Patents

Literature

240 results about "Subsoiler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A subsoiler or flat lifter is a tractor-mounted farm implement used for deep tillage, loosening and breaking up soil at depths below the levels worked by moldboard ploughs, disc harrows, or rototillers. Most such tools will break up and turn over surface soil to a depth of 15–20 cm (5.9–7.9 in), whereas a subsoiler will break up and loosen soil to twice those depths. Typically a subsoiler mounted on a compact utility tractor will reach depths of about 30 cm (12 in) and typically have only one thin blade with a sharpened tip.

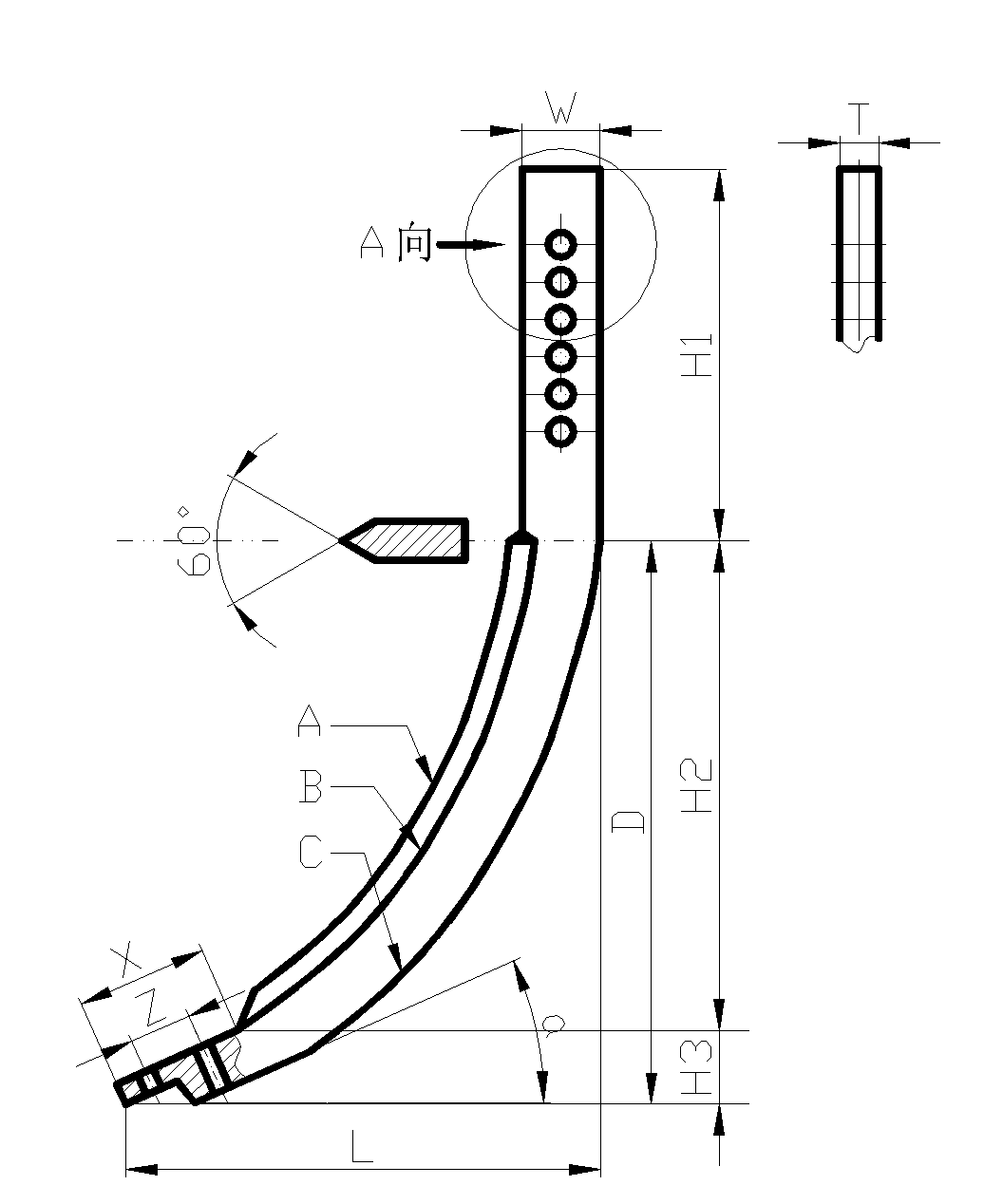

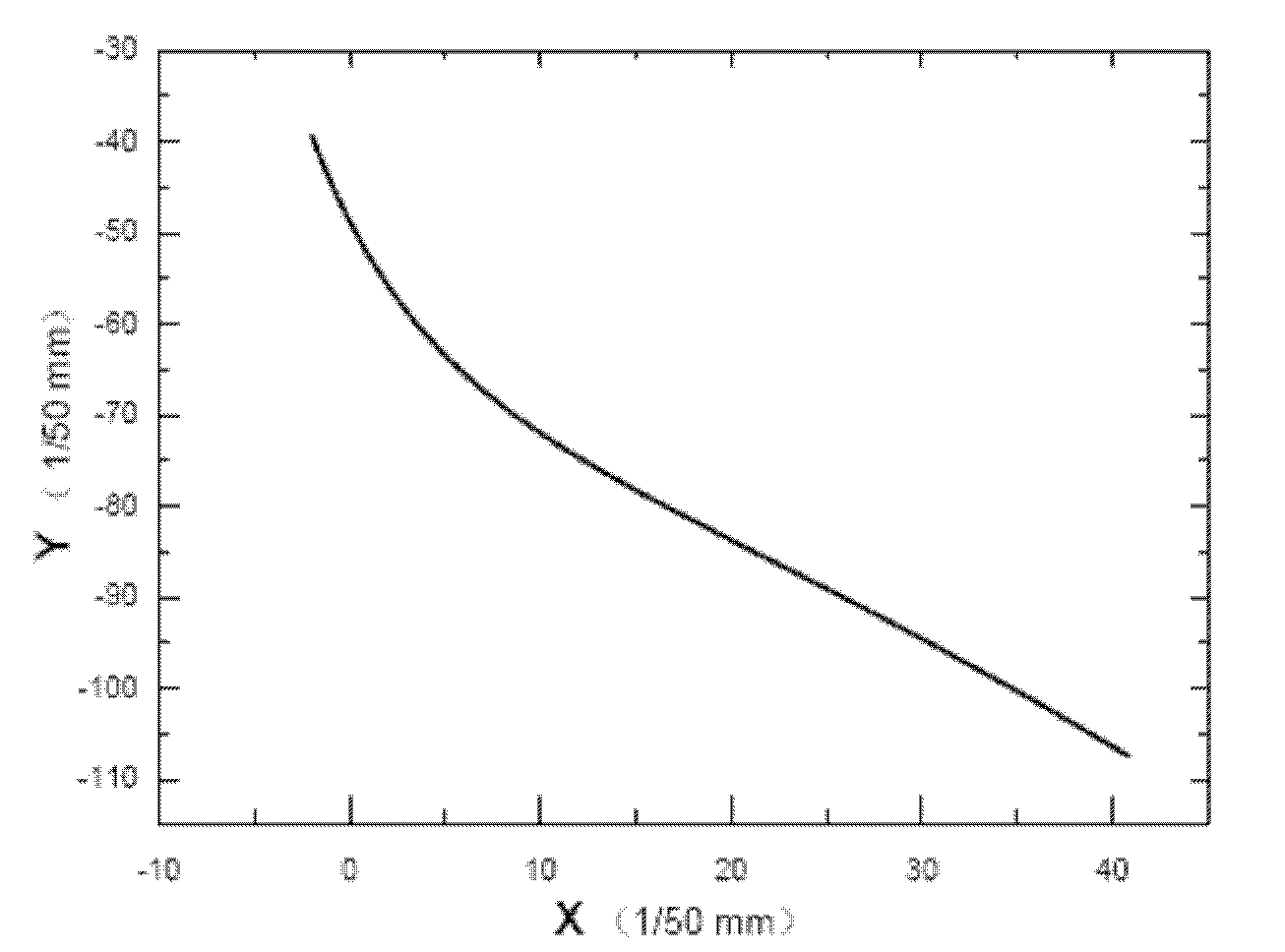

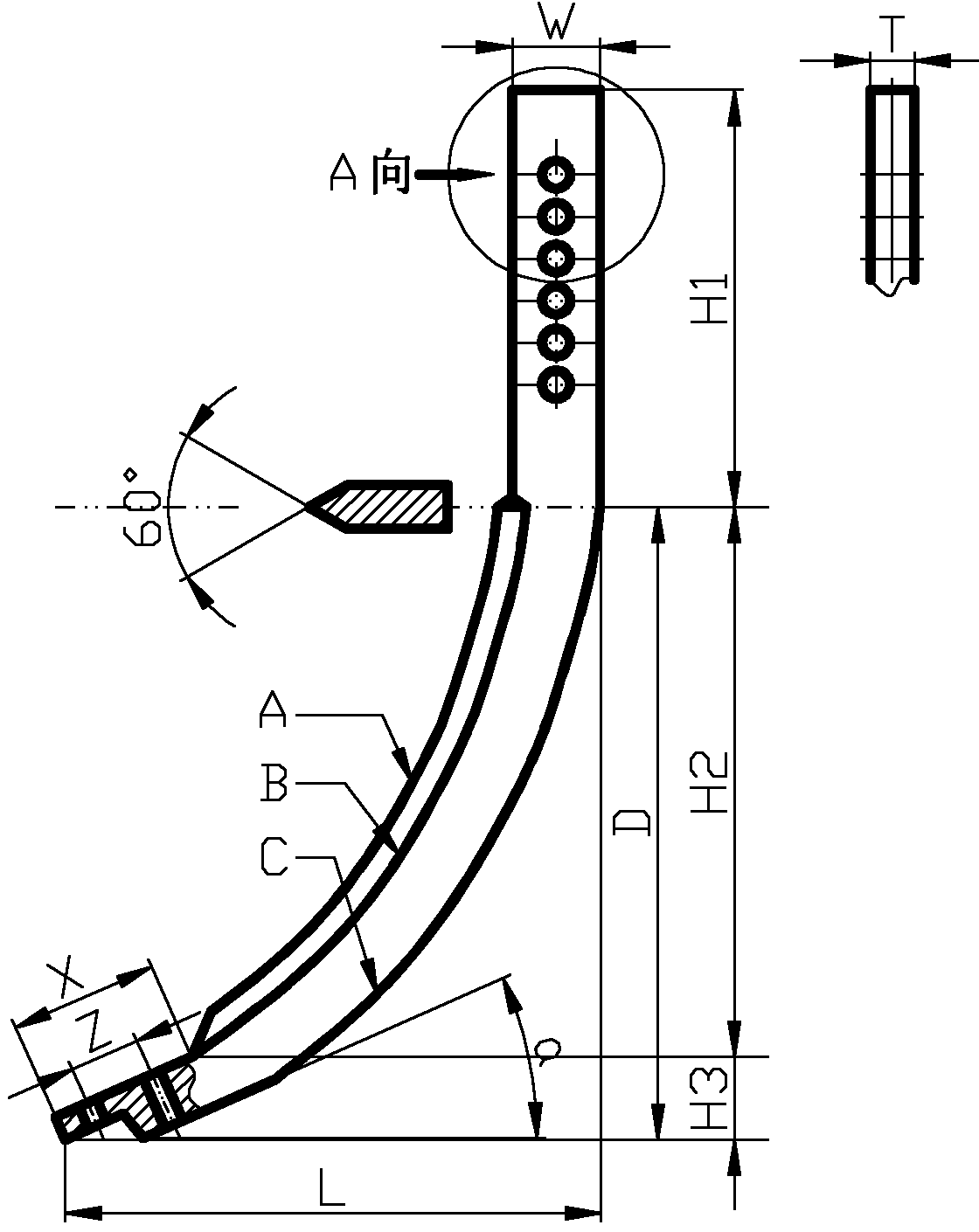

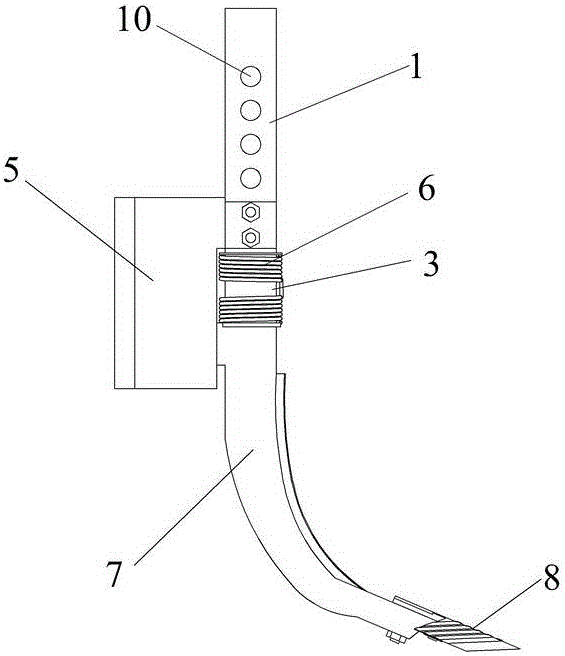

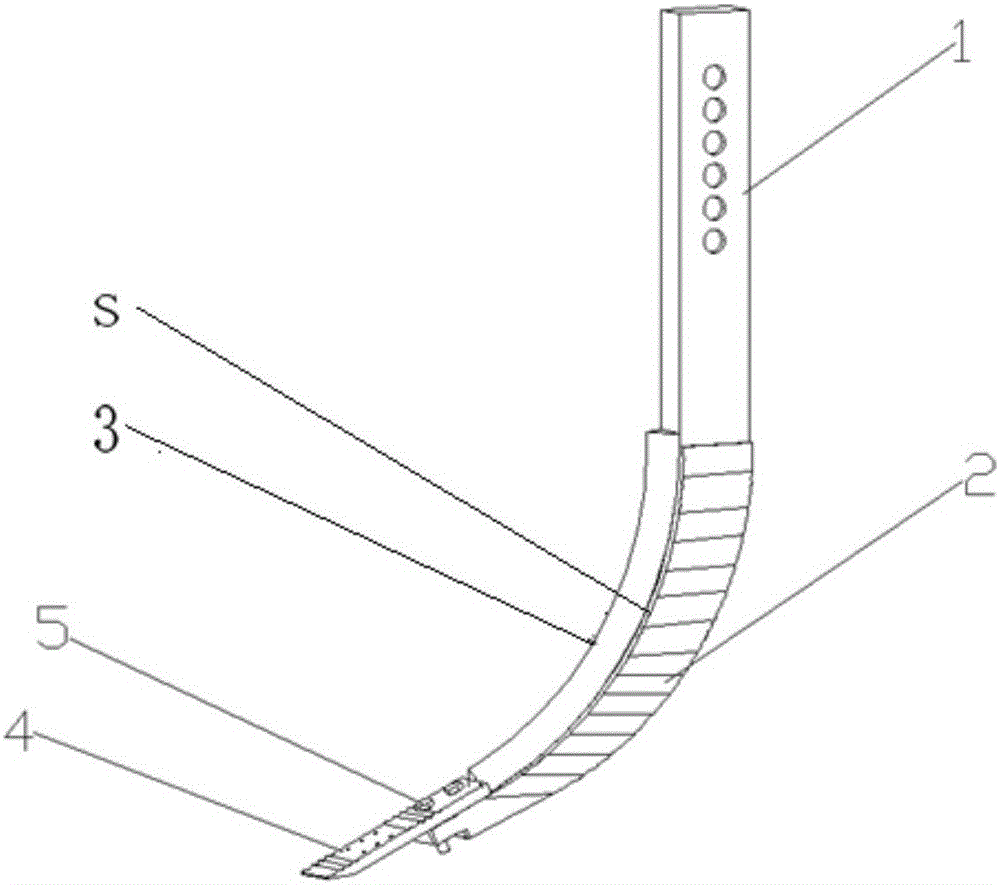

Exponential function curve type bionic drag reduction subsoiling shovel handle

The invention relates to a sub-soiling shovel, i.e. a typical soil working part of agricultural machinery, in particular to an exponential function curve type biomimetic resistance-reducing sub-soiling shovel handle with a biomimetic structure, aiming at solving the technical problems of excessive working resistance of the traditional sub-soiling shovel. The sub-soiling shovel handle is based on outlines of the upper surfaces of claw toes of a mus musculus and in the shape of an exponential function curve mode. The technical scheme of the invention is that the front-surface cutting edge of the biomimetic resistance-reducing sub-soiling shovel handle, which cuts soil, is in the shape of a longitudinal outline (in the exponential function curve mode) of the upper surface of a middle toe of a front claw of the mus musculus; and an exponential function equation is as follows: y=-66.61e<0.0117x> +17.78e<-0.1835x>, wherein x is more than or equal to -2 and less than and equal to 40, and x is more than or equal to -0.04 and less than and equal to 0.8 mm in terms of mm. A wedge angle alpha of the biomimetic resistance-reducing sub-soiling shovel is more than or equal to 15 degrees and less than or equal to 25 degrees. According to the biomimetic resistance-reducing sub-soiling shovel handle with exponential function characteristics, the working resistance of the sub-soiling shovel canbe reduced by 15 percent.

Owner:JILIN UNIV

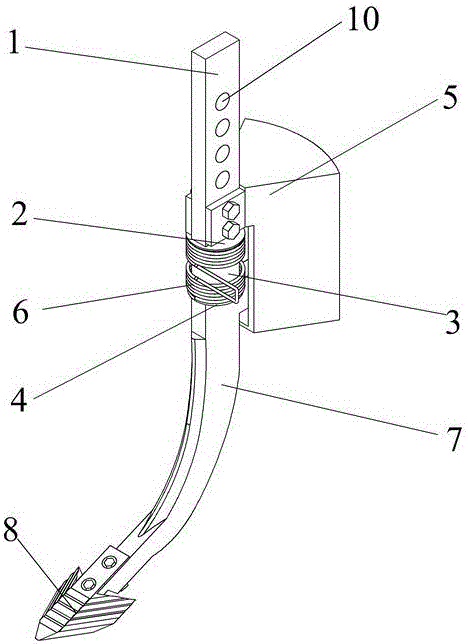

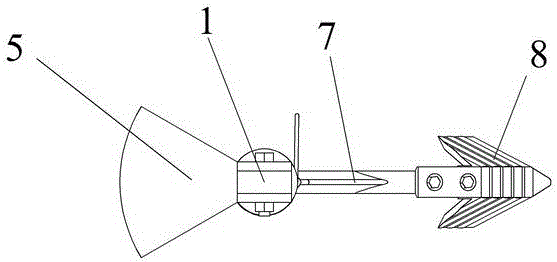

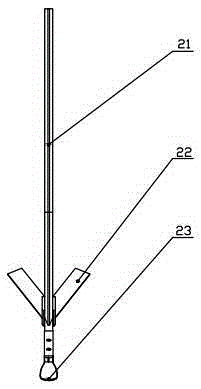

Subsoiler based on dynamic bionic principle

InactiveCN105874902AAchieve dynamic loosening effectImprove performance in soilPloughsEngineeringTorsion spring

The invention discloses a subsoiler based on a dynamic bionic principle. The subsoiler comprises a subsoiler mounting handle, a limiting device, a bidirectional torsion spring, a subsoiler handle, a subsoiler tip and a pulley, wherein the subsoiler mounting handle and the subsoiler handle are mounted through a bearing, so that the subsoiler handle can be rotated at the bottom of the soil; the pulley is mounted at the rear end of the subsoiler handle, is in contact with the limiting device and is used for supplying a support force along a heading direction and limiting the rotating angle; the bidirectional torsion spring is mounted at the external end of the bearing, so that the rotating resetting of the subsoiler is realized and the dynamic operation effect is achieved; the subsoiler is optimized through bionic curve design, so that the improvement of the soil-breaking property is ensured; the dynamic bionic principle is designed and the moving form of the whole subsoiler is similar to the forms of the animals, such as, earthworm, mole cricket, and the like, in the moving process, so that the dynamic bionic motion is realized.

Owner:JILIN UNIV

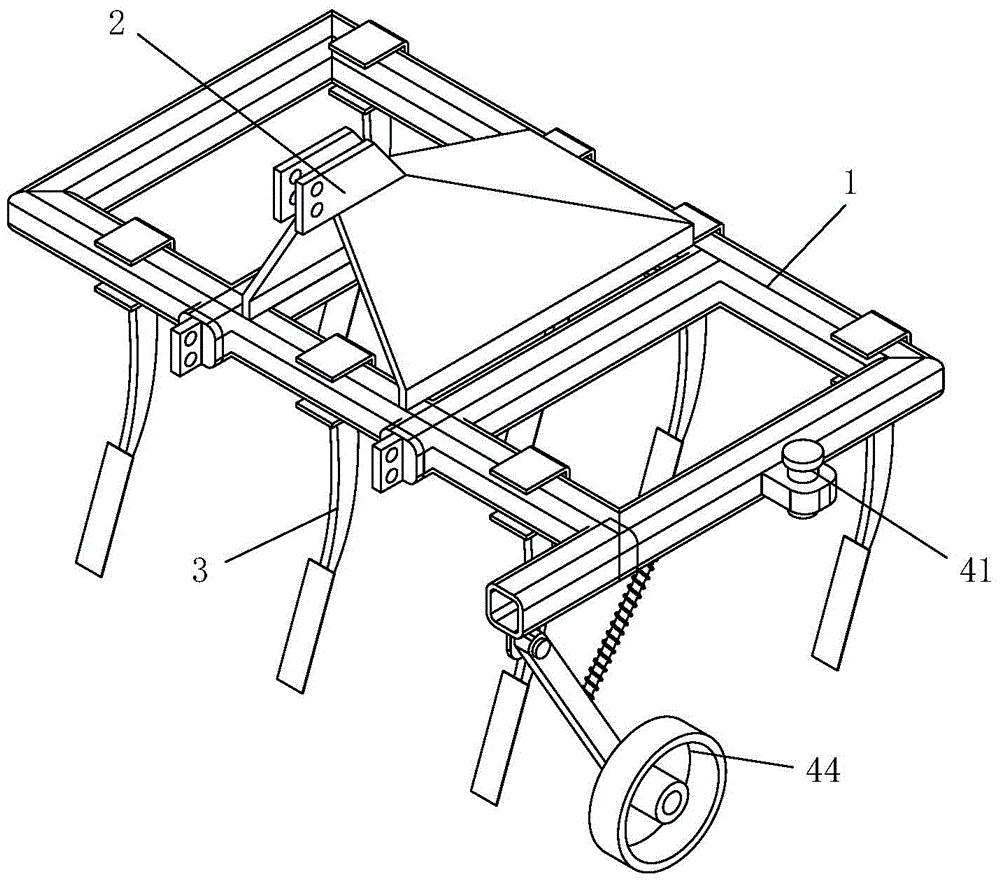

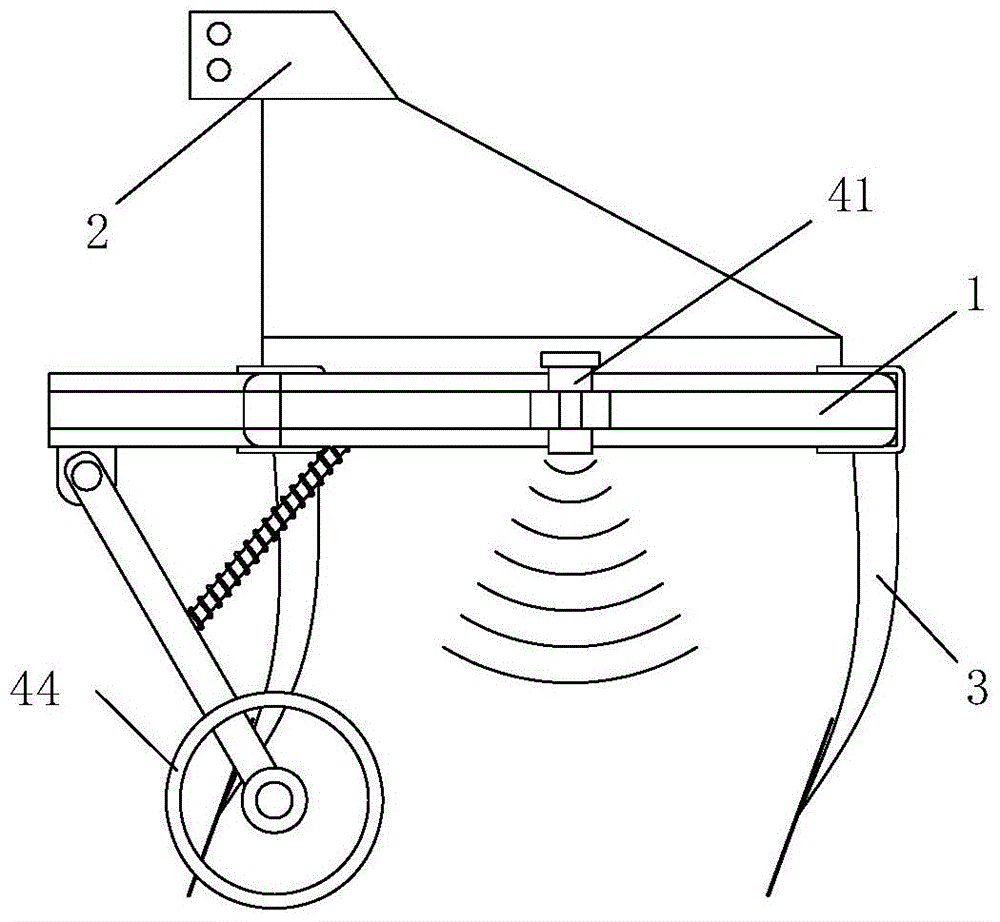

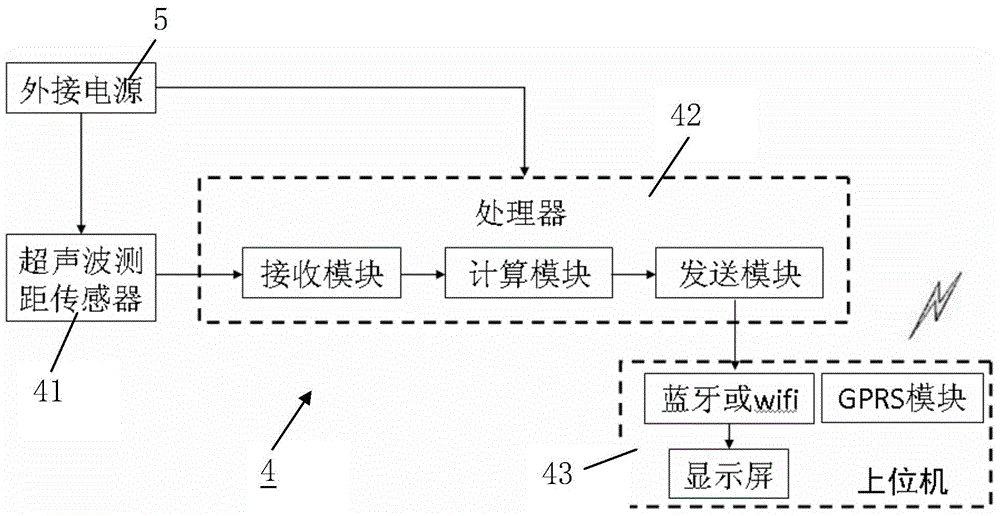

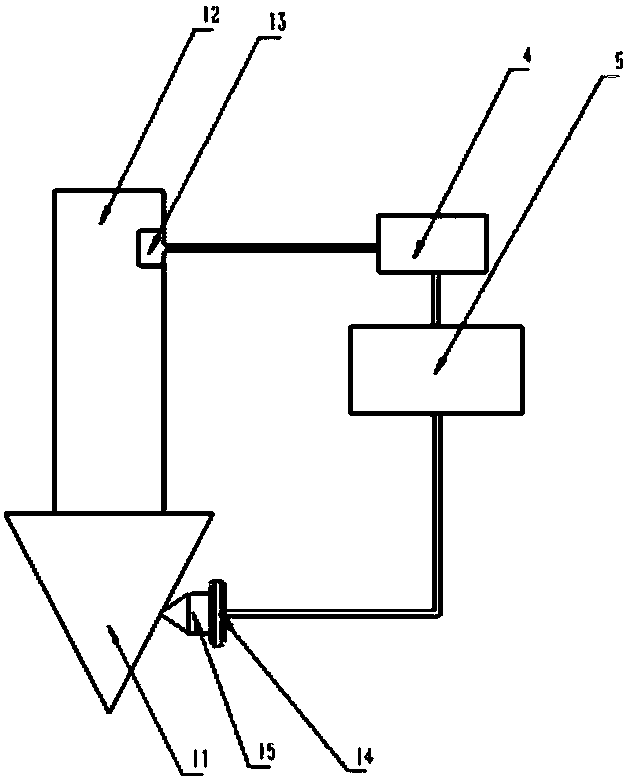

Suspension-type subsoiler and online tilling depth detection device and method

InactiveCN104977586AImprove convenienceReduce consumptionUsing subsonic/sonic/ultrasonic vibration meansAcoustic wave reradiationComputer scienceShovel

