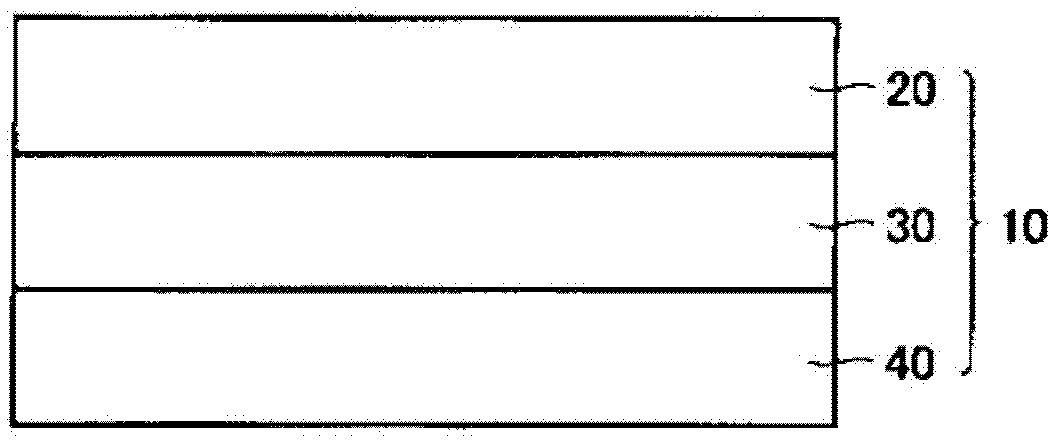

InactiveCN102395908AExcellent adhesionAchieve productivityLayered productsPolarising elementsPolypropyleneChemistry

Disclosed is an adhesive layer-attached retardation film (10), which comprises a retardation film (20) comprising a polypropylene resin, a primer layer (30) laminated on the surface of the retardation film (20), and an adhesive layer (40) laminated on the surface of the primer layer (30), wherein the primer layer (30) comprises a thermoplastic polyester resin composed of diol units and dicarboxylic acid units and having a weight average molecular weight of 10,000 to 150,000, and wherein a unit represented by formula (I) [wherein R represents a methylene group or an ethylene group; and n represents 1 or 0] makes up 40 to 80 mol% of the total amount of the diol units. In the adhesive layer-attached retardation film (10), the adhesion between the retardation film and an adhesive agent is improved. Also disclosed are an elliptical polarizing plate and a liquid crystal display device, each of which utilizes the adhesive layer-attached retardation film.

Owner:SUMITOMO CHEM CO LTD

Treatment method for mother liquid generated in preparation process of aspartic acid

The invention discloses a treatment method for a mother liquid generated in the preparation process of aspartic acid, and belongs to the field of green chemical synthesis. The treatment method uses the mother liquid to prepare a polyaspartic acid product. The method provided by the invention has no waste discharge, is safe environmentally friendly and pollution-free, and meets the requirements ofclean production; and the method has a simple production process, needs less equipment, has a high resource utilization rate, and is suitable for large-scale production.

Owner:HEBEI THINK DO ENVIRONMENT CO LTD

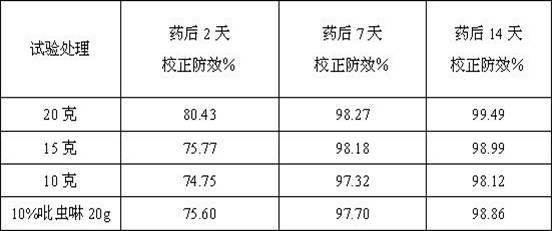

Synergistic pesticide containing chlorfenapyr and tebufenozide and production method thereof

InactiveCN102067837ASimple production processReasonable production processBiocideAnimal repellantsChlorfenapyrPlant disease

The invention discloses a synergistic pesticide containing chlorfenapyr and tebufenozide, and relates to the technical field of production of synergistic pesticide compositions. The synergistic pesticide comprises the following raw materials in percentage by weight: 1 to 20 percent of chlorfenapyr, 1 to 20 percent of tebufenozide, 2 to 25 percent of auxiliary agents and 35 to 96 percent of filler. A production method of the synergistic pesticide comprises the following steps of: adding the raw materials into a porcelain enamel stirring kettle and uniformly mixing; and jet-milling or grinding to prepare wettable powder or suspension, namely the synergistic pesticide composition containing the chlorfenapyr and the tebufenozide. After the chlorfenapyr and the tebufenozide are compounded, the synergistic pesticide has low toxicity, low residue, a wide bactericidal spectrum and high persistence, is low in cost, and is an ideal high-efficiency low-toxicity pesticide preparation for preventing and controlling various diseases of vegetables.

