Space curved face type subsoiler

A deep loosening shovel and curved surface technology, which is applied to agricultural machinery and implements, applications, plows, etc., can solve the problems of running moisture and soil, loss, etc., and achieve the effects of reducing working resistance, enhancing passability, and ensuring the sliding cutting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

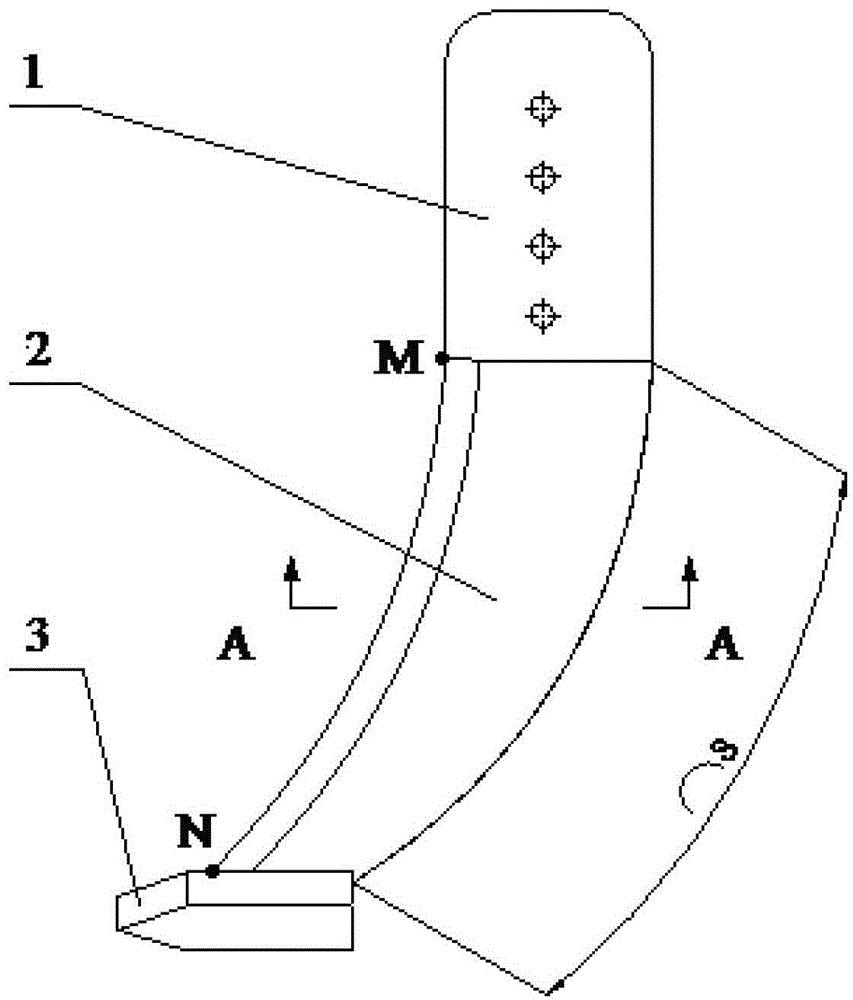

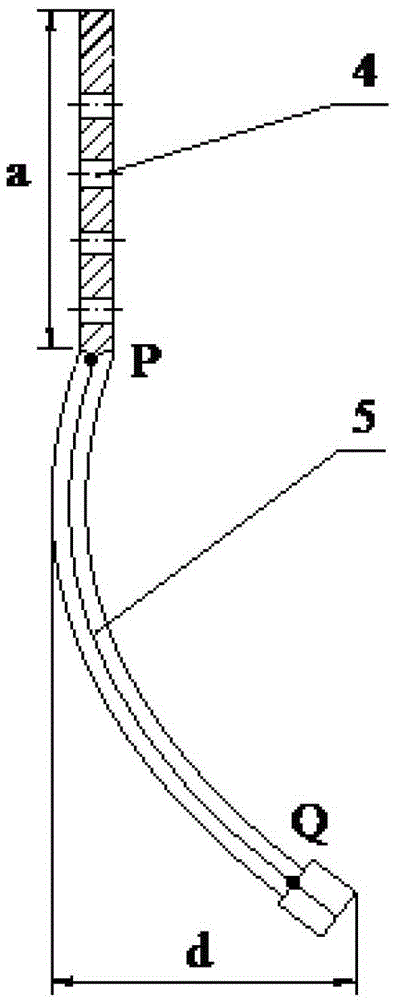

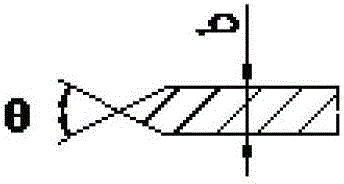

[0031]According to the invention, the space curved surface of the subsoiling shovel can be divided into two types: left-inclined and right-inclined, the length of the shovel handle is a=250mm, the arc length of the working surface is ∩s=300mm, the width of the subsoiling shovel is d=150mm, and the thickness of the blade is b=25mm. The space surface subsoiling shovels are symmetrically arranged according to the rules, and are symmetrically installed in pairs on the frame of the subsoiling machine with a working width of 1300mm (2 rows) ~ 3900mm (6 rows). The installation position is aligned with the furrows, and the implements are driven by 80-120 horsepower tractors to carry out inter-row subsoiling operations under conservation tillage conditions. The forward speed of subsoiling implements is 4km / h. The results of multiple measurements are: the depth of subsoiling can be adjusted by adjusting the positioning hole 4, the adjusted depth ranges from 250mm to 400mm, the stability ...

Embodiment 2

[0033] The length of the shovel handle is a=275mm, the arc length of the working surface ∩s=350mm, the subsoiling shovel width d=165mm, and the blade thickness b=27.5mm. Other conditions are identical with embodiment 1.

[0034] The results of multiple measurements are: the stability of tillage depth can reach 92%, and the broken soil rate can reach 85%.

Embodiment 3

[0036] The length of the shovel handle is a=300mm, the arc length of the working surface ∩s=400mm, the subsoiling shovel width d=180mm, and the blade thickness b=30mm. Reduce the distance between the two subsoiling shovels so that the distance is between 100mm and 150mm, and install them symmetrically on the main beam in pairs, which can achieve the effect of all-round subsoiling. The implements are driven by tractors with more than 120 horsepower to carry out inter-row subsoiling operations under conservation tillage conditions, and the forward speed of subsoiling implements is 4km / h. The results of multiple measurements are: the stability of tillage depth can reach 93%, and the broken soil rate can reach 86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com