The invention provides a suspension-type subsoiler and an online tilling depth detection device and method. The subsoiler comprises a rack, a suspension connection portion, a subsoiling device and the online tilling depth detection device, wherein the suspension connection portion, the subsoiling device and the online tilling depth detection device are arranged on the rack. The online tilling depth detection device obtains soil entering depth of a sub-soiling shovel of the subsoiler by detecting change of distance between the rack of the subsoiler and the ground so as to carry out real-time monitoring on the quality of subsoiling work. The online tilling depth detection device comprises an ultrasonic distance measuring sensor which is arranged on the rack and is used for measuring the distance between the rack and the ground online in real time to obtain a distance signal; a processor which is connected with the ultrasonic distance measuring sensor and is used for receiving the distance signal and carrying out data processing on the distance signal to obtain real-time tilling depth data of the subsoiler; and an upper computer which is connected with the processor and is used for receiving and outputting the real-time tilling depth data. The invention further discloses the online tilling depth detection method and the suspension-type subsoiler which can control the quality of the subsoiling work by utilizing the method above.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

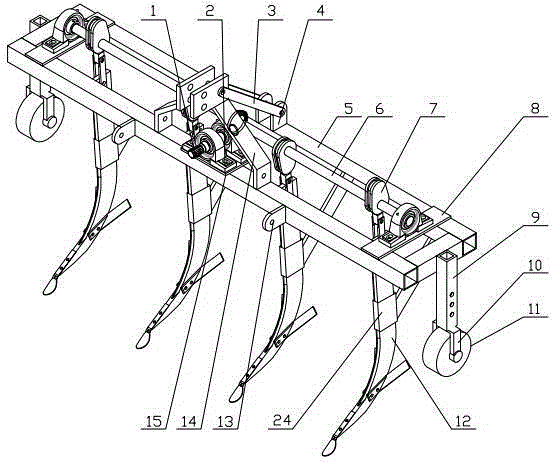

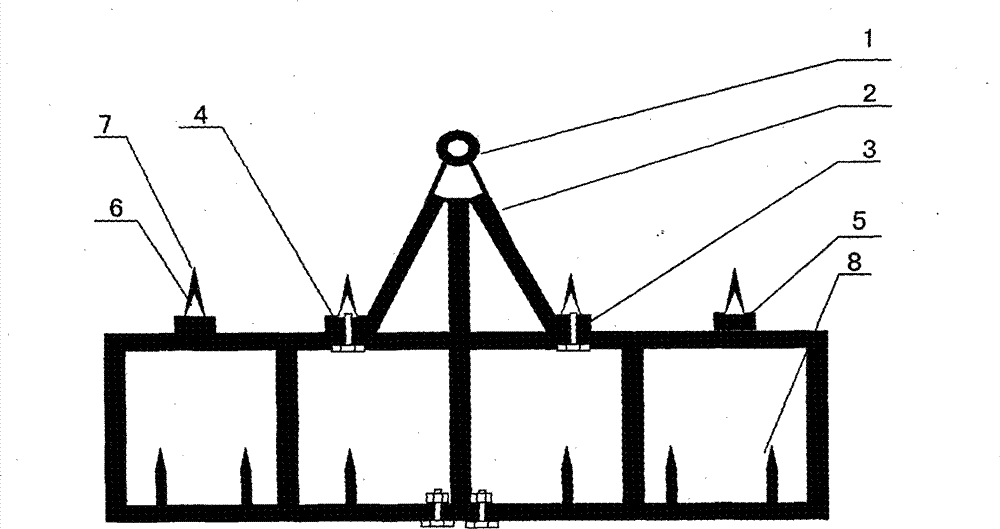

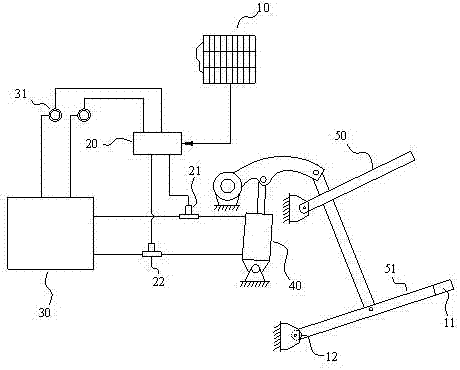

Vibration deep subsoiler

InactiveCN105393654ASimple structureLow failure rateSoil-working equipmentsPloughsDrive shaftAgricultural engineering

The invention relates to cultivation machinery loosening soil and deepening cultivation thickness, in particular relates to a vibration deep subsoiler and belongs to the field of agricultural machinery. A vibration deep subsoiler comprises a rack, a vibration deep subsoiling device, depth control devices and a traction device, wherein the vibration deep subsoiling device is arranged in the middle of the rack and connected with a power output shaft of a tractor; the depth control devices are arranged on two sides of the rack; and the traction device is mounted on the front part of the rack and connected with the traction device of the tractor. Cam sliding block mechanisms are employed in the vibration deep subsoiler; I-shaped grooves are formed in the sides of cams; deep subsoilers are connected with the cam sliding block mechanisms; cams are installed on a transmission shaft; the mechanism is compact and simple; each subsoiler tip is in a spoon-shaped structure; wing shovels are arranged on two sides of each subsoiler handle, so soil can be subsoiled and deep subsoiling area can be increased; and the vibration deep subsoiler is suitable for soil deep subsoiling and crop intertillage work.

Owner:SHIHEZI UNIVERSITY

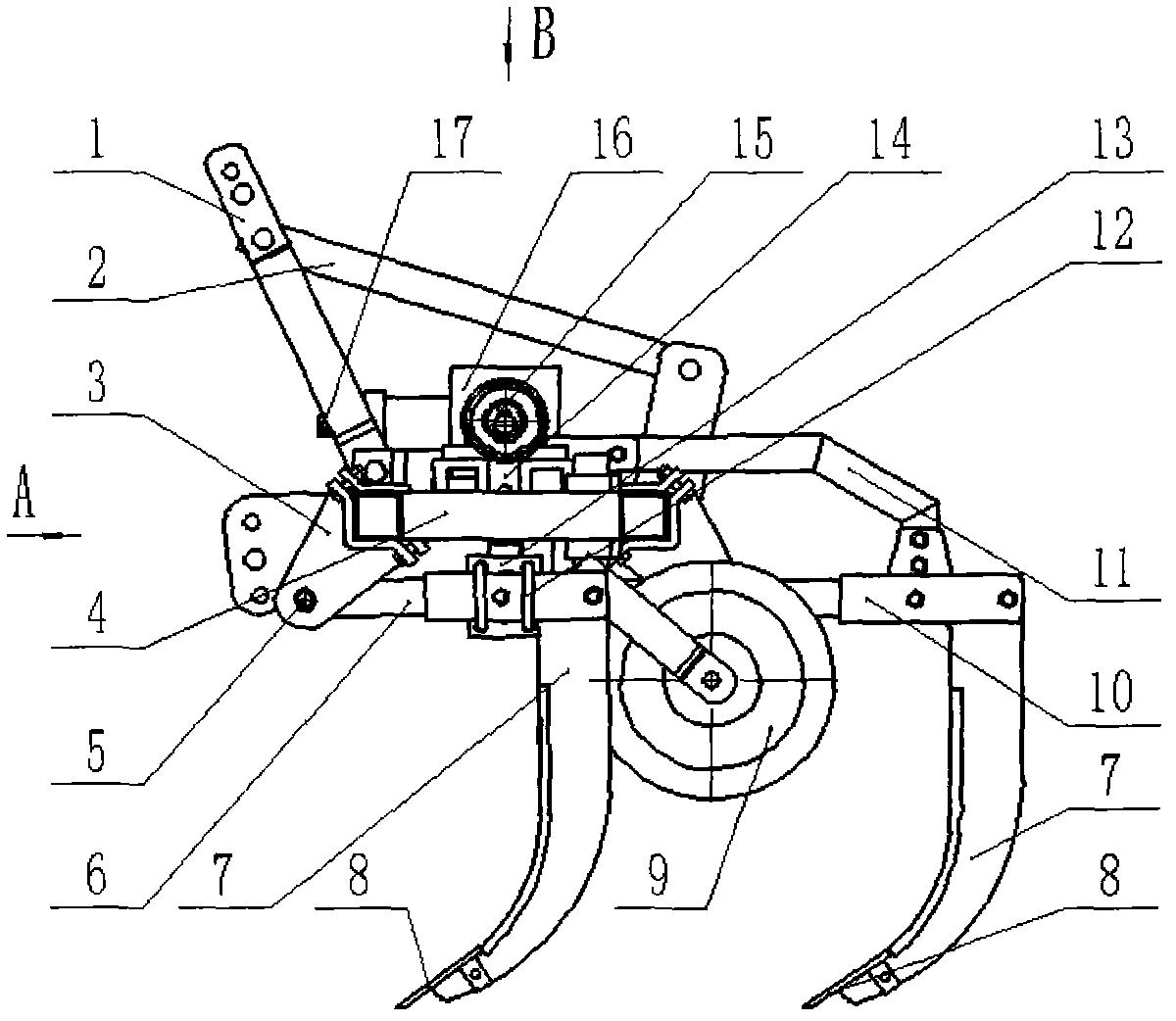

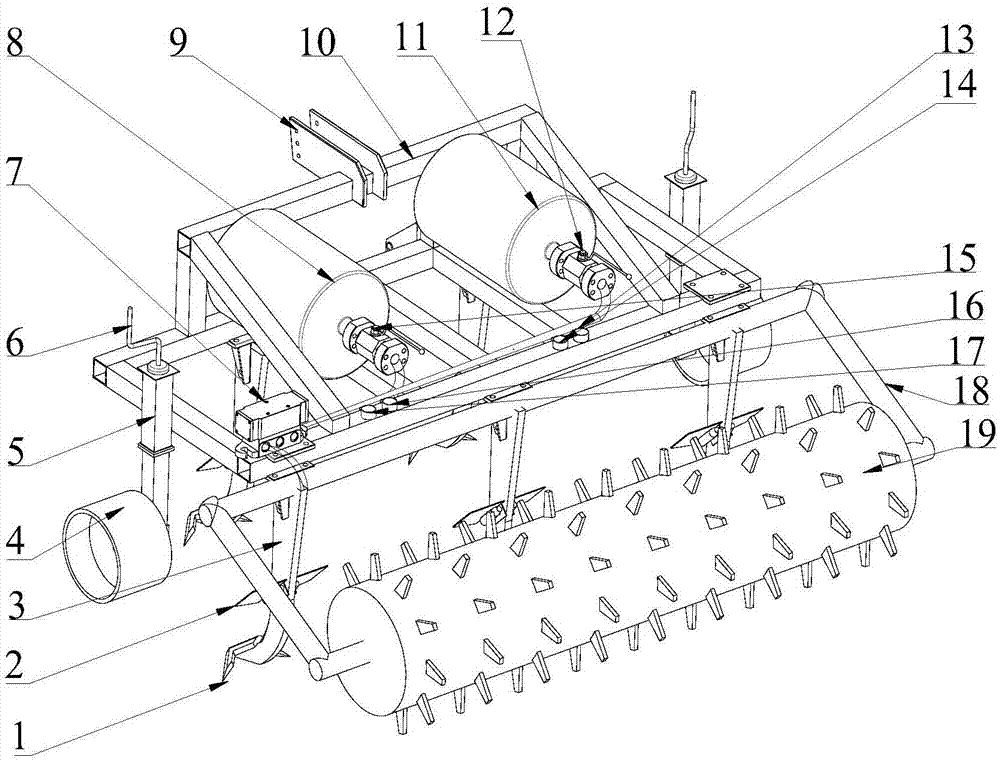

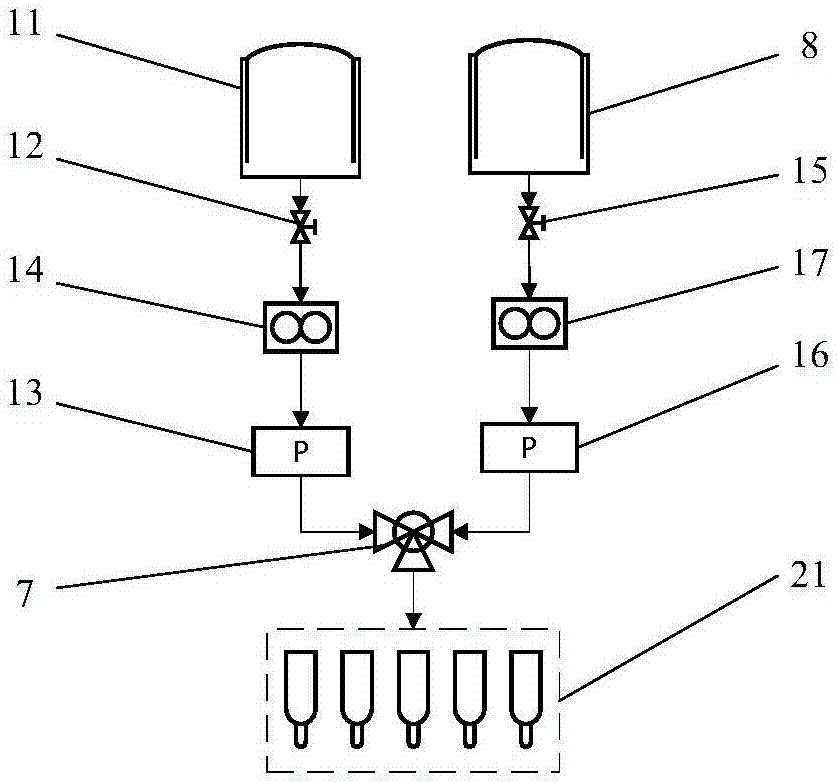

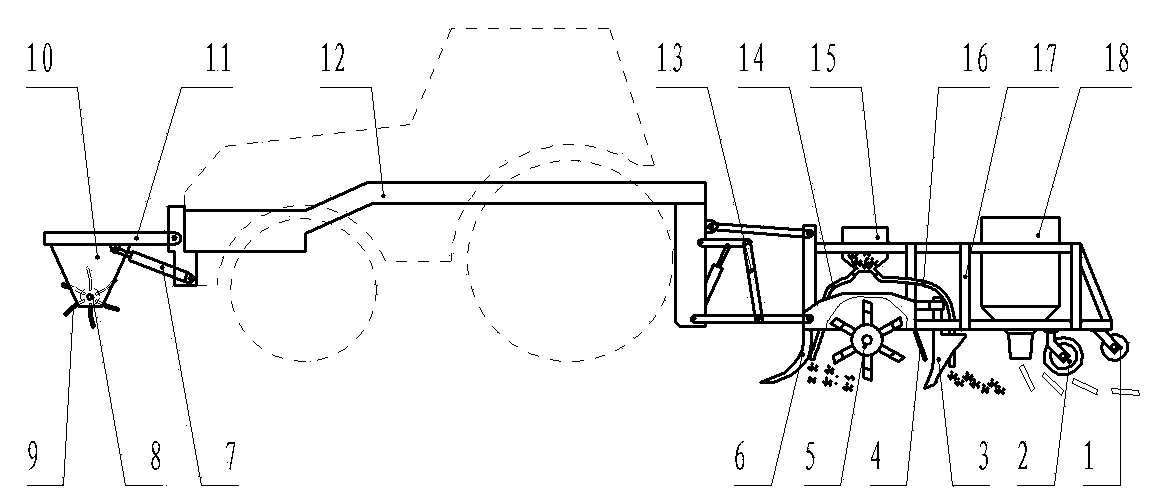

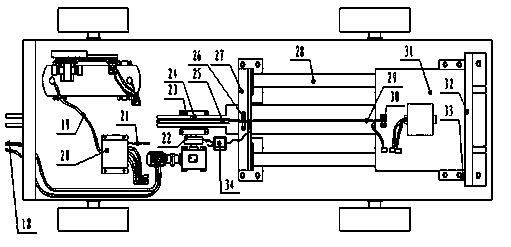

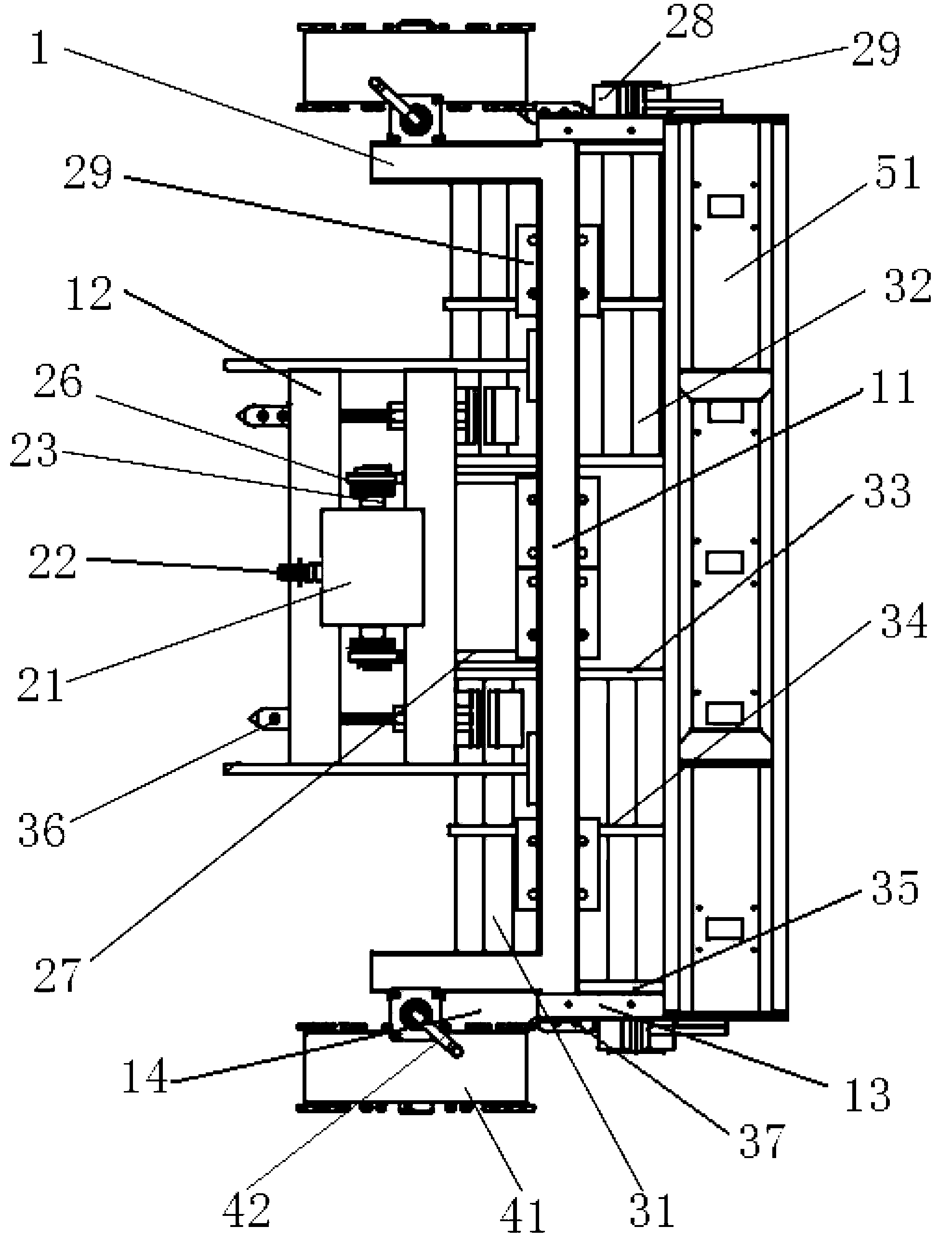

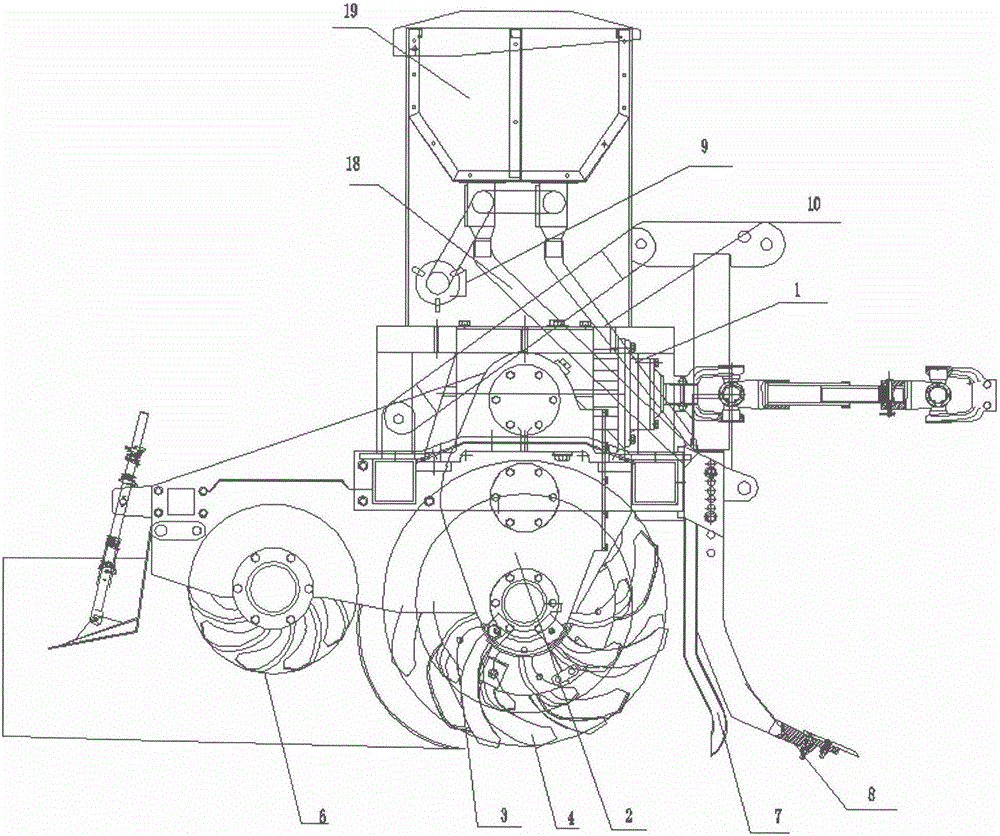

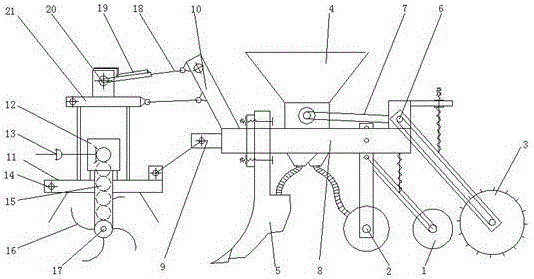

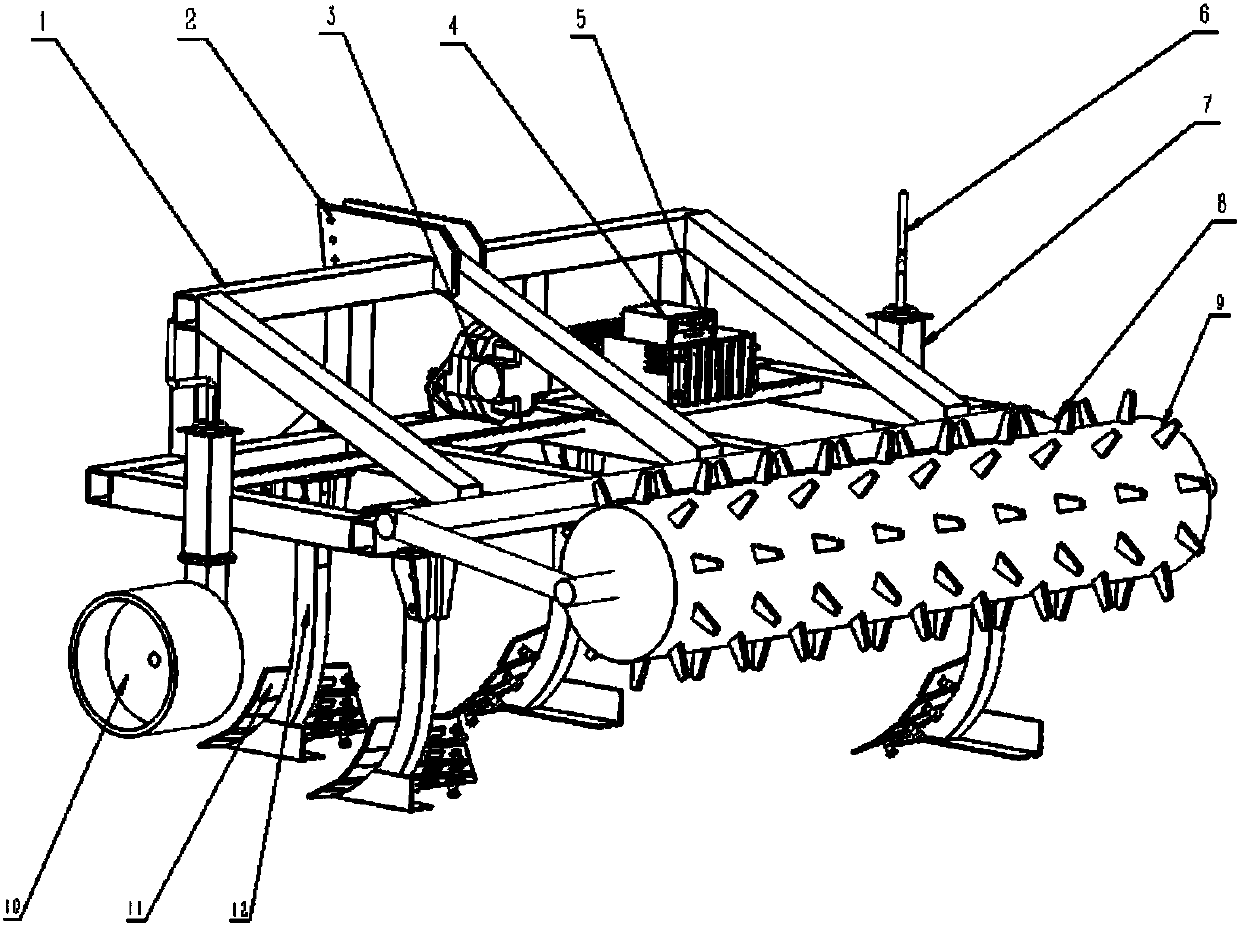

Alternate vibratory subsoiling and fertilizing all-in-one machine

InactiveCN103477741AAchieve loose but not overturned effectFully compactedSpadesPloughsAgricultural engineeringDepth limit

