Vibration digging and puling type cassava harvester

A harvester, cassava technology, applied in excavating harvesters, excavators, harvesters, etc., can solve the problems of poor soil adaptability, complex structure, high power consumption, etc., and achieve rapid and continuous pulling, wide application range, and flexibility. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

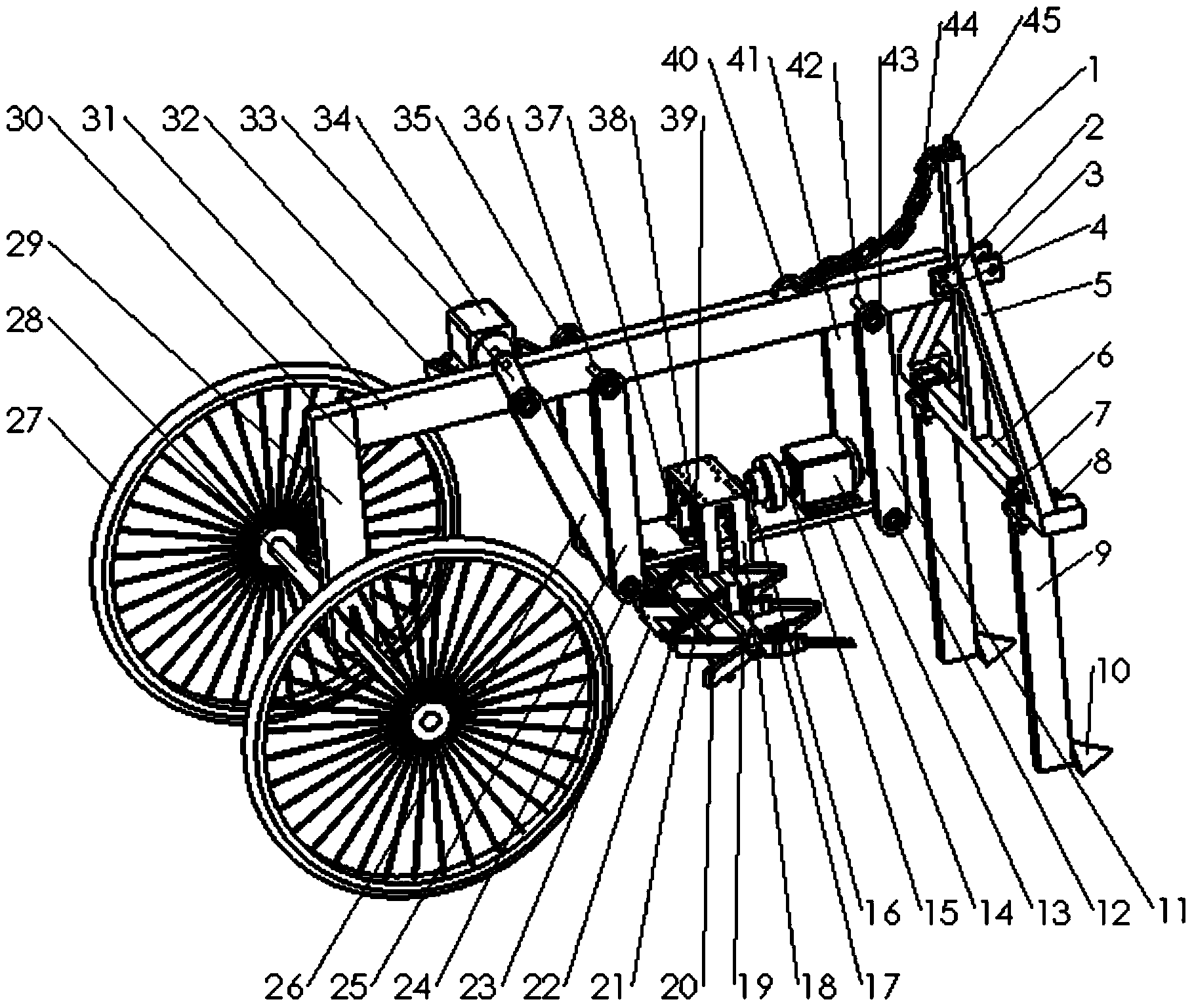

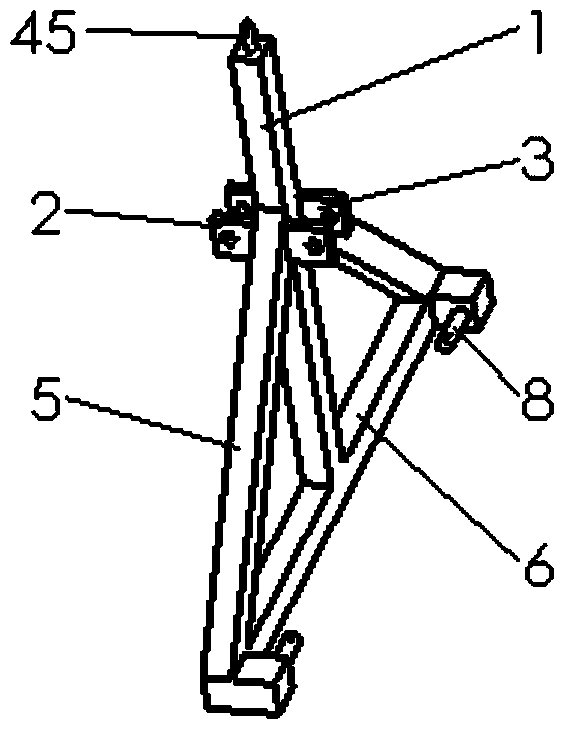

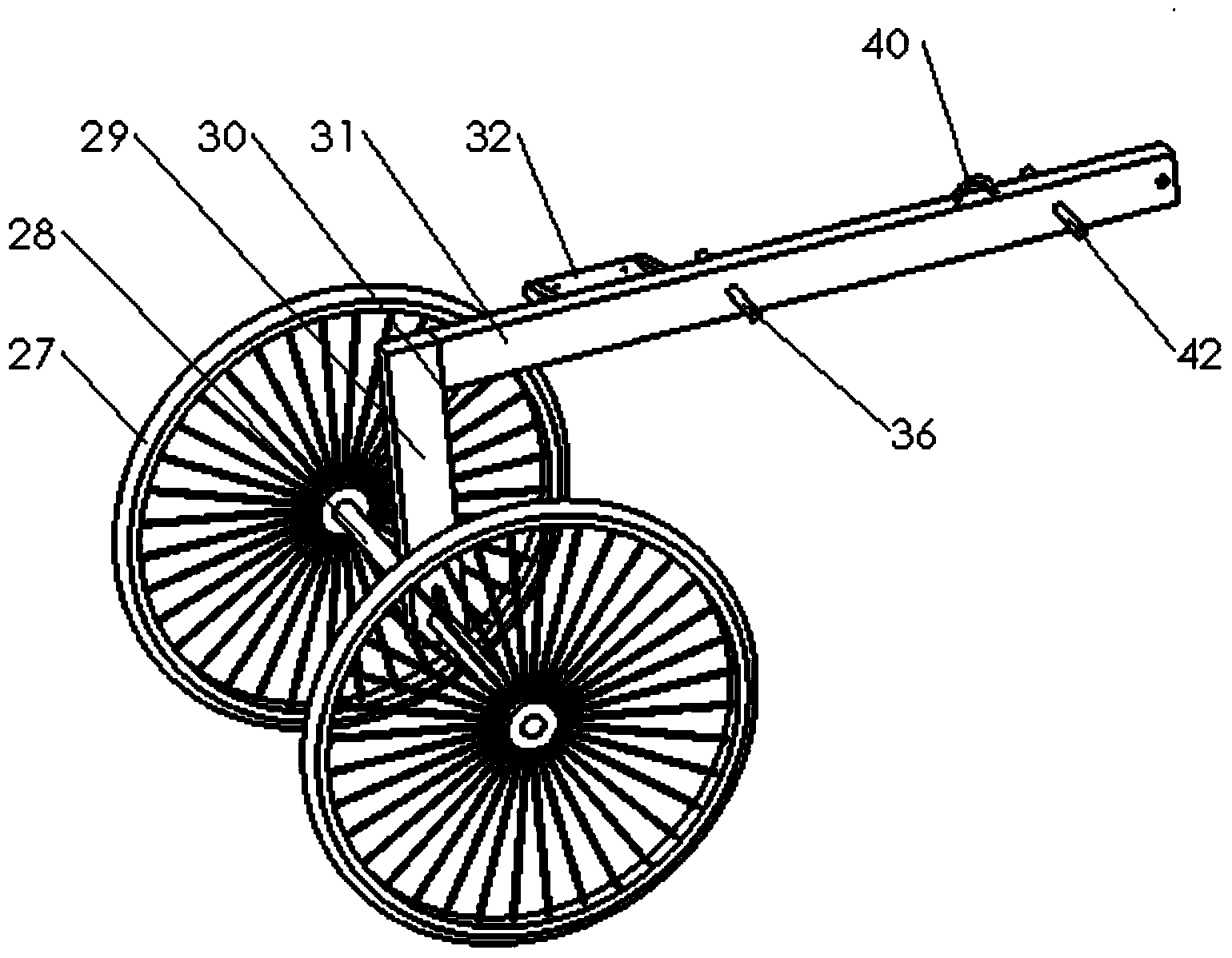

[0022] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0023] control figure 1 A vibration digging and pulling type cassava harvester includes a frame, a suspension frame, a root root pulling device, a digging shovel, and an electro-hydraulic control device. Frame is made up of beam frame, rear support wheel 27, and rear support wheel 27 is installed on the support wheel axle 28 of beam frame by bearing, and frame and suspension frame are hinged with cylindrical pin 4, limit frame relative suspension frame with steel chain 44 longitudinal displacement. The root root pulling device is composed of a pulling mechanism, a vibration mechanism and a clamping mechanism. The pulling mechanism is installed on the frame through bolts and double-row angular contact ball bearings 43, and the vibration mechanism is installed on the horizontal plate 14 of the pulling mechanism through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com