Owner:JIANGSU DONGBAO AGROCHEM

Method for recycling volatile solvent in varnished wire production

InactiveCN102553414AEnable recyclingAchieve emission standardsDispersed particle separationSolubilityCresol

The invention discloses a method for recycling volatile solvent in varnished wire production, which comprises the steps of cooling waste gas exhausted from the top of a varnishing machine firstly by utilizing air as cooling media through countercurrent flow; further condensing the waste gas precooled by the air through water; selecting organic solvent white mineral oil with excellent dissolubility to cresol and xylene as an absorbent to absorb the remained uncondensed cresol and xylene gas which are contained in the waste gas precooled by the air and condensed through the water in a cycle mode; and after the white mineral oil performs cycle absorption for twenty to thirty days, regenerating the absorbent white mineral oil through thin film evaporation, processing the xylene and the cresol simultaneously, and secondarily recycling the cresol and the xylene.

Owner:汉中厚华电工材料有限公司 +1

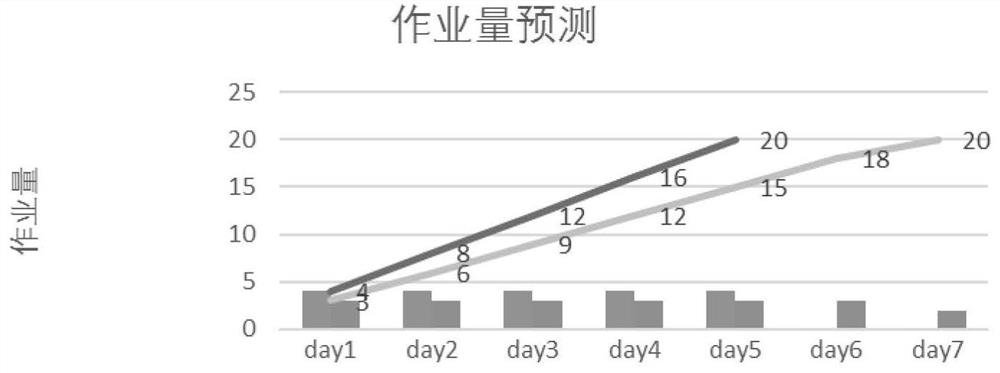

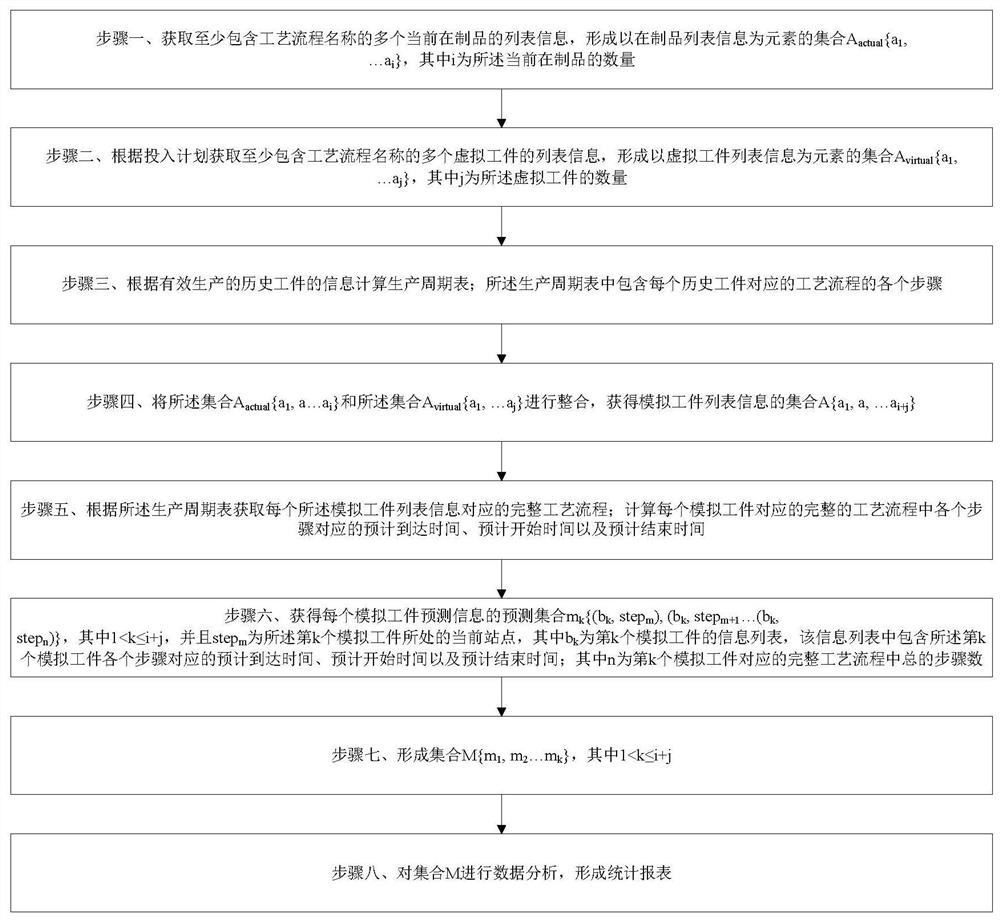

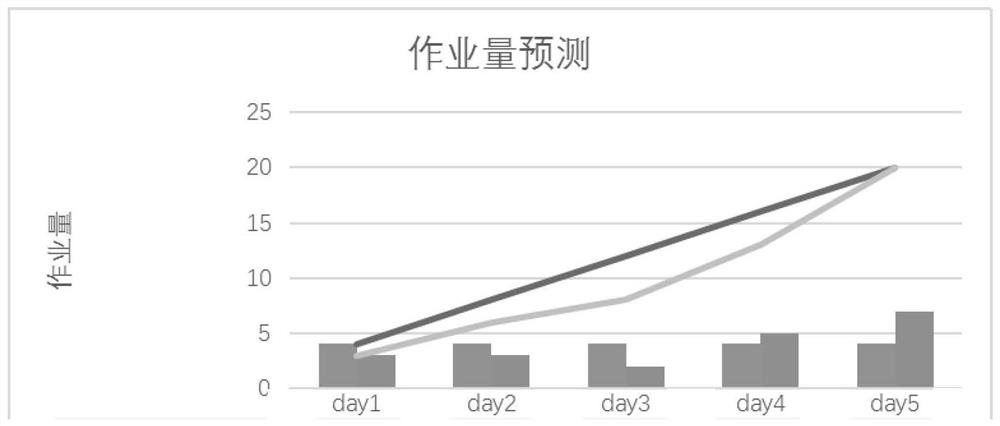

Line production line workload prediction method based on production cycle

PendingCN111784036AAchieve productivityTo achieve the purpose of production capacity early warning and other regulationForecastingOffice automationProduction lineStatistical Report

The invention provides a line production line workload prediction method based on a production cycle. The method comprises the steps of forming an in-process product list information set; forming a virtual workpiece list information set; calculating a production periodic table according to the historical workpiece information; integrating the in-process product list information and the virtual workpiece list information as a set of elements to obtain a simulated workpiece list information set; obtaining a complete process flow corresponding to each piece of simulated workpiece list informationaccording to the production periodic table; calculating the estimated arrival time, the estimated start time and the estimated end time of each step of each simulation workpiece; and obtaining a prediction set of the prediction information of each simulation workpiece to form a statistical report. According to the characteristics and known data of the flow production line, the prediction method is utilized to quickly realize workload prediction of the whole production line in a period of time in the future, detailed prediction data are reserved, analysis of each dimension is performed on thedata, and the regulation and control purposes of production regulation and control, productivity early warning and the like are achieved in combination with the condition of the actual production line.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