The invention discloses an alternate vibratory subsoiling and fertilizing all-in-one machine, which comprises a vibratory subsoiling device, a depth controller, a fertilizing device and a traction device, which are arranged on a rack; the traction device comprises a hanging support, the hanging support is arranged on the middle part of the front end part of the rack, a subsoiler of the vibratory subsoiling device comprises a half subsoiler, a full subsoiler and an alternate vibration generating device, the alternate vibration generating device comprises a plurality of groups of crank necks arranged on a rotating shaft at intervals, the back side of the full subsoiler is provided with a vertical fertilizer discharge pipe, the fertilizing device comprises a fertilizer box, a fertilizer outlet of the fertilizer box is connected with an inlet of the fertilizer discharge pipe through a hose, the depth controller is depth-adjustable depth-limiting wheels arranged on two sides of the rack, and two sides of the rack behind the depth-limiting wheels are provided with pressing wheels arranged at the hindmost part by virtue of a pull rod respectively. The all-in-one machine disclosed by the invention can be matched with a large / middle-sized tractor for use, dry land vibration subsoiling operation can be carried out, the production efficiency is high, the subsoiling effect is good, and the operation cost is low.

Owner:ANHUI AGRICULTURAL UNIVERSITY

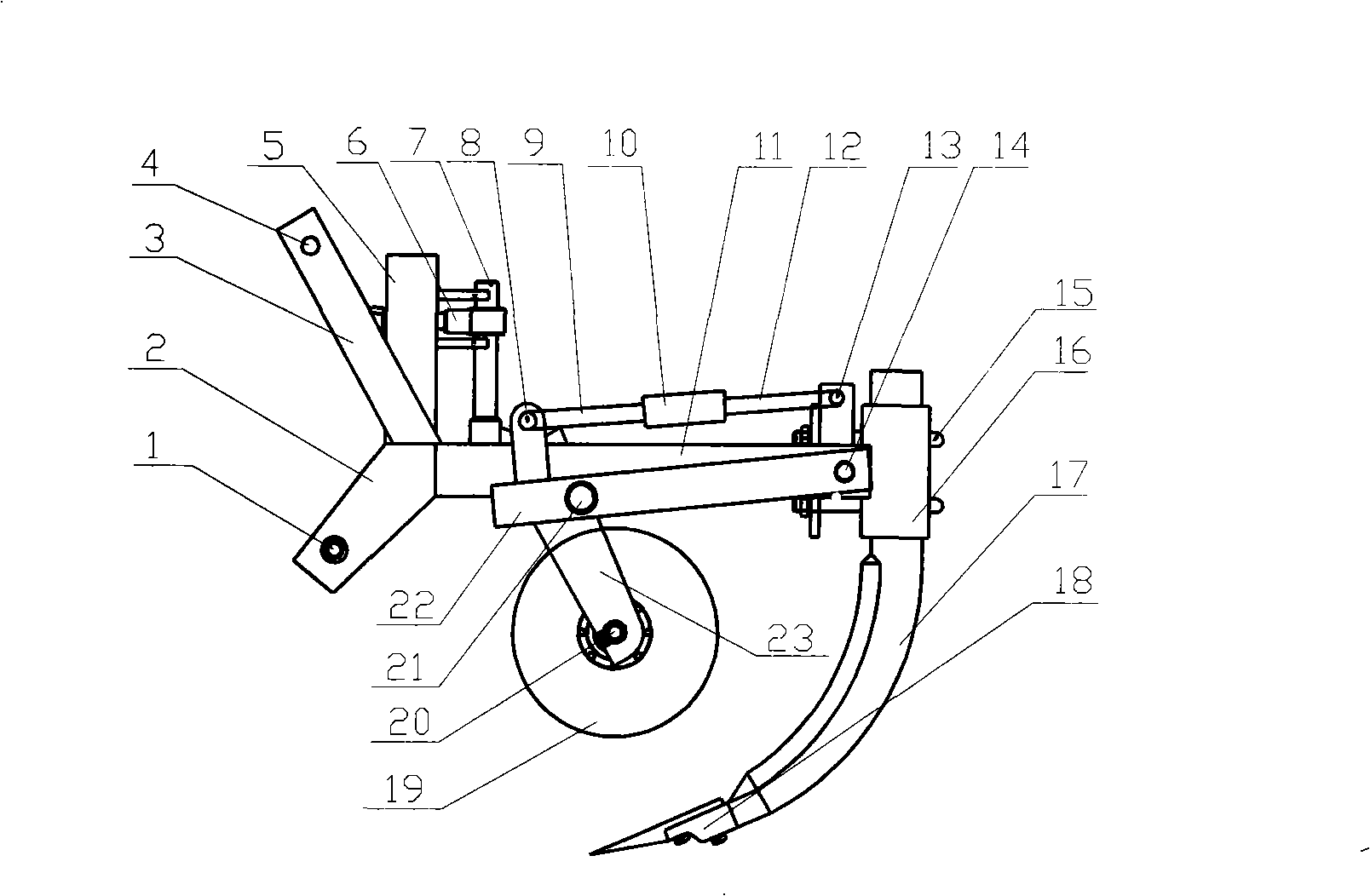

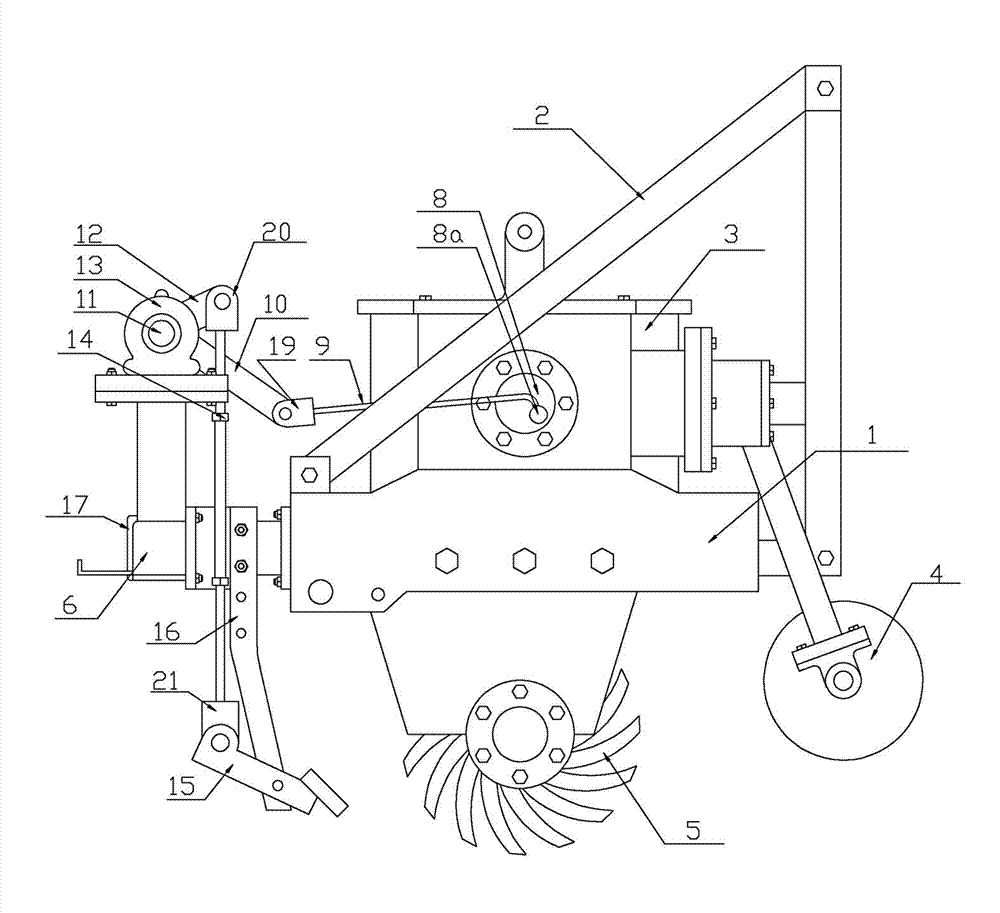

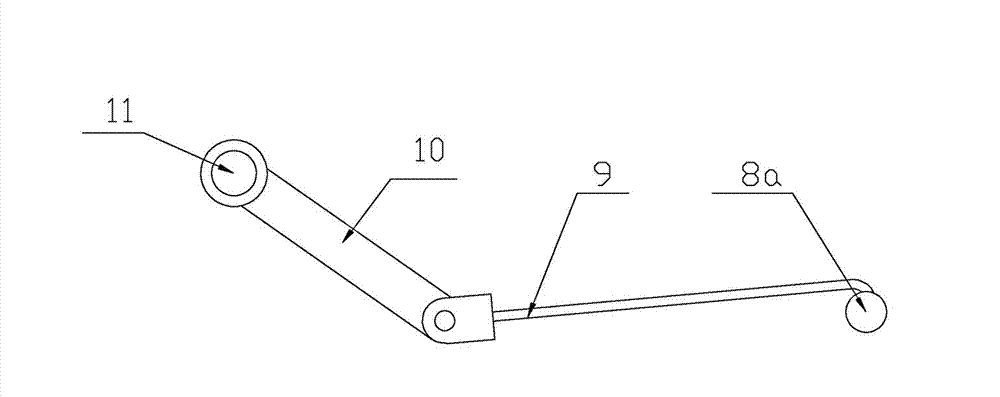

Vibration type subsoiler

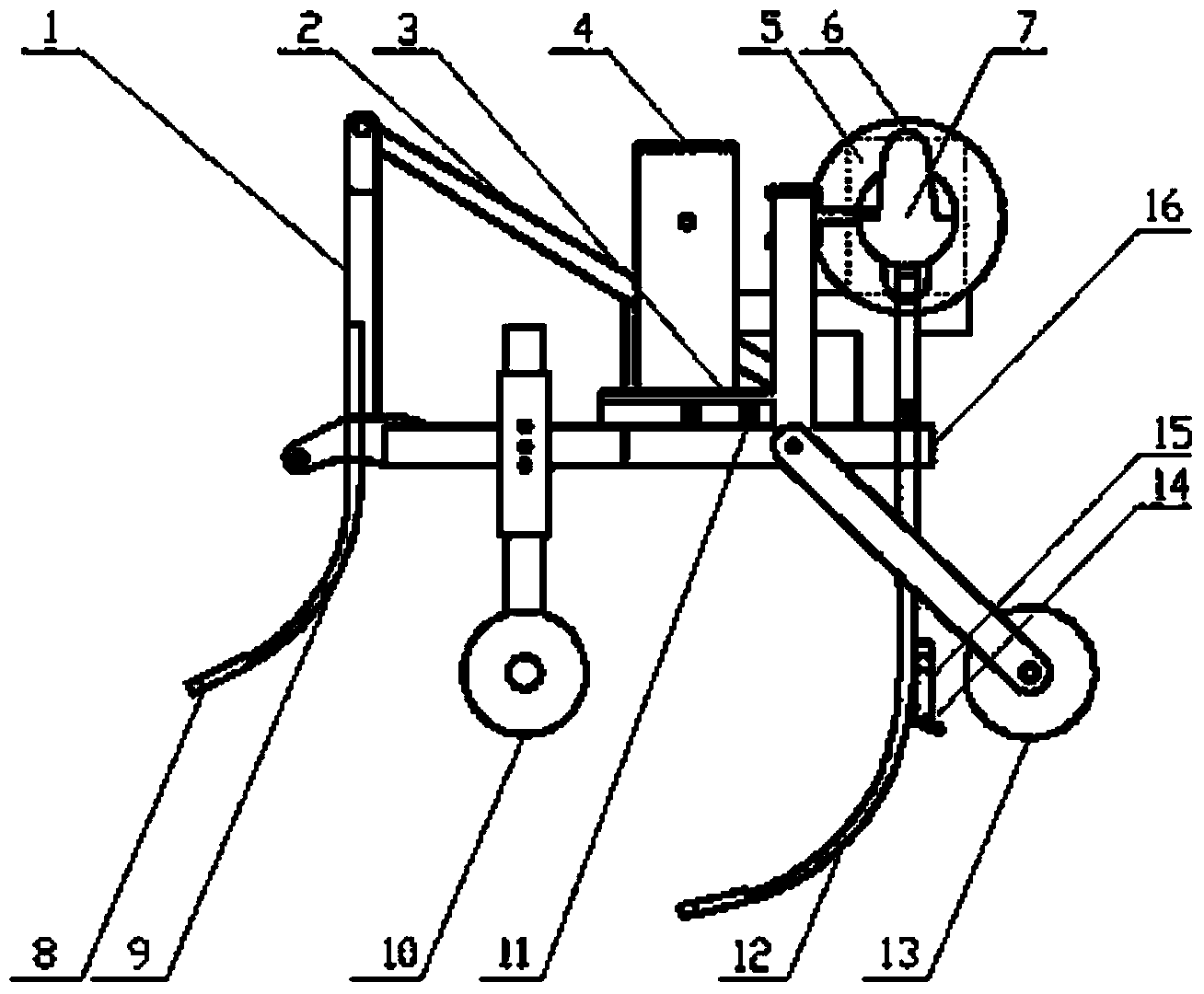

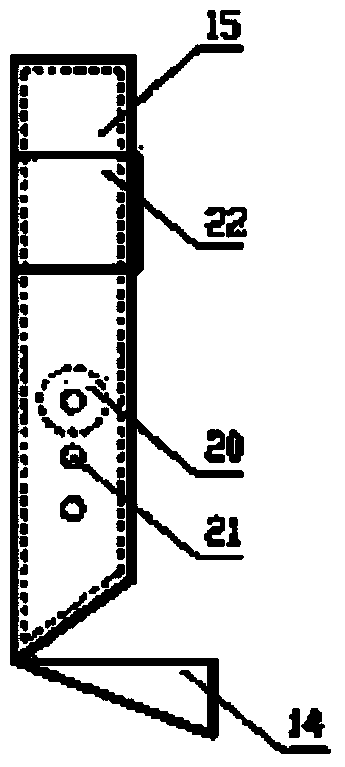

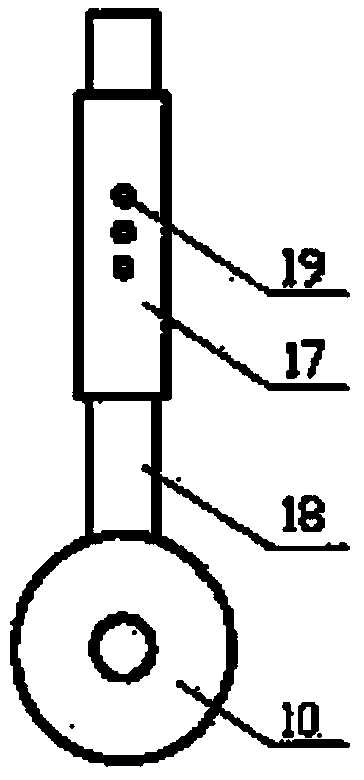

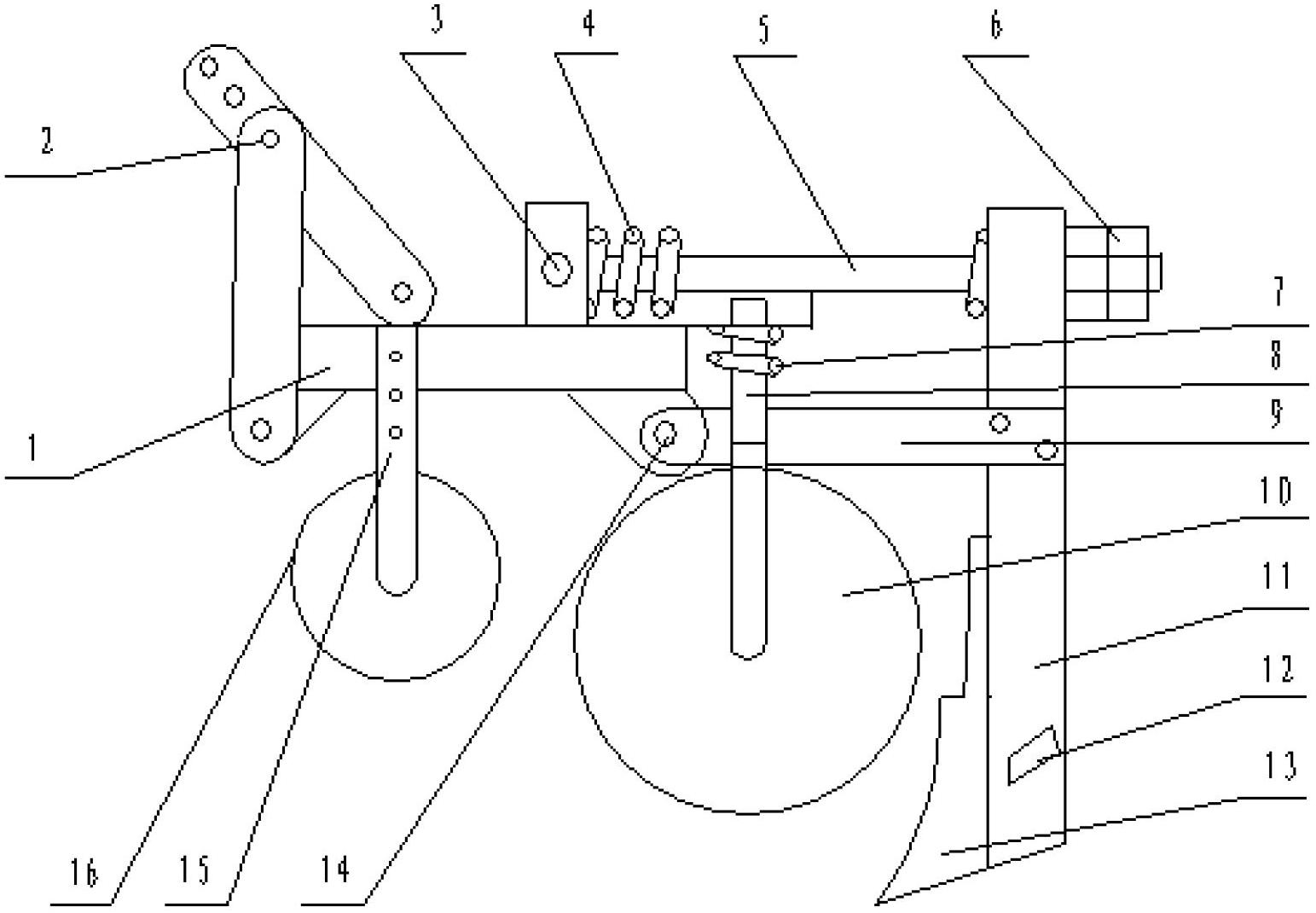

ActiveCN102668742AReduce operating costsSimple structurePloughsCircular discAgricultural engineering

The invention discloses a vibration type subsoiler, which comprises a machine frame (1), a hanging connecting frame (2), a support rod (8), a plough arm (9), a circular disc cutter (10), a plough post (11), a plough tip (13), a land wheel support rod (15), a land wheel (16), a vibration spring (4) and a spring support rod (5), wherein one end of the spring support rod is movably connected onto the machine frame through a support rod pin (3), the other end of the spring support rod is connected onto the tail end of the plough post, the vibration spring is sheathed on the spring support rod, one end of the vibration spring is butted on the machine frame, the other end of the vibration spring is butted on the plough post, one end of the plough arm is movably connected under the machine frame through a plough arm pin (14) and is positioned behind the land wheel support rod, and the other end of the plough arm is fixedly arranged on the plough post. The vibration type subsoiler has the advantages that the structure is simple, and the soil resistance change is utilized, so a subsoiling plough is pushed to do forward and backward vibration, under the condition that the motive power is not provided, the subsoiling resistance can be reduced, the subsoiling effect can also be improved, the operation efficiency improvement is realized, and the operation cost is reduced.

