Novel method for producing superfine calcium carbonate by using carbide slag as raw material

An ultra-fine calcium carbonate, carbide slag technology, applied in the direction of calcium carbonate/strontium/barium, animal feed, animal feed, etc., can solve the problems of great impact on product quality, unclear market prospects, limited amount of carbide slag, etc. Separation, reduce dust pollution, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

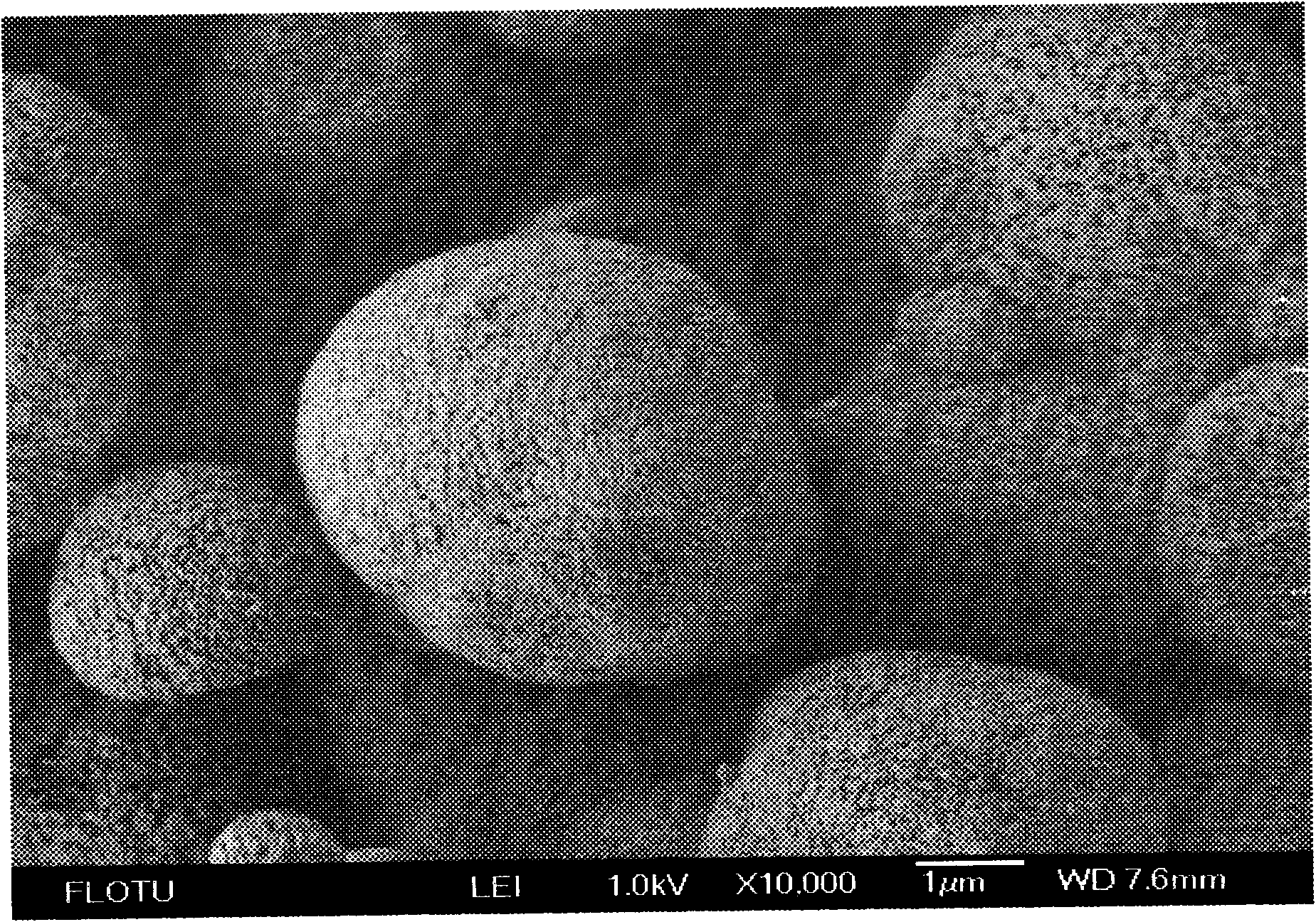

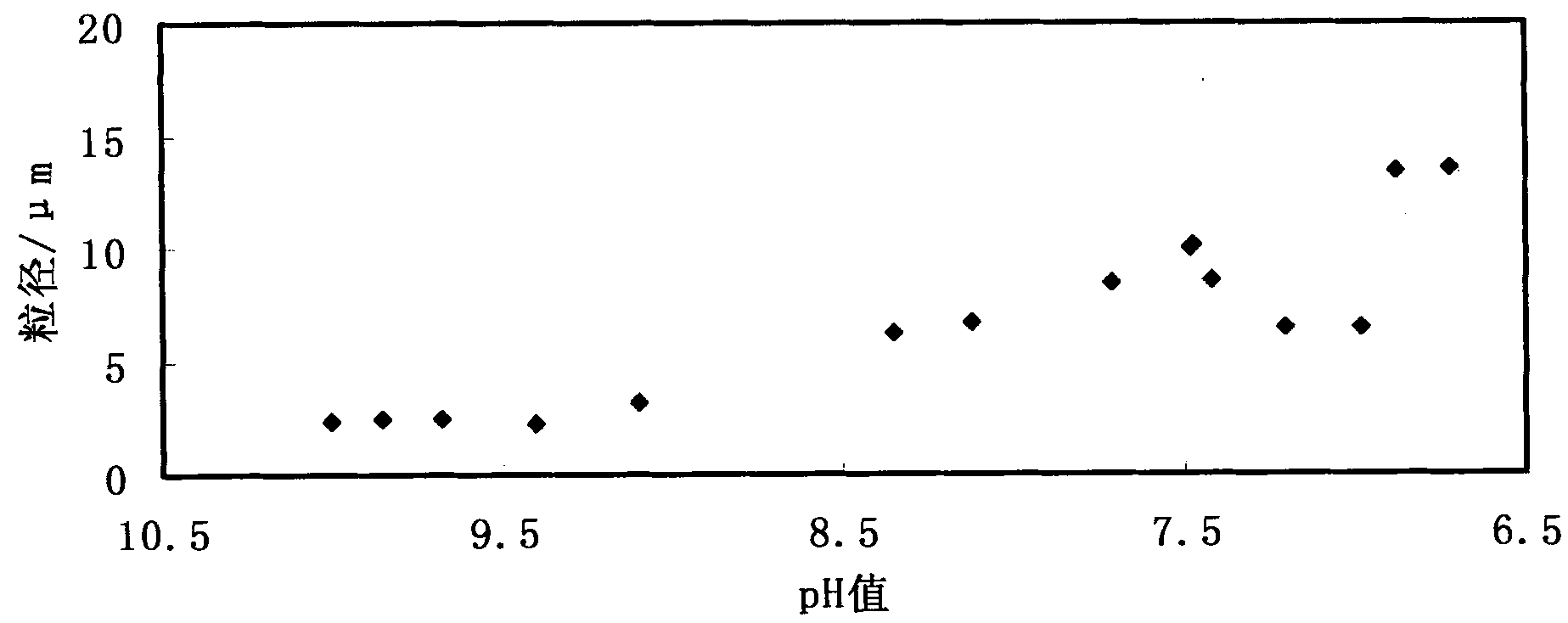

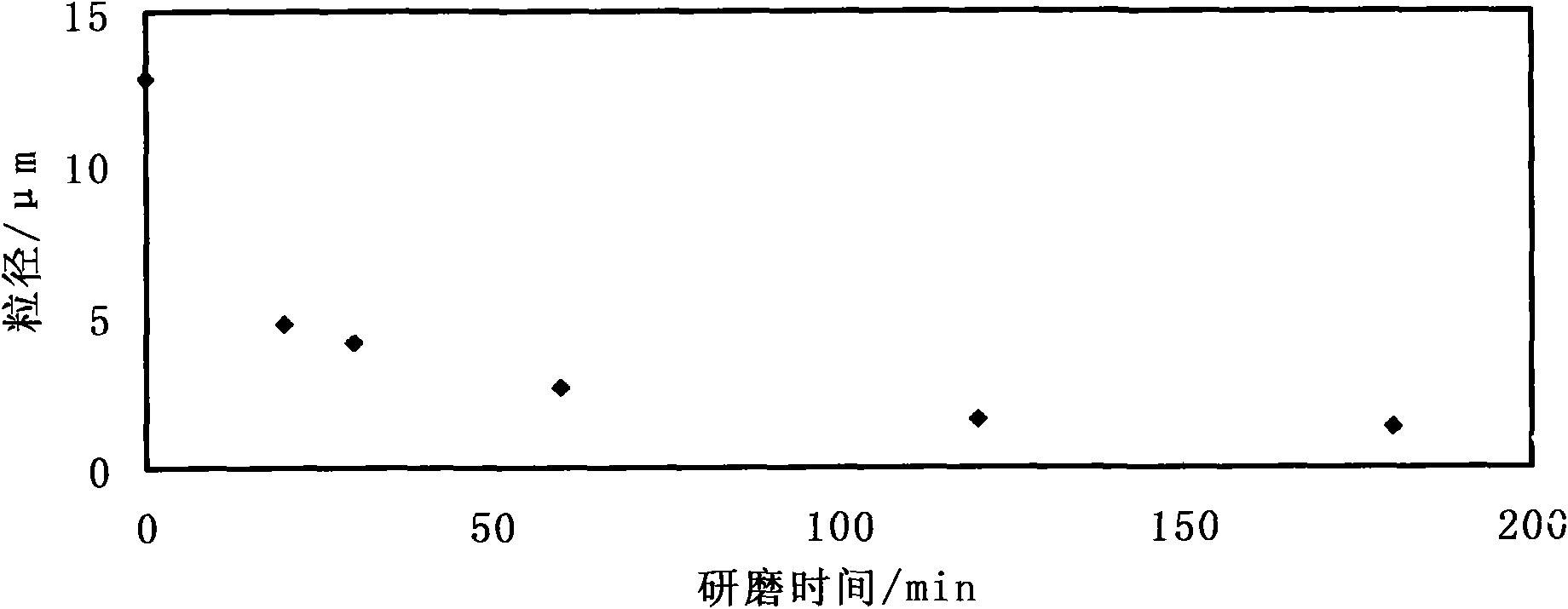

[0038] Example 1: The calcium glycinate extract generated by the reaction of glycine and calcium carbide slag is prepared by carbonization of carbon dioxide in an inner circulation tank reactor (with ultrasound) to obtain ultra-fine calcium carbonate

[0039] Add 1.45L of water into the reaction kettle, then add 140g of glycine (technical grade), and stir until dissolved. Then add 130g calcium carbide slag (about 52.5% of calcium hydroxide content) and continue to stir, finish after 2 hours of reaction, filter to obtain 1706g calcium glycinate extract, wherein the calcium glycinate concentration is 9.63%, the waste residue