Vibration deep subsoiler

A subsoiler and subsoiler technology, applied in the fields of soil preparation machinery, agricultural machinery and implements, ploughs, etc., can solve the problems of high-power tractors, high mass, increased subsoil cost, and complexity of subsoilers, so as to improve work efficiency, The effect of reducing operating costs and reducing traction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

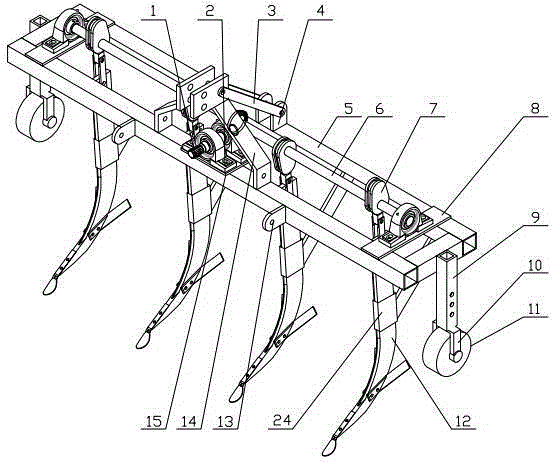

[0021] Embodiment 1: with reference to attached Figure 1 A vibrating subsoiling machine comprising a frame 5, a vibrating subsoiling device, a depth control device and a traction device, characterized in that the vibrating subsoiling device is placed in the middle of the frame 5, the vibrating subsoiling device is connected with the power output shaft of the tractor, and the depth The control device is arranged on both sides of the frame 5, and the traction device is arranged on the front portion of the frame to be connected with the tractor's traction device.

Embodiment 2

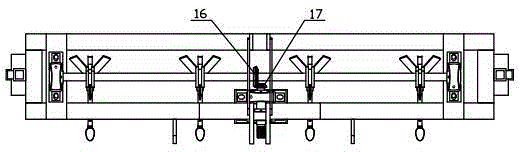

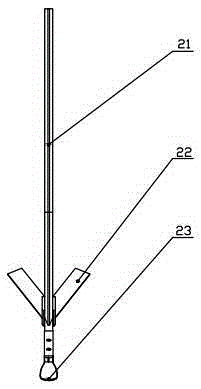

[0023] The difference between this example and Embodiment 1 is that the vibrating subsoiling device includes a power shaft 1, a bearing seat 2, a transmission shaft 6, a cam slider mechanism 7, a support plate 8, a subsoiling shovel 12, a base plate 15, and a driving cone. Gear 16, driven bevel gear 17, slider 19, connector 20, shovel handle 21, wing shovel 22, spoon-shaped shovel tip 23 and reinforcement support plate 24, the above-mentioned power shaft 1 is fixedly installed on the bearing seat 2, and the bearing The seat 2 is installed on the base plate 15, and the base plate 15 is fixed on the front beam of the frame 5. The front end of the power shaft 1 is an octagonal spline shaft end connected with the power output shaft of the tractor, and the driven bevel gear 17 is installed on the power shaft. The rear end of the shaft 1 meshes with the driving bevel gear 16 on the transmission shaft 6, the cam slider mechanism 7 is installed on the transmission shaft 6, the subsoili...

Embodiment 3

[0025] The difference between this example and Embodiment 1 is that the depth control device includes a depth adjuster 9, a wheel frame 10 and a depth gauge wheel 11, and the above-mentioned depth adjuster 9 is vertically connected to the outer surfaces of the left and right sides of the frame 5 respectively. Above, the depth gauge wheel 11 is connected to the wheel frame 10, and the threaded locking holes are distributed on the depth adjuster 9 and the wheel frame 10. The wheel frame 10 is embedded in the depth adjuster 9 and connected by bolts. way to adjust the height of the depth gauge wheel 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com