Owner:徐州万国生物能源科技有限公司

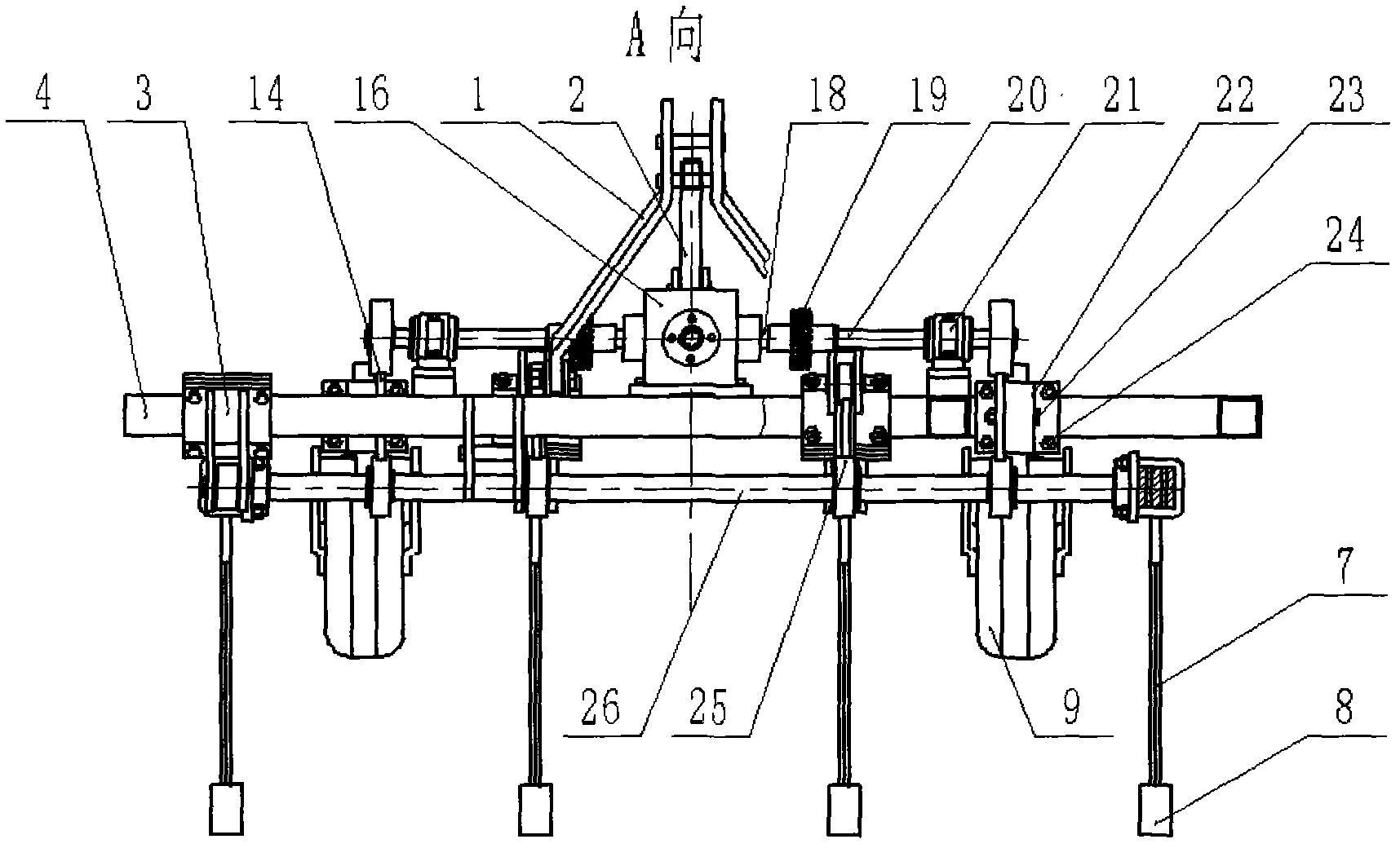

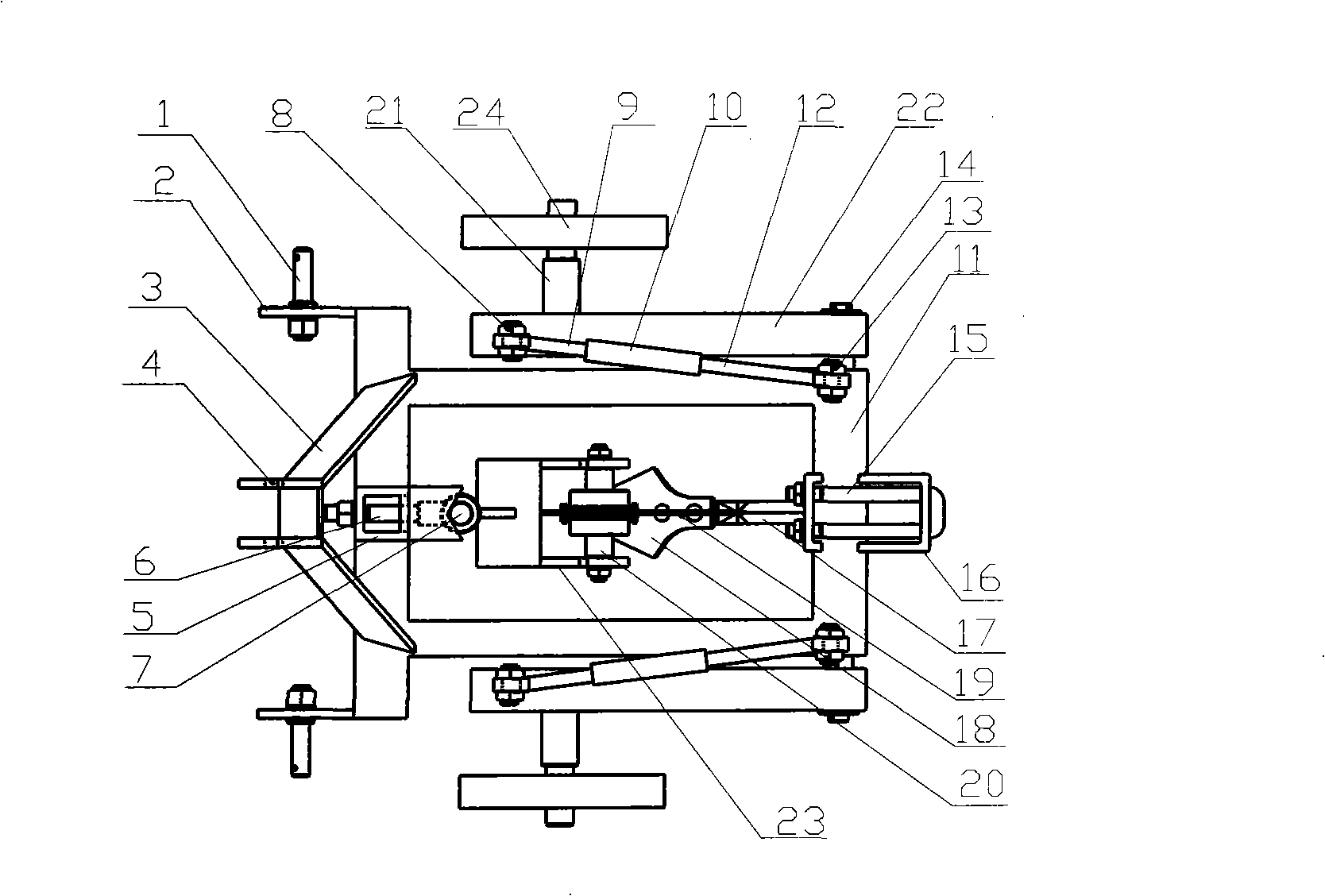

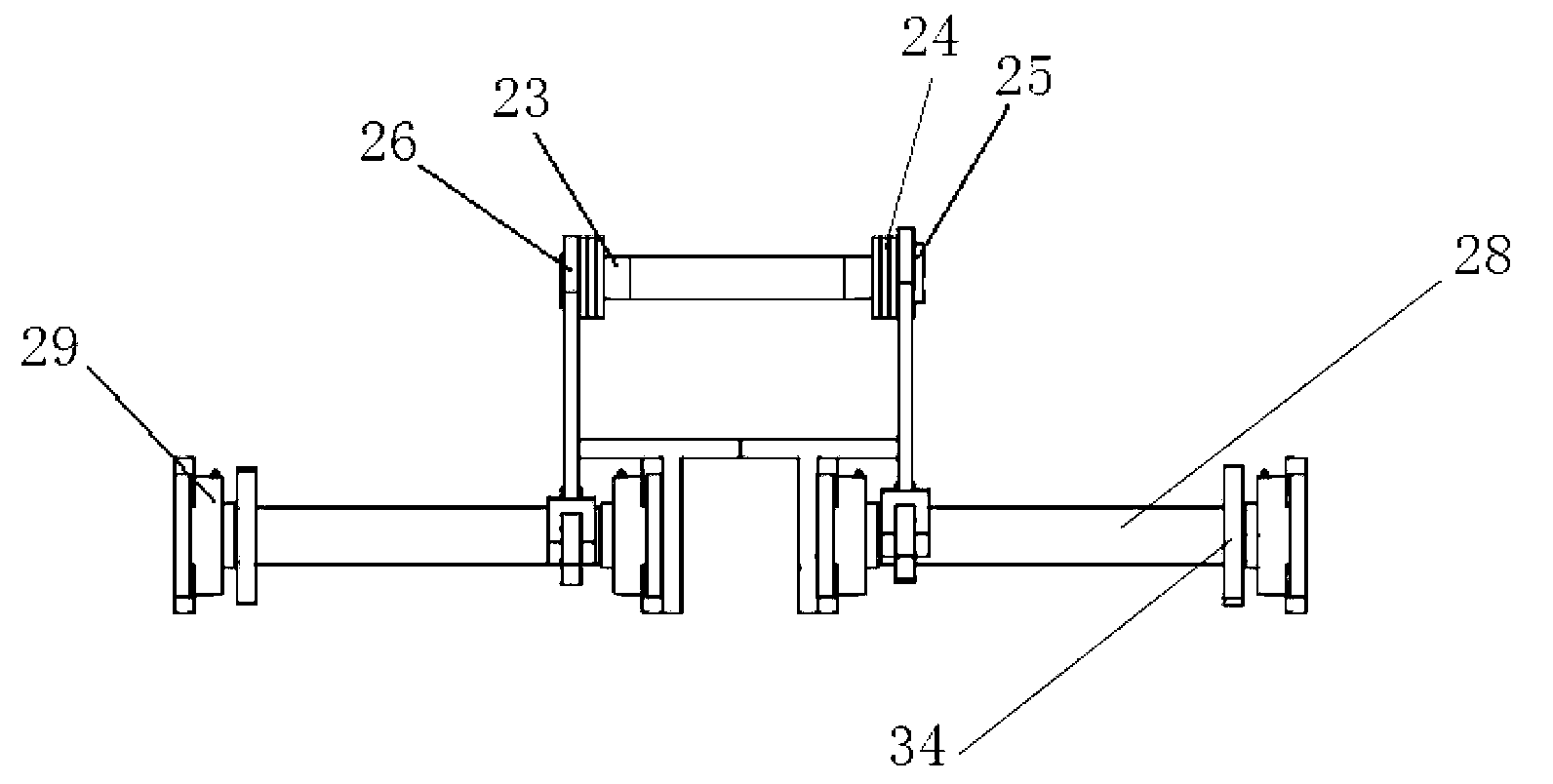

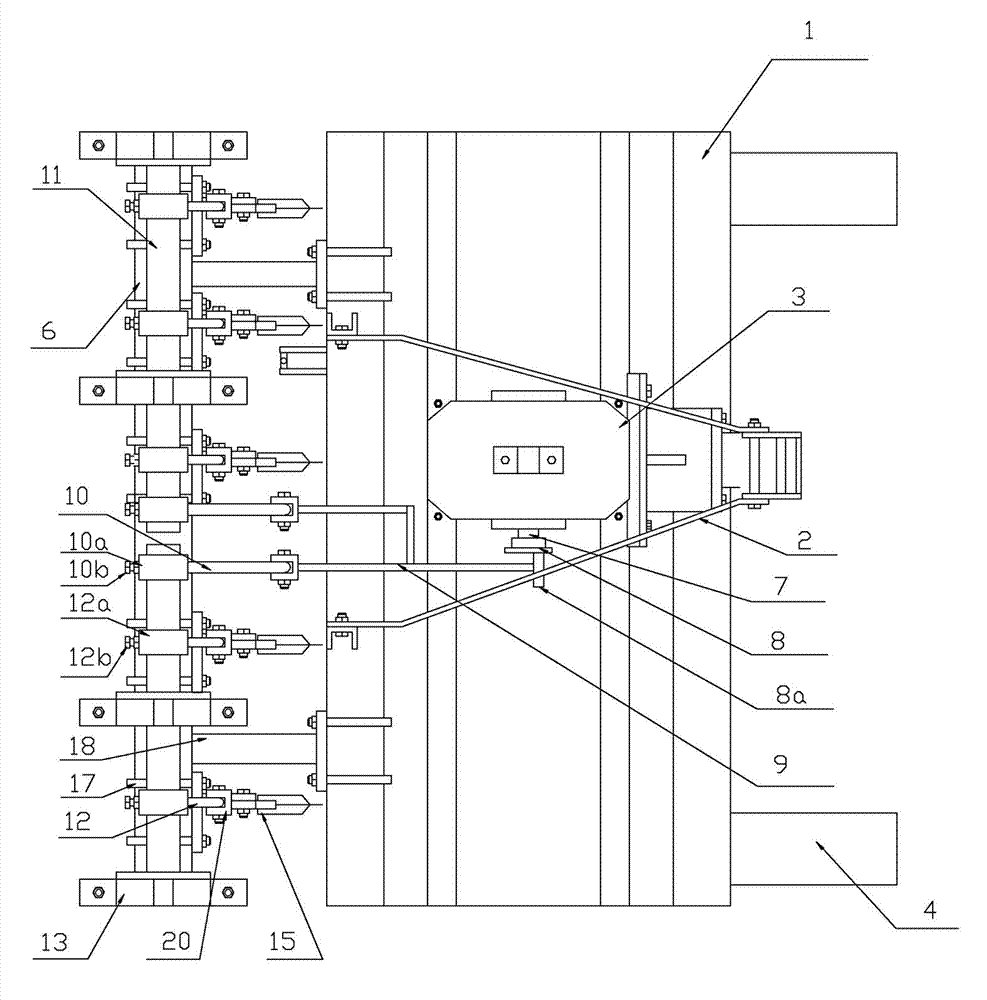

Dual-row reverse-vibration subsoiler

InactiveCN102626007AReduced drag drag peaksReduce vibration intensityAgricultural machinesPloughsTransmitted powerAgricultural engineering

The invention discloses a dual-row reverse-vibration subsoiler, belonging to the field of agricultural machinery. The dual-row reverse-vibration subsoiler comprises a transmission system, a vibration subsoiling device, a supporting and depth-limiting device, a suspension frame and a frame, wherein the transmission system is arranged at the upper front side of the frame and used for transmitting power to the vibration subsoiling device via a power output shaft of a tractor; the vibration subsoiling device is arranged below the frame; the supporting and depth-limiting device is arranged at two sides of the rear part of the frame; and the suspension frame is arranged in the front part of the frame and connected with a suspension device of the tractor. According to the vibration mechanism disclosed by the invention, a structure with eccentric wheels arranged symmetrically and a connecting rod is adopted, and subsoiling shovels in the front row and the rear row are driven by the same transverse shaft to realize reverse vibration; and the two rows of shovels alternatively act forward and backward to loosen soil. Compared with the vibrations of all subsoilers in the same direction, the dual-row reverse-vibration subsoiler can be used for reducing peak traction resistance and oil consumption of the tractor and reducing vibration transferred to the frame and the tractor, and is suitable for subsoiling, land preparation and medium cultivation of soil.

Owner:HENAN POLYTECHNIC UNIV

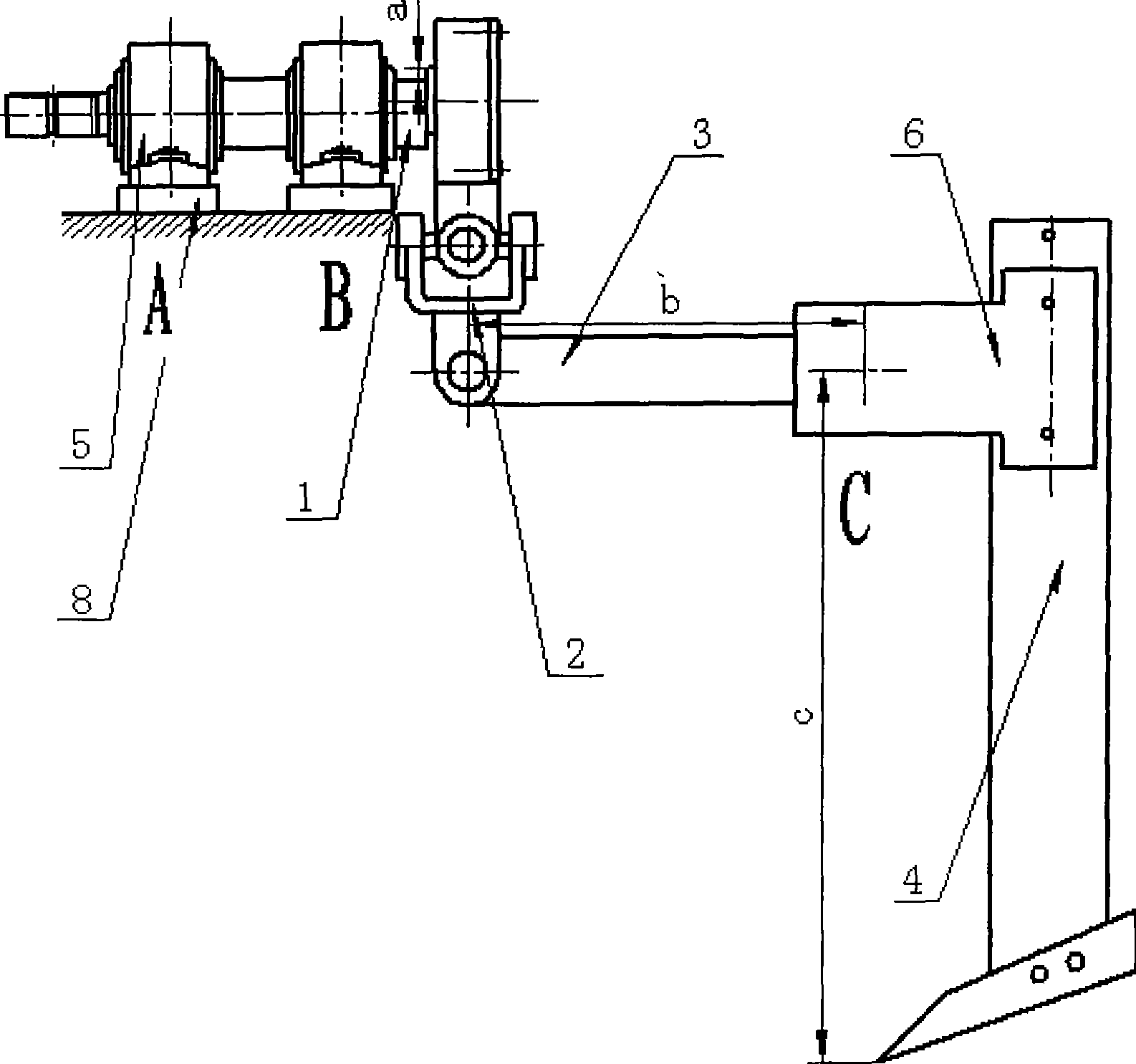

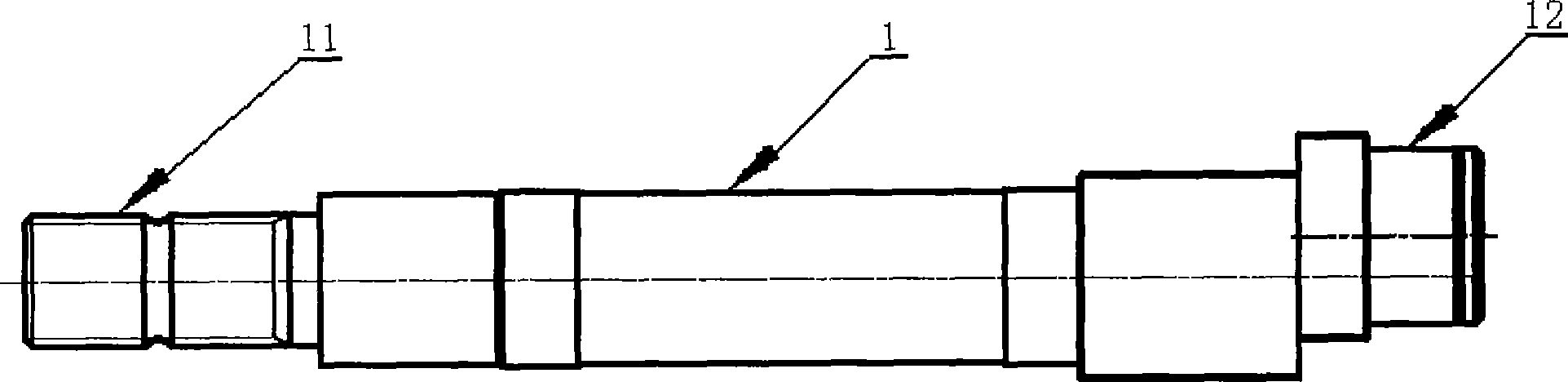

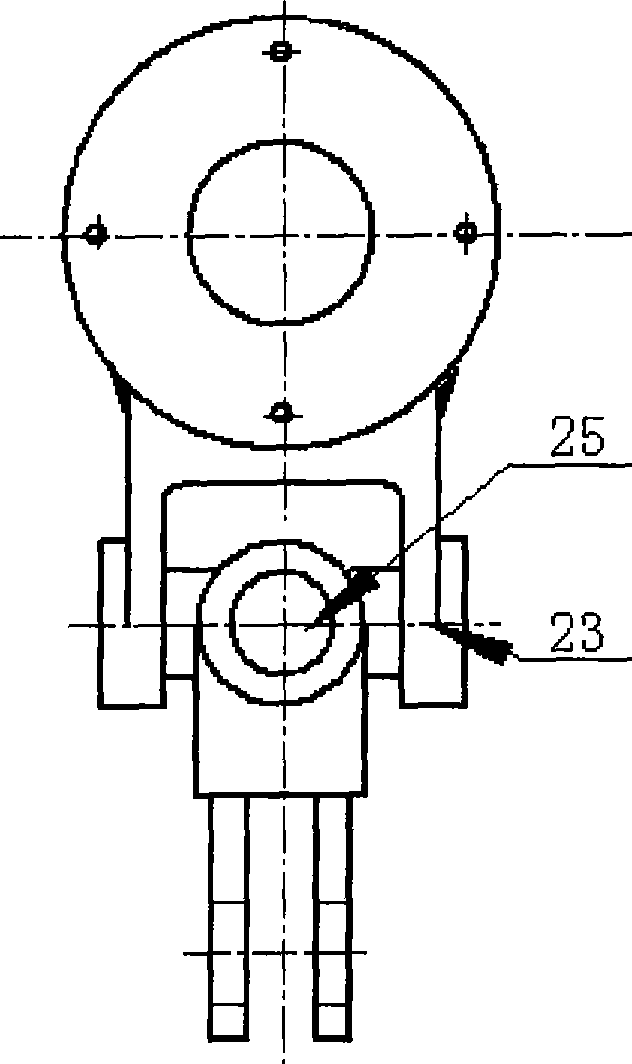

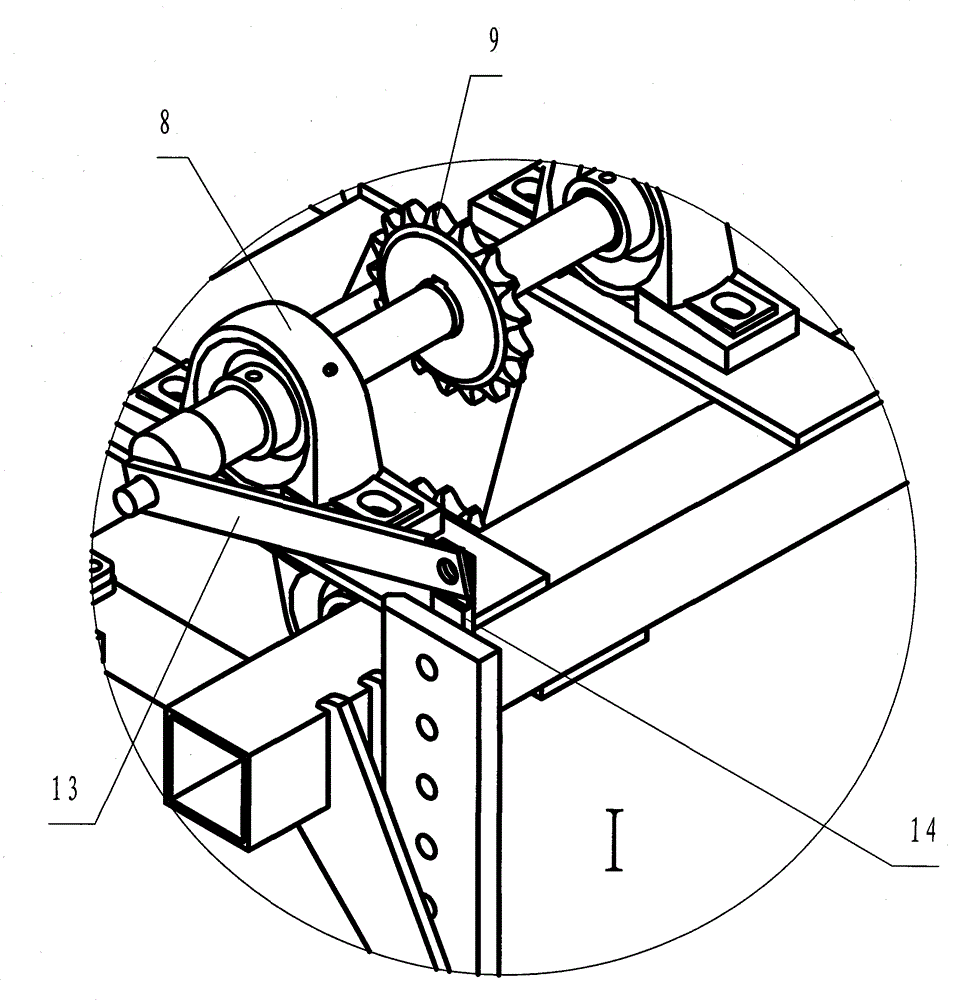

Vibration mechanism of vibrating subsoiler

The invention relates to a vibrating mechanism for a vibrating subsoiler. The vibrating mechanism is characterized by comprising an eccentric shaft, a cross-shaped shaft coupling, a lever and sub-soiling shovels; one end of the eccentric shaft is a hexagonus spline shaft end, the other end is an eccentric shaft end, and the eccentric shaft is a cantilever shaft formed by being supported by two bearing seats; the spline shaft end of the eccentric shaft is connected with the power output shaft of a tractor through the shaft coupling, and the eccentric shaft end of the eccentric shaft is articulated with the cross-shaped shaft coupling through a bearing and a clip spring; the lower end of the cross-shaped shaft coupling is hinged at one end of the lever, a pair of overhanging arms is arranged at the other end of the lever, and the sub-soiling shovels are vertically fixed on the pair of the overhanging arms. Due to the adoption of the lever principle, the penetration angles of the sub-soiling shovels are changeable, so that the sub-soiling shovels penetrate through the soil more easily, the resistance of the soil to the shovel surfaces is reduced, and the tractive resistance of the vibrating subsoiler is further reduced. The invention is widely applied to various vibrating subsoilers.