Synergistic bactericide composition and preparation method thereof

ActiveCN103947648AStrong disease prevention and treatment effectImprove securityBiocideDisinfectantsHas active ingredientCyanuric acid

The invention discloses a synergistic bactericide composition and a preparation method thereof. The synergistic bactericide composition is characterized in that the composition comprises effective compositions Xinjunan (of which the effective composition is Di-n-octyldiethylenetriamine) and chloroisobromine cyanuric acid, and an additive; and based on the total weight of the composition, Xinjunan accounts for 1-30%, chloroisobromine cyanuric acid accounts for 1-30%, the additive accounts for 2-25% and a filling material accounts for 15-96%. The above raw materials are added into an enamel stirred vessel, mixed uniformly and subjected to air-flow crushing or grinding, so that the bactericide composition containing Xinjunan and chlorobromoisocyanuric acid is prepared and exists in the form of a wettable powder or a suspending agent. Through combination of thifluzamide and chlorobromoisocyanuric acid for usage, the bactericide composition is low in toxicity, low in residue, wide in bacteriocidal spectrum, good in persistent effect and low in cost, especially has the characteristic of nuisanceless control, and is a relatively ideal pesticide kind for controlling paddy rice bacterial leaf streak and other diseases.

Owner:JIANGSU DONGBAO AGROCHEM

Polymer melt and polymer-melt conveying technology

InactiveCN109321989AImprove purityStabilize fiber qualitySpinnerette packsSpinning head liquid feederFiberPolymer science

The invention relates to a polymer melt and a polymer-melt conveying technology. The polymer melt comprises 30%-50% of a low-melting-point polymer melt and 50%-70% of a second polymer melt, and the second polymer melt is a mixture of 55%-65% of terephthalic acid and 35%-45% of glycol. A preparing method of the low-melting-point polymer melt includes the following steps that diacid and dihydric alcohol are prepared into slurry; a low polymer of diacid dihydric alcohol ester is obtained through esterification; the low polymer and polyether are mixed to be even and subjected to an ester exchangereaction to obtain a homogenized substance; the homogenized substance and a chain extender are mixed, a polycondensation reaction is carried out, and the polymer melt is obtained. According to the polymer melt and the polymer-melt conveying technology, the low-melting-point polymer melt is added into a conventional polymerization melt, so that the drying process of low-melting-point polyester is omitted, the production cost is reduced, and meanwhile the stability of the product quality is guaranteed. The conveying method is simple and convenient, the obtained polymer melt has the high purity degree and the stable fiber quality, waste materials are not discharged, and the aims of clean production, saving energy and reducing emission are achieved.

