Treatment method for mother liquid generated in preparation process of aspartic acid

A technology of aspartic acid and a processing method is applied in the processing field of mother liquor generated in the preparation process of aspartic acid, can solve the problems of difficult processing of mother liquor, high processing cost, low added value and the like, and achieves simple production process and resource utilization rate. High, low-equipment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The raw material is the mother liquor of the process of producing L-aspartic acid by the double-enzyme method. The process of producing L-aspartic acid by double enzyme method is to dissolve maleic anhydride in water to generate maleic acid, add ammonia water to pH 8.0 to obtain ammonium maleate solution, add maleic acid isomerase and L-aspartate converting enzyme, reaction for 24 hours, the conversion rate is over 99%. Raise the temperature to 80°C and keep it warm for 40 minutes to inactivate the enzyme. Then slowly add a maleic acid solution with a concentration of 40% under stirring, slowly adjust the pH value of the solution to 3.0 within 10 hours, and stop adding acid. Slowly lower the temperature to 25°C for 10 hours, and continue to keep warm for 4 hours, and L-aspartic acid crystals precipitate. The solid product is obtained by centrifugation, and the mother liquor is obtained at the same time. The detected solid content is about 27%.

[0042] Take 200ml of ...

Embodiment 2

[0044] The raw material is the mother liquor of L-aspartic acid produced by traditional enzymatic method. The process of traditional enzymatic production of L-aspartic acid is to hydrolyze maleic anhydride to maleic acid, use thiourea as a catalyst to obtain fumaric acid, add ammonia to fumaric acid to obtain ammonium fumarate, and then add invertase to Obtain L-ammonium aspartate solution under suitable conditions, then remove enzyme impurities, raise the temperature to 80°C, slowly add sulfuric acid to adjust the pH value to about 2.8 and slowly cool down to crystallize, centrifuge to separate the crystals and obtain the mother liquor, add ammonia to adjust the mother liquor The pH is about 5.5, and then the ammonium sulfate is separated by evaporation, concentration and recrystallization to obtain a concentrated mother liquor, which is used as the reaction raw material in this embodiment.

[0045] Detect that the solid content of mother liquor is 21%, get this mother liquor...

Embodiment 3

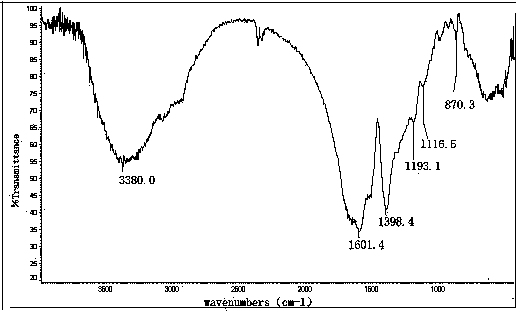

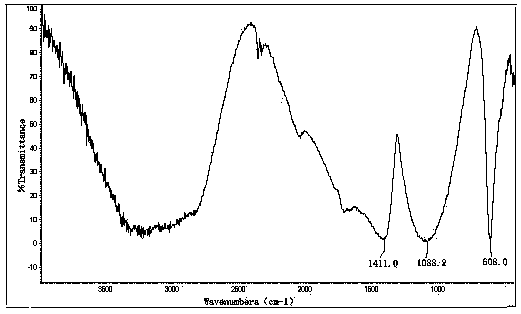

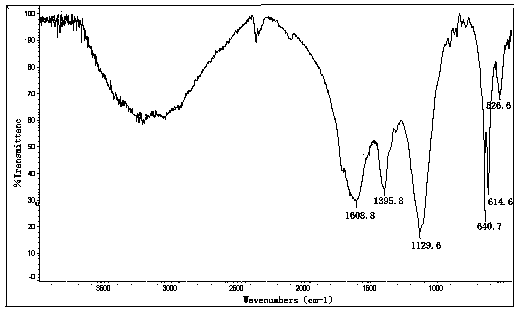

[0047] Taking the mother liquor in Example 2 as a raw material, take 300ml of the mother liquor in a 500ml beaker, add 50g of solid L-aspartic acid, stir evenly, put the beaker into a 210°C oven and heat it, take it out after 3 hours, and get Fluffy beige solid. Take 20g of the solid in a 200ml beaker, add 50ml of water, slowly add a 32% sodium hydroxide aqueous solution under stirring, adjust the pH value to about 10, heat it at 70°C for 4 hours, cool down, the reaction is complete, and dark red is obtained Transparent liquid, sodium polyaspartate solution. According to the industry standard HG / T3822-2006 detection of polyaspartic acid, the solid content is 30.7%, the pH value is 8.5, and the density is 1.16g / cm 3 , the limiting viscosity is 0.069dL / g, such as image 3 Chromatographic detection and polyaspartic acid spectrum shown Figure 1 Sincerely.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com