Owner:CHINA AGRI UNIV

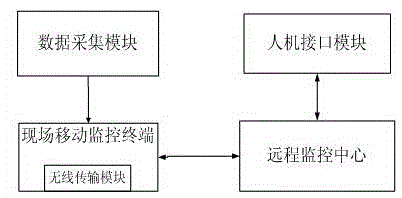

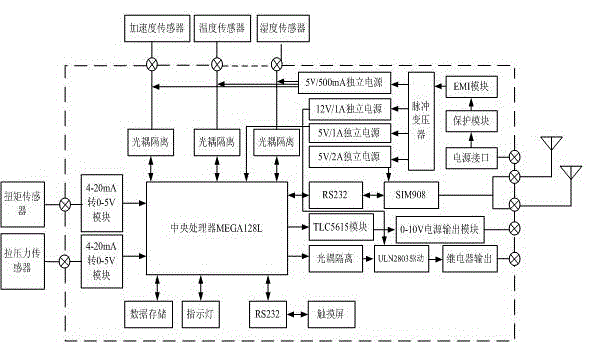

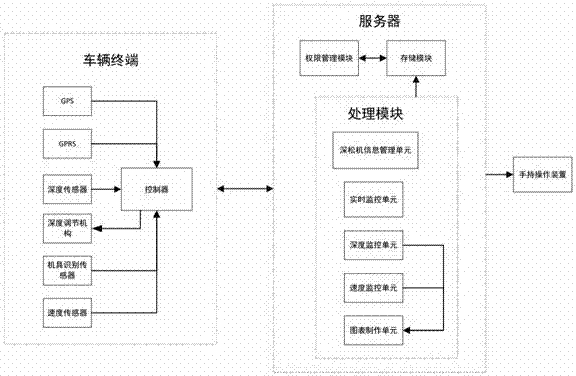

Operating condition monitoring system of vibratory subsoiler

ActiveCN104599474ARealize synchronous monitoringRealize online analysisTransmission systemsTransmissionScarificationNetwork model

The invention relates to an operating condition monitoring system of a vibratory subsoiler. The system not only can be used for field movement detection on the working performance and the key parameters of the subsoiler, but also can realize simultaneous monitoring of a remote computer, online analysis of data and batch storage by virtue of a GPS positioning and GPRS DTU wireless transmission technology. A computer inquires and analyzes data of a positioned block and combines with analysis of key technical data returned by the computer, and by establishing a BP neural network model, optimized parameters taking the lowest consumption as a target are output to obtain related parameters such as the optimum farming period of the block, the optimum farming depth, the work efficiency, and the highest deep scarification frequency and amplitude of the machines and tools. The related parameters are sent to a field mobile monitoring terminal as reference, so that true minimal tillage and optimum tillage are realized.

Owner:QINGDAO AGRI UNIV

Subsoiler

InactiveCN101317503ASolve the blockageProtects against moisture lossPloughsAgricultural undercarriagesCircular discEvaporation

The invention discloses a subsoiler, comprising a frame which is provided with a connecting plate arranged above the right front end, an upper cantilever and a lower cantilever which are arranged at the front end of the frame, a pair of depth wheels which are connected at two sides of the frame by a depth axle, a depth wheel supporting frame and a depth wheel supporting frame connecting screw, a subsoiler handle which is provided with a subsoiler tine point and connected with a rear arm of the frame by a subsoiler fixed plate and a subsoiler fastening screw. The subsoiler is characterized in that a disc coulter which is connected with the connecting plate by a coulter connecting rod fastening screw, a coulter connecting rod, a disc coulter shaft and a disc coulter bracket is arranged at the front upper part above the subsoiler tip; the center of the disc plow and the center of the subsoiler handle are on one line; the subsoiler tip is an arrow-shape and the subsoiler handle is a bow-shape. The subsoiler effectively solves the phenomena of weed blocking and large clod during the working process, reduces the width of the cracking surface of the ground surface, effectively restricts the ineffective evaporation of the water and reduces the working resistance.

Owner:NORTHWEST A & F UNIV

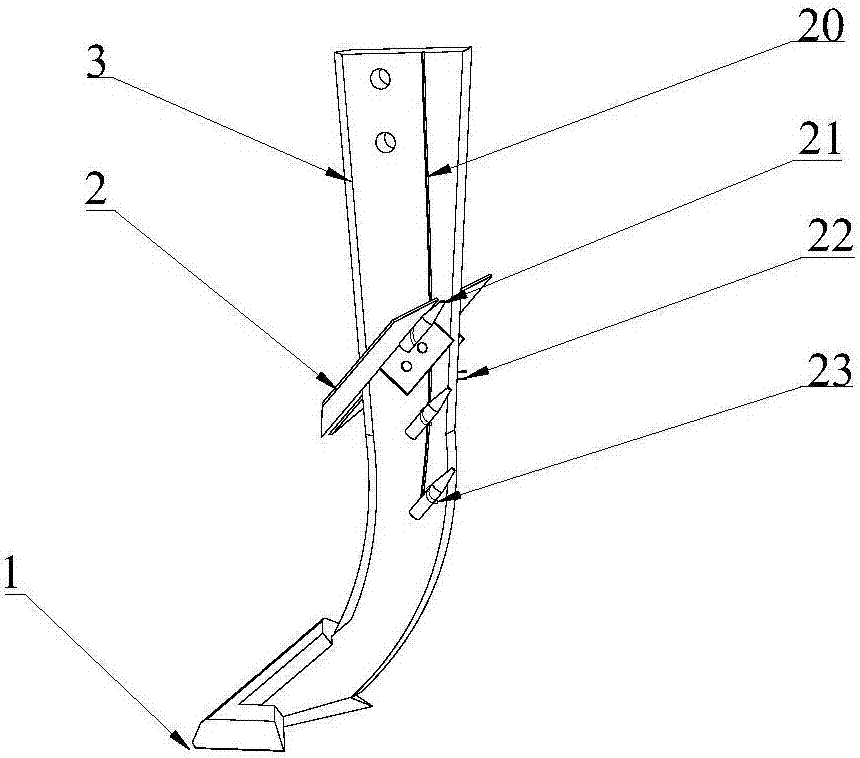

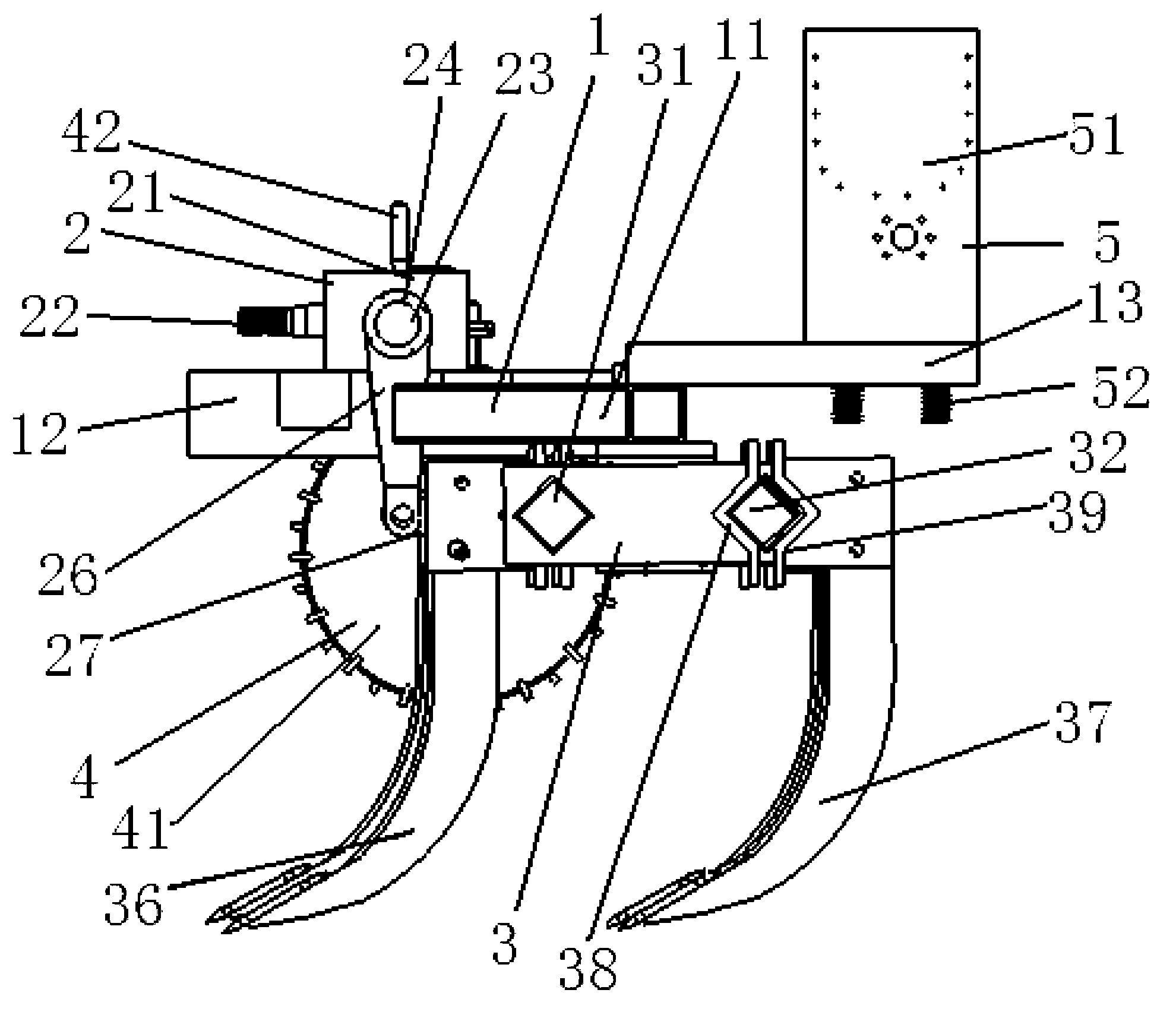

Soil disinfecting subsoiler with flame deep layer sterilizing function and method

The invention provides a soil disinfecting subsoiler with a flame deep layer sterilizing function and a method. The soil disinfecting subsoiler comprises a machine frame, a subsoiler compacting device and a high-temperature sterilizing device. The machine frame is used for supporting and fixing other devices and connected with a tractor hanging system in a hanging or traction mode and provides power for the tractor hanging system. The subsoiler compacting device is used for completing the soil deep loosening and land preparing work and the breaking and compacting work of earth surface soil blocks. The high-temperature sterilizing device is used for realizing fire spraying of multiple fire spraying heads to complete the high-temperature soil sterilizing and insect killing work. By means of the high-temperature flame sterilizing and insect killing mode, oxygen-enriched combustion gas is sprayed at a high speed through a space formed by turning soil at the rear portion of a subsoiler shovel handle underground, flame is located underground during combustion and used for killing bacteria, and the energy utilization rate is high; targeted soil disinfecting work is conducted for large fields with soil of different pollution conditions, the pollution caused for the environment and crops by using highly poisonous chemical pesticides is solved, and the aim of improving the environment is improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

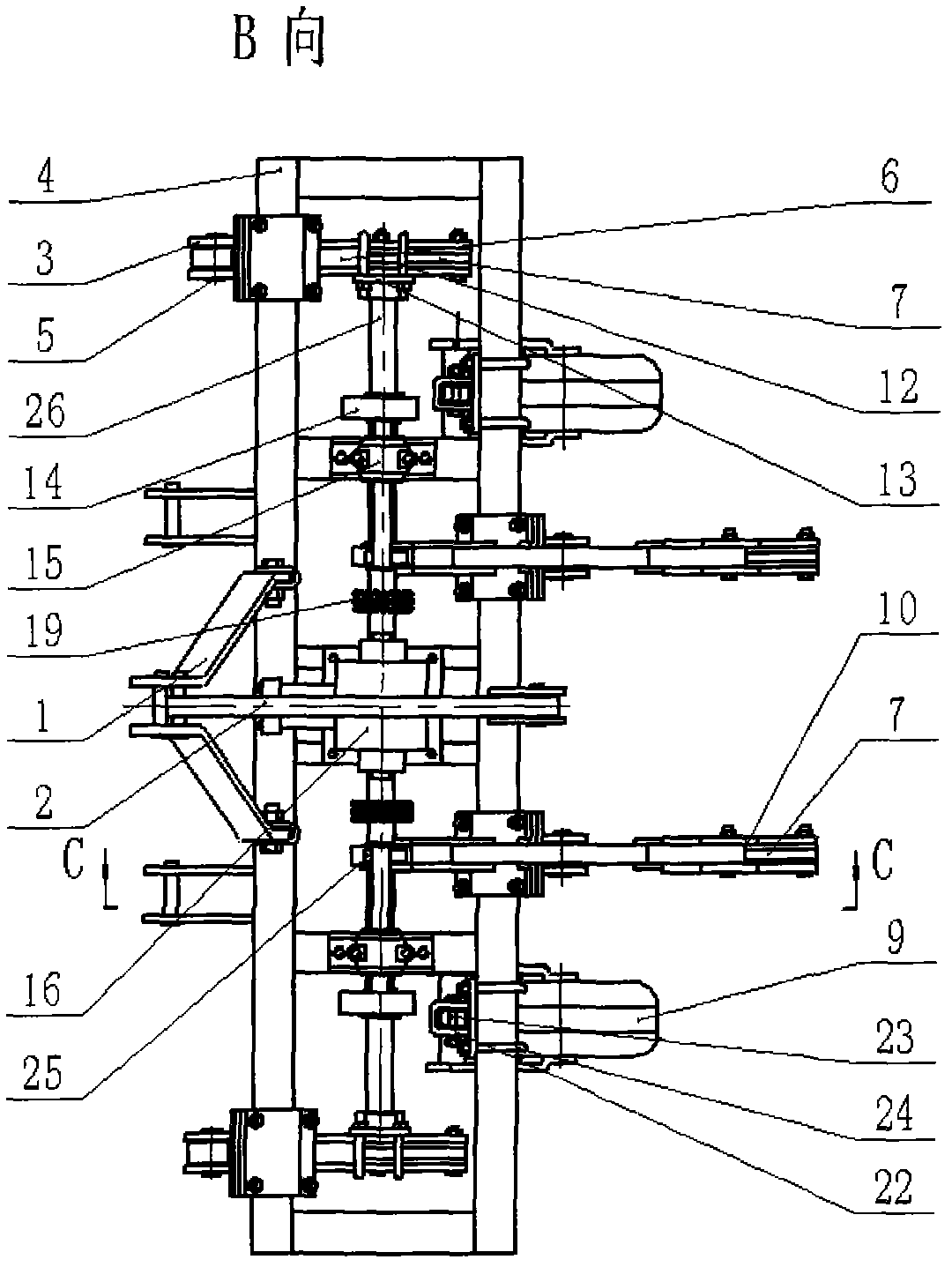

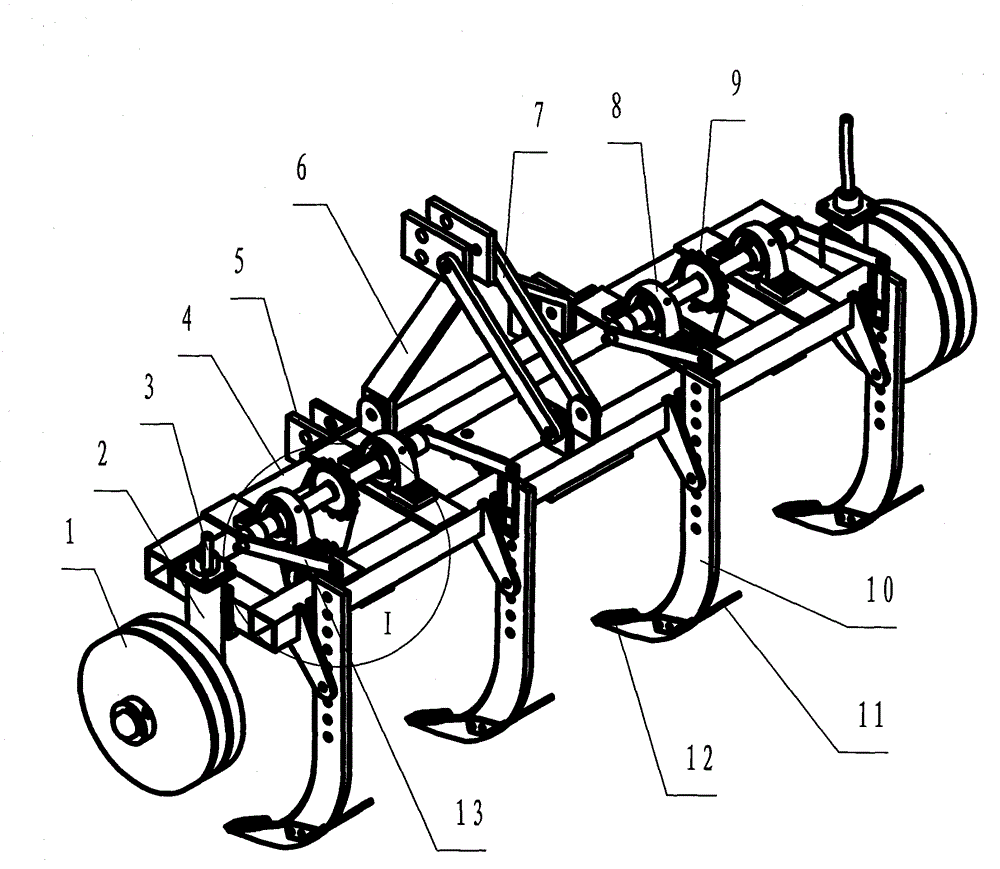

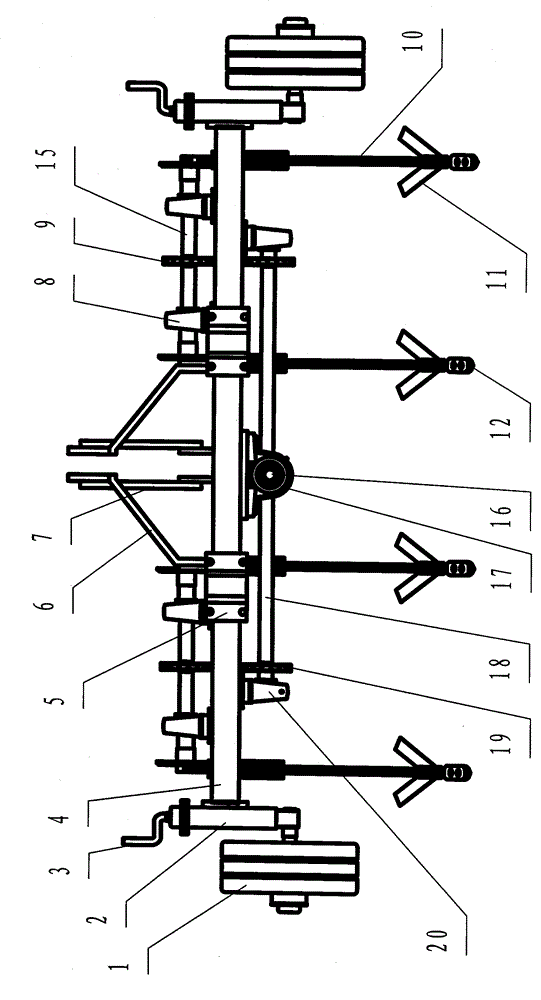

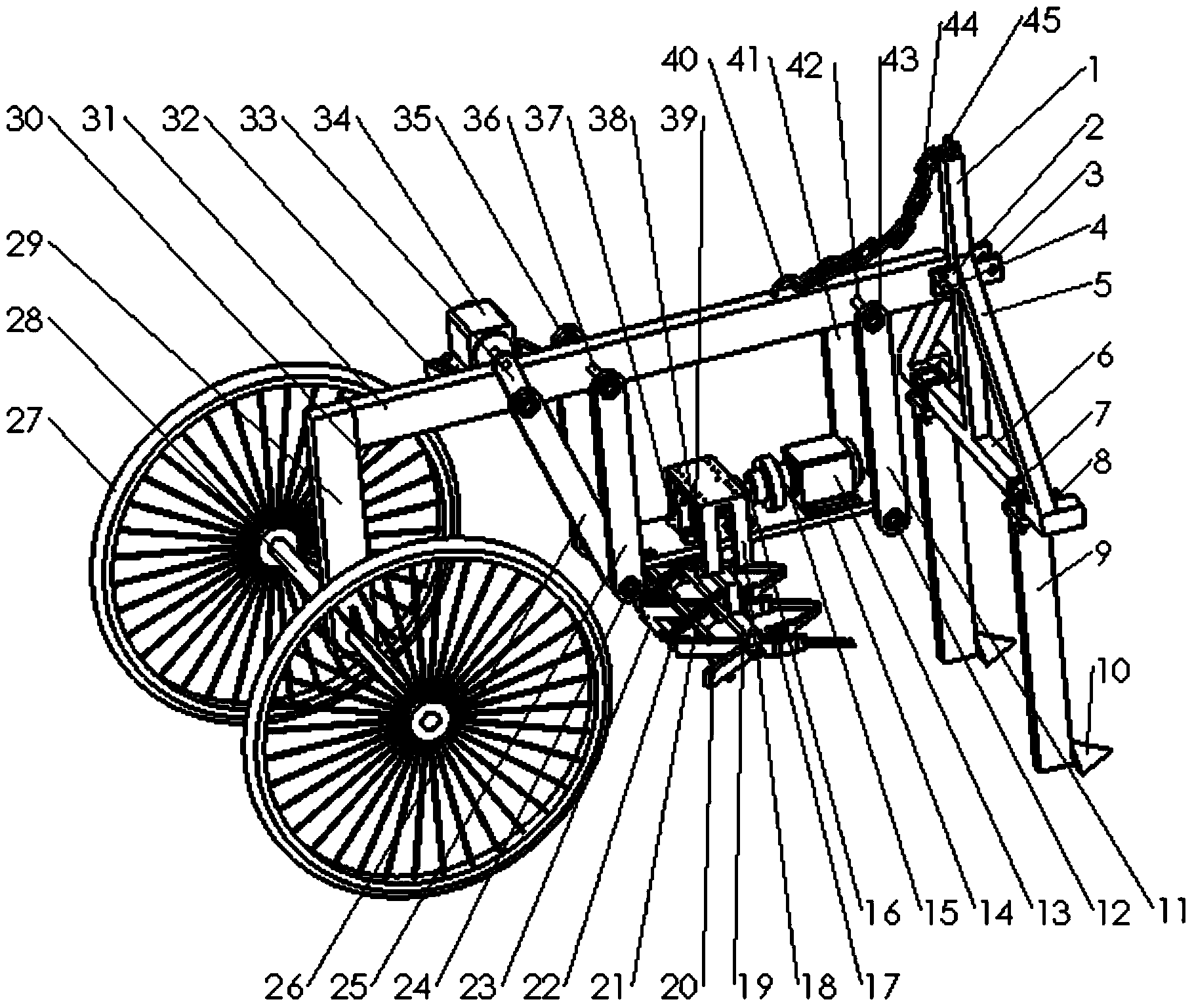

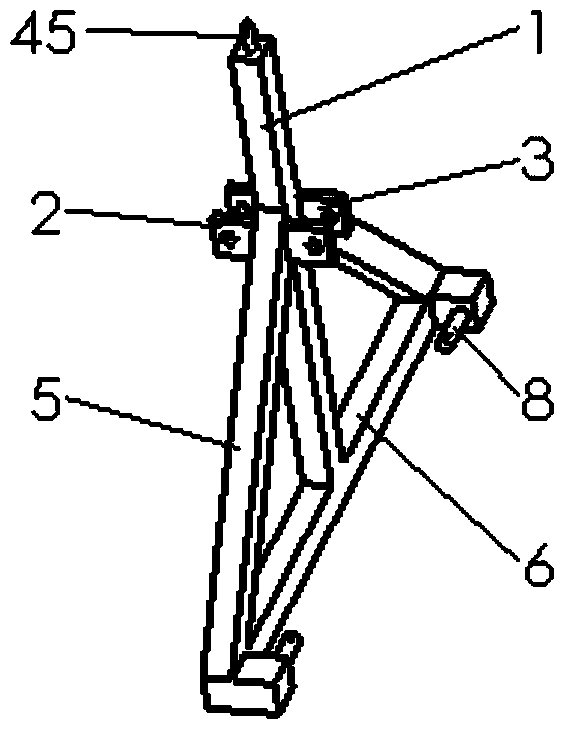

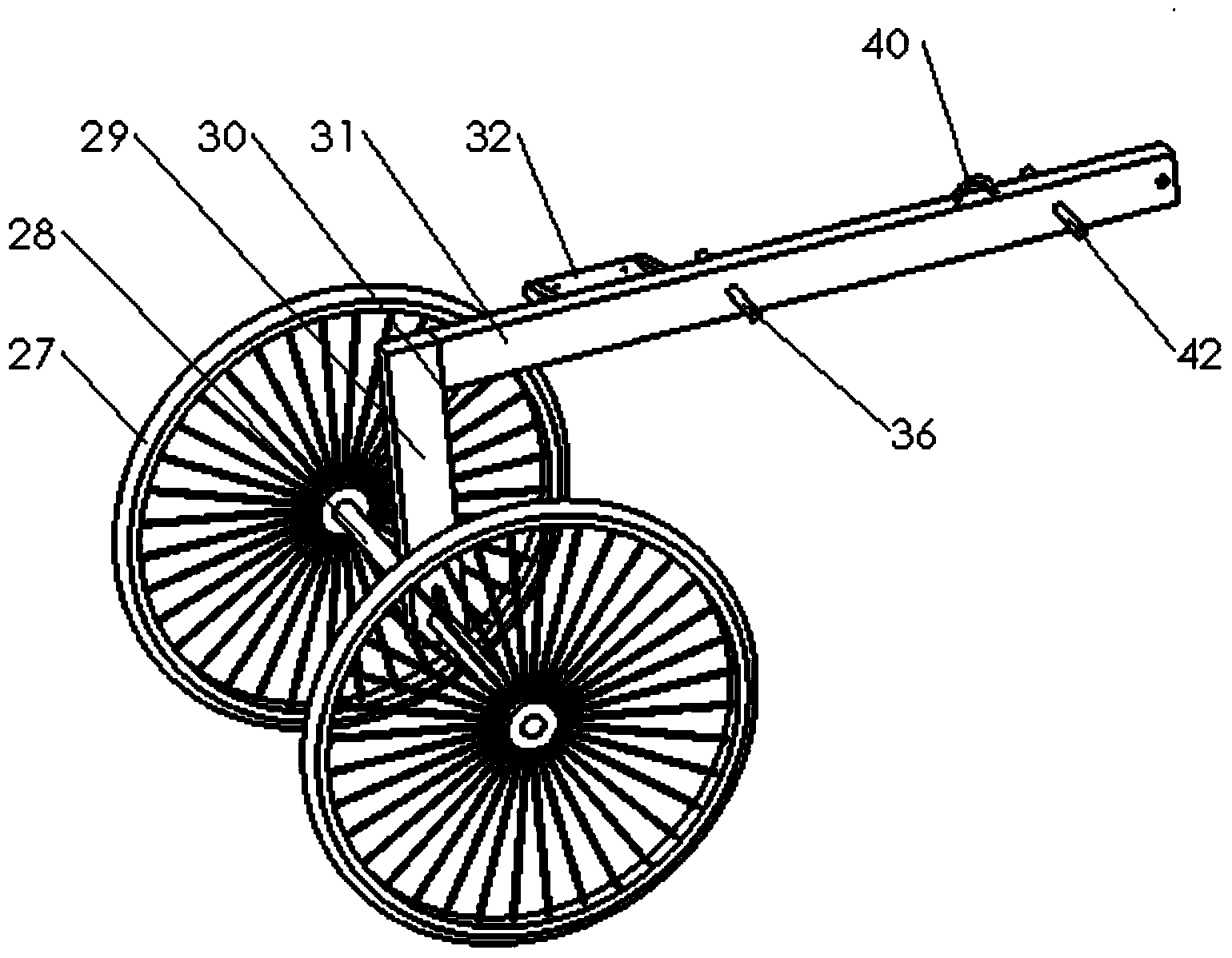

Vibration subsoiler

The invention relates to a vibration subsoiler, which is characterized by comprising a frame, a traction device, a transmission device, a vibration deep scarification device and depth controlling devices. The traction device is arranged at the front of the frame, the transmission device comprises a power input shaft, a transmission shaft, a drive sprocket, a crankshaft, a driven sprocket, a drive connecting rod and a driven connecting rod, wherein the power input shaft is arranged at the front of the frame, the transmission shaft is arranged on the lower portion of the frame, the drive sprocket is arranged on the transmission shaft, the crankshaft is arranged in the middle of the frame, the driven sprocket and the drive connecting rod are respectively arranged on the crankshaft, and the driven connecting rod is arranged on the drive connecting rod; the vibration deep scarification is arranged at the back of the frame, the depth controlling devices are arranged on the bilateral sides of the frame. By the application of the vibration subsoiler, tractive resistance on the vibration subsoiler can be effectively lessened, the effect of scarification is good, tractor vibration caused by the vibration of the vibration subsoiler is avoided, and the tractor drivers are prevented from feeling uncomfortable.