Owner:NINGBO HUAXING SCI & TECH

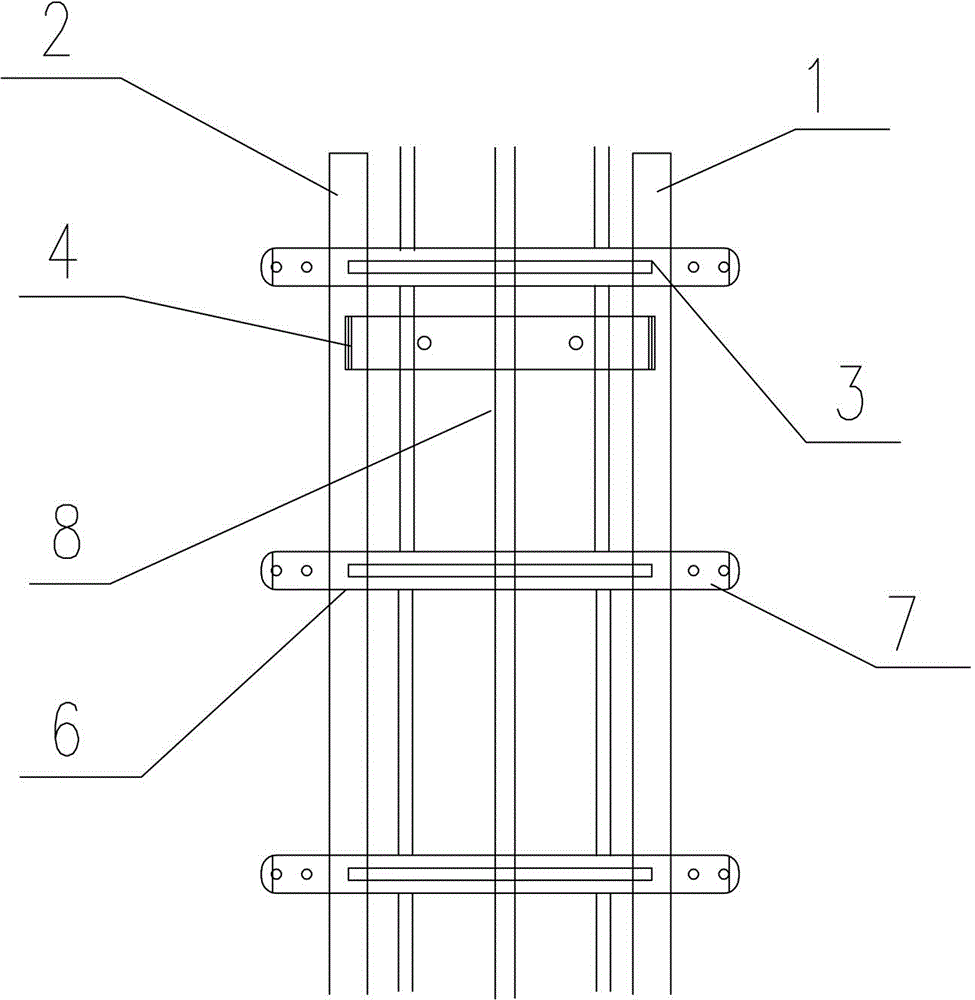

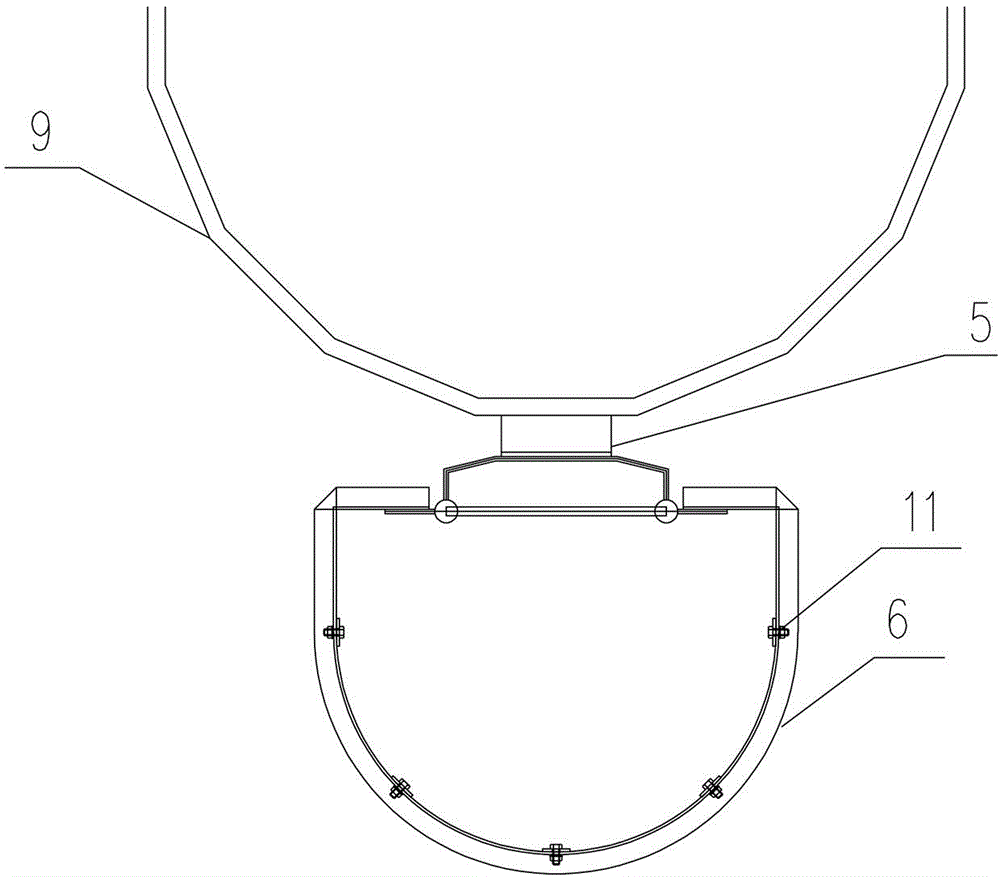

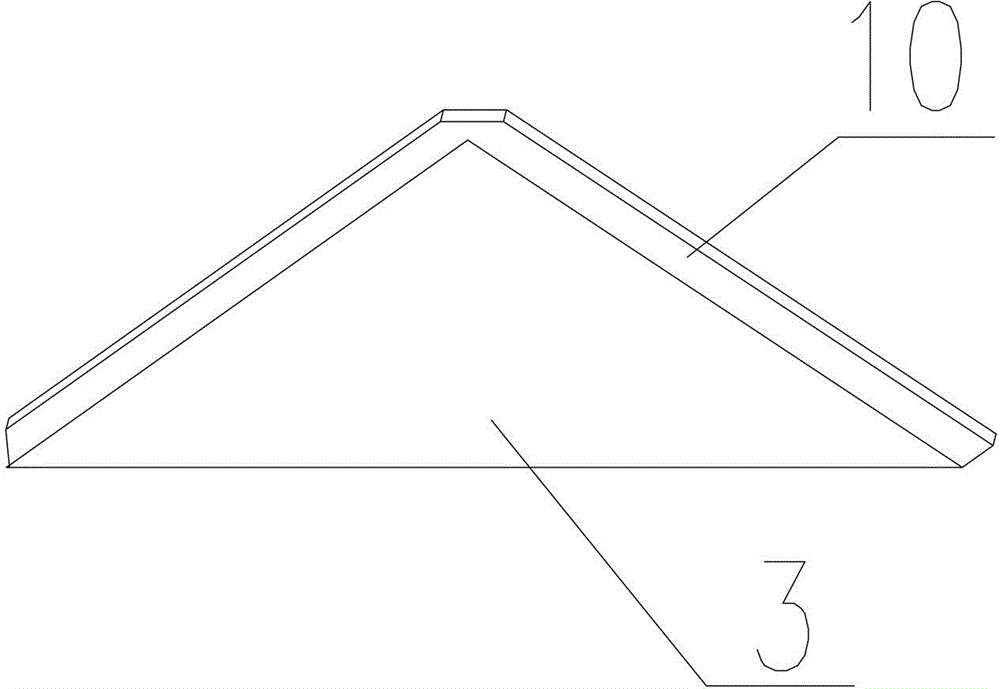

Crawling ladder with double pipes and safety cage for steel pipe pole

ActiveCN104863491AProtect personal safetyEase of subsequent maintenanceLaddersArchitectural engineeringProtection ring

The invention provides a crawling ladder with double pipes and a safety cage for a steel pipe pole. The crawling ladder comprises a climbing structure and a protection body, wherein the climbing structure comprises two steel pipes; climbing cross arms and climbing fixing iron pieces are arranged on the steel pipes; two ends of each climbing cross arm and those of each climbing fixing iron piece are respectively, vertically and fixedly connected with the two steel pipes; the number of the climbing cross arms as well as that of the climbing fixing iron pieces is more than one; connecting parts are arranged on the climbing fixing iron pieces; the protection body comprises a plurality of protection rings and protection body fixing iron piece; two ends of the protection rings are connected with the two steel pipes of the climbing structure through the protection body fixing iron pieces. A good guarantee is provided for stable mounting of the crawling ladder and the safety of maintainers. In addition, standard small-sized length design is adopted, rod sections of any standard lengths can be arranged, and the processing and mounting standardization is facilitated.

