Superoxide dismutase microcapsule powder and preparation method thereof

A technology of dismutase microcapsule powder and superoxide, applied in cosmetic preparations, pharmaceutical formulations, dressing preparations, etc., can solve problems such as product solution inactivation failure, light sensitivity, and accelerated SOD inactivation, and achieve improved Bioavailability, delayed release, reduced irritation and immunogenicity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of SOD microcapsule dry powder

[0032] 1: Dissolve 7g HP-β-CD in 10g purified water to form a saturated solution. Then take 1.4g of SOD powder, dissolve it with a small amount of purified water, add it to HP-β-CD saturated solution under stirring, and stir evenly. Place it at 4°C and continue stirring for 4 hours. Add 4g of lactose, stir evenly, freeze-dry to obtain SOD microcapsule dry powder.

[0033] 2: Dissolve 7g of HP-β-CD in 10g of purified water to form a saturated solution. Then take 7g of SOD powder, dissolve it with a small amount of purified water, add it to HP-β-CD saturated solution under stirring, and stir evenly. Place it at 4°C and continue stirring for 4 hours. Add 8g of trehalose, stir evenly, freeze-dry to obtain SOD microcapsule dry powder.

[0034] Note: The dosage of HP-β-CD is selected according to the type of its substituent. The specific dosage is subject to the saturation of the solution. The solubility of the three type...

Embodiment 2

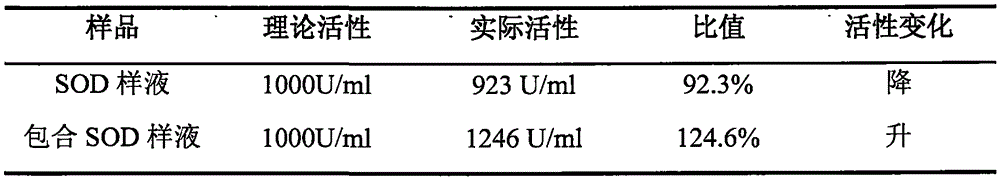

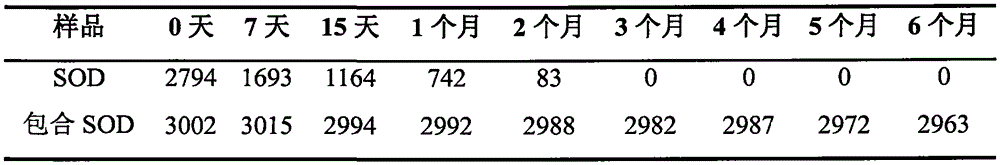

[0035] Example 2: Comparison and verification of the activity of SOD microcapsule dry powder

[0036] The inventors used the pyrogallol autooxidation method to study the inhibitory effect of pyrogallol autooxidation before and after the action of superoxide dismutase and HP-β-CD and the stability of SOD after inclusion. The data can prove: 1. The activity of SOD after inclusion is slightly higher than that of uninclusion. 2: After inclusion, SOD can be stored at room temperature for two years.

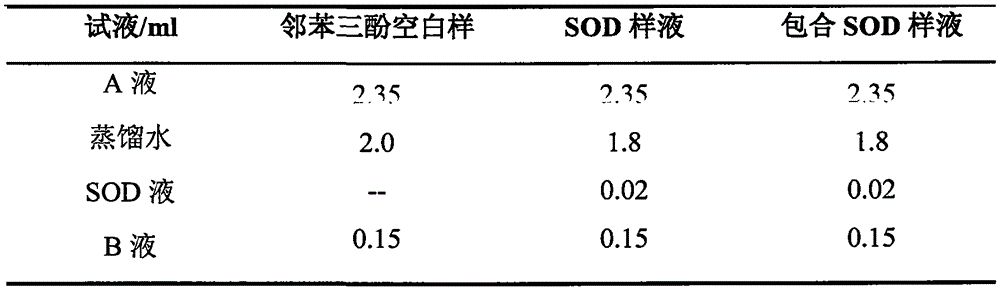

[0037] The inventors added the SOD powder before and after the inclusion to the pyrogallol auto-oxidation system, and calculated the activity of the SOD powder through the change rate of the absorbance of the pyrogallol system at a wavelength of 325nm. The detection method adopts the determination of superoxide dismutase (SOD) activity in GB / T5009.171-2003 health food (the first method), and the sample components are as follows:

[0038]

[0039] SOD sample solution: SOD powder before inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com