Owner:SHIHEZI UNIVERSITY

Combined operation machine

InactiveCN104365202APromote germinationAvoid repeated rollingSpadesPloughsAgricultural engineeringAgricultural machinery

The invention discloses a combined operation machine and relates to the technical field of agricultural machines. The combined operation machine comprises a frame and a farming bracket installed at the tail of the frame through a lifting pull rod. A subsoiler, a rotary blade, a grading dragging plate and a furrow opener are sequentially arranged on the framing bracket from front to back. A fertilizer storage box is installed on the farming bracket and provided with a soil feeding pipe and a planting feeding pipe, wherein the soil feeding pipe extends to the position between the subsoiler and the rotary blade, and the planting feeding pipe extends to the position behind the furrow opener. A seed discharge box is arranged at the position, behind the planting feeding pipe, of the farming bracket, and a soil sealing roller is arranged behind the seed discharge box. A straw smashing device is installed at the front end of the frame. Compared with the prior art, the combined operation machine can complete straw smashing and returning, land subsoiling, rotary tillage, flattening, furrow opening, fertilizer applying and seeding at a time, so that production efficiency is improved substantially; through the combined operation machine, soil is prevented from being compressed repeatedly, so that the ventilation and water permeability of the soil are maintained, and seeds are promoted to sprout and grow.

Owner:LIUZHOU HONGDA MACHINERY MFG

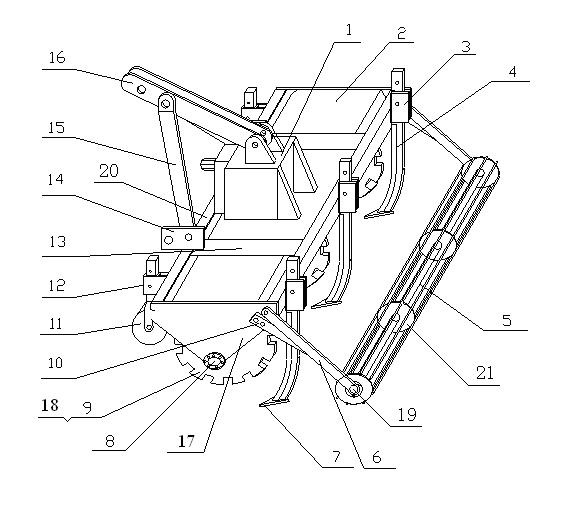

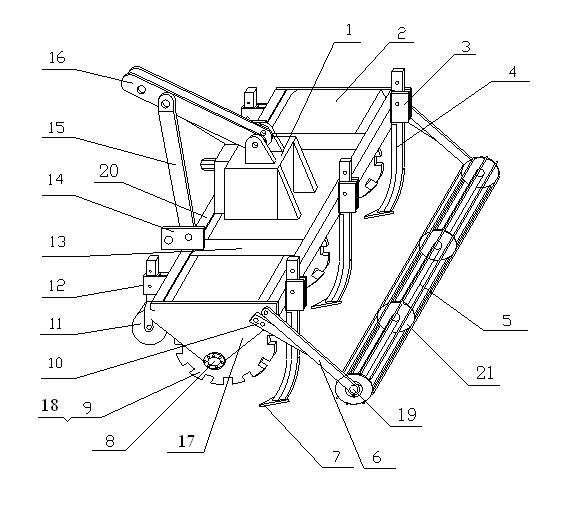

Vibration digging and puling type cassava harvester

ActiveCN103828531AIncrease flexibilityPull up in rapid successionDiggersHydraulic motorMicrocontroller

The invention discloses a vibration digging and pulling type cassava harvester which comprises a rack, a hanging frame, a tuberous root pulling device, a digging shovel and an electro-hydraulic control device. The rack is composed of a beam frame and a rear supporting wheel. The rack is hinged to the hanging frame, and longitudinal displacement, relative to the hanging frame, of the rack is limited through a steel chain. The tuberous root pulling device is composed of a pulling mechanism, a vibration mechanism and a clamping mechanism. The tuberous root pulling device is installed on the rack. The digging shovel is composed of a subsoiler and a subsoiler pillar and fixed below a cross rod of the hanging frame through a U type bolt. The electro-hydraulic control device is composed of a sensor, a single-chip microcomputer, an A / D, an electro-hydraulic servo valve and a D / A. The electro-hydraulic control device controls a hydraulic motor and an oil cylinder to work. The vibration digging and pulling type cassava harvester is connected with a tractor hanging device through the hanging frame in a three-point mode. The vibration digging and pulling type cassava harvester is simple in structure, high in flexibility of the pulling mechanism, easy to control and capable of achieving fast and continuous pulling and is little in loss, clean in soil and cassava separation and low in power consumption when cassava tuberous roots are harvested.

Owner:GUANGXI UNIV

Self-induced vibration subsoiler and deep tillage measuring and control method

ActiveCN107182313ARegulating pressureAvoid intermittent failuresSpadesPloughsEngineeringVibration source

The invention discloses a self-induced vibration subsoiler and a deep tillage measuring and control method. The self-induced vibration subsoiler includes a rack, a detection device, a hydraulic device and a plurality of self-induced vibration subsoiler components, wherein the detection device is installed on the rack, and the self-induced vibration subsoiler components and the hydraulic device are arranged on the rack too; the self-induced vibration subsoiler components are used for loosening soil, and the hydraulic device serves as a vibration source and conducts vibration through the combined action with the soil; the detection device is used for detecting the embedded depth of the self-induced vibration subsoiler components, and controlling the hydraulic device according to the embedded depth, and therefore, the variation of deep tillage is controlled within a permissible range.

Owner:CHINA AGRI UNIV

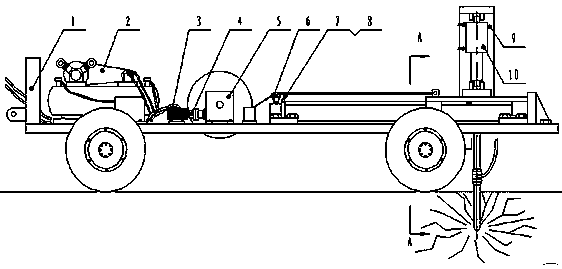

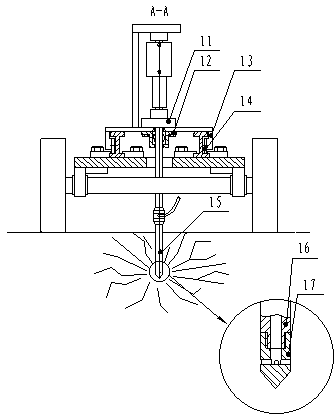

Electric control type air pressure subsoiler

InactiveCN104186039AHigh porosityIncrease contentSoil-working equipmentsAgricultural engineeringAir pump

An electric control type air pressure subsoiler comprises a rack, a high-pressure air pump, an intermittent mechanism, a guide rail sliding mechanism, an air gun press-in mechanism, an air gun and a control protection system assembly. The rack is connected with a traction device on the rear portion of a tractor through a hinge pin, the high-pressure air pump is arranged on the front portion of the rack, the intermittent mechanism is composed of a hydraulic motor, a speed reducer, a clutch, a coiling block and the like and is fixed to the middle of the rack, the guide rail sliding mechanism is composed of sliding rails and a tackle and is fixed to the rear portion of the rack, the air gun press-in mechanism is composed of an air cylinder, an air cylinder supporting frame and an air gun connecting plate and is arranged on the tackle, the air gun is composed of a vertical ventilation pipe and a guide cone, and is arranged on the air gun connecting plate of the air gun press-in mechanism, and the control protection system assembly is composed of a high-pressure air conveying pipe and a control and protection element and is arranged in the middle of the rack. The electric control type air pressure subsoiler is pulled by the tractor, the subsoiling work is implemented by injecting high-pressure air into a farmland soil deep layer in the running process of the tractor, the tillage plough bottom layer can be broken without turning over soil, the soil water storage capacity is improved, and the grain yield increase is achieved.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

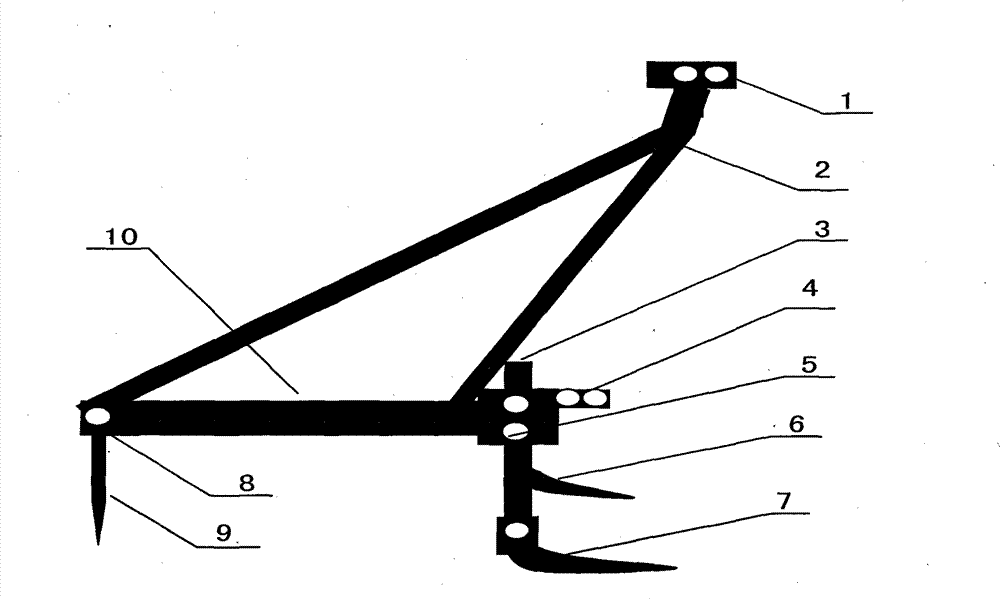

Self-induced vibration anti-drag subsoiler

InactiveCN107258112AAvoid deformationReduce power consumptionPloughsAgricultural engineeringSubsoiler

The invention discloses a self-induced vibration anti-drag subsoiler. The subsoiler solves the problems that existing subsoilers have complicate structures, high drag, and poor adaptability, and are easily damaged. According to the technical scheme, the subsoiler comprises an upper junction plate and a lower junction plate both fixed on a main beam. The upper junction plate is connected with a front end of a self-induced vibration device in a hinged mode, and the self-induced vibration device is connected with an upper end of the subsoiler in a hinged mode. The upside of the subsoiler is also connected with the lower junction plate through a junction adjusting device in a hinged mode. The subsoiler comprises a shovel shaft and a tine point. The part, buried in the ground, of the shovel shaft, and a horizontal plane form a 40-50 degree front slip cutting angle. The subsoiler has the advantages of simple structure, low tillage resistance, flexiblity and adjustability, good tillage adaptability, and long service life.

Owner:HUAZHONG AGRI UNIV

Subsoiler used together with four-wheel tractor

InactiveCN102077709AReduce resistanceAvoid damageSpadesPloughsAgricultural engineeringUltimate tensile strength

The invention relates to agricultural machinery, in particular to a subsoiler used together with a four-wheel tractor. In the subsoiler used together with the four-wheel tractor, a subsoiling shovel shaft fixing element is welded on the back side of a subsoiler large frame; a leveling roller is in hinged connection with the subsoiler large frame through the upper end of a leveling roller connecting piece; a subsoiling shovel arrow faces a ditching disc and is in welded connection with the lower end of a subsoiling shovel shaft; the ditching disc is fixed on a side plate of the subsoiler large frame through a ditching disc shaft and a bearing seat; and a depth limiting wheel is fixed at the front end of the subsoiler large frame through a depth limiting wheel positioning piece. The subsoiler realizes subsoiling operation of the four-wheel tractor, has a simple structure, is convenient to operate, improves operation efficiency and lowers the requirements on intensities of the subsoiling shovel shaft and parts. In particular, the problem of unavailable cultivating by using the ordinary subsoiler during grassland subsoiling is solved and the aim of performing protective cultivation is fulfilled. The subsoiler used together with the four-wheel tractor is suitable for subsoiling on hard soil or grasslands.

Owner:青海林丰农牧机械制造有限公司

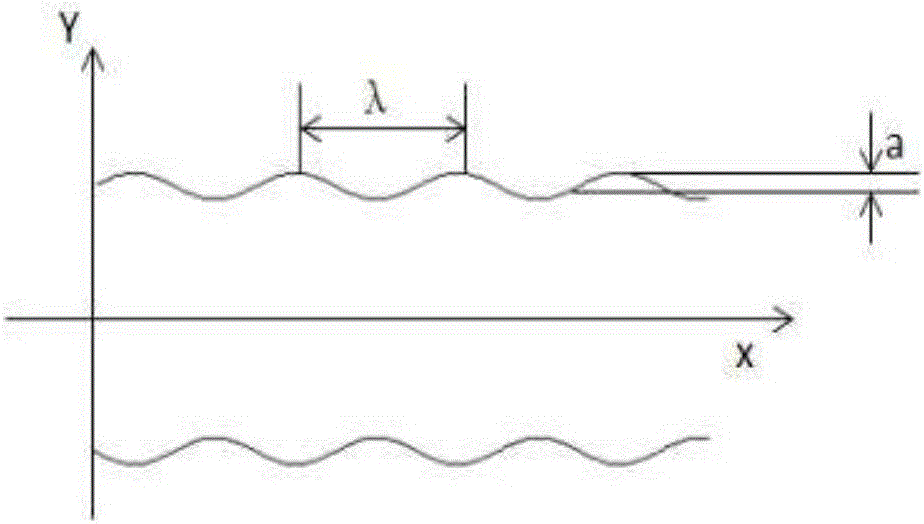

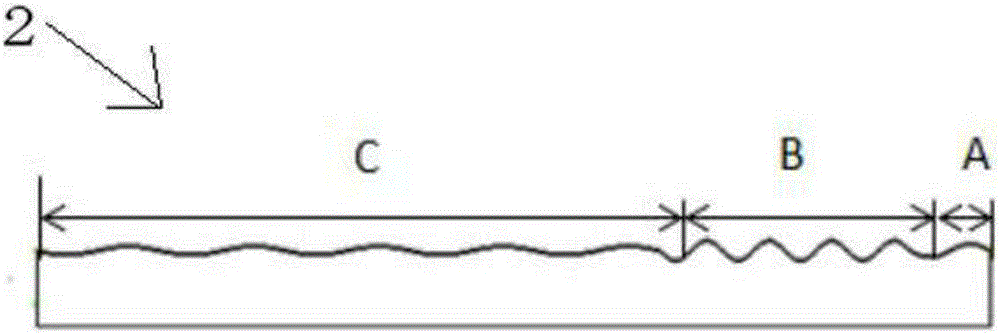

Earthworm-imitating corrugation lubrication body surface anti-drag subsoiler

The invention discloses an earthworm-imitating corrugation lubrication body surface anti-drag subsoiler which is composed of a shovel handle and a shovel blade. The shovel blade is fixedly arranged at the lower end of the shovel handle through a bolt group, and the shovel handle is provided with a first corrugation non-smooth structure and a second corrugation non-smooth structure. The corrugation lubrication function surface is designed based on the biological surface structure, biological lubrication and coupling bionic theory. When the earthworm-imitating corrugation lubrication body surface anti-drag subsoiler is used, a lubricant is conveyed to the positions of a plurality of lubricant spray holes through thin pipes and lubricant conveying holes and sprayed to the shovel blade, the blade surface of the shovel blade has a non-smooth surface to have a lubricating effect, and binary coupling bionics is achieved. The first corrugation non-smooth structure and the second corrugation non-smooth structure reduce soil adhesion. The earthworm-imitating corrugation lubrication body surface anti-drag subsoiler is simple in structure, safe, reliable, convenient to dismantle and high in working efficiency, has a small lubricating medium demanded quantity, reduces cost, is low in maintenance cost and small in resistance during work, effectively reduces soil adhesion, improves service life and is suitable for being widely applied.