Owner:STATE GRID CORP OF CHINA +2

Polymerized melt conveying process

InactiveCN109440198AImprove purityStabilize fiber qualitySpinning solution de-aeratingSpinnerette packsFiberMetering pump

The invention relates to a polymerized melt conveying process. The conveying process comprises the following steps: the polymerized melt is conveyed to a spinning box body through a delivery pump, passes a melt filter, a melt booster pump, a melt cooler, a melt distribution valve and a melt distribution pipe in sequence, and is extruded into a melt fine flow after going through a metering pump, aspinning assembly and a spinneret plate in the spinning box body; a bundle wire is obtained by adopting side blow wind cooling and solidifying; and finally, the bundle wire is wound up and takes formafter oiling. The conveying method is simple and convenient, the polymerized melt obtained by conveying has better purity and stable fiber quality with no waste discharged, and achieves the purposes of clean production, energy conservation and emission reduction.

Owner:NINGBO HUAXING SCI & TECH

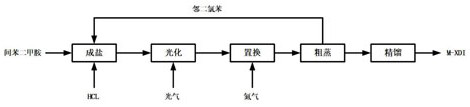

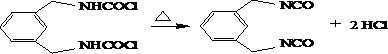

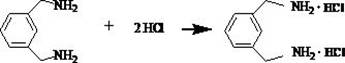

Method for synthesizing m-xylylene diisocyanate by low-temperature salifying method

PendingCN112358420AEmission reductionImprove product qualityIsocyanic acid derivatives preparationOrganic compound preparationXylyleneReaction temperature

The invention relates to a method for synthesizing m-xylylene diisocyanate (M-XDI) by a low-temperature salifying method, which comprises the following steps: dissolving m-xylylenediamine (M-XDA) in an organic solvent o-dichlorobenzene (ODCB) according to a certain proportion, slowly introducing hydrogen chloride gas under the test conditions of the temperature of -10 to -5 DEG C and the pressureof 0.1-0.2 MPa, and carrying out acid-base neutralization reaction to generate m-xylylenediamine hydrochloride (M-XDA. 2HCI); enabling the M-XDA. 2HCI to be subjected to luminescence and thermophotochemical reactions to synthesize M-XDI; and distilling the photochemical liquid containing the M-XDI product to remove the solvent, and rectifying to obtain the high-purity M-XDI product. The salt forming reaction temperature is low, isocyanate and acyl chloride generated in the photochemical reaction can be prevented from reacting with amine again to generate polymerization byproducts, and the saltforming conversion rate can reach 100%.

Owner:甘肃银光聚银化工有限公司

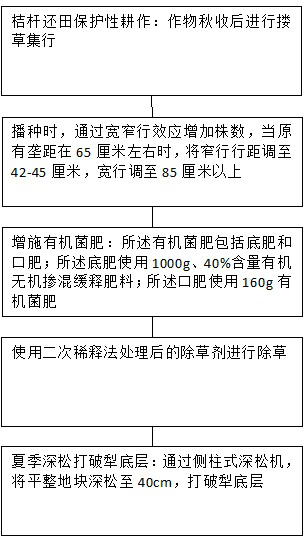

Corn cultivation and planting method for northeast black soil area

PendingCN112219654AAchieve productivityAchieving the goal of reducing costs and increasing productionBiocideFertilising methodsSubsoilerSowing

The invention discloses a corn cultivation and planting method for a northeast black soil area. The corn cultivation and planting method comprises the following non-sequential execution steps of A, performing straw returning protective cultivation, namely after crop autumn harvest, performing grass raking and row collecting; B, during sowing, arranging a front row returning machine to a sowing vehicle, and carrying out secondary row collection; C, during sowing, increasing the number of plants through the wide-narrow row effect, and when the original ridge spacing is about 65 cm, adjusting thenarrow row spacing to 42-45 cm and adjusting the wide row spacing to 85 cm or above; D, additionally applying organic bacterial fertilizer, wherein the organic bacterial fertilizer comprises base fertilizer and seed fertilizer, 1000g of organic-inorganic blended slow-release fertilizer with the content of 40% is used as the base fertilizer, and 160g of organic bacterial fertilizer is used as theseed fertilizer; E, performing weeding by using herbicide treated by a secondary dilution method; and F, in summer, performing deep scarification for breaking a plow pan, namely performing deep scarification on a flat land parcel to 40 cm through a side column type subsoiler, and breaking the plow pan. According to the method, the purposes of standardized production of corn cultivation and planting and cost reduction and yield increase are achieved.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com