is used for making putty, and the calcium extraction rate is 95% . The extract is transferred to an inner circulation tank reactor (with ultrasound), and carbon dioxide is introduced. When the pH<7, the reaction ends, and after direct filtration and washing, 164.71 g of superfine calcium carbonate paste is obtained (moisture content is 48%) , the carbonizat...

Embodiment 2

[0040] Example 2: The calcium glycinate extract generated by the reaction of glycine and calcium carbide slag is used to prepare superfine calcium carbonate paste by passing carbon dioxide in the reactor (with ultrasound) in the inner loop tower reactor

[0041] Add 2.0L of water into the reaction kettle, then add 195g of glycine, and stir until dissolved. Then add 180g of calcium carbide slag (about 52.5% of calcium hydroxide content) and continue to stir, finish after 2 hours of reaction, filter to obtain 2206g of calcium glycinate extract, wherein the calcium glycinate ion concentration is 11.75%, the waste residue is used to make putty, and the calcium extraction rate is 92.6% . The extract is transferred to the inner circulation tower reactor (with ultrasonic wave), feeds carbon dioxide, and when the pH<7, the reaction ends, obtains calcium carbonate paste 276g (moisture content is 50%) after directly filtering and washing, and its average particle size The diameter is 2...

Embodiment 3

[0042] Embodiment 3: The calcium glycinate extract that generates with the reaction of glycine and lime produces superfine calcium carbonate paste in the reactor (with ultrasonic wave) in the inner circulation tower reactor

[0043] Add 1.8L of water into the reaction kettle, then add 173.8g of glycine, and stir until dissolved. Then add 107g of lime (wherein calcium hydroxide content is about 80%) and continue to stir, finish after reacting for 2 hours, filter to obtain 2070g calcium glycinate extract, wherein the calcium glycinate ion concentration is 10.08%, the waste residue is used to make putty, and the calcium extraction rate is 96% . The extract is transferred to an inner circulation tower reactor (with ultrasonic wave), and carbon dioxide is introduced. When the pH<7, the reaction ends, and after direct filtration and washing, 207g of calcium carbonate paste (moisture content is 48%) is obtained, and the carbonization rate is 97%. %, the average particle size is 2.45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com