Owner:JILIN JIANZHU UNIVERSITY

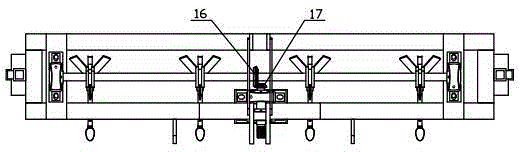

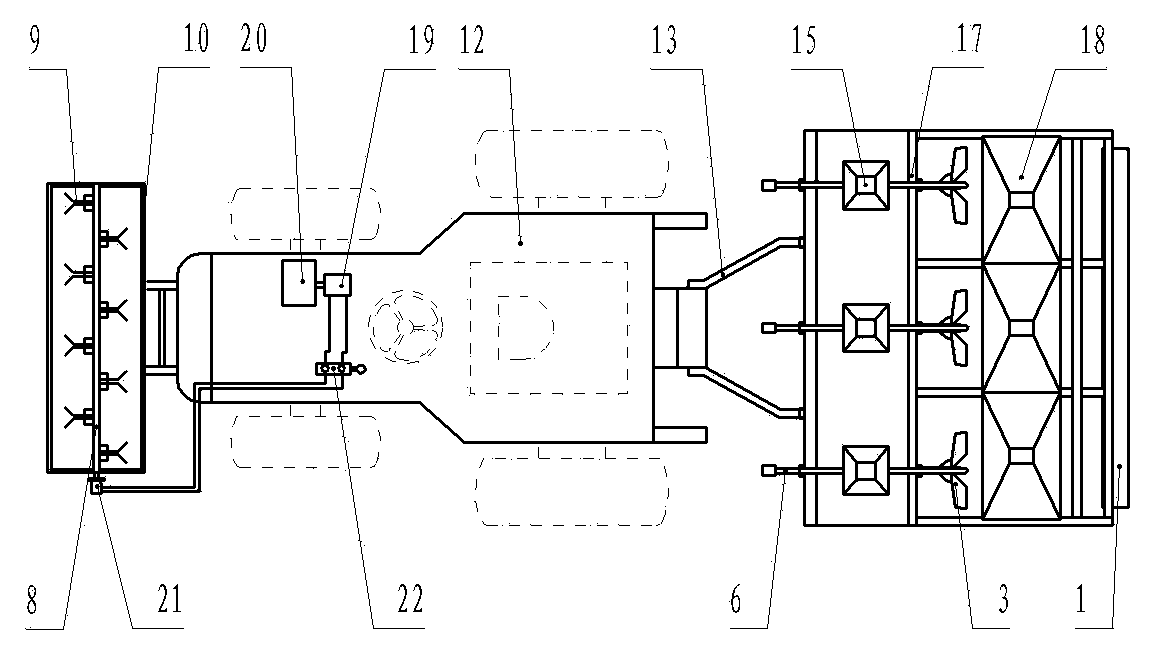

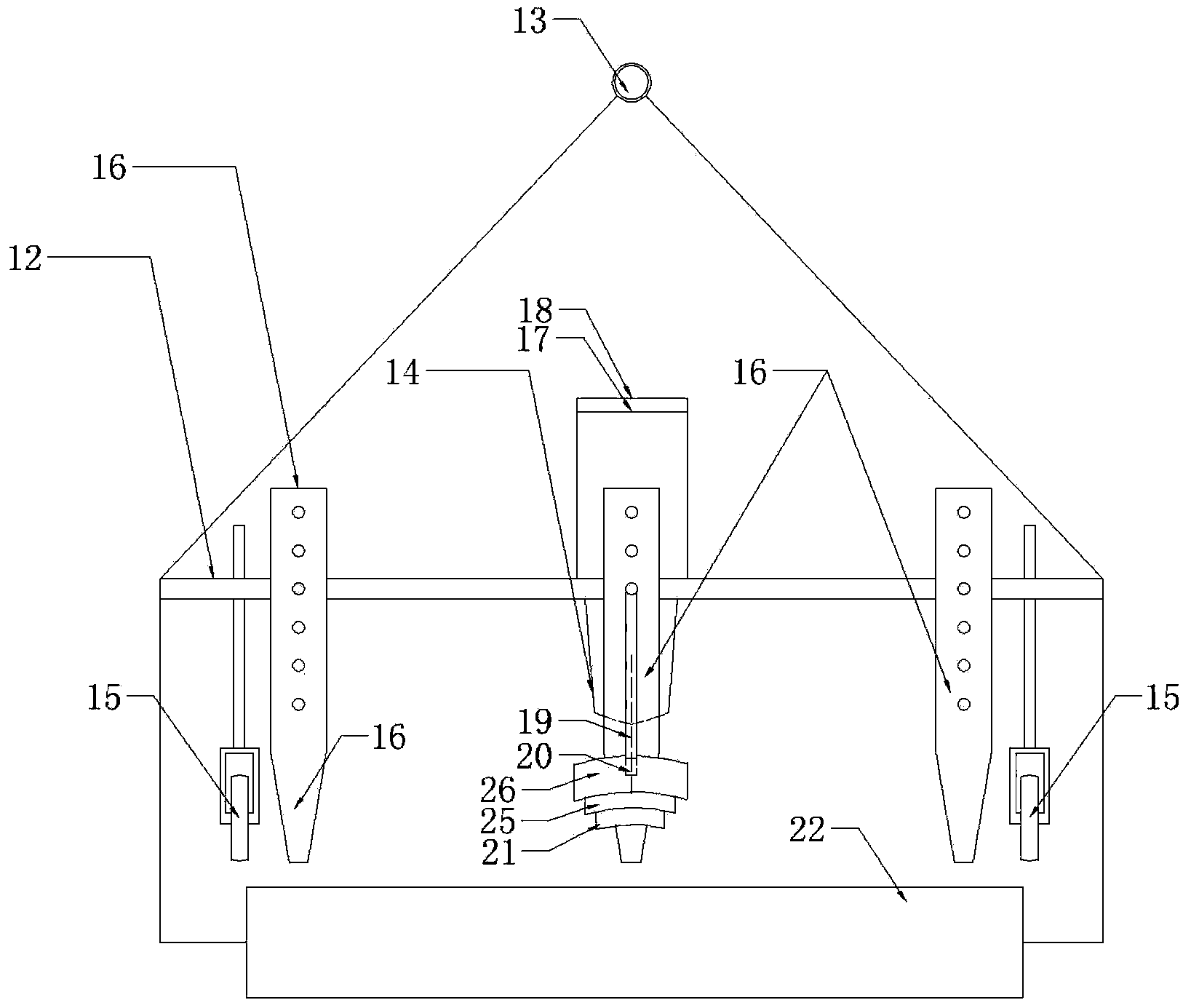

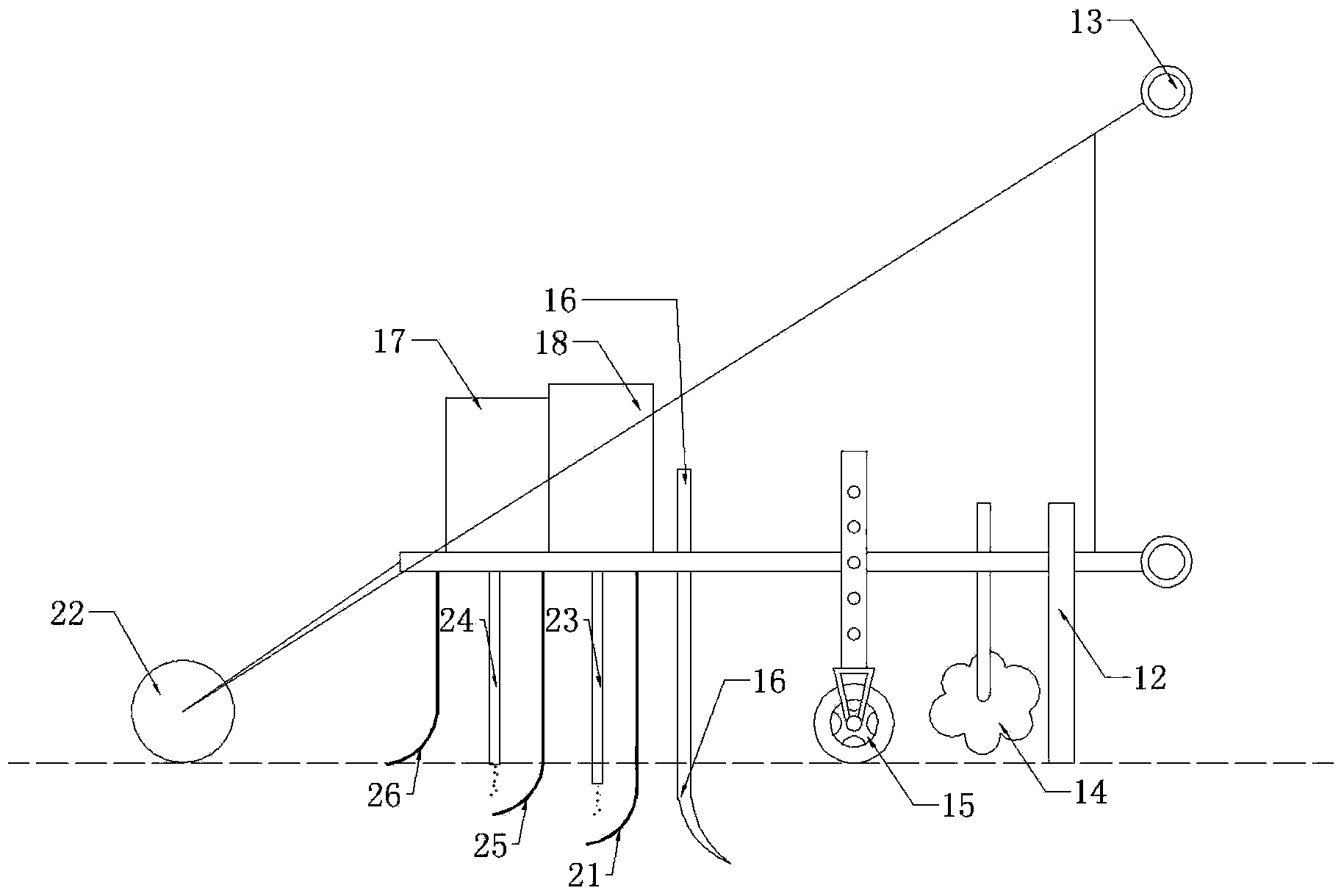

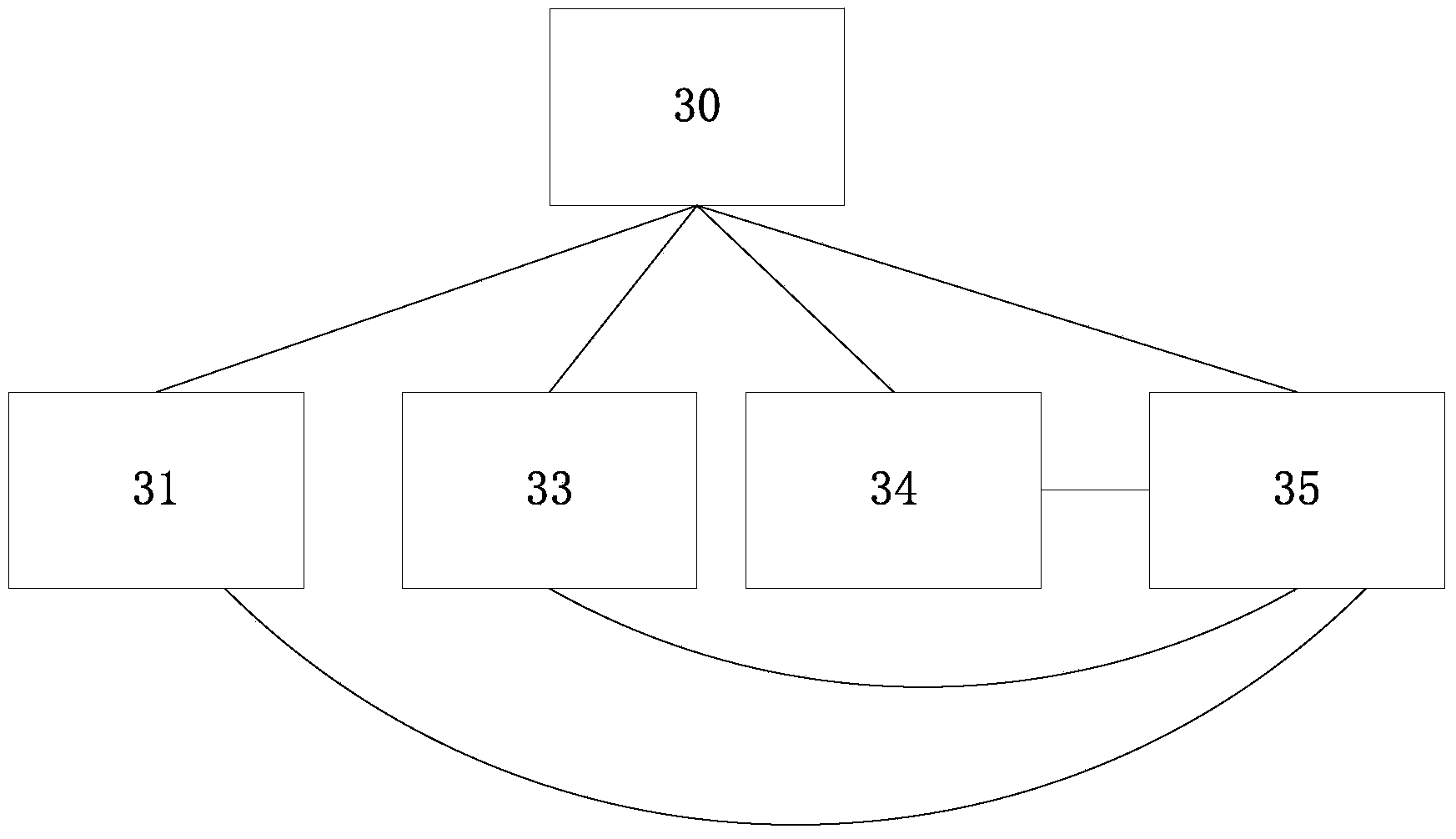

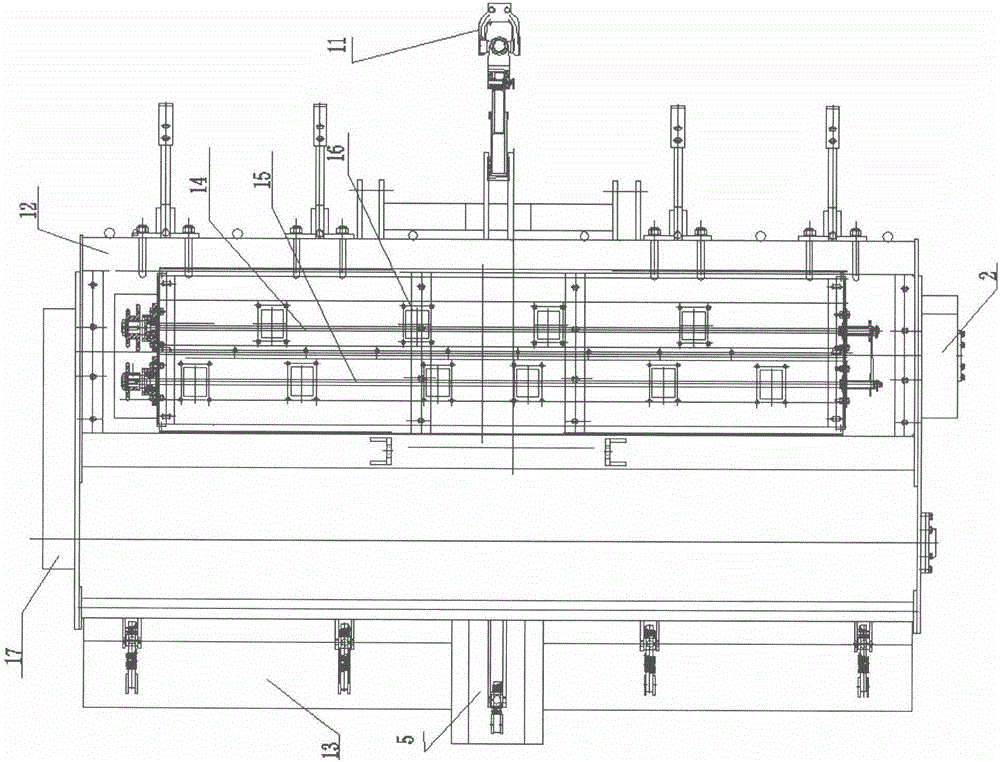

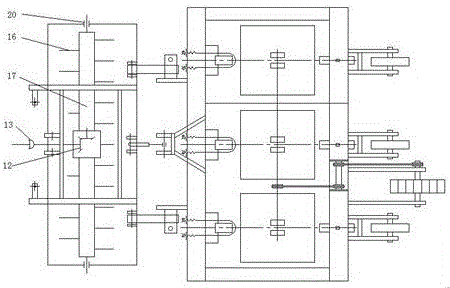

Deep-scarification, deep-fertilization and seed-and-manure-simulcasting machine

ActiveCN103650679AAchieving isotopic deep seedingPromote absorptionSpadesPloughsControl systemAgricultural engineering

The invention discloses a deep-scarification, deep-fertilization and seed-and-manure-simulcasting machine. The deep-scarification, deep-fertilization and seed-and-manure-simulcasting machine comprises a rack 12, a subsoiler 16, a seed box 17, a manure box 18, a seeding device 19 and a manure applying device 20, wherein the subsoiler 16 is connected to the top of the rack 12; the seed box 17 and the manure box 18 are respectively or jointly connected to the top of the rack 12; the manure applying device 20 and the seeding device 19 are sequentially connected to the top of the rack 12 according to the sequence; the drilling depth of the manure applying device 20 is greater than that of the seeding device 19; the seeding device 19 comprises a seeding control system for controlling seeding time; the seeding control system comprises a power source 30, an electromagnetic valve 31, a manure burying detector 33, a speed detector 34 and a time regulator 35; and the electromagnetic valve 31, the manure burying detector 33, the speed detector 34 and the time regulator 35 are respectively connected with the power source 30. By using the deep-scarification, deep-fertilization and seed-and-manure-simulcasting machine, uniform seeding can be carried out, and simulcasting of seed and manure can be carried out at the same position and in different depths.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Subsoiler vibrating in staggering way

InactiveCN102823348ASolve the problem of large and small vibration forceSolve big and small problemsSpadesPloughsCircular discDrive shaft

The invention relates to a subsoiler vibrating in staggering way, which comprises a frame, a subsoiling drive device, a subsoiling vibration device and a depth adjusting device. The subsoiler is characterized in that the subsoiling drive device comprises a gear case; an input shaft extends from the front wall of the gear case; two ends of an output shaft extends from two lateral walls of the gear case; two ends of the output shaft are both provided with an eccentric shaft through a disk; two eccentric shafts are symmetrical at 180 degrees; each eccentric shaft is connected with a vertical connection arm; the vertical connection arm is connected with a transmission shaft through a horizontal connection arm; each transmission shaft is connected to the frame through a bearing; the subsoiling drive device comprises two parts; each part comprises a front vibrating beam, a rear vibrating beam and at least three connection plates; each inner side connection plate and a middle connection plate are fixedly connected to the transmission shaft at the corresponding side; the front vibrating beam near the middle connection plate is fixedly connected with a front subsoiling shovel, and the rear fixing beam near the outer side connection plate is fixedly connected to a rear subsoiling shovel. The subsoiler can be widely applied to various soil subsoiling operations.

Owner:CHINA AGRI UNIV

Vibrating type rotary tillage deep scarification integral machine

The invention discloses a vibrating type rotary tillage deep scarification integral machine. A speed changing box is arranged on a machine frame of a rotary tiller, a cross beam of a subsoiler is connected with a shovel arm, an output shaft of the speed changing box is connected with an eccentric wheel, and a connecting rod which is swung in reciprocating mode along with rotation of the eccentric wheel is arranged in the circumferential direction of an eccentric shaft. The tail of the machine frame of the rotary tiller is fixedly connected with the cross beam of the subsoiler through a connecting arm, a rotation shaft is arranged above the cross beam of the subsoiler, a long transmission arm and a short transmission arm are fixedly arranged in the circumferential direction of the rotation shaft, the long transmission arm is hinged to the connecting rod, the short transmission arm is hinged to the upper end of a transmission rod which is vertically arranged, the lower end of the transmission rod is hinged to the tail of a wing-shaped shovel, and the lower end of the shovel arm is hinged to the middle section of the wing-shaped shovel. Through operation experiments of clayed land and black land, the vibrating type rotary tillage deep scarification integral machine is driven by a 70-90 hp four-wheel machine, the depth of rotary tillage is 15-20cm, and the depth of deep scarification is 35-40cm. Compared with an existing subsoilder with a four-wheel machine above 100 horsepower and the same depth of deep scarification, power is saved by 30%.

Owner:邓衍夫

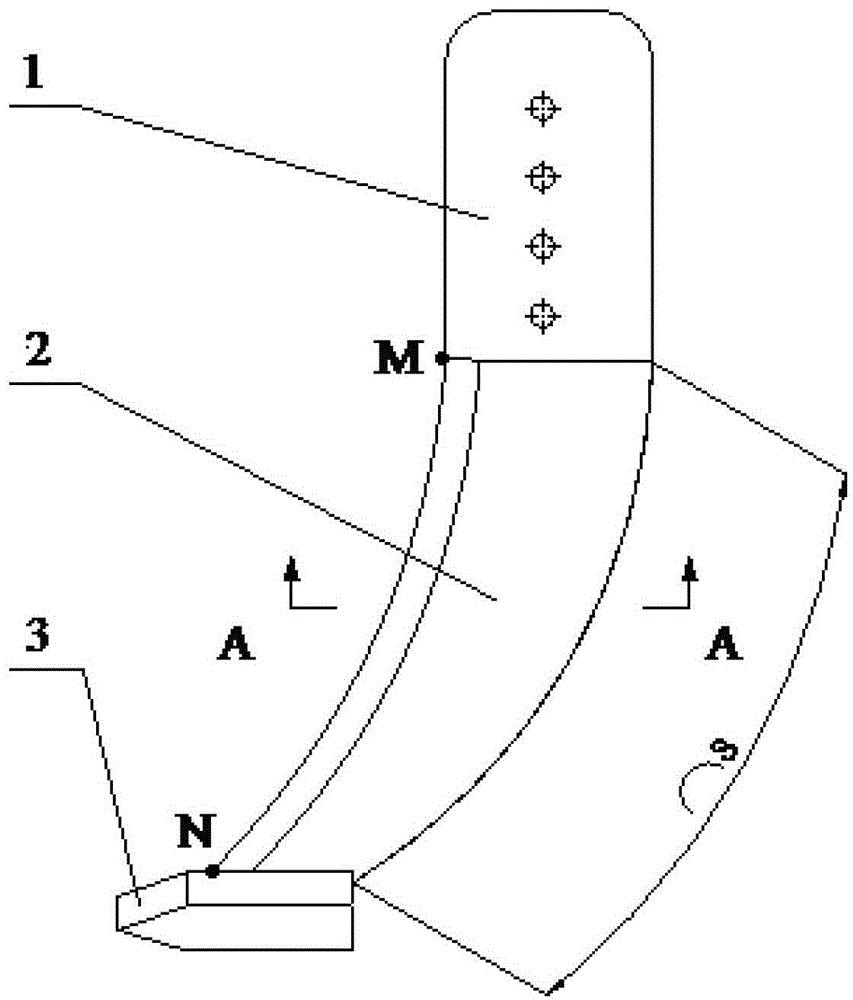

Space curved face type subsoiler

The invention relates to a space curved face type subsoiler which belongs to the technical field of agricultural machinery. The upper end of a blade is fixedly connected with a shovel handle provided with adjusting positioning holes, while the lower end is fixedly connected with a shovel point. The included angle theta of a shovel edge is 45-55 degrees. Four adjusting holes are arranged on a same line. The front part of the shovel point is triangular cone-shaped, and the rear part is cuboid. The shovel edge is a space curved line which can be placed in a spatial three-dimensional right-angled coordinate system. The vertical projections of the shovel edge on a plane YOZ parallel to the forwarding direction of the subsoiler and a plane XOZ vertical to the forwarding direction of the subsoiler are respectively a forerake soil cutting curve MN and a side inclined soil lifting curve PQ. The shape of the blade is obtained by negatively extending the shove edge along the Y-axis. According to the subsoiler, the service life of the subsoiling part is prolonged, transverse vibration of the whole machine is reduced, the soil breaking effect is improved, the effective deep scarification volume is increased, the operational efficiency is improved, and the energy consumption is reduced.

Owner:JILIN UNIV

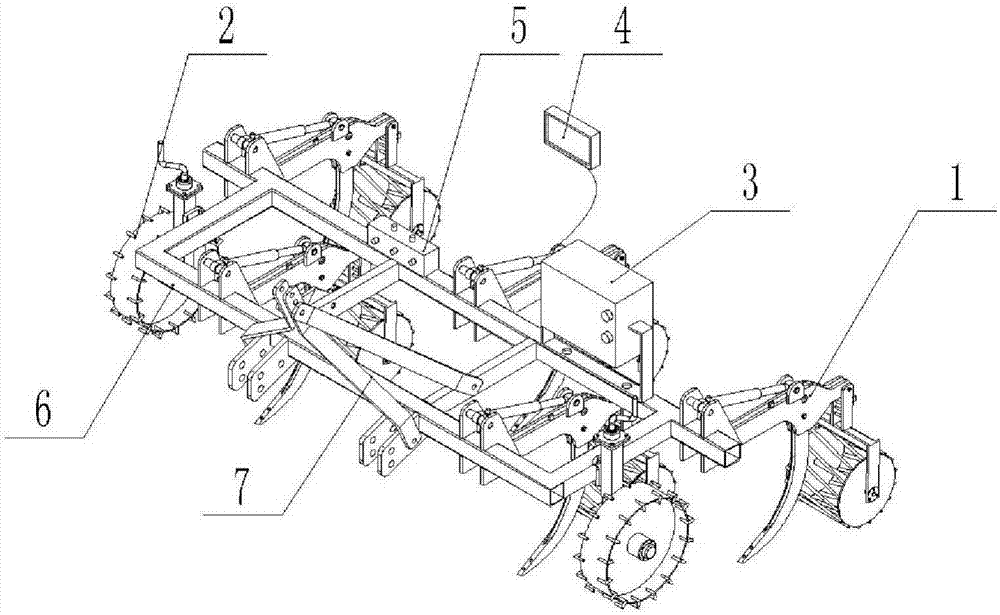

Machine and tool with combined operations of deep scarification, rotary tillage, ditching and intelligent fertilization

PendingCN106416482AReasonable structureHigh degree of mechanizationSpadesSaving energy measuresMotor speedScarification

The invention discloses a machine and tool with combined operations of deep scarification, rotary tillage, ditching and intelligent fertilization, and belongs to the technical field of agricultural equipment. The machine and tool comprises a machine frame and a tractor, an intermediate gear case and a broadside gear case are arranged on the machine frame, wherein the broadside gear case is connected respectively with a rotary blade shaft and a soil pulverizing blade shaft below the broadside gear; a ditching cutter is arranged on the rotary blade shaft, a power-driven fertilizer apparatus is arranged above the intermediate gear case, a speed adjustable motor in the power driven fertilizer apparatus drives a rear fertilization shaft to rotate through chain drive, a deep fertilization shaft drives the fertilization shaft to rotate through the chain drive and controls fertilizing amount by adjusting motor speed, wherein the motor speed is controlled through a signal control device, and the signal control device is connected with a velocity sensor arranged on the tractor; four fertilizing pipes of the fertilizing pipes are drawn forth from a fertilizer discharging hole and then put on the machine frame, and the other four fertilizing pipe are connected with a deep scarification fertilizing pipe, wherein the deep scarification fertilizing pipe is arranged at a rear part of a subsoiler. The machine and tool is reasonable in structure, can finish operation in one-time the deep scarification, rotary tillage, ditching, plough layer fertilizing and deep fertilizing, lowers frequency for the tractor to enter into the field, thus saving energy and lowering cost.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI +1

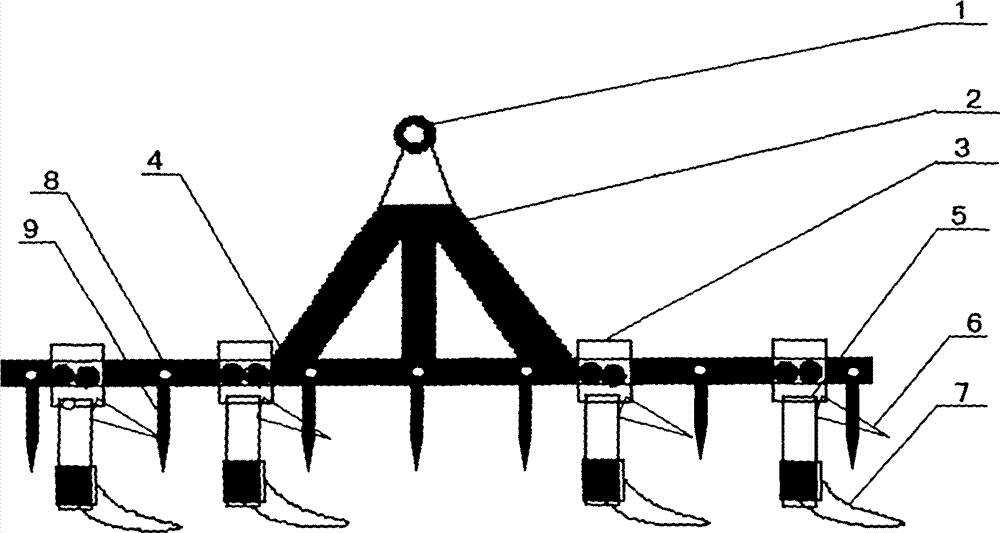

Combined subsoiler

InactiveCN103081590AImprove breathabilityPhysical and chemical enhancementHarrowsTraction frameAgricultural engineering

The invention discloses a combined subsoiler which comprises a main machine frame. A traction frame and a plurality of harrow needles are installed on the main machine frame in a detachable mode through fastening parts. A plurality of shovel handle fixing seats are arranged on the main machine frame, a two-layer sub-soiling shovel is arranged on each shovel handle fixing seat through a fastening part, each two-layer sub-soiling shovel comprises a shovel handle, a breaking shovel and a sub-soiling shovel are arranged on the shovel handle, and the breaking shovel is arranged above the sub-soiling shovel. The combined subsoiler is simple in structure, capable of achieving light weight, convenient to combine, easy and convenient to operate, little in operation resistance, low in manufacture cost and easy to popularize.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Rotary-tillage seeding machine

InactiveCN106717205ASimple structureFlexible operationSpadesPloughsUniversal jointAgricultural engineering

The invention discloses a rotary-tillage seeding machine. The rotary-tillage seeding machine is composed of a rotary tillage device and a seeding device. The rotary tillage device is composed of a support, a speed changer, a universal joint, a gear set, screw cutters and a main shaft; the seeding device is composed of a suppressing wheel, a ditching device, a land wheel, a seed fertilizer box, a machine frame and a subsoiler. An upper hanging pin of the rotary tillage device is connected with an upper connecting arm of the seeding device through an oil cylinder, and the oil cylinder is connected with a hydraulic oil tank installed on a tractor through an oil pipe; a hanging pin of the rotary tillage device is connected with a lower connecting arm of the seeding device. The rotary-tillage seeding machine is simple in structure, flexible in operation and capable of integrally completing rotary tillage operation, fertilization operation and seeding operation.

