Method for synthesizing m-xylylene diisocyanate by low-temperature salifying method

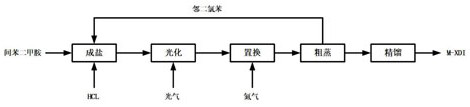

A technology of iso-xylylene diisocyanate and salt-forming method, which is applied in the chemical industry, can solve the problems of high salt-forming reaction temperature, large differences between batches, and severe reactions, so as to reduce photopolymerization side reactions, The effect of reducing the discharge of "three wastes" and increasing the product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

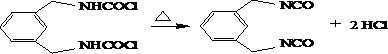

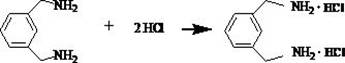

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0022] The "reaction temperature" and "reaction pressure" in the table below are the process parameters of the core technology salt-forming reaction

[0023]

[0024] Salt-forming reaction experimental conditions: 50L reactor (self-priming stirring is selected), the filling factor is 65%; the stirring speed is 350rpm; the reaction pressure is 2.5MPa; the excess ratio of hydrogen chloride is 3:1; End point titration PH=2~3.

[0025] The experimental results show that: within the research range, the lower the temperature of the salt-forming reaction, the higher the conversion rate of the salt-forming reaction. The higher the photochemical reaction product yield, the highest can reach 96.89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com