Owner:项鑫

Adaptive multi-frequency ultrasonic-vibration low-resistance wear-resistance subsoiler and operation method thereof

PendingCN108207130ALow powerAddressing the drawbacks of compacted landSpadesPloughsEngineeringEarth surface

The invention provides an adaptive multi-frequency ultrasonic-vibration low-resistance wear-resistance subsoiler and an operation method thereof. The adaptive multi-frequency ultrasonic-vibration low-resistance wear-resistance subsoiler comprises a frame, a subsoiling soil-preparation device and an ultrasonic vibration device. The frame is used for supporting and fixing the subsoiling soil-preparation device and the ultrasonic vibration device and is connected with a tractor suspension system; the subsoiling soil-preparation device is used for work of subsoiling and soil preparation, surface soil block breaking and compacting; the ultrasonic vibration device is used for generating ultrasonic waves and converting the same into high-frequency mechanical vibration for the subsoiling operationparts so as to realize ultrasonic vibration operation of the subsoiler. By means of ultrasonic-vibration resistance reducing, the subsoiler needs low power as compared with the conventional subsoilerduring operation; with the adaptive multi-frequency ultrasonic vibration working mode, the subsoiler is adaptable to different work environments; adhesion and resistance are both reduced by means ofultrasonic vibration on the shovel surface, the problem of severe wear to the subsoiler during operation can be solved, and accordingly, dependency to import parts is reduced.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

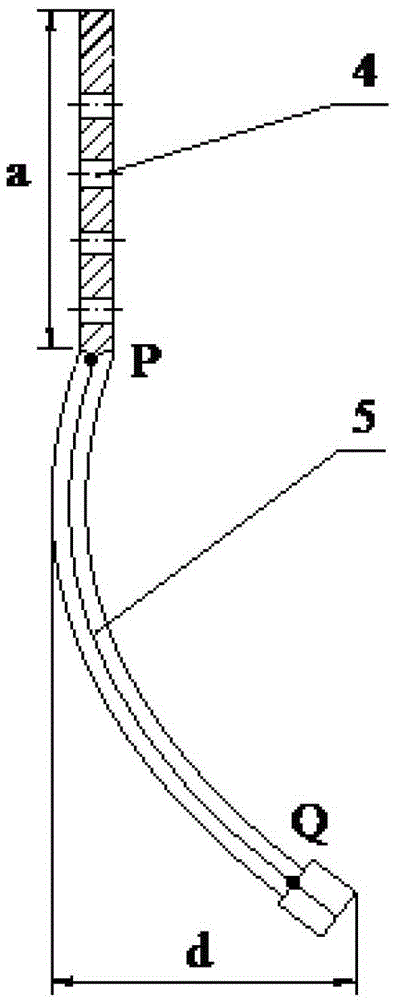

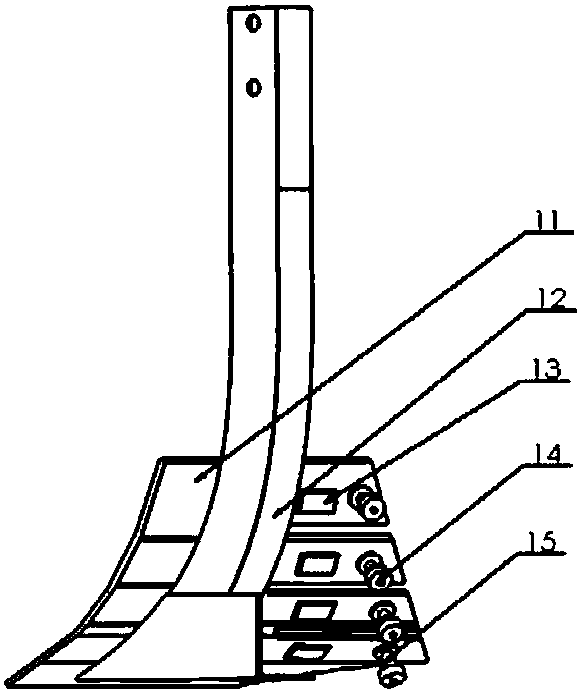

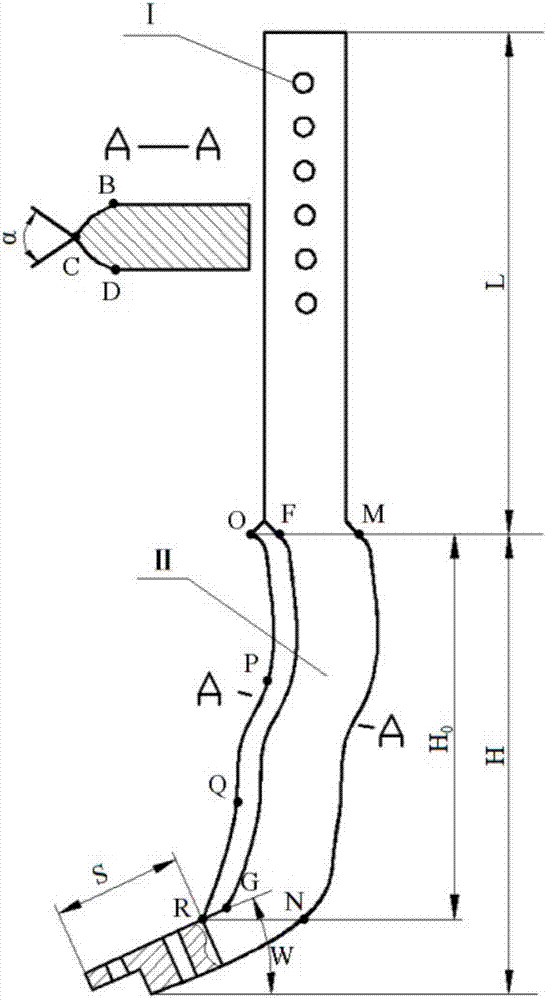

Fitting curve type subsoiler handle

ActiveCN107439061AReduce the amount of collisionTo achieve the effect of water storage and moisture conservationPloughsSurface layerAgricultural engineering

The invention discloses a fitting curve type subsoiler handle, and belongs to the field of tillage of agricultural machinery. The invention aims at designing a fitting curve type subsoiler handle which can significantly reduced tillage resistance and surface layer soil disturbance quantity via simulated analysis and optimal design. The fitting curve type subsoiler handle is composed of a shovel handle and rack connection segment (L), a shovel handle working segment (II), and a shovel handle and shovel tip connection segment (R), and is characterized in that the OP, PQ and QR segments of a shovel handle blade curve are separately formed by the following three fitting curve equations: y=-0.3845x<4>-700.4x<3>-4.785*10<10>x<2>-1.453*10<8>x-1.654*10<10>; y=8.951*10<5>x<5>-0.02656x<4>+3.148x<3>-186.2x<2>+5496x-6.52*10<4>; y=1.702*10<7>x<7>+1.718*10<5>x<6>+7.024*10<5>x<5>+0.01474x<4>+0.1653x<3>+0.944x<2>+2.342x-442.6. An inner directrix (FG) of the shovel handle working segment and an outer directrix (MN) of the shovel handle working segment are accordant with the blade curve; and a height of the OR and MN is H0. A cutting blade angle (alpha), a penetrating angle (w) and blade lines (BC, CD) are selected, so that the tillage resistance and the surface layer soil disturbance quantity can be effectively reduced, and the requirement of protective tillage is met.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

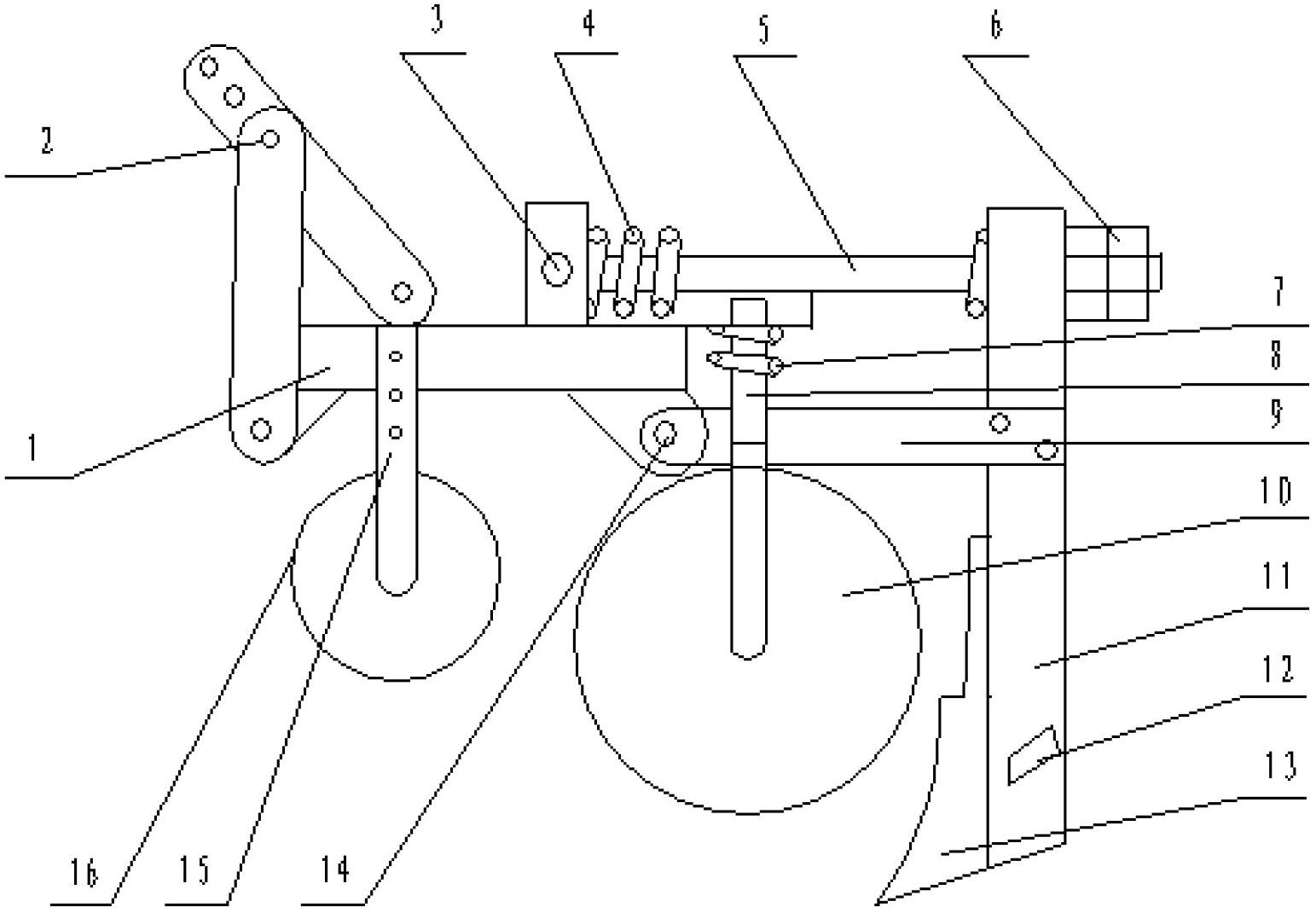

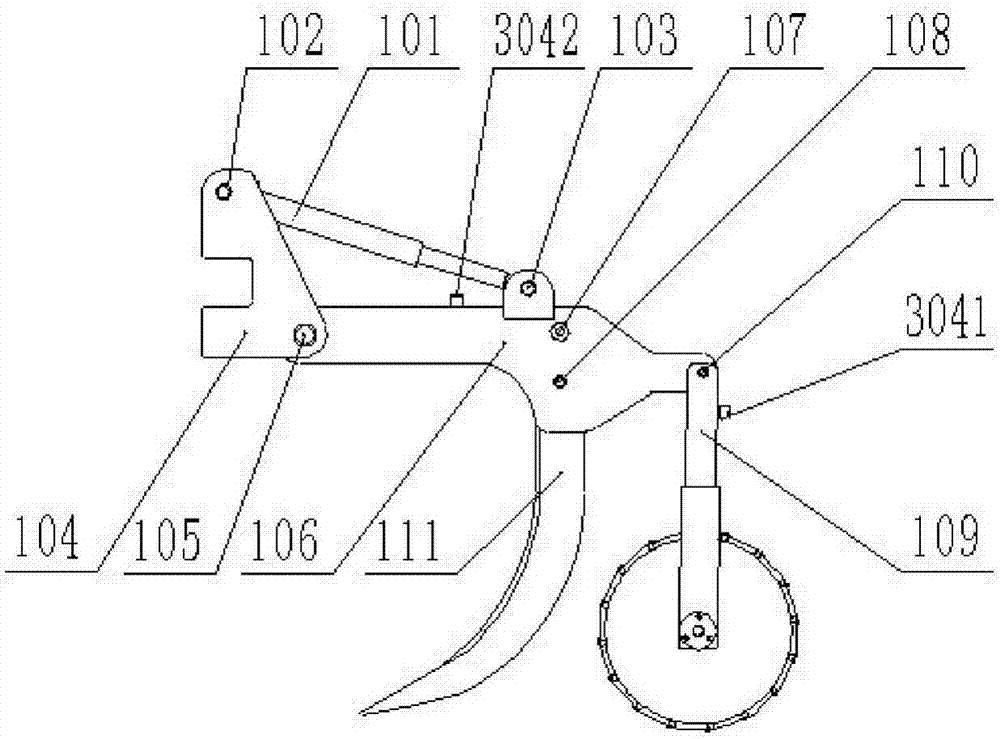

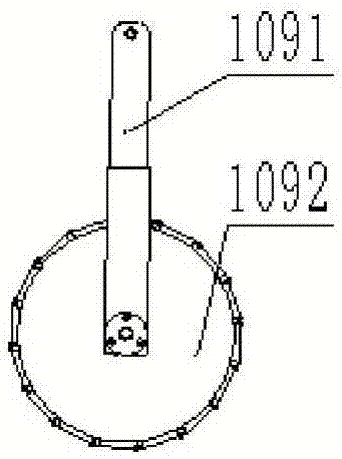

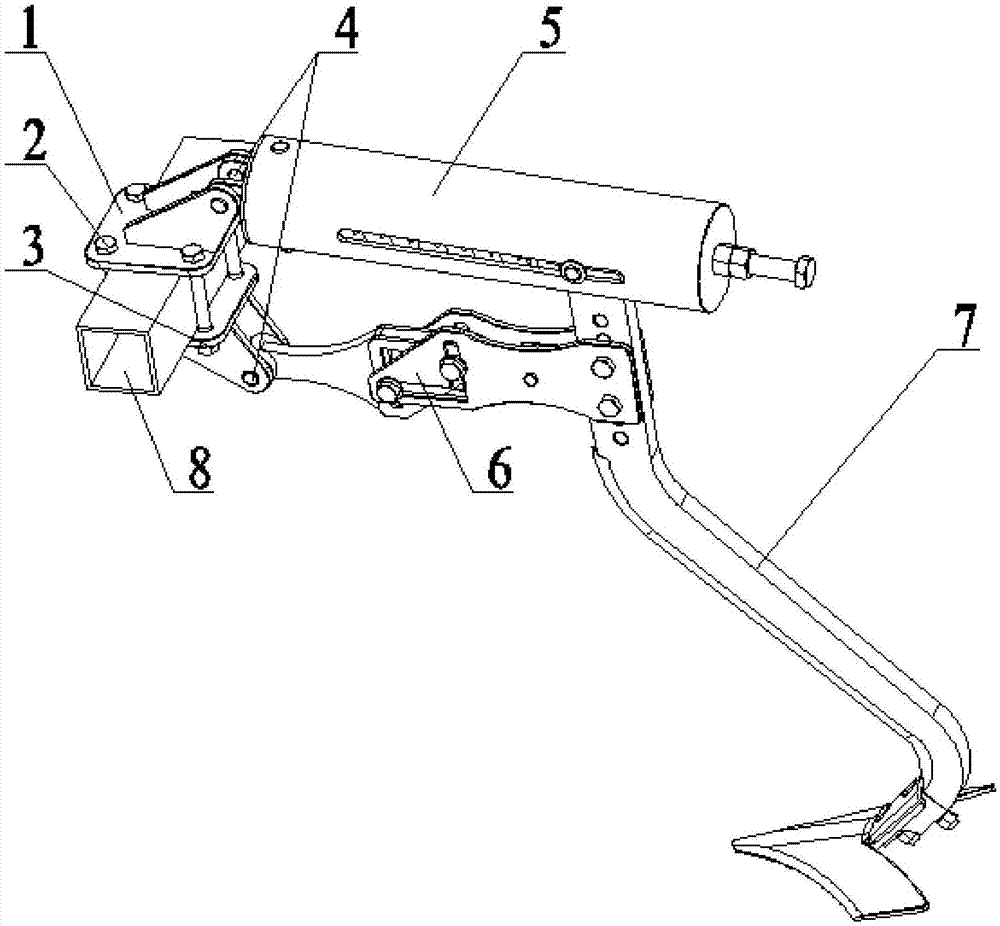

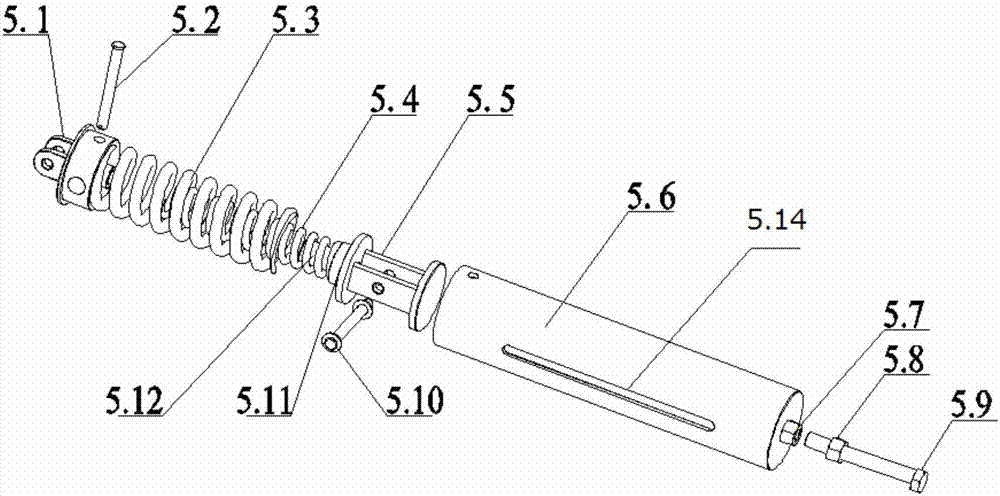

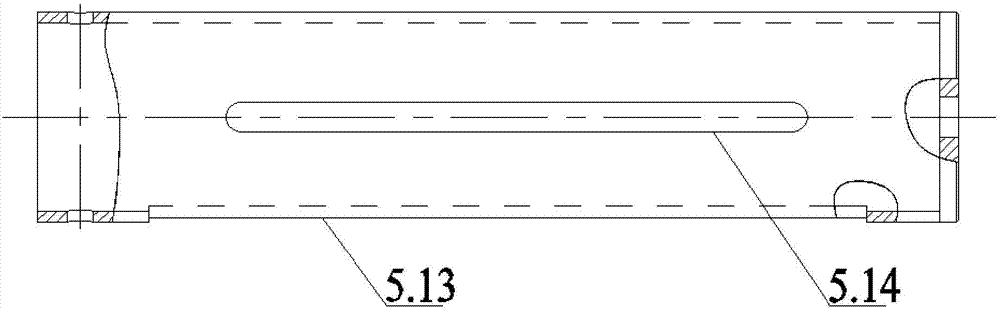

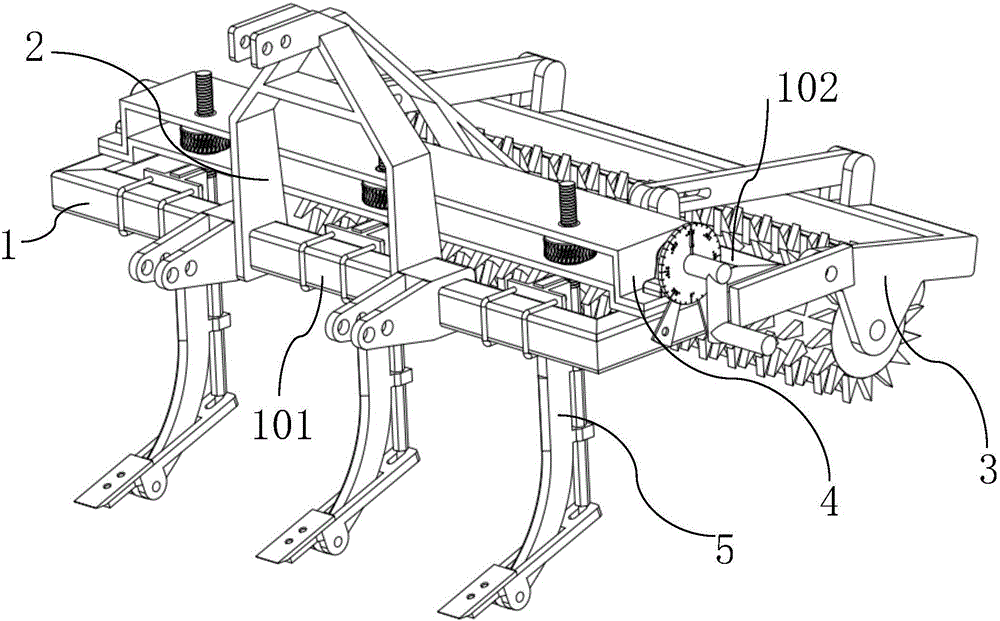

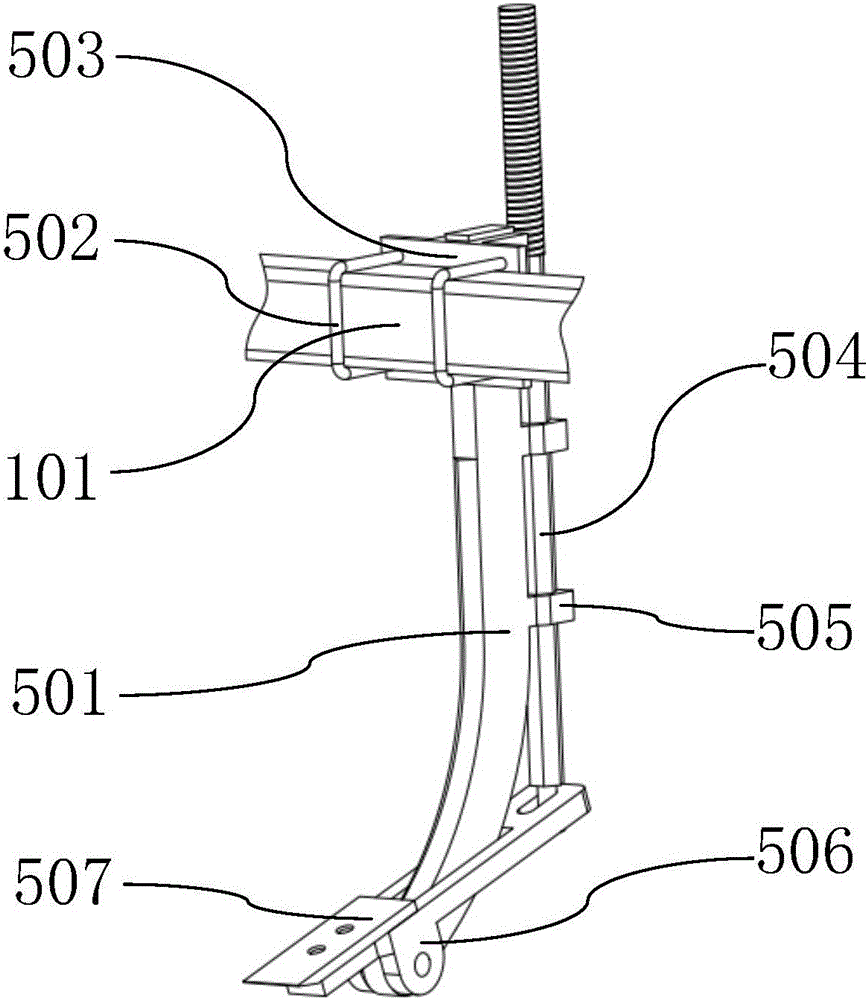

Subsoiler having sub-soiling shovel with adjustable earth shoveling angle

ActiveCN105027706AEasy to adjustHigh precisionSoil-working equipmentsEngineeringAgricultural machinery

The invention, which belongs to the technical field of agricultural machinery, especially relates to a subsoiler having a sub-soiling shovel with an adjustable earth shoveling angle. The invention aims at providing a subsoiler that can meet requirements of different earth shoveling angles of sub-soiling shovels at various areas and has advantages of convenient adjustment, high precision, compact integrated structure, and high safety and reliability. The provided subsoiler comprises a rack (1), a suspension device (2), suppressing device (3), a sub-soiling device (5), and an angle adjustment device (4) arranged above the rack (1). With the subsoiler, demands of different earth shoveling angles of sub-soiling shovels at various areas can be satisfied.

Owner:CHINA AGRI UNIV

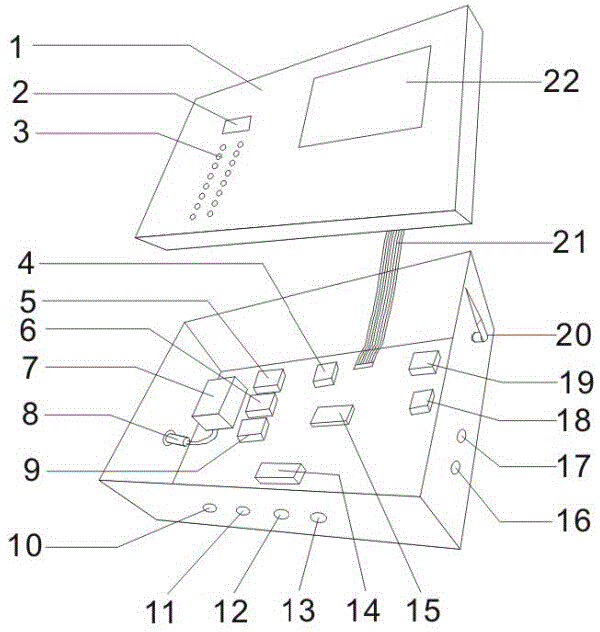

Intelligent management system of subsoiler capable of automatically adjusting tilling depth

InactiveCN106900190AAutomatic adjustment of tillage depthEasy to useAgricultural machinesHydraulic cylinderIntelligent management

The invention relates to an intelligent management system for a subsoiler that automatically adjusts the depth of tillage, wherein the oil inlet and the oil outlet of the hydraulic cylinder on the subsoiler are respectively connected with three-way joints for the oil inlet and the hydraulic control valve group of the tractor and the tee joint of the oil outlet, the tractor hydraulic control valve group controls the fluid flow entering the hydraulic cylinder; a depth adjustment mechanism is arranged between the tractor hydraulic control valve group and the hydraulic cylinder, and the depth adjustment mechanism includes a controller, a hydraulic valve, and a control The hydraulic valve is controlled by the hydraulic valve. The oil inlet and oil return port of the hydraulic valve are connected with the hydraulic output interface of the hydraulic control valve group. The two outlets on the hydraulic valve are respectively connected to the oil inlet The outlet tee joint is connected with the oil outlet tee joint. The invention controls the fluid flow rate entering the hydraulic cylinder by controlling the opening of the hydraulic valve, thereby controlling the position of the lower rod in real time and automatically adjusting the tillage depth.

Owner:合肥大顷农业智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com